Abstract

The world is moving towards a low-carbon economy through renewable energy sources. In this context, concentrating solar power (CSP) technologies can exploit the rich solar resource in Brazil, diversifying the national electricity mix. The aim of this paper is to support the insertion of CSP generation in the Brazilian bottom-up model MATRIZ by analyzing the environmental performance of three CSP technologies: (i) solar tower power (STP) with a thermal storage system (TSS) of 7.5 h; (ii) solar thermal parabolic trough (STPT) with a TSS of 6 h; and (iii) STPT without TSS. From a life cycle perspective, their freshwater consumption and greenhouse gas (GHG) emissions are addressed by employing the software SimaPro, the Ecoinvent database, and the ReCiPe 2016 method, as well as information from the system advisory model (SAM) and the literature. As a result, STP is the most environmentally sound CSP alternative, presenting lower GHG emissions and water consumption than the two STPT technologies. In general, CSP generation proves to be more environmentally attractive than some fossil-fired power plants and renewable energy sources. Moreover, moving the manufacturing of CSP technologies to Brazil has the potential to reduce GHG emissions from the upstream processes of their value chain.

1. Introduction

Brazil is a developing economy and therefore contributes to the increase in the global energy demand. At the same time, it is a continental-size country with a strong predominance of medium and large hydropower plants in its electricity mix. However, most of the remaining hydroelectricity potential is located in the Amazon region, which is very distant from the main centers of electricity consumption and has been the main focus of the increasing socio-environmental concerns in the country [1].

Given this scenario, the Brazilian energy policy projections indicate that the share of other renewable energies will rise in the national electricity mix. Today, energy sources like wind, biomass, solar, and small and micro hydropower plants correspond to more than 20% of the installed capacity of the electricity mix, and the expectation is that they will achieve approximately 33% in the ten-year horizon. After a fast rise in wind power share in the Brazilian electric matrix in the last decade, solar power generation by means of photovoltaic (PV) technologies stands out as one of the most promising energy sources, since it has experienced huge growth in the last years [2,3].

Although wind power and solar PV have proven to be central in meeting rising electricity demand in Brazil, both generation technologies are characterized by their intermittent nature. At high levels, the penetration of intermittent power generation technologies requires adaptations of the power system due to some of its particularities. For instance, these renewable energy sources need increased flexibility through expanded transmission systems and optimal use of storage [4]. These issues can increase the complexity and costs of the Brazilian national interconnected system operation (SIN as in its Portuguese acronym). Thus, expanding the range of renewable energy options for long-term power planning is crucial to its efficiency and economic viability without compromising sustainability.

Thermosolar power or concentrated solar power (CSP) is a renewable electricity generation technology that harnesses solar power and allows energy storage, enabling a greater dispatchability than wind power and solar PV [5]. CSP devices generate electricity by concentrating energy from the sun’s rays to heat a receiver. Unlike wind power and solar PV, CSP growth has been slow in Brazil. Its official energy expansion plans do not consider this and other promising technologies mainly due to technical-economic challenges [6,7,8,9,10].

However, assuming that the investment costs of CSP will fall over time [11], the question remains to what extent this technology would contribute to maintaining renewable energy sources expansion in the Brazilian energy system. The Brazilian Energy Research Office (EPE) carries out long-term simulations within the scope of the national expansion plan based on energy demand, investment/operation costs, and technical aspects of the available resources and technologies, using computational tools, which also have restrictions [12]. Considering the socio-environmental aspects of these energy generation technologies is a way to help in the viability of those that are more recent and a priori more sustainable, such as renewable energy sources.

In this context, the aim of the present paper is to support the insertion of CSP generation in the Brazilian bottom-up model MATRIZ [13] by analyzing the environmental performance of three CSP technologies: (i) solar tower power (STP) with thermal storage system (TSS) of 7.5 h; (ii) solar thermal parabolic trough (STPT) with a TSS of 6 h; and (iii) STPT without TSS. The MATRIZ model is a linear programming application formulated to analyze long-term energy-related policies. It was tested and validated using the MARKAL model, which was developed by the energy technology systems analysis program (ETSAP) of the International Energy Agency (IEA).

Inserting a new energy generation technology in the MATRIZ model demands information regarding its investment and operating costs. For renewable energy sources, such as solar and wind, seasonal and daily variability in their capacity factor must be taken into account [14]. In addition to this set of information, greenhouse gas (GHG) emissions and freshwater consumption can also be considered to incorporate environmental aspects in the model’s decision-making. This feature is particularly interesting when we realize that, although CSP technologies provide GHG emission mitigation opportunities, this kind of renewable energy source also presents GHG emissions throughout its value chain, as well as raises concerns about water use [15].

With this in mind, this paper estimates freshwater consumption and GHG emissions related to the three CSP options mentioned earlier from a life cycle perspective. Even though a considerable body of research has been concerned with the environmental issues related to the value chain of an energy carrier, less attention has been paid to environmental impacts throughout the CSP technologies’ life cycle.

Viebahn and colleagues [16] examined the material and energy flows of the life cycle of CSP technologies under future envisaged scenarios. Mazzaferro [17] carried out a life cycle assessment (LCA) of electricity generation from three different CSP technologies in Spain: STPT, STP, and the Linear Fresnel reflector. Mayo and colleagues [18] compared the environmental performance of two types of specific materials suited to STP plants from a life cycle perspective. In Gasa et al. [19], the environmental performance of an STP plant with molten salt storage was compared with another without TSS throughout their life cycle. Liang and colleagues [20] developed an optimization framework for the CSP-supercritical CO2 Brayton cycle plant considering economic and environmental life cycle-based criteria.

Concerning further studies focused on answering critical questions about the future of energy supply, few studies integrate life cycle-based analysis into a multi-objective model. For example, Barteczko-Hibbert and colleagues [21] integrate mixed-integer linear programming with LCA to optimize electricity supply considering costs and environmental impacts from a life cycle perspective. Rauner and Budzinski [22] combine a lifecycle-based sustainability assessment with an energy system model and apply this framework in a case study concerning the German electricity system expansion. More recently, Louis and colleagues [23] evaluated the evolution of the electricity system infrastructures through a multi-objective optimization model that considers environmental indicators based on a life cycle approach.

It is noteworthy that the lack of studies on this topic is even more notable in Brazil. Except for pilot CSP plants for research purposes, no commercial unities are currently operating in the country. Most of CSP’s academic studies focus on technical and economic issues, addressing power system expansion, renewable energy integration, and the economic feasibility of CSP generation. In this context, this paper covers a gap in the existing literature; no study has explicitly looked at the life cycle environmental impacts of CSP generation in the light of its expansion in the energy system in the country.

2. Materials and Methods

2.1. An Overview of Solar Thermal Technologies and Their Environmental Aspects

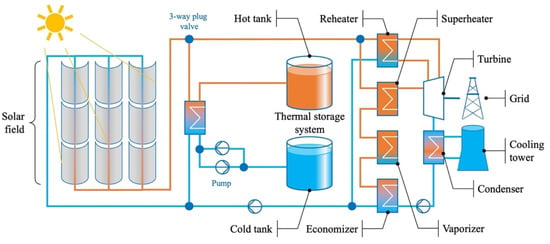

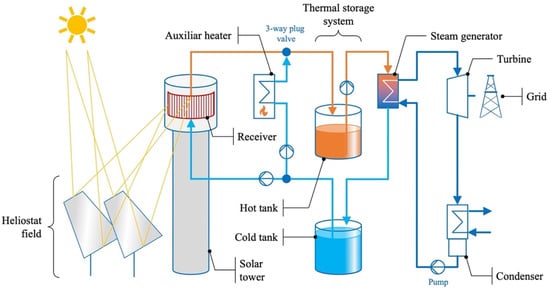

At this point, it is essential to briefly describe CSP technologies, focusing on those to be evaluated in our analysis. CSP (among other names) is a technology that uses an optical concentrator to create a flow of energy in the so-called receivers. In the receivers, solar radiation is absorbed and converted into thermal energy. The heat is transferred by means of a fluid transported to a thermal generation system of the Rankine type (or to a storage system). In the thermal generation system, heat is converted into electrical energy [24]. CSP generation encompasses four different technologies as follows: (i) the linear Fresnel reflector; (ii) parabolic trough (Figure 1); (iii) solar tower (Figure 2); and (iv) parabolic dish. In this study, to assess centralized electricity generation technologies, the solar thermal parabolic trough (STPT) and solar tower power (or central receiver) (STP) were considered.

Figure 1.

Scheme of an STPT power plant. Source: Elaborated by the authors, based on GIZ/MCTI [25].

Figure 2.

Scheme of an STP plant. Source: elaborated by the authors, based on GIZ/MCTI [26].

The STPT technology uses semi-cylinders with parabolic sections to concentrate solar energy in the absorber tubes. The main systems of STPT power plants are the solar field, thermal storage (TSS), heat transfer system, and power block (Figure 1). The solar field is basically composed of solar collectors’ modules and a system of tubes (or receivers) through which the heat transfer runs. TSS allows for regulating the dispatch of the energy generated in the power plant, is often measured in hours, and may not be present in an STPT power plant. The power block is represented by the heat exchangers (reheater, superheater, vaporizer, and economizer), turbine, condenser, and cooling tower. Typically, STPT power plants use fossil fuels to supplement the solar output during periods of low solar radiation [25].

The STP technology is a point-focus solar thermal power plant that consists of the following components: heliostat field; solar tower; receiver; TSS; and power block (Figure 2) [24,26]. The heliostat field is composed of heliostats that reflect solar radiation onto the receiver. The concentrated solar power is absorbed in the receiver, and the energy is transferred to a heat transfer medium [26].

Note that the three CSP alternatives to be evaluated in this paper are: (i) STPT without TSS and with air cooling; (ii) STPT with a TSS of 6 h with air cooling; and (iii) STP with a TSS of 7.5 h with air cooling. In these cases, the dispatch of the generated energy occurs at the same time when it is available. For CSP alternatives that include TSS, this study considers that the dispatch of the generated energy occurs at the same time when it is available.

Concerning the environmental aspects of CSP technologies, the primary concerns are related to the upstream processes of their value chain and some activities in their operation stage. On the one hand, a CSP plant demands a heat transfer fluid, such as molten salt, and its solar field generally requires more iron and cement than fossil fuel-fired power plants. On the other hand, CSP plants consume water mainly for cooling and washing mirrors and may also use grid electricity during their operation [24,27,28].

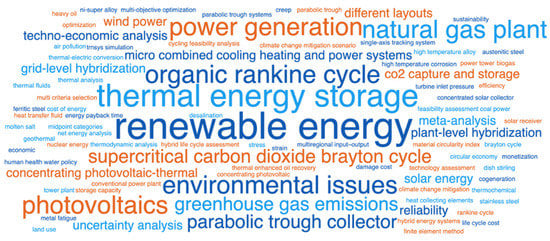

For this reason, life cycle-based analysis seems notably relevant to evaluating CSP technologies’ environmental performances. The available literature on LCA of CSP generation is focused on the knowledge and comparative analysis of its different technical and environmental aspects, especially concerning the possibilities related to TSS, Brayton/organic Rankine cycle, and hybridization aspects. Likewise, LCA is usually employed to compare different energy sources with CSP technologies, addressing dispatchability, GHG emissions, and energy costs. Note that GHG emissions are the central theme in the field of environmental assessment. On the other side, water requirements have not received much scientific attention. Figure 3 displays a generalized view of the themes addressed by this line of research.

Figure 3.

An overview of the themes addressed by the literature on LCA of CSP (word cloud of keywords from 35 papers collected from the CAPES database using LCA and CSP as keywords). Source: elaborated by the authors.

2.2. MATRIZ Model

Several computational models for integrated energy planning have been developed and used in a number of countries. In general, these models are classified into economic-energy models, or top-down models, and systems optimization energy models, or bottom-up models. Traditionally, the expansion planning of an energy system consists of increasing the energy transformation technologies capabilities in meeting future demands over the planning horizon of the various forms of available energy and minimizing up-to-date construction and operating costs [13].

The MATRIZ model was originally a linear programming application for the bottom-up analysis of the integrated energy systems expansion with exogenous energy demands. Its objective is to minimize the cost of investments in equipment (i.e., energy transformation technologies) that make up an energy system, as well as its operating costs, based on the evolution of energy demands, the operational life of existing equipment, the characteristics of future technologies, and the potential of their primary reserves. It is developed for long-term energy policy analysis, similar to the MARKAL Model [29].

In addition to its aim to minimize the cost of investments in equipment, MATRIZ’s mathematical formulation is also based on decision variables and a set of constraints. Technical coefficients and the efficiency of each energy technology represent the former. Given the form of reference energy for a specific technology, its technical coefficient related to energy input and output is calculated by the ratio between the amount of consumed or generated energy and the amount of energy associated with the reference energy. On the other hand, the constraints relate the energy flows to the operation of the technology [13].

In Lisboa et al. [13], the computational system’s validation process of the MATRIZ model is appropriately presented and described. It considers the oil, natural gas, biomass, coal, firewood, uranium, and electricity value chains, which were modeled taking into account the data from the Brazilian National Energy Balance [30]. From this perspective, several simulations were carried out with the MATRIZ model and the integrated MARKAL-EFOM system (TIMES) model [31], developed by the IEA, in order to explore energy scenarios based on energy and environmental analyses. In all simulated cases, the results obtained in both methods were in accordance, indicating that the MATRIZ model’s formulation and computational implementation were consistent [13].

The MATRIZ model has been updated to reflect the national energy trends. Additionally, it was enhanced to also consider environmental impacts by inserting their estimated costs and adding them to the investment and operational costs already included in the model. In this way, Medeiros and colleagues [32] developed and tested a methodology to estimate the costs of GHG emissions and freshwater consumption of the main electricity generation technologies in Brazil, namely, wind power, solar PV, sugarcane thermal power plant (TPP), wood TPP, hydro, nuclear, simple-cycle gas turbine (SCGT), combined-cycle gas turbine (CCGT), and coal TPP. Other environmental criteria to be further included in the model are job creation, impacts on biodiversity and land use, risks, etc.

To estimate the costs of GHG emissions, the authors [32] propose adopting the shadow price approach, developed by the High-Level Commission on Carbon Prices [33]. This method aims to indicate pathways that lead countries to move to a low-carbon economy, gradually restricting their emissions so that the global average surface temperature does not exceed 2.0 °C above pre-industrial levels [32,33].

Concerning the estimation of water costs, this was based on regional charges already in use on Brazilian river basins, which is one of the management instruments established by the National Water Resources Policy (Law No. 9433) [34]. This policy aims to encourage the rational use of water, generate financial resources for investments in the recovery and preservation of the watersheds, and provide the user with a suggestion of the real value of the water [34].

Previous calculations based on data from the Ecoinvent database [35] adapted for Brazil were carried out for the most-used electricity generation technologies in the country (Table 1). They indicate that the most significant contribution to global warming stems from non-renewable alternatives, except nuclear generation. In contrast, hydroelectric generation and sugarcane TPP stand out regarding water consumption.

Table 1.

GHG emissions and water consumption of the main electricity generation in Brazil included in the MATRIZ model.

In order to incorporate the electricity generation from CSP technology in the MATRIZ model, as well as its environmental performance concerning GHG emissions and water consumption throughout its value chain, it is necessary to quantify its GHG emissions and water requirements per kWh since the costs of these impacts are already available according to the previously presented information.

2.3. Life Cycle Assessment (LCA)

Life cycle assessment (LCA) is a technique for a holistic environmental assessment of a product or service’s life cycle and has been widely adopted in energy systems. Considering that the environmental impacts from renewable energy sources are not concentrated in the power plants’ operation stage, this approach seems particularly interesting for assessing this kind of energy source [36].

The principles, framework, requirements, and guidelines for carrying out an LCA study are described in ISO 14040 [37] and 14044 [38]. According to these standards, the LCA methodology is composed of four main phases: (i) goal and scope definition, (ii) life cycle inventory (LCI), (iii) life cycle impact assessment (LCIA), and (iv) interpretation [37].

The first step is to define the goal and scope of the analysis, which comprises determining the functional unit, system boundaries, and impact categories. Then, the LCI step compiles the relevant data to quantify energy and materials inputs and environmental releases associated with each process established in the system. With this information, the potential environmental impacts can be evaluated in the LCIA step. Lastly, the interpretation step assists decision-makers in making a more environmentally-based and informed decision [37].

Many LCI databases and LCIA methods are currently available. Typical databases include relevant inputs and outputs of a product system [37]. Ecoinvent [35] is the most comprehensive and commonly used LCI database, and provides accessible, transparent, and reliable LCI information encompassing several economic activities [35,39]. Hence, it helps analyze how decision-making affects the environmental and socio-economical dimensions. Furthermore, as data collection for the LCI step is typically time-consuming and onerous, Ecoinvent makes this task easier while enhancing the LCA results’ acceptance and credibility [35,40]. On the other hand, LCIA methods convert the LCI results into common units and aggregate the converted results within the same impact category [37]. CML [41] and ReCiPe [42,43] are the most used methods in LCIA.

2.4. Incorporating CSP Generation in the MATRIZ Model: Environmental Impacts

To support the incorporation of CSP generation in the MATRIZ model, this paper focuses on STPT and STP technologies, considering their freshwater consumption and GHG emissions throughout their entire life cycle. On the one hand, STPT and STP are the most mature and commercial CSP technologies worldwide [6], and also the study that estimates Brazil’s potential for CSP takes into consideration these two alternatives [44], which are more suitable for the centralized generation of electric power. On the other hand, water consumption and GHG emissions prove to be some of the main environmental issues related to CSP generation [7].

Although CSP technologies have much lower GHG emissions when compared to fossil-based plants during the electricity generation stage, they can have significant environmental impacts during other stages of their value chain. When we look more closely at CSP upstream and downstream chains, it is possible to verify that capital goods are the main drivers of their environmental impacts. Indeed, the raw materials extraction and processing and the production of CSP plants’ components are the primary causes of GHG emissions and water consumption [36]. In addition to these processes, CSP plants also need water to cool and condense the steam cycle, as well as to clean mirrors during their operation [7].

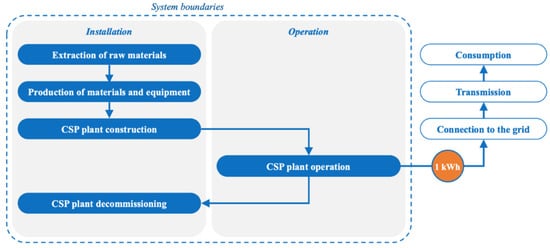

In this paper, the life cycle-based analysis under the standards ISO 14040 [37,38] is performed on three different CSP layouts with a capacity of 100 megawatts (MW) (see Table 2), considering their GHG emissions and water consumption related to 1.0 kilowatt-hour (kWh) of electricity generated in the Brazilian context. Its system boundaries are delimited from the extraction of raw materials to the CSP plant’s decommissioning and final disposal. Note that it does not include transport activities, connection to the distribution network, or transmission lines. This is due to the fact that the CSP technologies considered present the same characteristics for these life cycle stages, and the consumer cannot choose which energy technology is generating its electricity [45]. Following the MATRIZ model requirements, GHG emissions and water consumption were divided into the installation and operation stages (Figure 4).

Table 2.

CSP layouts’ characteristics.

Figure 4.

Scheme of the system boundaries considered in the life-cycle based analysis. Source: elaborated by the authors.

In this analysis, we used the software SimaPro 9, which is a well-known commercial LCA software. It allows for modeling and analyzing products’ and services’ life cycles, as well as collecting and monitoring their environmental performance data [46]. We adapted data from the attributional approach of the Ecoinvent database 3.5 [35] in order to reflect better the technologies studied and the Brazilian context, and considered the impact categories of global warming and water consumption from the ReCiPe 2016 Midpoint method [43].

We also considered data from the literature and information provided by the system advisory model (SAM) software [47] (see Supplementary Material Tables S3 and S4). This is a techno-economic computational model developed by the National Renewable Energy Laboratory (NREL) to support the decision-making process within the renewable energy sector. SAM includes performance models for solar PV systems, wind energy, biomass, CSP, geothermal energy, industrial process heat, and solar water heating. Moreover, it also encompasses conventional power systems that provide electricity to the grid or present interaction with the electric load of a grid-connected building or facility. Note that SAM comes with default input values and tools for obtaining further inputs from online data services [48].

As the Brazilian National Planning 2050 [12] was based on Burgi’s work [44] to establish the national expansion potential for CSP generation in Brazil, the CSP plants’ parameters used by this author were employed in our analysis as input in simulations performed in SAM. Note that CSP technologies considered here and their locations in Brazil can be found in Supplementary Material Table S1. Moreover, Burgi [44] also provides other relevant data, such as the discount rate of 10% p.a., the internal rate of return (IRR) of 15% p.a., and the lifetime of the simulated CSP plants of 30 years.

In order to obtain results that conform with the Brazilian planning criteria [12], some arrangements were made to adapt the LCI of CSP plants available in the Ecoinvent database 3.5 [35] (Supplementary Material Tables S3 and S5). In this way, we scaled up a 50 MW STPT to 100 MW (with and without TSS); and a 20 MW STP to 100 MW. Table 3 describes the major adaptations (More details about the calculation of scale-up factors can be found in Supplementary Material Table S6 and Equation S1).

Table 3.

Scale-up factors.

3. Results

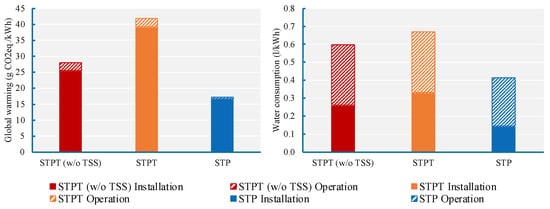

Table 4 lists the LCIA results using SimaPro. It can be seen that GHG emissions of STPT (without TSS) and STPT are estimated to be approximately 28.02 and 41.90 g CO2eq./kWh, respectively. In both cases, the installation stage is responsible for more than 90% of the total GHG emissions of their whole life cycle. In the case of STPT (without TSS), upstream processes related to its collector field area and power blocks are the two most significant contributors to the installation stage emissions. For STPT, its TSS and collector field stand out. Concerning STP technology, GHG emissions are estimated to be 17.22 g CO2eq./kWh, more than 95% can be attributed to the installation stage. It is worth pointing out that the largest contributor is the collector field area.

Table 4.

LCIA results for generating 1 kWh of electricity from STPT (w/o TSS), SPTP, and STP.

When looking at the water consumption, STPT (without TSS) and STPT are associated with 0.60 L/kWh and 0.67 L/kWh, respectively. In the case of STP, the water consumption is estimated to be 0.41 L/kWh. In this impact category, the operation stage of all technologies is responsible for at least 50% of the total water requirements of their whole life cycle. The most significant contributor is the water used to clean mirrors. Figure 5 clearly shows that the installation stage dominates the global warming impact category, whereas the operation stage dominates the water consumption of the three CSP technologies.

Figure 5.

LCIA comparison between the generation of 1 kWh of electricity from STPT (w/o TSS), STPT, and STP [ReCiPe 2016 Midpoint (H) V1.03/World (2010) H].

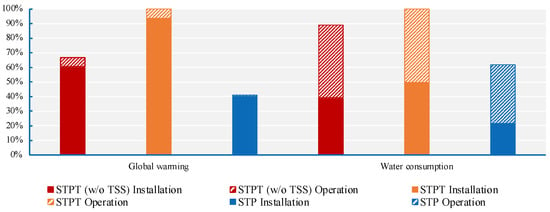

Comparing the three CSP options, it can be inferred that STPT has more impact than STPT (without TSS) and STP in the two impact categories considered. This CSP technology is followed by STPT (without TSS) and STP. It can also be verified that the GHG emissions associated with the generation of 1 kWh from STPT (without TSS) and STP represent 67% and 41% of those of STPT, respectively. Regarding water consumption, these proportions are 89% and 62% (Figure 6).

Figure 6.

LCIA comparison between the generation of 1 kWh of electricity from STPT (w/o TSS), STPT, and STP [ReCiPe 2016 Midpoint (H) V1.03/World (2010) H/Characterization].

These results conform with previous results [49,50,51], and our findings are consistent with what has been reported by the literature, which indicates not only those systems with TSS have more impact than those without TSS [52,53,54], but also that STP is the most environmentally sound system, which tends to have lower environmental impacts per kWh generated than STPT [17,50,51,55]. Given the focus on global warming and the small pool of water consumption estimates for CSP technologies in the literature, Table 5 highlights some results for GHG emissions associated with STPT and SPT power plants obtained by previous studies.

Table 5.

GHG emissions for STPT and SPT power plants reported in the literature.

Note that various factors can be responsible for discrepancies between studies found in the literature. For example, different configurations, distinct GHG emission intensities of materials and components, and factors related to the capacity factor, lifetime, and other operational characteristics of the CSP plants were investigated.

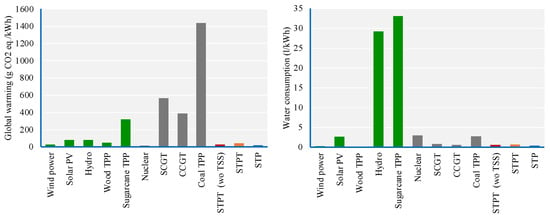

4. Discussion

Figure 7 compares our results for these three more suitable CSP technologies for electricity generation in Brazil with the environmental performance of the leading electricity generation technologies already inserted in the MATRIZ model (see Table 1 in Section 2.2). Concerning global warming concerns, one should realize that all CSP technologies analyzed here perform better when compared to fossil-fired power plants whose GHG emissions range from 390 g CO2eq./kWh to 1440 g CO2eq./kWh. Furthermore, for water requirements, our findings indicate that CSP generation presents a lower water footprint than some renewable energy sources, such as hydro, sugarcane TPP, and solar PV, which are associated with 29.3, 33.1, and 2.7 L/kWh, respectively.

Figure 7.

LCIA comparison between the generation of 1 kWh of electricity from technologies already inserted in the MATRIZ model and CSP technologies.

The general picture emerging from this comparative analysis is that incorporating environmental issues into the decision-making of the energy sector would make the available energy sources’ competition fairer. More specifically, for CSP generation, these data provide preliminary evidence that considering water consumption and GHG emissions costs by energy expansion plans could, to a certain extent, make CSP technologies more attractive from an economic point of view. As a result, there is a potential for advanced energy planning models to introduce CSP generation in the electricity mix in future scenarios.

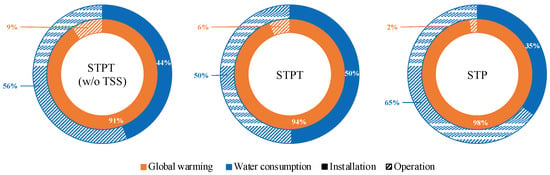

Moreover, it is worth mentioning that, although CSP technologies with air-cooled systems are not large consumers of water, nor large emitters of GHG when compared to other conventional technologies, mitigation measures can still be devised to minimize the water and carbon footprint of specific projects. Based on our findings, more clearly presented in Figure 8, we believe that moving the manufacturing of CSP technologies to Brazil is a way of reducing GHG emissions during the installation stage, which, in the present paper, includes the upstream processes of their value chain. This is because the country has a low-carbon energy mix, and imported goods generally entail extended supply chains, involving more GHG emissions and water requirements.

Figure 8.

The installation and operation stages participation in the global warming and water consumption impact categories of the CSP technologies analyzed.

Note that the GHG emissions from the electricity sector in terms of g CO2eq./kWh in North America were more than three times larger than those in Brazil in 2013. This variation might be even more significant when we consider China, whose electricity sector emitted more than five times more than the Brazilian electricity sector in the same year. At the time, fossil fuel’s share in the Brazilian electricity matrix was around 20%, while in the United States and China, this participation reached 68% and 77%, respectively [56,57]. Accordingly, it is possible to mitigate GHG emissions from the CSP value chain’s upstream processes when moving the production of their components to the country.

However, Brazil needs to develop its industrial sector and dominate the technologies for making CSP components more economically competitive. The most challenging areas of the CSP supply chain in Brazil require investments from the initial stages, being electronic equipment for the development of solar trackers, and the domestic production of receivers and solar salts for the TSS. In addition, a medium-scale investment is necessary to produce mirrors that meet the requirements of those used in CSP plants [24].

Concerning, more specifically, the relevant water consumption in the operation stage of a CSP plant (see Figure 8), it is essential to realize that there are two main processes: the cooling system and mirror washing. Among them, cooling is the most impactful process. Then, it can be inferred that choosing the cooling system of a CSP plant is the most effective way to reduce its water requirements. There are three types of cooling systems: (i) wet cooling, (ii) air cooling, or (iii) hybrid cooling systems. Water cooling consumes more water than other systems; however, it allows greater efficiency in the power cycle.

On the other hand, air cooling requires little water, but it demands more expensive equipment and presents less efficiency in the power cycle. Finally, hybrid cooling systems enhance complexity and costs and are halfway between air and water cooling concerning water demand [24]. For instance, if we select a dry cooling for an STPT power plant with TSS, we could reduce its water demand throughout its life cycle by 80% [49].

It should be noted that sites with good potential for implanting CSP plants are commonly situated in low-humid, semi-arid, and arid regions, thanks to their high direct normal irradiance (DNI) values. However, these regions are more susceptible to more significant water shortages. This is the case of the Northeast region of Brazil, which has the greatest potential for CSP development in the country, according to its DNI [58]. Despite this, most CSP plants in operation worldwide consist of STPT power plants with wet cooling, the most economically mature of the available CSP technologies.

Although less expressive, water consumption by mirror washing can also be optimized, not only maintaining the high reflectivity and generation efficiency but also saving cleaning costs associated with water, fuel, labor, etc. In this way, following some mirror cleaning strategies may significantly reduce water requirements, investment costs, and fuel consumption in a CSP plant. For example, adopting fixed and seasonal variable cleanliness thresholds seem to be promising pathways in this sense [59].

It is worth noting that there are some limitations in this analysis. First, our results are based on specific assumptions and estimations, such as the efficiency of CSP technologies in converting solar radiation into thermal energy. They also derive from our choices regarding the system boundaries and some arrangements made to adapt the LCI of CSP plants available in the Ecoinvent database 3.5. Therefore, these findings are not generalizable to every context, as the results can vary depending on the assumptions of the LCA study. Furthermore, whether our findings can change the final choice on long-term power planning in Brazil is still an open question. In addition to the environmental aspects considered in this paper, it relies on other variables, such as technical, economic, and social factors, locational issues, public policies, etc. Still, our work provides a first more accurate comparison between some of the leading CSP technologies for the country, helping to improve the quality of decision-making.

5. Conclusions

Since the global economy is advancing towards a low-carbon future by means of renewable energy sources, this paper addressed the environmental performance of three more suitable CSP technologies for electricity generation in Brazil: (i) STP with TSS of 7.5 h; (ii) STPT with a TSS of 6 h; and (iii) STPT without TSS. Our findings indicated that the STP system is the most environmentally sound CSP alternative, presenting lower GHG emissions and water consumption per kWh generated compared to the two STPT systems.

Compared to the main electricity generation technologies present in Brazil, CSP technologies prove to be more attractive than some fossil-fired power plants and renewable energy sources from an environmental point of view. Hence, against the current worldwide backdrop of growing environmental pressures, if integrated energy plans incorporate water consumption and GHG emissions costs in their computational models, there would be a potential for CSP generation to become more economically viable.

Although CSP technologies provide GHG emission mitigation opportunities when compared to fossil fuels, they emit these gases throughout their value chain. Since Brazil’s energy sector is low-carbon intensity, moving the manufacturing of these technologies to Brazil seems to be a promising pathway for reducing their carbon footprint, mainly their GHG emission from the upstream processes of their value chain. For this, however, the country needs to develop its industrial and technological park. Regarding the water consumption associated with the operation stage of CSP technologies, cooling systems and mirror washing correspond to the main water-consuming processes. Therefore, choosing air cooling systems and adopting some mirror strategies may significantly reduce water requirement in electricity generation from CSP plants.

Our immediate future works will be focused on feeding the MATRIZ model with the results obtained in this paper. Moreover, we would encourage researchers to evaluate scenarios in terms of different locations of CSP plants, examine other environmental impacts associated with CSP technologies, and analyze the effects of what would happen if their manufacturing was moved to Brazil. Lastly, considering that the urgency of addressing sustainability issues is encouraging a worldwide debate to incorporate socio-environmental aspects into the decision-making process within the energy sector, future research will have to expand our work in order to encompass the social and economic aspects of electricity generation from CSP technologies.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en15249286/s1, Table S1: CSP technologies and their location in Brazil considered in our analysis; Table S2: Sources for estimating the environmental impacts from CSP technologies; Table S3: LCIs from the Ecoinvent database v.3.5 adapted in the life cycle-based analysis of the CSP technologies; Table S4: Data from SAM used to estimate the water consumption during the operation stage of the CSP technologies; Table S5: Characteristics of CSP technologies from the Ecoinvent database 3.5; Table S6: Characteristics of CSP technologies used in the calculation of scale-up factors; Equation S1: Scale up factor. Reference [60] is cited in the supplementary materials.

Author Contributions

Conceptualization, D.M.; methodology, D.M. and J.G.L.; modelling and software, J.G.L.; validation, D.C.B. and A.O.P.J.; formal analysis, D.M. and J.G.L.; investigation, D.M.; resources, D.M.; writing—original draft preparation, D.M. and J.G.L.; writing—review and editing, J.G.L., D.C.B. and A.O.P.J.; supervision, D.C.B. and A.O.P.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the support of the Brazilian Electric Energy Research Center (CEPEL).

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations were used in this paper.

| CCGT | Combined-cycle gas turbine |

| CSP | Concentrating solar power |

| DNI | Direct normal irradiance |

| EPE | Brazilian Energy Research Office |

| ETSAP | Energy Technology Systems Analysis Program |

| GHG | Greenhouse gas |

| IEA | International Energy Agency |

| Inst. | Installation |

| kWh | Kilowatt-hour |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| MW | Megawatt |

| Opr. | Operation |

| PV | Photovoltaic |

| SAM | System advisory model |

| SCGT | Simple-cycle gas turbine |

| SIN | Brazilian National Interconnected System |

| STP | Solar tower power |

| STPT | Solar thermal parabolic trough |

| TIMES | The integrated MARKAL-EFOM system |

| TPP | Thermal power plant |

| TSS | Thermal storage system |

References

- Tolmasquim, M. Renewable Energy: Hydro, Biomass, Wind, Solar, Ocean; Brazilian Energy Research Office, Ed.; Brazilian Energy Research Office: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- Brazil. Brazilian Energy Balance 2020; Brazilian Energy Research Office: Brasília, Brazil, 2020. [Google Scholar]

- Brazil. The Ten-Year Energy Expansion Plan 2030; Brazilian Energy Research Office: Brasília, Brazil, 2021. [Google Scholar]

- Perez-Arriaga, I.J.; Batlle, C. Impacts of intermittent renewables on electricity generation system operation. Econ. Energy Environ. Policy 2012, 1, 3–18. [Google Scholar] [CrossRef]

- Trama, C.P.; Júnior, A.O.P.; Guimarães, A.P.C.; Diniz, A.L.; Vieira, L.D.S.R. Cost–benefit analysis of solar thermal plants with storage in a hydrothermal system. Energies 2021, 14, 5662. [Google Scholar] [CrossRef]

- Soria, R.; Lucena, A.F.P.; Tomaschek, J.; Fichter, T.; Haasz, T.; Szklo, A.; Schaeffer, R.; Rochedo, P.; Fahl, U.; Kern, J. Modelling concentrated solar power (CSP) in the Brazilian energy system: A soft-linked model coupling approach. Energy 2016, 116, 265–280. [Google Scholar] [CrossRef]

- Vieira de Souza, L.E.; Gilmanova Cavalcante, A.M. Concentrated Solar Power deployment in emerging economies: The cases of China and Brazil. Renew. Sustain. Energy Rev. 2017, 72, 1094–1103. [Google Scholar] [CrossRef]

- Brazil. The Ten-Year Energy Expansion Plan 2029; Brazilian Energy Research Office: Brasília, Brazil, 2020. [Google Scholar]

- Ma, R.; Yan, C.; Yu, J.; Liu, T.; Liu, H.; Li, Y.; Chen, J.; Luo, Z.; Tang, B.; Lu, X.; et al. High-Efficiency Ternary Organic Solar Cells with a Good Figure-of-Merit Enabled by Two Low-Cost Donor Polymers. ACS Energy Lett. 2022, 7, 2547–2556. [Google Scholar] [CrossRef]

- Yao, S.; Yang, T.; Shen, X.; Li, T.; Huang, B.; Liu, H.; Lu, X.; Liu, T.; Zou, B. Realizing the efficiency-stability balance for all-polymer photovoltaic blends. J. Mater. Chem. C 2022, 10, 9723–9729. [Google Scholar] [CrossRef]

- IRENA. The Power to Change: Solar and Wind Cost Reduction Potential to 2025; IRENA: Bonn, Germany, 2016. [Google Scholar]

- Brazil. 2050 Brazilian Energy Plan; Brazilian Energy Research Office: Brasília, Brazil, 2020. [Google Scholar]

- Lisboa, M.L.V.; Damásio, J.M.; Sabóia, C.H.M.; Maceira, M.E.P.; Melo, A.C.G.; Hollauer, G.; Masili, G.; Patusco, J.M. MATRIZ—A Model for Integrated Long-Term Planning Studies for the Brazilian Energy System. In Proceedings of the Symposium of Specialists in Electric Operational and Expansion Planning, Rio de Janeiro, Brazil, 20–23 May 2012. [Google Scholar]

- Tong, D.; Farnham, D.J.; Duan, L.; Zhang, Q.; Lewis, N.S.; Caldeira, K.; Davis, S.J. Geophysical constraints on the reliability of solar and wind power worldwide. Nat. Commun. 2021, 12, 6146. [Google Scholar] [CrossRef]

- IPCC. Annex I: Glossary—Global Warming of 1.5 °C. In Global Warming of 1.5 °C; An IPCC Special Report on the impacts of global warming of 1.5 °C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2018. [Google Scholar]

- Viebahn, P.; Lechon, Y.; Trieb, F. The potential role of concentrated solar power (CSP) in Africa and Europe—A dynamic assessment of technology development, cost development and life cycle inventories until 2050. Energy Policy 2011, 39, 4420–4430. [Google Scholar] [CrossRef]

- Mazzaferro, C. Life Cycle Assessment of Electricity Production from Concentrating Solar Thermal Power Plants; Universita Degli Studi Di Padova: Padua, Italy, 2017. [Google Scholar]

- Mayo, C.; Batuecas, E.; Díaz, R.; Pérez, F.J. Comparative environmental assessment of two materials suited to central tower CSP technology. Sol. Energ. 2018, 162, 178–186. [Google Scholar] [CrossRef]

- Gasa, G.; Lopez-Roman, A.; Prieto, C.; Cabeza, L.F. Life Cycle Assessment (LCA) of a Concentrating Solar Power (CSP) Plant in Tower Configuration with and without Thermal Energy Storage (TES). Sustainability 2021, 13, 3672. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, J.; Yang, Z.; Chen, J.; Luo, X.; Chen, Y. Economic-environmental evaluation and multi-objective optimization of supercritical CO2 based-central tower concentrated solar power system with thermal storage. Energy Convers. Manag. 2021, 238, 114140. [Google Scholar] [CrossRef]

- Barteczko-Hibbert, C.; Bonis, I.; Binns, M.; Theodoropoulos, C.; Azapagic, A. A multi-period mixed-integer linear optimisation of future electricity supply considering life cycle costs and environmental impacts. Appl. Energy 2014, 133, 317–334. [Google Scholar] [CrossRef]

- Rauner, S.; Budzinski, M. Holistic energy system modeling combining multi-objective optimization and life cycle assessment. Environ. Res. Lett. 2017, 12, 124005. [Google Scholar] [CrossRef]

- Louis, J.-N.; Allard, S.; Kotrotsou, F.; Debusschere, V. A multi-objective approach to the prospective development of the European power system by 2050. Energy 2020, 191, 116539. [Google Scholar] [CrossRef]

- GIZ/MCTI Basic Mapping of General Pre-Conditions for CSP Technologies in Brazil; GIZ/MCTI: Brasília, Brazil, 2014.

- GIZ/MCTI Parabolic Trough CSP Technology—State of the Art and Market Overview; GIZ/MCTI: Brasília, Brazil, 2014.

- GIZ/MCTI Tower CSP Technology—State of Art and Market Review; GIZ/MCTI: Brasília, Brazil, 2014.

- Ko, N.; Lorenz, M.; Horn, R.; Krieg, H.; Baumann, M. Sustainability Assessment of Concentrated Solar Power (CSP) Tower Plants—Integrating LCA, LCC and LCWE in One Framework. In Proceedings of the Procedia CIRP, Stockholm, Sweden, 16–18 May 2018; Volume 69. [Google Scholar]

- Pihl, E.; Kushnir, D.; Sandén, B.; Johnsson, F. Material constraints for concentrating solar thermal power. Energy 2012, 44, 944–954. [Google Scholar] [CrossRef]

- Seebregts, A.J.; Goldstein, G.A.; Smekens, K. Energy/Environmental Modeling with the MARKAL Family of Models. In Operations Research Proceedings 2001; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2002; pp. 75–82. [Google Scholar]

- Brazil. Brazilian Energy Balance 2012; Brazilian Energy Research Office: Brasília, Brazil, 2012. [Google Scholar]

- Loulou, R.; Remme, U.; Kanudia, A.; Lehtila, A.; Goldstein, G. Documentation for the TIMES Model Part I. IEA Energy Technology Systems Analysis Programme; IEA: Paris, France, 2005. [Google Scholar]

- Medeiros, A.; Raupp, I.; Damázio, J.; Costa, F. Incorporating the cost of water and carbon into long-term energy planning. In Proceedings of the XXV Seminário Nacional de Produção e Transmissão de Energia Elétrica, Belo Horizonte, Brazil, 10–13 November 2019. [Google Scholar]

- Carbon Pricing Leadership Coalition (CPLC). Report of the High-Level Commission on Carbon Prices; World Bank: Washington DC, USA, 2017. [Google Scholar]

- Brazil. Law No. 9433—Brazilian National Water Resources Policy; Brazil: Brasília, Brazil, 1997. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Laurent, A.; Espinosa, N.; Hauschild, M.Z. LCA of Energy Systems. In Life Cycle Assessment; Hauschild, M., Rosenbaum, R., Olsen, S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 633–668. [Google Scholar]

- ISO ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO ISO 14044; Environmental Management—Life Cycle Assessement—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Bjørn, A.; Moltesen, A.; Laurent, A.; Owsianiak, M.; Corona, A.; Birkved, M.; Hauschild, M.Z. Life cycle inventory analysis. In Life Cycle Assessment: Theory and Practice; Hauschild, M., Rosenbaum, R., Olsen, S., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 117–166. [Google Scholar]

- Lassio, J.G.; Magrini, A.; Castelo Branco, D. Life cycle-based sustainability indicators for electricity generation: A systematic review and a proposal for assessments in Brazil. J. Clean. Prod. 2021, 311, 127568. [Google Scholar] [CrossRef]

- CML-IA Characterisation Factors. Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 23 July 2022).

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008—A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Ministerie van VROM: The Hague, Netherlands, 2008. [Google Scholar]

- Huijbregts, M.; Steinmann, Z.; Elshout, P.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised LCIA method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Burgi, A. Assessment of the Technical Potential of Solar Thermal Electricity Production in Brazil Based on GIS Modeling and Simulation of Virtual Plants; Federal University of Rio de Janeiro: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Corona, B.; San Miguel, G. LCSA applied to an innovative configuration of concentrated solar power. Int. J. Life Cycle Assess. 2019, 24, 1444–1460. [Google Scholar] [CrossRef]

- Bjørn, A.; Owsianiak, M.; Molin, C.; Hauschild, M.Z. LCA history. In Life Cycle Assessment: Theory and Practice; Hauschild, M., Rosenbaum, R., Olsen, S., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 17–30. [Google Scholar]

- NREL. System Advisory Model (SAM) (Version 2018.11.11). 2020. Available online: https://sam.nrel.gov/ (accessed on 13 April 2022).

- Blair, N.; Dobos, A.P.; Freeman, J.; Neises, T.; Wagner, M.; Ferguson, T.; Gilman, P.; Janzou, S. System Advisor Model, SAM; NREL Rep. No. TP-6A20-61019; National Renewable Energy Laboratory—Golden Campus: Golden, CO, USA, 2014. [Google Scholar]

- Burkhardt, J.J.; Heath, G.; Cohen, E. Life Cycle Greenhouse Gas Emissions of Trough and Tower Concentrating Solar Power Electricity Generation. J. Ind. Ecol. 2012, 16, S93–S109. [Google Scholar] [CrossRef]

- Norton, B.; Eames, P.C.; Lo, S.N. Full-energy-chain analysis of greenhouse gas emissions for solar thermal electric power generation systems. Renew. Energy 1998, 15, 131–136. [Google Scholar] [CrossRef]

- Lechón, Y.; de la Rúa, C.; Sáez, R. Life Cycle Environmental Impacts of Electricity Production by Solarthermal Power Plants in Spain. J. Sol. Energy Eng. 2008, 130, 021012. [Google Scholar] [CrossRef]

- Caldés, N.; Lechón, Y. Socio-economic and environmental assessment of concentrating solar power systems. In Concentrating Solar Power Technology, 2nd ed.; Lovegrove, K., Stein, W., Eds.; Woodhead Publishing: Duxford, UK, 2021; pp. 127–162. [Google Scholar]

- Heath, G.; Turchi, C.; Decker, T.; Burkhardt, J.; Kutscher, C. Life Cycle Assessment of Thermal Energy Storage: Two-Tank Indirect and Thermocline. In ASME 2009 3rd International Conference on Energy Sustainability, Proceedings of the ASME 2009 3rd International Conference on Energy Sustainability Collocated with the Heat Transfer and InterPACK09 Conferences, San Francisco, CA, USA, 19–23 July 2009; ASME: San Francisco, CA, USA, 2009; pp. 689–690. [Google Scholar]

- Lenzen, M. Greenhouse gas analysis of solar-thermal electricity generation. Sol. Energy 1999, 65, 353–368. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, B.; Presciutti, A.; Baldassarri, C.; Scrucca, F. Comparative analysis of solar power technologies through life cycle assessment approach. In Proceedings of the 3rd International Energy, Life Cycle Assessment, and Sustainability Workshop & Symposium (ELCAS3), Nisyros, Greece, 7–9 July 2013; pp. 1059–1067. [Google Scholar]

- Brazil. Brazilian Energy Balance 2014; Brazilian Energy Research Office: Brasília, Brazil, 2014. [Google Scholar]

- IEA. World Energy Balances; IEA: Paris, France, 2014. [Google Scholar]

- Viana, T.S. Potential of Electricity Generation with Concentrating Photovoltaic System in Brazil. Ph.D. Thesis, Federal University of Santa Catarina, Florianópolis, Brazil, 9 April 2010. [Google Scholar]

- Rohani, S.; Abdelnabi, N.; Fluri, T.; Heimsath, A.; Wittwer, C.; Ainsua, J.G.P. Optimized mirror cleaning strategies in PTC plants reducing the water consumption and the levelized cost of cleaning. In Proceedings of the AIP Conference Proceedings, Atlantic City, NJ, USA, 25 July 2019; American Institute of Physics Inc.: College Park, MD, USA, 2019; Volume 2126. [Google Scholar]

- Telsnig, T. Location-Specific Analysis and Assessment of Solar Thermal Power Plants in South Africa; University of Stuttgart: Stuttgart, Germany, 2015. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).