Abstract

The growth in the number of cars and the increasing demand for fuels require scientific work to develop alternative fuels. The energy crisis, which is becoming more and more evident, is not unimportant. The manuscript presents an analysis of the possibility of using agricultural biofuels to power a diesel engine. The analysis was carried out in relation to the operation of the engine on conventional fuels. The D-241 engine under investigation is mainly used for agricultural tractors. During the tests carried out, the load characteristics of the diesel engine under investigation were determined as a function of fuel type and speed. The concentrations of CO, HC and NOx were analysed. Laboratory tests of the engine were carried out with a wide range of external loads to evaluate measurement errors for the measurement method. Experiments with the engine under investigation have shown that the hourly and specific biofuel consumption of diesel engines increases by an average of 11–16%. CO and NOx concentrations were found to be lower with increasing load compared to conventional diesel engines, while NOx concentrations are slightly increased. In all cases investigated, a decrease in exhaust development was observed.

1. Introduction

Internal combustion engines (ICE) have found wide application, especially in road transport. Road transport is one of the industries that largely determines the development of industry and agriculture in each country. This has resulted in a continuous increase in the world’s vehicle fleet, and at the same time road transport is one of the main sources of air pollution with harmful substances. It is related to the energy consumption of fossil fuels.

Modern trucks and vans are mainly equipped with diesel engines, which due to their advantages will remain in common use (at least in the near future).

Furthermore, taking into account the fact that traditional engine fuels are made of non-renewable raw materials, the world’s resources are gradually depleting. The problem of replacing petroleum-derived fuels in diesel is urgent and is associated with the search for alternative energy sources and comprehensive research into the possibility of using alternative fuels (AF) in vehicle diesel engines.

The most promising among AFs are fuels obtained from gaseous raw materials, coal and shale, as well as fuels from vegetable raw materials or from recycled animal raw materials [1,2,3,4,5,6]. It is also promising, from the point of view of cost reduction, to obtain fuel from various wastes such as eggshell, pineapple peel or animal bones [7,8].

At this stage of the development of alternative energy sources in Ukraine, it is more rational to use plant-based fuels in ICE. These fuels, whose main properties are similar to those of traditional diesel fuel, can be effectively used in diesel engines without structural changes or minor modifications.

Given the relatively low cost and availability, vegetable oils have a number of positive properties. For example, rapeseed oil has a high cetane number, and practically does not contain polycyclic aromatic hydrocarbons. When vegetable oils are burned, the amount of CO2 absorbed by plants in the photosynthesis process is released into the environment, and thus the balance of “greenhouse” gas in the atmosphere is maintained. Plant residues and seed processing products are available as raw materials for the production of fertilizers and animal feed. After hitting the ground, such fuel does not cause environmental damage, as compared to crude oil [9,10].

Liquid biofuel suitable for use in diesel engines can be obtained by refining, distilling or esterifying vegetable oil obtained by pressing various oilseeds [11].

Switching to the use of fuels based on vegetable oils and their processed products will partially solve the problem of modernity—to some extent, in order to meet the constantly growing energy needs without harming the environment [12,13].

The switch to clean fuels is just a moment’s need. To this end, many countries have developed a set of measures that include regulation, production planning, preferential taxation, state budget support and more.

The countries of the European Union (EU) occupy the leading position in the production and consumption of biofuel for diesel engines. This is explained by the developed regulatory and legal measures aimed at stimulating the use of cleaner energy sources rather than traditional diesel oil [14], as well as the adopted tax incentives for diesel biofuels producers.

Despite the rapid growth of rapeseed cultivated in Ukraine in recent years, a significant part of its seeds (approx. 90%) is exported to European countries [15]. Therefore, the dynamics of the production of this biofuel in Ukraine depends directly on the global trends in the development of this sector and related investment flows in the industry [16].

The use of biofuel for diesel engines will help solve a number of energy, economic and environmental problems in Ukraine and around the world, and will make a significant contribution to creating conditions for full or partial replacement of petroleum fuels [17].

The results of research on changes in fuel consumption indicators and environmental indicators during engine operation with biofuel were highlighted in their works by leading scientists.

In work [18], a study of the efficiency of using the additive of triethylene glycol monomethyl ether to diesel biofuel obtained from used cooking oil in an engine operating on a gas-diesel cycle was carried out. As a result of the addition of an oxygen-containing additive, an increase in thermal efficiency was established, as well as a decrease in emissions of harmful substances.

The work [19] is devoted to the study of the combustion process and the working process of a diesel engine when operating on diesel biofuel obtained by mixing conventional diesel fuel with melt oil in different proportions. As a result, it was established that with an increase in the proportion of tall oil in the fuel, the maximum pressure and temperature of the cycle decrease. The maximum torque and engine power also decrease. The maximum power decreases by 1.7%, which slightly affects the performance of the engine and indicates the possibility of using diesel biofuel instead of conventional fuel of petroleum origin.

The work [20] presents the results of studies of a single-cylinder diesel engine operating on mixed fuel, which consisted of ordinary diesel fuel with the addition of 10% diesel biofuel and various percentage values of ethyl alcohol. It has been established that emissions of unburned hydrocarbons and carbon monoxide with exhaust gases are reduced when working on mixed fuel.

In [21], the results of studies on the efficiency of using diesel biofuel from castor oil are given using modeling using an artificial neural network. The performance indicators of the engine were studied when working on pure biofuel and mixtures with diesel fuel. It was established that when working on clean biofuel, engine power decreases; hourly and specific effective fuel consumption increases. The best results are obtained for the operation of a diesel engine on mixed fuels.

Similar work was presented [22] giving the results of modeling and optimization of CI engine fueled with biodiesel blends. The fuzzy model was created for modeling, while a particle swarm optimization algorithm was used for determination of optimal parameters.

However, despite a significant number of scientific works, further research into the performance of internal combustion engines when fueled with diesel biofuel is relevant. One of the reasons is the wide variety of used biofuels, which differ significantly in their physicochemical and motor properties. Since vehicle diesels are one of the main consumers of motor fuels and a source of environmental pollution, there is a need to conduct additional theoretical and experimental research in this direction.

2. Materials and Methods

The aim of the experimental research is to determine the environmental and fuel-economic indicators of the D-241 diesel engine when operating on traditional diesel oil and diesel biofuel. The performance of a diesel engine running on conventional diesel fuel and two samples of diesel biofuel from two different manufacturers is investigated. Technical characteristics of the engine are given in Table 1.

Table 1.

Main characteristics of the diesel engine D-241.

Two samples of diesel biofuel were chosen for research, which was rapeseed oil methyl ester, which is a technical plant crop and belongs to the non-food group. These fuels comply with the Ukrainian national standard DSTU 6081:2009. As can be seen from Table 2, some physical and chemical properties of these two samples of diesel biofuel differ from each other, although they meet the same standard. Fuel characteristics are given in Table 2.

Table 2.

Physico-chemical properties of used fuels.

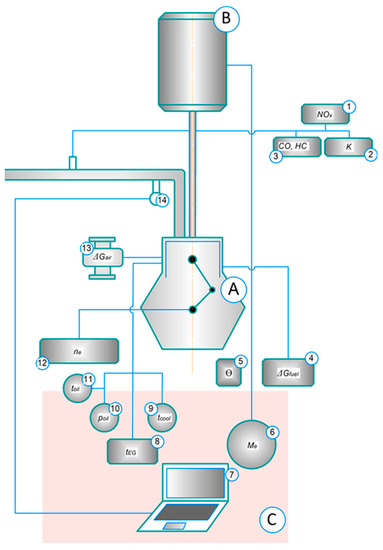

For engine tests, the laboratory of the Department of Engines and Thermal Engineering of the National Transport University has created an installation (Figure 1) which enables the engine to be tested in a wide range of external loads.

Figure 1.

Diagram of the experimental installation: (A)—D-241 diesel; (B)—AKB 82-4 electric machine; (C)—control panel; 1—344HL-14 gas analyzer; 2—INA-109 opacimeter; 3—INFRAKAR gas analyzer; 4—electronic scale MEASUREMENT VM 2/3; 5—SNAP-ON MT2261 (TAU-1000) electronic strobe with SNAP-ON MT257A attachment; 6—analog dynamometer; 7—personal computer; 8—analog HV temperature indicator; 9—analog coolant temperature gauge; 10—analog engine oil pressure indicator; 11—analog engine oil temperature gauge; 12—F5035 digital tachometer; 13—RG-600 rotary gas meter; 14—LC-1 broadband controller.

Multiple direct and indirect measurements were made during the experimental research. In particular, hourly fuel consumption, engine torque, rotation frequency, injection advance angle, engine temperature and concentration of harmful substances in exhaust gases were determined by direct measurements. Effective power and specific effective fuel consumption were determined by indirect measurements.

During the experimental research, the measurement errors were assessed with regard to the measurement method. In the case of direct and indirect one-off measurements, the measurement errors are determined by the errors of the devices used. Data on the measuring apparatus and devices used in the experimental tests are given in Table 3. The data show that all devices used during the tests met the requirements for measuring devices.

Table 3.

Measurement errors of devices and equipment Physico.

3. Results and Analysis

During the motor research, a number of load and speed characteristics of the D-241 diesel engine were obtained.

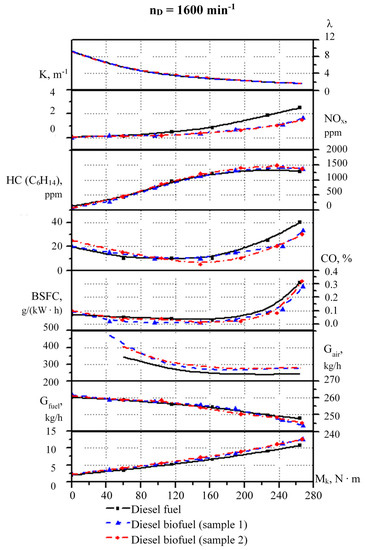

For example, Figure 2 shows the load characteristics when the diesel engine is running on different fuel samples and the rotation frequency ND = 1600 min−1.

Figure 2.

D-241 diesel engine load characteristics.

As can be seen from the characteristics of the engine operation using biofuel diesel oil, the presented samples are accompanied by an increase in hourly and specific fuel consumption by an average of 12%. At the same time, concentrations of nitrogen oxides (NOx) vary depending on the load of the diesel engine: at low loads, they are lower (by 3%) than when operating with traditional diesel fuel, and with increasing load, they are higher (up to 7%). At the same time, there is a significant reduction in exhaust gas opacity (to almost 34%).

The concentrations of carbon monoxides CO and HC hydrocarbons also change depending on the load with diesel fuel, and as the load increases, the concentrations of CO and HC are lower compared to traditional diesel fuel.

In general, the environmental indicators of the engine when working on rapeseed oil methyl esters change as follows:

- within wide speed limits and load regimes, an increase in hourly and specific fuel consumption is observed on average by 11 … 16%;

- the concentrations of carbon monoxides CO and HC hydrocarbons change depending on the load on diesel fuel, and with increasing load, the concentrations of CO and HC are lower, compared to traditional diesel fuel, by 3% and 23%, respectively;

- an increase in the concentration of nitrogen oxides NOx by 7 … 9% in relation to diesel fuel in all speed and load modes;

- diesel exhaust opacity during operation with biofuel decreases in all speed and load modes. The maximum reduction of exhaust smoke (up to 35 … 42%) is achieved at maximum load.

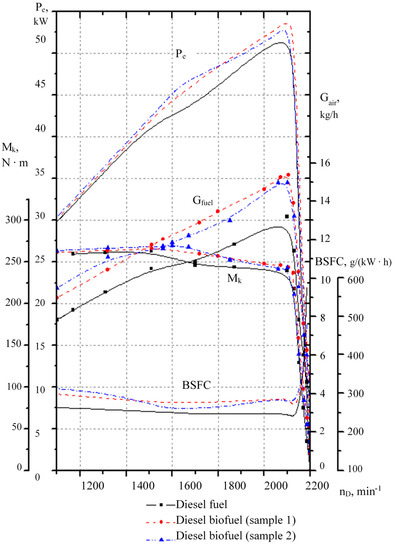

Figure 3 shows the external speed characteristics of a D-241 diesel engine when running on conventional diesel and biodiesel from various manufacturers. The reason for the change in the concentrations of harmful substances in the exhaust gases of the engine may be the presence of more oxygen in diesel biofuel and the different structure of the hydrocarbon chains of this fuel. These properties affect the combustion process in the engine cylinder, which determines the efficiency of the work cycle and the formation of harmful substances. In order to more accurately determine the reasons for changes in concentrations of harmful substances, it is necessary to conduct further study of the combustion process in the engine cylinder when operating on diesel biofuel.

Figure 3.

External speed characteristics of the D-241 diesel engine.

There was also an increase in maximum power. Hourly and specific fuel consumption when operating on biofuel increases by 14 … 16% and 13 … 14%, respectively, compared to traditional diesel fuel. Figure 4 shows the idling characteristics of a diesel engine.

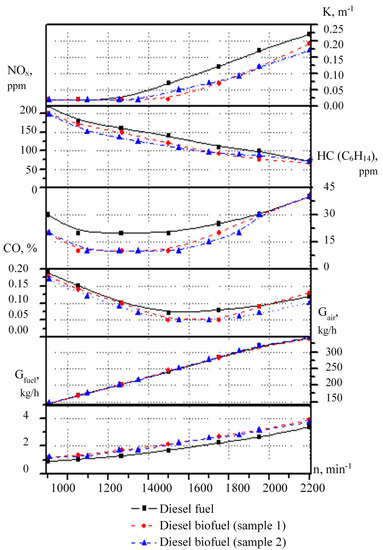

Figure 4.

Idle characteristics of the D-241 diesel engine.

The characteristics show that the operation of a diesel engine on diesel fuel is accompanied by an increase in hourly fuel consumption, while the concentrations of the main harmful substances in exhaust gases are lower when operating on diesel fuel compared to diesel fuel.

4. Conclusions

According to the results of the experimental tests on the laboratory scale of the D-241 diesel engine, the possibility of using biofuel in diesel engines of road tractors was confirmed without introducing changes to their design, and it was established:

- hourly and specific consumption of biofuel for diesel engines increases by an average of 11 … 16% compared with traditional diesel fuel in a wide range of speeds and load modes;

- the concentrations of carbon monoxides CO and HC hydrocarbons change depending on the load with diesel fuel, and with increasing load, the concentrations of CO and HC are lower by 3% and 23%, respectively, compared to traditional diesel fuel;

- concentrations of nitrogen oxides NOx at certain speeds and load modes are slightly increased (by 7 … 9%) compared to the operation of the engine on diesel fuel;

- there is a decrease in exhaust opacity in all engine operation modes by 35 … 42% of speed and load compared to operation with traditional diesel fuel.

It should be noted that biofuels of the same type that meet the same standard may differ slightly in some physical and chemical properties. As a result, the performance parameters of engines when they are used are also different. Therefore, for the expansion of the fuel base, it is relevant to conduct similar studies when new types of fuels appear. In our work, we obtained numerical values of parameters that characterize the engine as a consumer of fuel and air and a source of emissions of harmful substances with exhaust gases when operating on traditional diesel fuel and diesel biofuel in a wide range of load and speed modes. These results can be used to predict the efficiency of using diesel biofuel in other engines as well.

The depletion of readily available sources of fossil fuels, global disruptions in supplies, as well as the increasing threats resulting from the impact of exhaust emissions on the climate, force the search for new energy sources. In this situation, fuel obtained from biological sources, and especially from lignocellulosic waste and food industry waste, can be an important substitute. An important research problem is to determine to what extent such biofuels can be used in the engines currently utilised to power vehicles. The current work shows that biofuel for diesel engines can be used without the risk of engine deterioration or increased emissions of harmful substances. The use of biofuel also keeps CO2 emissions within the limits of the natural carbon cycle without introducing an additional contribution from fossil sources. As a result, the use of fossil fuels positively affects the mitigation of the greenhouse effect.

Author Contributions

Conceptualization, S.K., V.S., Y.S., S.G. and V.M.; methodology, S.K., V.S., Y.S., J.M., O.O.; software, S.K., V.S., V.M., A.W. and K.T.; validation, Y.S., J.M., O.O. and K.T.; formal analysis, S.K., V.S., Y.S., V.M. and A.W.; investigation, S.K., V.S., Y.S., J.M. and O.O.; data curation, S.K., V.S., Y.S., J.M. and O.O.; writing—original draft preparation, S.K., V.S., Y.S., J.M., O.O. and A.W.; writing—review and editing, S.K., V.S., Y.S., J.M., V.M. and O.O.; visualization, S.K., V.S., Y.S., J.M. and O.O.; supervision, Y.S., J.M., O.O. and K.T.; project administration, J.M. and O.O.; funding acquisition, J.M. and O.O. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out under financial support obtained from a research subsidy of the Faculty of Engineering Management (WIZ) of Bialystok University of Technology. From the grant No. WZ/WIZ-INZ/4/2022 (Olga Orynycz). Part of this research was carried out during the exchange stays of O. Orynycz at Vilnius University of Technology (Lithuania 2021, 2022), and cooperation stays at the Department of Computer Science Technology and Production Robotics, of the Faculty of Mechanical Engineering, Lublin University of Technology (2021, 2022). Part of the research was also carried out during the scientific stay of O. Orynycz at the Department of Transport and Logistics of Institute of Technology and Business in České Budějovice (2022).

Data Availability Statement

The study did not report any data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, Y.; Yang, X.; Zhu, Z. Economic evaluation and production process simulation of biodiesel production from waste cooking oil. Curr. Res. Green Sustain. Chem. 2021, 4, 100091. [Google Scholar] [CrossRef]

- Stopka, O.; Šarkan, B.; Vrabel, J.; Caban, J. Investigation of fuel consumption of a passenger car depending on aerodynamic resistance and related aspects: A case study. Arch. Automot. Eng.—Arch. Motoryz. 2018, 81, 129–136. [Google Scholar] [CrossRef]

- Zainudin, M.A.; Winaya, A.; Rahmadesi, Y. Biodiesel generated from Jatropha (Jatropha curcas Linn.) Seeds selected based on various genotypes crossbred. Energy Rep. 2020, 6, 345–350. [Google Scholar] [CrossRef]

- Helmiyati, H.; Budiman, Y.; Abbas, G.H.; Dini, F.W.; Khalil, M. Highly efficient synthesis of biodiesel catalyzed by a cellulose@hematite-zirconia nanocomposite. Heliyon 2021, 7, e06622. [Google Scholar] [CrossRef] [PubMed]

- Manko, I.; Shuba, Y.; Korpach, A.; Gutarevyc, S.; Ragulskiene, J.; Pauliukas, A. Measurement of Fuel Consumption and Harmful Emissions of Cars When Using Different Types of Fuel. J. Meas. Eng. 2020, 8, 182–196. [Google Scholar] [CrossRef]

- Adepoju, T.F.; Ibeh, M.A.; Asuquo, A.J. Elucidate three novel catalysts synthesized from animal bones for the production of biodiesel from ternary non-edible and edible oil blend: A case of Jatropha curcus, Hevea brasiliensis, and Elaeis guineensis oil. S. Afr. J. Chem. Eng. 2021, 36, 58–73. [Google Scholar] [CrossRef]

- Adekunle, A.S.; Oyekunle, J.A.O.; Oduwale, A.I.; Owootomo, Y.; Obisesan, O.R.; Elugoke, S.E.; Durodola, S.S.; Akintunde, S.B.; Oluwafemi, O.S. Biodiesel potential of used vegetable oils transesterified with biological catalysts. Energy Rep. 2020, 6, 2861–2871. [Google Scholar] [CrossRef]

- Mohiddin, M.N.B.; Tan, Y.H.; Seow, Y.X.; Kansedo, J.; Mubarak, N.M.; Abdullah, M.O.; Chan, Y.S.; Khalid, M. Evaluation on feedstock, technologies, catalyst and reactor for sustainable biodiesel production: A review. J. Ind. Eng. Chem. 2021, 98, 60–81. [Google Scholar] [CrossRef]

- Kovbasenko, S.V. Prospects for the production and use of biodiesel fuel in Ukraine. Bull. Natl. Transp. Univ. 2007, 15, 28–31. [Google Scholar]

- Kovbasenko, S.V. Perspektyvy zaminy tradytsiinykh palyv v Ukraini. In Proceedings of the Conference Materials SAKON’08 XIX–International Conference. Computational and Research Methods in the Development of Motor Vehicles and Self-Propelled Working Machines. Management and Marketing in the Automotive Industry, Rzeszów-Przecław, Poland, 24–27 September 2008; pp. 187–192. [Google Scholar]

- Orynycz, O.A. Influence of Tillage Technology on the Energy Efficiency of a Rapeseed Plantation, Procedia Engineering; Elsevier: Amsterdam, The Netherlands, 2017; Volume 182, pp. 532–539. [Google Scholar] [CrossRef]

- Orsik, L.S.; Sorokin, N.T.; Fedorenko, V.F.; Buklagin, D.S.; Mishurov, N.P.; Tikhonravov, V.S. Bioenergetics: Global Experience and Projected Growth, 1st ed.; FGNU “Rosinformagrotekh”: Moscow, Russia, 2008; pp. 1–404. [Google Scholar]

- Fedorenko, V.F. Status and Development of Biofuels. In Scientific Analytic Review, 1st ed.; Fedorenko, V.F., Kolchinskij, Y.L., Shilova, E.P., Eds.; FGNU “Rosinformagrotekh”: Moscow, Russia, 2007; pp. 1–130. [Google Scholar]

- Kotrba, R. Global biodiesel production and market report. Biodiesel Mag. 2010, 130, 24–28. [Google Scholar]

- Business Views. Agribusiness of Ukraine. Available online: http://businessviews.com.ua/ru/agroreport2014 (accessed on 23 September 2022).

- Kurbatova, T.A. Ekonomicheskie perspektivy i problemy razvitiya sektora zhidkogo biotopliva v Ukraine. Nauchnyj Vestn. Mosk. Gos. Gorn. Univ. 2013, 11, 126–133. [Google Scholar]

- Geng, L.; Bi, L.; Li, Q.; Chen, H.; Xie, Y. Experimental study on spray characteristics, combustion stability, and emission performance of a CRDI diesel engine operated with biodiesel–ethanol blends. Energy Rep. 2021, 7, 904–915. [Google Scholar] [CrossRef]

- Shoar, F.H.; Najafi, B.; Mosavi, A. Effects of triethylene glycol mono methyl ether (TGME) as a novel oxygenated additive on emission and performance of a dual-fuel diesel engine fueled with natural gas-diesel/biodiesel. Energy Rep. 2021, 7, 1172–1189. [Google Scholar] [CrossRef]

- Gautam, R.; Kumar, S. Performance and combustion analysis of diesel and tallow biodiesel in CI engine. Energy Rep. 2020, 6, 2785–2793. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Q.; Liang, J.; Yang, C. The performance and emissions characteristics of diesel/biodiesel/alcohol blends in a diesel engine. Energy Rep. 2021, 7, 1016–1024. [Google Scholar] [CrossRef]

- Umeuzuegbu, J.C.; Okiy, S.; Nwobi-Okoye, C.C.; Onukwuli, O.D. Computational modelling and multi-objective optimization of engine performance of biodiesel made with castor oil. Heliyon 2021, 7, e06516. [Google Scholar] [CrossRef] [PubMed]

- Alahmer, A.; Rezk, H.; Aladayleh, W.; Mostafa, A.O.; Abu-Zaid, M.; Alahmer, H.; Gomaa, M.R.; Alhussan, A.A.; Ghoniem, R.M. Modeling and Optimization of a Compression Ignition Engine Fueled with Biodiesel Blends for Performance Improvement. Mathematics 2022, 10, 420. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).