Abstract

Over 5.5 million tons of plastic waste are generated globally from the research sectors. A university laboratory, e.g., pathology, can generate 250 tons of clinical plastic waste annually. The UK National Health Service (NHS) generates 133 kilotons (kt) of clinical plastic waste annually. Healthcare facilities in the US generate 1.7 million tons of clinical plastic waste annually. In addition, 95% of the clinical plastics are single-use plastics derived from fossil resources, i.e., crude oils. These single-use clinical plastic wastes are incinerated, contributing to global warming, or go to the landfill, contributing to resource depletion. Plastic leakage is a major threat to the environment. This linear plastics economy model, take-make-dispose, must be replaced by a circular plastics economy, i.e., sort plastic wastes, wash, decontaminate, recover materials, blend with bio-based compounds as necessary and circulate recyclate plastics, for holistic systemic sustainability. While there are multi-faceted environmental drivers for a circular plastics economy, there are many uncertainties in the economic attributes, electricity price, labor cost and chemical cost being the primary ones influencing the cost of production of secondary or recyclate plastics, requiring government and policy support, such as a gate fee on plastic waste by the generators to the recyclers. An essential macroeconomic condition for techno-economically (or micro-economically) feasible plastic waste recycling is low oil and gas prices that influence the recyclate plastics and electricity prices. It is essential to de-fossilize the economy by decoupling renewable electricity generation from natural gas consumption and fossil-independent biopolymer productions displacing fossil-derived plastics to stimulate the circular economy. This study shows a comprehensive and robust technoeconomic analysis of mechanical recycling of clinical plastic wastes into secondary plastics recovery.

1. Introduction

Globally, plastics production has grown from 2 million tons in 1950 to 380 million tons in 2015; the 2015 production rate is further expected to double by 2035 and quadruple by 2050 [1]. Clinical or medical plastics have the poorest accountability and management. The healthcare and laboratory sectors’ clinical plastics have replaced ceramic or glass because their durability, non-breakability, tenacity, and multi-faceted functionalities offer superior health and safety performances. However, their pollution presents a major threat to the environment. They are primarily single-use plastics. Single-use clinical plastics pose major environmental and sustainability concerns because of the loss of fossil resources when landfilled and in the form of global warming potential when incinerated. Biochemical hazard levels of single-use clinical plastic wastes may not allow them to recycle for material recovery. Low-hazard level single-use clinical plastic wastes if segregated at the source can be recycled for secondary material recovery or remanufacturing of plastics. However, sorting and segregation of single-use clinical plastic wastes are not easy in the healthcare sector when the priority for doctors and nurses is saving lives. All single-use clinical plastic wastes are thrown away unsegregated, making them difficult to recycle. The waste disposal hierarchy prioritizes secondary material recovery over tertiary recovery i.e., chemical recovery, quaternary recovery i.e., energy recovery from incineration and landfilling. If the reuse of single-use clinical plastic wastes is not an option, secondary material recovery by mechanical recycling essentially returning remanufactured plastics into the value chain is the most preferred option for the environment and sustainability. However, in addition to segregation at the source challenge, the other challenge is the low-grade quality of the recovered secondary plastics because of contamination and potential decontamination methods. All these challenges make the economy of single-use clinical plastic waste recycling unfeasible, seeking public, government or policy support. The problem needs systematic scoping and techno-economic feasibility analyses that have not been addressed in the literature. The purpose of this study is to analyze the technical and economic feasibility of remanufacturing/mechanical/secondary recycling of clinical plastic waste to create conditions for a circular clinical plastics economy. The presented analysis is extremely valuable since no reliable economic data on clinical plastics is yet available.

2. Literature Review

The processing steps to recycle plastic waste by secondary or mechanical recycling method are well established; however, the application of the secondary or mechanical method to recycle clinical plastic waste is novel. The secondary recycling method comprises washing, sterilization, drying, shredding, and micro-extrusion into recyclable plastic pellets [2]. A foundational assumption is that the healthcare and laboratory sectors have source segregation protocols and strategies in place. Given the flexible unit sizes and capacities, the processing steps are adaptable and allow adjacent recycling facilities to the clinical plastic waste generation source. Alternatively, washing, sterilization, and drying could be done on-site at the point of their waste generation and transported to a site with extrusion facilities to blend additives appropriately to pelletize the plastics. A comprehensive analytical testing suite must complement the processing steps to ensure that the remanufactured plastics have recyclable qualities. All these processing steps and research and development capabilities must be costed in to determine whether a single-use clinical plastic waste recycling project is viable or not and which post-use clinical plastic products are recyclable by which processing steps at what cost. There is no literature to answer this research question.

A high-level macro-scale economic analysis based on material flow analysis has been done to conclude that reductions in illegal or mixed disposal of medical plastics in China through incineration with energy recovery could lead to environmental and economic benefits [3]. The macroeconomic parameters assumed include material volumes, efficiencies, carbon taxation, and various emission factors. A combined mechanical and chemical recycling process has been proposed for mixed lightweight packaging containing polypropylene, polyethylene, polyvinyl chloride, and polystyrene [4]. For such bulk materials, mechanical processing alone may not give virgin or high-quality plastics. Chemical recycling such as pyrolysis recovers monomers from the mechanically recovered secondary plastics and monomers are re-polymerized into high-quality quality plastics. Chemical recycling using the pyrolysis of plastic wastes has been the major focus of the literature and the most common industrial practice [5,6,7]. Primarily focused on policy interventions to help plastics recycling, a review article gives a life cycle cost (capital, operating, and maintenance costs) estimate of 204 EUR/t of recycled plastics by mechanical recycling methods [8]. Mechanical recycling of plastic wastes has been undoubtedly the cheapest among all other less-preferred waste hierarchical options, pyrolysis, gasification, and incineration. However, incineration becomes cheaper when sorting is manpower intensive. The capital, operating, and maintenance costs of mechanical recycling of plastics applicable to polypropylene, polyethylene terephthalate and polyvinylchloride can be up to 230 USD/t, giving rise to new products [8]. The environmental incentives result from the avoidance of climate impact potential that would have resulted from incinerating plastic wastes. The study signifies the key parameters for economic viability, labor cost, chemical cost, energy cost, maintenance cost, insurance, and taxation [8]. Recycled plastics can save 2, 0.7, 0.6, and 0.5 kg CO2 equivalent per kg against virgin polymers, polyethylene terephthalate and polystyrene, low-density polyethylene, polypropylene, and high-density polyethylene and polyvinyl chloride [8,9,10,11,12]. With the assumption of like-by-like displacement of virgin plastics with secondary plastics from mechanical recycling, the global warming potential savings are estimated to be 3.1, 1.18, and 1.16 kg CO2 equivalent per kg for polystyrene, polypropylene, and polyethylene film [13]. The variations in these estimates are due to inventory data, reference year, geographic location, supply chain assumptions, etc. Overall, the ranking between circular economy models has a consensus; these, in the decreasing order of preference, are secondary (mechanical), tertiary (chemical), and quaternary (incineration with energy recovery), respectively, from environmental and economic perspectives and therefore sustainability perspectives. Despite their top ranking in the waste disposal hierarchy after reuse, data on mechanical recycling methods are scarce in the literature because most mechanical recycling technologies are proprietary to developers [14,15]. In a techno-economic analysis study, assumptions have been made regarding plant capacity, operating time, land, operators, plant lifetime, discount rate, corporate tax rate, working capital, depreciation rate, infrastructure, project management costs, contingency charges, labor cost, plant overheads, insurance, land, utility, and chemical and feedstock costs [14]. Most techno-economic cost items are sourced from general engineering cost estimations [16]. Feedstock costs have been considered as gate fees, which can be positive or negative depending on whether the feedstock was purchased, or the waste generator had to pay for recycling the waste feedstock. The energy consumption has been calculated from enthalpy differences across the dryer and micro-extrusion [14]. This kind of thermodynamic analysis is possible when a plant is running. However, for the cost of a plastics recycling project, stream properties are unlikely to be available and energy rating of equipment from vendors can replace such measurements. Unlike [14], most literature has dealt with pure fractions, such as high-density polyethylene bottles. Although recycling mixed films and tray-like plastics has been considered [14], medical plastics recycling data are practically missing from the open literature, making such project evaluations extremely challenging. More importantly, there are no reliable economic data yet available to assess the economic feasibility conditions of recycling clinical plastic waste. To fill such data gaps, an attempt has been made to itemize various cost parameters and assign standard values to the items to make them transparent all the way through this study. Hotspots have been identified and sensitivity analyses have been performed to establish the cost of production ranges based on extreme limits on sensitive parameters. The paper is structured as follows. The Materials and Methods section has two parts: clinical plastics material evaluations and techno-economic analysis methodology. The Results and Discussion section shows the baseline economic analysis results, followed by discounted cash flow and sensitivity analysis results. The final section draws on the main conclusions of the study.

3. Materials and Methods

This section discusses the methodology developed and adopted in this study. The researchers engaged with recyclers, medical plastic production and remanufacturing equipment providers, hospital procurement and sustainability teams, and a mechanical recycling small-to-medium enterprise business to gather data and insights. For the scoping analysis of a circular clinical plastics economy project, data requirements are the plastic waste constituent, plastic product constituent and the various economic parameters. For the latter, engineering correlations [16,17] have been adopted as shown later in this section. For the former, in the absence of data, the researchers have relied on literature-based data on limited types of clinical plastic products reported. Clinical plastics can be of two types depending on their use, laboratory clinical plastics and healthcare clinical plastics. The latter has further divisions into catering and non-catering plastics. This study is focused on laboratory and healthcare non-catering clinical plastics. Table 1 shows the material constituents of laboratory clinical plastics or labware plastics [18]. A major problem in recycling these polymers is the wide number of these polymers with varying properties and melting points. Every polymer has a characteristic that is very specific for a particular application, and this can also be seen clearly within the laboratory clinical plastics space.

Table 1.

Base polymers in laboratory clinical plastics.

There are other materials such as silicone, polyethylene terephthalate glycol, polyethylene terephthalate, nylon, and polyethersulfone present within these above products and need to be separated before palettization. For example, products such as centrifuge filters have different materials for housing and membranes. The materials used in membranes are polyvinylidene fluoride, nylon, polytetrafluoroethylene, polyethersulfone, and polypropylene [54]. The housing material could be polystyrene or high-density polyethylene. Some products are used for the labelling of the sample bottle. These labelled materials are also developed to be temperature resistant and will be difficult to remove by cleaning the plastic samples with cold or warm water. It would require boiling water which could be an energy or cost-intensive process [55]. Limited healthcare clinical plastic product types have been identified for the base polymers present [56] (Table 2).

Table 2.

Base polymers of some common medical plastic products.

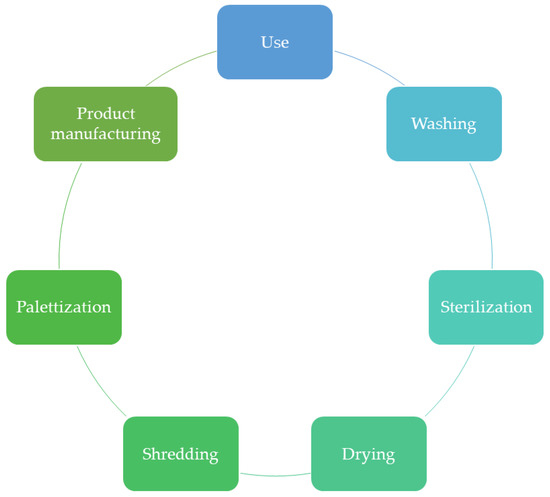

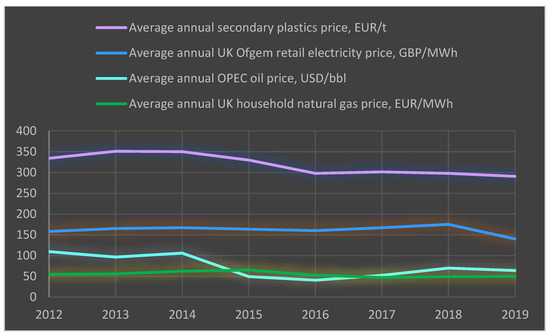

Used clinical plastic products with low to moderate hazard levels, which rarely cause diseases and do not lead to lethal conditions, are suitable to recycle through a system configuration, shown in Figure 1. The processing steps of clinical plastic waste are washing, sterilization, drying, shredding, and pelletization to produce recyclate plastics. There is a market for secondary/remanufactured plastics. Clinical plastic product manufacturers can blend secondary plastics with bioplastics if applicable to meet the product properties. Clinical plastic products are distributed to various laboratories and hospitals, where they are used. It is assumed that post-use, the clinical plastic streams are segregated according to the base polymer type. An important step is therefore the analytical characterization of plastic products to establish their material constituents and properties. These tests can indicate the polymers in the products, which will be pre-determined to decide which plastic products could be put together for remanufacturing. Segregated streams would go through washing and other steps. It can also be assumed that with time, more and more virgin polymers would be replaced with biopolymers and all the reagents, energy and materials needed in the life cycle would be fossil-free renewable or bio-based resources, thus, de-fossilizing the economy [57]. It can be noted that secondary plastic prices are dependent on crude oil prices. The processes in circular plastics systems consume electricity, the price of which has recently seen an upsurge due to the high gas price. Figure 2 demonstrates the dependency of secondary plastics prices on crude oil prices and electricity prices on gas prices (from 2012 to 2019 with 2019 being the final year for the data collection because the open-source data have been stabilized up to 2019). The data sources are [57,58,59,60]. The secondary plastic prices have stayed between 220 and 360 EUR/t with an average of 320 EUR/t. The average electricity price has been 162 GBP/MWh. However, due to the natural gas price rise in recent times, the retail electricity price in the UK has gone up. It can be noted that in summer, the UK grid electricity is 100% renewable and is not dependent on natural gas prices. For high electricity demand, electricity price is dependent on fossil resource (natural gas) prices. As the mechanical recycling of plastics is dependent on electricity price, the sensitivity of electricity price must be analyzed.

Figure 1.

Circular clinical plastics economy configuration.

Figure 2.

Average annual secondary plastics, UK retail electricity, OPEC oil, and UK household natural gas prices from 2012 to 2019.

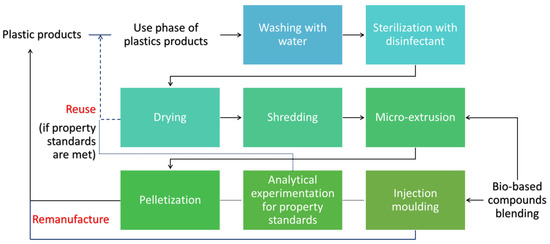

Figure 3 shows the flowchart with processing and life cycle stages for the conceptual design, development, and analyses of circular plastics systems. Plastic products can be analytically tested to establish their properties, mechanical, physical, and chemical. Properties of the products are essential to finding out if the recycled products had to go back to the value chain with the same purpose and functionalities. Due to stringent standards and policies in the healthcare sector, an extensive set of properties may be required for clinical plastics which are maximum use temperature, heat deflection temperature or heat distortion temperature, brittleness temperature, melting point, glass transition temperature, clarity, microwave ability, specific gravity, permeability, water vapor transmission rate, water adsorption, non-cytotoxicity, refractive index, transparency, haze, hardness, coefficient of friction, etc. [61]. From the product code from the supplier, base polymers in plastic products can be found. A combination of analytical tests can give comprehensive insights into the base polymer and additive constituents in plastic products. XPS (X-ray photoelectron spectroscopy) provides an elemental composition as well as the chemical and electronic state of the atoms within a material. FTIR (Fourier-transform infrared spectroscopy) identifies chemical bonds in a molecule by producing an infrared absorption spectrum. WDS (wavelength-dispersive X-ray spectroscopy) provides elemental and chemical state and molecular information from surfaces of solid materials. ToF-SIMS (time-of-flight secondary ion mass spectrometry) analyzes the composition of solid surfaces. Post-use, clinical plastic products become wastes that are usually thrown away in a special bag that goes to landfill or incineration. However, reuse or remanufacturing is necessary for a circular plastics economy (Figure 3). Products containing the same polymers after use with low-to-medium hazard levels, after washing, can be put together in a special tray with a disinfectant solution for at least 24 h. Washwaters including sterilized solution after decontamination of post-use clinical plastics can be separately collected and analyzed to develop a protocol for water recovery [8] (not shown in Figure 3). Known disinfectants are benzalkonium chloride, formalin/formaldehyde, hydrogen peroxide, and ethanol [61]. The applicability of the sterilization methods depending on the base polymers can be determined. Alternative to disinfectants, the other methods to decontaminate plastics are autoclave, ethylene oxide gas, dry heat, and radiation treatments [61]. All these other treatments however may disturb the bonds and structures due to the application of energy. Decontaminated plastics are dried and re-examined for property standards for reuse. If reuse is not an option and remanufacturing is needed, decontaminated and dried plastics are shredded, micro-extruded (with blending with bio-based compounds if needed), and palettized. These pellets are secondary plastics. Their chemical constituents and other properties as discussed before need to be examined for property standards and marketability. Bio-based fossil-free environmentally benign compounds can be added [17,62,63] to the recovered plastics to meet the required product properties and to lower the fossil resource inputs into the economy. The pellets can be moulded into products.

Figure 3.

Plastics reuse and remanufacturing for a circular economy system.

While with the configuration in Figure 3 we can circularize clinical plastics that have low-to-medium level bearing concerning the hazard level during the use phase, the fossil resources may be entrapped within the economy. We must therefore introduce new clinical products with biopolymers as the base polymers to displace their fossil-based counterparts [17,64]. Moreover, the design for the environment must be applied to allow post-use segregation/addition or disassembling/assembling of materials on demand.

The economic analysis of plastics recycling consists of capital cost, operating cost, and discounted cash flow analyses. The starting point to calculate the capital cost is the delivered cost of equipment from vendors or providers. From Figure 3, thus, the delivered cost of equipment for the recyclers comprises that of a dryer, shredder, micro-extruder and optional pelletizer and injection moulder. This cost estimate is for the recycler. The recycler produces or remanufactures product-grade plastics from used contaminated plastics. The buyers of plastics from the recyclers are the manufacturers of plastic products. The manufacturers would need the injection moulder to mould secondary plastics into shapes. Bio-based compounds may be blended with recyclates or secondary materials to improve sustainability and properties. The blending (by the recycler) can occur in micro-extrusion if the input material to the micro-extrusion does not meet the property standards. If the decontaminated materials meet the property requirements, the products can be reused and directly re-enter the value chain. As mentioned before, analytical tests are needed to examine the physical, mechanical and chemical properties of output materials from the drying, micro-extrusion and injection moulding stages, as shown in Figure 3, to minimize post-consumption processing to avoid the environmental and cost burdens. In the remanufacturing route, bio-based compounds may also be a choice for the plastic product manufacturer (injection moulding) to improve the sustainability and quality of the plastic product.

Apart from the delivered cost of equipment, installation, instrumentation and control, piping, electrical systems, building (including services), yard improvements and service facilities make up the direct cost towards capital investment. The direct cost including the delivered cost of equipment is up to 2.69, 3.02, and 3.6 times the delivered cost of equipment for solid, solid-fluid, and fluid processing systems. The exact multiplier of the delivered cost of equipment to calculate the direct cost would be unknown before gathering all the quotes from various vendors/service providers. The indirect cost towards capital investment is up to 1.28, 1.26, and 1.44 times the delivered cost of equipment for solid, solid-fluid and fluid processing systems. The indirect cost consists of engineering and supervision, construction expenses, legal expenses, contractor fees, and contingency. The working capital is 0.7, 0.75, and 0.89 times the delivered cost of equipment for solid, solid-fluid and fluid processing systems. Thus, for a solid-fluid system, which applies to the plastics recycling case, the total capital investment that includes the delivered equipment cost is up to 5.03 times the delivered cost. For the detailed total capital investment cost break-up, see Chapter 2 of [17].

The operating cost is made up of variable, fixed, and miscellaneous costs. The variable costs are feedstock, reagent, and utility costs, that are purchased. Some components of fixed operating costs are dependent on indirect capital costs; these are maintenance, capital charges, insurance, local taxes, and royalties. The indirect cost-dependent fixed operating costs are 0.25 times the annualized indirect capital costs. The rest of the fixed operating cost components are dependent on personnel or labor costs; these are personnel, laboratory, supervision, and plant overhead costs. The personnel-dependent fixed operating costs are 1.9 times the personnel or labor costs. The miscellaneous operating costs including sales expenses, general overheads, and research and development, are 20–30% of the direct production cost, which is the summation of the variable and fixed operating costs. It can be noted that the analytical equipment’s capital investment is not regarded in the capital cost calculations for the recycler. However, the analytical services can be externally purchased, and such costs are included in the operating costs, instead. For the detailed total operating cost break-up, see Chapter 2 of [17]. Table 3 summarizes the various cost parameters applied for the economic analysis of a plastics recycling plant.

Table 3.

Capital and operating cost items.

The discounted cash flow analysis is shown in Equation (1). The numerator in Equation (1) is the difference between product value and total cost on an annualized basis. The product value is the amount of secondary plastics or recyclates produced multiplied by its market price. The total annual cost is the summation of the operating cost and the annualized capital cost. The denominator of Equation (1) accounts for the time value of money through a discounted rate. The internal rate of return is the discount rate for which the net present value is zero after the number of years considered; this means that after those years, the plant would break even the cost and start profiting, making money, or the product value would exceed the plant costs.

is the net present value. is the internal rate of return for a payback period at which the plant would break even the cost or the is zero. is the value of the product, which is the amount of secondary plastics or recyclates produced multiplied by its market price. is the total operating costs on an annual basis. is the annualized total capital investment, i.e., the product of total capital investment and weighted average capital charge () [65]. includes all the capital cost items, direct, indirect, and working capital costs, as shown in Table 3. The net present value or discounted cash flow analysis assumes annual payments. The cost of production of the product is the ratio between the summation of and , and the product throughput per year.

The starting point for the economic analysis is the delivered cost of equipment collated from the vendors. The delivered cost of equipment will apply to a given plant capacity. For a different plant capacity, the delivered cost of equipment can be updated for the new capacity by applying the cost-capacity power law, with the economy of scale factor 0.6–0.7, implying that with increasing plant capacity the delivered cost of equipment per unit capacity would decrease [66,67]. For a different year of reference, the Chemical Engineering Plant Cost Index (CEPCI) can be applied to update the cost to the recent most year; CEPCI accounts for the impacts of inflation on plant capital costs [17,68,69]. The labor cost, product value, and variable operating costs are obtained from the market. Thus, with the collected delivered cost of equipment, labor cost, product value, and variable operating costs, the capital and operating cost calculation methods are applied in Table 3 to calculate the capital and operating costs. Then, Equation (1) is applied to show the investment, cash flow, and payback protocols for the recycler.

4. Results and Discussion

The results of the economic analysis show the feasibility and conditions for the processing steps and research and development capabilities. They determine whether a single-use clinical plastic waste remanufacturing project is viable or not. From the literature assessment and stakeholders’ engagement, it was found that the post-use clinical plastic products made up of polyethylene terephthalate (grade 1 plastics), high-density polyethylene (grade 2), low-density polyethylene (grade 4), and polypropylene (grade 5), with low-to-medium hazard levels, are recyclable by the mechanical or secondary recycling or remanufacturing methods (Figure 1 and Figure 3). However, without an actual project on clinical plastic waste recycling, it is impossible to determine which clinical plastic waste can be recycled by which processing steps at what cost. This is because the actual quality and quantity of plastics depending on constituents and hazard levels need to be examined. So far, there has not been any project reported on clinical plastic waste remanufacturing. Hence, 100% product recovery and the same quality as virgin products are assumed after washing, sterilization, drying, shredding, and micro-extrusion (Figure 3). The delivered cost of equipment is obtained from the vendors for washing tank, dryer, shredder, and micro-extrusion, for 0.5 tph (tons per hour) plastic waste capacity, in 2020 [18]. To update the cost, CEPCI and plant capacity can be applied [17]. The delivered costs of 7000 USD, 75,000 USD, 5700 USD, and 46,000 USD were obtained for the washing tank, dryer, shredder and micro-extrusion, for 0.5 tph plastic waste capacity, from vendors in 2020 [18]. Disinfectant is the main chemical consumed by the plant. Its recovery or make-up cost (or purchase price) has been assumed to be 10 USD/kg [70]. Its consumption rate is 1% of the mass of the plastic waste feed [18]. The labor cost is 250,000 USD/y based on the assumption that the plant would need five personnel to operate [71]. Laboratory, supervision, and plant overheads would cost 0.9 times the labor cost [17], i.e., 225,000 GBP. As shown in the Materials and Methods section, analytical tests (on-site or buy-in services) are essential to ensure the quality standards of plastics. The electricity consumption was obtained from the equipment rating from the supplier. The total electricity consumption for the plant is 180 kW [18]. 8000 operating hours per year are assumed [17]. The present electricity price is capped at 0.34 USD/kWh [72]. The price of recyclate plastics is assumed to be 455 USD/t, way above the plastic recyclate price [73] for a viable discounted cash flow scheme shown later. The incomes from the plastic waste feedstock or the usual gate fees paid to the recycler by the waste generators [74,75] are identified based on the viable discounted cash flow analysis. Table 4 shows the calculated capital and operating costs using the correlations shown in Table 3.

Table 4.

Capital and operating costs of a 0.5 tph secondary plastic waste recycling plant.

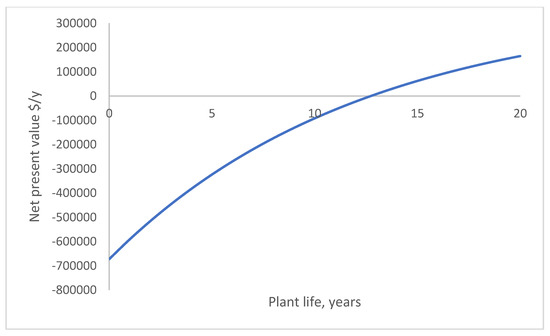

Figure 4 shows the net present value analysis for the calculated capital and operating costs in Table 4, an of 8.5% and of 13% [17]. The breakeven point or payback time obtained is 13 years.

Figure 4.

Net present value analysis for the calculated capital and operating costs in Table 4, an of 8.5% and of 13%.

The cost of production of the product, as the ratio between the summation of and and the product throughput per year, is 433 USD/t.

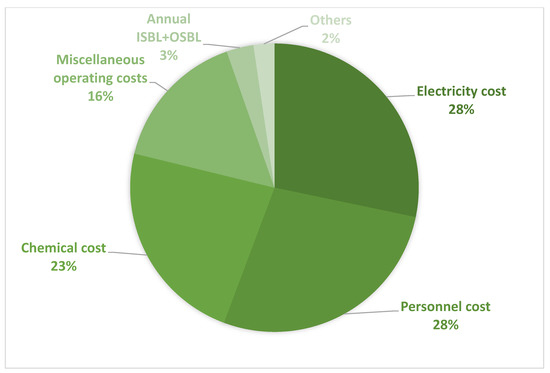

As long as the cost of production (433 USD/t) of the product is less than its value (455 USD/t), the plant is profitable, i.e., with a margin of 22 USD/t after the 13th year of operation. The 0th year is the start of the operation of the plant. The cost contribution of the mechanical recycling plant for the given data is shown in Figure 5. Electricity, labor, and chemical costs are the major contributors.

Figure 5.

The various cost contributions towards the cost of production of recyclate plastics.

The recyclate plastics price has been varying between 287 and 348 USD/t, depending on the crude oil price, varying between 40 and 110 USD/bbl, from 2012 to 2019 (Figure 2). The crude oil price is forecasted to be 87–89 USD/bbl in 2022 and 2023. It is unlikely that recyclate plastics price would exceed 350 USD/t, which depends on the crude oil price. (Due to the currency volatility, the conversion factors applied must be noted, 1 EUR = 0.99 USD; 1 GBP = 1.15 USD, to update future analyses using the study findings.) Thus, to achieve a viable cash flow from a clinical plastic waste recycling project (Figure 4), a gate fee is required: (455 − 350) = 105 USD/t on the plastic waste feedstock. This gate fee would be paid by the waste generator to the recycler [74,75]. A gate fee also helps to reduce the plastics used by the sector. A recent report in 2022 also suggests that the plastics gate fee is likely to increase to offset the cost of recycling [76]. The gate fee of plastic containers has been shown with a median of 63–92 USD/t, a mean of 66–84 USD/t, and a maximum of 92–121 USD/t obtained at the material recovery facility (MRF) [76]. A gate fee of ~90 USD/t for plastic waste by the generators to the recyclers is still not enough to break even product value against cost (Equation 1) requiring further reductions in electricity, personnel, and chemical costs. Thus, sensitivity analyses were undertaken to establish the economic conditions for a circular clinical plastics economy.

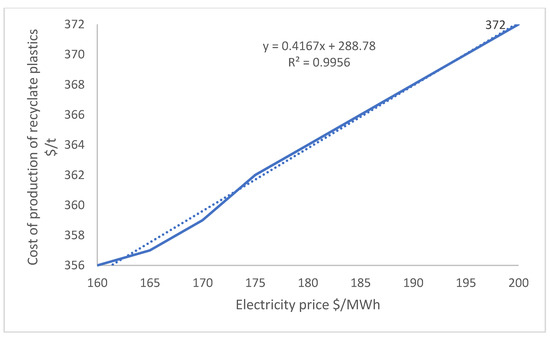

Figure 2 shows that the price of electricity varies between 160 and 200 USD/MWh, depending on the gas price, varying between 47–65 USD/MWh, from 2012 to 2019. This electricity price is less than the recent high price (due to the natural gas price rise) captured in Table 4 and Figure 4 and Figure 5. Thus, Figure 6 analyzes the effect of electricity price reductions on the cost of production of recyclate plastics. It shows that with decreasing electricity prices, the cost of production of recyclate plastics reduces, following a linear equation or function shown in Figure 6. is the coefficient of determination, the ratio of the summation of squares of residuals (), and the total sum of squares () subtracted from 1. Thus, the summation of squares of residuals approaching zero is desirable making close to 1 for the best fit equations. Equation (2) shows the expression for . is the actual value of the dependent variable at point , while is its predicted value using the function of . is the mean value of all across . The linear functions have been generated in Excel spreadsheet.

Figure 6.

The effect of electricity price reductions on the cost of production of recyclate plastics.

It is thus clear that the lowest electricity price can achieve a target cost of production of recyclate plastics, 356 USD/t. This also means that the prices of natural gas and crude oil would be at a lower end of ~47 USD/MWh and 40 USD/bbl. At this mark, the recyclate plastics market price is also at the lowest level, 287 USD/t. This condition leaves a gate fee of (356 − 287) = 69 USD/t from the waste generators to the recyclers, which is more realistic, albeit the lowest levels of fossil fuel prices.

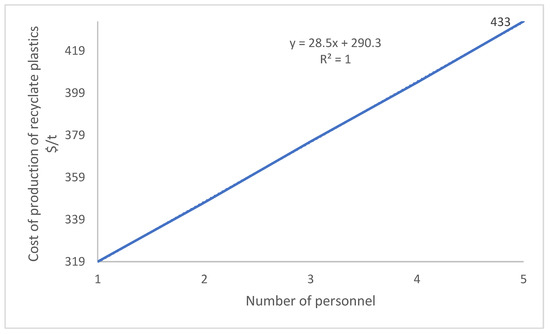

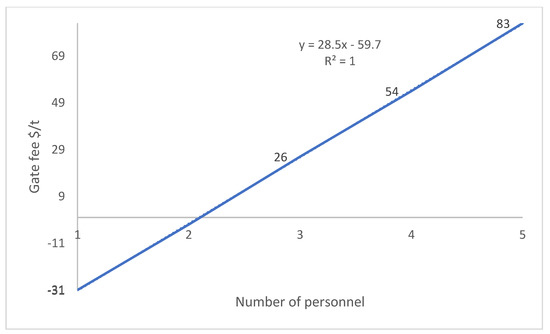

Next, the sensitivity of labor cost is examined in Figure 7. Figure 7 shows that with decreasing number of personnel, the cost of production of recyclate plastics reduces, following a perfectly fit linear equation shown in the figure. The cost of production of recyclate plastics varies between 319 and 433 depending on the number of personnel between 1 and 5. For the number of personnel 1–2, there is no gate fee requirement for plastic waste as the cost of production of recyclate plastics is less than its market price of 350 USD/t. Above personnel number 2, the minimum gate fee must be sought to meet the cost of recycling plastic waste. The linear dependency of the plastic waste minimum gate fee on the number of personnel is shown in Figure 8. It must be noted that the actual gate fee must exceed the minimum gate fee, 26, 54, and 83 USD/t for personnel number 3, 4, and 5, to offset the cost of recycling plastic waste and make the plastic recycling project economically feasible. As can be shown before, 105 USD/t gate fee gives a payback period of 13 years for an of 8.5% and a of 13%.

Figure 7.

The effect of labor cost on the cost of production of recyclate plastics.

Figure 8.

The effect of labor cost on the minimum gate fee for plastic waste.

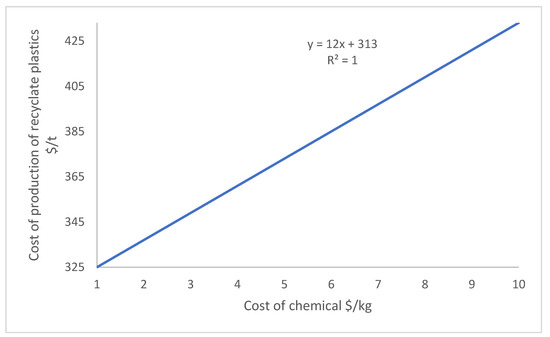

Figure 9 shows that with decreasing chemical costs, the cost of production of recyclate plastics reduces, following a perfectly fit linear equation shown in the figure. The cost of production of recyclate plastics varies between 325 and 433 depending on the price of chemical between 1 and 10 USD/kg. For the chemical cost lower than 3 USD/kg, there is no gate fee requirement for plastic waste as the cost of production of recyclate plastics is less than its market price of 350 USD/t.

Figure 9.

The effect of chemical cost on the cost of production of recyclate plastics.

From Figure 6, Figure 7 and Figure 9, zero electricity cost, zero labor cost, and zero chemical cost would result in the least cost of production of recyclate plastics of 289, 290, and 313 USD/t. Moreover, clinical plastics recycling cannot be stimulated at all under any condition of gas or electricity price. The lowest electricity price of 160 USD/MWh at the lowest gas price of 47 USD/MWh still result in an infeasible cost of production of 356 USD/t of recyclate plastics that is on the higher side of their prices. Recyclate plastics price at the least price of gas and crude oil is likely to be on the lower side of prices, 287 USD/t. At this low selling price, plastics recycling can only be stimulated by applying a gate fee to plastic waste from the waste generators to the waste recyclers. With two personnel or chemical costs of less than 3 USD/kg, the cost of production of recyclate plastics would just be below its highest selling price of 350 USD/t. Thus, in all cases, a gate fee will be a necessity to stimulate the clinical plastics circular economy or recycling business. A significant way forward to stimulate the plastics recycling business is the de-fossilization of the economy, i.e., decoupling electricity prices from natural gas prices, and recyclate plastics prices from crude oil prices. Renewable electricity generation for the former and manufacturing de-fossilized bioplastics for the latter could offer sustainability to the system. Furthermore, if biopolymers, designed for the environment, could displace fossil-derived plastics, the embedded renewable carbon in them can remain entrapped in the value chain preventing global warming potential from their embedded carbon that would have resulted from their post-consumption incineration. Biopolymers are sustainable if produced from excess biomass residues in de-fossilized process networks. Thus, future work can explore on-site renewable electricity generation [17,65,66,68,77,78,79,80,81] and bio-polymer synthesis/additives [17,74,75,82,83,84], and the applications of the value analysis [17,85,86,87,88] and economic value and environmental impact analysis [17,89,90,91] tools to circularize the plastics economy.

5. Conclusions

The healthcare and laboratory sectors’ clinical/medical plastics offer superior health and safety performances compared to their glass or ceramic counterparts. However, these plastics are made up of fossil-derived single-use polymers. Of post-use clinical plastics, 95% go to incineration or landfill contributing to resource depletion. Plastic waste can stay in the environment forever, harming various species. The spearheading of plastics disposal is secondary or mechanical recycling or remanufacturing, which is the least destructive and most effective method towards a circular plastics economy when reuse is not an option. The method consists of washing, sterilization, drying, shredding and micro-extrusion with blending as appropriate with bio-based compounds to meet property standards of recyclate. This study evaluates the techno-economic feasibility of post-use clinical plastic recovery by mechanical recycling. Polyethylene terephthalate (grade 1), high-density polyethylene (grade 2), low-density polyethylene (grade 4), and polypropylene (grade 5) based plastics are recyclable by this method. Because post-use clinical plastics can be hazardous including contributions to lethal conditions, low-to-medium hazard level products, which rarely cause disease, are suitable for material recovery by secondary recycling. Recycling clinical plastic waste is novel and the literature lacks project or experimental data. Medical plastics recycling data are scarce in the open literature, making such project evaluations extremely challenging. To fill such data gaps, various cost parameters have been itemized and standard values have been assigned to the items. Hotspots have been identified and sensitivity analyses have been performed to establish the cost of production ranges based on extreme limits on sensitive parameters. The laboratory plastic products, such as cluster tubes, screw caps, cell culture flasks, cryotubes, falcon tubes, carboys, bottles, pans pipet cleaning sets, wash bottles and dropper bottles with control dispensing tips, and healthcare non-catering or clinical or medical plastic products, such as IV bag, tubing, sharps, gloves, labware, nursery items and medical packaging, containing polypropylene, high-density and low-density polyethylene as the base polymers, are recyclables especially those with low-to-medium hazard levels, by remanufacturing that can displace incineration or landfill of these plastic wastes. It is assumed that post-use, the clinical plastic streams are segregated according to the base polymer type. An important step is the analytical characterization of plastics to establish their material constituents and properties. These tests can indicate the polymers in the products, which will be pre-determined to decide which plastic products could be put together and which could not be. Considering stringent policy regulations for the health sector, an extensive set of properties may be required for the clinical plastics recycling, which are maximum use temperature, heat deflection temperature or heat distortion temperature, brittleness temperature, melting point, glass transition temperature, clarity, microwave ability, specific gravity, permeability, water vapor transmission rate, water adsorption, non-cytotoxicity, refractive index, transparency, haze, hardness, coefficient of friction, etc. From the product code from the supplier, base polymers in plastic products can be found. A combination of analytical tests such as XPS, FTIR, WDS, and ToF-SIMS can give comprehensive insights into base polymers as well as additives present in plastic products. Products containing the same polymers after use with low-to-medium hazard levels, after washing, can be put together in a special tray with a disinfectant solution for at least 24 h. Decontaminated plastics are dried, shredded, micro-extruded, and palettized. These pellets are secondary or recyclate plastics. Their chemical constituents and other properties are examined for standardization and marketability. Bio-based fossil-free environmentally benign compounds can be added to the secondary plastics to meet the required product properties and lower the fossil resource inputs into the economy. With time, more and more virgin polymers would be replaced with biopolymers and all the reagents, energy and materials needed in the life cycle would be renewable or fossil-free renewable and bio-based resources. The design for the environment at the plastic product design stage must be applied to allow post-use segregation, remanufacturing and indefinite life cycles, thus assembling and disassembling material constituents on demand. The economic analysis of plastics recycling consists of capital cost, operating cost and discounted cash flow analyses. The starting point to calculate the capital cost is the delivered cost of equipment from vendors or providers. The delivered costs of equipment obtained for the washing tank, dryer, shredder and micro-extrusion, for 0.5 tph plastic waste capacity, from vendors, in 2020, are 7000 USD, 75,000 USD, 5700 USD, and 46,000 USD. Based on the total electricity consumption of 180 kW over 8000 h per year at 0.34 USD/kWh, labor cost of 250,000 USD/y for five personnel to run the plant, disinfectant consumption rate of 1% of the mass of the plastic waste feedstock at a cost of 10 USD/kg and recyclate plastics price of 455 USD/t, an of 8.5%, a of 13% and a breakeven or payback time of 13 years are obtained from the discounted cash flow analysis. The cost of production of recyclate plastics is calculated as 433 USD/t. It is unlikely that recyclate plastics price would exceed 350 USD/t for a forecasted crude oil price of 87–89 USD/bbl in 2022–23. Thus, to achieve the viable cash flow from a clinical plastic waste circular economy project, a gate fee of 105 USD/t on plastic waste by the generators to the recyclers is needed. The cost hotspots, i.e., electricity, labor, and chemical costs need to be decreased to lower the gate fee. The cost of production of recyclate plastics is linearly dependent on the electricity, labor and chemical costs by the correlations, y = 0.4167x + 288.78, y = 28.5x + 290.3 and y = 12x + 313, where y is the cost of production of recyclate plastics and x is the electricity, labor and chemical costs, respectively. The lowest electricity price of 160 USD/MWh depending on the lowest gas price of 47 USD/MWh results in a higher cost of production of 356 USD/t of recyclate plastics than its highest market price since 2012. With two personnel (100,000 USD/y) or chemical costs of less than 3 USD/kg, the cost of production of recyclate plastics would just be below its highest selling price of 350 USD/t. Thus, the dependency of a circular plastics economy on gate fees remains significant. A meaningful way forward to stimulate the plastics circular economy is the de-fossilization of the economy, i.e., decoupling electricity prices from natural gas prices, and recyclate plastics prices from crude oil prices. Renewable electricity generation for the former and manufacturing de-fossilized bioplastics for the latter could offer the sustainability of the plastics recycling system.

Author Contributions

Conceptualization, methodology, software, validation, formal analysis, investigation, resources, data curation, writing—original draft preparation, J.S. Methodology, investigation, data collection, review, K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Available online: https://www.eea.europa.eu/publications/the-plastic-waste-trade-in (accessed on 1 November 2022).

- Joseph, B.; James, J.; Kalarikkal, N.; Thomas, S. Recycling of medical plastics. Adv. Ind. Eng. Polym. Res. 2021, 4, 199–208. [Google Scholar] [CrossRef]

- Liu, M.; Wen, J.; Feng, Y.; Zhang, L.; Wu, J.; Wang, J.; Yang, X. A benefit evaluation for recycling medical plastic waste in China based on material flow analysis and life cycle assessment. J. Clean. Prod. 2022, 368, 133033. [Google Scholar] [CrossRef]

- Volk, R.; Stallkamp, C.; Steins, J.J.; Yogish, S.P.; Müller, R.C.; Stapf, D.; Schultmann, F. Techno-economic assessment and comparison of different plastic recycling pathways: A German case study. J. Ind. Ecol. 2021, 25, 1318–1337. [Google Scholar] [CrossRef]

- Gear, M.; Sadhukhan, J.; Thorpe, R.; Clift, R.; Seville, J.; Keast, M. A life cycle assessment data analysis toolkit for the design of novel processes–A case study for a thermal cracking process for mixed plastic waste. J. Clean. Prod. 2018, 180, 735–747. [Google Scholar] [CrossRef]

- Dharmaraj, S.; Ashokkumar, V.; Pandiyan, R.; Munawaroh, H.S.H.; Chew, K.W.; Chen, W.H.; Ngamcharussrivichai, C. Pyrolysis: An effective technique for degradation of COVID-19 medical wastes. Chemosphere 2021, 275, 130092. [Google Scholar] [CrossRef] [PubMed]

- Dogu, O.; Pelucchi, M.; Van de Vijver, R.; Van Steenberge, P.H.; D’hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Prog. Energy Combust. Sci. 2021, 84, 100901. [Google Scholar] [CrossRef]

- Nikiema, J.; Asiedu, Z. A review of the cost and effectiveness of solutions to address plastic pollution. Environ. Sci. Pollut. Res. 2022, 29, 24547–24573. [Google Scholar] [CrossRef]

- Luijsterburg, B.J. Mechanical Recycling of Plastic Packaging Waste; Universiteit Eindhoven: Eindhoven, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782-10. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Devasahayam, S.; Raju, G.B.; Hussain, C.M. Utilization and recycling of end of life plastics for sustainable and clean industrial processes including the iron and steel industry. Mater. Sci. Energy Technol. 2019, 2, 634–646. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Nhu, T.T.; Van Gorp, B.; Kresovic, U.; Larrain, M.; Billen, P.; Ragaert, K.; De Meester, S.; Dewulf, J.; Huysveld, S. Moving from linear to circular household plastic packaging in Belgium: Prospective life cycle assessment of mechanical and thermochemical recycling. Resour. Conserv. Recycl. 2021, 171, 105633. [Google Scholar] [CrossRef]

- Larrain, M.; Van Passel, S.; Thomassen, G.; Van Gorp, B.; Nhu, T.T.; Huysveld, S.; Van Geem, K.M.; De Meester, S.; Billen, P. Techno-economic assessment of mechanical recycling of challenging post-consumer plastic packaging waste. Resour. Conserv. Recycl. 2021, 170, 105607. [Google Scholar] [CrossRef]

- Bora, R.R.; Wang, R.; You, F. Waste polypropylene plastic recycling toward climate change mitigation and circular economy: Energy, environmental, and technoeconomic perspectives. ACS Sustain. Chem. Eng. 2020, 8, 16350–16363. [Google Scholar] [CrossRef]

- Sinnott, R.; Towler, G. Chemical Engineering Design; Butterworth-Heinemann: Oxford, UK, 2019. [Google Scholar]

- Sadhukhan, J.; Ng, K.S.; Martinez-Hernandez, E. Biorefineries and Chemical Processes: Design, Integration and Sustainability Analysis; Wiley: Chichester, UK, 2014; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9781118698129 (accessed on 1 November 2022).

- Sekar, K. Recycling of Laboratory Plastics: A Material and Design Study. Master’s Thesis, University of Surrey, Guildford, UK, 2021. [Google Scholar]

- Sigma-Aldrich. Corning® Closed System Spinner Flask Disposable, Pre-Assembled, Capacity 1 L, Sterile. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls3546 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning® Costar® Stripette® Serological Pipettes, Bulk Packed Capacity 1 mL. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls4010 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning® 96 Well Clear Polystyrene Microplate Round Bottom Clear, Tissue Culture (TC)-Treated Surface, Bag of 20, Sterile, Lid. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls3358 (accessed on 1 November 2022).

- Sigma-Aldrich. CELLine Classic Bioreactor Flask CL 1000 (for 1L Volumes). Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/z688029 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning 96 Well PP 1.2 mL Cluster Tubes 96 Well Polypropylene Cluster Tubes, Individual Tube Format, Non-Treated, Non-Sterile, without Rack, Clear, 960/cs Cap Tubes. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls4401 (accessed on 1 November 2022).

- Sigma-Aldrich. DURAN® Membrane Screw Cap Polypropylene, GL 32 Cap, Pore Size 0.2 μm. Available online: https://www.sigmaaldrich.com/GB/en/product/aldrich/dwk291181907 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning Erlenmeyer Baffled Cell Culture Flasks 500 mL Erlenmeyer Flask w/Vented Cap, Polycarbonate, Sterile, 25/cs Cell Culture Flasks. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls431401 (accessed on 1 November 2022).

- Sigma-Aldrich. TPP Cryotubes Polypropylene, Capacity 1.2 mL Cryo Tubes. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/z760943 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning 15 mL Centrifuge Tubes Natural Polypropylene Conical Bottom, Sterile, Self Standing: No (Rack Packed), Cap (Plug Seal), Case of 500 15 ml Centrifuge Tubes. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls430052?gclid=Cj0KCQiA6NOPBhCPARIsAHAy2zDcvD7-KK8h0EMxtx8i7otOverEySsqLTjXN7W927hkkmNpl_qp3EaAs30EALw_wcB (accessed on 1 November 2022).

- Nalgene™ HDPE, Carboy with Spigot. Available online: https://www.thermofisher.com/order/catalog/product/2320-0050 (accessed on 1 November 2022).

- Nalgene™ HDPE Pans. Available online: https://www.thermofisher.com/order/catalog/product/7120-0020 (accessed on 1 November 2022).

- Nalgene™ Wide-Mouth Lab Quality HDPE Bottles. Available online: https://www.thermofisher.com/order/catalog/product/2104-0016 (accessed on 1 November 2022).

- Nalgene™ Pipet Cleaning Equipment Sets. Available online: https://www.thermofisher.com/order/catalog/product/5250-0050 (accessed on 1 November 2022).

- Nalgene™ Dropper Bottles with Control Dispensing Tip. Available online: https://www.thermofisher.com/order/catalog/product/2750-9125 (accessed on 1 November 2022).

- Nalgene™ Right-to-Understand Safety Wash Bottles featuring Globally Harmonized System (GHS) Labeling. Available online: https://www.thermofisher.com/order/catalog/product/2428-0504 (accessed on 1 November 2022).

- Nalgene™ LDPE, Round Carboy with Spigot. Available online: https://www.thermofisher.com/order/catalog/product/2318-0050 (accessed on 1 November 2022).

- Nalgene™ 980 Braided Clear PVC Tubing. Available online: https://www.thermofisher.com/order/catalog/product/8005-0100 (accessed on 1 November 2022).

- PVC Membrane Filter|PVC502500. Available online: https://www.merckmillipore.com/GB/en/product/PVC-Membrane-Filter,MM_NFPVC502500 (accessed on 1 November 2022).

- Nalgene™ Polycarbonate Baffled Culture Flasks. Available online: https://www.thermofisher.com/order/catalog/product/4110-0500 (accessed on 1 November 2022).

- Nalgene™ Square Polycarbonate Bottles with Closure. Available online: https://www.thermofisher.com/order/catalog/product/2015-0250 (accessed on 1 November 2022).

- Nalgene™ Straight-Sided Wide-Mouth Polycarbonate Jars with Closure. Available online: https://www.thermofisher.com/order/catalog/product/2116-0125V (accessed on 1 November 2022).

- Nalgene™ 870 Tubing. Available online: https://www.thermofisher.com/order/catalog/product/8051-0125 (accessed on 1 November 2022).

- Nalgene™ Fluorocarbon (PFA) Resin Plastic Graduated Cylinder. Available online: https://www.thermofisher.com/order/catalog/product/3666-0100 (accessed on 1 November 2022).

- Nalgene™ Griffin Low-Form PFA Plastic Beakers. Available online: https://www.thermofisher.com/order/catalog/product/1510-0250 (accessed on 1 November 2022).

- Nalgene™ Narrow-Mouth Bottles Made of Teflon™ PFA with Closure. Available online: https://www.thermofisher.com/order/catalog/product/1630-0032 (accessed on 1 November 2022).

- PTFE Tissue Grinders and Homogenisers. Available online: http://www.cowie.com/catalogue/homog.htm (accessed on 1 November 2022).

- PTFE Bottle Pourer. Available online: http://www.cowie.com/catalogue/pourer.htm (accessed on 1 November 2022).

- PTFE Labware. Available online: http://www.celscientific.com/PTFELabware.html (accessed on 1 November 2022).

- Lab Unlimited UK. LLG Labware LLG-Syringe Filter from PVDF, 0,22 μm 6285697. Available online: https://www.labunlimited.co.uk/s/pg_dl_28587/4AJ-6285697/LLG-Labware-LLGSyringe-filter-from-PVDF,-0,22-μm-6285697 (accessed on 1 November 2022).

- POLYCASA® SAN. Extruded Styrene-Acrylonitrile Copolymer Sheets. Available online: https://www.display.3acomposites.com/polycasa-san/ (accessed on 1 November 2022).

- Nalgene™ Right-to-Understand FEP Safety Wash Bottles with Globally Harmonized System (GHS) Labeling for Harsh Chemicals. Available online: https://www.thermofisher.com/order/catalog/product/2429-0503 (accessed on 1 November 2022).

- Nalgene™ Separatory Funnels made with Teflon™ Fluoropolymer with Closure Made with Tefzel™. Available online: https://www.thermofisher.com/order/catalog/product/4301-1000 (accessed on 1 November 2022).

- Nalgene™ Oak Ridge High-Speed Centrifuge Tubes made with Teflon™ Fluoropolymer and Closure made with Tefzel™. Available online: https://www.thermofisher.com/order/catalog/product/3114-0050 (accessed on 1 November 2022).

- Nalgene™ Narrow-Mouth Bottles Made of Teflon™ FEP with Closure. Available online: https://www.thermofisher.com/order/catalog/product/1600-0032 (accessed on 1 November 2022).

- Lab Unlimited. LLG Labware LLG-Adhesive PCR-Film, Polyester 6313398. Available online: https://www.labunlimited.com/s/pg_dl_18111/4AJ-6313398/LLG-Labware-LLGAdhesive-PCR-Film,-polyester-6313398 (accessed on 1 November 2022).

- Fisher Scientific. Merck Amicon™ Ultra-15 Centrifugal Filter Units: Centrifuges and Microcentrifuges Products. Available online: https://www.fishersci.co.uk/shop/products/amiconultra-15-centrifugal-filter-units/p-7232219 (accessed on 1 November 2022).

- Sealing Films, Foils & Tapes. Available online: https://www.sigmaaldrich.com/GB/en/products/labware/sealing-films-foils-andtapes#Tapes (accessed on 1 November 2022).

- Lee, B.K.; Ellenbecker, M.J.; Moure-Eraso, R. Analyses of the recycling potential of medical plastic wastes. Waste Manag. 2002, 22, 461–470. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Recycling_%E2%80%93_secondary_material_price_indicator (accessed on 1 November 2022).

- Available online: https://www.ofgem.gov.uk/sites/default/files/docs/2019/11/20191030_state_of_energy_market_revised.pdf (accessed on 1 November 2022).

- Available online: https://albayanmagazine.com/average-annual-opec-oil-price-from-2011-to-2021-in-usd-per-barrel/?lang=en (accessed on 1 November 2022).

- Available online: https://www.statista.com/statistics/418046/natural-gas-prices-for-households-in-the-uk/ (accessed on 1 November 2022).

- Available online: https://static.thermoscientific.com/images/D20826~.pdf (accessed on 1 November 2022).

- Sadhukhan, J. Net-Zero Action Recommendations for Scope 3 Emission Mitigation Using Life Cycle Assessment. Energies 2022, 15, 5522. [Google Scholar] [CrossRef]

- Ozimek, J.; Pielichowski, K. Recent advances in polyurethane/POSS hybrids for biomedical applications. Molecules 2021, 27, 40. [Google Scholar] [CrossRef] [PubMed]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Sadhukhan, J.; Sen, S.; Randriamahefasoa, T.M.S.; Gadkari, S. Energy System Optimization for Net-Zero Electricity. Digit. Chem. Eng. 2022, 3, 100026. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Sadhukhan, J.; Aburto, J.; Amezcua-Allieri, M.A.; Morse, S.; Murphy, R. Modelling to analyse the process and sustainability performance of forestry-based bioenergy systems. Clean Technol. Environ. Policy 2022, 24, 1709–1725. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Sen, S.; Gadkari, S. The mathematics of life cycle sustainability assessment. J. Clean. Prod. 2021, 309, 127457. [Google Scholar] [CrossRef]

- Wan, Y.K.; Sadhukhan, J.; Ng, K.S.; Ng, D.K. Techno-economic evaluations for feasibility of sago-based biorefinery, Part 1: Alternative energy systems. Chem. Eng. Res. Des. 2016, 107, 263–279. [Google Scholar] [CrossRef]

- Ng, K.S.; Zhang, N.; Sadhukhan, J. Techno-economic analysis of polygeneration systems with carbon capture and storage and CO2 reuse. Chem. Eng. J. 2013, 219, 96–108. [Google Scholar] [CrossRef]

- Available online: https://www.echemi.com/produce/pr2208311290-hydrogen-peroxide-99-white-liquid-7722-84-1-tingxuan.html (accessed on 1 November 2022).

- Available online: https://www.payscale.com/research/UK/Job=Process_Engineer/Sala (accessed on 1 November 2022).

- Available online: https://www.ofgem.gov.uk/information-consumers/energy-advice-households/check-if-energy-price-cap-affects-you (accessed on 1 November 2022).

- Available online: https://blog.recycleduklimited.com/current-plastic-recycling-price (accessed on 1 November 2022).

- Sadhukhan, J.; Martinez-Hernandez, E. Material flow and sustainability analyses of biorefining of municipal solid waste. Bioresour. Technol. 2017, 243, 135–146. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Ng, K.S.; Martinez-Hernandez, E. Novel integrated mechanical biological chemical treatment (MBCT) systems for the production of levulinic acid from fraction of municipal solid waste: A comprehensive techno-economic analysis. Bioresour. Technol. 2016, 215, 131–143. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://wrap.org.uk/sites/default/files/2022-07/WRAP%202021-22%20Gate%20Fees%20Report%20FINAL%20-%20%2823.05.22%29%20%28clean%29_0.pdf (accessed on 1 November 2022).

- Sadhukhan, J. Net zero electricity systems in global economies by life cycle assessment (LCA) considering ecosystem, health, monetization, and soil CO2 sequestration impacts. Renew. Energy 2022, 184, 960–974. [Google Scholar] [CrossRef]

- Honorato-Salazar, J.A.; Sadhukhan, J. Annual biomass variation of agriculture crops and forestry residues, and seasonality of crop residues for energy production in Mexico. Food Bioprod. Process. 2020, 119, 1–19. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Amezcua-Allieri, M.A.; Sadhukhan, J.; Anell, J.A. Sugarcane bagasse valorization strategies for bioethanol and energy production. In Sugarcane-Technology and Research; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Ng, K.S.; Lopez, Y.; Campbell, G.M.; Sadhukhan, J. Heat integration and analysis of decarbonised IGCC sites. Chem. Eng. Res. Des. 2010, 88, 170–188. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Ng, K.S.; Shah, N.; Simons, H.J. Heat integration strategy for economic production of combined heat and power from biomass waste. Energy Fuels 2009, 23, 5106–5120. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Pollet, B.G.; Seaman, M. Hydrogen Production and Storage: Analysing Integration of Photoelectrolysis, Electron Harvesting Lignocellulose, and Atmospheric Carbon Dioxide-Fixing Biosynthesis. Energies 2022, 15, 5486. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Gadkari, S.; Martinez-Hernandez, E.; Ng, K.S.; Shemfe, M.; Torres-Garcia, E.; Lynch, J. Novel macroalgae (seaweed) biorefinery systems for integrated chemical, protein, salt, nutrient and mineral extractions and environmental protection by green synthesis and life cycle sustainability assessments. Green Chem. 2019, 21, 2635–2655. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Lloyd, J.R.; Scott, K.; Premier, G.C.; Eileen, H.Y.; Curtis, T.; Head, I.M. A critical review of integration analysis of microbial electrosynthesis (MES) systems with waste biorefineries for the production of biofuel and chemical from reuse of CO2. Renew. Sustain. Energy Rev. 2016, 56, 116–132. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Mustafa, M.A.; Misailidis, N.; Mateos-Salvador, F.; Du, C.; Campbell, G.M. Value analysis tool for feasibility studies of biorefineries integrated with value added production. Chem. Eng. Sci. 2008, 63, 503–519. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Smith, R. Synthesis of industrial systems based on value analysis. Comp. Chem. Eng. 2007, 31, 535–551. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Zhang, N.; Zhu, X.X. Analytical optimisation of industrial systems and applications to refineries, petrochemicals. Chem. Eng. Sci. 2004, 59, 4169–4192. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Zhang, N.; Zhu, X.X. Value analysis of complex systems and industrial application to refineries. Ind. Eng. Chem. Res. 2003, 42, 5165–5181. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Campbell, G.M.; Sadhukhan, J. Economic and environmental impact marginal analysis of biorefinery products for policy targets. J. Clean. Prod. 2014, 74, 74–85. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Campbell, G.; Sadhukhan, J. Economic value and environmental impact (EVEI) analysis of biorefinery systems. Chem. Eng. Res. Des. 2013, 91, 1418–1426. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Campbell, G.; Sadhukhan, J. Economic Value and Environmental Impact analysis tool for sustainable biorefinery design. Comp. Aided Chem. Eng. 2012, 30, 11–15. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).