Abstract

Because of rapid urbanization, traffic problems, and other factors, underground spaces have been used more in the twenty-first century. Large underground spaces are required for underground city, metro, tunnel, mine, industrial and agricultural engineering, and civil air defense engineering. Underground spaces with varying thermal, ventilation, and lighting environments can face problems of comfort, health, and safety. High temperatures, high humidity, difficulty in flue gas emission, harmful microorganisms, radon, and physical and psychological problems are examples of issues. Air quality control technologies for underground spaces, such as ventilation, dehumidification, natural energy utilization, smoke extraction, and ventilation resistance reduction, are discussed. Ventilation for smoke-proofing/evacuation is also extensively addressed.

1. Introduction

1.1. Diversity of Underground and Semi–Underground Spaces

Underground space development and utilization has a long history. The use of underground spaces has increased, from caves in primitive society to drainage facilities in slave society, from catacombs of ancient emperors to subway spaces in industrial society, from underground air raid shelters in the twentieth century to underground cities in modern society.

The development of underground spaces is becoming increasingly important as urban population density rises. In recent decades, underground spaces have been shown to provide an additional 25–40% livable space [1]. Furthermore, as the problem of urban land scarcity worsens, underground spaces show great promise in alleviating urban land scarcity [2,3]. Underground spaces in modern times have primarily been used in the following ways.

- Underground residential buildings;

- Underground commercial facilities and some public buildings, such as underground shopping malls and underground hotels;

- Underground public transport facilities, such as subway, underground tunnels and garages;

- Municipal facilities, such as utility tunnels;

- Underground industrial buildings, such as underground power stations and mines;

- Underground air raid shelters, coal mine refuge rooms, agricultural engineering underground spaces;

- Underground storage spaces.

1.2. Aims

Underground space has shown great potential in the urbanization process. It has the advantages of saving energy, reducing urban congestion, providing living and working spaces. The development of underground spaces also contributes to eco-friendly developments by reducing impacts to natural landscapes in cities [4]. Due to the influence of soil-surrounded structural characteristics, the distinction between underground spaces and above ground spaces is very clear. Underground spaces have high relative humidity (RH), easy mold and fungi growth, poor air quality due to insufficient ventilation, and a lack of natural light [5]. The lack of natural light is considered to be the greatest disadvantage of underground spaces [6].

In addition, there is a potential impact of possible environmental exposure of underground spaces on human health [7]. Underground working environments are noisy, dusty and dark. Heat cannot be released in a timely manner due to insufficient ventilation. Therefore, workers in harsh environments may feel very uneasy [8], and their safety may be jeopardized to some extent.

Underground spaces have a negative impact on human physiology, psychology, and safety. This review paper will provide a retrospective focusing on current underground space issues and their solutions.

2. Moisture and Heat Transfer Mechanisms

2.1. Moisture Transfer

When compared to above-ground spaces, one distinguishing feature of underground spaces is high humidity, particularly in the summer. Humid environments in underground spaces have a significant impact on human health and comfort, as well as the safe operation and service life of equipment. Microbial growth in humid underground spaces can lead to corrosion and damage to building surfaces and equipment. For example, Gomez-Agustina et al. [9] observed that rising temperatures and humidity values on underground platforms reduce speech-related parameters of voice alarm systems. As a result, moisture control is important and required. Moisture conditions are directly related to factors such as local geological and hydro-logical conditions, rock ruptures, structural forms of coatings, building materials, moisture diffusion from the construction process, outdoor climate (seasons), and ventilation application.

One of the causes of high humidity in underground spaces during the early stages of construction is evaporation of construction residual water. Water is required in the construction process for the construction of walls and grounds. The majority of the water will evaporate into underground spaces, which can reach 95% relative humidity (RH) within the first two years of construction.

Groundwater penetration through the coating layer could be another cause of high humidity in the underground. Groundwater can flow through rock cracks to the middle spaces of rocks and coating layers due to gravity effects. Groundwater may penetrate through the coating layer under osmotic pressures if the coating layer is not carefully designed and constructed. The impact is more severe during the rainy season, when groundwater levels are high.

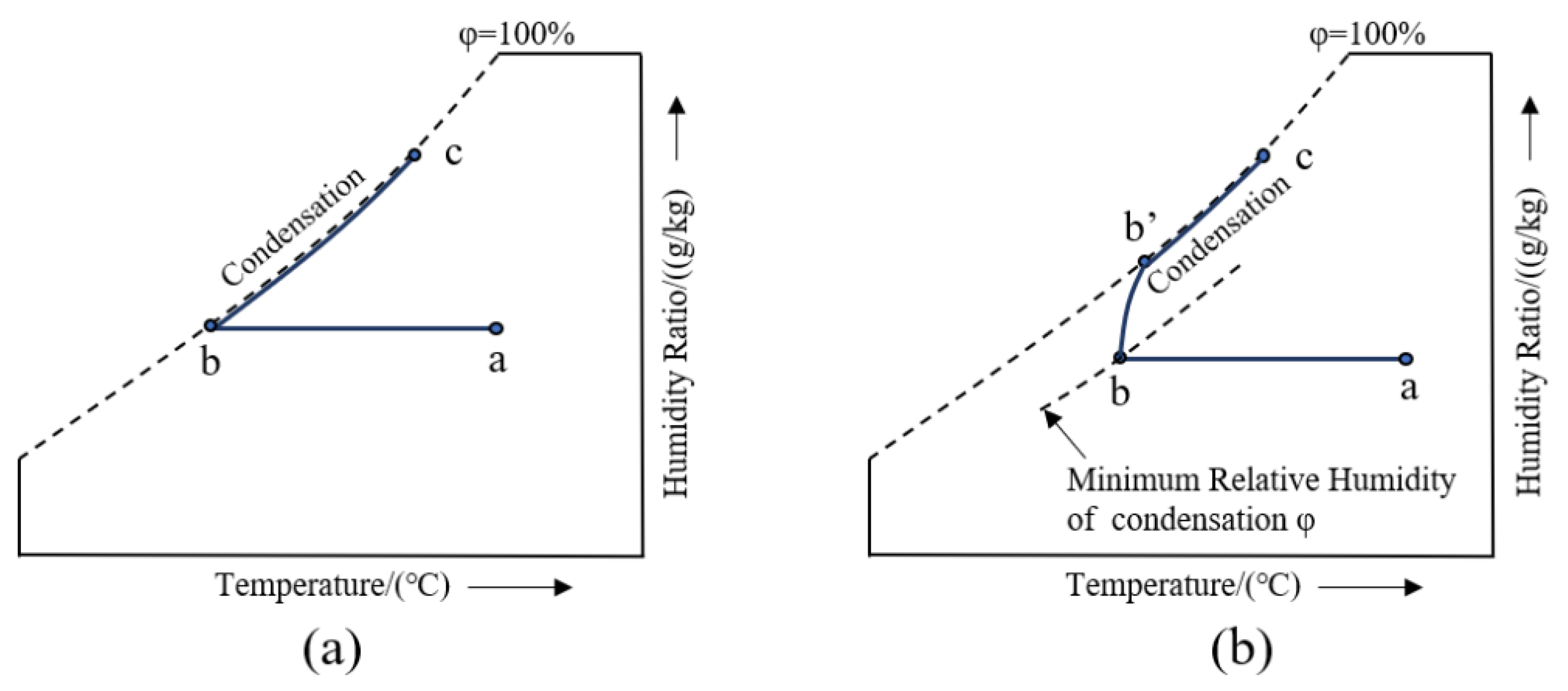

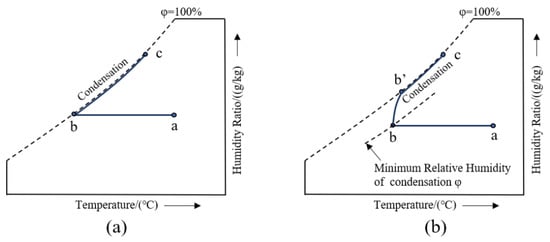

A common moisture transfer process occurs in underground spaces when partial pressure of water vapour inside the constructed spaces is lower than that outside the constructed spaces. Water vapour from the outside of the envelop diffuses into the interior. Ventilation can transport weather fluctuations in moisture, and moisture exchange within walls can help to partly buffer weather temperature fluctuations. They will be progressively smoothed out as the distance from the inlet increases [10]. In the winter, outdoor air with low humidity can be supplied to remove moisture from underground spaces. Temperature would be reduced by exchanging air with outside air. Excessive air change, on the other hand, may increase RH. During the summer, ventilation and air exchange could transfer net moisture into underground spaces. At the same time, RH would be reduced by outdoor warm air [11]. Generally, the wall surface temperature is below or close to air dew point temperature at entrances of underground tunnels or spaces. Condensation occurs during the cooling and dehumidification processes when outside air enters tunnels [12]. Fog and condensation in underground ducts are unavoidable in a long hot and humid season. The condensation process of air can be divided into two models: the saturated condensation model and the unsaturated condensation model, as shown in Figure 1. When the temperature of the wall falls below the dew point temperature, the air cools without changing its specific humidity and condenses with the saturation line, a process known as saturated condensation (Figure 1a). However, the air cooling and dehumidifying processes of underground ducts differ in practice. First, the air cools with a constant specific humidity, i.e., the RH reaches a specific point B, known as the minimum RH of condensation, and the vapour in the air begins to condensate on the tunnel wall. Finally, as the RH increases, the state of the air reaches the saturation line and then cools along with it [13].

Figure 1.

Condensation process of air in psychrometric chart: (a) saturated condensation model; (b) unsaturated condensation model. Where φ is relative humidity.

In the case of rising damp phenomena, surface condensation can also occur. Rising damp can increase indoor high humidity and materials deterioration, especially for porous materials [14,15]. The presence of moisture in the material pores, coupled with other environmental factors, may lead to biological erosion, salt crystallization, chemical erosion, clay-containing stone expansion, freezing damage, etc., and ultimately lead to material loss and even structural problems [15]. A large amount of literature is devoted to studying the mechanism of underground capillary water rise [14,16]. Ground and concrete are generally porous mediums affected by moisture to some degree [17]. Therefore, using these materials in underground spaces may have negative consequences. Emery et al. showed that it was very inappropriate to cover the masonry surface with ordinary waterproof materials (such as impermeable gypsum, asphalt), because this would make the rise of moisture more serious [18]. Field measurements and simulation studies have revealed that appropriate air exchange rates and ground coverings should be used to prevent moisture from entering the building structure [19,20]. In terms of moisture resistance, using straw boards as indoor materials can help to reduce changes in daily and monthly humidity. These are used to create a good humidity environment in underground civil air defense projects without occupants [11]. They also mentioned that we should create a database to track the temperature and humidity of underground spaces over time and analyze the factors causing moisture problems.

Moreover, moisture is one of the major components of thermal environments in underground structures and surrounding grounds. Moisture in the ground and concrete has a great influence on the surrounding areas. Moisture transfer will not only make surfaces of underground spaces humid, but it will also affect heat loads in underground spaces. Heat transfer is affected not only by conduction but also by the distribution of wet components in the building envelope [21]. Mass transfer is influenced by both moisture diffusion and thermal diffusion. Heat transfer and moisture transfer in underground ducts are a coupled unstable process, which is influenced by time, space, inlet state and other factors together [22]. A numerical model was developed to describe simultaneous heat transfer between air and tunnel surfaces while accounting for condensation inside the tunnel [23].

2.2. Heat Transfer

In most cases, when air flows through underground tunnels, the heat exchange between the airflow and the isothermal surfaces is a complicated and unstable heat transfer process. Because of heat-generating equipment and hot water, the rocks that surround the roadway are constantly cooled. The air’s humidity is constantly changing. As a result, heat transfer in ventilation tunnels is a difficult fluid–solid–coupled heat transfer problem [24,25]. Mihalakakou et al. [1] and Li et al. [2] proposed models to describe thermal influences of key variables such as length, diameter, and air velocity, which were validated by long-term measurements. Wu et al. [5] developed a numerical model to predict the thermal performance and cooling capacity of underground soil-to-air systems. The ubiquitous inhomogeneities in soil were discovered by Rees et al. [26] and Naylor et al. [27]. However, the dimensional simplified mesh generation method based on the isotropic assumption causes thermal simulation to deviate. Subway environment simulation (SES) is a design-oriented tool that is commonly used in underground tunnel environments to predict temperature, cooling load, and airflow in subway stations [28]. The SES has limitations in terms of heat transfer direction. It employs a one-dimensional simplified model, but soil inhomogeneities are common [29,30]. As a result, new calculation methods must be developed in order to improve calculation accuracy. To effectively estimate the tunnel temperature, Zhang and Li [29] proposed a specific formalism that suits the demand of the underground tunnel unsteady heat transfer problem. More research is required to validate the efficacy of this method. Soil surrounds underground spaces, and the thermophysical properties of the soil have a large influence on heat transfer. When developing the model, take into account the inhomogeneity. Sadokierski and Thiffeault [31] observed that the instantaneous change in air temperature in the tunnel causes a change in the temperature of the surrounding soil. As a result, further research into the heat transfer model of underground spaces is required, and it is not appropriate to simplify all forms of underground spaces into a constant line source or a cylindrical source.

Energy tunnels have been developed in recent years, which can effectively reduce the use of fossil fuels while mitigating the increase in greenhouse gas emissions [32]. The most significant advantage of an energy tunnel is its high heat transfer potential [33]. There are many factors affecting tunnel heat transfer, such as tunnel shape (rectangular, horseshoe, ellipse, round, etc.), tunnel size, air inlet temperature, wall roughness, airflow rate and mass transfer (moisture, condensation, evaporation). Ren et al. [34] observed that air temperature and velocity have a direct impact on the heat exchange capacity of a dam tunnel network. Peltier et al. [32] pointed that cross–section shapes of tunnels influence the development of a thermal boundary layer but not the development of a velocity boundary layer. Inlet airflow velocity influences the development of a thermal boundary layer but has no effect on the development of a velocity boundary layer. Tunnel wall roughness has an effect on the development of both thermal and velocity boundary layers. However, there have been few studies on the effect of thermal and velocity boundary layers on convective heat transfer in tunnels [32]. The most common system involves inserting large-diameter plastic pipes into the lining of an energy tunnel. Although this system provides significant economic and environmental benefits, laying large-diameter pipes in the tunnel lining is difficult and costly. As a result, the capillary net is proposed as the front-end heat exchanger [35]. Tong et al. [36] investigated the heat transfer characteristics of subway tunnel capillary heat exchangers with varying tube spacings using numerical simulation methods. They used simulation to determine the optimal pipe spacing and experiments to validate the simulation’s accuracy. Tong et al. [37] simulated the heat transfer process between the capillary tube, surrounding rock, and tunnel air and determined the heat flow range of the capillary tube. They also compared the efficiency of capillary intermittent and continuous operation and discovered that intermittent operation is relatively efficient. Liu et al. [35] proposed a one-dimensional simplified plate heat transfer calculation method for surface heat sources in capillary heat exchangers. Capillary tube research in energy tunnels is still in its early stages, and its performance needs to be validated in real-world projects. Energy tunnels have demonstrated their benefits in terms of energy savings, but fundamental scientific issues and practical engineering gaps, such as the impact of underground penetration, remain to be addressed.

3. Unsolved Problems in Underground Spaces

3.1. Pollutants

Pollutants in underground spaces mainly include TVOC, CO, PM10, radioactive Rn, and so on. Concentrations of formaldehyde and TVOC in underground malls are higher than those in outdoor environments. Tao et al. [7] investigated concentration levels of formaldehyde and TVOC in 9 underground malls in Xi’an, China. Mean mass concentrations of formaldehyde and TVOC range from 0.05 mg/m3 to 0.26 mg/m3 and from 0.34 mg/m3 to 3.56 mg/m3, respectively. Liu et al. [38] investigated patterns of pollutant concentrations and their sensitivities to traffic volume in naturally ventilated underground parking garages. They found that the PM2.5 concentrations in underground parking garages were slightly higher than in ambient environments, but PM10 concentrations were significantly higher. Chow et al. [39] investigated indoor CO concentrations in a large underground parking garage in Hong Kong. CO concentration does not necessarily rise when the total number of cars increases. Oh et al. [40] investigated the exposure of particulate matter and TVOC in underground parking garages under various ventilation modes and their impact on health. The levels of inhalation exposure to PM and TVOC as well as the health effects associated with them, are affected by the ventilation types used in underground parking garages. For most residential underground parking garages in China, natural ventilation is the most popular ventilating mode, when construction and operating costs are considered. Therefore, more effective ventilation systems are required depending on the traffic–volume and indoor air quality (IAQ). Yang et al. [41] investigated IAQ in an underground shopping mall. Although the CO2 concentration can meet the requirement stipulated in the standard, people also recommended that IAQ, the maximum acceptable CO2 concentration stipulated in the standard, should be investigated further. Li et al. [42] investigated the combined effect of elevated temperature, RH and CO2 concentration on human responses. They found that high RH and CO2 concentration degrade air quality, and that the combined effects of high air temperature, RH and CO2 concentrations result in a variety of human responses. Braniš [8] compared PM concentrations measured on streets, in underground spaces and within subway trains. The highest PM10 concentrations were found inside Metro trains (113.7 mg/m3 and 1.44 mg/m3), followed by underground station spaces (102.7 mg/m3 and 1.29 mg/m3), and outdoor environments (74.3 mg/m3 and 0.85 mg/m3). In Europe, related agreements stipulate that subway air-conditioning filters should be replaced regularly every month [43]. However, Moreno et al. found that filters could maintain air quality for at least 3 months, and if pathogens can also be maintained within the standard range during this period, then the current agreement needs to be changed. They also pointed out that the WHO should give additional and equally important attention to improving underground air quality [43]. “Construction specifications on underground excavation engineering of hydraulic structures” stipulates that the minimum air velocity used when calculating the ventilation of large underground spaces is 0.15 m/s [44]. Li et al. found that the air velocity could control the dust level, provide the required oxygen concentration and control the temperature within an acceptable range, but it was not enough to reduce the CO concentration below the acceptable safety limit [45].

Radon is a major environmental carcinogen identified by the World Health Organization, and it is primarily emitted by soil and building materials. In reality, the radon risk is primarily caused by short-lived radon progeny. The increased exposure caused by short-lived radon progeny in underground mines is primarily due to inadequate ventilation and increased radon exhalation from surface materials [46]. Li et al. [47] investigated the daily and seasonal variations of radon concentrations in underground buildings in major cities of China. Radon concentrations in the underground buildings fluctuate in two cycles per day. In winter, radon concentrations in the underground buildings are lower than in summer, which is the opposite of the situation above ground level. The primary external factor causing this phenomenon is seasonal variation in outdoor temperature [48]. Jin et al. [49] summarized the characteristics of underground indoor radon, its progeny, and the source to those of unequilibrium radon and its progeny. Underground indoor radon levels are influenced not only by building materials, but also by geological structure, air tightness of houses, indoor ventilation rate, people’s living habits, and other factors.

During the construction phase, common harmful components in underground spaces are CO, CO2, NO2, SO2, dust and exhaust gas from construction equipment. Ventilation during the construction phase, which is used for comprehensive control of underground space construction environments, has a direct impact on the body health and construction efficiency of tunnel construction workers. In general, we assumed that CO in coal mines is primarily caused by spontaneous combustion of residual coal in goaf. Tang [50] found that crushing and oxidation at ambient temperatures are also potential sources of CO in coal mines. Sasmito et al. [51] studied several ventilation scenarios in cross-cut regions where active mining occurred and found that a brattice-exhausting system combination provides the best performance. Right-cut scenarios can be considered and implemented during excavation to reduce the presence of recirculation zones. In order to improve gas control, additional auxiliary ventilation is required during excavation. Liu et al. [52] studied construction ventilation in deep diversion tunnels using the Euler–Lagrange method. A three-dimensional unsteady Euler–Lagrange two-phase turbulence model was used to simulate the construction ventilation of deep diversion tunnels with construction branch tunnels and transverse passageways, taking into account air leakages, gas–solid heat exchanges, gas–solid interaction forces, and particle collisions.

3.2. Smoke Control and Exhaust

When a fire breaks out in an underground building, several characteristics emerge. First, hot smoke fumes cannot be discharged in a timely manner, space temperature rises rapidly, heat dissipation is difficult, and flashover occurs. Second, a lot of smoke builds up for a long time. Incomplete combustion occurs as a result of insufficient ventilation. Toxic gas concentrations, such as CO and CO2, rapidly increase. The layer of smoke is thick and easily spreads to other areas. Finally, because underground buildings have few entrances and exits and long evacuation distances, evacuation and firefighting are difficult. When a fire breaks out in an underground space building, massive losses are often the result. A subway fire in Daegu, Korea, for example, killed 198 people and injured 147 others. Another subway fire killed 289 people and injured 265 in Baku, Azerbaijan [53]. A fire will result in significant losses and casualties.

When a fire breaks out in an underground space, the main cause of casualties and property loss is fire-induced smoke. For many years, researchers have studied the characteristics of fire-induced smoke in both uniform and thermally stratified environments. The temperature of smoke emitted by fire sources is significantly higher than the temperature of the surrounding air. The buoyancy caused by the temperature difference can propel smoke upward. During the rising process, the smoke plume entrains cooler air from the surroundings. The amount of smoke produced by a fire is primarily determined by the amount of air entrained by the plume. The maximum gas temperature beneath the tunnel ceiling is proportional to heat release rate (HHR), longitudinal ventilation rate, and ceiling height [54]. Cetegen et al. [55] measured entrainments in near and far fields of fire plumes rising from fire sources with different diameters and HHR. Experiments show that there are three regions above the fire source. Heskestad [56] proposed a model of virtual origins and a rationale for temperature correlations. Hu et al. [57] used full-scale burning tests to investigate the rise time of a buoyant plume front at three different locations (center, near a wall, and corner of the atrium floor). Early fire smoke movement and detection were also investigated in large volume spaces with stratified environments inside. A thermally stratified environment accelerates the decreases in axial temperature and velocity of a fire smoke plume until it reaches a maximum height [58]. In long and narrow structures, a ceiling jet would be constrained by vertical walls, resulting in smoke backflows and an increase in smoke temperature under the ceiling [59]. Li et al. [60] investigated smoke properties in a reduced scale (1:12) corridor model of an underground hydraulic machinery plant under natural filling conditions. When the HHR is less than 1500 kW, the maximum smoke temperatures under the ceiling are all less than 200 °C. Ji et al. [59] used two sets of small-scale experiments to conduct theoretical and experimental research on the maximum smoke temperature under the ceiling. They developed a relationship to determine the maximum smoke temperature. The method is appropriate for subway station fire engineering designs. Ventilation is the most effective way to control fire-induced smoke. Traditional ventilation systems used to control fires include the longitudinal ventilation system, supply air semi-transverse ventilation system, exhaust air semi-transverse ventilation system, full transverse ventilation system, and natural ventilation system [61,62,63,64,65,66]. The temperature distribution of fire-induced flow along mechanically ventilated tunnels was investigated by Li et al. [67]. To predict the temperature distribution of a fire flow with enough accuracy for engineering use, a model was proposed that took tunnel ventilation velocities and fire heat release rates into account. Khattri [68] investigated the effect of ventilation velocity on variables such as maximum ceiling temperature, maximum floor temperature, maximum ceiling flux, maximum flux on the floor and fire growth rate. Gao et al. [69] pointed out that hybrid ventilation can prevent smoke dispersion more effectively than conventional mechanical ventilation. Hybrid ventilation is an effective way to exhaust fire induced smoke with a 3 × 3 m or larger roof window in an atrium ceiling. Hu et al. [70] suggested that in an emergency scenario involving a train on fire stopping beside the platform of a subway station, the most effective strategic cooperative ventilation mode is only to activate the over track exhaust system of the tunnel rail track area with the aid of the activation smoke exhaust pattern of a platform ventilation system. Natural ventilation through vertical shafts or roof openings has the benefits of saving space, lowering costs, simplifying maintenance, and saving electricity. Because of the benefits listed above, the use of vertical shafts for natural ventilation has gained popularity. The effect of tunnel smoke exhaust on shaft geometry, shaft height, shaft cross-sectional area, and shaft aspect ratio has been extensively studied [71,72]. Vertical shafts connected at oblique angles provide better natural ventilation. The height of shafts has a critical value. To avoid entrainment of fresh air, the shaft’s large section length and width should be divided into several smaller shafts. The phenomenon of smoke layer separation and blockage in shaft smoke extraction results in low smoke extraction efficiency [71]. Cong et al. [73] proposed a method of the board-coupled shaft to alleviate the blocking effect (BCS). The results show that this method can improve smoke extraction efficiency, but special consideration should be given to the size of the plate and the distance from the well. Despite extensive research into natural ventilation of vertical shafts, there are still many challenges to overcome. Gao et al. [74] investigated the effects of domes on the confluence, storage, and suppression of fire-induced smoke control in subway stations. Preliminary findings indicate that when the fire source is located beneath the dome, the CO concentration in the hall of a subway station is significantly lower. As a result, some architectural features aid in smoke control.

Generally, traditional ventilation systems reduce average smoke concentration of the entire spaces, which results in high-level smoke concentration in the lower part of the spaces when utilizing traditional ventilation systems. From the perspective of human evacuation, the aim of ventilation is to create a safe, smoke-free evacuation path of lower part of underground spaces, rather than that of entire spaces. Gao et al. [75] introduced a breathing air supply zone that was combined with an upward ventilation-assisted tunnel evacuation system (ATES), and they found that maximum CO concentration in the evacuation passageway with an ATES is below 10 ppm throughout the entire combustion. Lei et al. [76] investigated the characteristics of pedestrian evacuation in a large-scale terminal subway station using FDS + Evac simulation software. The study looked at how evacuees and fire interact. They discovered a linear relationship between population density and evacuation time.

The air curtain systems are commonly installed to avoid effects of high-temperature smoke and harmful gases in fire spaces. Hu et al. [77] demonstrated that an air curtain can effectively confine transportation of smoke and carbon monoxide species in long channel fires. Gupta et al. [78] compared and discussed the efficiency of various air curtains experimentally and found that the double stream-twin jets (DS-TJ) configuration was an efficient way to minimize heat and smoke propagation. Zhang et al. [79] demonstrated that air curtain systems for a refuge chamber with air curtains installed on two sides of door frame behind a door wall that ejected air parallel to the door frame provided a relatively good barrier effect. An air curtain system that uses pipeline air curtains with a nozzle diameter of 1 mm and a nozzle distance of 15 mm exhibited a relatively good barrier effect with barrier efficiency of 55–60%. The purpose of water-based fixed compartmentation systems is to form a water curtain to block smoke, similar to the role of an air curtain system (Table 1). This system, however, is only applicable to a few countries [80].

Table 1.

Main studies on water mist [66,80,81,82,83,84,85,86,87].

3.3. Harmful Microorganism

Fungi, bacteria, and viruses are the most common causes of microbial contamination. The underground structure is relatively closed, with a constant temperature and high humidity environment that is ideal for the growth of wall mold [88,89]. Moisture in underground buildings is the main reason for microorganism increases. When there is water ingress or excess condensation within built environments, fungal growth usually occurs [90]. Fifty-one underground spaces were investigated from 1992 to 2004 [91]. It was found that anaerobes in aisles are 4.2 and 3.8 times of those in semi-closed and open aisles, respectively. Appropriate temperature and humidity promote growth of microorganisms on polluted surfaces. Li et al. [92] investigated the effect of air conditioning parameters (temperature, RH and supply air velocity) and deposited dust on microbial growth in supply air ducts. RH is the main influential factor to fungal growth at 3.0 m/s supply air velocity. Yu et al. [89] analyzes the influence of environmental factors on mold present on inner surfaces of Shenyang’s underground walls, and found that the mold growth rate is most sensitive to humidity. They suggested that the humidity on the surface of the wall should be controlled below 84% to prevent rapid mold growth. Some microorganism growth shows evident changes related to seasonal and meteorological conditions. Heo and Lee [93] found that bacterial aerosol concentration increased by more than three times from March to April, and decreased by more than two times from October to November. The number of passengers had a small effect on the concentration of bacterial aerosols in the subway station. However, fungal aerosols are relatively unaffected by seasonal changes and a human presence. By contrast with underground stations, a field investigation indicated that the bacterial concentration in the utility tunnel was similar to that of underground stations with few passengers, and the fungal concentration was 3.2 times higher than that of underground stations [94]. Studies of aerosol microbiology in subway environments have focused on culture-dependent techniques, and the current study may have found only a small fraction of the actual microbial content, because the vast majority of microorganisms are not cultured by standard techniques [95].

Ventilation has been shown to be an effective method of controlling airborne microorganism contamination in underground spaces. Hwang et al. [96] measured the concentrations of culturable airborne bacteria (CABs) in the underground environment of 16 subway stations in Seoul, South Korea and found that CAB concentrations in stations with ventilation systems were significantly lower than those in stations without ventilation systems (p < 0.001). Zhang et al. [94] found that after ventilation for 1.0 h, 86.0% of airborne bacteria and 28.7% of airborne fungi were removed in an urban utility tunnel. In underground spaces with no ventilation systems, it is critical to reduce harmful microorganism concentrations and improve IAQ.

To ensure good environmental quality in underground spaces, comprehensive control measures such as keeping underground spaces dry and clean, disinfecting underground spaces with disinfectant, using moisture proof coating/hygroscopic material, proper design, operation, and maintenance of ventilation and air conditioning systems, using ultraviolet lamps to disinfect air, and so on should be implemented. However, there are no statutory restrictions on airborne bacteria and fungi in underground workplaces, including underground integrated pipes, which are required to provide a safe environment for employees working in underground spaces [94].

3.4. Comfort and Psychological Problems

Underground space environments frequently have significant physiological and psychological consequences, such as psychological depression, boredom, and a sense of fear (Table 2). The reasons include a lack of sunlight and visibility to the outside world, high humidity, close proximity, poor air quality, and so on.

Table 2.

Potential health effects and causes of underground space personnel [97,98].

Extensive research has been conducted on ventilation technologies, temperature and humidity control technologies, noise control technologies, daylight transmission technologies, and environmental quality requirements in underground spaces. Racz and Petrilean [99] found that underground mines face the issue of condensate which drips down on the walls of the underground work especially in summer periods, thereby substantially changing the comfort of working conditions. Han et al. [100] selected six subway stations in Seoul for physical environment measurements and performed a survey of 5282 passengers. Based on standard equivalent temperature (SET*), comfort range is 16.1 to 31.2 °C for concourses and 15.9 to 31.5 °C for platforms. Li et al. [101] conducted both thermal comfort field measurements and questionnaires in different underground air-defense basements in 95 cities in China. Thermal acceptable temperature range is not symmetrically distributed with respect to thermal neutral temperature and changes with the ground temperature. Li et al. [42] found when RH was more than 80%, most of the occupants’ thermal acceptability (TA) was less than −0.3. Ko et al. [102] conducted a randomized crossover experiment with 86 participants in windowed and windowless spaces. The temperature of the air and window surface was kept at 28 °C, which is a slightly warmer condition. The results showed that compared with the space without windows, the thermal feeling of the space with windows was significantly colder, and more than 12% of the participants felt thermal comfort. Tan et al. [103] proposed planting fast-growing plants in underground space or humanized interior design imitating nature, as well as personal control of physical working space (such as adjustment), as beneficial design aspects and effective means to overcome the windowless environment of underground spaces.

Fanger proposed predicted mean vote (PMV) in 1970, this model is only suitable for mechanical ventilation and is used to evaluate steady-state thermal environment. Therefore, many new prediction models have been proposed. Nicol and Humphreys [104] proposed an adaptive model in 2002. This model is only suitable for natural ventilation environments under specific conditions. In this environment, there is the possibility of thermal regulation such as opening windows and adjusting clothes. Recent studies have found that there is a “scissors gap” between PMV and thermal sensation vote (TSV) voting. Therefore, Yao et al. [105] used the “black box” theory to adaptively predict the average voting model, which takes cultural, climatic, social, psychological and behavioral adaptation factors into account. The environment of underground spaces is very different from that of above-ground spaces, so the existing thermal comfort model cannot be directly used to evaluate underground spaces. However, the majority of thermal comfort research is based on above-ground spaces, and prediction models for underground spaces are scarce. Li et al. [106] collected 5862 valid questionnaires from typical underground buildings in 249 Chinese cities over an 8-year period. The underground buildings in China are divided into four zones based on the analysis of observation data and questionnaires, and the corresponding thermal neutral temperature prediction model is proposed (see Table 3). In order to characterize the thermal comfort of transition areas such as the platform level and hall level of subway stations, the relative warmth index (RWI) and heat deficit rate (HDR) proposed by the Transportation Air Conditioning Committee of the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) are introduced [107,108]. HDR means that human body is in a cold environment, and the mean skin temperature is the heat loss rate at the lower limit of the comfortable skin temperature (about 30.6–35 °C), that is, the negative human body heat storage rate [108]. Table 4 shows the corresponding relationship between the RWI value and the ASHRAE thermal sensation scale [107,109].

Table 3.

Developed comfort models for different climatic zones [106].

Table 4.

American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) comfort classification using RWI [107,109].

The psychological issues caused by underground spaces are more complex. Research results show that even if the inner space environment of underground buildings reaches the same comfort level as that of above ground buildings, psychological barriers still exist. Other studies show that people ignore actual situations, despite the fact that some underground buildings have adequate artificial light sources, good mechanical ventilation and humidity control. In underground buildings, it is easy to lose one’s bearings in underground buildings, causing tension, anxiety and fear because of the invisibility of building forms and the lack of external reference points provided by windows. Long-term exposure to underground buildings causes subjective perception of time to worsen, sight and memory to deteriorate, fatigue to increase, working capacity and protective functions of an organism to decrease, and hallucinations [110]. Ko et al. [102] pointed out that compared with windowless state, people with windows had higher positive emotions (such as happiness and satisfaction) and lower negative emotions (such as sadness and sleepiness). When there were windows, working memory and concentration ability were improved, but there were no significant differences in short-term memory, planning and creativity. As a result, the connection between underground space and the natural environment is an important factor influencing human psychology. Kim et al. [111] investigated the effects of indoor plants and artificial windows in an underground laboratory. Plants have a positive impact on the underground environment, whereas artificial windows have a less significant impact. According to Dai et al. [112], developers should transform the underground negative space into a positive space to satisfy the place plot of people in the above ground space, in order to better attract people to participate in it. To a large extent, how to complete the transformation from “space” to “place” is the main strategy for improving the spiritual factors of underground spaces. Psychological recognition of underground spaces is a critical issue that necessitates extensive research.

3.5. Air Quality Control and Ventilation

Because underground buildings are relatively closed and humid environments, ventilation is especially important. Natural ventilation and mechanical ventilation are the two types of ventilation based on the driving forces of airflow. Depending on the application, ventilation can be classified as general ventilation, emergency ventilation, construction ventilation, and so on.

Natural ventilation is typically powered by natural forces such as wind, thermal buoyancy and geothermal energy. As previously stated, the concept of natural ground–coupled ventilation makes use stable soil temperature to preheat or precool air for buildings. In the early millennium B.C., Iranian architects used wind towers and underground air tunnels for passive cooling and ventilation. Natural ventilation solutions in Iran are integrated with the country’s famous qanat systems, which are typically dug into the slope of a mountain or hillside. The ancient Egyptians used pressure differences caused by temperature changes between day and night to ventilate the construction of underground tombs and temples [113]. The airflow of natural ventilation in underground structures is complex and strongly influenced by temperature differences. During the autumn and winter seasons, the impact of outdoor air is amplified. In the spring and summer, it is significantly reduced. As transition areas, the access tunnel and ventilation chimney experience the greatest temperature changes and play an important role in regulating natural ventilation [114]. Underground engineering has a moisture problem due to its unique environment, especially in the summer when natural ventilation is used, because outdoor air humidity is high and easily condenses after passing through the basement. As a result, mechanical auxiliary natural ventilation can not only effectively avoid condensation, but also ensure good underground engineering air quality [115]. Throughout the year, natural ventilation varies. Natural ventilation in underground spaces should take into account the influences of outdoor seasonal wind direction and speed, and wind pressure should be used to enhance natural ventilation. Ventilation outlets and ventilation pipes should be strategically placed. The area of ventilation outlets should be appropriately enlarged to minimize ventilation resistance in order to enhance natural ventilation.

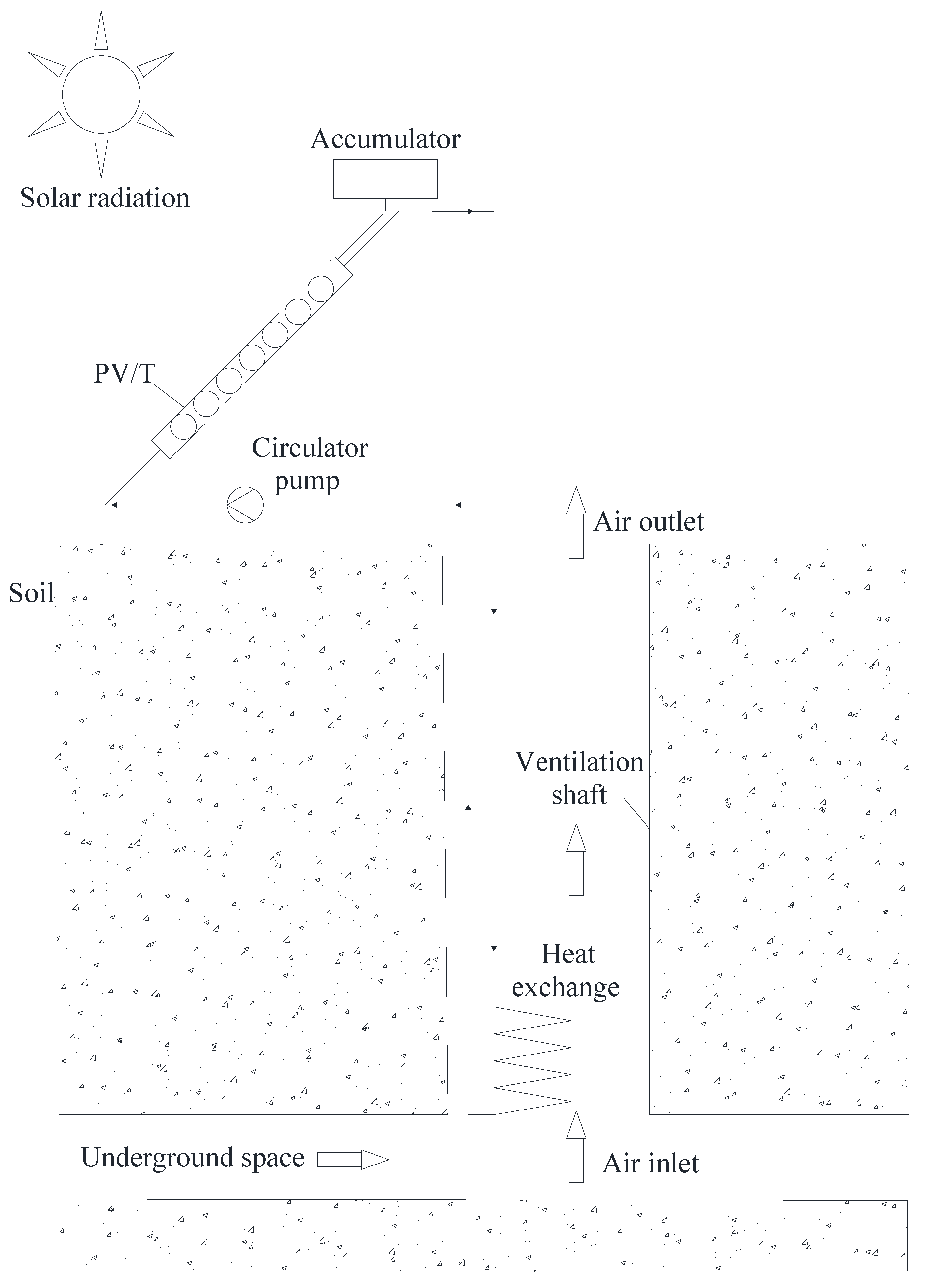

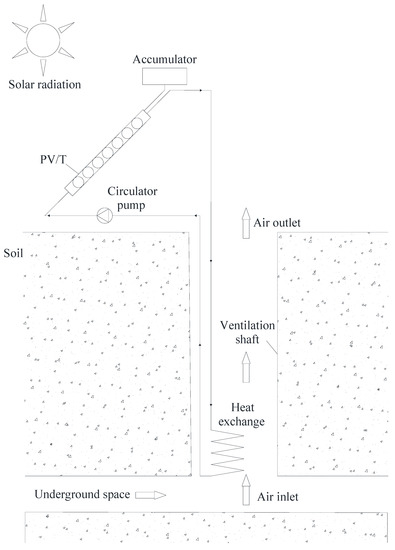

The use of thermal pressure in a solar chimney is an effective way to improve natural ventilation. It uses solar radiation to heat the air in the chimney, causing temperature differences between the air inside and outside the chimney, which causes density differences. As a result, thermal pressure is used to provide additional buoyancy for airflow and strengthen natural ventilation, thereby improving internal thermal environments of buildings and obtaining a better ventilation effect [116]. Guo et al. [117] proposed combining the solar chimney effect with a solar water heater to provide ventilation for underground buildings. Xiang et al. [118] propose technical measures for combining the solar chimney effect with PV/T technology and using the waste heat generated by the PV/T collector to ventilate underground spaces (Figure 2). The underground space design strategy of combining natural ventilation and daylighting has grown in popularity in northern China in recent years [119]. The key to the design is to reasonably organize underground spaces and various space forms and elements in the environment, and to design underground spaces by utilizing seasonal changes and plant growth habits, as well as certain artificial auxiliary management and mechanical equipment.

Figure 2.

Ventilation system combining solar chimney effect and PV/T [118].

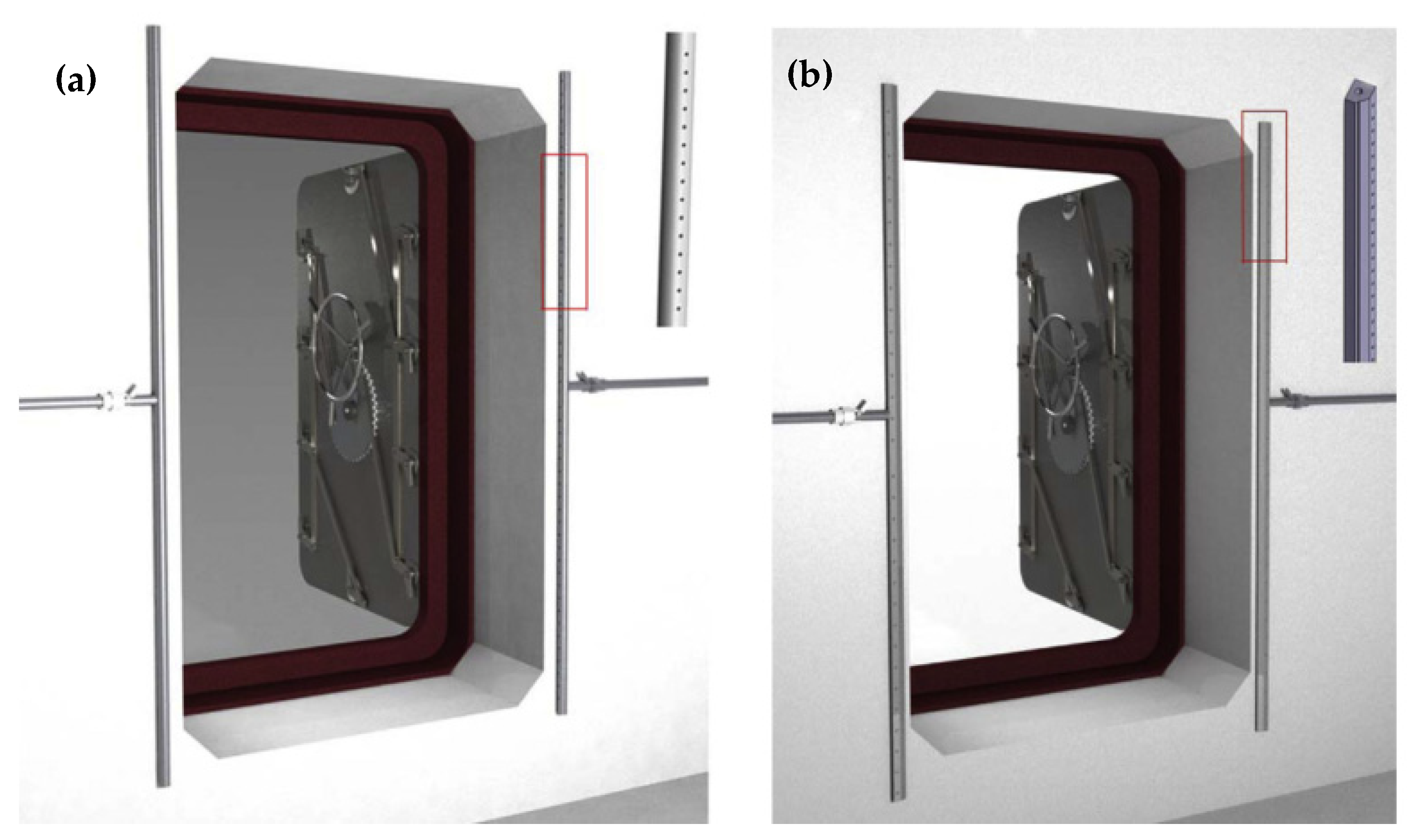

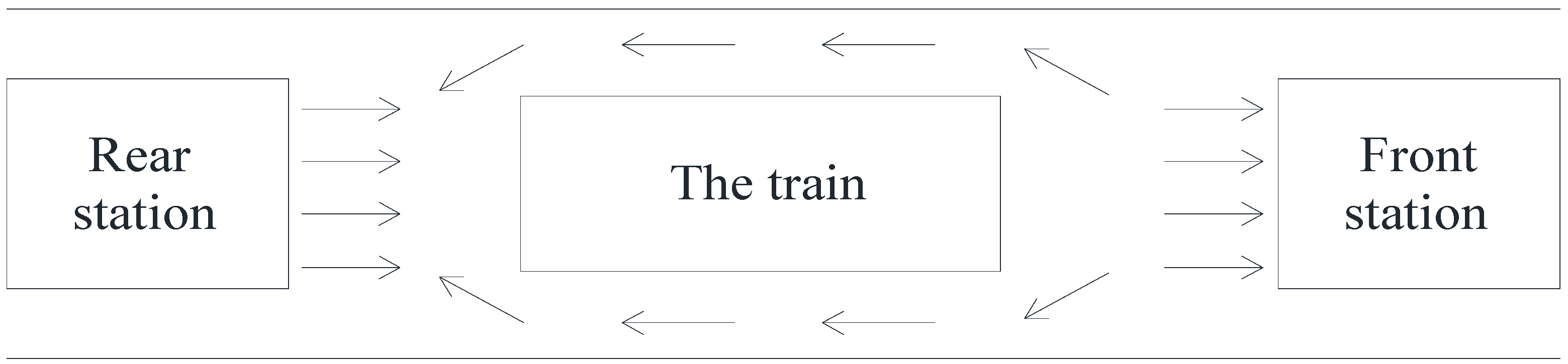

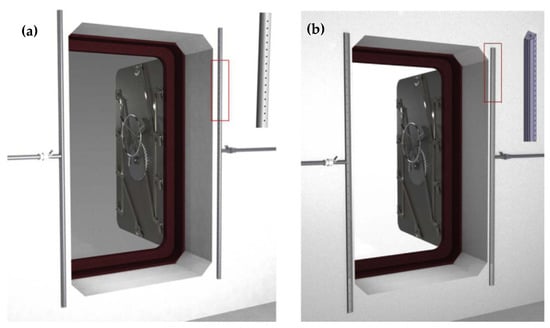

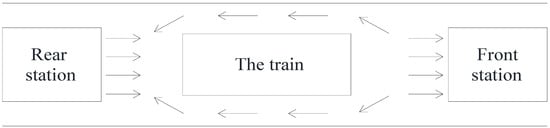

Mechanical ventilation has also been widely studied and applied as an effective method of underground space environmental control in mines, tunnels, metro stations, hydropower stations, and storage facilities, among other places. Two auxiliary ventilation systems, forcing and exhausting, are used in dead end roadways to reduce concentrations of harmful substances such as methane and ensure the safety of workers in underground coal mining. Air curtain systems (Figure 3) for mine refuge chambers keep dangerous gases from entering the chamber. Their barrier efficiency is influenced by structural parameters, installation location, airflow angle, and chamber door size [79]. The size of the system’s barrier to hazardous gases is referred to as the barrier efficiency. Zhang et al. [79] pointed out that air curtain systems, with air curtains installed on two sides of the door frame behind the door wall and ejecting air parallel to the door frame, provide a relatively good barrier effect. An air curtain system that uses pipeline air curtains with a nozzle diameter of 1 mm and a nozzle distance of 15 mm demonstrates a relatively good barrier effect with efficiency of 55% to 60%. For hydropower stations, a proper thermal and humid environment is of significance for human safety and steady operation of power generation systems. Ventilation technologies for underground large spaces, i.e., generator floor, are cutting-edge studies. At present, the main air distribution forms of underground generator main workshop of hydropower station are stratified air distribution of generator floor workshop, upper (top) air supply air distribution of powerhouse, air supply air distribution of lower powerhouse, and series direct current ventilation system for an underground powerhouse [120]. Key factors affecting underground train systems are types of ventilation operating in tunnels and station platforms, which have been widely studied. The train piston effect is also important, which may help to reduce energy consumption. When a subway train travels through a relatively narrow tunnel, the positive pressure formed at the head pushes the foul air out, while the negative pressure formed at the tail sucks fresh air in (Figure 4). This results in a piston wind [121]. Wang et al. [122] concluded that the piston wind speed is influenced by the shaft area, the length, the one-way resistance coefficient, the local resistance coefficient, and a variety of other factors. Han et al. [123] simulated the effect of different forms of piston vents on tunnel ventilation. They noted that a direct air shaft outperformed an inclined air shaft. Architectural design, gradual extension of storage zones, ventilation rates, and weather conditions, which are likely to influence ambient conditions along shafts, galleries, and storage modules, should all be considered when designing ventilation for an underground repository [10].

Figure 3.

Two main types of air curtain systems for mine refuge chambers in China [79]. (a) Pipeline air curtain. (b) Air knife.

Figure 4.

Formation mechanism of piston wind [79].

The piston effect allows tunnels and platforms to be ventilated, which saves energy. Wen et al. [98] discovered, however, that the piston effect may worsen indoor air quality in subway stations. They argue that reasonable space design can provide a foundation for effective ventilation and air pollution control in subway stations. To improve the complex environment of a subway station, architectural layout design must be combined with indoor ventilation design. Their research also found that the station design with an atrium improves ventilation and pollution control [124]. Hwang et al. [125] discovered that the bacterial concentration on the subway platform increased in the absence of a platform screen door (PSD). Particulate matter inflow can be reduced by combining a ventilation system and PSD [126]. Dong [127] devised a novel system for outfitting the PSD with a programmable air vent. Physical methods are increasingly being used to remove organic pollutants, bacteria, and microbes from subway platforms. These methods, however, may produce other pollutants such as ozone and nitrogen oxides [124]. According to Kim et al. [128], current research only focuses on environmental monitoring, and it is necessary to establish a prediction model to reasonably regulate the indoor air quality in subway stations. They proposed a seasonal variation-based IAQ monitoring and forecasting model. Liu et al. [129] presented a multi-objective optimization approach for determining the optimal set point for model predictive control in order to maintain healthy IAQ while consuming the least amount of energy. They discovered that this method outperforms manual control. Future research could look into the long-term health effects of exposure to other types of air pollution besides PM [130].

4. Conclusions

The difficult problems of underground spaces were reviewed and summarized in terms of their research and practical application. Due to lack of natural light, insufficient natural ventilation, and special heat and humidity environments, human safety, physical and mental health, and work efficiency are influenced. The improvement of the underground space environment is inextricably linked to moisture control, which has an impact on human health, microbial growth, heat transfer, and equipment operation. The most significant shortcoming of underground spaces is a lack of natural light. It has a significant impact on human psychological health. Ventilation technology is an important tool for improving the environment of underground spaces. It can provide fresh air, control microbial pollution, improve hot and humid environments, and reduce fire smoke emissions. Some underground space problems have been effectively solved by utilizing new technologies. However, additional research is still required to address unresolved issues.

Because of the significant impact of moisture on the underground space environment, moisture control is critical. As a result, high-performance waterproof materials should be investigated further. Energy tunnels have demonstrated energy-saving characteristics, but numerous basic scientific problems and practical engineering gaps must still be addressed. On the other hand, regulations should be put in place to limit airborne bacteria and fungi in underground workplaces in order to protect workers’ health.

Author Contributions

Conceptualization, B.Y.; methodology, B.Y.; software, H.Y.; validation, F.W.; investigation, H.Y.; resources, B.Y.; data curation, H.Y.; writing—original draft preparation, B.Y., H.Y. and F.W.; writing—review and editing, F.W.; supervision, B.Y. and F.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key R&D Program of China (Grant No. 2019YFC0605105).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available upon request from the corresponding authors.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relation-ships that could have appeared to influence the work reported in this paper.

Abbreviations

The following abbreviations are used in this review article.

| ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers |

| ATES | Assisted tunnel evacuation system |

| BC | Before century |

| BCS | Blocking effect |

| CAB | Culturable airborne bacteria |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| DS-T | Double stream-twin jets |

| FDS | Fire dynamics simulator |

| HDR | Heat deficit rate |

| HHR | Heat release rate |

| IAQ | Indoor air quality |

| NO2 | Nitrogen dioxide |

| PM | Particulate matter |

| PM10 | Particulate matter of 10 microns in diameter or smaller |

| PMV | Predicted mean vote |

| PSD | Platform screen door |

| PV/T | Photovoltaic thermal |

| RH | Relative humidity |

| RWI | Relative Warmth Index |

| SET* | Standard equivalent temperature |

| SES | Subway environment simulation |

| SO2 | Sulfur dioxide |

| TA | Thermal acceptability |

| TSV | Thermal sensation vote |

| TVOC | Total volatile organic compounds |

| WHO | World Health Organization |

References

- Mihalakakou, G.; Santamouris, M.; Asimakopoulos, D.; Tselepidaki, I. Parametric prediction of the buried pipes cooling potential for passive cooling applications. Sol. Energy 1995, 55, 163–173. [Google Scholar] [CrossRef]

- Li, A.; Li, H.; Dang, Y.; Lin, Q. Temperature measurement and energy saving potential analysis of traffic tunnel of SSL Hydropower Station. Acta Energ. Sol. 2010, 31, 1215–1219. [Google Scholar]

- Derbel, H.; Kanoun, O. Investigation of the ground thermal potential in Tunisia focused towards heating and cooling applications. Appl. Therm. Eng. 2010, 30, 1091–1100. [Google Scholar] [CrossRef]

- Krarti, M.; Kreider, J. Analytical model for heat transfer in an underground air tunnel. Energy Conv. Manag. 1996, 37, 1561–1574. [Google Scholar] [CrossRef]

- Wu, H.J.; Wang, S.; Zhu, D. Modelling and evaluation of cooling capacity of earth–air–pipe systems. Energy Conv. Manag. 2007, 48, 1462–1471. [Google Scholar] [CrossRef]

- Hokoi, S.; Ueda, S.; Yoshida, T. Cooling effect of cool tube. Part 1: Evaluation of cooling effect without moisture transfer. ASHRAE Trans. 1998, 104, 1511–1519. [Google Scholar]

- Tao, H.; Fan, Y.; Li, X.; Zhang, Z.; Hou, W. Investigation of formaldehyde and TVOC in underground malls in Xi’an, China: Concentrations, sources, and affecting factors. Build. Environ. 2015, 85, 85–93. [Google Scholar] [CrossRef]

- Braniš, M. The contribution of ambient sources to particulate pollution in spaces and trains of the Prague underground transport system. Atmos. Environ. 2006, 40, 348–356. [Google Scholar] [CrossRef]

- Gomez-Agustina, L.; Dance, S.; Shield, B. The effects of air temperature and humidity on the acoustic design of voice alarm systems on underground stations. Appl. Acoust. 2014, 76, 262–273. [Google Scholar] [CrossRef]

- Bénet, L.; Tulita, V.C.; Calsyn, L.; Wendling, J. Evolution of temperature and humidity in an underground repository over the operation period. Geol. Soc. Lond. Spec. Publ. 2014, 400, 413–426. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Li, C.; Lian, Z. Long-term investigation of moisture environment in underground civil air defence work. Indoor Built Environ. 2017, 26, 744–757. [Google Scholar] [CrossRef]

- Jin, H.; Xiao, Y. The thermal-wet environment testing and analysis of underground plant traffic tunnel. Adv. Mater. Res. 2011, 243, 4988–4993. [Google Scholar] [CrossRef]

- Gao, X.; Qu, Y.; Xiao, Y. A numerical method for cooling and dehumidifying process of air flowing through a deeply buried underground tunnel with unsaturated condensation model. Appl. Therm. Eng. 2019, 159, 113891. [Google Scholar] [CrossRef]

- Franzoni, E. Rising damp removal from historical masonries: A still open challenge. Constr. Build. Mater. 2014, 54, 123–136. [Google Scholar] [CrossRef]

- Sandrolini, F.; Franzoni, E. An operative protocol for reliable measurements of moisture in porous materials of ancient buildings. Build. Environ. 2006, 41, 1372–1380. [Google Scholar] [CrossRef]

- Franzoni, E. State-of-the-art on methods for reducing rising damp in masonry. J. Cult. Herit. 2018, 31, S3–S9. [Google Scholar] [CrossRef]

- Park, K.; Nagai, H.; Iwata, T. Study on the heat load characteristics of underground structures part 1. field experiment on an underground structure under an internal heat generation condition. J. Asian Archit. Build. Eng. 2006, 5, 421–428. [Google Scholar] [CrossRef]

- Emery, S.N.D.; Charola, A.E. Coatings on brick masonry: Are they protective or can they enhance deterioration? J. Am. Inst. Conserv. 2007, 46, 39–52. [Google Scholar] [CrossRef]

- Kumitski, J. Ground moisture evaporation in crawl space. Build Environ. 2001, 36, 359–573. [Google Scholar] [CrossRef]

- Kumitaki, J.; Matilainen, M. Moisture conditions of outdoor air-ventilated crawl spaces in apartment buildings in a cold climate. Energ Build. 2000, 33, 15–29. [Google Scholar]

- Luikov, A.V. Heat and mass transfer in capillary-porous bodies. Adv. Heat Transf. 1964, 1, 123–184. [Google Scholar]

- Liu, Y.; Liu, S.; Zhang, H. Numerical simulation of heat and moisture transfer in deep air buried. Procedia Eng. 2017, 205, 1927–1933. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, Y.; Inthavong, K.; Tu, J. A fast and simple numerical model for a deeply buried underground tunnel in heating and cooling applications. Appl. Therm. Eng. 2014, 62, 545–552. [Google Scholar] [CrossRef]

- Yue, G.; Li, M.; Xu, M. Heat transfer characteristics of seasonal ventilation and surrounding rock in deep mines. Sci. Technol. Rev. 2016, 34, 195–199. [Google Scholar]

- Loredo, C.; Ordóñez, A.; Garcia–Ordiales, E.; Álvarez, R.; Roqueñi, N.; Cienfuegos, P.; Peña, A.; Burnside, N. Hydrochemical characterization of a mine water geothermal energy resource in NW Spain. Sci. Total Environ. 2017, 576, 59–69. [Google Scholar] [CrossRef] [Green Version]

- Rees, S.W.; Zhou, Z.; Tomas, H. Ground heat transfer: A numerical simulation of a full–scale experiment. Build. Environ. 2007, 42, 1478–1488. [Google Scholar] [CrossRef]

- Naylor, S.; Ellett, K.; Gustin, A. Spatiotemporal variability of ground thermal properties in glacial sediments and implications for horizontal ground heat exchanger design. Renew. Energy 2015, 81, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Steinemann, U.; Zumsteg, F.; Wildi, P. Measurements of air flow, temperature differences and pressure differences in road tunnels. In Proceedings of the International Conference Tunnel Safety and Ventilation, Graz, Austria, 19–21 April 2004; pp. 220–226. [Google Scholar]

- Zhang, Y.; Li, X. Heat transfer formalism using GFM and FEM in underground tunnels. Build. Environ. 2018, 143, 717–726. [Google Scholar] [CrossRef]

- Thompson, J.; Maidment, G.; Missenden, J. Modelling low-energy cooling strategies for underground railways. Appl. Energy 2006, 83, 1152–1162. [Google Scholar] [CrossRef]

- Sadokierski, S.; Thiffeault, J. Heat transfer in underground rail tunnels. arXiv 2007, arXiv:0709.1748. [Google Scholar]

- Peltier, M.; Loria, A.; Lepage, L.; Garin, E.; Laloui, L. Numerical investigation of the convection heat transfer driven by airflows in underground tunnels. Appl. Therm. Eng. 2019, 159, 113844. [Google Scholar] [CrossRef]

- Cousin, B.; Loria, A.; Bourget, A.; Rognon, F.; Laloui, L. Energy performance and economic feasibility of energy segmental linings for subway tunnels. Tunn. Undergr. Space Technol. 2019, 91, 102997. [Google Scholar] [CrossRef]

- Ren, T.; Li, A.; Lv, W. Field and laboratory tests and analyses on temperature and relative humidity in underground multi–tunnels. Procedia Eng. 2017, 205, 27–34. [Google Scholar] [CrossRef]

- Liu, G.; Li, C.; Hu, S.; Ji, Y.; Tong, Z.; Wang, Y.; Tong, L.; Mao, Z.; Lu, S. Study on the heat transfer model of capillary exchanger in subway source heat pump system. Renew. Energy 2020, 150, 1074–1088. [Google Scholar] [CrossRef]

- Tong, L.; Hu, S.; Lu, S.; Wang, Y. Study on heat transfer performance of metro tunnel capillary heat exchanger. Sustain. Cities Soc. 2019, 5, 683–685. [Google Scholar] [CrossRef]

- Tong, Z.; Cao, T.; Zang, G.; Hu, S.; Liu, G.; Wang, Y. Performance analysis of capillary front-end heat exchanger for subway tunnel. Appl. Therm. Eng. 2020, 174, 115360. [Google Scholar] [CrossRef]

- Liu, Z.J.; Yin, H.; Ma, S.; Jin, G.; Gao, J.; Ding, W. On–site assessments on variations of PM2.5, PM10, CO2 and TVOC concentrations in naturally ventilated underground parking garages with traffic volume. Environ. Pollut. 2019, 247, 626–637. [Google Scholar] [CrossRef]

- Chow, W.K.; Wong, L.; Fung, W. Field study on indoor thermal environment and carbon monoxide levels in a large underground car park. Tunn. Undergr. Space Technol. 1996, 11, 333–343. [Google Scholar] [CrossRef]

- Oh, H.; Sohn, J.; Roh, J.; Kim, J. Exposure to respirable particles and TVOC in underground parking garages under different types of ventilation and their associated health effects. Air Qual. Atmos. Health 2020, 13, 297–308. [Google Scholar] [CrossRef]

- Yang, J.; Wu, X.; Chan, K.; Yang, X. Investigation of indoor air quality in the underground shopping mall. In Proceedings of the 4th International Conference on Bioinformatics and Biomedical Engineering, Chengdu, China, 18–20 June 2010. [Google Scholar]

- Li, Y.; Yuan, Y.; Li, C.; Han, X.; Zhang, X. Human responses to high air temperature, relative humidity and carbon dioxide concentration in underground refuge chamber. Build. Environ. 2018, 131, 53–62. [Google Scholar] [CrossRef]

- Moreno, T.; Reche, C.; Minguillón, M.C.; Capdevila, M.; de Miguel, E.; Querol, X. The effect of ventilation protocols on airborne particulate matter in subway systems. Sci. Total Environ. 2017, 584, 1317–1323. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Water Resources of the People’s Republic of China. In Construction Specifications on Underground Excavation Engineering of Hydraulic Structures; China Water and Power Press: Beijing, China, 2007.

- Li, M.; Aminossadati, S.D.; Wu, C. Numerical simulation of air ventilation in super-large underground developments. Tunn. Undergr. Space Technol. 2016, 52, 38–43. [Google Scholar] [CrossRef]

- Skubacz, K.; Wysocka, M.; Michalik, B.; Dziurzyński, W.; Krach, A.; Krawczyk, J.; PałkA, T. Modelling of radon hazards in underground mine working. Sci. Total Environ. 2019, 695, 133853. [Google Scholar] [CrossRef] [PubMed]

- Li, X.Y.; Zheng, B.; Wang, Y.; Wang, X. A study of daily and seasonal variations of radon concentrations in underground buildings. J. Environ. Radioact. 2006, 87, 101–106. [Google Scholar] [CrossRef]

- Tchorz-Trzwciakiewicz, D.; Parkitny, T. Radon as a tracer of daily, seasonal and spatial air movements in the Underground Tourist Route “Coal Mine” (SW Poland). J. Environ. Radioact. 2015, 149, 90–98. [Google Scholar] [CrossRef]

- Jin, J.J.; Tang, Z. Underground building unequilibrium radon and its progeny analysis and control. In Proceedings of the 2011 International Conference of Information Technology, Computer Engineering and Management Sciences, Nanjing, China, 24–25 September 2011. [Google Scholar]

- Tang, Y.B. Sources of underground CO: Crushing and ambient temperature oxidation of coal. J. Loss Prev. Process Ind. 2015, 38, 50–57. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Birgersson, E.; Ly, H.; Mujumdar, A. Some approaches to improve ventilation system in underground coal mines environment—A computational fluid dynamic study. Tunn. Undergr. Space Technol. 2013, 34, 82–95. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Cheng, Z.; Sun, R.; Zhang, A. Simulation of construction ventilation in deep diversion tunnels using Euler–Lagrange method. Comput. Fluid 2014, 105, 28–38. [Google Scholar] [CrossRef]

- Duckworth, I.J. Fires in vehicular tunnels. In Proceedings of the 12th U.S./North American Mine Ventilation Symposium, Reno, NV, USA, 9–11 June 2008. [Google Scholar]

- Li, Y.; Ingason, H. Overview of research on fire safety in underground road and railway tunnels. Tunn. Undergr. Space Technol. 2018, 81, 568–589. [Google Scholar] [CrossRef]

- Cetegen, B.M.; Zukoski, E.; Kubota, T. Entrainment in the near and far field of fire plumes. Combust. Sci. Technol. 1984, 39, 305–331. [Google Scholar] [CrossRef]

- Heskestad, G. Virtual origins of fire plumes. Fire Saf. J. 1983, 5, 109–114. [Google Scholar] [CrossRef]

- Hu, L.H.; Li, Y.; Huo, R.; Yi, L.; Shi, C.; Chow, W. Experimental studies on the rise-time of buoyant fire plume fronts induced by pool fires. J. Fire Sci. 2004, 22, 69–86. [Google Scholar] [CrossRef]

- Fang, J.; Jie, J.; Hong-Yong, Y.; Yong-Ming, Z. Early fire smoke movements and detection in high large volume spaces. Build. Environ. 2006, 41, 1482–1493. [Google Scholar] [CrossRef]

- Ji, J.; Zhong, W.; Li, K.; Shen, X.; Zhang, Y.; Huo, R. A simplified calculation method on maximum smoke temperature under the ceiling in subway station fires. Tunn. Undergr. Space Technol. 2011, 26, 490–496. [Google Scholar] [CrossRef]

- Li, A.; Zhang, Y.; Hu, J.; Gao, R. Reduced-scale experimental study of the temperature field and smoke development of the bus bar corridor fire in the underground hydraulic machinery plant. Tunn. Undergr. Space Technol. 2014, 41, 95–103. [Google Scholar] [CrossRef]

- Lin, P.; Lo, S.; Li, T. Numerical study on the impact of gradient on semi-transverse smoke control system in tunnel. Tunn. Undergr. Space Technol. 2014, 44, 68–79. [Google Scholar] [CrossRef]

- Ura, F.; Kawabata, N.; Tanaka, F. Characteristics of smoke extraction by natural ventilation during a fire in a shallow urban road tunnel with roof openings. Fire Saf. J. 2014, 67, 96–106. [Google Scholar] [CrossRef]

- Tanaka, F.; Majima, S.; Kato, M.; Kawabata, N. Performance validation of a hybrid ventilation strategy comprising longitudinal and point ventilation by a fire experiment using a model-scale tunnel. Fire Saf. J. 2015, 71, 287–298. [Google Scholar] [CrossRef]

- Zhou, Y.; Bi, H.; Wang, H.; Lei, B. Fire characteristics of rescue station inside railway tunnel with semi-transverse ventilation. Tunn. Undergr. Space Technol. 2020, 98, 103303. [Google Scholar] [CrossRef]

- Chaabat, F.; Salizzoni, P.; Creyssels, M.; Mos, A.; Wingrave, J.; Correia, H.; Marro, M. Smoke control in tunnel with a transverse ventilation system: An experimental study. Build. Environ. 2020, 167, 106480. [Google Scholar] [CrossRef]

- Sun, J.; Tang, Z.; Fang, Z.; Beji, T.; Merci, B. Flow fields induced by longitudinal ventilation and water spray system in reduced-scale tunnel fires. Tunn. Undergr. Space Technol. 2020, 104, 103543. [Google Scholar] [CrossRef]

- Li, L.; Li, S.; Wang, X.; Zhang, H. Fire-induced flow temperature along tunnels with longitudinal ventilation. Tunn. Undergr. Space Technol. 2012, 32, 44–51. [Google Scholar] [CrossRef]

- Khattri, S.K. From small-scale tunnel fire simulations to predicting fire dynamics in realistic tunnels. Tunn. Undergr. Space Technol. 2017, 61, 198–204. [Google Scholar] [CrossRef]

- Gao, R.; Li, A.; Hao, X.; Lei, W.; Zhao, Y.; Deng, B. Fire-induced smoke control via hybrid ventilation in a huge transit terminal subway station. Energy Build. 2012, 45, 280–289. [Google Scholar] [CrossRef]

- Hu, L.; Wu, L.; Lu, K.; Zhang, X.; Liu, S.; Qiu, Z. Optimization of emergency ventilation mode for a train on fire stopping beside platform of a metro station. Build. Simul. 2014, 7, 137–146. [Google Scholar] [CrossRef]

- Ji, J.; Gao, Z.; Zhong, C.; Sun, J. A study of the effect of plug–holing and boundary layer separation on natural ventilation with vertical shaft in urban road tunnel fires. Int. J. Heat Mass Transf. 2012, 55, 6032–6041. [Google Scholar] [CrossRef]

- Ji, J.; Han, J.; Fan, C.G.; Gao, Z.H.; Sun, J.H. Influence of cross-sectional area and aspect ratio of shaft on natural ventilation in urban road tunnel. Int. J. Heat Mass Transf. 2013, 67, 420–431. [Google Scholar] [CrossRef]

- Cong, H.; Wang, X.; Zhu, P.; Jiang, T.; Shi, X. Experimental study of the influences of board size and position on smoke extraction efficiency by natural ventilation through a board-coupled shaft during tunnel fires. Appl. Therm. Eng. 2018, 128, 614–624. [Google Scholar] [CrossRef]

- Gao, R.; Li, A.; Zhang, Y.; Luo, N. How domes improve fire safety in subway stations. Saf. Sci. 2015, 80, 94–104. [Google Scholar] [CrossRef]

- Gao, R.; Li, A.; Lei, W.; Zhao, Y.; Zhang, Y.; Deng, B. A novel evacuation passageway formed by a breathing air supply zone combined with upward ventilation. Phys. A Stat. Mech. Appl. 2013, 392, 4793–4803. [Google Scholar] [CrossRef] [Green Version]

- Lei, W.; Li, A.; Gao, R.; Hao, X.; Deng, B. Simulation of pedestrian crowds’ evacuation in a huge transit terminal subway station. Phys. A Stat. Mech. Appl. 2012, 391, 5355–5365. [Google Scholar] [CrossRef]

- Hu, L.H.; Zhou, J.W.; Huo, R.; Peng, W.; Wang, H.B. Confinement of fire-induced smoke and carbon monoxide transportation by air curtain in channels. J. Hazard. Mater. 2008, 156, 327–334. [Google Scholar] [CrossRef]

- Gupta, S.; Pavageau, M.; Elicer-Cortés, J. Cellular confinement of tunnel sections between two air curtains. Build. Environ. 2007, 42, 3352–3365. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Yuan, Y.; Wang, K.; Gao, X.; Cao, X. Experimental investigation on Influencing Factors of air curtain systems barrier efficiency for mine refuge chamber. Process Saf. Environ. Prot. 2016, 102, 534–546. [Google Scholar] [CrossRef]

- Li, Q.; Tang, Z.; Yuan, J.; Wang, J. Experimental study of the effectiveness of a water mist segment system in blocking fire-induced smoke and heat in mid-scale tunnel tests. Tunn. Undergr. Space Technol. 2019, 88, 237–249. [Google Scholar] [CrossRef]

- Amano, R. Applicability of water screen fire disaster prevention system to road tunnels in Japan. In Proceedings of the 3rd International Conference “Tunnel Safety and Ventilation”, Graz, Austria, 15–17 May 2006; pp. 162–173. [Google Scholar]

- Pan, L.W.; Lo, S.M.; Liao, G.X.; Cong, B.H. Experimental study of smoke control in subway station for tunnel area fire by water mist system. Procedia Eng. 2011, 11, 335–342. [Google Scholar]

- Chow, W.; Ma, E.; Ip, M. Recent experimental studies on blocking heat and smoke by a water curtain. Int. J. Eng. Perform.-Based Fire Codes 2011, 10, 89–95. [Google Scholar]

- Zhu, P.; Wang, X.; Wang, Z.; Cong, H.; Ni, X. Experimental and numerical study on attenuation of thermal radiation from large-scale pool fires by water mist curtain. J. Fire Sci. 2015, 33, 269–289. [Google Scholar] [CrossRef]

- Sun, J.; Fang, Z.; Tang, Z.; Beji, T.; Mercib, B. Experimental study of the effectiveness of a water system in blocking fire-induced smoke and heat in reduced–scale tunnel tests. Tunn. Undergr. Space Technol. 2015, 56, 34–44. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Wang, X.; Huang, Y.; Tao, C.; Zhang, H. Experimental study on fire smoke control using water mist curtain in channel. J. Hazard. Mater. 2018, 342, 231–241. [Google Scholar] [CrossRef]

- Liang, Q.; Li, Y.; Li, J.; Xu, H.; Li, K. Numerical studies on the smoke control by water mist screens with transverse ventilation in tunnel fires. Tunn. Undergr. Space Technol. 2017, 64, 177–183. [Google Scholar] [CrossRef]

- Carmody, J.C.; Sterling, R.L. Design strategies to alleviate negative psychological and physiological effects in underground space. Tunn. Undergr. Space Technol. 1987, 2, 59–67. [Google Scholar] [CrossRef]

- Yu, S.; Yu, Z.; Liu, P.; Feng, G. Influence of environmental factors on wall mold in underground buildings in Shenyang City, China. Sustain. Cities Soc. 2019, 46, 101452. [Google Scholar] [CrossRef]

- Savory, E.; Dooreleyers, M.; Spiler, K.; Li, E.; Sabarinathan, J.; Scott, J. Evaluation of an optoelectronic mould sensor for use in building health monitoring and in post–remediation performance assessment. Sustain. Cities Soc. 2018, 36, 311–318. [Google Scholar] [CrossRef]

- Zheng, S.; Zhang, Y.; Zhi, Q.; Xing, L.; Zheng, T.; Bi, J.; Han, S.; Zhang, Z. The investigation of air microorganisms pollution in underground spaces. J. Environ. Health 2006, 23, 239–241. [Google Scholar]

- Li, A.; Liu, Z.; Liu, Y.; Xu, X.; Pu, Y. Experimental study on microorganism ecological distribution and contamination mechanism in supply air ducts. Energy Build. 2012, 47, 497–505. [Google Scholar] [CrossRef]

- Heo, K.J.; Lee, B. Seasonal variation in the concentrations of culturable bacterial and fungal aerosols in underground subway systems. J. Aerosol. Sci. 2016, 92, 122–129. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, D.; Kong, Q.; Li, A.; Li, Y.; Geng, S.; Dong, X.; Liu, Y.; Chen, P. Exposure level and distribution of airborne bacteria and fungi in an urban utility tunnel: A case study. Tunn. Undergr. Space Technol. 2020, 96, 103215. [Google Scholar] [CrossRef]

- Robertson, C.; Baumgartner, L.; Harris, J.; Peterson, K.; Stevens, M.; Frank, D.; Pace, N. Culture-independent analysis of aerosol microbiology in a metropolitan subway system. Appl. Environ. Microb. 2013, 79, 3485–3493. [Google Scholar] [CrossRef] [Green Version]

- Hwang, S.H.; Park, W.; Ahn, J.; Lee, K.; Min, K.; Park, J. Relationship between culturable airborne bacteria concentrations and ventilation systems in underground subway stations in Seoul, South Korea. Air Qual. Atmos. Health 2016, 9, 173–178. [Google Scholar] [CrossRef]

- Nang, E.E.K.; Abuduxike, G.; Posadzki, P.; Divakar, U.; Visvalingam, N.; Nazeha, N.; Dunleavy, G.; Christopoulos, G.I.; Soh, C.-K.; Jarbrink, K.; et al. Review of the potential health effects of light and environmental exposures in underground workplaces. Tunn. Undergr. Space Technol. 2019, 84, 201–209. [Google Scholar] [CrossRef]

- Wen, Y.; Leng, J.; Shen, X.; Han, G.; Sun, L.; Yu, F. Environmental and health effects of ventilation in subway stations: A literature review. Int. J. Environ. Res. Public Health 2020, 17, 1084. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Racz, M.D.; Petrilean, D. The influence of humidity on air Temperature in underground mines as a factor of air quality assessment. Qual.-Access Success 2019, 20, 371–376. [Google Scholar]

- Han, J.; Kwon, S.; Chun, C. Indoor environment and passengers’ comfort in subway stations in Seoul. Build. Environ. 2016, 104, 221–231. [Google Scholar] [CrossRef]

- Li, Y.; Geng, S.; Zhang, X.; Zhang, H. Study of thermal comfort in underground construction based on field measurements and questionnaires in China. Build. Environ. 2017, 116, 45–54. [Google Scholar] [CrossRef]

- Ko, W.H.; Schiavon, S.; Zhang, H.; Graham, L.; Brager, G.; Mauss, I.; Lin, Y. The impact of a view from a window on thermal comfort, emotion, and cognitive performance. Build. Environ. 2020, 175, 106779. [Google Scholar] [CrossRef] [Green Version]

- Tan, Z.; Roberts, A.; Christopoulosd, G.; Kwok, K.; Car, J.; Li, X.; Soh, C. Working in underground spaces: Architectural parameters, perceptions and thermal comfort measurements. Tunn. Undergr. Space Technol. 2018, 71, 428–439. [Google Scholar] [CrossRef]

- Nicol, J.F.; Humphreys, M.A. Adaptive thermal comfort and sustainable thermal standards for buildings. Build. Environ. 2002, 34, 563–572. [Google Scholar] [CrossRef]

- Yao, R.; Li, B.; Liu, J. A theoretical adaptive model of thermal comfort–Adaptive Predicted Mean Vote (aPMV). Build. Environ. 2009, 44, 2089–2096. [Google Scholar] [CrossRef]

- Li, Y.; Geng, S.; Yuan, Y.; Wang, J.; Zhang, X. Evaluation of climatic zones and field study on thermal comfort for underground engineering in China during summer. Sustain. Cities Soc. 2018, 43, 421–431. [Google Scholar] [CrossRef]

- Abbaspour, M.; Jafari, M.J.; Mansouri, N.; Moattar, F.; Nouri, N.; Allahyari, M. Thermal comfort evaluation in Tehran metro using Relative Warmth Index. Int. J. Environ. Sci. Technol. 2008, 5, 297–304. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Li, Z.; Du, X.; Tang, D.; Shen, L. A measurement analysis of subway thermal environment characteristics of the coupling airflow between air-conditioning air supply and piston wind. J. Chongqing Univ. 2011, 34, 116–122. [Google Scholar]

- ASHRAE Standards 62-1989; Ventilation for Acceptable Indoor Air Quality. American Society of Heating Ventilation and Air Conditioning: Peachtree Corners, GA, USA, 1989.

- Romanova, E. Negative influence of underground constructions on mental health of the person. Procedia Eng. 2016, 165, 1176–1183. [Google Scholar] [CrossRef]

- Kim, J.; Cha, S.; Koo, C.; Tang, S. The effect of indoor plants and artificial windows in an underground environment. Build. Environ. 2018, 138, 53–62. [Google Scholar] [CrossRef]

- Dai, P.; Xie, A. Analysis on spiritual influence of city underground space. Chin. J. Undergr. Space Eng. 2006, 2, 1196–1198. [Google Scholar]

- Gribble, D. Natural ventilation, harnessed by New Kingdom Egyptian tomb builders, may explain the changed floor levels in the Valley of the Kings tomb KV5. Tunn. Undergr. Space Technol. 2009, 24, 62–65. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Porras-Amores, C.; Cañas, I. Annual evolution of the natural ventilation in an underground construction: Influence of the access tunnel and the ventilation chimney. Tunn. Undergr. Space Technol. 2015, 49, 188–198. [Google Scholar] [CrossRef]

- Chu, H.R.; Xie, G. Discussion on natural ventilation with mechanical reversing device for underground engineering. In Proceedings of the National Annual Conference on HVAC refrigeration, Hangzhou, China, 9 December 2010. [Google Scholar]

- Ma, R.; Qin, K.; Liu, Q. Numerical study of enhanced natural ventilation of solar chimney in underground garage. Refrig. Air Cond. 2016, 30, 321–324. [Google Scholar]

- Guo, M.; Liao, Y.; Tan, W.; Chen, F.; Liu, X. Research on ventilation system of underground building based on chimney effect. J. Wuhan Inst. Technol. 2010, 32, 85–87. [Google Scholar]

- Xiang, B.; Yu, T.; Yuan, Y.; Sun, L.; Cao, X. Study on influencing factor of solar chimney effect in underground space based on photovoltaic–thermal. Trans. Chin. Soc. Agric. Eng. 2017, 33, 141–147. [Google Scholar]

- Wu, Z.W. Ecological Design of Combination of Natural Lighting and Ventilation of the Northern Underground Space. Archit. Technol. 2011, 10, 67–70. [Google Scholar]

- Li, A.; Li, G. Advancement about ventilation air distribution and reduced–scale model test for underground large plants in hydropower stations. Heat. Vent. Air Cond. 2015, 2, 1–9. [Google Scholar]

- Pan, S.; Fan, L.; Liu, J.; Xie, J.; Sun, Y.; Cui, N.; Zhang, L.; Zhang, B. A Review of the Piston Effect in Subway Stations. Adv. Mech. Eng. 2013, 5, 1–7. [Google Scholar] [CrossRef]

- Wang, L.; Shi, K.; Song, J. Velocity fields characteristics research on the piston air shaft and the bypass duct in subway. Fluid Mach. 2010, 38, 22–27. [Google Scholar]

- Han, Y.; Zhao, L.; Xing, L. Study on the influence of subway air shaft form on tunnel ventilation effect. Railw. Stand. Des. 2010, S2, 62–64. [Google Scholar]

- Wen, Y.M.; Leng, J.; Yu, F.; Yu, C. Integrated design for underground space environment control of subway stations with atriums using piston ventilation. Indoor Built Environ. 2020, 29, 1–16. [Google Scholar] [CrossRef]