Abstract

Ventilation plays a key role in underground mining. It is essential due to the natural hazards and technological processes that come with the nature of mining. However, it is highly energy consuming and generates significant operating expenditures. Fan station parameters are selected based on the needs of a particular mine but mainly consider the requirements for the period of developed mining activities. When the period of mine decommissioning begins, the parameters of the main fan station often exceed its needs. In Poland, many mines have been closed in recent years. However, sometimes, due to the necessity of pumping underground water, it cannot be done thoroughly. In such a situation, it usually turns out that the parameters of the existing fan station significantly exceed the mine’s needs. The main fan stations are devoid of control systems, and even if they have them, they do not allow for a significant reduction of their volume flow rate. Modernising of the station to meet new requirements of the mine is expensive and time consuming. Solving the presented problem is possible by developing a fan station to replace main fans that are too big. The idea is easy to implement and consists of connecting it to an existing upcast shaft or downcast shaft, which will then be changed to upcast. The solution presented in the article has been implemented in two Polish coal mines and is in progress in a third mine. The examples presented in the article clearly show the energy benefits of replacing main fans that are too large.

1. Introduction

Ensuring proper ventilation is crucial for the safe operation of underground mining facilities. The necessity and requirements for ventilation of underground workings result from the applicable regulations and mining practice. The incoming airflow depends on the hazards present in each facility and the technical solutions applied. The airflow must also ensure the minimum air velocity, in accord with national mining regulations.

The operation of fan stations incurs considerable electrical operating expenditures. In addition, in most cases, it is necessary to provide stand-by equipment and regular servicing of the devices.

Fan dimensions and their related operation parameters are selected according to the conditions and requirements in a particular mine. The selection of operational parameters usually concerns the time when the mining facility runs a developed mining activity. Consequently, fan stations very often cannot regulate their parameters within a wide range of parameters. Usually, such regulation can be carried out only within a small range of optimal parameters of their work.

In the case of operational mines, a frequent problem is the change of air distribution in the ventilation network or temporary ventilation limitations in selected places of the mine or the entire mine for the time of non-productive shifts. Aspects of optimisation and electricity saving in mine-ventilation systems have often been taken into account in publications [1,2]. Most often, the presented solutions concern ventilation on demand and time-of-use tariffs. Presented solutions could be implemented in existing and developed mines for reorganisation or decreasing intensity of the ventilation in particular areas. Furthermore, ventilation network regulations must be taken into account, considering miners’ safety [3,4]. For this reason, many scientists have used computer programs, CFD simulations, and other optimisation algorithms [5,6,7]. However, the biggest problem with mine-ventilation optimisation occurs in multiple-fan ventilation systems [8,9,10,11].

Feng et al. [12] used a 3D simulation system in mine-ventilation management. The authors indicated that the model was helpful for optimal economic crosscut selection, thermal simulation, and other functions in the system have further enhanced the ability of mine-ventilation management and saved a great amount of ventilation expenses.

Gao [13] used the bionics algorithm–Ant colony algorithm to solve the very complicated combination optimisation problem of the mine-ventilation system. The author summarised that his method is suitable for optimising a new mine-ventilation system and improving the ones working in old mines.

Tang and Yuanchun [14] analysed the reliability of ergonomics in the ventilation system of an underground metal mine. They indicated the main factors that will impact the fan’s regular operation. Consequently, the authors pointed out that ventilation management significantly affects the reliability of a mine-ventilation system.

Chatterjee et al. [15] applied the demand-side management (DSM) technique to an underground mine-ventilation network. They solved the minimisation model to find the optimal speeds of the main mine’s fan. A presented case study that combines energy efficiency and load shifting can lead to annual energy and cost savings.

Chen et al. [16] conducted optimisation of air-quantity regulation in mine-ventilation networks by using the improved differential evolution algorithm and critical path method. The results showed that use of the algorithm has the advantages of high effectiveness, fast convergence, good robustness, and flexibility. Furthermore, the authors pointed out that this method could solve future large-scale generalised ventilation network optimisation problems.

Euler [17] describes how a ventilation-management program can be developed and implemented to ensure regulation compliance, increase safety, improve operational efficiency, and reduce the operating costs of an operating mine. The presented ventilation-management program provides mining operations with an iterative process that can standardise day-to-day ventilation practices, audit the ventilation system, and ensure compliance with regulatory bodies and company policies. In addition, it provides effective means for proper control and management of complex ventilation networks, resulting in significant safety, efficiency, and economic benefits to the mining operation.

Sjöström et al. [18] presented optimized, model-based control of main mine-ventilation airflows with minimised energy consumption. Authors applied dynamic empirical models to mine-ventilation systems to optimise the overall air distribution, bringing multiple benefits connected with reduced running costs and working environment benefits from optimised air flows that best fit the activity in that location.

Nikolakis et al. [19] developed a cyber-physical system for monitoring the concentration of gases enabling adaptive control of the ventilation system. In the procedure, long-range communication modules were used to collect field data that were processed to allow for awareness of underground conditions. In addition, a ventilation on-demand module and an energy-consumption evaluation component enabled dynamic control of the ventilation system based on the measured gases concentration. A prototype implementation has been tested on a simulated use case with real-world sensor data.

Acuña et al. [20] presented a state-of-the-art ventilation control system implementation in North America and Sweden to deliver what is known as ventilation on demand. In terms of savings, the current implementation of the software has shown the potential to achieve 50% savings or more when considering energy for main and auxiliary fans and natural gas.

Decommissioning is a special moment in the life of a mining facility. It takes place gradually, and during this time, the structure of the excavations and, consequently, the ventilation network of the mine changes.

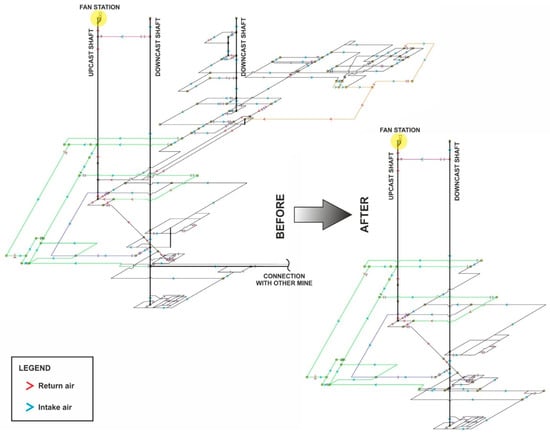

In Poland, the process involving decommissioning the mining facilities in the Upper Silesian Coal Basin (USCB) has been taking place recently and will continue. USCB is characterised by many mines operating in the adjacent areas. Some of them were merged into multirole mines, and some of them have already been liquidated. A characteristic feature of USCB is that some of the mines were connected by dewatering systems. As a result, some of the decommissioning mines must ensure the continuity of the water pumping to protect the neighbouring operating mines. In such a case, the structure of the excavations of such a partially decommissioned mine is most often limited to two shafts and an undeveloped structure of the excavations connecting those shafts, in which the most important are the dewatering chambers and power supply switching stations. Liquidation of excavation or its part causes the required ventilation air volumes to drop significantly and increases the resistance of the ventilation system. Figure 1 presents the scheme of the mine-ventilation network in the period before decommissioning and the target model which will serve as a pumping station.

Figure 1.

Mine scheme before and after the decommissioning.

The necessity to leave a part of the structure of the workings at a decommissioned mine results in a significant decrease in air requirements for their ventilation. The resistance of the system increases. When an upcast shaft remains in the scope of the excavations left behind, it is necessary to analyse the possibilities of regulating the fans. Most often, however, the fans have parameters that are too large, significantly exceeding the needs of the mine being decommissioned. Increasing system resistance may cause the fan’s operating point to the area left of the peak of the characteristic (stall region). Operation in this area is discouraged because of erratic airflow that generates excessive noise and vibration. Then the fan will be working in an unstable state, and it may be damaged. In such a case, one may consider applying one of the methods to regulate the parameters of an operation. Implementing changes allowing for controlling fan operational parameters is troublesome for two reasons. First, it has a limited range of fan capacity reduction and secondly, it is challenging to implement them when necessary to ensure the continuity of fan station operation. When there is no possibility of leaving an upcast shaft in the structure of the excavations of a decommissioned mine, it is necessary to build an appropriate fan station.

The proper ventilation of the mines with significantly reduced air requirements in a short time is possible by quickly implementing a solution designed to replace overlarge fan stations in upcast shafts. The concept of the developed station can also be an answer for mines in which the target model of the workings does not include an upcast shaft. It fully complies with the Polish mining regulations [21]. Such a solution makes it possible to change the function of an air intake shaft into a ventilation shaft. The solution was implemented in two Polish mines being decommissioned in USCB. In a third mine, construction of the station is in progress. Shortly, other mines will also be decommissioned, so it can also be used there. This article analyses the benefits of replacing an overlarge fan station with the suggested solution.

2. Possibilities of Changing Fan Operation Parameters

Various methods of regulating fan operation parameters are used in the ventilation practice. The most common methods include throttling the flow by using dampers, modulating the fan speed, adjusting wheel blades, or using inlet vanes dampers. In the main fan stations, air bleed can be applied by increasing the share of external losses at the shaft.

However, all the methods mentioned above have their constraints. The problems of applying each technique of regulation are:

- ➢

- throttling regulation requires the installation of control dams;

- ➢

- modulating the fan speed; and

- ➢

- modification of blade geometry or rotor dimensions.

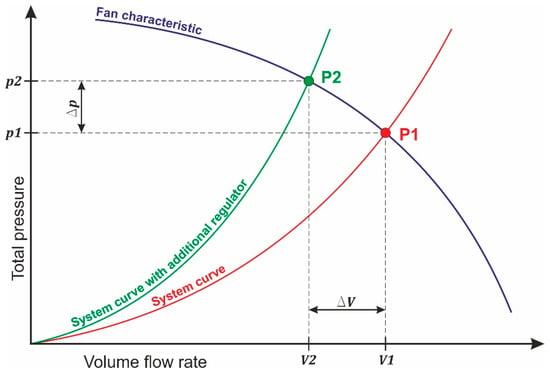

Throttling regulation requires the installation of control dams, which upcast shafts typically do not have. The method is relatively simple to implement but very uneconomical in the long run. The scope of possible regulations depends on the fan characteristics and is limited by its highest position. The idea of regulation by throttling is presented in Figure 2. Additional regulators cause air volume to be reduced from to , but then the total pressure of the fan increases from to . This method is the most uneconomical.

Figure 2.

Idea of regulation by throttling.

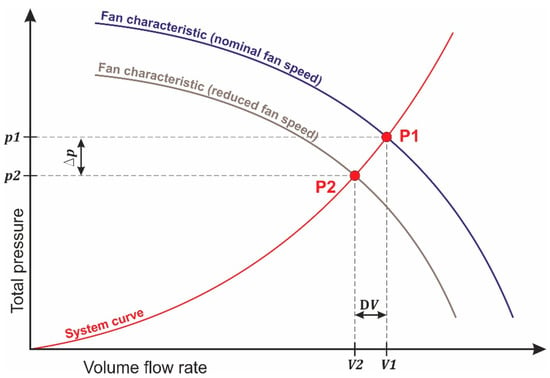

Modulating the fan speed method requires costly systems (depending on the fan, voltage control, thyristor control, transformer control, and frequency control can be applied). In addition, the control range is limited and depends on the fan speed method used in modulation. The available techniques can be assumed to reduce the fan’s speed to approximately 50% of its nominal speed. The idea of the control by changing the fan speed is shown in Figure 3. It is assumed that reducing volume flow from to decreases total pressure from to . Therefore, modulating fan speed is the most economical method but requires significant investment.

Figure 3.

Idea of modulating the fan speed.

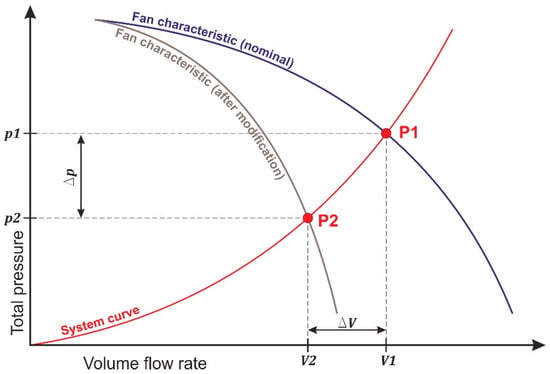

Modifying blade geometry or rotor dimensions is a complicated and time-consuming operation requiring a temporary shutdown of the fan station or one of the fans. In the case of mining facilities, at least one fan must operate continuously, and at least one has to constitute a reserve. The idea of control by changing the geometry of blades is shown in Figure 4. In this method, reducing volume flow from to also reduces total pressure from to .

Figure 4.

Idea of fan control by changing blade geometry.

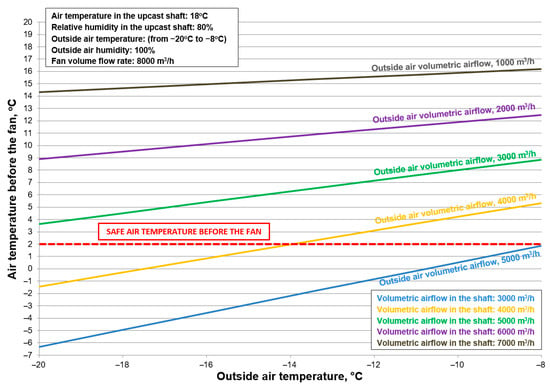

A possible way of solving the problem involving the excessive volume flow rate of the main fan may be increasing the external losses on the upcast shaft. However, this solution has its constraints, mainly in the winter period due to the necessity to protect fan blades against icing. Therefore, reducing the output in the mine workings with this method is also limited. Furthermore, this method requires maintaining constantly high fan output, which is also highly uneconomical. An example of the limits for using bleed in the winter by increasing external losses is shown in Figure 5.

Figure 5.

Opportunities to increase external losses at an upcast shaft in the winter.

The majority of main fan stations of USCB mines are not adapted to significant volume flow rate reduction. Therefore, the installation of control systems on such stations or their modernization is complicated. It is also challenging when it is necessary to ensure ventilation continuity and incurring considerable investment costs. Therefore, the solution to such a problem may be installing a new fan station with smaller parameters meeting the required volume flow rate. After switching ventilation to the new station, it is possible to liquidate unnecessary infrastructure of the decommissioned station and its surroundings.

3. Fan Station Solution Concept

Developing the main ventilation fan station solution could solve the abovementioned problems of limiting the airflow supplied to the mine. But first, it is applied in decommissioned underground mining facilities or in such plants where the airflow must be restricted, and the main ventilation fans do not have the required regulating capacity.

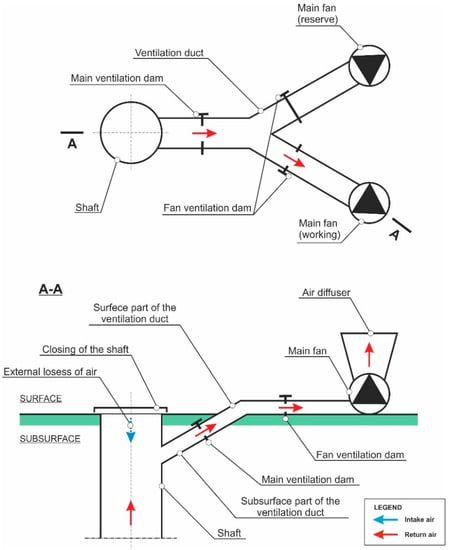

The design of the proposed solution enables the quick replacement of big main fans by a new fan station, which is connected to the existing upcast shaft infrastructure on the surface, i.e., ventilation ducts of the main ventilation fan station. Figure 6 presents an example of such a solution with the place where it is connected. It is also possible to apply it in the mines where the target structure of excavations does not include an upcast shaft.

Figure 6.

Diagram regarding a typical solution of the ventilation ducts at the main ventilation station.

The solution allows for the preparation of the entire station without switching off the working fans. Only for the time needed for the connection, it is necessary to switch off one of the station’s fans in the duct to which the new fan station will be connected (main ventilation fan stations have a minimum of two fans—working and back-up). It is also possible to use the station or its elements in other places, which is another advantageous feature of the developed solution, especially in the case of decommissioned mines, where the necessity to provide ventilation for the excavations may be relatively short-lived.

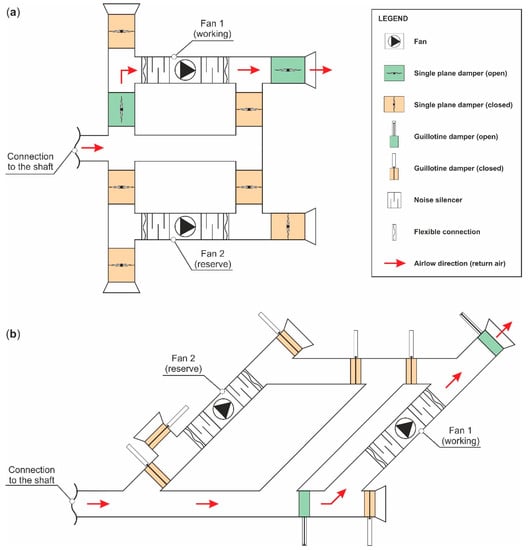

The solution assumes the construction of at least a two-fan station. During normal operation, one of the fans will be working, and the second will constitute a reserve. If necessary, the station may consist of more fans.

The duct system of the fan station can be made of insulated steel ducts and shapes with anti-corrosion protection. In addition to the ventilation ducts, dampers should be installed at the station. They can be made as circular single-plane or guillotine dampers. Connecting pipes, shapes, dampers, and fans can be made in a flanged manner. Due to the prevailing weather conditions, the fan station ducts should be insulated.

Additionally, the station may be roofed. The diameter of station ducts should be selected to the required airflow, which must be provided in the mine-ventilation network. At the required air flow rate of 25–50 m3/s the duct diameter should be from 1.4 m to 1.6 m. An exemplary ductwork layout and fan station equipment is presented in Figure 7. In the first solution, single-plane dampers are applied, whereas in the second solution guillotine dampers are used. The first solution has been implemented in two Polish mines decommissioned in USCB. In a third mine, the station’s construction according to the second solution is still in progress.

Figure 7.

Example of fan station ducting layout: (a) solution no. 1; (b) solution no. 2.

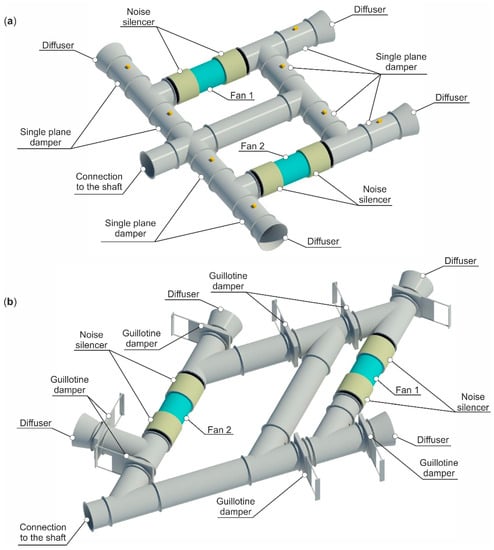

A visualisation of exemplary fan station solutions is shown in Figure 8. It can be equipped with necessary control-measuring devices for, among other things, measuring air speed, air temperature, and humidity in station ducts. The station can work fully automatically.

Figure 8.

Visualization of a fan station solution. (a) Solution no. 1. (b) Solution no. 2.

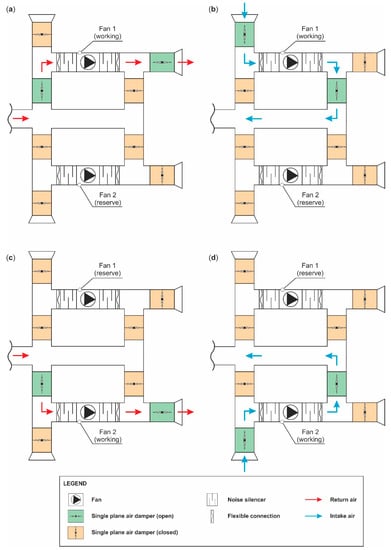

The station’s ductwork and the corresponding dampers allow the reversion of ventilation in the mine. It is possible after changing damper positions. Positions of individual dampers for each fan’s normal and reversing operation are shown for the first solution in Figure 9. In the case of the second solution, the positions of gate valves will be analogous.

Figure 9.

Damper positions during normal and reversed fan operation (solution no. 1): (a) fan 1 working—normal ventilation; (b) fan 1 working—reverse ventilation; (c) fan 2 working—normal ventilation, (d) fan 2 working—reverse ventilation.

The main advantage of the presented solution regarding the fan station is the possibility of its construction and start-up in the vicinity of the existing upcast shaft without long-term interference in the operation of the main fans being replaced. The station may be built outside the ducts of the working fans, which are to be replaced. It is crucial in decommissioning mining facilities which have only one upcast shaft in the final stage of their existence, and the fans cannot be shut down because the ventilation cannot be interrupted. Only at the moment when the station is connected to the duct of one of the main fans is it necessary to switch it off. During this time, the second fan can provide the ventilation function.

The procedure of designing the main fan station should include:

- ➢

- analysing the mine ventilation system before decommissioning (especially taking into account the pressure drop on ventilation routes); for analysis a computer program could be applied (for example VenSim, Vuma3D or Ventrgaph [5]);

- ➢

- determining the final model of the mine-ventilation system;

- ➢

- determining required air volume in each excavation;

- ➢

- balancing air in the final model of the mine-ventilation system;

- ➢

- calculating pressure drop in the final model of the mine-ventilation system;

- ➢

- selecting fans’ parameters (considering flow rate and total pressure); and

- ➢

- designing diameters of ventilation ducts and equipment.

4. The Benefits of the Station Solution

Reduction of underground infrastructure and the necessity to replace fans for new ones with lower flow rates could bring benefits. On the one hand, we can reduce the costs of electricity consumption by using new fans. On the other hand, we could reduce expenditures on thermal energy for air heating in the downcast shafts. According to Polish mining regulations, the temperature in a downcast shaft can’t be lower than 1 °C, so intake air must be heated during winter.

The reduction of the energy consumption by fans is not only due to a reduction flow rate but also is connected to the efficiency difference between old and new fans. Annual reduction of energy consumption could be calculated by the following formula:

where is the number of hours in a year, is the new fan total pressure in Pa, is the new fan flow rate in m3/s, is the new fan efficiency, is the replaced fan total pressure in Pa, is the replaced fan flow rate in m3/s; and is the replaced fan efficiency.

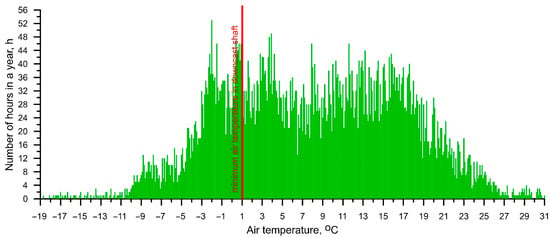

The use of local climatic data should calculate the reduced expenditure on thermal energy. In the article, air parameters from weather station Katowice (TMY—typical meteorological year) were used [22]. This weather station is in the central part of USCB, the nearest to the analysed mines. Figure 10 presents the frequency of temperatures occurring during a typical meteorological year for Katowice. The graph shows that in Katowice, air must be heated in a downcast shaft for about 2220 h throughout the year.

Figure 10.

Frequently of occurrence temperatures during typical meteorological year for Katowice.

Reduction of expenditure on thermal energy for air heating in the downcast shafts could be calculated as the following formula:

for , where is theair density in kg/m3, is the specific air heat in kJ/(kg·K), is the required air temperature in a downcast shaft in the Celsius degree (in Poland minimum 1 °C), and is the instantaneous outside air temperature in the Celsius degree (according to the data from typical meteorological year).

5. Results and Discussion

Based on the data originating from three mining facilities in the state of partial de-commissioning, the benefits of limiting the airstream supplied to the mine by using the applied fan station were analysed. Benefits connected with reducing the energy consumption by fans and expenditure on thermal energy for air heating in the downcast shafts have been calculated according to the Formulas (1) and (2). Analysed mines are located in USCB in Poland and can’t be decommissioned entirely because they have an essential dewatering system for other active mines. Analysis performed for these mines showed that the underground structure could be significantly reduced. Such a reduction forced changing the parameters of the main fans. In the mines in question, the station has already been constructed according to the solution presented, or the investment is still in progress.

Fans designed for these mines have the following parameters.

- ➢

- Station in mine A (investment completed according to the solution no. 1): flow rate 40 m3/s, total pressure 1700 Pa and efficiency 0.77;

- ➢

- Station in mine B (investment completed according to the solution no. 1): flow rate 40 m3/s, total pressure 1700 Pa and efficiency 0.77;

- ➢

- Station in mine C (investment according to the solution no. 2 is in progress): flow rate 40 m3/s, total pressure 2700 Pa and efficiency 0.75.

In mine A, the target model of the ventilation network included an upcast shaft but the fans built on this shaft had flow parameters that were too high. In case of leaving the existing fan station, about 100 m3/s of air would have to flow through the excavations left. Such an airflow volume results from the position of the peak of the used fan’s characteristics. The application of the presented solution limited the airflow in the mine to 33.3 m3/s. In addition, the fan flow rate was 40 m3/s because it considered external losses on the upcast shaft. Therefore, the energy consumption of the mine ventilation system was reduced; the reduction of the airflow rate in the mine resulted in savings of 3.300 MWh of electricity per year. An additional effect of this solution was the reduction of expenditures on air heating in the shaft, which, taking into account the frequency of temperatures in this location, amounted to over 2.500 GJ per year.

In mine B, the target model of the ventilation network did not include the upcast shaft, which was sent for decommissioning due to its technical condition. The mine also removed the connection with the neighbouring mine to which a part of the air was discharged. Leaving the existing ventilation connections would cause about 75 m3/s of air to flow through the mine workings. The application of the presented solution made it possible to limit the airflow in the mine to 33.3 m3/s. The fan flow rate was 40 m3/s because it considered external losses on the upcast shaft. Therefore, the energy consumption of the mine-ventilation system was reduced; the reduction of the airflow rate in the mine resulted in savings of 1.100 MWh of electricity per year. An additional effect of this solution was the reduction of expenditure on heating the air in the shaft, which, considering the temperature frequency for this location, decreased by almost 1600 GJ per year.

In the case of mine C, the target model of the ventilation network did not include the upcast shaft decommissioned due to the analysis of its parameters and importance for the neighbouring mine. If this shaft had been left and the external losses on this shaft had been increased, about 125 m3/s of air would have to flow through the mine workings. The application of the presented solution made it possible to reduce the airflow in the mine to 33.3 m3/s. Therefore, the energy consumption of the mine ventilation system was reduced. Reduction of the airflow rate in the mine will result in the savings of 3.800 MWh of electricity per year. An additional effect of this solution is the reduction of expenditures on air heating in the shaft, which, taking into account the frequency of temperatures for this location, will decrease by almost 3.400 GJ per year.

An essential aspect in the context of the applicability of the presented solution is its mobility, which allows the entire or partial use of the station components in another location. For example, the fans are a precious component of the station, which can be freely used in another station. It is already known that a part of the mines being partly decommissioned will be completely decommissioned in the near future. This is because there are plans to liquidate neighbouring mines, so the pumping station function maintained at these mines will no longer be needed. Full decommissioning will also mean the end of ventilating the underground workings at these plants.

6. Conclusions

The article presents a new conception of the main fan station. The proposed solution can be implemented in decommissioned underground mines, which can’t yet be fully decommissioned. It can also be used in mines where the airflow must be limited, and the main fans do not have the required regulating capacity.

The main advantages of the presented solution of the fan station are:

- ➢

- the possibility of the quick replacement of oversized main fans by a new fan station;

- ➢

- the possibility of a connection to the existing upcast shaft infrastructure on the surface, (i.e., ventilation ducts of the main fan station);

- ➢

- the option of applying the fan station in the mines in which the target structure of excavations does not include an upcast shaft;

- ➢

- the possibility of preparing the entire station without having to switch off the working fans; and

- ➢

- the possibility of using the station or some of its elements in another place.

The most important takeaway is that replacing an overlarge fan station contributes to reducing airflow in the mine-ventilation system. Thanks to this, a significant reduction in fan electricity consumption can be achieved, as well as a reduction of thermal energy for air heating in the downcast shafts. The article presents benefits that were and will be performed in three decommissioning coal mines in USCB in Poland.

Author Contributions

Conceptualization, N.S. and M.K.; methodology, N.S. and M.K.; software, M.K.; validation, N.S.; formal analysis, M.K.; investigation, M.K.; resources, N.S.; data curation, M.K.; writing—original draft preparation, M.K.; writing—review and editing, M.K.; visualization, M.K.; supervision, N.S.; project administration, N.S. All authors have read and agreed to the published version of the manuscript.

Funding

The article was prepared as part of the Subsidy for the Maintenance and Development of Research Potential at Faculty of Civil Engineering and Resource Management AGH University of Science and Technology No. 16.16.100.215.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Upon authors’ request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- De Souza, E. Improving the energy efficiency of mine fan assemblages. Appl. Therm. Eng. 2015, 90, 1092–1097. [Google Scholar] [CrossRef]

- Nel, A.J.H.; Arndt, D.C.; Vosloo, J.C.; Mathews, M.J. Achieving energy efficiency with medium voltage variable speed drives for ventilation-on-demand in South African mines. J. Clean. Prod. 2019, 232, 379–390. [Google Scholar] [CrossRef]

- Massanés, M.B.; Pera, L.S.; Moncunill, J.O. Ventilation management system for underground environments. Tunn. Undergr. Space Technol. 2015, 50, 516–522. [Google Scholar] [CrossRef]

- Belle, B. Real-time air velocity monitoring in mines—A quintessential design parameter for managing major mine health and safety hazards. In Proceedings of the 13th Coal Operators’ Conference, Woollongong, NSW, Australia, 14–15 February 2013; Aziz, N., Ed.; University of Wollongong: Wollongong, Australia, 2013; pp. 184–198. [Google Scholar]

- Dziurzyński, W.; Krach, A.; Pałka, T. Airflow Sensitivity Assessment Based on Underground Mine Ventilation Systems Modeling. Energies 2017, 10, 1451. [Google Scholar] [CrossRef]

- Xu, G.; Huang, J.; Nie, B.; Chalmers, D.; Yang, Z. Calibration of Mine Ventilation Network Models Using the Non-Linear Optimization Algorithm. Energies 2018, 11, 31. [Google Scholar] [CrossRef]

- Zhong, D.; Wang, L.; Wang, J.; Jia, M. An Efficient Mine Ventilation Solution Method Based on Minimum Independent Closed Loops. Energies 2020, 13, 5862. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, H. Study and Application on Simulation and Optimization System for the Mine Ventilation Network. Procedia Eng. 2011, 26, 236–242. [Google Scholar] [CrossRef]

- El-Nagdy, K.A. Stability of multiple fans in mine ventilation networks. Int. J. Min. Sci. Technol. 2013, 23, 569–571. [Google Scholar] [CrossRef]

- Szlązak, N.; Obracaj, D.; Korzec, M. Analysis of connecting a forcing fan to a multiple fan ventilation network of a real-life mine. Process Saf. Environ. Prot. 2017, 107, 468–479. [Google Scholar] [CrossRef]

- Chimunhu, P.; Topal, E.; Ajak, A.D.; Asad, W. A review of machine learning applications for underground mine planning and scheduling. Resour. Policy 2022, 77, 102693. [Google Scholar] [CrossRef]

- Feng, W.; Zhu, F.; Lv, H. The use of 3D simulation system in mine ventilation management. Procedia Eng. 2011, 26, 1370–1379. [Google Scholar] [CrossRef]

- Gao, W. Optimization of Mine Ventilation System Based on Bionics Algorithm. Procedia Eng. 2011, 26, 1614–1619. [Google Scholar] [CrossRef]

- Tang, M.; Ding, Y. The Reliability of Ergonomics in the Ventilation System of an Underground Metal Mine. Procedia Eng. 2011, 26, 1705–1711. [Google Scholar] [CrossRef][Green Version]

- Chatterjee, A.; Zhang, L.; Xia, X. Optimization of mine ventilation fan speeds according to ventilation on demand and time of use tariff. Appl. Energy 2015, 146, 65–73. [Google Scholar] [CrossRef]

- Chen, K.; Si, J.; Zhou, F.; Zhang, R.; Shao, H.; Zhao, H. Optimization of air quantity regulation in mine ventilation networks using the improved differential evolution algorithm and critical path method. Int. J. Min. Sci. Technol. 2015, 25, 79–84. [Google Scholar] [CrossRef]

- De Souza, E. Application of ventilation management programs for improved mine safety. Int. J. Min. Sci. Technol. 2017, 27, 647–650. [Google Scholar] [CrossRef]

- Sjöström, S.; Klintenäs, E.; Johansson, P.; Nyqvist, J. Optimized model-based control of main mine ventilation air flows with minimized energy consumption. Int. J. Min. Sci. Technol. 2020, 30, 533–539. [Google Scholar] [CrossRef]

- Nikolakis, N.; Kantaris, G.; Bourmpouchakis, K.; Alexopoulos, K. A cyber-physical system approach for enabling ventilation on-demand in an underground mining site. Procedia CIRP 2020, 97, 487–490. [Google Scholar] [CrossRef]

- Acuña, E.I.; Alvarez, R.A.; Hurtado, J.P. Updated Ventilation on Demand review: Implementation and savings achieved. In Proceedings of the 1st International Conference of Underground Mining, Santiago, Chile, 19–21 October 2016. [Google Scholar]

- Regulation of the Minister of Energy on Detailed Requirements for the Operation of Underground Mining Facilities. 2016. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170001118 (accessed on 4 May 2022).

- Ministry of Investments and Development. Typical Meteorological Years–Data for Building Energy Analysis. Available online: https://www.gov.pl/web/archiwum-inwestycje-rozwoj/dane-do-obliczen-energetycznych-budynkow (accessed on 18 February 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).