Abstract

Nowadays, electrical machines and drive systems are playing an essential role in different applications. Eventually, various failures occur in long-term continuous operation. Due to the increased influence of such devices on industry, industrial branches, as well as ordinary human life, condition monitoring and timely fault diagnostics have gained a reasonable importance. In this review article, there are studied different diagnostic techniques that can be used for algorithms’ training and realization of predictive maintenance. Benefits and drawbacks of intelligent diagnostic techniques are highlighted. The most widespread faults of electrical machines are discussed as well as techniques for parameters’ monitoring are introduced.

1. Introduction

Condition monitoring and fault diagnostics of electrical machines are gaining heightened popularity. It is because the vital role that electrical machines play in industry and domestic life is increasing day by day. Electrical machines always remain prone to faults because of the mechanically moving parts associated with them, the harsh industrial environment, and no doubt the increasing probability of failure with life. Conventional maintenance techniques can be broadly classified into two categories: reactive maintenance and preventive maintenance. Preventive maintenance is mainly related to the scheduled overhauling of a system and whether or not it requires maintenance, while reactive maintenance comes into play when the failure has already occurred. Unfortunately, both methods are not suitable in industry, as they have a substantial economic impact. In the case of reactive maintenance, the machine is already broken, disrupting the process.

In contrast, overhauling all machines, whether healthy or faulty, is not a good solution in preventive maintenance. In comparison, predictive maintenance is a better choice, one in which the machine’s health can be continuously monitored, and only faulty machines can be selected for maintenance. Moreover, since the fault can be detected at an early stage, the machine can be repaired before any catastrophic situation. However, predictive techniques are rather complicated depending upon the type of the machine, the drive control mechanism, and the load behavior. This is why a great many research fields are involved in the predictive maintenance of electrical machines. Those fields may include signal processing, statistical data analysis, artificial intelligence, mathematical modelling, and the design and optimization of sensors and processing boards. This paper presents a glimpse of the state of the art of condition monitoring of electrical machines so that the reader can know the trends and challenges in this field. A wide range of diagnostic fields, with many citations, is summarized, along with corresponding attributes.

2. Intelligent Diagnostic Techniques

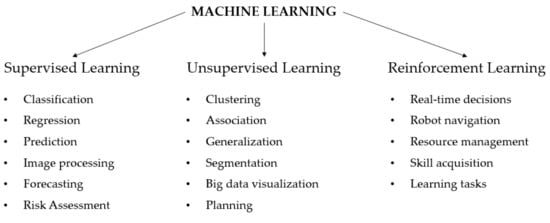

Due to increasing computational power and cloud computation, different mathematical models of motors’ faults can be trained in artificial intelligence algorithms. Machine learning is an optimal tool in machine health monitoring for dealing with extensive amounts of data []. Machine learning is compared frequently to data mining as both attempt to discover new data patterns in numerous datasets. The principal difference is that machine learning deals mostly with adaptive behavior and operative utilization, while data mining processes large amounts of data []. By the usage of training data, machine learning algorithms can create a forecasting and decision-making model. There are many algorithms for machine learning. As shown in Figure 1, these algorithms can be generally divided into three groups: supervised, unsupervised, and reinforcement learning [,,].

Figure 1.

Machine learning algorithms.

In the case of supervised machine learning (“learning with a teacher”), the training dataset and test dataset are set so that the algorithm can map inputs to the desired outputs by the labelled examples. These algorithms are suitable for classification and regression tasks [,]. Unlike supervised learning, unsupervised machine learning (“learning without a teacher”) is dedicated to understanding and discovering patterns from an unknown dataset. Unsupervised algorithms are primarily used for the generalization and association of datasets [,]. In this case, the primary function is to group objects into clusters and reduce the amount of data. Reinforcement learning is used to decrease errors and increase accuracy by analyzing the data after each iteration. These algorithms are spread in robot navigation, resource management, and real-time decisions [,,]. In diagnostics of electrical machines, the following algorithms are used: decision trees [], support vector machines [], principal component analysis [], and genetic algorithm [].

2.1. Decision Trees

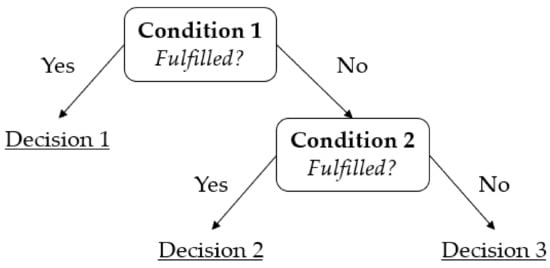

Decision trees represent supervised machine learning that is widely used for data prediction and analysis []. In this case, the algorithm is focused on creating a model that can forecast the desired output based on multiple inputs. The general algorithm of decision trees is shown in Figure 2.

Figure 2.

The general algorithm of decision trees.

Decision trees are the simplest among decision-making algorithms and require a very small amount of data to achieve a result. To obtain more accurate results, decision trees are frequently used in parallel with other algorithms. However, decision trees are considered unstable algorithms; insignificant changes in input data can lead to serious changes in decision trees’ structure, leading to inaccurate results. Additionally, regression algorithms usually fail.

2.2. Support Vector Machines

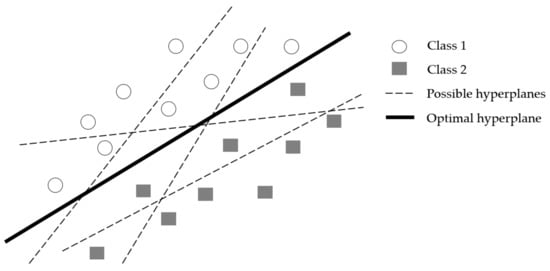

Another widely used supervised machine learning algorithm is support vector machines, which are suitable for regression tasks, feature extraction, and classification [,]. In the case of classification tasks, where support vector machines are preferable, algorithms can deal with linear and non-linear cases []. For linear classification, each dataset represents a vector in n-dimensional space and belongs to two classes. Therefore, the algorithm focuses on separating these data points so that there would be a maximum gap between them. In the case of non-linear classification, the kernel machine acts the same way as for linear algorithms but replaces the datasets []. The method of support vector machines is described in Figure 3.

Figure 3.

Finding an optimal hyperplane.

Generally, support vector machines are an optimal tool if there is no initial information about datasets. Similar to decision trees, less computation power is needed to provide accurate results. However, it can take a lot of time to process the information in datasets that are especially large. Moreover, managing a kernel machine for non-linear processes can be a complicated task.

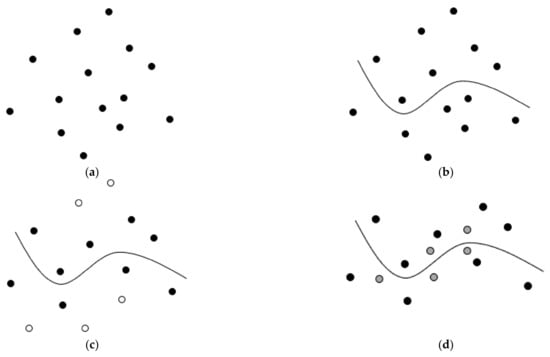

2.3. Principal Component Analysis

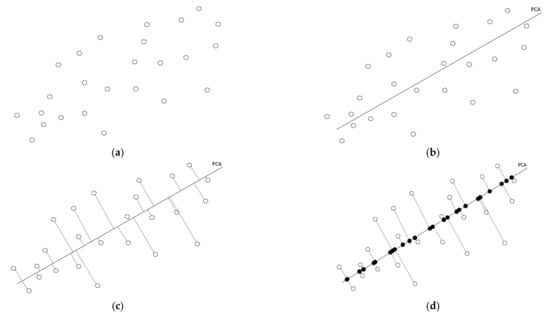

Unsupervised algorithms can learn spontaneously and perform a given task by finding connections between system responses []. However, if datasets are extremely large, it can be challenging to extract important information. For this reason, algorithms find similarities between objects and divide objects into groups (clusters) []. The principal component analysis is a good solution for reducing data dimensionality, while losing a minimal amount of information at the same time. A general algorithm of principal component analysis is shown in Figure 4. The algorithm can be described as follows [].

Figure 4.

Principal component analysis: (a) initial data points, (b) creation of optimal vector PCA, (c) projection of initial data points on the vector PCA, (d) definition of new datasets [].

Firstly, experimental data points with the specific coordinates are set on a plane. Then, the vector of maximum data change is set on the plane. Next, experimental points are projected on the vector. Finally, these projections create new datasets on the vector, and any deviations from the vector are considered to be noise. The main benefit of principal component analysis is that the algorithm considers each data point as an independent component and does not correlate between them. Thus, this method can significantly reduce training as well as processing time. Nonetheless, considering each datapoint as an independent component can lead to a loss of information and reduced accuracy of the results.

2.4. Genetic Algorithm

Reinforcement algorithms of machine learning differ clearly from basic approaches. In this case, the system learning process is performing by interaction with the environment []. These algorithms are mostly focused on solving optimization problems. One of them is a genetic algorithm, the principle of which is shown in Figure 5.

Figure 5.

Genetic algorithm: (a) definition of initial population, (b) fitness function application, (c) selection of coincidences, (d) definition of resultant population.

The algorithm can be described as follows. Each data point is represented in genes. A vector of genes creates the genotype of the population. Initially, the so-called fitness function is created, which describes how well the genotype performs the task. Then, the most accurate coincidences are selected, which will be used to create the next generation. The given process continues until the task is fulfilled and the resultant population is formed.

A genetic algorithm is considered as an optimal solution if there is no clarified knowledge about the data domain. In this case, the result is generated through genetic operators. The main drawback is that this genetic population can suffer from degeneracy (different chromosomes represent the same solution). In this case, an accurate result is not possible.

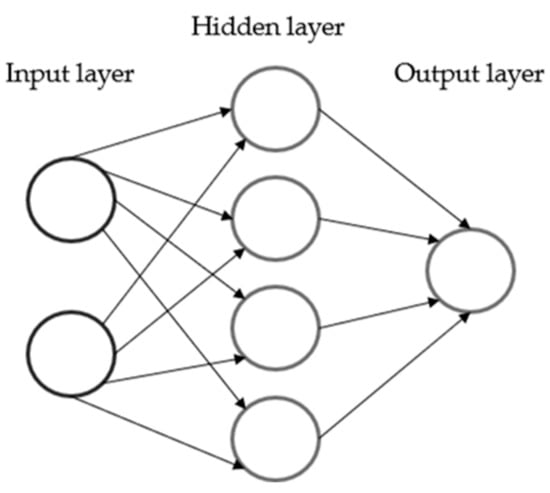

2.5. Artificial Neural Networks

Another machine learning method, which is often considered a separate field, is the artificial neural network approach. This technique is widely applicable to condition monitoring of machine parameters []. Network algorithms can cover classification [], prediction [], and feature extraction []. In addition, artificial neural networks can be a part of supervised, unsupervised, or reinforcement learning []. In simple models, as shown in Figure 6, an artificial neural network consists of three layers: input, hidden, and output layer.

Figure 6.

The architecture of artificial neural networks.

To solve a problem, neurons transfer signals between the input and output layer through connections. These algorithms are not to be programmed; they are supposed to be learned. Searching for the connection coefficients between neurons is meant to occur by learning. The easy and fast learning process is one of the main benefits of neural networks. Algorithms are also able to restore incomplete or even destroyed data when training has been successful.

Neural networks also have several limitations. For accurate results, a balance must be found between overfitted and underfitted data; an overly approximated model will not give precise results, while an extremely detailed algorithm will be too flexible but too complicated for further implementation. Additionally, the “black box” phenomenon is quite widespread in the case of neural networks, where approximating a hidden layer can lead to mistakes in artificial structure [,].

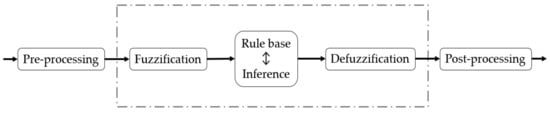

2.6. Fuzzy Logic

Fuzzy logic is another algorithm successfully applied in various control applications of energy systems, which resembles human perception processes and cognition []. Fuzzy logic, as well as machine learning, are sub-fields of artificial intelligence. The main difference between fuzzy logic and traditional logic is that in traditional logic, an outcome can be represented only by true or false values (1 or 0), while an outcome in fuzzy logic can be represented in any value between 1 and 0 (true, false, partially true, etc.). As shown in Figure 7, the classical model of fuzzy logic consists of the following stages: fuzzification, rule base, and defuzzification []. Fuzzification converts input data into fuzzy sets. The rule-based stage is a block of the decision-making system. Finally, defuzzification converts fuzzy sets back into real values.

Figure 7.

Control principle of fuzzy logic.

In fuzzy fault diagnosis, there are many approaches available, such as the Mamdani approach [], fuzzy neural network [], Takagi–Sugeno approach [], etc. Therefore, it is essential to select the best-suited algorithm to be applied to the system. Each of them has certain benefits and drawbacks. Generally, fuzzy logic is considered a simple solution in decision-making tasks. Fuzzy logic can also perform approximate reasoning by a combination of membership functions through a set of rules []. However, to develop a fuzzy system, a large amount of data is needed. Moreover, the development of fuzzy rules can complicate data analysis.

2.7. Summary

In Table 1, the benefits and drawbacks of all of the aforementioned diagnostic techniques are summarized.

Table 1.

Benefits and drawbacks of intelligent diagnostic techniques.

Under industry conditions, data collection can be a complicated task. Due to the regular controls in production, only a limited number of faulty rotating machines are possible, which means a limited number of tests to be performed for training purposes. Additionally, data collected in cases of composite faults in the same machine are not straightforward in another scenario. Therefore, for effective AI training, mathematical models with different faulty conditions must make diagnostic algorithms more reliable. Therefore, it is important to understand the nature of machine failures, causes, and impacts.

3. Faults of Rotating Electrical Machine

As electrical machines operate under different industrial conditions, various failures eventually occur after long-term continuous operation. The failures’ distribution depends mainly on the machine parameters; in low-voltage motors, bearing-related faults are the majority, while high-voltage motors receive mostly stator winding-related failures []. In general, the biggest portion of overall failures in electrical machines results in mechanical faults, such as bearing faults, eccentricities, broken rotor bars, broken end rings []. In addition, electrical stresses and demagnetization problems can contribute to the shortening of motor lifespan. All of the faults will be discussed in detail in the following sub-chapters.

3.1. Bearing Faults

One of the key parts of a rotating electrical machine is its bearings. The design and production of the bearing are to be conducted according to stringent quality requirements. Nonetheless, during motor running, different internal and external loads affect the bearings. This, in turn, reduces the duration of the actual life of the bearing. Different defects and mechanical damage are frequently met due to the wrong placement, manufacturing mistakes, or misalignment of bearing details []. For this reason, it is important to control possible manufacturing damage before bearing mounting and motor running launch.

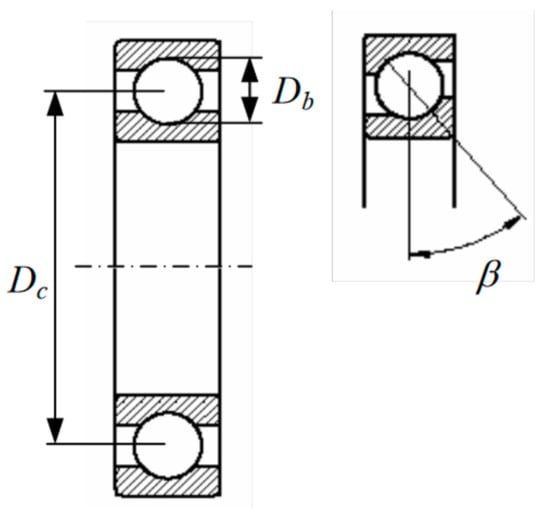

To avoid disastrous consequences, different parameters of bearing must be monitored. Bearing failures can be described through mathematical equations that refer to the natural frequencies of a faulty bearing. Based on bearing geometry, which is shown in Figure 8, faulty frequencies can be defined for the outer raceway (1), inner raceway (2), rolling elements (3), and cage (4).

Figure 8.

Bearing geometry [].

Faulty frequencies for these cases can be defined as follows:

where Nb—number of rolling elements, Db—diameter of rolling element (mm), Dc—bearing pitch diameter (mm), β—contact angle (degrees), n—mechanical rotor speed (Hz) [].

Bearings are affected by different environmental factors, such as moisture, increased ambient temperature, dust, etc. Lubricant coating at the contact points between surfaces can be torn if humid air enters the bearing. Additionally, without a proper seal, different substances can pollute the lubricant and spoil its properties. Environmental processes resulting in material resolution cause bearing corrosion. An example of a corroded bearing is shown in Figure 9. However, increasing a bearing’s cleanliness does not always improve its fatigue properties []. Cyclic and continuous loads have a remarkable effect on the running performance of the bearing, including material fatigue, wear, and stiffness []. These stresses cause micro-cracks in the structure of the bearing. Without timely maintenance, cracking eventually expands, and the bearing becomes incompatible for further operation. Bearing durability can be referred to as the number of revolutions made before the first fatigue signs appear on bearing surfaces []. This phenomenon can be avoided or remarkably recessed by timely analysis of the bearing lubricant.

Figure 9.

Bearing fluting.

The proper lubrication of a bearing is one of the critical points determining its motor’s durability and reliability in general. When the lubricant is selected correctly, it forms the needed coating between elements and softens the impact of the rolling bodies against the bearing rings and cage. Additionally, lubricant is used to reduce the risk of corrosion and wear []. To increase the bearing lifetime, a fully flooded bearing and the corresponding base oil viscosity should be considered [].

Additionally, the bearing lubricant directly affects the strength of shaft currents and influence on the bearing, which in the long term can lead to serious damage and destroy the bearing []. Due to the development of energy systems and power electronics, electrical machines, and particularly the bearing, can be injured by electrical corrosion, causing danger to the whole motor system []. The effect of shaft currents on a bearing depends mostly on several parameters, such as rotational speed, lubricant properties, current value, operation time, and bearing material. Bearing current-related damage can be revealed by increased noise and vibration, but in the late stages when the surface of the bearing is already damaged []. The damage is visible on the bearing surfaces at places where the load is the largest. Practically, the following bearing current-related damage can be classified as fluting, frosting, pitting, and dull-finish. Fluting occurs in a combination with low voltage and constant rotational speed, which does not appear for a longer period of time []. In Figure 9, an example of bearing fluting is shown in magnification.

At the same time, frosting can appear in cases of varying rotational speeds. Pitting usually appears in applications with a high-voltage source, causing a multiplicity of small craters on the bearing surface []. In the case of dull-finish, this phenomenon resembles pitting but with much smaller craters that can be studied in detail only by a microscope with a particularly high magnification [].

Bearings, as a critical part of rotating machinery, are prone to damage and failure. For this reason, it is extremely important to monitor the condition of the bearing operation. Temperature measurement, noise, and vibration analysis, as well as periodical control of the lubricant quality can significantly reduce the risk of bearing damage.

3.2. Rotor Faults

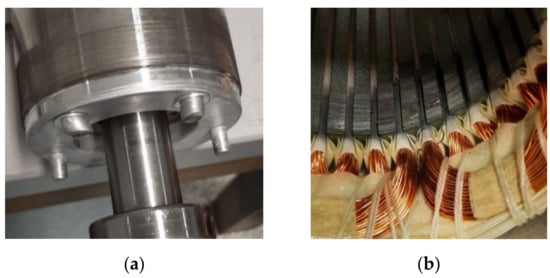

Eccentricity can be described as an inconsistent air gap between the rotor and stator of the motor, which is mainly caused by improper installation, lack of or missing bolts, misalignment of the shaft, and rotor imbalance []. Centrifugal forces contribute as well to rotor wear, as shown in Figure 10.

Figure 10.

Damages caused by centrifugal force: (a) rotor wear and (b) stator wear.

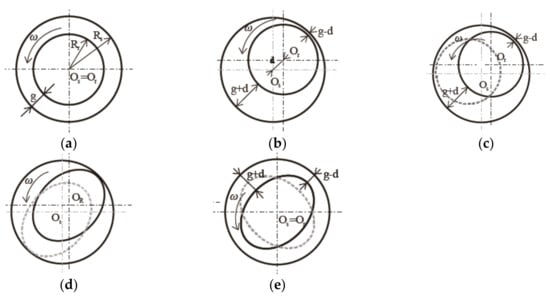

An air gap is considered to be faulty if it exceeds 10% of the nominal value []. As shown in Figure 11, there are the following types of rotor eccentricity: static [], dynamic [], and elliptic []. Authors in [] have discussed these cases.

Figure 11.

Types of rotor eccentricity: (a) healthy; (b) static; (c) and (d) dynamic; and (e) elliptic eccentricities [].

Static eccentricity (SE) is the most widespread type of eccentricity in the motor, where the rotation axis of the rotor is parallel to the stator axis and fixed in time. In the case of dynamic eccentricity (DE), the air-gap length changes in time. Elliptic eccentricity (EE) occurs when stator and rotor center points match; however, a non-uniform air gap still exists because the elliptical shape of the rotor and angles change over time. The width of the air-gap in cases of different eccentricities can be found with the following equations []:

where g—air-gap, RS—radius of the stator, Rr—rotor radius, d—deviation, β—initial eccentricity angle, Ow—rotational center, Os—stator symmetry center, p—number of poles.

Practically, mixed eccentricity can also be found when rotor and stator center points and rotational axis are shifted from each other.

The most frequent permanent magnet fault is demagnetization, which means partial or complete magnetization loss []. Partial demagnetization that produces additional harmonics in the stator currents can be found at the following frequencies []:

where fpdem is a faulty frequency, ff is a fundamental frequency, k is an integer, and p is the number of poles.

Demagnetization of permanent magnets can be frequently caused by machine overload and thermal expansion []. Machines operate in high-temperature ranges, and the absence of a proper cooling system significantly increases a demagnetization risk. Another factor that can impact magnet properties is electrical stress, including short circuits []. It is also reasonable to control magnet manufacturing defects and signs of corrosion. Another widespread form of rotor damage is related to rotor bars and broken end rings []. One of the most common reasons for such a failure is natural degradation, which causes rotor wear []. Additionally, thermal expansion can lead to cracked rotor bars []. As rotor bars are made of copper, while laminations are made of steel, bars will expand more quickly in cases of increased operating temperature.

3.3. Stator Faults

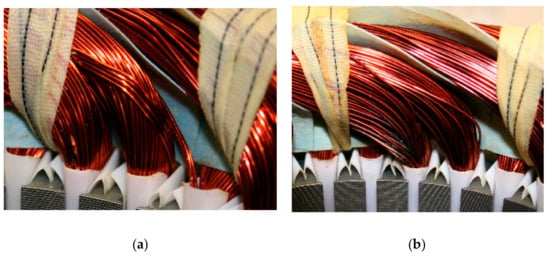

Insulation is one of the most prone-to-fault parts among the components of an electrical machine []. In overall statistics, stator winding failures are 36% of all the faults []. Winding failures usually start from a turn-to-turn short circuit. Subsequently, without timely maintenance, the failure can grow to a phase-to-phase or phase-to-ground short circuit []. Since this inter-turn fault is hardly detectable in the early stages of development, this topic is immensely challenging in the electrical machine industry []. Even if control test results meet defined values, each insignificant damage of stator winding can lead to the future breakdown of the machine []. Spread winding failures are shown in Figure 12.

Figure 12.

Stator winding faults: (a) improper winding placement, (b) insulation damage.

Asymmetrical faults, such as winding faults, induce additional sideband harmonic components at the fundamental frequency and can be defined by the following frequencies:

where fh—harmonic frequency, fs—supply frequency, s—slip [].

Many factors can influence the degradation of the winding insulation. More frequently, the degradation rate of winding insulation is affected by four main stresses, also known as TEAM (thermal, electrical, ambient, and mechanical) stresses []. In addition, damage can also be inflicted on motors due to the manufacturing process and production. During the designing process, manufacturing damage is not usually considered, but it tends to occur during the exploitation of a machine [].

4. Overview of Diagnostic Methods Used in Condition Monitoring

To provide reliable and effective exploitation of an electrical machine, many parameters, such as current, vibration, temperature, magnetic flux, are to be monitored. In addition, different faults have certain signatures that give a signal about upcoming failure. For this reason, condition-based monitoring is a solution that allows one to be informed and make decisions regarding the maintenance of the machine.

4.1. Vibration Analysis

Vibrations can come from many different sources in an electrical machine, including magnetic fields, fluid flow, imbalances, and, especially, rotating elements, such as bearings, gearboxes, or rotors []. Vibration analysis can be defined as change monitoring from defined vibration signatures and extracting deviations in the system. Deviations are to be found in acceleration amplitude, frequency value, and intensity. Nowadays, many sensor types can be used. By measuring technology, sensors can be piezoelectric [], capacitive [], inductive [], piezoresistive [], and strain gauge [].

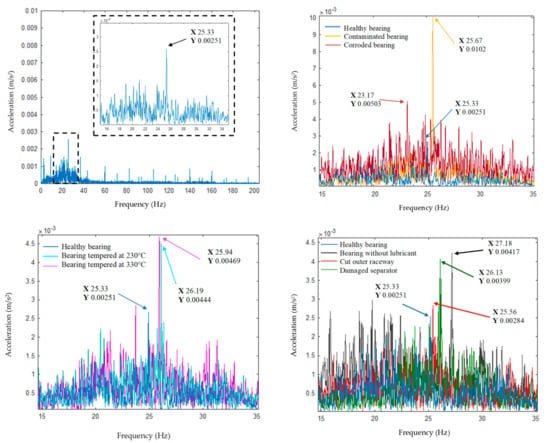

Vibration analysis can provide useful information about the health of electrical equipment; thus, it is widely used for diagnostics. Regarding classical diagnostic approaches, authors in [] used vibration signals of healthy as well as faulty bearings to identify specific frequencies on the FFT spectrum, where frequency variation of harmonic amplitudes, particularly in fundamental components, is presented as a fault indicator, which is shown in Figure 13.

Figure 13.

FFT spectra of healthy as well as faulty bearings [].

Classical and intelligent approaches are frequently used in combination. In [], authors propose a novel method for predicting the remaining useful lifetime of bearings based on continuous wavelet transform and convolutional neural networks, where image features improve result accuracy. At the same time, in [], the authors propose a novel hybrid method of convolutional neural network and support vector machine to effectively identify an incipient fault in rotating machinery. The proposed solution does not need manual feature extraction or data processing. Authors in [] also propose a condition-monitoring method of bearing fault based on deep convolutional neural network and random forest ensemble learning to achieve high accuracy in failure diagnosis under complex operating conditions. However, there are several limitations: computational time and quality of raw data. Authors in [] use a genetic algorithm for diagnostics of gearboxes based on vibration signals to improve the process of data exploration and exploitation.

4.2. Electrical and Electromagnetic Monitoring

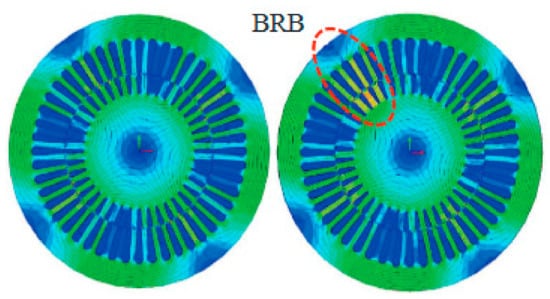

Monitoring magnetic flux has become a widespread and effective method for fault detection in electrical machines, as many early failures create a magnetic asymmetry that can be detected []. Electromagnetic measurement can be efficiently used to monitor the electrical machine as an additional or alternative tool to stator current monitoring. By definition, an electric machine produces electromagnetic flux, where any small unbalance in the magnetic or electric circuit is reflected in some of the transmitted fluxes []. There are many research studies on the monitoring of bearings damage [], rotor faults [], short circuits [], and magnet problems [] through the stray magnetic flux. Authors in [] provide an example of flux distribution in the case of healthy and faulty rotor bars, as shown in Figure 14.

Figure 14.

Flux distribution of healthy and faulty rotor bars in an induction motor [].

Most of the rotating electrical machines are symmetrical, generating uniformly distributed magnetic flux. Any fault in the machine results in asymmetrical flux distribution, resulting in more local magnetic stresses. An example of flux distribution in the case of healthy and faulty rotor bars is shown in Figure 14. It is clear from the figure that the flux density across the broken bar increases in magnitude, which increases the peak induced current in subsequent rotor bars. These increased current and magnetic forces make them vulnerable to a fault, leading to a kind of chain reaction. A machine’s performance parameters such as torque, speed, voltage, and currents function to distribute flux. The analysis of those performance parameters can detect any change in flux distribution due to any fault. These facts make the diagnostic algorithms non-invasive and open a broad field of signal processing techniques that can be used for condition monitoring of electrical machines.

In harmonic spectrum and data analysis-based techniques, the frequency components of any global signal are evaluated according to cause of production. The discovered frequency components can be further used for the health monitoring of electrical machines, either by visual inspection or with the help of advanced statistical data analysis techniques. A variety of research articles dealing with spectrum analysis for various machines can be found in the literature. The stator winding insulation degradation fault analysis of permanent magnet synchronous motor (PMSM) using the harmonic analysis of fault current is presented in []. The authors of [] used matching pursuit and wavelet transformation for current features extraction and machine learning-based fault diagnostic algorithms for induction motor analysis. The detection of bearing faults by statistical analysis of a motor’s stray flux is presented in []. The inter-turn short circuit fault analysis in permanent magnet multiphase machines using spectrum analysis of combined voltage space vector is presented in []. The fault diagnosis of induction machines using harmonic order tracking analysis of a stator’s current is presented in []. The use of wavelet transform for stator current analysis during motor startup is presented in [,]. The utilization of non-stationary stray flux harmonics for training feed-forward neural networks for monitoring wound rotor induction motors is presented in []. The use of transient stray fluxes and the currents for the fault diagnosis of damper winding in synchronous motors is presented in [], while a similar work for fault detection of circular pumps is reported in []. Based on the type of the signal, the harmonic spectrum and data analysis-based techniques can be broadly classified into two categories: transient analysis and steady-state analysis. Although both types are very diverse fields, a good glimpse of induction machines fault diagnosis can be seen in: transient [,,], steady-state [,].

The harmonic spectrum analysis-based techniques are very old and well established because most of those techniques are based on non-invasive signals. Various signal processing techniques can be easily deployed, computationally less intense, and no kind of sophisticated apparatus is required. The measured signals can be analyzed at any remote location. However, with the increasing trend of drive utilization, special purpose machines and different working environments make the conventional current and flux monitoring techniques very challenging. The reliability of diagnostic algorithms will no doubt increase if the algorithm mathematically knows the machine under inspection. Moreover, if the mathematical models in the drive are compatible with the diagnostic algorithm, the drive can continuously monitor the machine’s health.

Due to these factors, researchers are moving towards modelling- and parameters estimation-based diagnostic techniques. For this purpose, the development of mathematical models with reduced simulation time and that are compatible with faults simulation is the first milestone to be achieved. Various modelling techniques are available in the literature, e.g., modified winding function-based models [,,,], circular convolution theory-based [], the hybrid FEM-analytical [,]. These models can be used in parallel with the real working machine to estimate design parameters. For example, authors in [] proposed utilizing an induction motor’s FEM model for parameters estimation using hardware in the loop environment. In [], the induction motor’s inversion model was used to estimate different performance parameters for health monitoring.

4.3. Wear Monitoring

As mentioned, the bearing is one of the essential parts of a rotating machine that is to be affected by various loads and forces, which reduce the motor’s intended lifespan. Generally, most friction losses in rotating machines are referred to as bearings. Therefore, wear monitoring of bearings can significantly affect a machine’s proper operation and reliability in general. The most common causes for bearing wear are high friction load and lack of proper lubrication. Bearing faults tend to occur in areas where lubricant coating is the thinnest. Authors in [] discuss a method for bearing state monitoring by simulating lubricant state under different pressure conditions.

Regarding lubricant conditions, which directly impact the bearing’s durability, authors in [] use ultrasonic sensors that were instrumented on the inner and outer bearing raceways to detect lubricant conditions. In [], the authors propose an improved grey k-means clustering model for monitoring bearing wear conditions. Finally, authors in [] propose a fault tree analysis for wear monitoring in wind turbine bearings.

4.4. Temperature Measurement

Thermal monitoring is an important component of proper functioning. Excessive temperature increases shorten the lifespan of an electrical machine, destroy winding insulation, cause short circuits, lead to aging of bearings, and degrade the rotor permanent magnets []. The most common reasons for temperature increase are cooling-system failures and excessive currents through windings [].

Generally, temperature-based monitoring can be divided into two approaches: thermal image analysis and local spot measurement. For local thermal measurement, there resistance thermometer detectors and thermocouples are mostly used. At the same time, local monitoring using thermocouples or resistance temperature detectors can be limited by safety applications, especially due to the usage of electrically conductive material in the sensor structure []. Therefore, they cannot be placed in the hottest spot.

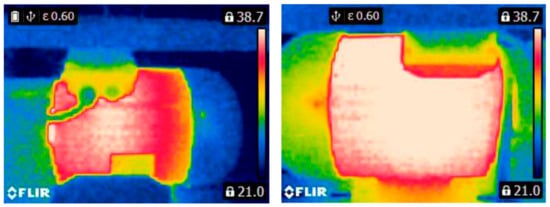

Thermal imaging is another potential option for thermal monitoring in rotating machinery. In [], as shown in Figure 15, the authors present a method of feature extraction using thermal images. For classification, the nearest neighbor classifier, k-means, and back-propagation neural network were used.

Figure 15.

Thermal image of healthy as well as a faulty motor with damaged ring of squirrel-cage [].

Authors in [] discuss a study to determine thermal conditions using thermal imaging, which allowed effective and accurate measurement results. In [], the authors propose a fault diagnosis method based on thermal images, where several intelligent algorithms were used for model training. Finally, authors in [] discuss a novel image classification method—cloud detection using a random forest classifier.

5. Discussion and Conclusions

Electrical machines fault diagnostics and predictive maintenance have gained increasing popularity. This is because of the increasing influence of electrical machines and drives in industry and everyday human life. Condition monitoring and predictive maintenance are essential for a system’s reliability and have a direct influence on economic aspects. Because of the different types of machines, the various control mechanisms, and the wide range of different working environments, no one condition-monitoring algorithm can be considered uniquely suitable.

These algorithms vary for different systems depending upon several parameters. This is the reason why the field of fault diagnostics and condition monitoring depends upon various technical matters. The associated research areas may include signal processing, sensors design and optimization, statistical data analysis, artificial intelligence, numerical methods, calculus, mathematical modelling, etc. The dependency of the fault diagnostic algorithm on single or multiple topics makes this field very diverse and makes it challenging to summarize easily and quickly.

In order to give the reader a glimpse of the state of the art of this field, a variety of advanced fault diagnostic and condition monitoring techniques are summarized in this paper. Different diagnostic techniques that can be used for algorithms’ training and predictive maintenance are presented. The benefits and drawbacks of each intelligent diagnostic technique are highlighted. The most widespread faults of electrical machines are discussed, and techniques for parameters’ monitoring are introduced.

Author Contributions

Conceptualization, K.K.; methodology, B.A.; writing—original draft preparation, K.K. and B.A.; writing—review and editing, T.V., A.R. and H.V.K.; visualization, K.K.; supervision, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [EEA]/[Norway] Grants 2014–2021, “Industrial Internet methods for electrical energy conversion systems monitoring and diagnostics”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dineva, A.; Mosavi, A.; Gyimesi, M.; Vajda, I.; Nabipour, N.; Rabczuk, T. Fault Diagnosis of Rotating Electrical Machines Using Multi-Label Classification. Appl. Sci. 2019, 9, 5086. [Google Scholar] [CrossRef] [Green Version]

- Wang, L. Data Mining, Machine Learning and Big Data Analytics. Int. Trans. Electr. Comput. Eng. Syst. 2017, 4, 55–61. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez, L.; Patiño, J.; Duque-Grisales, E. A Comparison of the Performance of Supervised Learning Algorithms for Solar Power Prediction. Energies 2021, 14, 4424. [Google Scholar] [CrossRef]

- Gittler, T.; Scholze, S.; Rupenyan, A.; Wegener, K. Machine Tool Component Health Identification with Unsupervised Learning. J. Manuf. Mater. Process. 2020, 4, 86. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Q.; Tian, Q.; Li, S.; Wang, X.; Lane, D.; Petillot, Y.; Wang, S. Learning Mobile Manipulation through Deep Reinforcement Learning. Sensors 2020, 20, 939. [Google Scholar] [CrossRef] [Green Version]

- Xu, H.; Zhou, J.; Asteris, P.G.; Armaghani, D.J.; Tahir, M.M. Supervised Machine Learning Techniques to the Prediction of Tunnel Boring Machine Penetration Rate. Appl. Sci. 2019, 9, 3715. [Google Scholar] [CrossRef] [Green Version]

- Riese, F.M.; Keller, S.; Hinz, S. Supervised and Semi-Supervised Self-Organizing Maps for Regression and Classification Focusing on Hyperspectral Data. Remote Sens. 2019, 12, 7. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Yang, S.; Gan, C. Unsupervised Fault Diagnosis of a Gear Transmission Chain Using a Deep Belief Network. Sensors 2017, 17, 1564. [Google Scholar] [CrossRef]

- Jozdani, S.E.; Johnson, B.A.; Chen, D. Comparing Deep Neural Networks, Ensemble Classifiers, and Support Vector Machine Algorithms for Object-Based Urban Land Use/Land Cover Classification. Remote Sens. 2019, 11, 1713. [Google Scholar] [CrossRef] [Green Version]

- Bae, H.; Kim, G.; Kim, J.; Qian, D.; Lee, S. Multi-Robot Path Planning Method Using Reinforcement Learning. Appl. Sci. 2019, 9, 3057. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Li, W.; Xu, K.; Zahid, T.; Qin, F.; Li, C. Energy Management Strategy for a Hybrid Electric Vehicle Based on Deep Reinforcement Learning. Appl. Sci. 2018, 8, 187. [Google Scholar] [CrossRef] [Green Version]

- Ji, Y.; Wang, J.; Xu, J.; Fang, X.; Zhang, H. Real-Time Energy Management of a Microgrid Using Deep Reinforcement Learning. Energies 2019, 12, 2291. [Google Scholar] [CrossRef] [Green Version]

- Tran, V.T.; Yang, B.-S.; Oh, M.-S.; Tan, C. Fault diagnosis of induction motor based on decision trees and adaptive neuro-fuzzy inference. Expert Syst. Appl. 2009, 36, 1840–1849. [Google Scholar] [CrossRef] [Green Version]

- Li, S.-Y.; Xue, L. Motor’s Early Fault Diagnosis Based on Support Vector Machine. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 032047. [Google Scholar] [CrossRef]

- Atanasov, N.; Zhekov, Z.; Grigorov, I.; Alexandrova, M. Application of Principal Component Analysis for Fault Detection of DC Motor Parameters. Appl. Sci. 2017, 680, 312–322. [Google Scholar] [CrossRef]

- Toma, R.N.; Prosvirin, A.E.; Kim, J.-M. Bearing Fault Diagnosis of Induction Motors Using a Genetic Algorithm and Machine Learning Classifiers. Sensors 2020, 20, 1884. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mosavi, A.; Ozturk, P.; Chau, K.-W. Flood Prediction Using Machine Learning Models: Literature Review. Water 2018, 10, 1536. [Google Scholar] [CrossRef] [Green Version]

- Savas, C.; Dovis, F. The Impact of Different Kernel Functions on the Performance of Scintillation Detection Based on Support Vector Machines. Sensors 2019, 19, 5219. [Google Scholar] [CrossRef] [Green Version]

- Parrado-Hernández, E.; Robles, G.; Ardila-Rey, J.A.; Martínez-Tarifa, J.M. Robust Condition Assessment of Electrical Equipment with One Class Support Vector Machines Based on the Measurement of Partial Discharges. Energies 2018, 11, 486. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Tian, Y.; Kou, G.; Peng, Y.; Li, J. Support Vector Machines for Classification Problems. In Advanced Information and Knowledge Processing; Springer: London, UK, 2011; pp. 3–13. [Google Scholar] [CrossRef]

- Nanda, M.A.; Seminar, K.B.; Nandika, D.; Maddu, A. A Comparison Study of Kernel Functions in the Support Vector Machine and Its Application for Termite Detection. Information 2018, 9, 5. [Google Scholar] [CrossRef] [Green Version]

- Windrim, L.; Ramakrishnan, R.; Melkumyan, A.; Murphy, R.J.; Chlingaryan, A. Unsupervised Feature-Learning for Hyperspectral Data with Autoencoders. Remote Sens. 2019, 11, 864. [Google Scholar] [CrossRef] [Green Version]

- Swana, E.; Doorsamy, W. An Unsupervised Learning Approach to Condition Assessment on a Wound-Rotor Induction Generator. Energies 2021, 14, 602. [Google Scholar] [CrossRef]

- Kudelina, K.; Vaimann, T.; Asad, B.; Rassõlkin, A.; Kallaste, A.; Demidova, G. Trends and Challenges in Intelligent Condition Monitoring of Electrical Machines Using Machine Learning. Appl. Sci. 2021, 11, 2761. [Google Scholar] [CrossRef]

- Varghese, N.V.; Mahmoud, Q.H. A Survey of Multi-Task Deep Reinforcement Learning. Electronics 2020, 9, 1363. [Google Scholar] [CrossRef]

- Skowron, M.; Orłowska-Kowalska, T. Efficiency of Cascaded Neural Networks in Detecting Initial Damage to Induction Motor Electric Windings. Electronics 2020, 9, 1314. [Google Scholar] [CrossRef]

- Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Application of Self-Organizing Neural Networks to Electrical Fault Classification in Induction Motors. Appl. Sci. 2019, 9, 616. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Son, Y. Motor Load Balancing with Roll Force Prediction for a Cold-Rolling Setup with Neural Networks. Mathematics 2021, 9, 1367. [Google Scholar] [CrossRef]

- Zimnickas, T.; Vanagas, J.; Dambrauskas, K.; Kalvaitis, A.; Ažubalis, M. Application of Advanced Vibration Monitoring Systems and Long Short-Term Memory Networks for Brushless DC Motor Stator Fault Monitoring and Classification. Energies 2020, 13, 820. [Google Scholar] [CrossRef] [Green Version]

- Basheer, I.; Hajmeer, M. Artificial neural networks: Fundamentals, computing, design, and application. J. Microbiol. Methods 2000, 43, 3–31. [Google Scholar] [CrossRef]

- Heinert, M. Artificial neural networks—How to open the black boxes? Appl. Artif. Intell. Eng. Geod. 2008, 42–62. [Google Scholar]

- Oh, S.J.; Schiele, B.; Fritz, M. Towards Reverse-Engineering Black-Box Neural Networks. In Explainable AI: Interpreting, Explaining and Visualizing Deep Learning; Springer: Berlin/Heidelberg, Germany, 2017; pp. 121–144. [Google Scholar] [CrossRef] [Green Version]

- Demidova, G.; Rassolkin, A.; Vaimann, T.; Kallaste, A.; Zakis, J.; Suzdalenko, A. An Overview of Fuzzy Logic Approaches for Fault Diagnosis in Energy Conversion Devices. In Proceedings of the 28th International Workshop on Electric Drives Improving Reliability of Electric Drives, IWED 2021 Proceedings, Virtual, 27–29 January 2021. [Google Scholar] [CrossRef]

- Alshejari, A.; Kodogiannis, V.S.; Leonidis, S. Development of Neurofuzzy Architectures for Electricity Price Forecasting. Energies 2020, 13, 1209. [Google Scholar] [CrossRef] [Green Version]

- Kothamasu, R.; Huang, S.H. Adaptive Mamdani fuzzy model for condition-based maintenance. Fuzzy Sets Syst. 2007, 158, 2715–2733. [Google Scholar] [CrossRef]

- Li, X.; Palazzolo, A.; Wang, Z. Rotating Machinery Monitoring and Fault Diagnosis with Neural Network Enhanced Fuzzy Logic Expert System. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Manikandan, P.; Geetha, M. Takagi Sugeno fuzzy expert model based soft fault diagnosis for two tank interacting system. Arch. Control. Sci. 2014, 24, 271–287. [Google Scholar] [CrossRef]

- Zaccaria, V.; Rahman, M.; Aslanidou, I.; Kyprianidis, K. A Review of Information Fusion Methods for Gas Turbine Diagnostics. Sustainability 2019, 11, 6202. [Google Scholar] [CrossRef] [Green Version]

- Tavner, P.J. Review of condition monitoring of rotating electrical machines. IET Electr. Power Appl. 2008, 2, 215–247. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Kallaste, A.; Rassõlkin, A.; Belahcen, A.; Iqbal, M.N. Improving Legibility of Motor Current Spectrum for Broken Rotor Bars Fault Diagnostics. Electr. Control Commun. Eng. 2019, 15, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Nabhan, A.; Ghazaly, N.M.; Samy, A.; Mousa, M.O. Bearing Fault Detection Techniques—A Review. Turk. J. Eng. Sci. Technol. 2015, 3, 1–18. [Google Scholar]

- Silva, J.; Cardoso, A. Bearing failures diagnosis in three-phase induction motors by extended Park’s vector approach. In Proceedings of the 31st Annual Conference of IEEE Industrial Electronics Society, Raleigh, NC, USA, 6 November 2005; pp. 2591–2596. [Google Scholar] [CrossRef]

- Gu, C.; Wang, M.; Bao, Y.; Wang, F.; Lian, J. Quantitative Analysis of Inclusion Engineering on the Fatigue Property Improvement of Bearing Steel. Metals 2019, 9, 476. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, M.; Wang, Y.; Xie, L. Fatigue Life Analysis of Ball Bearings and a Shaft System Considering the Combined Bearing Preload and Angular Misalignment. Appl. Sci. 2020, 10, 2750. [Google Scholar] [CrossRef] [Green Version]

- Kudelina, K.; Asad, B.; Vaimann, T.; Rassõlkin, A.; Kallaste, A. Bearing Fault Analysis of BLDC Motor Intended for Electric Scooter Application. In Proceedings of the 13th Edition of the IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Dallas, TX, USA, 22–25 August 2021. [Google Scholar]

- Aditya, M.; Amarnath, M.; Kankar, P. Failure Analysis of a Grease-Lubricated Cylindrical Roller Bearing. Procedia Technol. 2014, 14, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Fischer, D.; Mues, H.; Jacobs, G.; Stratmann, A. Effect of Over Rolling Frequency on the Film Formation in Grease Lubricated EHD Contacts under Starved Conditions. Lubricants 2019, 7, 19. [Google Scholar] [CrossRef] [Green Version]

- Gonda, A.; Capan, R.; Bechev, D.; Sauer, B. The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants 2019, 7, 108. [Google Scholar] [CrossRef] [Green Version]

- Ren, X.; Liu, R.; Yang, E. Modelling of the Bearing Breakdown Resistance in Bearing Currents Problem of AC Motors. Energies 2019, 12, 1121. [Google Scholar] [CrossRef] [Green Version]

- Berhausen, S.; Jarek, T. Method of Limiting Shaft Voltages in AC Electric Machines. Energies 2021, 14, 3326. [Google Scholar] [CrossRef]

- Sar, M.Z.; Barella, S.; Gruttadauria, A.; Mombelli, D.; Mapelli, C. Impact of Warm Rolling Process Parameters on Crystallographic Textures, Microstructure and Mechanical Properties of Low-Carbon Boron-Bearing Steels. Metals 2018, 8, 927. [Google Scholar] [CrossRef] [Green Version]

- Raadnui, S.; Kleesuwan, S. Electrical pitting of grease-lubricated rolling and sliding bearings: A comparative study. J. Phys. Conf. Ser. 2012, 364, 012041. [Google Scholar] [CrossRef] [Green Version]

- Bishop, T. Dealing with Shaft and Bearing Currents. EASA Tech. Pap. 2017. Available online: http://www.kyservice.com (accessed on 10 September 2021).

- Chen, Y.; Liang, S.; Li, W.; Liang, H.; Wang, C. Faults and Diagnosis Methods of Permanent Magnet Synchronous Motors: A Review. Appl. Sci. 2019, 9, 2116. [Google Scholar] [CrossRef] [Green Version]

- Rosero, J.A.; Cusido, J.; Garcia, J.R.; Ortega, J.; Romeral, L. Broken Bearings and Eccentricity Fault Detection for a Permanent Magnet Synchronous Motor. In Proceedings of the IECON 2006—32nd Annual Conference on IEEE Industrial Electronics, Paris, France, 6–10 November 2006; pp. 964–969. [Google Scholar] [CrossRef]

- Del Pizzo, A.; Di Noia, L.P.; Fedele, E. A Simple Analytical Model of Static Eccentricity for PM Brushless Motors and Validation through FEM Analysis. Energies 2020, 13, 3420. [Google Scholar] [CrossRef]

- Lorencki, J.; Radkowski, S.; Gontarz, S. Diagnostically Oriented Experiments and Modelling of Switched Reluctance Motor Dynamic Eccentricity. Sensors 2021, 21, 3857. [Google Scholar] [CrossRef]

- Voloshin, S.A.; Poskanzer, A.M.; Tang, A.; Wang, G. Elliptic flow in the Gaussian model of eccentricity fluctuations. Phys. Lett. Sect. B Nucl. Elem. Part. High-Energy Phys. 2008, 659, 537–541. [Google Scholar] [CrossRef] [Green Version]

- Kallaste, A.; Belahcen, A.; Kilk, A.; Vaimann, T. Analysis of the eccentricity in a low-speed slotless permanent-magnet wind generator. In Proceedings of the 8th International Conference Electric Power Quality and Supply Reliability Conference (PQ), Tartu, Estonia, 11–13 June 2012; pp. 47–52. [Google Scholar] [CrossRef]

- Da, Y.; Shi, X.; Krishnamurthy, M. Health monitoring, fault diagnosis and failure prognosis techniques for Brushless Permanent Magnet Machines. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar] [CrossRef]

- Urresty, J.-C.; Riba, J.-R.; Delgado, M.; Romeral, L. Detection of Demagnetization Faults in Surface-Mounted Permanent Magnet Synchronous Motors by Means of the Zero-Sequence Voltage Component. IEEE Trans. Energy Convers. 2011, 27, 42–51. [Google Scholar] [CrossRef]

- Choi, G. Analysis and Experimental Verification of the Demagnetization Vulnerability in Various PM Synchronous Machine Configurations for an EV Application. Energies 2021, 14, 5447. [Google Scholar] [CrossRef]

- Mynarek, P.; Kołodziej, J.; Młot, A.; Kowol, M.; Łukaniszyn, M. Influence of a Winding Short-Circuit Fault on Demagnetization Risk and Local Magnetic Forces in V-Shaped Interior PMSM with Distributed and Concentrated Winding. Energies 2021, 14, 5125. [Google Scholar] [CrossRef]

- Wang, J.; Gao, R.X.; Yan, R. Broken-Rotor-Bar Diagnosis for Induction Motors. J. Phys. Conf. Ser. 2011, 305. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, J.; Li, H.; Zhen, D.; Xu, Y.; Gu, F. Fault Identification of Broken Rotor Bars in Induction Motors Using an Improved Cyclic Modulation Spectral Analysis. Energies 2019, 12, 3279. [Google Scholar] [CrossRef] [Green Version]

- Ying, X. Performance Evaluation and Thermal Fields Analysis of Induction Motor with Broken Rotor Bars Located at Different Relative Positions. IEEE Trans. Magn. 2010, 46, 1243–1250. [Google Scholar] [CrossRef]

- Frosini, L. Novel Diagnostic Techniques for Rotating Electrical Machines—A Review. Energies 2020, 13, 5066. [Google Scholar] [CrossRef]

- Sarkhanloo, M.S.; Ghalledar, D.; Azizian, M.R. Diagnosis of Stator Winding Turn to Turn Fault of Induction Motor Using Space Vector Pattern based on Neural Network. In Proceedings of the 3rd Conference on Thermal Power Plants, Tehran, Iran, 18–19 October 2013; pp. 1–6. [Google Scholar]

- Pietrzak, P.; Wolkiewicz, M. Comparison of Selected Methods for the Stator Winding Condition Monitoring of a PMSM Using the Stator Phase Currents. Energies 2021, 14, 1630. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Li, J. Diagnosis of Inter-Turn Short Circuit of Synchronous Generator Rotor Winding Based on Volterra Kernel Identification. Energies 2018, 11, 2524. [Google Scholar] [CrossRef] [Green Version]

- Kudelina, K.; Asad, B.; Vaimann, T.; Rassõlkin, A.; Kallaste, A. Production Quality Related Propagating Faults of Induction Machines. In Proceedings of the 2020 XI International Conference on Electrical Power Drive Systems (ICEPDS), St. Petersburg, Russia, 4–7 October 2020. [Google Scholar]

- Lee, C.-Y.; Huang, K.-Y.; Jen, L.-Y.; Zhuo, G.-L. Diagnosis of Defective Rotor Bars in Induction Motors. Symmetry 2020, 12, 1753. [Google Scholar] [CrossRef]

- Gyftakis, K.N.; Marques-Cardos, A.J. Reliable Detection of Low Severity Level Stator Inter-Turn Faults in Induction Motors. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 1290–1295. [Google Scholar]

- Kallaste, A.; Vaimann, T.; Belahcen, A. Possible manufacturing tolerance faults in design and construction of low speed slotless permanent magnet generator. In Proceedings of the 2014 16th European Conference on Power Electronics and Applications, Lappeenranta, Finland, 26–28 August 2014. [Google Scholar] [CrossRef]

- Toh, G.; Park, J. Review of Vibration-Based Structural Health Monitoring Using Deep Learning. Appl. Sci. 2020, 10, 1680. [Google Scholar] [CrossRef]

- Papathanasopoulos, D.A.; Giannousakis, K.N.; Dermatas, E.S.; Mitronikas, E.D. Vibration Monitoring for Position Sensor Fault Diagnosis in Brushless DC Motor Drives. Energies 2021, 14, 2248. [Google Scholar] [CrossRef]

- Bai, Y.; Lu, Y.; Hu, P.; Wang, G.; Xu, J.; Zeng, T.; Li, Z.; Zhang, Z.; Tan, J. Absolute Position Sensing Based on a Robust Differential Capacitive Sensor with a Grounded Shield Window. Sensors 2016, 16, 680. [Google Scholar] [CrossRef] [Green Version]

- Rokicki, E.; Przysowa, R.; Kotkowski, J.; Majewski, P. High Temperature Magnetic Sensors for the Hot Section of Aeroengines. Aerospace 2021, 8, 261. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, B.; Xu, L.; Qiao, Y.; Wang, F.; Xia, Q.; Lu, Z. A Sandwich-Structured Piezoresistive Sensor with Electrospun Nanofiber Mats as Supporting, Sensing, and Packaging Layers. Polymers 2018, 10, 575. [Google Scholar] [CrossRef] [Green Version]

- Schotzko, T.; Lang, W. Embedded Strain Gauges for Condition Monitoring of Silicone Gaskets. Sensors 2014, 14, 12387–12398. [Google Scholar] [CrossRef] [Green Version]

- Kudelina, K.; Asad, B.; Vaimann, T.; Belahcen, A.; Rassõlkin, A.; Kallaste, A.; Lukichev, D.V. Bearing Fault Analysis of BLDC Motor for Electric Scooter Application. Designs 2020, 4, 42. [Google Scholar] [CrossRef]

- Yoo, Y.; Baek, J.-G. A Novel Image Feature for the Remaining Useful Lifetime Prediction of Bearings Based on Continuous Wavelet Transform and Convolutional Neural Network. Appl. Sci. 2018, 8, 1102. [Google Scholar] [CrossRef] [Green Version]

- Gong, W.; Chen, H.; Zhang, Z.; Zhang, M.; Wang, R.; Guan, C.; Wang, Q. A Novel Deep Learning Method for Intelligent Fault Diagnosis of Rotating Machinery Based on Improved CNN-SVM and Multichannel Data Fusion. Sensors 2019, 19, 1693. [Google Scholar] [CrossRef] [Green Version]

- Xu, G.; Liu, M.; Jiang, Z.; Söffker, D.; Shen, W. Bearing Fault Diagnosis Method Based on Deep Convolutional Neural Network and Random Forest Ensemble Learning. Sensors 2019, 19, 1088. [Google Scholar] [CrossRef] [Green Version]

- Cerrada, M.; Sánchez, R.V.; Cabrera, D.; Zurita, G.; Li, C. Multi-Stage Feature Selection by Using Genetic Algorithms for Fault Diagnosis in Gearboxes Based on Vibration Signal. Sensors 2015, 15, 23903–23926. [Google Scholar] [CrossRef] [Green Version]

- Tian, P.; Platero, C.A.; Gyftakis, K.N.; Guerrero, J.M. Stray Flux Sensor Core Impact on the Condition Monitoring of Electrical Machines. Sensors 2020, 20, 749. [Google Scholar] [CrossRef] [Green Version]

- Negrea, M.; Jover, P.; Arkkio, A. Electromagnetic flux-based condition monitoring for electrical machines. In Proceedings of the 2005 5th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Vienna, Austria, 7–9 September 2005. [Google Scholar] [CrossRef]

- Harlisca, C.; Szabo, L.; Frosini, L.; Albini, A. Diagnosis of rolling bearings faults in electric machines through stray magnetic flux monitoring. In Proceedings of the 2013 8th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 23–25 May 2013. [Google Scholar] [CrossRef]

- Rigoni, M.; Sadowski, N.; Batistela, N.J.; Bastos, J.A.; Nau, S.L.; Kost, A.R. Detection and analysis of rotor faults in induction motors by the measurement of the stray magnetic flux. J. Microw. Optoelectron. Electromagn. Appl. 2012, 11, 68–80. [Google Scholar] [CrossRef]

- Frosini, L.; Borin, A.; Girometta, L.; Venchi, G. A novel approach to detect short circuits in low voltage induction motor by stray flux measurement. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1538–1544. [Google Scholar] [CrossRef]

- Goktas, T.; Zafarani, M.; Lee, K.W.; Akin, B.; Sculley, T. Comprehensive Analysis of Magnet Defect Fault Monitoring Through Leakage Flux. IEEE Trans. Magn. 2016, 53, 1–10. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassolkin, A. Rotor Fault Diagnostic of Inverter Fed Induction Motor Using Frequency Analysis. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; pp. 127–133. [Google Scholar] [CrossRef] [Green Version]

- Barater, D.; Arellano-Padilla, J.; Gerada, C. Incipient Fault Diagnosis in Ultrareliable Electrical Machines. IEEE Trans. Ind. Appl. 2017, 53, 2906–2914. [Google Scholar] [CrossRef]

- Ali, M.Z.; Shabbir, N.S.K.; Liang, X.; Zhang, Y.; Hu, T. Machine Learning-Based Fault Diagnosis for Single- and Multi-Faults in Induction Motors Using Measured Stator Currents and Vibration Signals. IEEE Trans. Ind. Appl. 2019, 55, 2378–2391. [Google Scholar] [CrossRef]

- Frosini, L.; Harlisca, C.; Szabo, L. Induction Machine Bearing Fault Detection by Means of Statistical Processing of the Stray Flux Measurement. IEEE Trans. Ind. Electron. 2014, 62, 1846–1854. [Google Scholar] [CrossRef]

- Immovilli, F.; Bianchini, C.; Lorenzani, E.; Bellini, A.; Fornasiero, E. Evaluation of Combined Reference Frame Transformation for Interturn Fault Detection in Permanent-Magnet Multiphase Machines. IEEE Trans. Ind. Electron. 2014, 62, 1912–1920. [Google Scholar] [CrossRef]

- Sapena-Bano, A.; Pineda-Sanchez, M.; Puche-Panadero, R.; Perez-Cruz, J.; Roger-Folch, J.; Riera-Guasp, M.; Martinez-Roman, J. Harmonic Order Tracking Analysis: A Novel Method for Fault Diagnosis in Induction Machines. IEEE Trans. Energy Convers. 2015, 30, 833–841. [Google Scholar] [CrossRef] [Green Version]

- Antonino-Daviu, J.A.; Riera-Guasp, M.; Folch, J.; Palomares, M. Validation of a new method for the diagnosis of rotor bar failures via wavelet transform in industrial induction machines. IEEE Trans. Ind. Appl. 2006, 42, 990–996. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Pineda-Sanchez, M.; Puche-Panadero, R.; Perez-Cruz, J. A General Approach for the Transient Detection of Slip-Dependent Fault Components Based on the Discrete Wavelet Transform. IEEE Trans. Ind. Electron. 2008, 55, 4167–4180. [Google Scholar] [CrossRef]

- Zamudio-Ramirez, I.; Antonino-Daviu, J.A.; Osornio, R.A.; Dunai, L. Tracking of high-order stray-flux harmonics under starting for the detection of winding asymmetries in wound-rotor induction motors. IEEE Trans. Ind. Electron. 2021, 1. [Google Scholar] [CrossRef]

- Castro-Coronado, H.; Antonino-Daviu, J.; Quijano-Lopez, A.; Llovera-Segovia, P.; Fuster-Roig, V.; Serrano-Iribarnegaray, L.; Dunai, L. Evaluation of the Damper Condition in Synchronous Motors Through the Analysis of the Transient Stray Fluxes and Currents Considering the Effect of the Remanent Magnetism. IEEE Trans. Ind. Appl. 2021, 57, 4665–4674. [Google Scholar] [CrossRef]

- Becker, V.; Schwamm, T.; Urschel, S.; Antonino-Daviu, J. Fault Detection of Circulation Pumps on the Basis of Motor Current Evaluation. IEEE Trans. Ind. Appl. 2021, 57, 4617–4624. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassõlkin, A.; Ghafarokhi, P.; Kudelina, K. Transient Modeling and Recovery of Non-Stationary Fault Signature for Condition Monitoring of Induction Motors. Appl. Sci. 2021, 11, 2806. [Google Scholar] [CrossRef]

- Pasqualotto, D.; Navarro, A.N.; Zigliotto, M.; Antonino-Daviu, J.A. Automatic Detection of Rotor Faults in Induction Motors by Convolutional Neural Networks applied to Stray Flux Signals. In Proceedings of the 2021 22nd IEEE International Conference on Industrial Technology (ICIT), Valencia, Spain, 10–12 March 2021; Volume 1, pp. 148–153. [Google Scholar] [CrossRef]

- Antonino-Daviu, J.A.; Zamudio-Ramirez, I.; Osornio-Rios, R.A.; Dunai, L.; Quijano-Lopez, A. Application of Transient Analysis to Detect Rotor and Stator Asymmetries in Wound Rotor Induction Motors: A Field Case. In Proceedings of the 2021 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Modena, Italy, 8–9 April 2021; pp. 237–242. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassõlkin, A.; Iqbal, M.N. Broken rotor bar fault detection of the grid and inverter-fed induction motor by effective attenuation of the fundamental component. IET Electr. Power Appl. 2019, 13, 2005–2014. [Google Scholar] [CrossRef]

- Gyftakis, K.N.; Panagiotou, P.A.; Spyrakis, D. Detection of simultaneous mechanical faults in 6-kV pumping induction motors using combined MCSA and stray flux methods. IET Electr. Power Appl. 2021, 15, 643–652. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassõlkin, A.; Iqbal, M.N. Modified winding function-based model of squirrel cage induction motor for fault diagnostics. IET Electr. Power Appl. 2020, 14, 1722–1734. [Google Scholar] [CrossRef]

- Nandi, S. Modeling of Induction Machines Including Stator and Rotor Slot Effects. IEEE Trans. Ind. Appl. 2004, 40, 1058–1065. [Google Scholar] [CrossRef]

- Nandi, S.; Ahmed, S.; Toliyat, H.A. Detection of rotor slot and other eccentricity related harmonics in a three phase induction motor with different rotor cages. IEEE Trans. Energy Convers. Eng. 2001, 16, 253–260. [Google Scholar] [CrossRef]

- Toliyat, H.A.; Lipo, T. Transient analysis of cage induction machines under stator, rotor bar and end ring faults. IEEE Trans. Energy Convers. 1995, 10, 241–247. [Google Scholar] [CrossRef]

- Sapena-Bano, A.; Martinez-Roman, J.; Puche-Panadero, R.; Pineda-Sanchez, M.; Perez-Cruz, J.; Riera-Guasp, M. Induction machine model with space harmonics for fault diagnosis based on the convolution theorem. Int. J. Electr. Power Energy Syst. 2018, 100, 463–481. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassõlkin, A.; Iqbal, M. The Cluster Computation-Based Hybrid FEM–Analytical Model of Induction Motor for Fault Diagnostics. Appl. Sci. 2020, 10, 7572. [Google Scholar] [CrossRef]

- Sapena-Bano, A.; Chinesta, F.; Pineda-Sanchez, M.; Aguado, J.; Borzacchiello, D.; Puche-Panadero, R. Induction machine model with finite element accuracy for condition monitoring running in real time using hardware in the loop system. Int. J. Electr. Power Energy Syst. 2019, 111, 315–324. [Google Scholar] [CrossRef]

- Schantz, C.J.; Leeb, S.B. Self-Sensing Induction Motors for Condition Monitoring. IEEE Sens. J. 2017, 17, 3735–3743. [Google Scholar] [CrossRef]

- Wan, B.; Yang, J.; Sun, S. A Method for Monitoring Lubrication Conditions of Journal Bearings in a Diesel Engine Based on Contact Potential. Appl. Sci. 2020, 10, 5199. [Google Scholar] [CrossRef]

- Nicholas, G.; Clarke, B.P.; Dwyer-Joyce, R.S. Detection of Lubrication State in a Field Operational Wind Turbine Gearbox Bearing Using Ultrasonic Reflectometry. Lubricants 2021, 9, 6. [Google Scholar] [CrossRef]

- Wang, S.-Y.; Yang, D.-X.; Hu, H.-F. Evaluation for Bearing Wear States Based on Online Oil Multi-Parameters Monitoring. Sensors 2018, 18, 1111. [Google Scholar] [CrossRef] [Green Version]

- Tazi, N.; Châtelet, E.; Bouzidi, Y. Wear analysis of wind turbine bearings. Int. J. Renew. Energy Res. 2017, 7, 2120–2129. [Google Scholar]

- Czerwinski, D.; Gęca, J.; Kolano, K. Machine Learning for Sensorless Temperature Estimation of a BLDC Motor. Sensors 2021, 21, 4655. [Google Scholar] [CrossRef]

- Sonnaillon, M.O.; Bisheimer, G.; De Angelo, C.; García, G. Online Sensorless Induction Motor Temperature Monitoring. IEEE Trans. Energy Convers. 2010, 25, 273–280. [Google Scholar] [CrossRef]

- Mohammed, A.; Djurovic, S. Stator Winding Internal Thermal Monitoring and Analysis Using In Situ FBG Sensing Technology. IEEE Trans. Energy Convers. 2018, 33, 1508–1518. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, Z. Diagnosis of the three-phase induction motor using thermal imaging. Infrared Phys. Technol. 2017, 81, 7–16. [Google Scholar] [CrossRef]

- Szurgacz, D.; Zhironkin, S.; Vöth, S.; Pokorný, J.; Spearing, A.; Cehlár, M.; Stempniak, M.; Sobik, L. Thermal Imaging Study to Determine the Operational Condition of a Conveyor Belt Drive System Structure. Energies 2021, 14, 3258. [Google Scholar] [CrossRef]

- Fanchiang, K.-H.; Huang, Y.-C.; Kuo, C.-C. Power Electric Transformer Fault Diagnosis Based on Infrared Thermal Images Using Wasserstein Generative Adversarial Networks and Deep Learning Classifier. Electronics 2021, 10, 1161. [Google Scholar] [CrossRef]

- Chen, X.; Liu, L.; Gao, Y.; Zhang, X.; Xie, S. A Novel Classification Extension-Based Cloud Detection Method for Medium-Resolution Optical Images. Remote Sens. 2020, 12, 2365. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).