Hydraulic Fracture Propagation in a Poro-Elastic Medium with Time-Dependent Injection Schedule Using the Time-Stepped Linear Superposition Method (TLSM)

Abstract

1. Introduction

2. Pore Pressure and Localized Principal Stress Changes

3. Accounting for Poro-Elasticity in LSM and TLSM Models

3.1. Method of Solution: LSM and TLSM

3.2. Basic LSM Equations

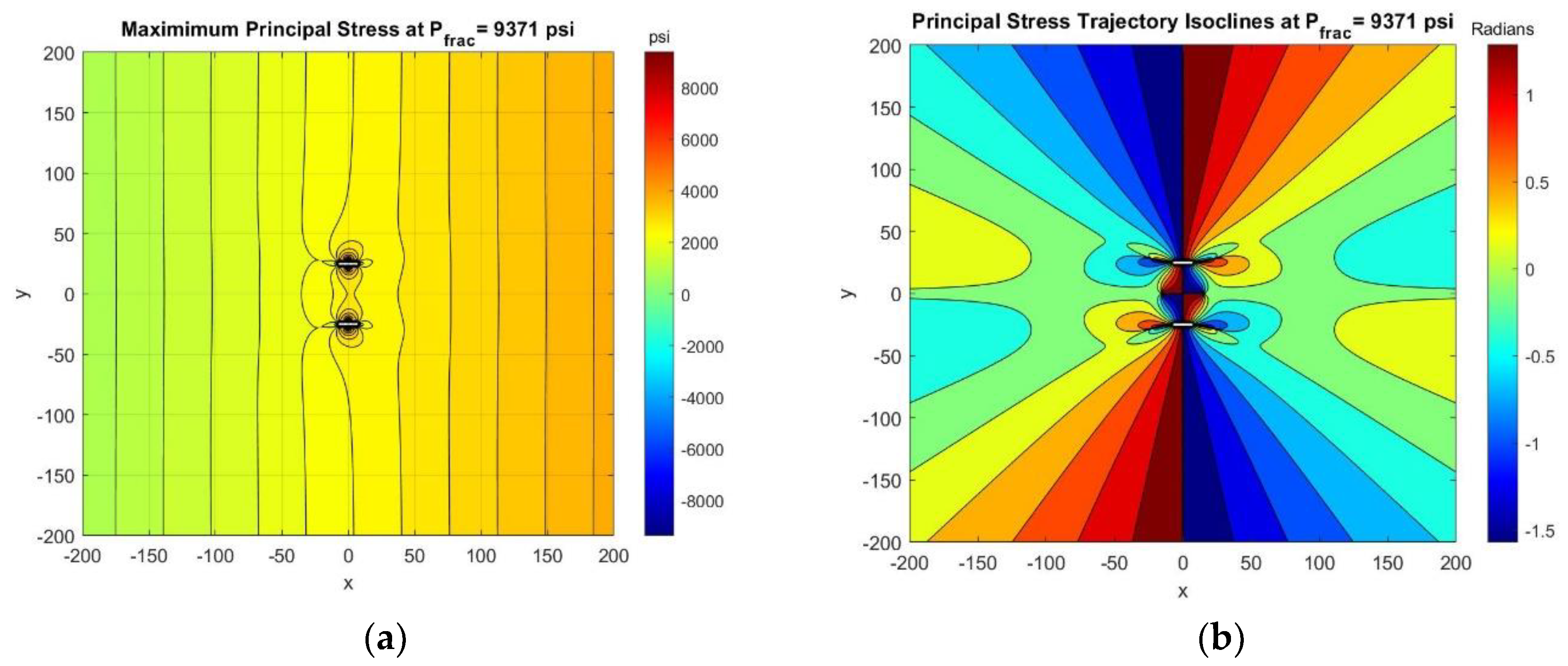

3.3. Static LSM Model Results

3.4. Sub-Conclusions

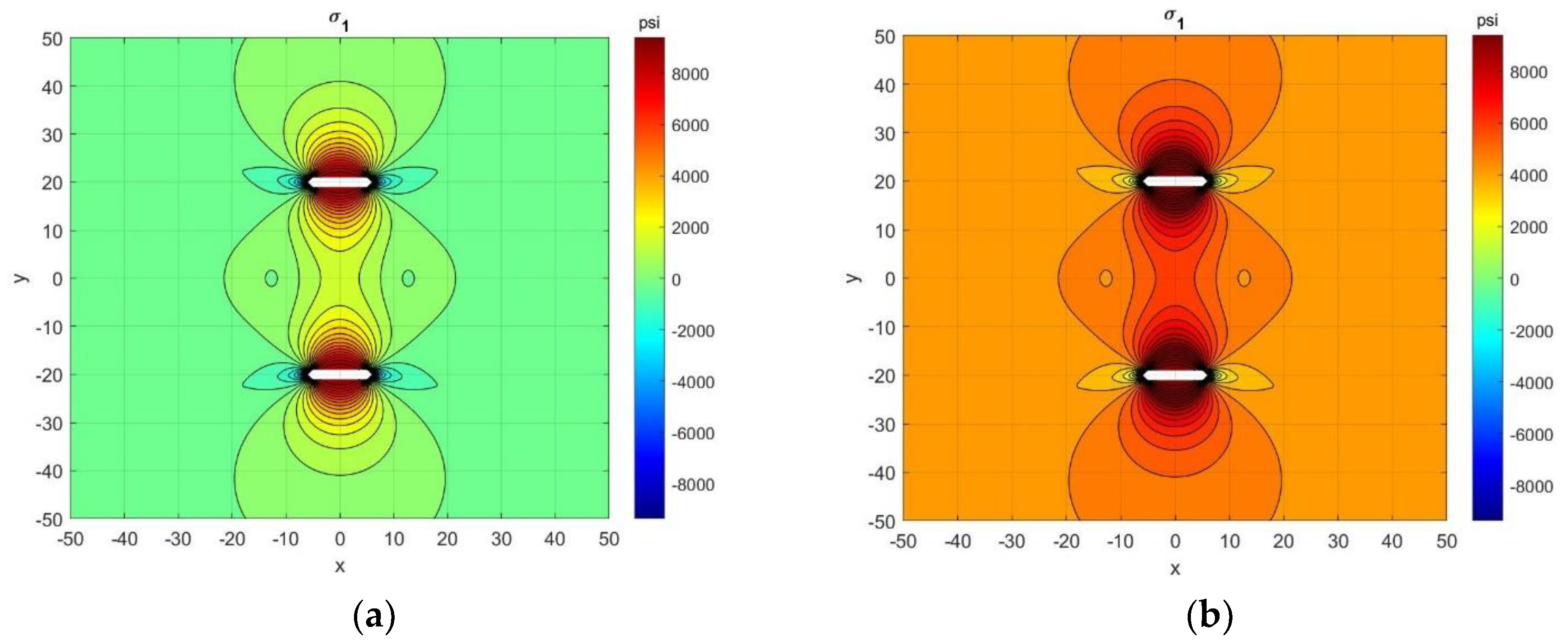

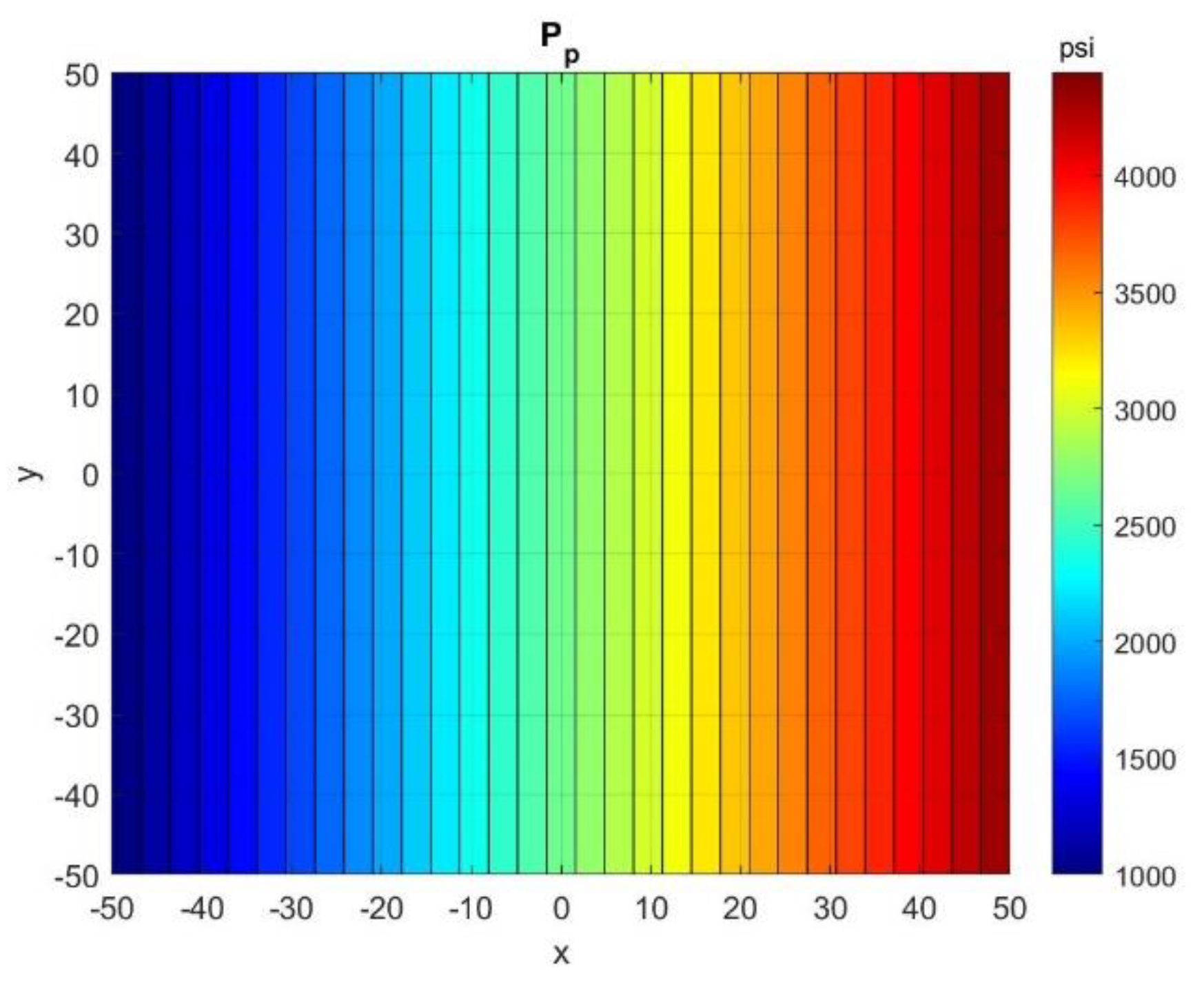

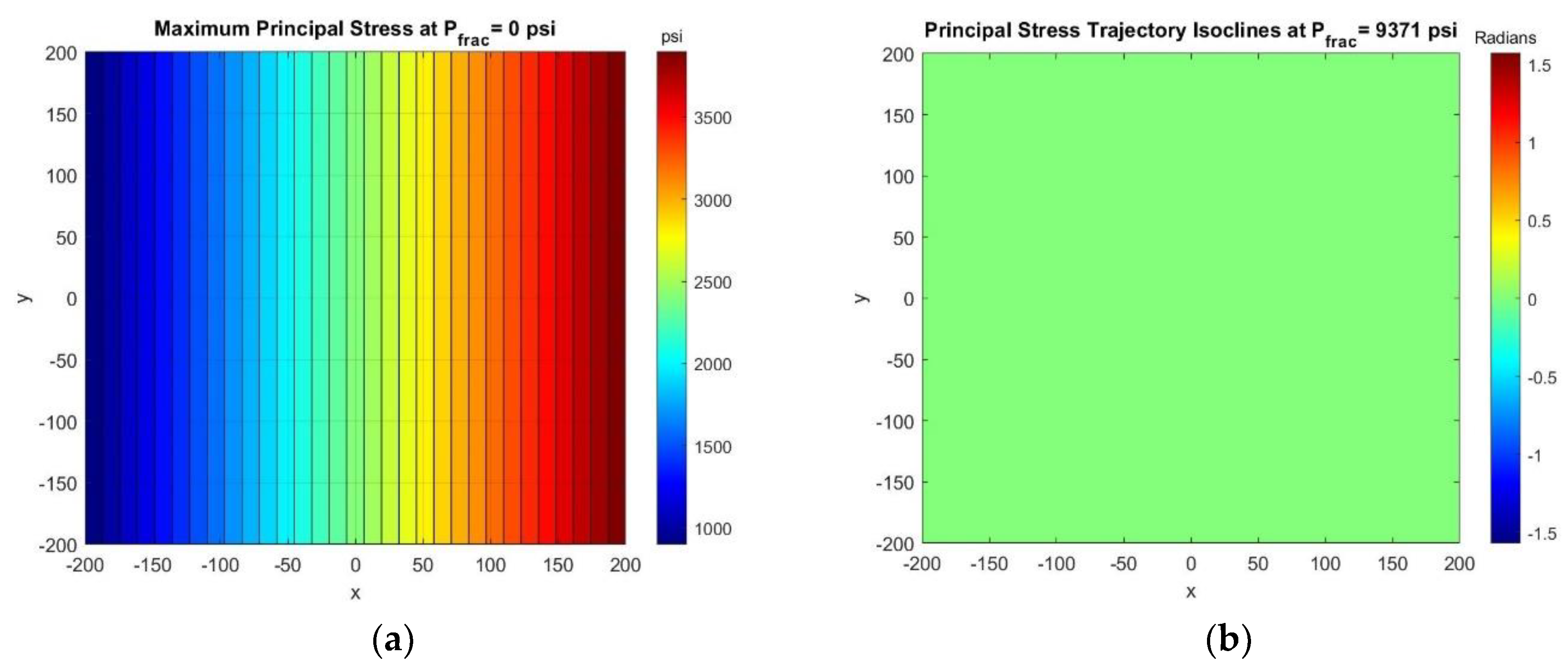

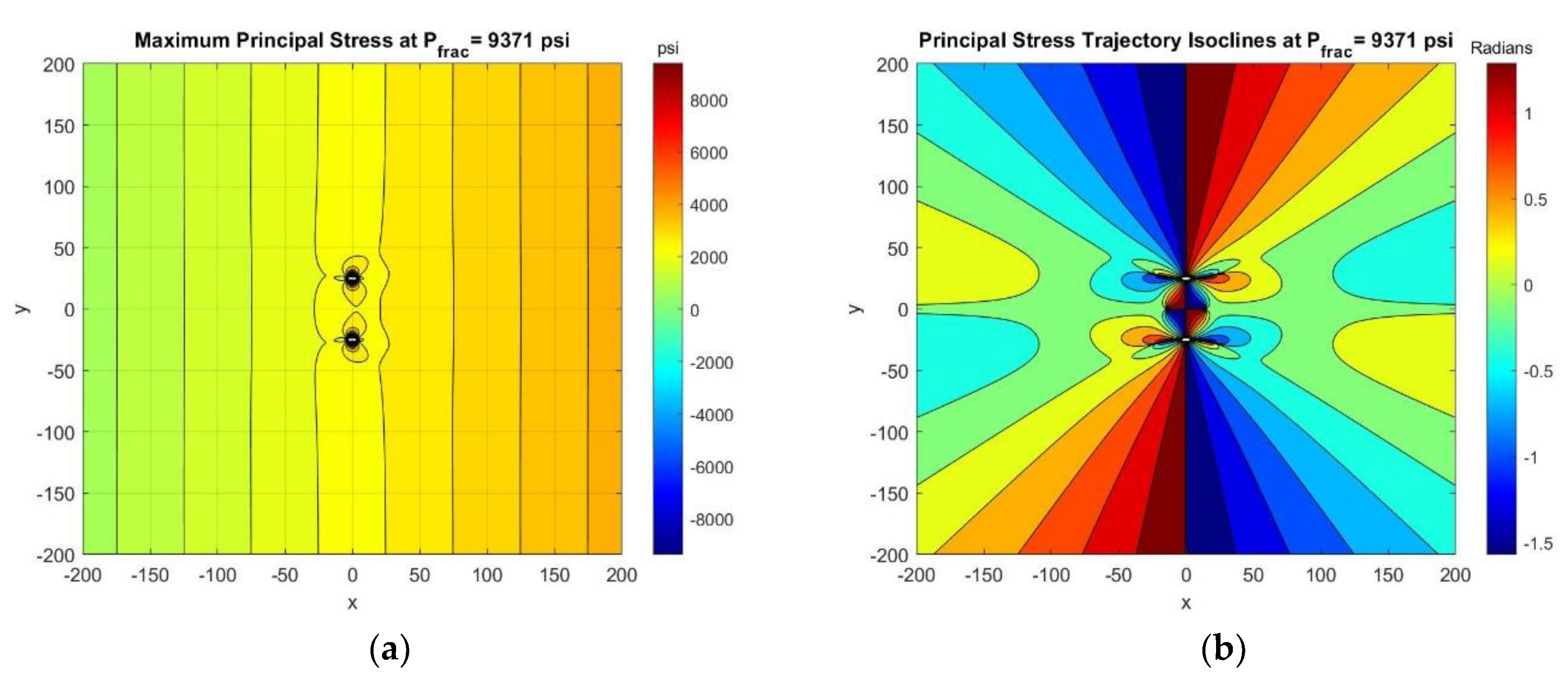

- Principal stress trajectories are not affected by the regional pore pressure variations (Figure 4b).

- However, pore pressure changes have a direct relationship with principal stress magnitudes—as pore pressure increases, the principal stress magnitudes will increase (Figure 4a).

- Changes in the principal stress magnitude, induced by the pore pressure, were constant for all spatial coordinates in the elastic medium.

- Induced changes in the principal stress magnitudes are equal to the pore pressure multiplied by the Biot’s constant.

4. Advancing TLSM with Time-Dependent Pressure

4.1. Time-Dependent Pressure Equations and Assumptions

4.2. Dynamic Fracture Propagation

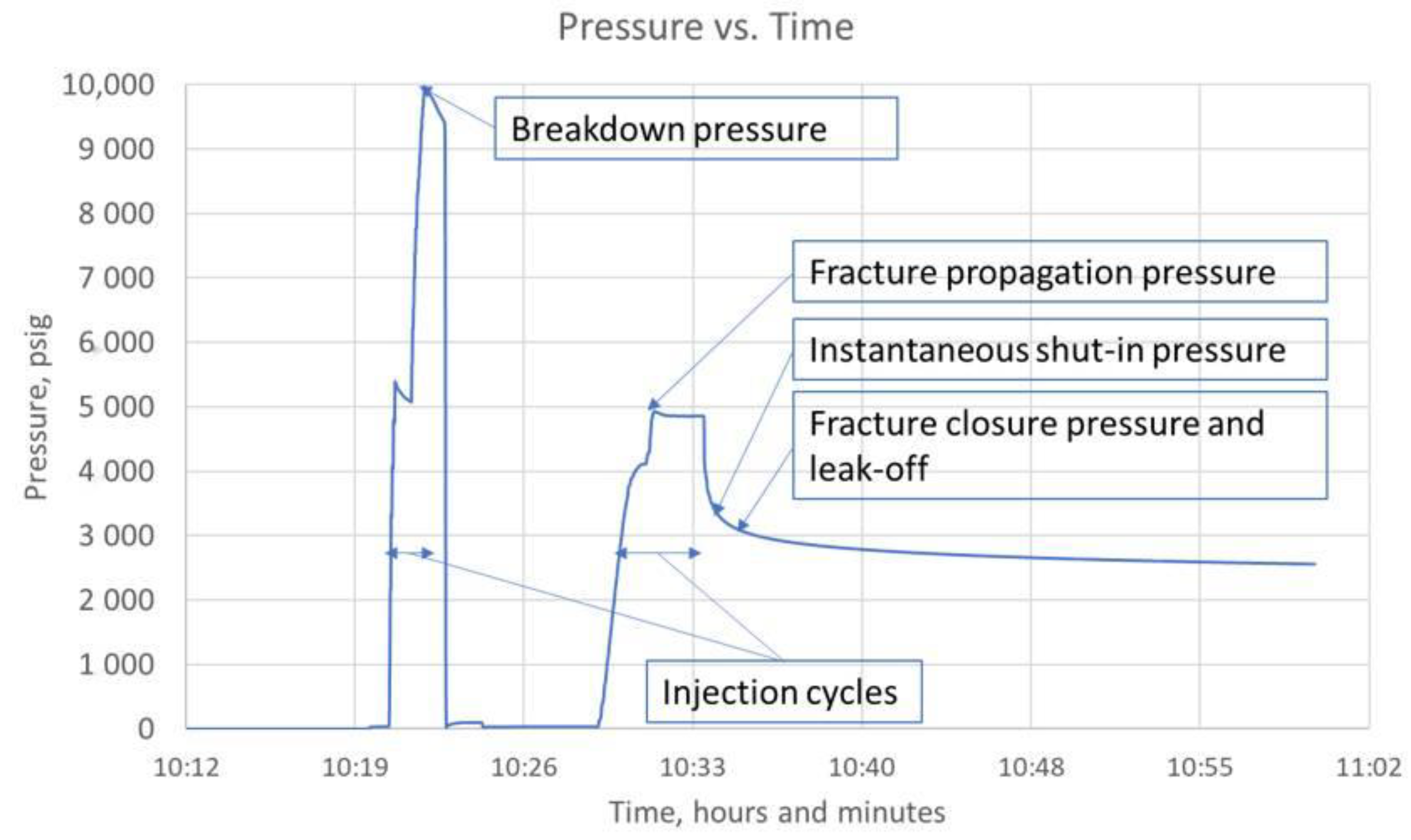

4.3. Diagnostic Fracture Injection Tests (DFIT)

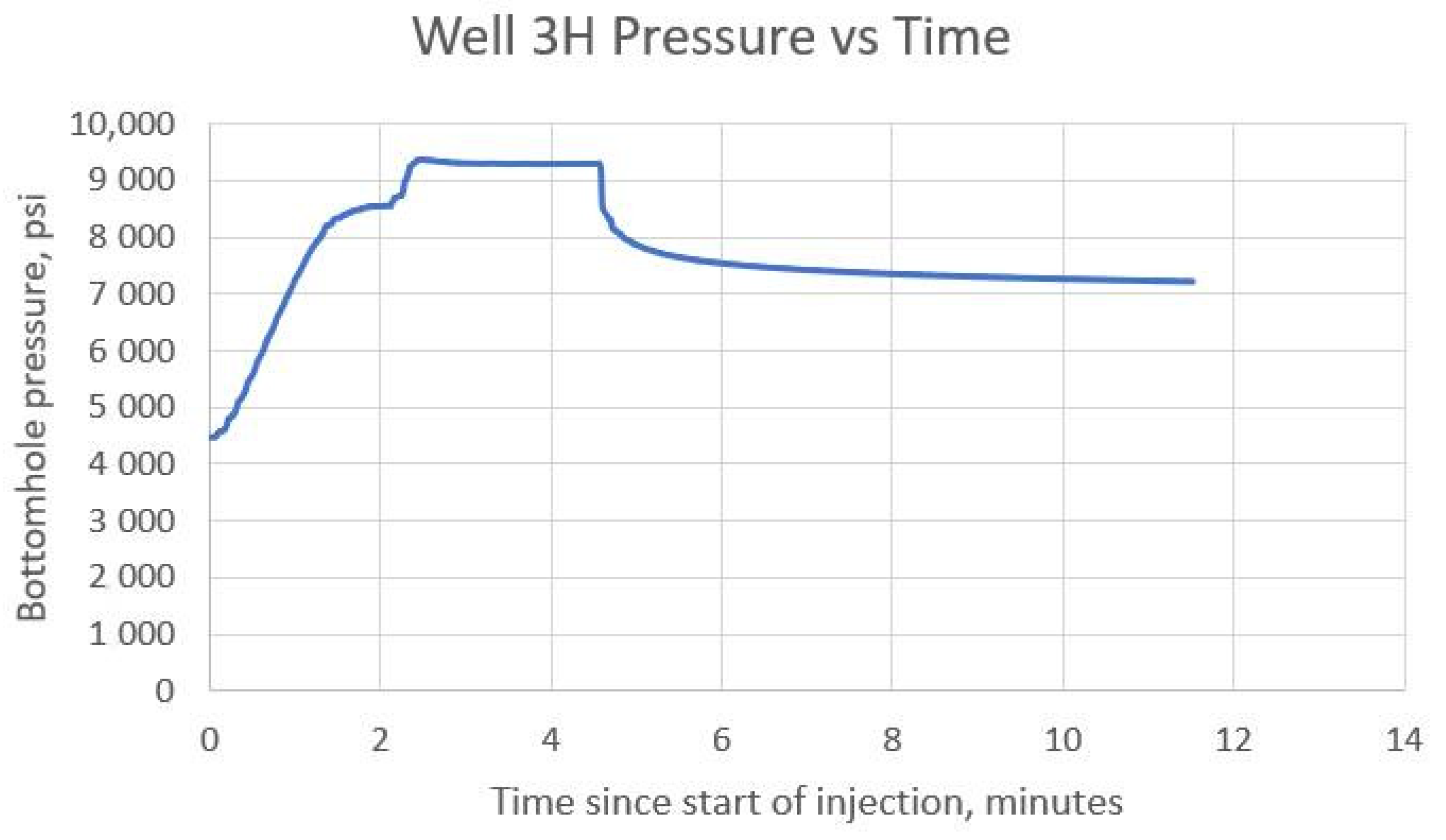

4.4. Field DFIT Data and Simulation Parameters

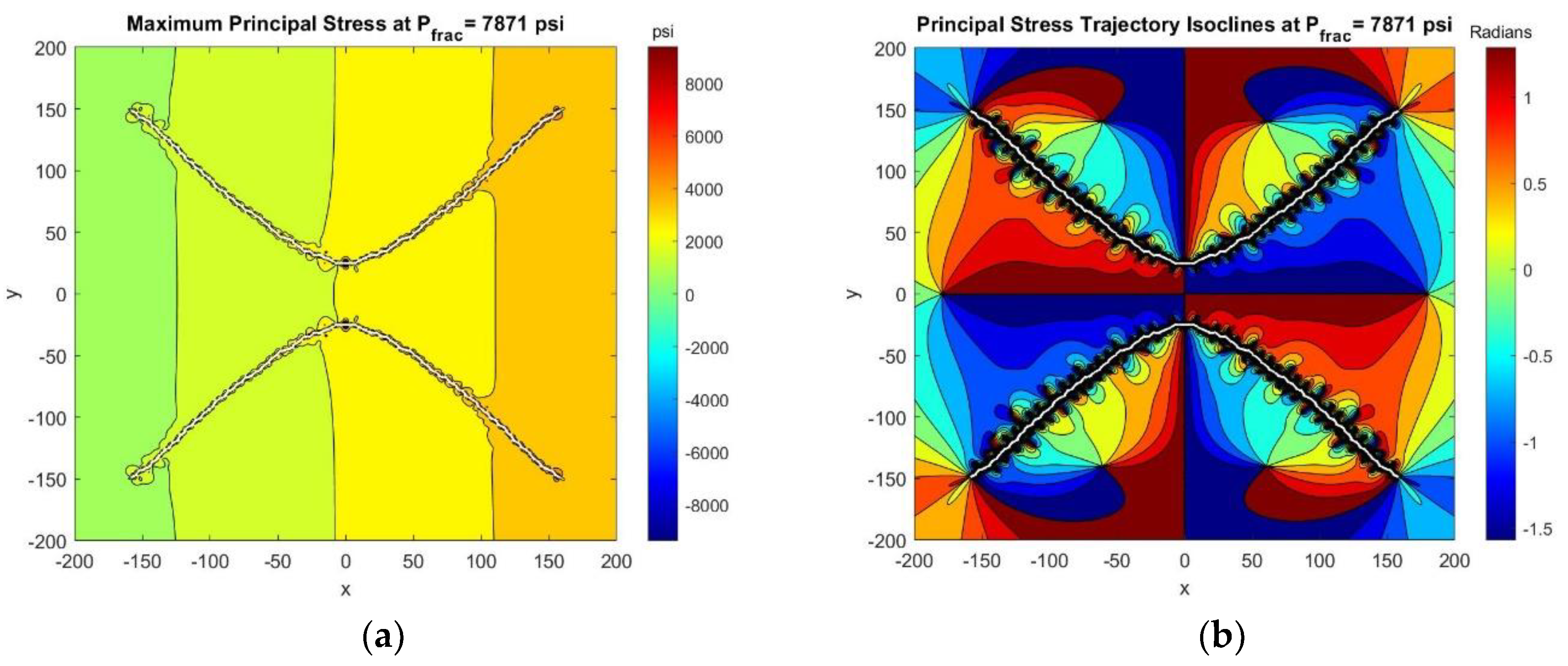

4.5. TLSM DFIT Model Results

4.6. Sub-Conclusions

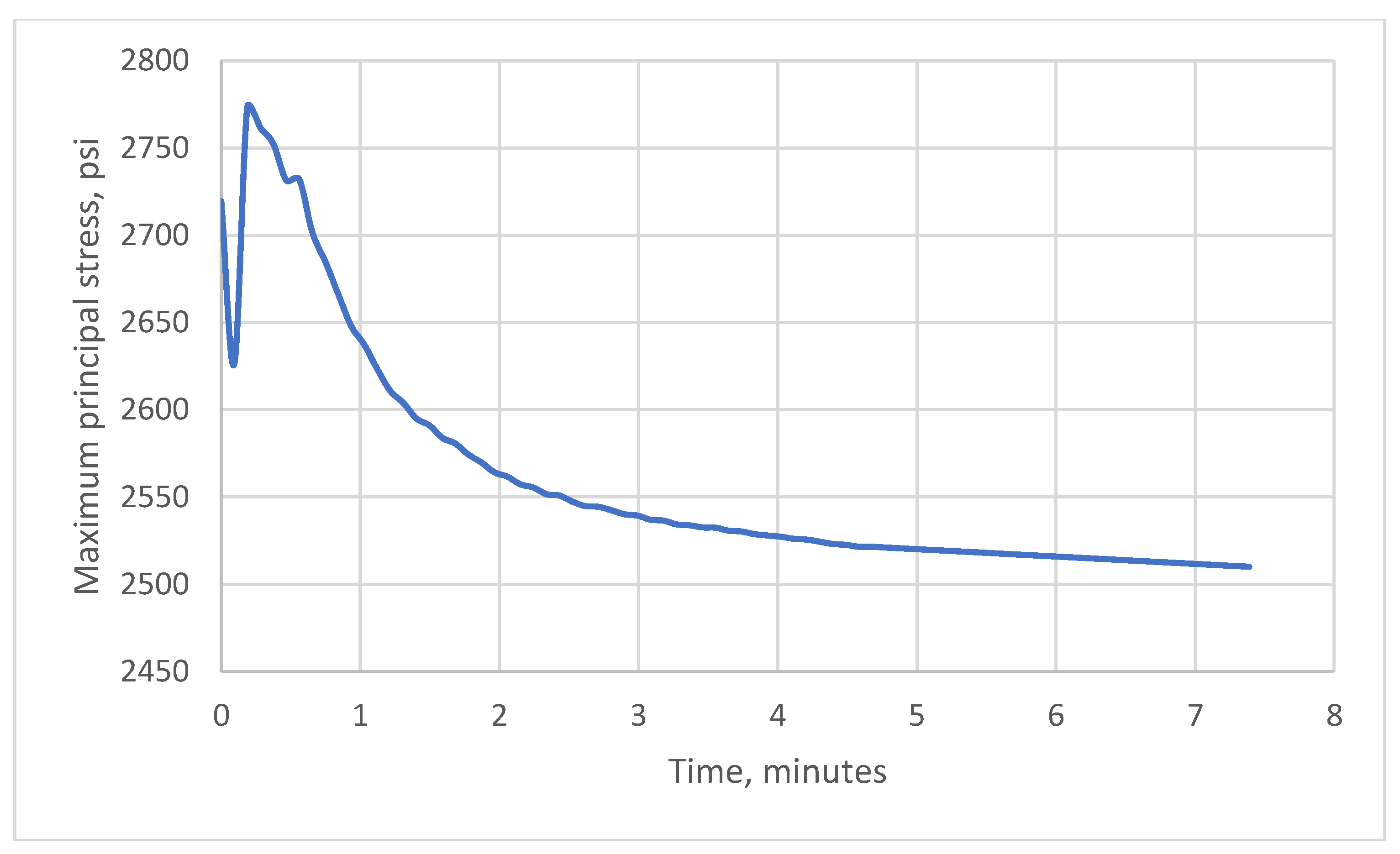

- The maximum principal stress at (x,y) = (0,0) during injection increases dramatically as the fracture propagates, exponentially drops, and steadies on a plateau value as the fracture closes, while injection pressure remained constant (Figure 9).

- Hence, the variation in maximum principal stress is primarily caused by the changes in fracture geometry as the fracture propagates, rather than by changes in injection pressure.

5. TLSM Results with Imposed Pore Pressure Gradient

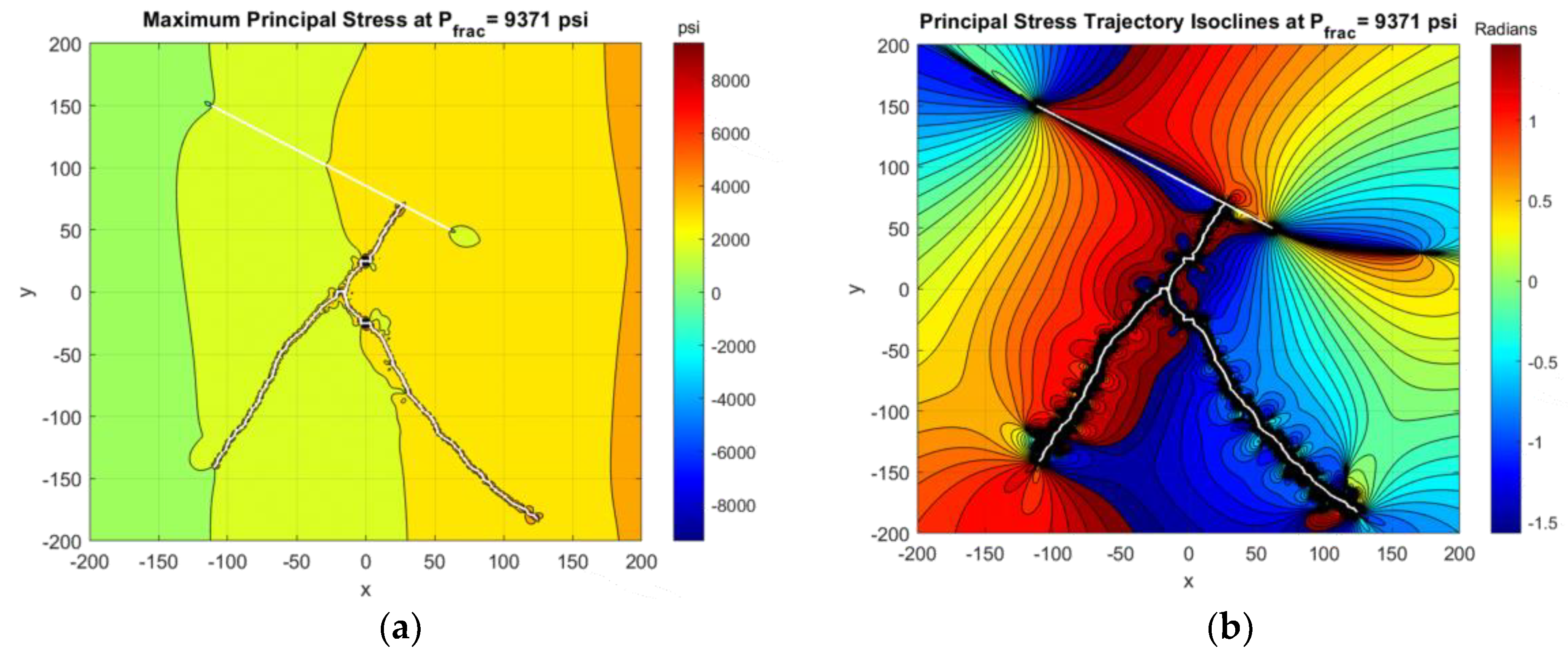

5.1. Hydraulic Fracture Propagation—Pre-Existing Pore Pressure Gradient

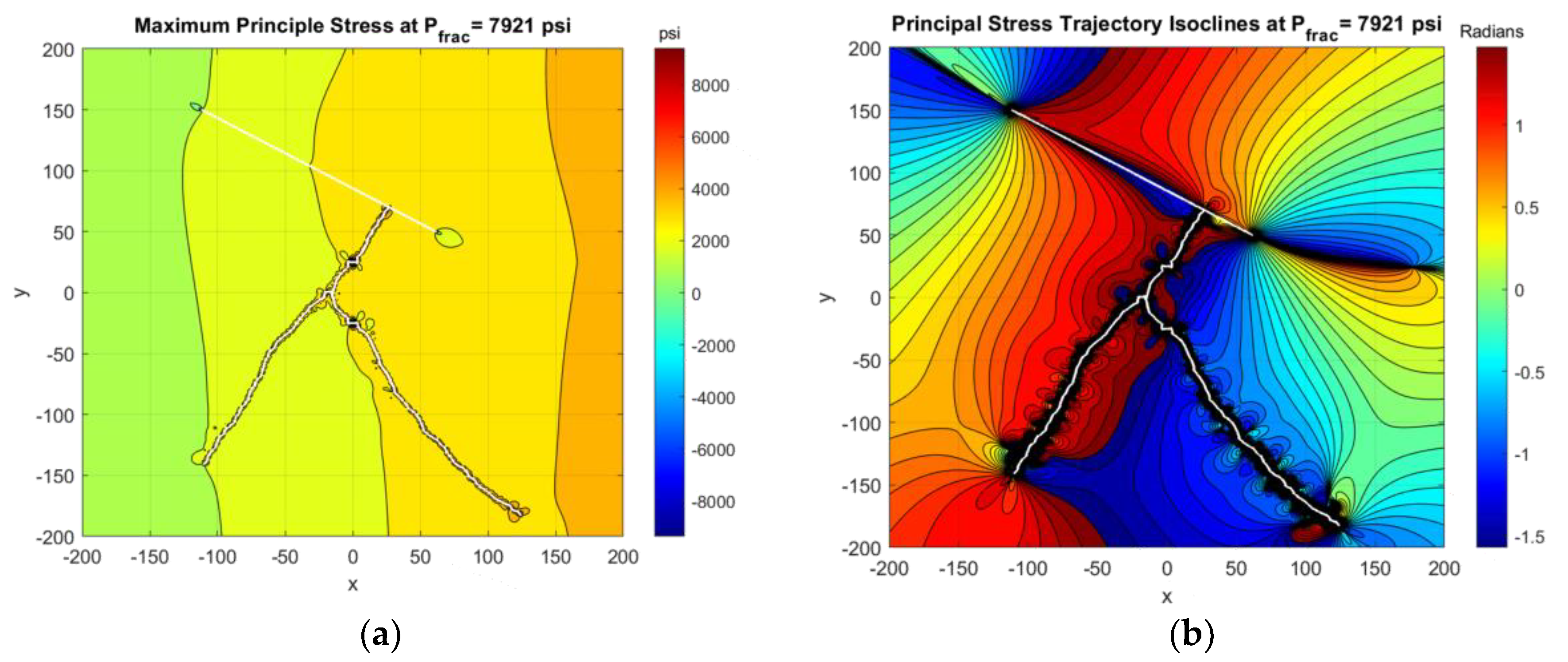

5.2. Hydraulic Fracture Propagation—Uniform Pressure Gradient and a Pre-Existing Near-Field Stress

5.3. Sub-Conclusions

- The spatial variation of pore pressure does not affect the fracture propagation direction (Figure 13).

- Changes in stress state are concentrated in areas closest to the hydraulic fractures.

- The superposition of a near-field stress, in this case a pressurized natural fracture, causes stress reversals, as well as the reorientation of what previously would be symmetric hydraulic fracture patterns.

6. Discussion

6.1. Pore Pressure and Principal Stress Reorientation

6.2. Strengths and Weaknesses

6.3. Future Work

7. Conclusions

- Principal stress trajectories were not affected by the regional pore pressure variations (Figure 4b).

- However, pore pressure changes have a direct relationship with principal stress magnitudes—as pore pressure increases, the principal stress magnitudes will increase (Figure 4a)

- Induced changes in the principal stress magnitudes were equal to the pore pressure multiplied by the Biot’s constant.

- The maximum principal stress at (x,y) = (0,0) during injection increases dramatically as the fracture propagates, and the principal stress magnitude exponentially first drops, and then plateaus as the fracture closes, while injection pressure remained constant (Figure 9).

- Hence, the variations in the maximum principal stress are primarily caused by the changes in fracture geometry as the fracture propagates, rather than changes in injection pressure.

- Changes in stress state are concentrated in areas closest to the hydraulic fractures (Figure 13).

- The superposition of a near-field stress, in this case a pressurized natural fracture, caused stress reversals, as well as the reorientation of what previously would be symmetric hydraulic fracture patterns (Figure 15).

- For all cases, pore pressure effects related to Type B well interventions do not seem to be a primary driver of stress reorientation in the reservoir.

- Instead of pore pressure, the stress reorientation in the reservoir can be attributed to a change in imposed near-field stresses related to Type A well interventions.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Masouleh, S.F.; Kumar, D.; Ghassemi, A. Three-Dimensional Geomechanical Modeling and Analysis of Refracturing and “Frac-Hits” in Unconventional Reservoirs. Energies 2020, 13, 5352. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, J.; Yu, W.; Sepehrnoori, K. Investigation of Lateral Fracture Complexity to Mitigate Frac Hits During Interwell Fracturing. In Proceedings of the 8th Unconventional Resources Technology Conference Virtual, Austin, TX, USA, 20–22 July 2020. [Google Scholar]

- Ciezobka, J.; Courtier, J.; Wicker, J. Hydraulic Fracturing Test Site (HFTS)—Project Overview and Summary of Results. In Proceedings of the 6th Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar]

- Raterman, K.; Farrell, H.; Mora, O.; Janssen, A.; Gomez, G.; Busetti, S.; Warren, M. Sampling a stimulated rock volume: An eagle ford example. In Proceedings of the 6th Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2018. [Google Scholar]

- Raterman, K.; Liu, Y.; Warren, L. Analysis of a Drained Rock Volume: An Eagle Ford Example. In Proceedings of the 7th Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019. [Google Scholar]

- Stegent, N.; Candler, C. Downhole Microseismic Mapping of More Than 400 Fracturing Stages on a Multiwell Pad at the Hydraulic Fracturing Test Site (HFTS): Discussion of Operational Challenges and Analytic Results. In Proceedings of the 6th Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar]

- Stegent, N.; Dusterhoft, R.; Menon, H. Insight into Hydraulic Fracture Geometries Using Fracture Modeling Honoring Field Data Measurements and Post-Fracture Production. In Proceedings of the SPE Europec Featured at 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019. [Google Scholar]

- Weijermars, R.; Pham, T.; Stegent, N.; Dusterhoft, R. Hydraulic fracture propagation paths modeled using time-stepped linear superposition method (TSLM): Application to fracture treatment stages with interacting hydraulic and natural fractures at the Wolfcamp Field Test Site (HFTS). In Proceedings of the 54th US Rock Mechanics/Geomechanics Virtual, Golden, CO, USA, 28 June–1 July 2020. [Google Scholar]

- Sesetty, V.; Ghassemi, A. Simulation and analysis of fracture swarms observed in the Eagle Ford Field experiment. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019. [Google Scholar]

- Weijers, L.; Pater, C.J. Fracture Reorientation in Model Tests. In Proceedings of the SPE Formation Damage Control Symposium, Lafayette, LA, USA, 26–27 February 1992. [Google Scholar]

- Wright, C.A. Reorientation of Propped Refracture Treatments in the Lost Hills Field. In Proceedings of the SPE Western Regional Meeting, Long Beach, CA, USA, 23–25 March 1994. [Google Scholar]

- Bruno, M.S.; Nakagawa, F.M. Pore Pressure Influence on Tensile Fracture Propagation in Sedimentary Rock. Int. J. Rock Mech. 1991, 28, 251–273. [Google Scholar] [CrossRef]

- Agrawal, S.; Sharma, M.M. Impact of Pore Pressure Depletion on Stress Reorientation and Its Implications on the Growth of Child Well Fractures. In Proceedings of the 6th Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar]

- Wright, C.A.; Conant, R.A. Hydraulic Fracture Reorientation in Primary and Secondary Recovery from Low-Permeability Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 1995. [Google Scholar]

- Pham, T.; Weijermars, R. Solving Stress Tensor Fields around Multiple Pressure-Loaded Fractures using a Linear Superposition Method (LSM). Appl. Math. Model. 2020, 88, 418–436. [Google Scholar] [CrossRef]

- Pham, T.; Weijermars, R. Development of Hydraulic Fracture Hits and Fracture Redirection Visualized for Consecutive Fracture Stages with Fast Time-stepped Linear Superposition Method (TLSM). In Proceedings of the Unconventional Resources Technology Conference Virtual, Golden, CO, USA, 20–22 July 2020. [Google Scholar]

- Weijermars, R.; Wang, J.; Pham, T. Borehole Failure Mechanisms in Naturally and Hydraulically Fractured Formations Investigated with a Fast Time-stepped Linear Superposition Method (TLSM). In Proceedings of the 54th US Rock Mechanics/Geomechanics Symposium Virtual, Austin, TX, USA, 28 June–1 July 2020. [Google Scholar]

- Zhai, Z.; Sharma, M.M. Estimating Fracture Reorientation due to Long Term Fluid Injection/Production. In Proceedings of the Production and Operations Symposium, Oklahoma City, OK, USA, 31 March–3 April 2007. [Google Scholar]

- Elbel, J.L.; Mack, M.G. Refracturing: Observations and Theories. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, OK, USA, 21–23 March 1993. [Google Scholar]

- Weijermars, R.; Zhang, X.; Schultz-Ela, D. Geomechanics of fracture caging in wellbores. Geo. J. Int. 2013, 193, 1119–1132. [Google Scholar] [CrossRef]

- Weijermars, R. Stress Cages and Fracture Cages in Stress Trajectory Models of Wellbores: Implications for Pressure Management During Drilling and Hydraulic Fracturing. J. Nat. Gas Sci. Eng. 2016, 36, 986–1003. [Google Scholar] [CrossRef]

- Thomas, N.; Weijermars, R. Comprehensive Atlas of Stress Trajectory Patterns and Stress Magnitudes Around Cylindrical Holes in Rock Bodies for Geoscientific and Geotechnical Applications. Earth Sci. Rev. 2018, 179, 303–371. [Google Scholar] [CrossRef]

- Weijermars, R.; Wang, J.; Nelson, R. Stress concentrations and failure modes in horizontal wells accounting for elastic anisotropy of shale formations. Earth Sci. Rev. 2020, 200, 102957. [Google Scholar] [CrossRef]

- Gao, Q.; Ghassemi, A. Pore Pressure and Stress Distributions Around a Hydraulic Fracture in Heterogeneous Rock. Rock Mech. Rock Eng. 2017, 50, 3157–3173. [Google Scholar] [CrossRef]

- Hidayati, D.T.; Chen, H.Y.; Teufel, L.W. Flow-Induced Stress Reorientation in a Multiple-Well Reservoir. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference, Keystone, CO, USA, 21–23 May 2001. [Google Scholar]

- Weijermars, R.; Pham, T.; Ettehad, M. Linear Superposition Method (LSM) for Solving Stress Tensor Fields and Displacement Vector Fields: Application to Multiple Pressure-Loaded Circular Holes in an Elastic Plate with Far-Field Stress. Appl. Math. Comput. 2020, 381, 125234. [Google Scholar] [CrossRef]

- Zhuang, Z.; Liu, Z.; Cheng, B.; Liao, J. Extended Finite Element Method; Computational Mechanics Series; Tsinghua University Press: Beijing, China, 2014. [Google Scholar]

- Wallace, J.; Kabir, C.S.; Cipolla, C. Multiphysics Investigation of Diagnostic Fracture Injection Tests in Unconventional Reservoirs. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2014. [Google Scholar]

- Barree, R.D.; Miskimins, J.L.; Gilbert, J.V. Diagnostic Fracture Injection Tests: Common Mistakes Misfires, and Misdiagnoses. In Proceedings of the SPE Western North American and Rocky Mountain Join Regional Meeting, Denver, CO, USA, 16–18 April 2014. [Google Scholar]

- Hawkes, R.V.; Bachman, R.; Nicholson, K.; Cramer, D.D.; Chipperfield, S.T. Good Tests Cost Money, Bad Tests Cost More—A Critical Review of DFIT and Analysis Gone Wrong. In Proceedings of the SPE International Hydraulic Fracturing Technology Conference and Exhibition, Muscat, Oman, 16–18 October 2018. [Google Scholar]

- Zheng, S.; Manchanda, R.; Wang, H.; Sharma, M. DFIT Analysis and Interpretation in Layered Rocks. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar]

- Nolte, K.G.; Maniere, J.L.; Owens, K.A. After-Closure Analysis of Fracture Calibration Tests. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar]

- Wang, H.; Sharma, M.M. Estimating Unpropped Fracture Conductivity and Compliance from Diagnostic Fracture Injection Tests. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018. [Google Scholar]

- Zheng, S.; Manchanda, R.; Wang, H.; Sharma, M. Fully 3-D Simulation of Diagnostic Fracture Injection Tests with Application in Depleted Reservoirs. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019. [Google Scholar]

- Zanganeh, B.; MacKay, M.K.; Clarkson, C.R.; Jones, J.R. DFIT Analysis in Low Leakoff Formations: A Duvernay Case Study. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 13–14 March 2018. [Google Scholar]

- Kamali, A.; Ghassemi, A. DFIT Considering Complex Interactions of Hydraulic and Natural Fractures. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019. [Google Scholar]

- Prabhakaran, R.; Pater, H.; Shaoul, J. Pore Pressure Effects on Fracture Net Pressure and Hydraulic Fracture Containment: Insights from an Empirical and Simulation Approach. J. Pet. Sci. Eng. 2017, 157, 724–736. [Google Scholar] [CrossRef]

- Morales, R.H. An Interesting Look at Multiple Fractures: Stress Shadowing and Propagation. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar]

- Harmelen, A.; Weijermars, R. Complex analytical solutions for flow in hydraulically fractured hydrocarbon reservoirs with and without natural fractures. App. Math. Model. 2018, 56, 137–157. [Google Scholar] [CrossRef]

- Weijermars, R.; Ettehad, M. Displacement field potentials for deformation in elastic media: Theory and application to pressure-loaded boreholes. App. Math. Comput. 2019, 340, 276–295. [Google Scholar] [CrossRef]

| Property | Value | Unit |

|---|---|---|

| Fracture propagation pressure | 9371 | psi |

| Fracture half-length | 5 | ft |

| Bulk Poisson’s ratio, v | 0.3 | |

| Bulk Young’s modulus, E | 5.6 E6 | psi |

| Biot’s constant, α | 0.9 | |

| Fracture spacing | 40 | ft |

| Assumed TVD | 7398 | ft |

| Pore pressure gradient | 0.6 | psi/ft |

| Calculated pore pressure | 4439 | psi |

| Physical Quantity | No Pore Pressure (Pp = 0) | Elevated Pore Pressure (Pp = 4439) | Stress Difference | Unit of Measure |

|---|---|---|---|---|

| σ1 | 1631 | 5626 | 3995 | psi |

| σ2 | −508 | 3487 | 3995 | psi |

| Physical Quantity | No Pore Pressure (Pp = 0) | Elevated Pore Pressure (Pp = 4439) | Stress Difference | Unit of Measure |

|---|---|---|---|---|

| σ1 | 747 | 4742 | 3995 | psi |

| σ2 | −458 | 3537 | 3995 | psi |

| Physical Quantity | Stress at (x,y) = (−20, 20) | Stress at (x,y) = (20, 20) | Stress or Pore Pressure Difference | Unit of Measure |

|---|---|---|---|---|

| σ1 | 1660 | 2898 | 1238 | psi |

| σ2 | 1452 | 2690 | 1238 | psi |

| PP | 2032 | 3407 | 1375 | psi |

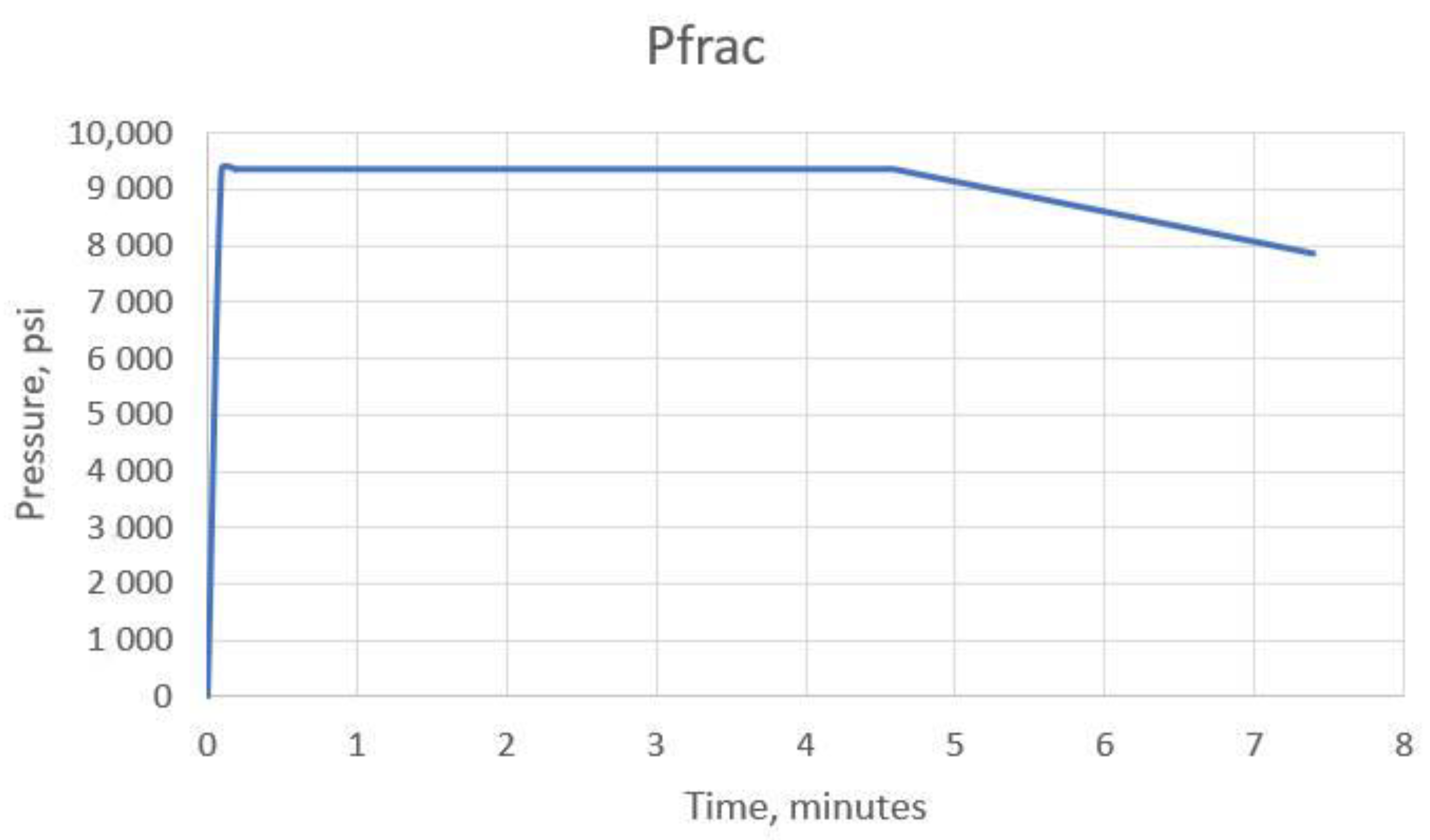

| Property | Value | Unit |

|---|---|---|

| Propagation Pressure | 9371 | psi |

| Fracture reopen/propagation start time | 0 | hours |

| Time at injection end | 0.076389 | hours |

| Duration of injection | 4.58334 | minutes |

| Time at leak-off end of model | 7.38946 | minutes |

| Pressure at leak-off end of model | 7871 | psi |

| Property | Value | Unit |

|---|---|---|

| Injection Rate | 6 | bbl/min |

| 0.561 | ft3/s | |

| Fracture length | 4 | ft |

| Fracture width | 0.5 | ft |

| Fracture volume, V = π(w/2)2 L | 0.785398163 | ft3 |

| Injection duration | 275.0004 | Seconds |

| Total injection volume | 154.2752244 | ft3 |

| Number of fractures | 196 | |

| Propagation pressure | 9370.83 | psi |

| Fracture spacing | 50 | ft |

| Fracture positions | (0, 25) (0, −25) | ft |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, T.; Weijermars, R. Hydraulic Fracture Propagation in a Poro-Elastic Medium with Time-Dependent Injection Schedule Using the Time-Stepped Linear Superposition Method (TLSM). Energies 2020, 13, 6474. https://doi.org/10.3390/en13246474

Pham T, Weijermars R. Hydraulic Fracture Propagation in a Poro-Elastic Medium with Time-Dependent Injection Schedule Using the Time-Stepped Linear Superposition Method (TLSM). Energies. 2020; 13(24):6474. https://doi.org/10.3390/en13246474

Chicago/Turabian StylePham, Tri, and Ruud Weijermars. 2020. "Hydraulic Fracture Propagation in a Poro-Elastic Medium with Time-Dependent Injection Schedule Using the Time-Stepped Linear Superposition Method (TLSM)" Energies 13, no. 24: 6474. https://doi.org/10.3390/en13246474

APA StylePham, T., & Weijermars, R. (2020). Hydraulic Fracture Propagation in a Poro-Elastic Medium with Time-Dependent Injection Schedule Using the Time-Stepped Linear Superposition Method (TLSM). Energies, 13(24), 6474. https://doi.org/10.3390/en13246474