Demand-Based Control Design for Efficient Heat Pump Operation of Electric Vehicles

Abstract

1. Introduction

1.1. Background and Problem

1.2. Previous Research in the Field

1.3. Current Study Novelties and Focus

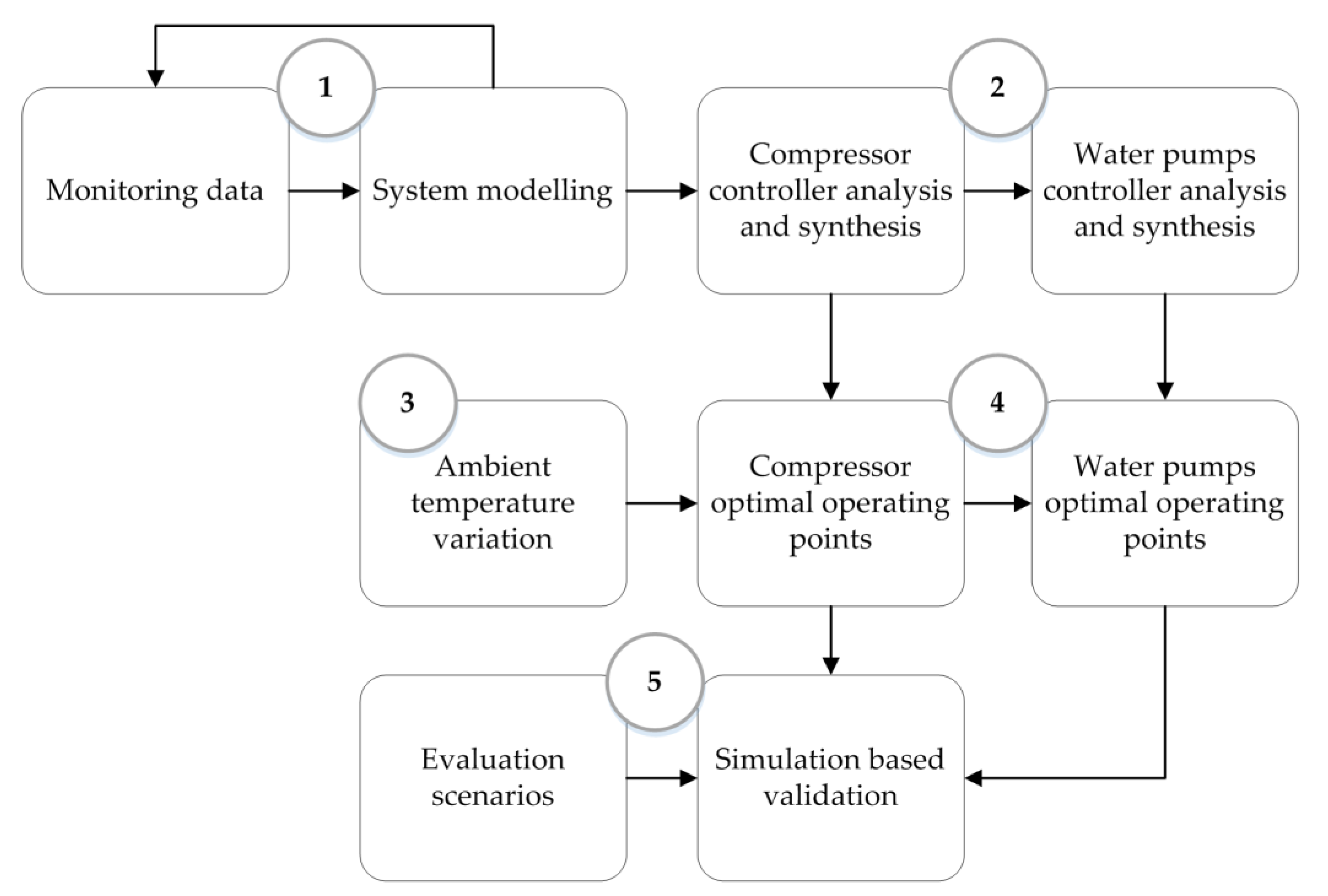

2. Methodology

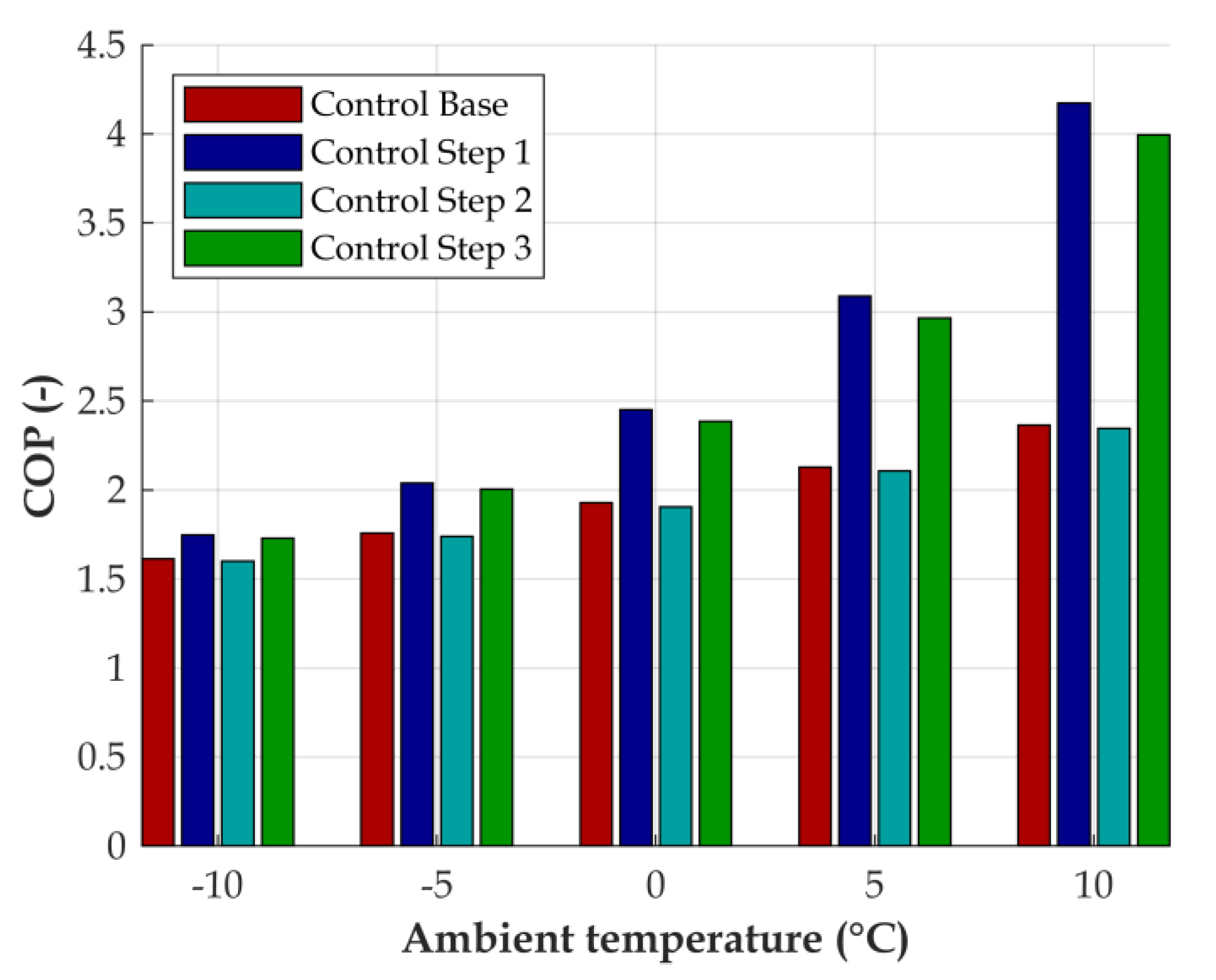

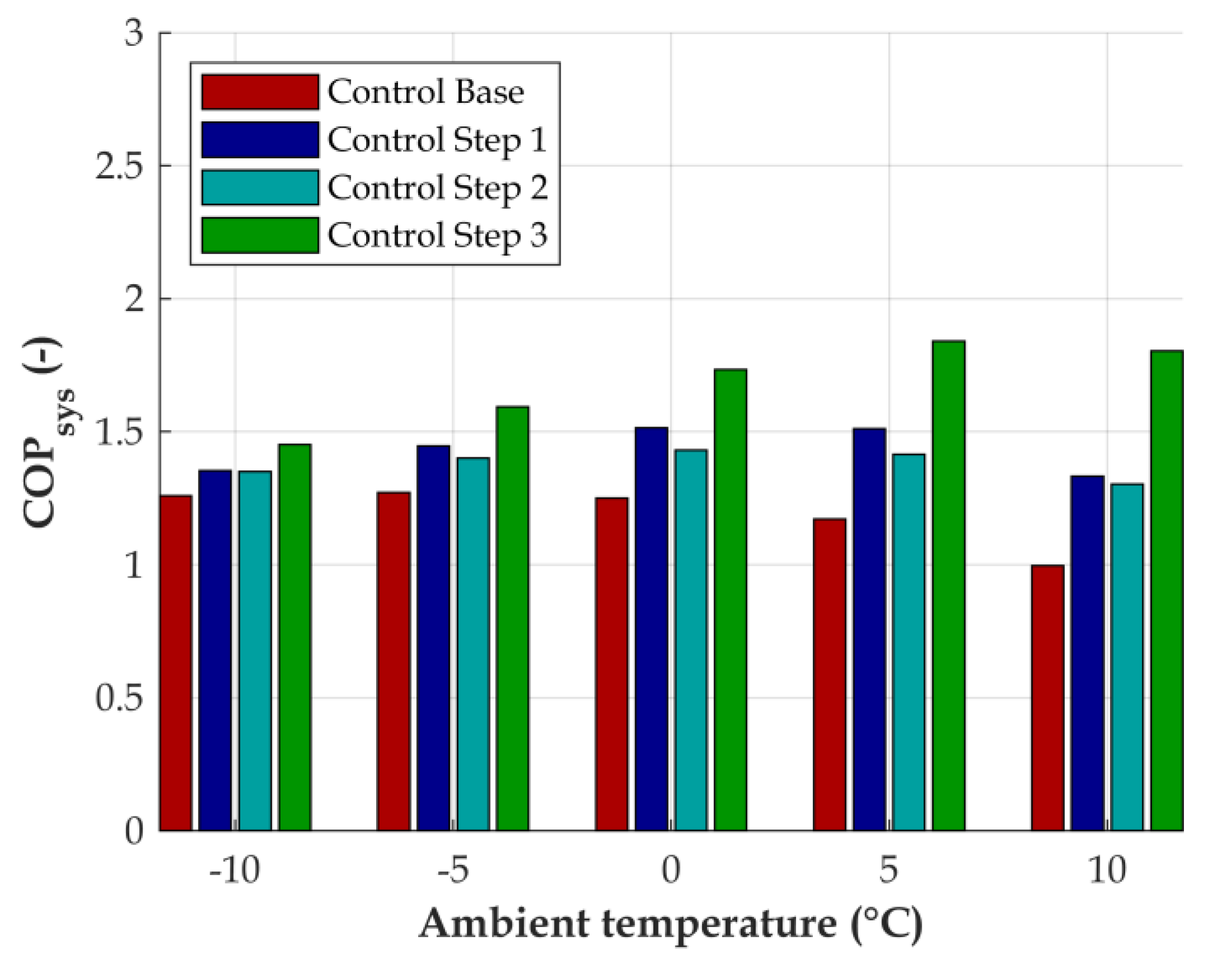

- Reference scenario (Control Base),

- 1st improvement step: load controlled-compressor scenario with demand-dependent air-outlet-temperature setpoint of the HVAC system (Control Step 1),

- 2nd improvement step: load controlled-water-pumps scenario with demand-dependent speed of the water pumps (Control Step 2),

- 3rd improvement step: combination of steps 1 and 2 (Control Step 3).

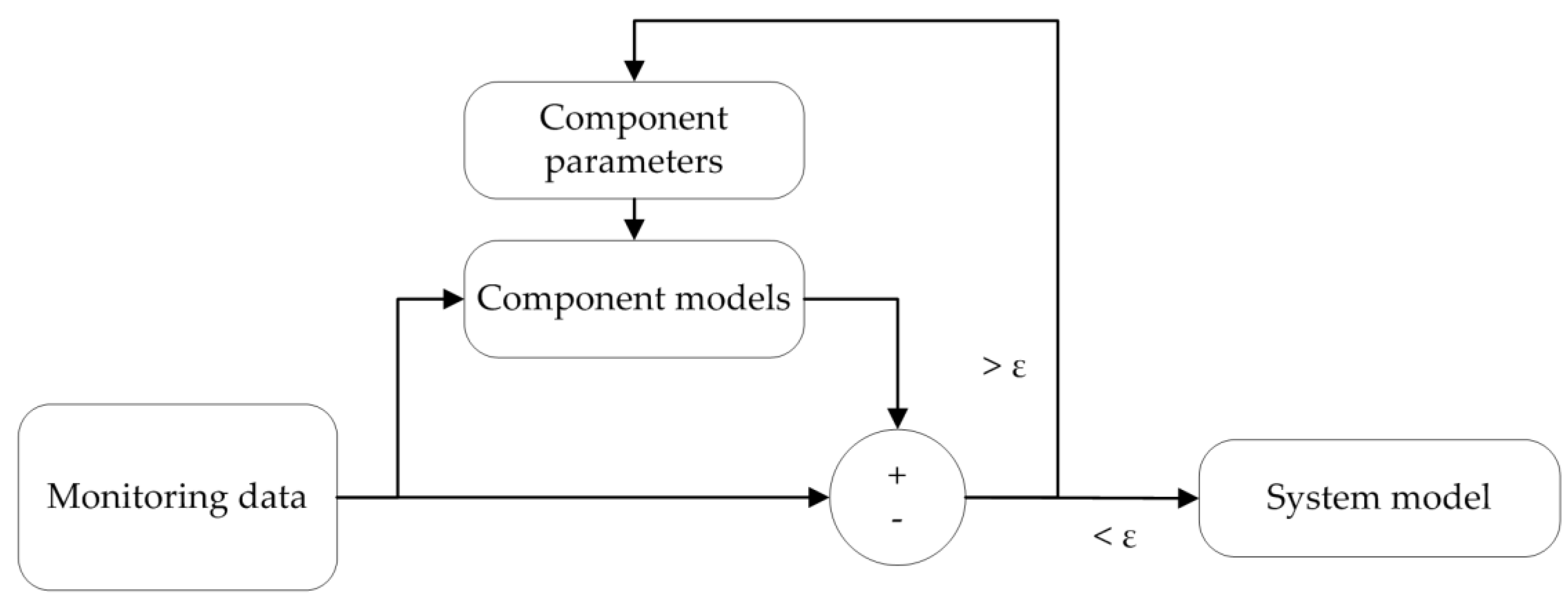

- System identification and modelling in an iterative process: models and measured data from the real-world system have been used for the parametrization;

- HVAC-compressor and water-pumps controller analysis and synthesis: identification of the dynamic characteristics of the system model and definition of an appropriate controller;

- Ambient temperature variation: simulation allows the investigation under various conditions to find the optimal setpoints;

- Determination and extrapolation of the demand-based optimal operating points of the HVAC compressor and the water pumps at various boundary conditions;

- Deployment and validation of the developed component control strategy by quantifying the improvement potentials of the measures.

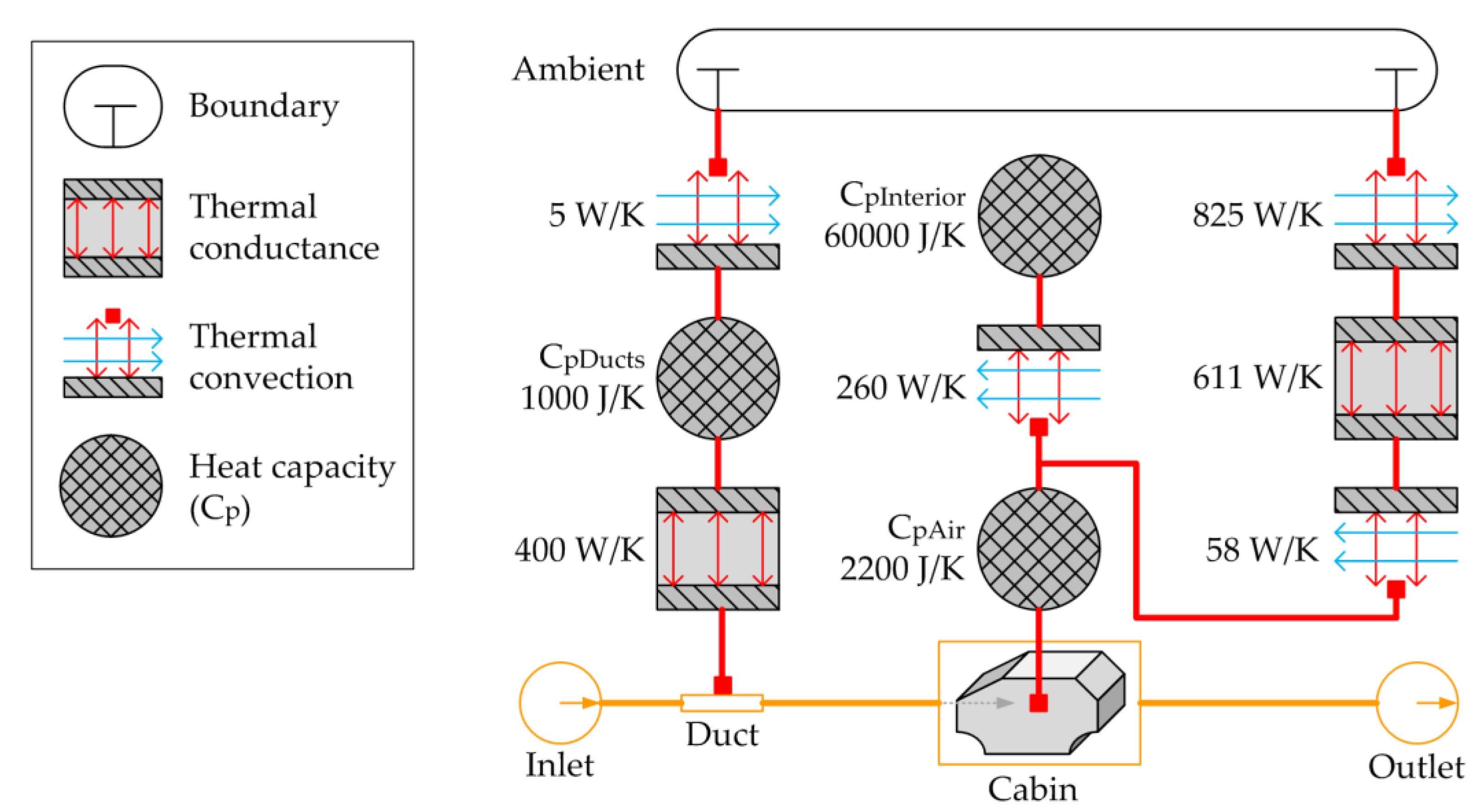

2.1. 1D Thermal Cabin Model

- Qtrans [W], transmission losses through the body of the cabin;

- Qvent [W], ventilation losses through the air leakage of the cabin (depending strongly on the operation mode: fresh air or recirculated air);

- Qrad [W], solar radiation load gain (excluded from the study to reduce the complexity otherwise introduced by a large number of combinations between ambient temperature and solar radiation conditions);

- Qmet [W], metabolic load from the passengers (excluded from the study for the same reason of the solar radiation).

- kcab [W/K.m²], overall heat-loss coefficient of the cabin;

- Acab [m²], overall external area of the cabin;

- Tcab [K], average cabin temperature;

- Tamb [K], ambient temperature;

- min [kg/s], volume flow of the fresh air into the cabin;

- cpAir [J/kg.K], thermal capacity of the air;

- Tvent [K], exhaust air temperature through the air leakages of the cabin.

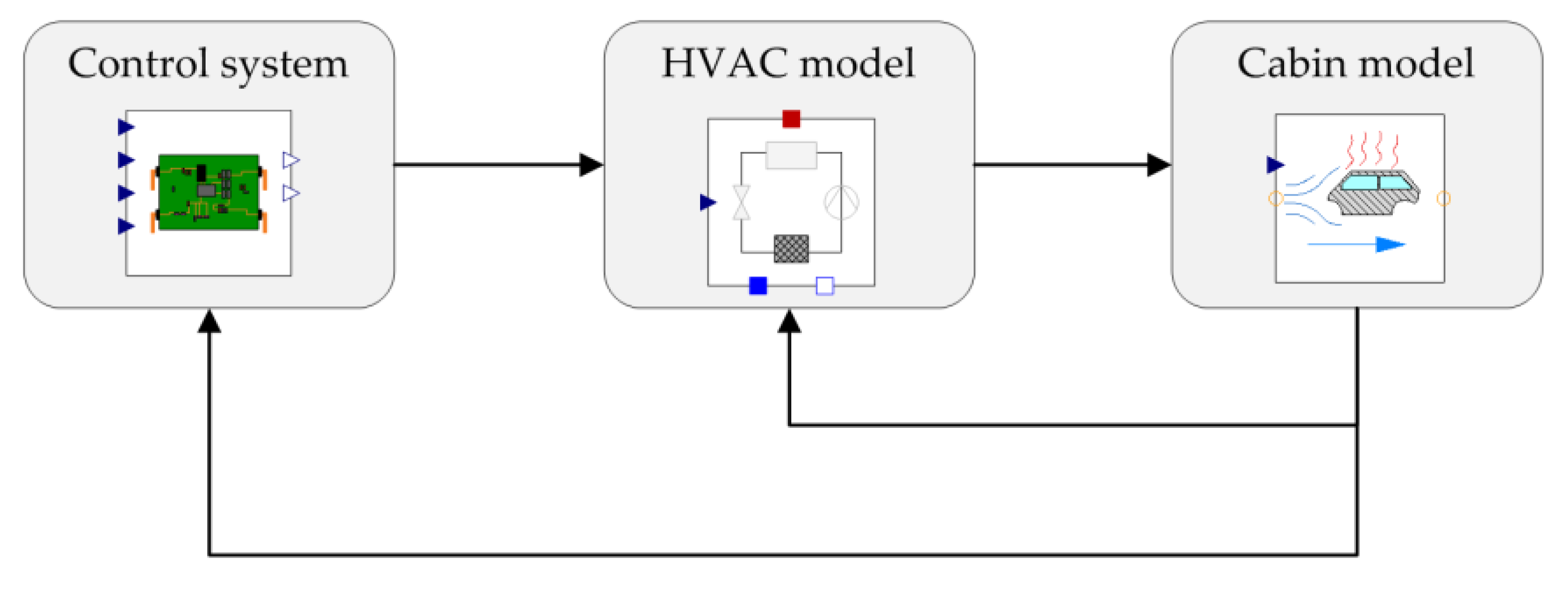

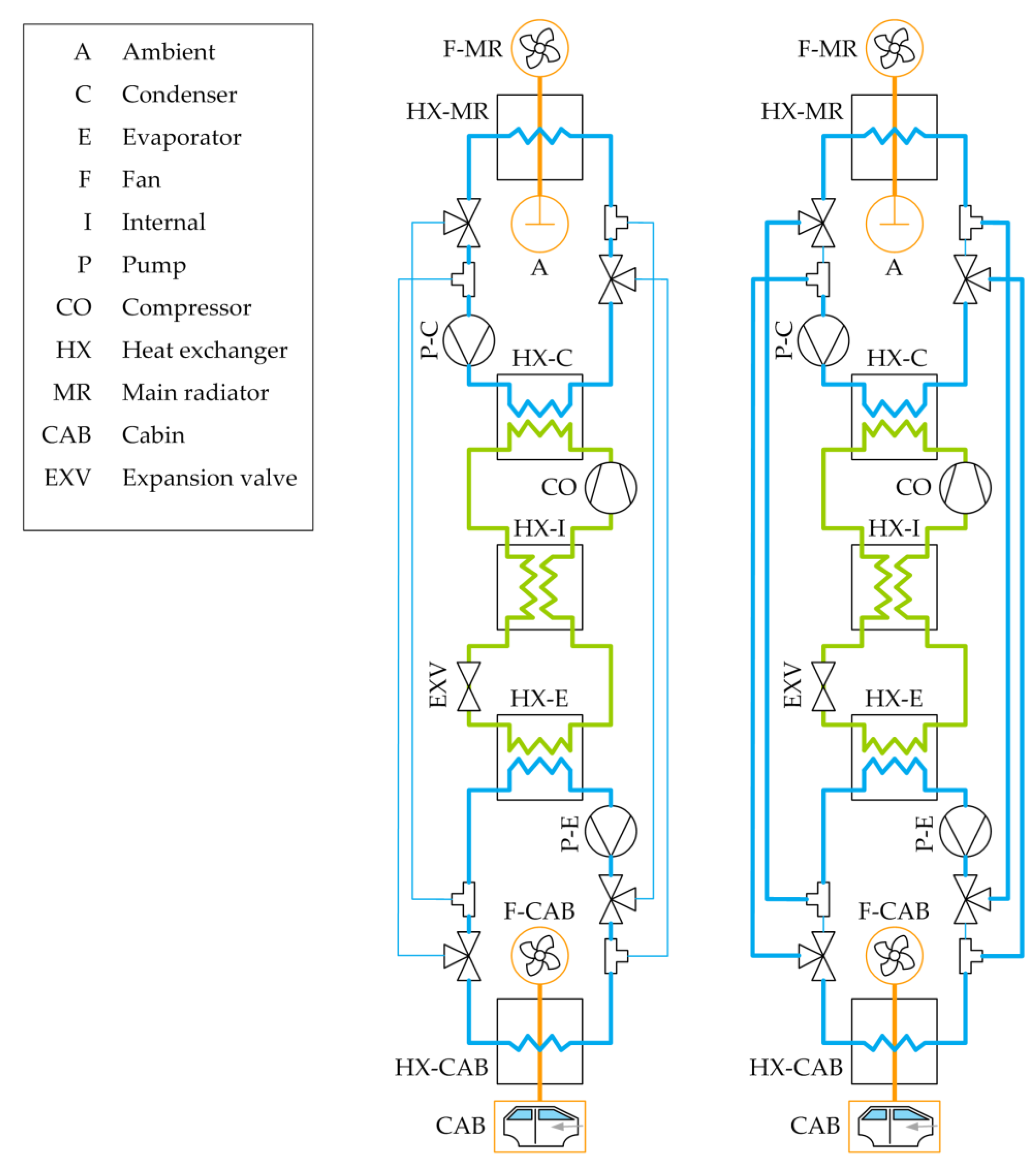

2.2. HVAC System and Control System

- Electrical power consumption PelectricalSys [W], as the electrical energy demand of the entire HVAC system (consisting of compressor, water pumps and cabin fan);

- Average cabin temperature;

- Coefficient of performance (COP and COPsys), related to the heating mode and determined as:

- Qcondenser [W], thermal energy output of the condenser on the refrigerant side;

- Pelectrical [W], the electrical energy of the compressor.

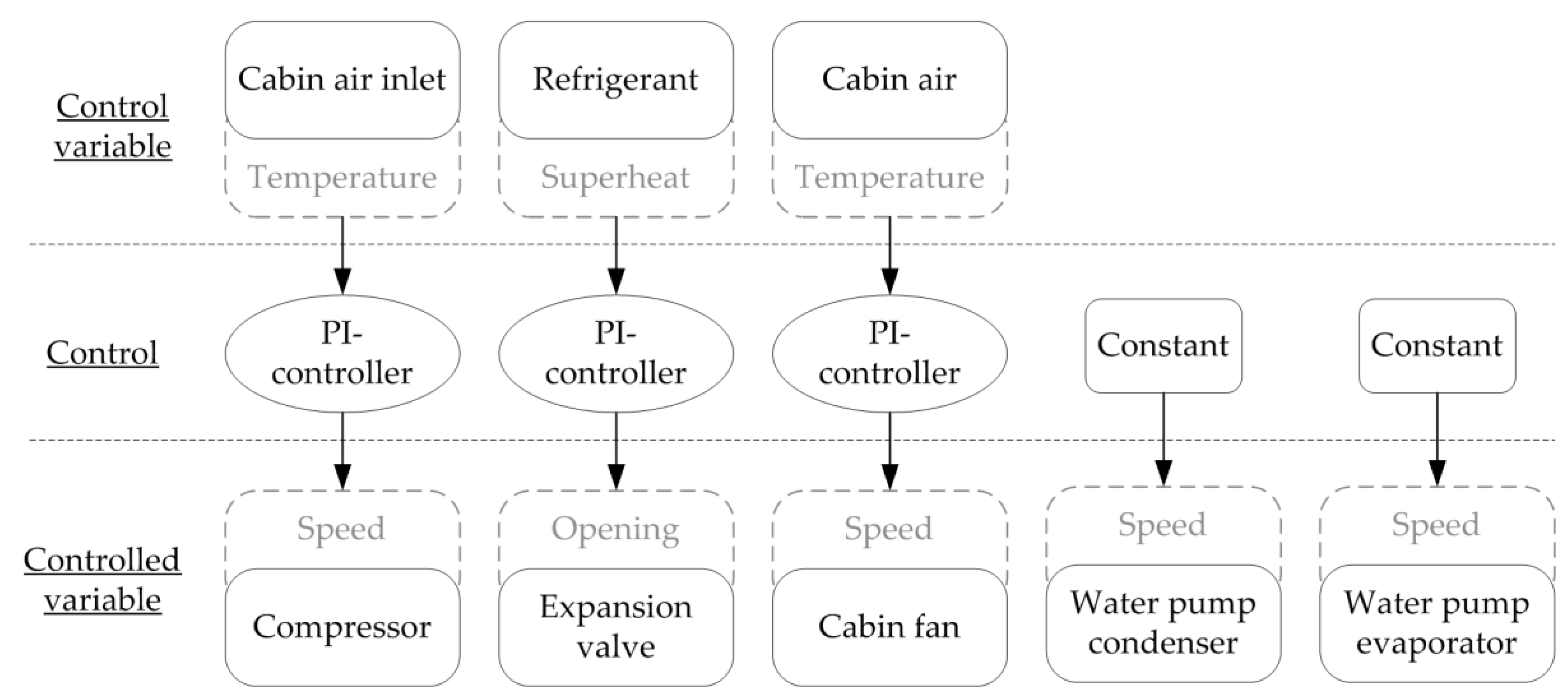

- Compressor: a PI (proportional-integral) controller controls the compressor speed to keep the target air temperature to be supplied by the HVAC system (TinTarget) at a constant value of 70 °C;

- Expansion valve (EXV): a PI controller ensures that no liquid refrigerant is sucked into the compressor by keeping the superheat temperature (Tsh) of the refrigerant after the evaporator at 5 K;

- Cabin fan: a PI controller regulates the air mass flow of the cabin fan via the fan voltage to keep the cabin temperature (Tcab) at a specific target value, which was considered 22 °C in the study;

- Water pumps (condenser and evaporator): constant pump speed on the condenser and evaporator side were set corresponding to the design point at −10 °C.

2.3. Models Parametrization

2.4. Demand-Based Control Design

- Control Step 1: compressor,

- Control Step 2: water pump on condenser side, water pump on evaporator side,

- Control Step 3: combination of all measures.

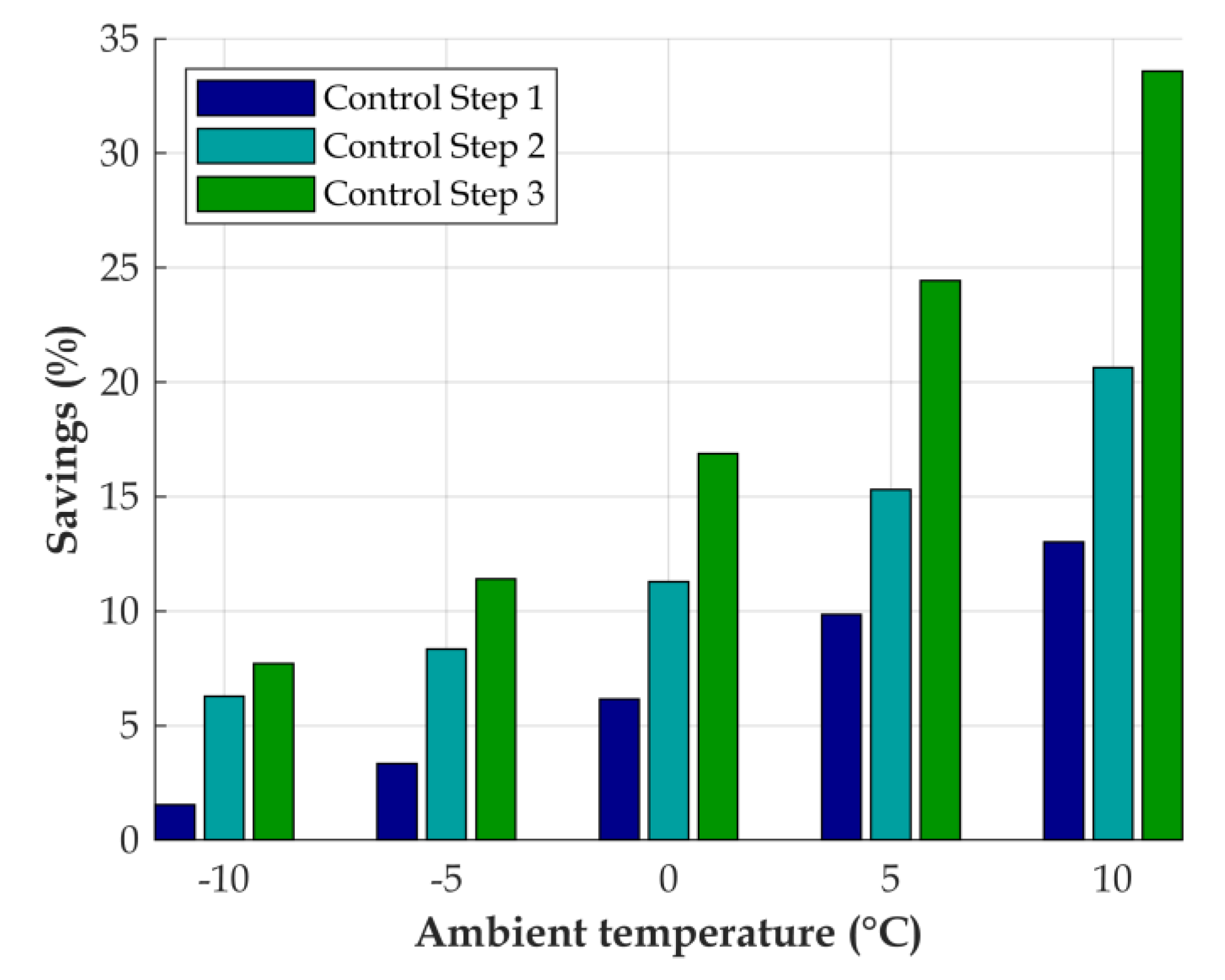

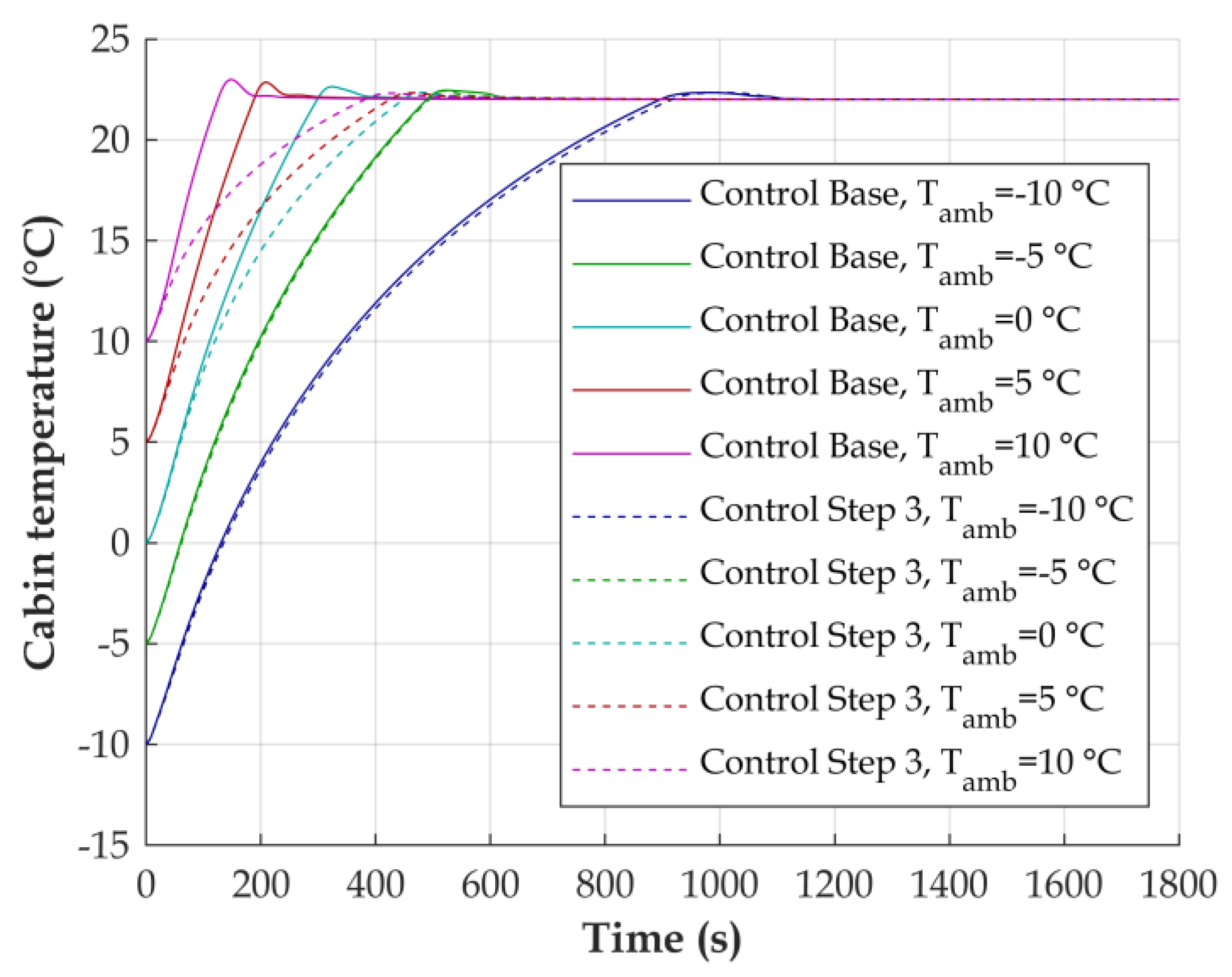

3. Results

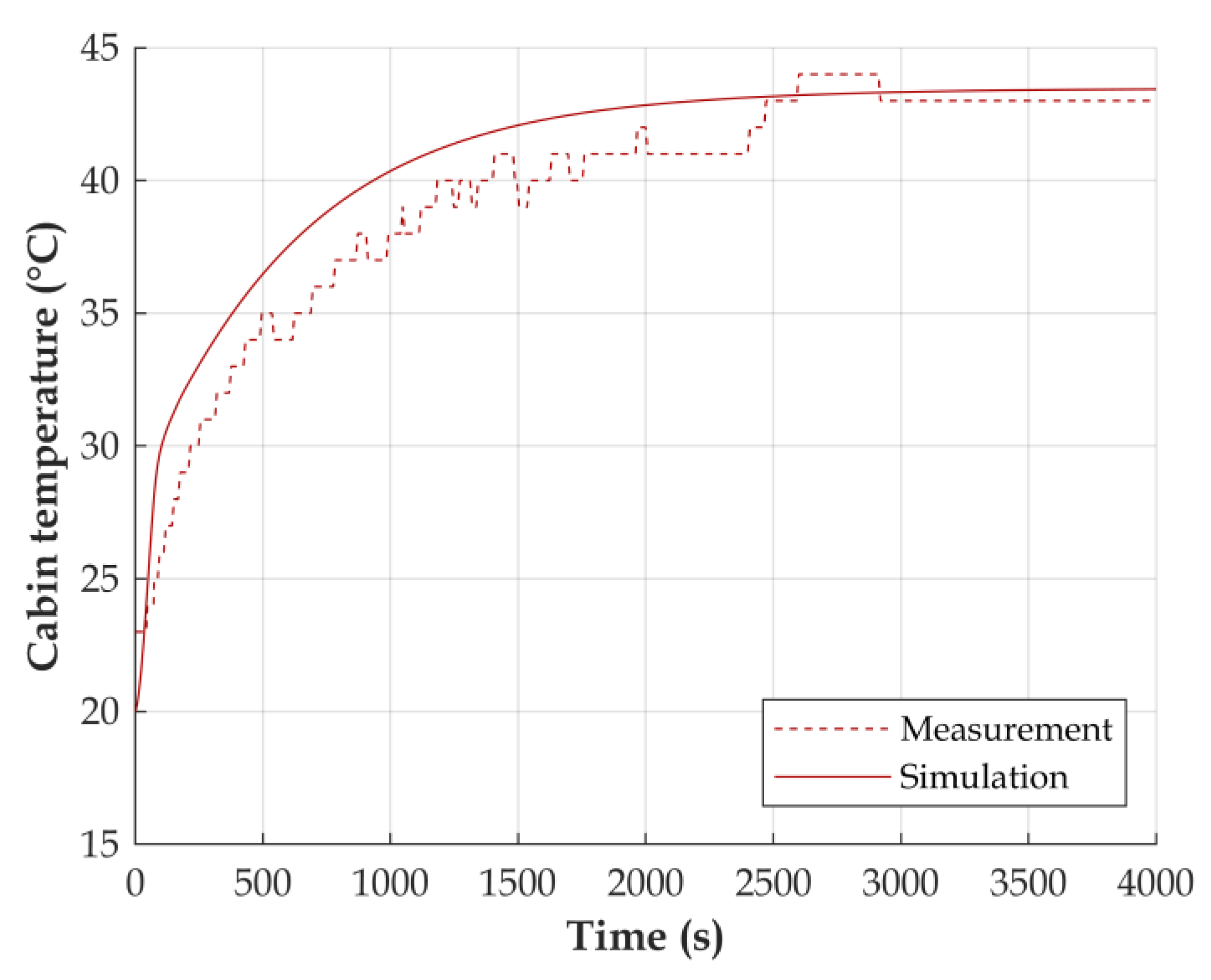

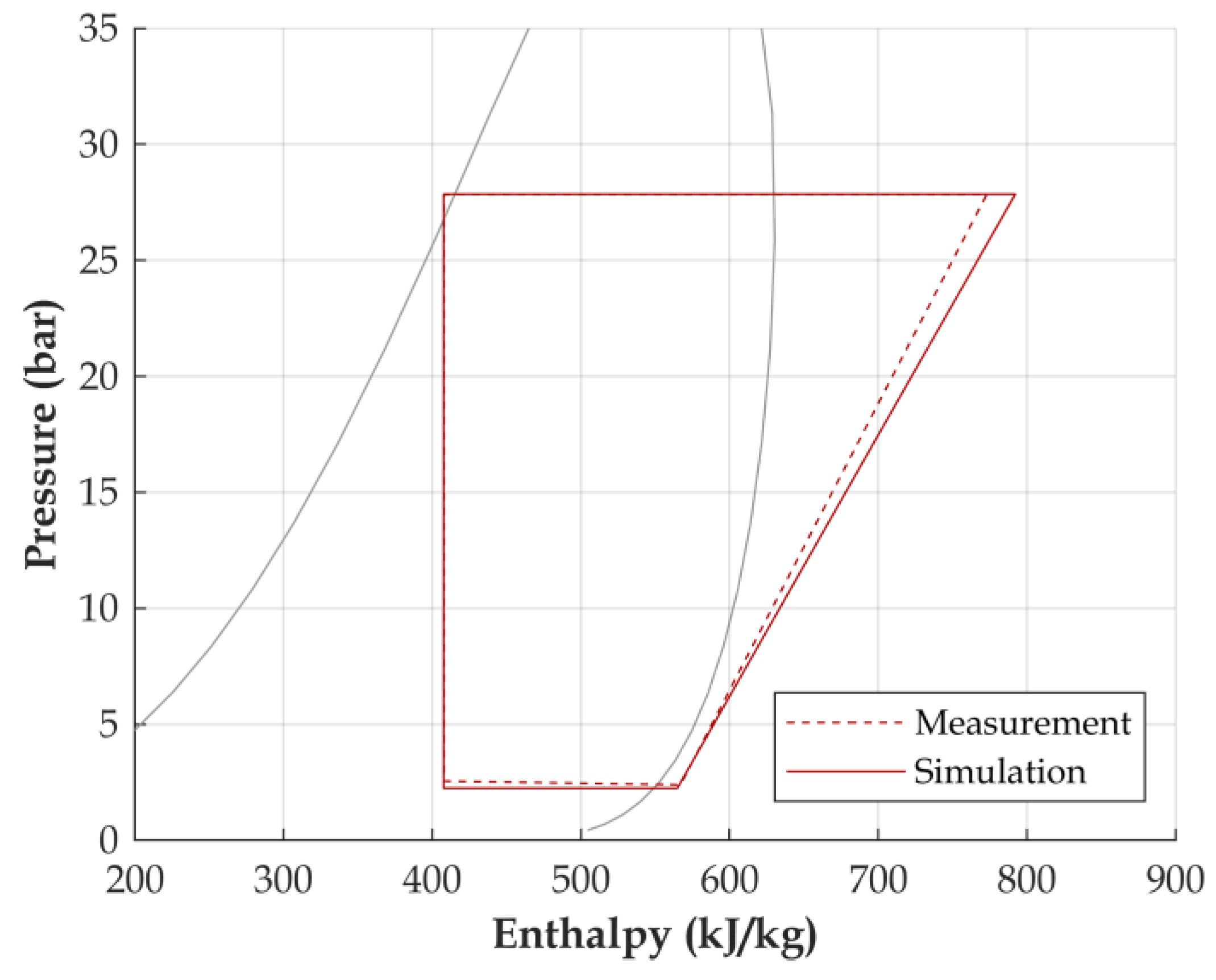

3.1. Models Validation

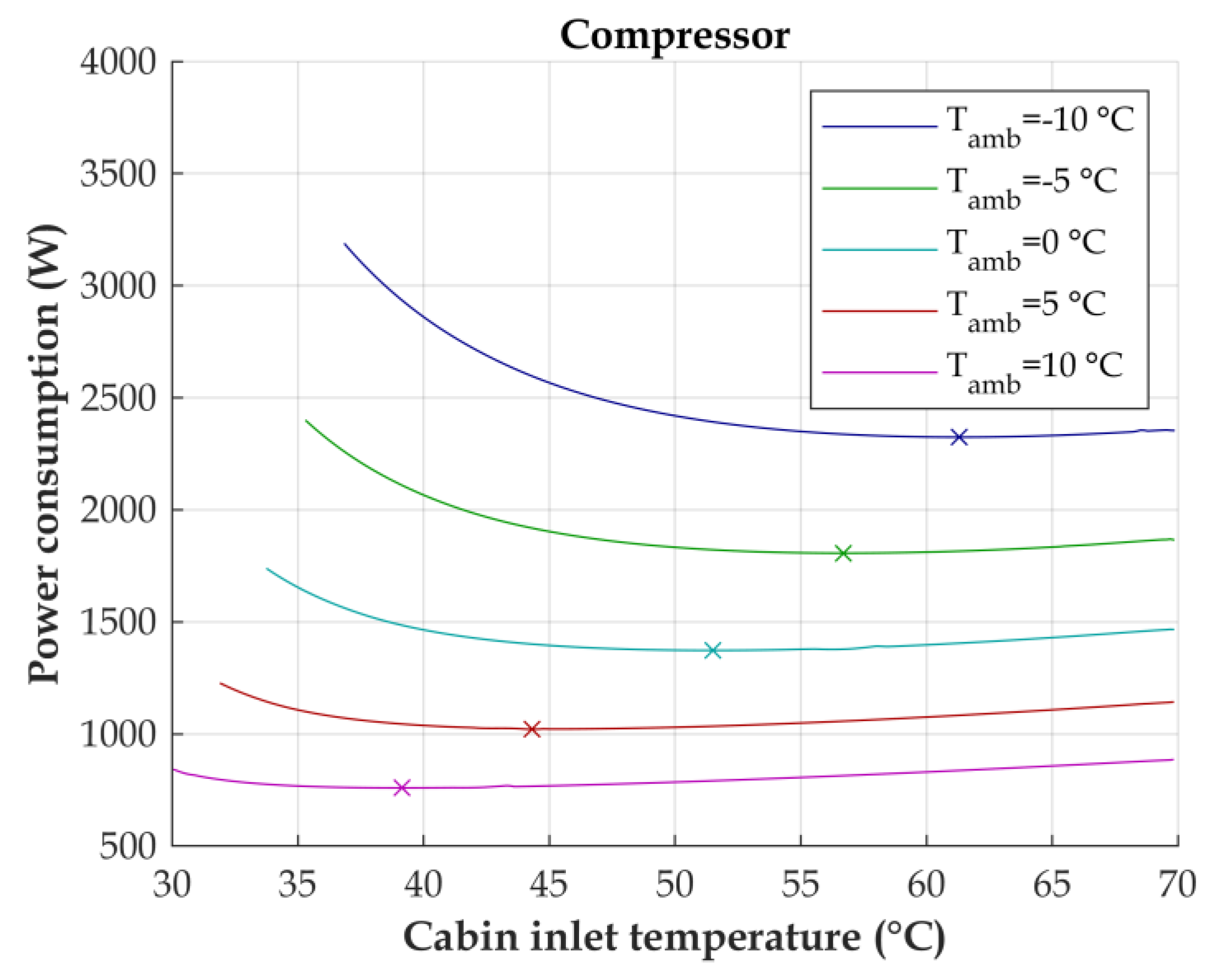

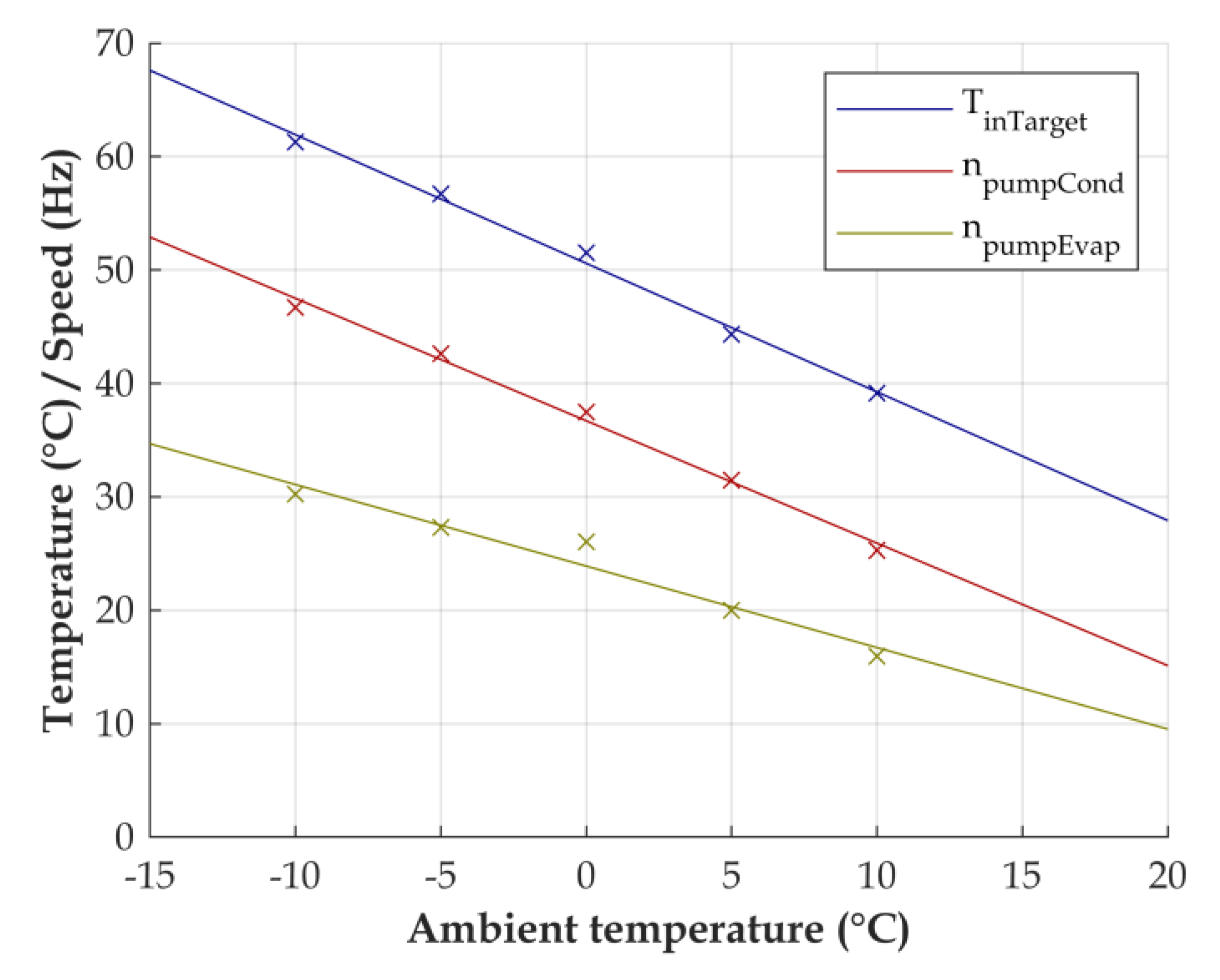

3.2. Demand-Based Control Strategy

3.3. Use Case Results

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- New Electric Vehicles. Elektro Auto Mobil, Das Magazine für Elektromobilität, Overview BEV & PHEV, February/March 2019. Available online: https://www.elektroautomobil.com (accessed on 16 April 2020).

- ERTRACT. European Roadmap Electrification of Road Transport; ERTRACT: Brussels, Belgium, 2017. [Google Scholar]

- Thomas, C.E. Sustainable Transportation Options for the 21st Century and Beyond; Appendix A Range Limitations of Battery Electric Vehicles; Springer International Publishing: Cham, Switzerland, 2015; p. 119. [Google Scholar] [CrossRef]

- Franke, T.; Rauh, N.; Günther, M.; Trantow, M.; Krems, J.F. Which Factors Can Protect Against Range Stress in Everyday Usage of Battery Electric Vehicles? Toward Enhancing Sustainability of Electric Mobility Systems. Hum. Factors 2015, 58, 13–26. [Google Scholar] [CrossRef] [PubMed]

- Basciotti, D.; Dvorak, D.; Gellai, I. A Novel Methodology for Evaluating the Impact of Energy Efficiency Measures on the Cabin Thermal Comfort of Electric Vehicles. Energies 2020, 13, 3872. [Google Scholar] [CrossRef]

- Shete, K. Influence of Automotive Air Conditioning load on Fuel Economy of IC Engine Vehicles. Int. J. Sci. Eng. Res. 2015, 6, 1367–1372. [Google Scholar]

- Farrington, R.; Rugh, J. Impact of Vehicle Air Conditioning on Fuel Economy, Tailpipe Emissions, and Electric Vehicle Range. In Proceedings of the Earth Technologies Forum, Washington, DC, USA, 31 October 2000. [Google Scholar]

- Iora, P.; Tribioli, L. Effect of Ambient Temperature on Electric Vehicles’ Energy Consumption and Range: Model Definition and Sensitivity Analysis Based on Nissan Leaf Data. World Electr. Veh. J. 2019, 10, 2. [Google Scholar] [CrossRef]

- Paffumi, E.; Otura, M.; Centurelli, M.; Casellas, R.; Brenner, A.; Jahn, S. Driving Range and Cabin Temperature Performances at Different Ambient Conditions in Support to the Design of a User-Centric Efficient Electric Vehicle: The QUIET Project. In Proceedings of the 14th Conference on Sustainable Development of Energy, Water and Environment Systems 2019, Dubrovnik, Croatia, 1–6 October 2019. [Google Scholar]

- Park, J.; Lee, M.; Kim, G.; Park, S.; Kim, J. Integrated Approach Based on Dual Extended Kalman Filter and Multivariate Autoregressive Model for Predicting Battery Capacity Using Health Indicator and SOC/SOH. Energies 2020, 13, 2138. [Google Scholar] [CrossRef]

- Maletić, F.; Hrgetić, M.; Deur, J. Dual Nonlinear Kalman Filter-Based SoC and Remaining Capacity Estimation for an Electric Scooter Li-NMC Battery Pack. Energies 2020, 13, 540. [Google Scholar] [CrossRef]

- Ali, M.U.; Zafar, A.; Nengroo, S.H.; Hussain, S.; Park, G.-S.; Kim, H.-J. Online Remaining Useful Life Prediction for Lithium-Ion Batteries Using Partial Discharge Data Features. Energies 2019, 12, 4366. [Google Scholar] [CrossRef]

- Liang, K.; Zhang, Z.; Liu, P.; Wang, Z.; Jiang, S. Data-Driven Ohmic Resistance Estimation of Battery Packs for Electric Vehicles. Energies 2019, 12, 4772. [Google Scholar] [CrossRef]

- Chen, Y.; He, Y.; Li, Z.; Chen, L. A Combined Multiple Factor Degradation Model and Online Verification for Electric Vehicle Batteries. Energies 2019, 12, 4376. [Google Scholar] [CrossRef]

- Barcellona, S.; Piegari, L. Effect of current on cycle aging of lithium ion batteries. J. Energy Storage 2020, 29, 101310. [Google Scholar] [CrossRef]

- Vatanparvar, K.; Faezi, S.; Burago, I.; Levorato, M.; Al Faruque, M.A. Extended Range Electric Vehicle with Driving Behavior Estimation in Energy Management. IEEE Trans. Smart Grid 2018, 10, 2959–2968. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, W.; Shi, J.; Chen, J. A Study on Electric Vehicle Heat Pump Systems in Cold Climates. Energies 2016, 9, 881. [Google Scholar] [CrossRef]

- Rabl, B. Heat Pump Air Conditioning Systems for Optimized Energy Demand of Electric Vehicles. Comprehensive Energy Management—Safe Adaptation Predictive Control and Thermal Management. In SpringerBriefs in Applied Sciences and Technology; Graz University of Technology: Graz, Austria, 2018; pp. 81–92. [Google Scholar]

- Ozbek, M.; Gyorog, T.; Hunemorder, W.; Kohli, V.; Caldevilla, A.; Savi, A.; Vitali, D.; Biglia, M.; Nakagawa, M. A compact and efficient water-to-water heat-pump system for electric vehicles. In Proceedings of the 1st International FEV Conference: Zero C02 Mobility, Aachen, Germany, 9–10 November 2017. [Google Scholar]

- Lajunen, A. Energy Efficiency and Performance of Cabin Thermal Management in Electric Vehicles. SAE Tech. Pap. 2017. [Google Scholar] [CrossRef]

- Weustenfeld, T.A.; Bauer-Kugelmann, W.; Menken, J.C.; Strasser, K.; Köhler, J. Heat flow rate based thermal management for electric vehicles using a secondary loop heating and cooling system. In Proceedings of the Vehicle Thermal Management Systems Conference and Exhibition, Nottingham, UK, 10–13 May 2015. [Google Scholar]

- Osborne, S.; Kopinsky, J.; Norton, S.; Sutherland, A.; Lancaster, D.; Borgwarner, E.N.; Isenstadt, A.; German, J. Automotive Thermal Management Technology; The International Council on Clean Transportation (ICCT): Washington, DC, USA, 2016. [Google Scholar]

- Suh, I.-S.; Lee, M.; Kim, J.; Oh, S.T.; Won, J.-P. Design and experimental analysis of an efficient hvac (heating ventilation air-conditioning) system on an electric bus with dynamic on-road wireless charging. Energy 2015, 81, 262–273. [Google Scholar] [CrossRef]

- Leighton, D. Combined Fluid Loop Thermal Management for Electric Drive Vehicle Range Improvement. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8, 711–720. [Google Scholar] [CrossRef]

- Kitanoski, F.; Hofer, A. A contribution to energy optimal thermal management for vehicles. In Proceedings of the IFAC Symposium on Advances in Automotive Control, Munich, Germany, 14 July 2010; pp. 87–92. [Google Scholar]

- Fischer, T.; Götz, F.; Berg, L.F.; Kollmeier, H.-P.; Gauterin, F. Model-based development of a Holistic Thermal Management System for an Electric Car with a High Temperature Fuel Cell Range Extender. In Proceedings of the 11th International Modelica Conference, Versailles, France, 21–23 September 2015; pp. 127–133. [Google Scholar]

- De Nunzio, G.; Sciaretta, A.; Steiner, A.; Mladek, A. Thermal Management Optimization of a Heat-Pump-Based HVAC System for Cabin Conditioning in Electric Vehicles. In Proceedings of the International Conference on Ecological Vehicles and Renewable Energies, Monte-Carlo, Monaco, 10–12 April 2018. [Google Scholar]

- Hosoz, M.; Direk, M. Performance evaluation of an integrated automotive air conditioning and heat pump system. Energy Convers. Manag. 2006, 47, 545–559. [Google Scholar] [CrossRef]

- Al Faruque, M.A.; Vatanparvar, K. Modeling, analysis, and optimization of Electric Vehicle HVAC systems. In Proceedings of the 21st Asia and South Pacific Design Automation Conference (ASP-DAC), Macau, China, 25–28 January 2016. [Google Scholar]

- Hendricks, T.J. Vehicle Transient Air Conditioning Analysis: Model Development & System Optimization Investigations; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2001.

- Lee, H.; Hwang, Y.; Song, I.; Jang, K. Transient thermal model of passenger car’s cabin and implementation to saturation cycle with alternative working fluids. Energy 2015, 90, 1859–1868. [Google Scholar] [CrossRef]

- Modelica Standard Library. Available online: https://www.modelica.org/libraries (accessed on 16 April 2020).

- TIL Suite. Available online: https://www.tlk-thermo.com/index.php/en/software/til-suite (accessed on 16 April 2020).

- QUIET. Available online: http://www.quiet-project.eu (accessed on 16 April 2020).

| Heat Pump Mode | |

|---|---|

| Cabin air inlet temperature [°C] | [22–70] |

| Speed of water pump on condenser side [Hz] | [5–100] |

| Speed of water pump on evaporator side [Hz] | [5–100] |

| Ambient temperature [°C] | [−10, −5, 0, 5, 10] |

| Component | Quantity | Control Base | Control Step 1 | Control Step 2 | |

|---|---|---|---|---|---|

| Target air supply | Temperature | Constant | Ramp | f(Tamb) | f(Tamb) |

| Compressor | Speed | PI = f(Tin) | PI = f(Tin) | PI = f(Tin) | PI = f(Tin) |

| Expansion valve | Opening | PI = f(Tsh) | PI = f(Tsh) | PI = f(Tsh) | PI = f(Tsh) |

| Water pump condenser | Speed | Constant | Constant | Ramp | Constant |

| Water pump evaporator | Speed | Constant | Constant | Constant | Ramp |

| Cabin fan | Speed | PI = f(Tcab) | PI = f(Tcab) | PI = f(Tcab) | PI = f(Tcab) |

| Control Step | Component | Variation Variable | Start Value | End Value | Duration |

|---|---|---|---|---|---|

| 1 | Compressor | TinTarget | 70 °C | 22 °C | 10,000 s |

| 2 | Pump condenser | npumpCond | 100 Hz | 5 Hz | 10,000 s |

| Pump evaporator | npumpEvap | 100 Hz | 5 Hz | 10,000 s |

| Component | Controlled Variable | Control Base | Control Step 3 |

|---|---|---|---|

| Target air supply | Temperature | Constant | f(Tamb) |

| Compressor | Speed | PI = f(Tin) | PI = f(Tin) |

| Expansion valve | Opening | PI = f(Tsh) | PI = f(Tsh) |

| Water pump condenser | Speed | Constant | f(Tamb) |

| Water pump evaporator | Speed | Constant | f(Tamb) |

| Cabin fan | Speed | PI = f(Tcab) | PI = f(Tcab) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvorak, D.; Basciotti, D.; Gellai, I. Demand-Based Control Design for Efficient Heat Pump Operation of Electric Vehicles. Energies 2020, 13, 5440. https://doi.org/10.3390/en13205440

Dvorak D, Basciotti D, Gellai I. Demand-Based Control Design for Efficient Heat Pump Operation of Electric Vehicles. Energies. 2020; 13(20):5440. https://doi.org/10.3390/en13205440

Chicago/Turabian StyleDvorak, Dominik, Daniele Basciotti, and Imre Gellai. 2020. "Demand-Based Control Design for Efficient Heat Pump Operation of Electric Vehicles" Energies 13, no. 20: 5440. https://doi.org/10.3390/en13205440

APA StyleDvorak, D., Basciotti, D., & Gellai, I. (2020). Demand-Based Control Design for Efficient Heat Pump Operation of Electric Vehicles. Energies, 13(20), 5440. https://doi.org/10.3390/en13205440