Abstract

This study examined the use of waste plastic oil (WPO) combined with biodiesel as an alternative fuel for diesel engines, also commonly known as compression ignition engines, and focused on comparison of the basic physical and chemical properties of fuels, engine performance, combustion characteristics, and exhaust emissions. A preliminary study was conducted to determine the suitable ratio for the fuel blends in consideration of fuel lubricity and viscosity, and these results indicated that 10% biodiesel—derived from either palm oil or castor oil—in waste plastic oil was optimal. In addition, characterization of the basic properties of these fuel blends revealed that they had higher density and specific gravity and a lower flash point than diesel fuel, while the fuel heating value, viscosity, and cetane index were similar. The fuel blends, comprised of waste plastic oil with either 10% palm oil biodiesel (WPOP10) or 10% castor oil biodiesel (WPOC10), were selected for further investigation in engine tests in which diesel fuel and waste plastic oil were also included as baseline fuels. The experimental results of the performance of the engine showed that the combustion of WPO was similar to diesel fuel for all the tested engine loads and the addition of castor oil as compared to palm oil biodiesel caused a delay in the start of the combustion. Both biodiesel blends slightly improved brake thermal efficiency and smoke emissions with respect to diesel fuel. The addition of biodiesel to WPO tended to reduce the levels of hydrocarbon- and oxide-containing nitrogen emissions. One drawback of adding biodiesel to WPO was increased carbon monoxide and smoke. Comparing the two biodiesels used in the study, the presence of castor oil in waste plastic oil showed lower carbon monoxide and smoke emissions without penalty in terms of increased levels of hydrocarbon- and oxide-containing nitrogen emissions when the engine was operated at high load.

1. Introduction

The demand for and consumption of energy is expected to increase, especially for fossil fuels. In Thailand, fossil fuels, also known as conventional energy, are widely used in various forms of transportation and industrial plants because of their convenience and ability to provide a high heating value. Fossil fuels are a nonrenewable resource which continues to be used by humans, with demand steadily increasing. Thus, these fossil fuels will soon be entirely consumed. For this reason, many countries are beginning to rely more on alternative energy or renewable energy sources.

Thailand still lacks any significant alternative sources of energy. Moreover, it produces insufficient energy to meet the demand, resulting in the import of over 49% of its consumed energy in 2017 [1]. The value of crude oil and imported petroleum products in Thailand increased by 39.8% and 23.0%, in 2016 and 2017, respectively, due to the higher oil demand. Thailand has mainly imported crude oil from Middle Eastern countries. In Thailand, the share of energy from renewable sources is expected to increase steadily. To increase this share and reduce primary energy consumption, waste plastic oil has been proposed as a new option for use in transportation. While there is less demand for transportation energy, this initiative represents a move toward the direction of diversification of fuels through energy conversion technologies. It also focuses on using oil from plastic waste in diesel engines. Plastic waste is a petroleum waste that comes from both household and industrial sectors, leading to a large amount of plastic waste. These wastes require hundreds of years for decomposition and are a burden to manage. Most plastic is recycled using mechanical recycling, while only 2% of chemicals are recycled [2]. Generally, the waste management process that is currently popular is the landfill method, which normally requires a lot of landfill space and has an impact on the environment, resulting in soil pollution.

Plastic waste is composed of hydrocarbons, which are the main component of conventional fuels. This raises the possibility of recycling these plastic wastes through their conversion into fuel. Products can also be obtained from the production process, in addition to being used as an energy source similar to conventional fuels. It is also able to provide environmental benefits in terms of waste management for maximum benefits and reduction in the amount of plastic waste, reduced plastic waste disposal, and also minimizing the problem of finding places for garbage landfills. The use of plastic waste as a renewable energy feedstock also helps in mitigating the energy crisis.

Several studies have investigated the use of waste plastic oil in diesel engines as an alternative fuel. Waste plastic pyrolysis oil has properties that are similar to diesel fuel, including the heating value, density, and cetane index, and can be used as a substitute for diesel fuel [3]. The literature also shows that diesel engines use waste plastic oil to provide stability in performance and a similar efficiency [4]. The different types of plastics are also basically impacted by their different compositions. Recent studies have shown that the oil product of HDPE (high-density polyethylene), mixed with LDPE (low-density polyethylene), has a higher heating value than LDPE, PP (polypropylene), and HDPE alone. It was revealed that LDPE produces the highest yields [5]. Waste plastic oil has also been studied with regard to engine power, and it was found that there was no significant difference from diesel fuel [6]. The thermal efficiency of waste plastic oil was higher when compared to diesel fuel [7,8]. However, one study examined the exhaust emissions of a four-cylinder, direct-injection diesel engine running on diesel blended with different ratios of waste plastic oil and found that the amount of nitrogen oxides increased because of the longer ignition delay [9] and that there was greater hydrocarbon emission in comparison to diesel fuel [10].

In addition, it is expected that biodiesel will be used as a renewable energy source in the energy transportation sector. A great deal of research supports the use of biodiesel as a suitable alternative in replacing diesel fuel. The presence of oxygen in fuel molecules is expected to result in cleaner biodiesel combustion, leading to improvements when considering emission. However, there are only a few reports on the use of biodiesel mixed with waste plastic oil. For example, Ramesha et al. [11] reported that B20 algae biodiesel blended with waste plastic oil can be a suitable fuel for diesel engines. The waste plastic oil-biodiesel blend showed an increase of 16% in brake thermal efficiency with respect to diesel engines. Additionally, the carbonaceous gas emissions, including hydrocarbons and carbon monoxide, were decreased, but nitrogen oxides slightly increased, as compared to diesel fuel. In the study by Senthilkumar et al. [12], waste plastic oil was mixed with Jatropha biodiesel for diesel engines. The brake thermal efficiency and brake specific fuel consumption of the waste plastic oil-biodiesel blend were higher than the waste plastic oil. The hydrocarbon and carbon monoxide emissions decreased when waste plastic oil was blended with Jatropha biodiesel.

In the present work, waste plastic oil-biodiesel blends were used as an alternative fuel in a diesel engine without any engine modifications. The selected biodiesels were produced from castor oil and palm oil through a transesterification process and were then blended with waste plastic oil. Palm is an important economic crop and main feedstock for biodiesel production in Thailand. To avoid the use of edible feedstock, castor oil was considered because of its benefits of high oxygen content in fuel molecules and excellent fuel lubricity. These properties are attributed to the presence of ricinoleic acid, which is the main component of castor oil [13]. The oxygen in the fuel molecules contributes to better combustion processes in terms of emissions. In this study, we evaluated the effect of biodiesel addition to waste plastic oil in terms of basic physical and chemical fuel properties of the resulting fuel mixture, mainly focusing on fuel lubricity and viscosity, engine performance, combustion characteristics, and exhaust gas emissions of a single-cylinder diesel engine. In the section of combustion characteristics, basic parameters comprised of in-cylinder pressure and crank angle were recorded during the engine test. After that, heat release rate of test fuels was calculated on the basic principles of the first law of thermodynamics, which the specific heat ratio was calculated based on the in-cylinder pressure and combustion chamber volume through the assumption of polytropic process.

2. Materials and Methods

As part of this research, some physical and chemical properties of test fuels were determined. Experimental tests were carried out on a single-cylinder diesel engine (model Kirloskar TV1 with product code 240PE). The engine was connected to an eddy current dynamometer to simulate the load and was tested at a constant speed of 1500 rpm under variable load conditions, i.e., low, medium, and high load conditions (25%, 50%, and 75% of the maximum torque). The gas detector was used to determine the levels of carbon monoxide (CO), nitrogen oxides (NOX), hydrocarbon (HC), and smoke. The fuel consumption of the engine was tested by adjusting the load of the diesel engine. Therefore, the scope of this research project was limited to the following:

- To find a suitable ratio of the fuel blend by mainly considering fuel lubricity and viscosity; the fuel blends were prepared at various ratios, i.e., 0%, 5%, 10%, and 15% (by volume) of the biodiesel to the waste plastic oil.

- To test the suitable fuel blends with a single-cylinder diesel engine without any engine modifications. The objective of this test was to evaluate engine performance, combustion characteristics, and exhaust emissions.

2.1. Materials

In this experimental investigation, waste plastic oil (WPO) was used as the main fuel, whereas the other fuels included castor oil methyl ester (COME) and palm oil methyl ester (POME) as components for blending with WPO. The diesel fuel was commercial diesel fuel (B7) containing 7% biodiesel, according to the department of energy business in Thailand. The waste plastic oil used in this research project was produced from waste plastic by the pyrolysis method. The pyrolysis process is a chemical process of heating that decomposes plastics in the absence of oxygen. The master plant that processes waste plastic to oil is located at Suranaree University of Technology.

2.1.1. Waste Plastic Oil

The raw materials used in this study were from plastic waste, such as plastic waste bags collected from waste in Suranaree Subdistrict, Nakhon Ratchasima, Thailand. The composition of these plastics includes polyethylene (PE) and polystyrene (PS) and about 70% was contaminated organic matter. The waste plastics obtained from mechanical biological treatment (MBT) were processed into raw materials using an agglomerator, which processed the plastic into small pieces that could be continuously fed into the oil processing plant. The waste plastic oil was recycled using pyrolysis and did not undergo distillation.

The pyrolysis process involves the breakdown of large molecules into smaller molecules by chemically decomposing organic matter through heating in an oxygen-free environment. Waste plastic is processed to maintain a temperature of 300–350 °C inside the reactor, where the waste plastic is then vaporized and the outlet gas condensed through the condenser unit at this high temperature. The obtained liquid was taken as fuel, and this process happened constantly in converting the waste plastic back into usable oil. All gases from this process were treated before being released into the atmosphere. The exhaust gas was treated through scrubbers and chemical treatment for neutralization. From the pyrolysis process, the following output products were collected: Waste plastic oil (70%), gas (10%), and solid (20%), with values based on the weight of the input. The plastics yielded approximately 600 L per ton.

2.1.2. Production of Castor Oil Biodiesel and Palm Oil Biodiesel

The experimental work was carried out in a laboratory at Suranaree University of Technology. Castor oil was used in the transesterification process to convert castor oil into castor oil methyl ester. Methanol and potassium hydroxide (KOH) catalyst were used for the reaction. The reaction was carried out using methanol and castor oil in a 9:1 molar ratio with 0.5% KOH (by weight of oil). The KOH was first dissolved in methanol and was then mixed with the castor oil. This mixture was heated and stirred using an electric heater and a magnetic stirrer. The reaction was carried out at a constant temperature of 50 °C for about 120 min. Then, the mixture was poured into a separating funnel to separate the methyl ester of castor oil and glycerol. The layers were separated and were allowed to settle for a minimum period of 8 h, with glycerol at the bottom layer and the ester at the top layer. The castor oil methyl ester was then washed with water to remove any traces of methanol or potassium hydroxide that was not reacted. The castor oil methyl ester was heated to 120 °C for moisture removal.

However, palm oil was also used with methanol and potassium hydroxide (KOH) in the reaction. The reaction was carried out by taking methanol and palm oil in a 12:1 molar ratio and 2% KOH (according to the weight of the oil). KOH was dissolved in methanol and this mixture was then mixed with palm oil. This mixture was heated and stirred using an electric heater and a magnetic stirrer. The reaction was carried out at a constant temperature of 60 °C for about 30 min. Then, the mixture was poured into a separating funnel to separate the methyl ester of the palm oil and glycerol. The layers were separated and allowed to settle for 24 h, with glycerol at the bottom layer and the ester at the top layer. The palm oil methyl ester was then washed with water to remove any traces of methanol or potassium hydroxide that was not reacted. The palm oil methyl ester was heated to 120 °C for moisture removal.

2.2. Gas Chromatography Analysis

The column for GC–MS analysis was a DB-wax capillary column (60 m length × 0.25 mm inner diameter, 0.25 μm film thickness). Helium was used as a carrier gas with a constant flow rate of 1.0 mL/min. The oven temperature was programmed to operate from 70 °C to 250 °C, with the initial temperature of 70 °C that was held for 3 min, followed by a rate of heating of 3 °C/min to a temperature of 180 °C and then a rate of 10 °C/min to a final temperature at 250 °C, which was held for 25 min. The inlet was held at 250 °C with a split ratio of 20:1. The injection volume was 1 μL per sample. The mass spectrometer was scanned from mass to charge ratio (m/z) of 35 to 550 with the source at 250 °C.

2.3. Experimental Setup

An experimental investigation was tested to evaluate and compare the results obtained for the use of different types of test fuels. This study aimed to investigate the effect of waste plastic oil blended with biodiesel on engine performance and the emission of a single-cylinder diesel engine. WPOC10 and WPOP10 were selected for experimental comparison based on initial experiment data regarding the lubrication and viscosity of the blended fuels, whereby 10% biodiesel and 90% waste plastic oil was determined to be the optimal ratio for further testing in the engine. The total number of samples was four test fuels (using either WPOC10, WPOP10, WPO, diesel), which were prepared for testing with the equipment and measuring tools used in the laboratory as follows: A four-stroke, single-cylinder diesel engine (Kirloskar TV1) with a water cooler system, direct injection, and a rated output power of 3.5 kW at 1500 rpm, unmodified and under different loading conditions. The engine was mounted on a fixed bed floor in the laboratory room and the load was applied on the engine. A picture of the experimental setup is shown in Figure 1 and Figure 2, and the engine specifications are given in Table 1.

Figure 1.

Experimental setup for engine testing.

Figure 2.

A schematic diagram of the experimental installation.

Table 1.

Test engine specifications.

The observation results during testing in the engine were used to evaluate the use of different fuel blends in comparison to the commercial diesel fuel and waste plastic oil as a reference. Three repetitions were carried out in each test to obtain the average values for analysis. The used confidence intervals corresponded to a 95% confidence level with respect to statistical significance of the result trends.

2.3.1. Testing by Adjusting Engine Load

Engine tests were done by loading the engine to a level that simulated the workload condition of the engine. Three engine loading conditions (25%, 50%, and 75% of the maximum engine torque) were chosen for engine experiments, and the engine loads were adjusted by the eddy current dynamometer, which acted as a brake and an enabling measurement of the engine’s torque. The knob on the dynamometer loading unit was rotated to gradually adjust the engine load to ensure that the load on the load indicator gradually changed for each load value before the test. The experiment was performed using various blends at different loads, from low to high loads, at a constant speed. Furthermore, before testing the engine output with different fuels, the engine was always cleaned prior to installing the fresh oil to ensure the new oils were tested according to the intended compositions.

The fuel consumption was measured using a burette and stopwatch to determine the change in the fuel volume divided by the testing time. The burette with a unit of volume in mL was used to determine the volume of spent fuel. The tests were performed by counting the time needed using a stopwatch to determine the length of time before the fuel ran out. This required a fixed test fuel volume in a burette of 10 mL, and this measurement was repeated three times. The determination of each output value, such as the brake-specific fuel consumption, thermal efficiency, combustion, and amount of gas emission, was based on recordings at each engine load change using the four tested fuels.

2.3.2. Emission Testing

In each engine test, the engine load was gradually adjusted using the knob, and the actual engine speed was measured through encoder wheel monitoring, to measure the tested value of the exhaust gas emission of fuel blends.

The data corresponding to the parameters of engine combustion characteristics were collected through the signals from an in-cylinder pressure sensor and shaft encoder, both of which were analyzed using IC Engine Soft of Apex Innovations’ software. The amount of nitrogen oxides (NOX), hydrocarbon (HC), carbon monoxide (CO), and smoke in emissions was measured by the engine exhaust emission analyzer using a Testo 350 Gas analyzer for CO, NOX, and HC, and a Testo 308 for smoke by installing the equipment for the experiment, as shown in Figure 2.

The Testo 350 and Testo 308 exhaust gas analyzers were used to measure the exhaust gas. The exhaust emission probe was placed in the tailpipe of the engine and the exhaust gas emissions were measured. The test engine was run to idle for approximately 10 min in order to ensure the stability of the engine before measuring the exhaust gas emissions. The Testo 350 was analyzed by using a nondispersive infrared and electronic chemical method. Furthermore, the Testo 308 was analyzed using the principles of absorption photometry.

3. Results and Discussions

3.1. Test Fuels

In order to improve the properties of waste plastic oil by combination with biodiesel, such as through increasing the oxygen content in the waste plastic oil for better combustion and to improve the viscosity and lubricity of the waste plastic oil, COME and POME were blended with waste plastic oil at different volumetric ratios, ranging from 0% to 15%, and the basic physical and chemical properties of the blended fuels were investigated, which mainly focused on fuel lubrication and viscosity. It can be concluded that the presence of 10% biodiesel in waste plastic oil is the optimal ratio because the smallest scar diameter was obtained after lubrication testing and the viscosity was within the acceptable criteria prescribed by the standard specification for diesel fuel, as shown in Figure 3. The lubricity testing was evaluated by a high-frequency reciprocating rig (HFRR) and was conducted according to EN ISO 12156 [14]. From the preliminary experiment, 10% biodiesel was enough to maintain the lubrication of the blended fuel and there was no significant improvement in the lubrication of the blend when exceeding this percentage of biodiesel in waste plastic oil. Therefore, a combination of either 10% castor oil biodiesel or 10% palm oil biodiesel with 90% waste plastic oil (WPOC10 and WPOP10, respectively) was selected for further investigation in the engine test to study the effect of biodiesel addition to waste plastic oil on engine performance, combustion characteristics, and exhaust emissions.

Figure 3.

Lubricity and viscosity of biodiesel blending.

The fatty acid profile of castor oil and palm oil are summarized in Table 2, which confirms that the most abundant fatty acid in castor oil is ricinoleic acid, comprising about 85% by weight of the total fatty acid content, while the major constituents of palm oil are palmitic and oleic acid, at about 46% and 37% of the weight. Palmitic acid is a fatty acid that naturally occurs in vegetable and animals, and it is the main component of human milk fat. Furthermore, oleic acid is also the major component of many oils and fats.

Table 2.

Fatty acid composition of palm oil and castor oil.

The physicochemical properties of fuels were carried out, based on the ASTM standards, and the properties of the test fuels are given in Table 3.

Table 3.

Properties of the test fuels.

Characterization of Waste Plastic Oil

The waste plastic oil or pyrolysis oil used in this study was extracted from mixed plastic wastes. The chemical compounds contained in the waste plastic oil were analyzed by gas chromatography–mass spectrometry (GC–MS), using a gas chromatograph Agilent 7890A coupled to a mass spectrometer Agilent 7000B. The results of the GC–MS analysis of waste plastic oil and diesel are presented in Figure 4, and it is an important chemical compound contained in plastic oil and the percentage of the area is shown in Table 4.

Figure 4.

Total ion current chromatogram for: (a) Waste plastic oil and (b) diesel.

Table 4.

Components identified from waste plastic oil and diesel by GC–MS analysis.

The waste plastic oil consisted of different hydrocarbons contents, which separate according to the light and heavy fractions, from the lowest carbon atom (C4) to the highest carbon atoms (>C20) and can be divided into three groups. The C4–C11 group represented the light fraction or gasoline, and typical gasoline consists of hydrocarbons between five and nine carbon atoms. The C12–C20 group represented the middle fraction or diesel. Diesel has a high percentage of carbon atoms of C16–C20 [15]. Table 4 presents the results of the comparison between fuels, and a similar trend was observed between waste plastic oil and diesel. The waste plastic oil and diesel produced the highest C12–C20 fraction.

3.2. Engine Performance

Figure 5 illustrates the results of the brake specific fuel consumption (BSFC) of the engine for four kinds of test fuels according to three engine-operating loads. The results showed that the BSFC increased at the low loading (25% of the maximum torque) rather than at medium and high loading, respectively (50% and 75% of the maximum torque). The results also showed that the increment in the engine load seems to result in less specific fuel consumption for all the fuels [16,17]. The increase in engine loading resulted in an increase of fuel flow rate, brake thermal efficiency, and exhaust gas temperature while also decreasing the brake specific fuel consumption at the same time.

Figure 5.

Variation of brake specific fuel consumption.

The brake specific fuel consumption was slightly increased for biodiesel-waste plastic oil. In general, brake specific fuel consumption was found to increase when the biodiesel quantity of the blends was increased, which was due to its lower heating value [16,18,19,20].

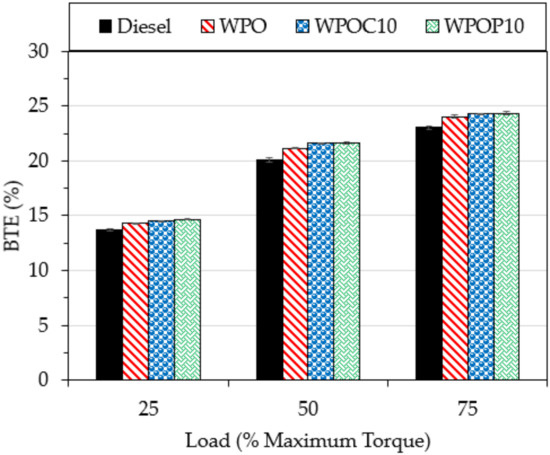

Figure 6 shows the variation of brake thermal efficiency (BTE) and engine load. Higher BTE was obtained with the use of waste plastic oil and its blends. The addition of biodiesel tended to improve the combustion of waste plastic oil. This may be attributed to the increase in oxygen content, due to oxygen in the fuel molecule of the fatty acid in biodiesel, resulting in more effective combustion [20,21,22,23,24,25]. In addition, the proper lubricating properties of biodiesel may play a role in reducing the friction to the level that the brake efficiency was enhanced from pure waste plastic oil [26,27].

Figure 6.

Variation of the brake thermal efficiency.

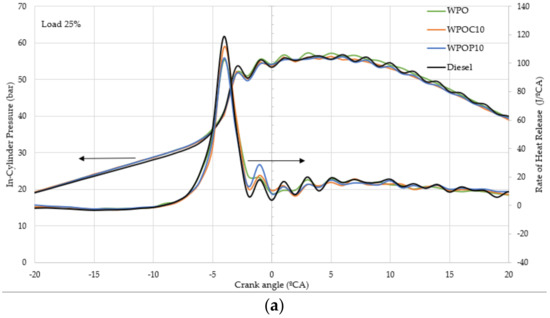

3.3. Combustion Characteristics

The combustion characteristics were examined as in-cylinder pressure and the rate of heat release based on the basic principles of the first law of thermodynamics, as shown in Figure 7. It was found that the combustion of waste plastic oil was similar to diesel fuel for all tested engine loads. The addition of castor oil biodiesel to waste plastic oil caused a delay in the start of the combustion rather than the addition of palm oil biodiesel. This was explained by the lower cetane number in castor oil. Additionally, the higher viscosity of castor oil biodiesel can be used to justify the delay in the combustion process due to the difficulty of fuel injection and the quality of fuel spray [27,28]. When considering peak of heat release rate, it was found that a higher peak was obtained for fuel blends with castor oil as biodiesel compared to palm oil. The accumulation of fuel volume during the longer ignition delay, which impacted the higher peak of premixed combustion, was used to justify the higher peak of the heat release rate obtained by the combustion of WPOC10 with respect to WPOP10 [29,30].

Figure 7.

In-cylinder pressure and rate of heat release at different levels of maximum torque: (a) 25%; (b) 50%; (c) 75%.

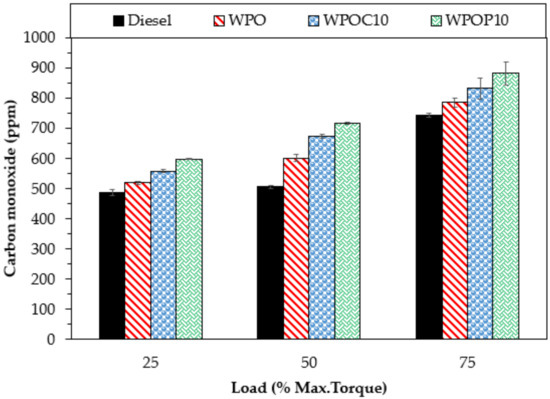

3.4. Emissions

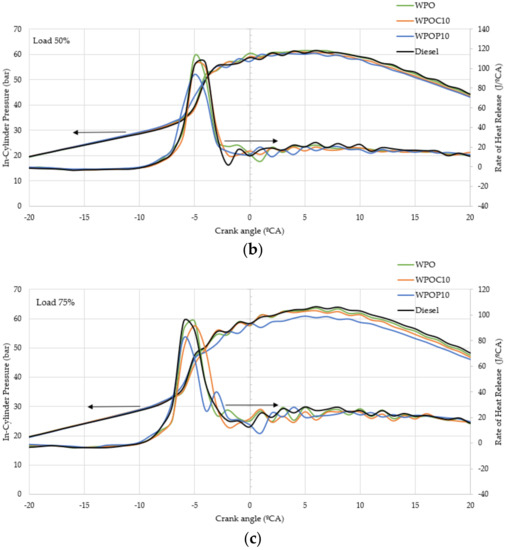

From Figure 8, the blends of the biodiesel-waste plastic oil showed a disadvantage in carbon monoxide emissions because of the higher viscosity and lower calorific value. Therefore, the combustion temperature was lowered due to ineffective atomization of the fuel blends, leading to an increase in carbon monoxide emissions. Comparing the two biodiesels used in this study, the presence of castor oil in fuel blends showed lower CO emissions. Although, castor oil possesses higher viscosity than palm oil, which can generate poor fuel atomization that results in more incomplete combustion. The higher oxygen content of castor oil may improve the quality of the combustion and can be compensated for by the effect of higher viscosity, leading to lower CO emissions by the addition of castor oil biodiesel to waste plastic oil as compared to the addition of palm oil biodiesel.

Figure 8.

Carbon monoxide emissions.

From Figure 9, it can be seen that the amount of nitrogen oxide emissions increased with increasing engine load, and the nitrogen oxide emission levels of plastic waste oil were higher compared to diesel fuel. Comparing waste plastic oil and its blends, lower NOx emissions were found when biodiesel was added. The reduction in the peak of the heat release in the premixed combustion phase was caused by the combustion of biodiesel blends, which tended to attenuate the increase in combustion temperature and did not favor NOx formation. The results of biodiesel addition were similar to diesel fuel blends and resulted in NOX reduction, which was also observed in another study by Pumpuang et al. [22] using blends of diesel with castor oil ethyl ester biodiesel. Considering the addition of castor oil and palm oil biodiesel, the castor oil biodiesel blends showed higher NOx emissions than those of palm oil biodiesel. The longer ignition delay due to the lower cetane value, caused by the addition of castor oil biodiesel, led to a higher combustion temperature, and this can explain the higher NOx emissions observed with the combustion of waste plastic oil blended with castor oil biodiesel.

Figure 9.

Nitrogen oxide emissions.

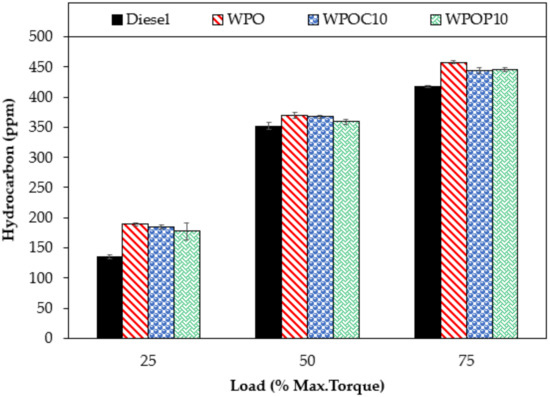

The variation of hydrocarbons with engine loads is shown in Figure 10. Higher levels of hydrocarbon emissions were found with the combustion of waste plastic oil with respect to diesel fuel. However, the addition of biodiesels may have contributed to reducing hydrocarbon emissions [31]. In the case of palm oil biodiesel, the shorter ignition delay due to the lower cetane index, in comparison to castor oil biodiesel, can improve (reduce) hydrocarbon emissions by allowing more time for the combustion process, resulting in lower levels of hydrocarbon emission. However, the blend with castor oil biodiesel, containing a higher oxygen content for the same volumetric percentage when comparing the two biodiesels, was blended with the waste plastic oil. This is expected to promote lower levels of hydrocarbon emission compared to the blend of palm oil biodiesel. The effect of the extremely high viscosity of castor oil, however, tended to increase the emission of hydrocarbons and could counteract the beneficial reductions in hydrocarbon emission due to the higher oxygen content [32]. These effects were more obviously seen at low engine operating loads where the temperature in the combustion chamber was not high enough to vaporize all the injected fuels. Consequently, WPOC10 produced higher hydrocarbons with respect to WPOP10.

Figure 10.

Hydrocarbon emissions.

Figure 11 shows the smoke emissions obtained by the combustion of the tested fuels. The combustion of the waste plastic oil was evidently associated with less smoke emission than diesel fuel. The addition of biodiesels to waste plastic oil tended to result in increased smoke emissions of these fuel blends. This increase in smoke emissions was apparent when the engine was operated at higher load conditions. Comparing castor oil and palm oil biodiesel, it was found that lower smoke emissions were obtained with the use of castor oil biodiesel. The two main factors had opposing effects on particulate matter emission, which was directly related to the smoke emissions. First, the higher viscosity of castor oil biodiesel caused more difficulty in fuel injection. The ineffective fuel atomization resulted in more incomplete combustion, which was related to a higher amount of unburnt fuel, resulting in higher smoke emissions. Second, the higher oxygen content present in the castor oil biodiesel and hydroxyl group belonged to ricinoleic acid as the primary fatty acid of castor oil can contribute to the enhancement of combustion quality, leading to less smoke emission [33]. It was notable that the effect of higher oxygen content may be more likely to reduce smoke emissions in this study as a result of lower smoke emissions associated with the combustion of WPOC10 compared to WPOP10.

Figure 11.

Smoke emissions.

4. Conclusions

The effects of biodiesel addition on fuel properties, combustion characteristics, engine performance, and exhaust emissions of crude waste plastic oil were studied. Two types of biodiesel, palm oil biodiesel and castor oil biodiesel, were selected as components for blending with waste plastic oil. The findings can be summarized as follows:

- Considering fuel lubricity and viscosity, the presence of 10% (v/v) biodiesel was the optimal ratio for improving the waste plastic oil.

- The brake thermal efficiency of the engine was slightly improved with the addition of biodiesel to waste plastic oil.

- The addition of castor oil as compared to palm oil biodiesel caused a delay in the start of the combustion, resulting in a higher peak of heat release rate.

- The reduction in the level of hydrocarbon- and oxide-containing nitrogen emissions was found with the addition of biodiesel, while carbon monoxide and the smoke emissions were increased.

- Comparing the two tested biodiesels, the presence of castor oil in waste plastic oil showed lower carbon monoxide and smoke emissions without any penalty regarding the levels of hydrocarbon- and oxide-containing nitrogen emissions when the engine was operated at a high load.

- Future studies on engine modification, such as to the piston, injection timing, and injection pressure, can be considered for further improvements through the reduction of exhaust emissions by the use of biodiesel as a blend component in waste plastic oil.

Author Contributions

Conceptualization, E.S.; investigation, C.K., S.M., and N.K.; writing—Original draft preparation, C.K.; writing—Review and editing, C.K. and E.S.; supervision, J.S. and W.A.; resources, K.W. and P.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| BSFC | brake-specific fuel consumption |

| BTE | brake thermal efficiency |

| CO | carbon monoxide |

| COME | castor oil methyl ester |

| HC | hydrocarbon |

| HDPE | high-density polyethylene |

| HFRR | high-frequency reciprocating rig |

| KOH | potassium hydroxide |

| LDPE | low-density polyethylene |

| MBT | mechanical biological treatment |

| NOX | nitrogen oxides |

| PE | polyethylene |

| POME | palm oil methyl ester |

| PP | polypropylene |

| PS | polystyrene |

| WPO | waste plastic oil |

| WPOC10 | fuel blend of 10% castor oil biodiesel and 90% waste plastic oil |

| WPOP10 | fuel blend of 10% palm oil biodiesel and 90% waste plastic oil |

| GC-MS | gas chromatography–mass spectrometry |

References

- Energy Policy and Planning Office, Ministry of Energy, Thailand. Energy Statistics of Thailand. Available online: http://www.eppo.go.th/index.php/th/informationservices/ct-menu-item-56?orders[publishUp]=publishUp&issearch=1 (accessed on 28 July 2019).

- Gabbar, H.A.; Aboughaly, M.; Stoute, C.A. DC thermal plasma design and utilization for the low density polyethylene to diesel oil pyrolysis reaction. Energies 2017, 10, 784. [Google Scholar] [CrossRef]

- Damodharan, D.; Sathiyagnanam, A.P.; Rana, D.; Kumar, B.R.; Saravanan, S. Extraction and characterization of waste plastic oil (WPO) with the effect of n-butanol addition on the performance and emissions of a DI diesel engine fueled with WPO/diesel blends. Energy Convers. Manag. 2016, 131, 117–126. [Google Scholar] [CrossRef]

- Kaimal, V.K.; Vijayabalan, P. A detailed study of combustion characteristics of a DI diesel engine using waste plastic oil and its blends. Energy Convers. Manag. 2015, 105, 951–956. [Google Scholar] [CrossRef]

- Areeprasert, C.; Asingsamanunt, J.; Srisawat, S.; Kaharn, J.; Inseemeesak, B.; Phasee, P.; Khaobang, C.; Siwakosit, W.; Chiemchaisri, C. Municipal plastic waste composition study at transfer station of Bangkok and possibility of its energy recovery by pyrolysis. Energy Procedia 2017, 107, 222–226. [Google Scholar] [CrossRef]

- Baskaran, R.; Sathish Kumar, P. Evaluation on performance of CI engine with waste plastic oil-diesel blends as alternative fuel. Int. J. Res. Appl. Sci. Eng. Technol. 2015, 3, 642–646. [Google Scholar]

- Syamsiro, M.; Saptoadi, H.; Kismurtono, M.; Mufrodi, Z.; Yoshikawa, K. Utilization of waste polyethylene pyrolysis oil as partial substitute for diesel fuel in a DI diesel engine. Int. J. Smart Grid Clean Energy 2018, 8, 38–47. [Google Scholar] [CrossRef]

- Sachuthananthan, B.; Reddy, D.R.; Mahesh, C. Production of diesel like fuel from municipal solid waste plastics for using in CI Engine to study the combustion, performance and emission characteristics. Int. J. Pure Appl. Math. 2018, 119, 85–98. [Google Scholar]

- Kalargaris, I.; Tian, G.; Gu, S. Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process. Technol. 2017, 157, 108–115. [Google Scholar] [CrossRef]

- Mani, M.; Nagarajan, G.; Sampath, S. Characterisation and effect of using waste plastic oil and diesel fuel blends in compression ignition engine. Energy 2011, 36, 212–219. [Google Scholar] [CrossRef]

- Ramesha, D.K.; Kumara, G.P.; Lalsaheb; Mohammed, A.V.T.; Mohammad, H.A.; Kasma, M.A. An experimental study on usage of plastic oil and B20 algae biodiesel blend as substitute fuel to diesel engine. Environ. Sci. Pollut. Res. 2015, 23, 9432–9439. [Google Scholar] [CrossRef]

- Senthilkumar, P.; Sankaranarayanan, G. Effect of Jatropha methyl ester on waste plastic oil fueled DI diesel engine. J. Energy Inst. 2016, 89, 504–512. [Google Scholar] [CrossRef]

- Keera, S.T.; El Sabagh, S.M.; Taman, A.R. Castor oil biodiesel production and optimization. Egypt. J. Pet. 2018, 27, 979–984. [Google Scholar] [CrossRef]

- ISO12156-1: Diesel Fuel—Assessment of Lubricity Using the High Frequency Reciprocating Rig. 2016. Available online: https://www.iso.org/standard/65227.html (accessed on 1 June 2020).

- Wathakit, K.; Sukjit, E.; Maithomklang, S.; Srisertpol, J. Fuel properties, performance and emission of alternative fuel from pyrolysis of waste plastics. In Proceedings of the 2019 the 6th International Conference on Mechatronics and Mechanical Engineering, Wuhan, China, 9–11 November 2019; IOP Publishing Ltd.: Bristol, UK, 2020. [Google Scholar]

- Shirneshan, A.; Almassi, M.; Ghobadian, B.; Borghei, A.M.; Najafi, G. Brake specific fuel consumption of diesel engine by using biodiesel from waste cooking oil. World Sci. J. 2013, 1, 45–52. [Google Scholar]

- Kumar, S.; Prakash, R.; Murugan, S.; Singh, R.K. Performance and emission analysis of blends of waste plastic oil obtained by catalytic pyrolysis of waste HDPE with diesel in a CI engine. Energy Convers. Manag. 2013, 74, 323–331. [Google Scholar] [CrossRef]

- Tarabet, L.; Loubar, K.; Lounici, M.S.; Hanchi, S.; Tazerout, M. Experimental evaluation of performance and emissions of DI diesel engine fueled with eucalyptus biodiesel. In Proceedings of the Internal Combustion Engines: Performance, Fuel Economy and Emissions, London, UK, 29–30 November 2011; pp. 167–176. [Google Scholar]

- Adaileh, W.M.; Alqdah, K.S. Performance of diesel engine fuelled by a biodiesel extracted from a waste cocking oil. Energy Procedia 2012, 18, 1317–1334. [Google Scholar] [CrossRef]

- Yusop, A.F.; Mamat, R.; Yusaf, T.; Najafi, G.; Yasin, M.H.M.; Khathri, A. Analysis of particulate matter (PM) emissions in diesel engines using palm oil biodiesel blended with diesel fuel. Energies 2018, 11, 1039. [Google Scholar] [CrossRef]

- Arato, K.; Takashima, T. A study on reduction of heat loss by optimizing combustion chamber shape. SAE Int. J. Engines 2015, 8, 596–608. [Google Scholar] [CrossRef]

- Pumpuang, A.; Maithomklang, S.; Sukjit, E.; Dejvajara, D.; Samaiklang, P.; Sanluecha, S. Utilization of Castor Oil-Based Ethyl Ester Biodiesel in a Diesel Engine; No. 2019-32-0606; SAE Technical Paper: 2019; SAE International: Pennsylvania, PA, USA, 2019. [Google Scholar]

- Kaimal, V.K.; Vijayabalan, P. A study on synthesis of energy fuel from waste plastic and assessment of its potential as an alternative fuel for diesel engines. Waste Manag. 2016, 51, 91–96. [Google Scholar] [CrossRef]

- Mrityunjaya, S.K.M.; Ramesha, D.K.; Premkumara, G.; Ranaprapareddy, N. Performance and emission characteristics of a compression ignition engine using blends of bio-oil as a fuel. J. Middle Eur. Constr. Des. Cars 2011, 9, 40–44. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, M.; Datta, A.; Santra, A.K. An experimental study on the combustion, performance and emission characteristics of a diesel engine fuelled with diesel-castor oil biodiesel blends. Renew. Energy 2018, 119, 174–184. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Muraleedharan, C.; Jayaraj, S. Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew. Energy 2005, 30, 1789–1800. [Google Scholar] [CrossRef]

- Sukjit, E.; Herreros, J.M.; Dearn, K.; Tsolakis, A. Improving Ethanol-Diesel Blend through the Use of Hydroxylated Biodiesel; No. 2014-01-2776; SAE Technical Paper: 2014; SAE International: Pennsylvania, PA, USA, 2014. [Google Scholar]

- Panwar, N.L.; Shrirame, H.Y.; Rathore, N.S.; Jindal, S.; Kurchania, A.K. Performance evaluation of a diesel engine fueled with methyl ester of castor seed oil. Appl. Therm. Eng. 2010, 30, 245–249. [Google Scholar] [CrossRef]

- Sukjit, E.; Liplap, P.; Maithomklang, S.; Arjharn, W. Experimental Investigation on a DI Diesel Engine Using Waste Plastic Oil Blended with Oxygenated Fuels; No. 2017-24-0116; SAE Technical Paper: 2017; SAE International: Pennsylvania, PA, USA, 2017. [Google Scholar]

- Azad, A.K.; Rasul, M.G.; Khan, M.M.K.; Sharma, S.C.; Bhuiya, M.M.K. Recent development of biodiesel combustion strategies and modelling for compression ignition engines. Renew. Sustain. Energy Rev. 2016, 56, 1068–1086. [Google Scholar] [CrossRef]

- Niculescu, R.; Clenci, A.; Iorga-Siman, V. Review on the use of diesel-biodiesel-alcohol blends in compression ignition engines. Energies 2019, 12, 1194. [Google Scholar] [CrossRef]

- Sukjit, E.; Maithomklang, S.; Trirak, N.; Klinkaew, N. Emission benefits from the use of castor oil in a compression ignition engine fuelled with diesel-ethanol blends. Int. J. Electr. Energy 2018, 6, 57–63. [Google Scholar] [CrossRef]

- Sukjit, E.; Herreros, J.M.; Piaszyk, J.; Dearn, K.D.; Tsolakis, A. Finding synergies in fuels properties for the design of renewable fuels-hydroxylated biodiesel effects on butanol-diesel blends. Environ. Sci. Technol. 2013, 47, 3535–3542. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).