Abstract

Studies related to biomass production, with a focus on energy uses for short-rotation woody crops (SRWCs), are limited in Latin America. The research that is available relates to a variety of tested SRWC species (50 species), however, the most important species are Populus, Salix, Eucalyptus, Acacia, and Gmelina arborea. In the existing studies, stocking densities varied from 1111 to 20,000 trees per hectare, with square or rectangular spacing. One important advantage of SRWC systems in this region, compared to most regions worldwide, is the predictability of biomass yields due to the tropical climate conditions of the majority of the Latin American countries. Rotations of three and four years can be projected to produce total biomass yields of 30–50 tons/ha, with increments of 10–20 tons/ha/yr. Fertilization is performed in SRWC with the aim of preventing soil degradation and maintaining further production. In regards to possible uses of biofuel generated from SRWC in Latin America, an inconvenience is that there are neither well-established harvesting systems nor conventional pre-treatments to process the biomass. Processes that are available in the region that use biomass from SRWC for energy production are gasification and pellet production. Other potential biofuel processes, such as torrefaction and biochemical conversion, are limited in this area.

1. Introduction

Currently, energy demands worldwide are estimated at approximately 14,000 million tonnes of Oil Equivalent (Mtoe) [1] and are expected to reach 18,000 Mtoe in the year 2050 [2]. In Latin America (Argentina, Belize, Brazil, Bolivia, Chile, Costa Rica, Colombia, El Salvador, Ecuador, Guatemala, Guayana, Honduras, Mexico, Nicaragua, Panama, Suriname, Uruguay, and Venezuela), the current energy demand is estimated to be 4.7% of the total global energy demand, at around 658 million Mtoe [1]. It is expected that this demand will increase to 1.0 billion Mtoe by the year 2050 [2]. In Mexico and Central America, the energy demand is 200 million Mtoe [1].

A variety of different energy resources around the world are currently used to meet these demands. The most important resources are fossil fuels, carbon, and natural gas. These resources are utilized to meet 81.1% of the total world energy demand, or 31.3%, 28.6%, and 21.2%, respectively [1]. Nevertheless, although these types of energy resources are important, they are considered to be the main cause of global warming [3]. Specifically, for Latin America, total emissions are 15.7% and fossil fuels contribute 9.5%, carbon 1.3%, and natural gas 4.9% [1,4]. Renewable energy resources in Latin America, such as hydroelectricity and bioenergy, represent 2.4% and 11.4% of the total global demand, respectively [1]. The production of solar energy has increased compared to other renewable sources in this region [5,6].

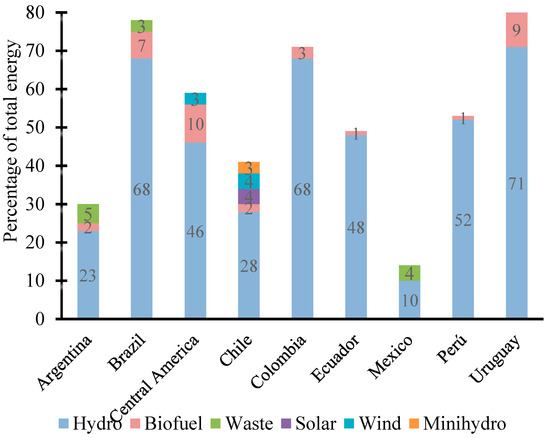

Latin America is a leader in the production of renewable energy, with hydro energy being the most important in all the countries across the region (Figure 1), followed by biofuels, agricultural wastes and, to a lesser extent, solar energy, wind, and mini hydro-energy (Figure 1). The countries of Central America, together with Mexico, Argentina and Chile, show the lowest levels of energy production from renewable resources (Figure 1) [4,7].

Figure 1.

Energy generation by source type in Latin American countries [6].

Biomass is considered one of the key renewable energy resources of the future [8]. This is due to its significant potential, economic viability, renewability, and various social and environmental benefits, especially in the European Union [3,9]. According to Rodríguez et al. [3,10], energy obtained from solid biomass is primary energy, meaning the energy came from plant species used specifically to produce biomass for energy.

Woody species cultivated as short-rotation woody crops (SRWC) have been established in many countries around the world, especially in the European Union (EU) and North America [11,12]. SRWC is a silvicultural system based on short clear-felling cycles, generally of 1 to 15 years. These cycles utilize genetically superior planting material, and sometimes required intensive techniques such as fertilization, irrigation, and weed control [13].

Although SRWCs are extensively implemented in many regions of the world [14], their use has been expanded very little in Latin America [7,15,16,17]. However, Latin America has an extension from Mexico to the southern part of Chile, where there are diverse habitats and climates, therefore different SRWCs are going to vary in how well they perform in these environments. According to these factors, there have been different outcomes achieved in the establishment of SWRCs, and nowadays it is necessary to review the status of these types of plantations.

The present study summarizes the experiences gathered thus far in Latin American regarding the establishment of SRWCs, with reference to species, spacing, stocking density, species rotation, production levels, utilization, and potential further applications.

2. Renewable Energy and Biomass in Latin America

The development of renewable energy resources has increased in the last 30 years, as they have been recognized as an alternative to fossil fuels [18]. Renewable energy is a potential solution to increasing global energy demand, climatic change, and ecological challenges [19], but must be environmentally, socially, and economically sustainable if its benefits are to be fully recognized [18]. However, despite the advantages of renewable energy, some Latin American countries are still highly dependent on fossil fuels (from 40%–80% of total energy demand) or other forms of energy production, mainly hydroelectric power (11%) [6,7].

Renewable energy in Latin America has great potential because many of the countries in this region have good weather conditions for energy crop development [18]. However, the main source of this energy, so far, is sugar cane [20], with Brazil as the main biofuel producer in the region [21], followed by Colombia [22]. Other renewable energy resources are also considered important, such as palm oil [23] and biogas [24,25].

Biomass as a renewable energy resource is important, however, some authors have pointed out that this energy must be used smartly [26,27]. Cooking and heating in developing countries, such as in Central America [7], utilizes one-third of the biomass produced around the world [18]. Meanwhile, developed countries utilize biomass in industrial applications, such as in the heating, power, and road transportation sectors, and for heating purposes in the private sector [1].

Biomass has the potential to be considered the best option to sustainably satisfy global energy demand and reduce the impact of polluting energy resources [20,28,29,30,31]. Conversion of biomass into energy is possible through thermo-chemical and biochemical/biological processes [29,32,33,34], and all of these processes can be implemented in Latin American.

Energy production from biomass in Latin America contributes between 10% and 14% of the world’s primary sources [18,19]. As already mentioned, a high percentage (9.5%) comes from agricultural crops used for the production of biofuels [27,35,36], mainly for heating and cooking, and another significant proportion comes from hydroelectricity [31,37,38].

Biomass resources or feedstock can be: (I) agriculture, generally including agricultural residues such as cane bagasse, oil palm and corn, among others [31]; (II) forest residues consisting of non-usable products resulting from harvesting or sawing processes, products from agroforestry systems, and short-rotation woody crops [18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39]. Sugar cane is the most important feedstock in Brazil for transport, which continues to grow in production [22] but other important crops produced in the Latin America region include soya, oil palm, castor oil, peanut and sunflower oil, parsed, and jatropha [22,23].

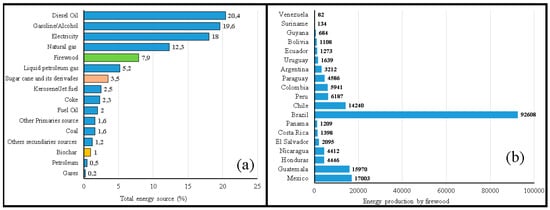

Renewable resources represent 11.4% of all the forms of energy production in Latin America [37,40], with an estimated 7.9% arising from wood sources for firewood, and 3.5% from sugar cane and its by-products (Figure 2a). This data shows that the biomass from lignocellulose material is still unimportant. However, some types of biomass are important in some areas. In various Latin American countries, energy from biomass is produced in the form of 17.83 million tons of wood grown for firewood [40], of which a high percentage is produced in Brazil, Chile, Peru, Guatemala, and Mexico (Figure 2b).

Figure 2.

(a) Percentage of the energy production generated by the different energy sources used and (b) percentage of energy production by firewood in Latin America [40].

3. Short Rotation Woody Crops

SRWCs are of interest because they have a short return time compared to traditional wood plantations, which require longer year intervals [41]. Additionally, SRWCs differ from forestry in that the trees are intensively managed using agricultural techniques that include high-density plantings, regular harvests, and rotations occurring every two to six years without replanting [42]. The choice of species for SRWCs depends on the local climate and soil conditions and is generally confined to fast-growing tree species, mainly from the genera Populus, Salix, Eucalyptus and Robinia [43,44,45]. SRWC plantations are characterized by fast-growing trees of uniform size, grown in a properly designed planting scheme with regular spacing [10]. Planned spacing should facilitate mechanical planting and harvesting of the crop [42].

Zamora et al. [39] present an interesting review of short rotation woody crops (SRWCs). The authors defined SRWCs as “highly productive, purpose-grown plantations in which the bolewood and much of the limbs and tops are used as feedstocks for energy”. Bolewood is the section of the tree trunk, from the ground to the crown break, that is utilizable for commercial products and is cut square at both ends to be made ready for delivery for processing. Moreover, Dikemann [43] and Volk et al. [44] indicate that SRWC production is an ideal biomass management system, as it produces renewable energy feedstock for biofuel production and can provide a plethora of ecological services, including carbon sequestrations and wildlife habitat, when strategically planted [45]. An additional advantage of the species used in SRWC systems is that genetic modifications are easy to propagate, and have relatively short generation times of 3 to 10 years [46].

However, there are some disadvantages of SRWCs in relation to environmental sustainability [47] and they must be considered in the politics of their establishment [48]:

- Soil erosion. SRWCs represent possibly the greatest threat to long-term soil productivity, due to loss of organic matter and nutrient-rich soil surfaces.

- Soil compaction. Machinery used in SWRC harvesting produces soil compaction, which can reduce water infiltration. However, there are many techniques for reducing the soil compaction, and a good selection of species or good soil condition can reduce soil compaction [39].

- Herbicide application. Herbicide is used to control weeds, and if it enters ground water can affect water quality.

- Fertilization. If the nutrients applied are not captured by the plant but instead leach into the ground water or run off into surface waters, this can affect water quality.

- Pest and diseases. The crops utilized in the SRWC systems present narrow genetic bases, making them more susceptible to pest and diseases.

- Biodiversity. Few species are used in SRWC systems, so the biodiversity decreases, or if one species is non-native and/or invasive it can have negative impacts on biodiversity.

- A SRWC prevents the establishment of a plantation that can be used for feedstock for human crops on that piece of land.

- The degree of land conversion can be high and have impacts on both agricultural production and native habitats.

- The harvesting step of SRWCs produces high costs for harvesting and transportation.

Although very well-known systems of SRWCs are used in the USA [11,39], Canada [49], and many countries of the EU [3], SRWCs for biomass production have only recently been implemented in more Latin American countries [50,51,52,53,54,55,56]. Brazil established short rotation plantations and SRWCs long ago [56]. With the development of the iron industry in Brazil occurring since 1960, the demand for calorific power increased, promoting the development of strong incentives to establish short rotation plantations for firewood production [56]. Here, reforestation programs used eucalyptus species for energy purposes [57], with 1.0 x 1.5 m spacing [58]. Nicaragua [55] has been using SRWCs for many years and, most recently, the establishment of SRWCs has been reported in Chile [50], Costa Rica [51,52], Mexico [53], and Uruguay [54].

An important aspect to point out regarding timber or pulp plantations in Latin American is their agroforestry contextualization [43], with the exception of Brazil, Argentina and Chile, which do have large extensions of monocultures. SRWC plantations in Costa Rica [51,52], Nicaragua, and Mexico, among other countries in the region, are established as part of multiple-purpose farms. This is why some think that, despite the potential of the region with its tropical and subtropical climate [59], the development of this type of biomass production system would be limited [43].

4. Species

SRWC systems can utilize various species [43]. For example, Populus, Salix, Robinia and Eucalyptus species are used in the EU [45,60], while in North America Populus, Salix, Pinus, Eucalyptus, and Liquidambar styraciflua are frequently planted [11,30,49,60,61].

Only 50% of the countries in Latin America have established biomass production systems based on SRWCs. There are reports of SRWC plantations in Mexico, Honduras, Nicaragua, Costa Rica, Colombia, Brazil, Uruguay, Chile and Argentina, but not in Guatemala, Belize, El Salvador, Venezuela, French Guiana, Surinam, Ecuador, Peru, and Bolivia (Table 1).

Table 1.

Short rotation woody crops in the different countries of Latin America.

A great diversity of species (50 species) for SRWCs are used in Latin America, possibly due to the tropical climate conditions of many of the region’s countries (Table 1). From Mexico to the southern part of Chile, there are a variety of diverse habitats and climates. Different SRWCs vary in how well they perform in these environments, and each country has tested different species for each condition. As in the European Union and North America, plantations of Populus, Salix, and Eucalyptus are planted, especially in Brazil, Chile and Argentina, and other semitropical and temperate countries. As for Eucalyptus, seven varieties were tested. Approximately 45 various species are present in countries with tropical climates, including native and exotic species such as G. arborea or Acacia mangium (Table 1).

Stocking density and spacing in SRWCs in Latin America are similar to those used for timber production. In the case of Schizolobium amazonicum in Brazil, the spacing is less than 1100 trees per hectare. Schizolobium amazonicum was tested with densities of 1100, 833 and 625 n/ha (spacings of 3 x 3 m, 4 x 3 m and 4 x 4 m, respectively) [84]. Common stocking densities for pulp production are between 1111 and 5000 trees per hectare, in order to obtain logs for chips (Table 2).

Table 2.

Summary of plantation density, spacing, production, height, and diameter of different species of short rotation woody crops utilized in plantations in different countries of Latin America.

Spacing for these trees can be as square systems (1.41 x 1.41 m and 2.0 x 2.0 m) or rectangular systems (2 x 1 m, 2 x 1.5 m, 2 x 2.8 m, 2 x 3 m, 2 x 4 m, 2.8 x 1 m, 2.8 x 1.5 m, 2.8 x 2.5 m, 3 x 0.75 m, 3 x 1 m, and 3 x 1.5 m) (Table 2). It is important to note that these spacings were not applied to the various species tested in the countries of Latin America. Lastly, although SRWCs are associated with high densities of over 5000 trees/hectare [41], few species and countries have used densities of 6666, 7100, 7500, 9000, 10,000, 15,000, 17,500 and 20,000 trees/hectare, with spacings of 3.0 x 0.5 m, 1.0 x 1.0 m, 2.0 x 0.75 m, 1.0 x 0.8 m and 2.8 x 0.5 m (Table 2).

The above spacings clearly show that square and rectangular systems are the most used in these species (Table 2). However, furrow-type spacing has not yet been reported, due to the practicalities of using harvester equipment. This type of planting usually employs systems of two or three plants in rows and spacing of 1–2 meters between rows [95]. This is found only in plantations of Salix and Populus in Argentina, where a cluster system of four plants may be used, separated by 1.5 and 1.2 m from the other four plant clusters [94]. In general, the use of similar spacings for timber or logs for pulp production clearly shows the lack of experience in the region in regards to the different spacing and harvesting methods that can be used for SRWCs (Table 2).

Recommended high densities from 5000 to 20,000 trees ha-1 and short rotations (1–5 years) are ideal in order to produce raw material for bioenergy production. Still, these densities and spacings should be associated with high nutrient absorption [96]. In addition, SRWCs generally involve several rotations, which worsens the problems with nutrients. With this in mind, some researchers suggest the establishment of SRWCs with width spacing (3 x 3 m and 2 x 2 m) and longer rotations (8–12 years) [43].

Experience in Latin America regarding the rotation of various species is scarce since plantations emerged only a few years ago. For example, in Chile, where Pinus and Eucalyptus plantations are common, there are reports of 10 and 16 year rotations for densities similar to those used for timber production [86] (Table 2). Conversely, in high-density plantations, reports describe rotations of fewer years. In Populus, for example, reports described an 8 year rotation for a 6666 density [86]. However, these recommended rotations were put forward before 2010, when the concepts of high density and short rotations in SRWCs were not developed [43]. With the new concepts in SRWCs for densities above 5000 trees/ha, a rotation of less than 5 years is to be expected, as is the case of Populus [92,93], E. globulus [85], A. melanoxylum [87], and Gmelina arborea [51] (Table 2).

Regarding the production of SRWCs, a large variety of biomass production rates have been achieved. This variation can be observed in Table 2, from 1.00 to 50 Tn/ha. The reported ranges for G. arborea were from 4 to 22 Tn/ha for the first year of growth in the tropical region of Costa Rica. In two species of Salix, Populus x deltoides and Eucalyptus camaldulensis, the lowest production levels were reported in the region of Argentina, from 0.13 to 0.78 Tn/ha for the first year. An important aspect to highlight regarding biomass production in this region is the possibility of achieving values between 30 to 50 Tn/ha within two to three years in the different species—values that are reached in the USA or the EU at older ages [43].

Another important parameter related to production is the increase of the biomass, which for the few species reported is moderately high. For example, an increment of 9.2 to 11.5 Tn/ha/yr was found for Populus deltoides [93]; several species of Eucalyptus report a range from 17 to 50 Tn/ha/yr [87], from 18.1 to 33.4 Tn/ha/yr has been observed in Acacia mangium and Acacia auriculiformis in Brazil [83], and from 12 to 64 Tn/ha/yr was found for G. arborea in Costa Rica [52].

5. Potential Utilization of Biofuels Produced by SRWCs

Biomass utilization relates to its chemical composition [30]. Due to the high amount of carbon present in the main carbohydrate chains of wood, one of the main uses of biomass is energy production [28]. Two fundamental requirements related to biomass use for fuel are [30]: (1) to extend and improve the basic knowledge on its composition and properties; and (2) to apply this knowledge for the most advanced and environmentally safe utilization.

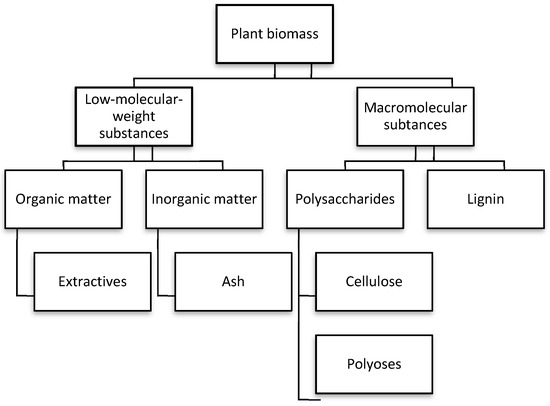

The major structural chemical components (Figure 3), with high molar masses, are cellulose and hemicellulose (65%–75%) and lignin. Other low molar mass substances (extractives and inorganic minerals) are present in wood (usually 4%–10%) [100], which varies in different biomass woody species [30].

Figure 3.

General components in biomass produced from short rotation woody crops [100].

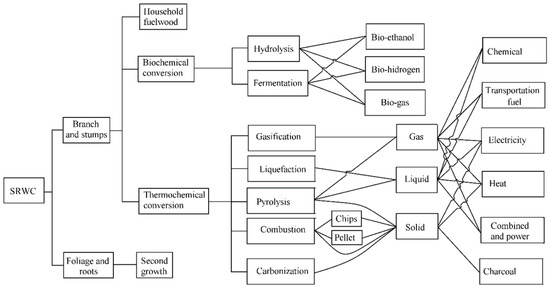

Extracting the energy stored in chemical bonds and combining the subsequent energy product with oxygen oxidizes the carbon to produce CO2 and water for efficient processing of SRWCs, or other sources of lignocellulosic biomass. This process occurs either chemically or biologically [29]. Biomass produced in SRWCs focuses on four different plant parts: roots, foliage, stem, and branches [101]. When producing energy, all of the parts can be used (Figure 4); however, it is advised to extract only the branches and the stem and allow the roots and leaves return to the soil [41]. The roots are the growing basis of the plants for future harvests [102,103], however, in many European countries’ energy extraction occurs through the roots [104]. As for the foliage, it is recommended to leave this at the site to return to the soil because of the high nutrient content. Unfortunately, there are some logistical challenges, such as the separation of the trunk from the foliage [105,106].

Figure 4.

Route of conversion and possible final products of biomass generated in short-rotation woody crops in Latin America [31,107,108,109].

The potential uses of the stem and branches are ample, including uses that require little biomass transformation, like firewood, through to complex processes of extraction that demand more energy, such as biochemical conversion processes (Figure 4).

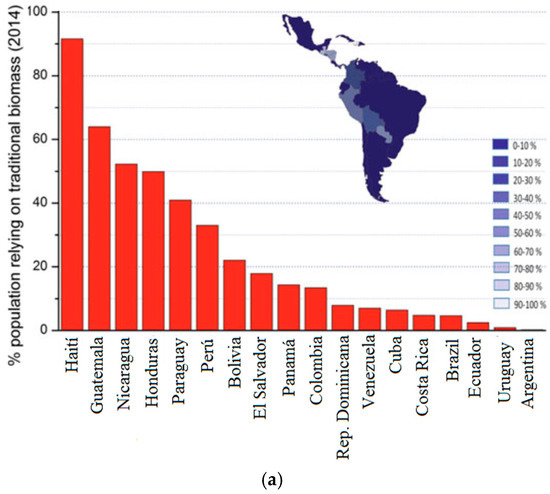

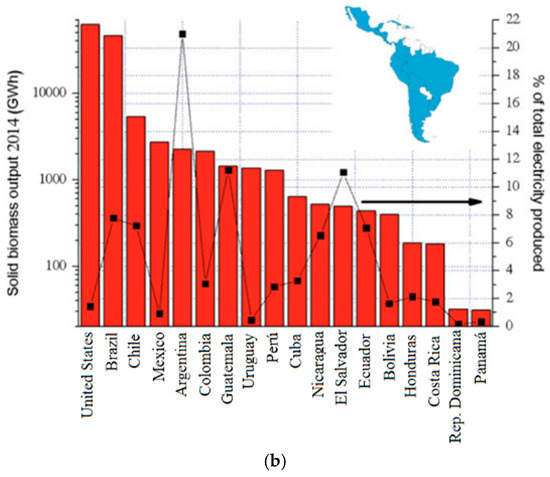

Combustion for heating and cooking in traditional fireplaces and stoves mainly utilizes biomass in the form of firewood. It remains the most popular residential energy system for 40% of the world population [110,111]. In Latin America, the possibilities of using biomass as firewood are abundant, since a high percentage of the population in this region uses raw materials in houses or some kind of industry (Figure 5a) [112]. In Central America, for example, an estimated 44% of the population utilize firewood for stoves to cook and some for steam boilers [40]. However, a series of disadvantages are of concern in the utilization of biomass for domestic stoves, such as low energy efficiency, high levels of contamination, and health problems for the population [110,111].

Figure 5.

(a) Percentage of the population relying on traditional biomass in Latin America in 2014 [112], and (b) electricity output from biomass and shared total electricity produced in different Latin American countries in 2014 [112].

Direct combustion is another use of the potential of SRWC-produced biomass and is classified as a process of thermochemical conversion (Figure 4). This process is the most used worldwide, mainly because of the following factors: (i) reasonable cost in comparison to other renewable energies and (2) biomass fuels are considered environmentally friendly since there is no net increase in CO because of burning it [29].

Biomass from SRWCs can be burned directly, without any chemical processing, to produce steam for making electricity. Direct combustion for electricity production from biomass has been found to be a promising method for the near future. In addition, biomass can be burned to provide heat for industries and homes [108]. The potential for biomass utilization in Latin America is quite broad, and it is estimated that the region contributes 18% of the total global demand [108], which is roughly 17.83 million tons [40]. Production of electricity is another important possibility from producing biomass from SRWCs, with the advantage that in Latin America there is already infrastructure for the generation of electric energy by means of biomass, with values below 10,000 GWh in the various countries (Figure 5b), and particularly outstanding figures Brazil and Chile [112].

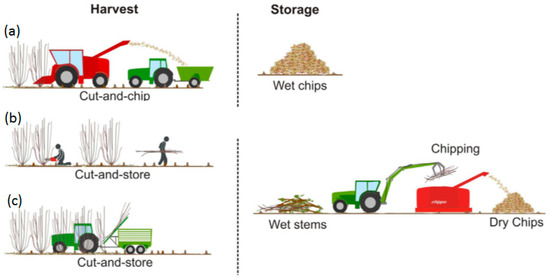

Some pre-treatments have been implemented to enhance biomass properties prior to biomass conversion that can be applied to SRWC biomass [29,102]. Among these pre-treatments, chipping, densification (e.g., pelletizing, briquetting), and torrefaction have been applied to woody biomass. Chipping increases the bulk density and facilitates transportation [102,104,113,114,115]. For example, Pecenka et al. [116] described the potential for deploying and adapting harvesting systems in Brazil for SRWCs, where there is existing experience in the development of equipment [97] and different drying methods in chip production [117].

Chip production from SRWCs in Latin America is possible using different techniques or processes, as detailed in Figure 6. Despite the lack of technology developed for the soil, topography, and climate conditions in Latin America, there are two possibilities for harvesters, or more specifically felling and chipping operations. One possibility would be to adapt the various technologies developed in European countries [116], such as harvest-and-chip systems (Figure 6a), harvest-and-storage systems (Figure 6c) [118,119], or other types of harvesters [120,121,122]. A second option, for countries like Brazil, Argentina and Chile, in particular, would be to develop their own harvesters, since these countries are highly developed in regards to the construction of harvesters for agricultural crops [119] that may be adaptable for harvesting SRWC plantations.

Figure 6.

Schematic overview of the different harvesting methods for short-rotation woody crops. [97].

Guerra et al. [98] harvested Eucalyptus SRWC plantations in Brazil and achieved high biomass production. Modified foragers represent an effective option in relation to cost for harvesting SRWCs. However, new energy plantations grown in Brazil far exceed the stocking and stem size characterization of plantations in the Northern hemisphere, which raises a question about the ability of modified foragers to perform effectively. A study conducted on five Eucalyptus plantations occurred in different Brazilian states, and spanned a wide range of work conditions in terms of cloning, age, planting density, and row system (e.g., single or twin rows). These researchers modified a New Holland 9060 forager, equipped with a 130 FB energy wood header. Field stocking varied between 90 and 157 Tn/ha, and breast-height diameter varied between 5 and 8 cm. This machine was capable of negotiating all test fields and reached a level of productivity on these sites between 39 and 65 Tn/ha. This productivity was comparable to productivity values recorded in Europe and North America.

Manual harvesting of SRWCs (Figure 6b) has been analyzed for many years. An extensive study by Vanbeveren et al. [119] indicates manual harvesting is very labor intensive and is only of interest if a mechanical system is not available or possible, or when the plantation yields are less than 0.4 to 1.2 Tn/hour. Although some studies utilized a bow or brushsaw, chainsaws are most commonly used. A team of two generally carries out the harvesting: one person cuts the trees while the other pushes them into the desired direction or pre-piles the cut trees to facilitate the subsequent (mechanical) forwarding process [123]. This type of harvesting could be possible in many countries in Latin America since many agricultural crops are manually harvested [124,125].

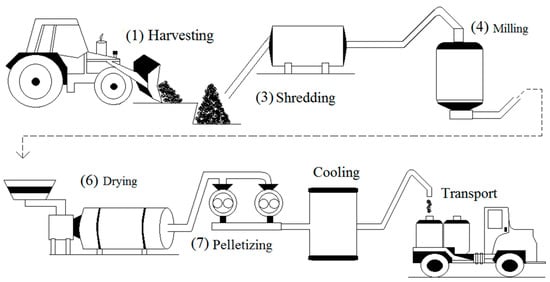

If the production of pellets from SRWCs is to be considered, harvesting processes must be incorporated. In general, wood pellets are an energy-dense fuel source derived from forest biomass, including logging and sawmill residues, pulpwood, roundwood, and other lignocellulosic sources [126]. Pellets from SRWCs are a viable option for Latin American countries. Importantly, consumption of this kind of fuel is expected to increase from 25 to 70 million metric tons by 2020 in Europe [127]. This would mean an increased demand for biomass produced in SRWCs in Latin America, thus promoting the economic viability of SRWCs, as acknowledged by by Jenkins et al. [128] in Costa Rica, Muñoz et al. [129] in Chile, Hässig et al. [130] in Colombia, Moreno-López et al. [131] in Mexico, Felfli et al. [132], García et al. [133] in Brazil, and Amaya et al. [134] in Uruguay.

Conversion of biomass to pellets significantly reduce storage and transportation costs [135]. Wood pellets undergo mechanical manufacturing, which requires applying pressure to crush the cell structure and increase its density [136]. The normal process of producing wood pellets consists of (Figure 7): (i) using grinders and mills (discs, rollers, balls, blades, or hammers) to reduce the size of the material; (ii) drying the biomass with a rotary drum or pneumatic type to a 10% moisture content and (iii) compressing the material using rotary rollers, which pushes the particles from the inside of a ring or die (cylindrical or annular type or flat matrix)) outward through a series of holes [136].

Figure 7.

General wood pellet manufacturing process in Agrep Forestal S.A., established in Costa Rica [136].

Current pellet production systems in Latin American have a production capacity of 114,536 Tn/yr [126], distributed in Brazil (54,013 Tn/yr), Chile (33,069 Tn/yr), Argentina (12,125 Tn/yr), México (4409 ton/ yr), Honduras (4409 Tn/yr), Uruguay (4409 Tn/yr) and Costa Rica (1102 Tn/yr). These production values show the potential for biomass produced from SRWCs to become part of the feedstock of the pelletizing industry.

The process of gasification consists of partial combustion of the biomass to produce synthesis gas (syngas), carried out at temperatures in the range of 750–900 °C [137,138]. The dominant system of the identified gasification plants is the downdraft gasifier, connected to a gas engine and with a production of 15 to 280 kW. In the case of Latin America, although many species have been studied in SWRC systems, the development of gasification, liquefaction and pyrolysis has been limited [139]. For example, for the gasification process, some countries currently have established gasification equipment (Table 3), however, the biomass utilized comes from commercial plantations for pulp or residues of sawlogs [140,141,142,143,144,145].

Table 3.

Presence of gasifiers in some countries of Latin America.

In those countries where SRWC plantations are established, important installed gasification capacity is observed, as is the case in Chile [146,147,148,149], Costa Rica, Mexico and Argentina, among others. Utilization of biomass produced by SRWCs is possible in those countries since these plantations show biomass production levels above 20 Tn/ha (Table 2), which would be enough to supply the gasification plants [139,140]. However, in countries where SRWC development is limited, there are fewer opportunities for implementing biomass gasification, as is the case of Uruguay [145] and Colombia [150], where production of hydroelectricity or other clean energy sources is high. It is important to acknowledge the production of biomass by SRWC systems via gasification requires adequate preparation, and meeting specific conditions for the raw material for the proper performance of the biomass in the gasification equipment [137].

6. SRWCs in Latin American, US and the European Union Countries

The estimated area of SRWC plantations in Latin American is a minimum of about 3000 hectares, compared to the European Union (EU) countries, where there are between 7–21 million hectares planted [3,11,151], and the US, where these plantations cover about 3 million hectares [152].

An important aspect to emphasize is the high number of different SRWC species that have been tested in Latin America compared to the US and the EU. Between 45–50 species have been tested in Latin America (Table 1), compared to a maximum of five species in the US and the EU [3,11,151,153]. Different species have been tested in Latin America, especially in tropical areas, because of the different conditions in terms of climate, soils, altitude, and so forth [8], and possibly due to the tropical climate conditions present in many of the region’s countries (Table 1). From Mexico to the southern part of Chile, there is a range of diverse habitats and climates. Different SRWCs vary in how well they perform in these environments, and each country has tested different species for each set of conditions. The diversity of these species represents a challenge since it is not easy to establish standardized processes for better exploitation of the biomass resources [152]. Another disadvantage of the Latin American region compared to the EU and US is the rotation times of SWRCs (between 3–4 years), which are highly nutrient demanding [105]. On the other hand, the rotation time can be a big advantage and SWRCs in Latin America, compared to the EU and US, have short rotation times and higher yields (5–30 ton/hectare/year).

7. Production Costs of SRWCs for Use as Bioenergy

Data on the costs of SRWCs use in Latin America are limited to data available for Chile and Brazil [154,155]. In the Chilean case, Acuña et al. [87,154] presented a detailed analysis of the production costs for the first two years for different plantation densities of Eucalyptus globulus. This analysis indicated that the main cost is incurred in the first year, during the SRWC establishment (plantation, fertilization and irrigation system), and then due to fertilization and weed control. For Brazil, Souza et al. [155] presented a final SRWC production value between US $19–22 Mg-1 of SRWC biomass. A “Mg” is a land measure and corresponds to 1000 g or 1 ton.

The SRWC market price reported by the Chilean and Brazilian reports is $26.5 Mg-1, and between $25–30 Mg-1, respectively [154,155]. Using a reference heat value of 17.5 MJ/kg for biomass [49], the final prices will be $1.51 GJ-1 and between $1.3–1.6 GJ-1, for Chile and Brazil, respectively. Considering that there is no available information regarding prices of biomass from other sources in the Latin American region, the comparison may be performed using data available for biomass feedstock in the US (Table 4) [154]. In this regard, the prices are similar to the reported prices for poplar as woody biomass in 2011.

Table 4.

Biomass feedstock characteristics and cost in the United States in 2011.

8. Conclusions

The Latin American region currently has a wide variety of SRWCs, of approximately 40 species. The reported production levels vary from 5 to 30 tons/ha/yr, and the rotation period from 3 to 4 years. These values demonstrate that, for several countries of the region, the establishment of this type of crop to produce energy is economically feasible, and they have been in use for several years now. One factor that was not included in the present study, and that determines the policies for establishing the SRWC systems, is the economic aspect of producing biomass using SRWCs. Considering the high number of species used in Latin America, it is not simple to present their economic evaluations individually. The information may be available per country and for the most relevant SRWCs, as in the case of Chile and Brazil. However, this information cannot be generalized to the rest of the Latin American region. Finally, it is important to mention that gathering the material presented in this review was not an easy task due to the lack of follow-up of several studies and, most importantly, because of the diverse quantity of information published mostly internally for each country.

Author Contributions

R.M. contributed with the coordination and conceptualization of review, and the analysis of all the data obtained. C.T. elaborated the analysis of the data and helped with the writing of the paper. G.O. helped with data analysis, formal analysis, writing-review and editing.

Funding

This research was funded by Vicerrectoria de Investigación y Extensión del Instituto Tecnologico de Costa Rica.

Conflicts of Interest

The authors declare no conflict of interest.

References

- IEA—International Energy Agency. Key World Energy Statistics 2016; International Energy Agency: Paris, France, 2016; 74p.

- World Energy Council. World Energy Scenarios: Composing Energy Futures to 2050; World Energy Council: London, UK, 2013; 280p. [Google Scholar]

- Griffiths, N.A.; Rau, B.M.; Vaché, K.B.; Starr, G.; Bitew, M.M.; Aubrey, D.P.; Martin, J.; Benton, E.; Jackson, C.R. Environmental effects of short-rotation woody crops for bioenergy: What is and isn’t known. Available online: https://onlinelibrary.wiley.com/doi/full/10.1111/gcbb.12536 (accessed on 26 November 2018).

- IRENA-International Renewable Energy Agency. Renewable Energy Market Analysis: Latin America; IRENA: Abu Dhabi, UAE, 2016. [Google Scholar]

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Norton Rose Fullbright. Renewable Energy in Latin America, New York, USA. 2017. Available online: http://www.nortonrosefulbright.com/files/renewable-energy-in-latin-america-134675.pdf (accessed on 2 June 2008).

- Cutz, L.; Haro, P.; Santana, D.; Johnsson, F. Bioenergy production in Central America: Integration of sweet sorghum into sugar mills. Renew. Sustain. Energy Rev. 2013, 25, 529–542. [Google Scholar] [CrossRef]

- Beringer, T.M.; Lucht, W.; Schaphoff, S. Bioenergy production potential of global biomass plantations under environmental and agricultural constraints. GCB Bioenergy 2011, 3, 299–312. [Google Scholar] [CrossRef]

- Hall, D.O. Biomass energy in industrialised countries—A view of the future. For. Ecol. Manag. 1997, 91, 17–45. [Google Scholar] [CrossRef]

- Fiala, M.; Bacenetti, J. Economic, energetic and environmental impact of short rotation coppice harvesting operations. Biomass Bioenergy 2012, 42, 107–113. [Google Scholar] [CrossRef]

- Djomo, S.N.; Ac, A.; Zenone, T.; De Groote, T.; Bergante, S.; Facciotto, G.; Sixtoe, H.; Ciria, C.P.; Wegerg, J.; Ceulemans, R. Energy performances of intensive and extensive short rotation cropping systems for woody biomass production in the EU. Renew. Sustain. Energy Rev. 2015, 41, 845–854. [Google Scholar] [CrossRef]

- Shifflett, S.D.; Hazel, D.W.; Frederick, D.J.; Nichols, E.G. Species trials of short rotation woody crops on two wastewater application sites in North Carolina, USA. BioEnergy Res. 2014, 7, 157–173. [Google Scholar] [CrossRef]

- Drew, A.P.; Zsuffa, L.; Mitchell, C.P. Terminology relating to woody plant biomass and its production. Biomass 1987, 12, 79–82. [Google Scholar] [CrossRef]

- Civitarese, V.; Faugno, S.; Picchio, R.; Assirelli, A.; Sperandio, G.; Saulino, L.; Crimaldi, M.; Sannino, M. Production of selected short-rotation wood crop species and quality of obtained biomass. Eur. J. For. Res. 2018, 137, 541–552. [Google Scholar] [CrossRef]

- Shonnard, D.; Solomon, B. Special issue on Pan American biofuel and bioenergy sustainability. Environ. Manag. 2015, 56, 1273–1275. [Google Scholar] [CrossRef]

- Kline, K.L.; Martinelli, F.S.; Mayer, A.L.; Medeiros, R.; Oliveira, C.O.F.; Sparovek, G.; Walter, A.; Venier, L.A. Bioenergy and biodiversity: Key lessons from the pan American region. Environ. Manag. 2015, 56, 1377–1396. [Google Scholar] [CrossRef] [PubMed]

- Laurent, A.; Pelzer, E.; Loyce, C.; Makowski, D. Ranking yields of energy crops: A meta-analysis using direct and indirect comparisons. Renew. Sustain. Energy Rev. 2015, 46, 41–50. [Google Scholar] [CrossRef]

- Gollany, H.T.; Titus, B.D.; Scott, D.A.; Asbjornsen, H.; Resh, S.C.; Chimner, R.A.; Kaczmarek, D.J.; Leite, L.F.C.; Ferreira, A.C.; Rod, K.A.; et al. Biogeochemical research priorities for sustainable biofuel and bioenergy feedstock production in the Americas. Environ. Manag. 2015, 56, 1330–1355. [Google Scholar] [CrossRef] [PubMed]

- Achten, M.J.; Trabucco, A.; Maes, W.H.; Verchot, L.V.; Aerts, R.; Mathijs, E.; Vantomme, P.; Singh, V.P.; Muys, B. Global greenhouse gas implications of land conversion to biofuel crop cultivation in arid and semi-arid lands—Lessons learned from Jatropha. J. Arid. Environ. 2012, 98, 135–145. [Google Scholar] [CrossRef]

- Koçar, G.; Civaş, N. An overview of biofuels from energy crops: Current status and future prospects. Renew. Sustain. Energy Rev. 2013, 28, 900–916. [Google Scholar] [CrossRef]

- Srivastava, N.; Rawat, R.; Singh, H.; Ramteke, P.W. A review on fuel ethanol production from lignocellulosic biomass. Int. J. Green Energy 2015, 12, 949–960. [Google Scholar] [CrossRef]

- Janssen, R.; Rutz, D.D. Sustainability of biofuels in Latin America: Risks and opportunities. Energy Policy 2011, 39, 5717–5725. [Google Scholar] [CrossRef]

- Plath, M.; Moser, C.; Bailis, R.; Brandt, P.; Hirsch, H.; Klein, A.M.; Walmsleya, D.; von Wehrden, H. A novel bioenergy feedstock in Latin America? Cultivation potential of Acrocomia aculeata under current and future climate conditions. Biomass Bioenergy 2016, 91, 186–195. [Google Scholar] [CrossRef]

- Garfí, M.; Martí-Herrero, J.; Garwood, A.; Ferrer, I. Household anaerobic digesters for biogas production in Latin America: A review. Renew. Sustain. Energy Rev. 2016, 60, 599–614. [Google Scholar] [CrossRef]

- Ni, J.Q.; Naveau, H.; Nyns, E.J. Biogas: Exploitation of a renewable energy in Latin America. Renew. Energy 1993, 3, 763–779. [Google Scholar] [CrossRef]

- Cavalett, O.; Norem Slettmo, S.; Cherubini, F. Energy and environmental aspects of using eucalyptus from Brazil for energy and transportation services in Europe. Sustainability 2018, 10, 4068. [Google Scholar] [CrossRef]

- Heinimö, J.; Junginger, M. Production and trading of biomass for energy—An overview of the global status. Biomass Bioenergy 2009, 33, 1310–1320. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 2): Conversion technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Lauri, P.; Havlík, P.; Kindermann, G.; Forsell, N.; Böttcher, H.; Obersteiner, M. Woody biomass energy potential in 2050. Energy Policy 2014, 66, 19–31. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, N.; Baredar, P.; Shukla, A. A review on biomass energy resources, potential, conversion and policy in India. Renew. Sustain. Energy Rev. 2015, 45, 530–539. [Google Scholar] [CrossRef]

- Gunaseelan, V.N. Anaerobic digestion of biomass for methane production: A review. Biomass Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Zhong, Y.; Ruan, Z.; Zhong, Y.; Archer, S.; Liu, Y.; Liao, W. A self-sustaining advanced lignocellulosic biofuel production by integration of anaerobic digestion and aerobic fungal fermentation. Bioresour. Technol. 2015, 179, 173–179. [Google Scholar] [CrossRef]

- Field, C.B.; Campbell, J.E.; Lobell, D.B. Biomass energy: The scale of the potential resource. Trends Ecol. Evol. 2008, 23, 65–72. [Google Scholar] [CrossRef]

- Balat, M.; Ayar, G. Biomass energy in the world, use of biomass and potential trends. Energy Sources 2005, 27, 931–940. [Google Scholar] [CrossRef]

- Sheinbaum-Pardo, C.; Ruiz, B.J. Energy context in Latin America. Energy 2012, 40, 39–46. [Google Scholar] [CrossRef]

- Hoogwijk, M.; Faaij, A.; Eickhout, B.; de Vries, B.; Turkenburg, W. Potential of biomass energy out to 2100, for four IPCC SRES land-use scenarios. Biomass Bioenergy 2005, 29, 225–257. [Google Scholar] [CrossRef]

- Zamora, D.S.; Apostol, K.G.; Berguson, W.E.; Volk, T.A.; Wright, J.; Ogdahl, E.J. Short rotation woody crops biomass production, Chapter 3. In Biomass and Biofuels: Advanced Biorefineries for Sustainable Production and Distribution; Jose, S., Bhaskar, T., Eds.; CRC Press: New York, NY, USA, 2015; pp. 49–76. [Google Scholar]

- OLADE. Energy Statistics Report 2016; Technical Report; Latin American Energy Organization—OLADE: Lima, Peru, 2016.

- Pleguezuelo, C.R.; Zuazo, V.H.D.; Bielders, C.; Bocanegra, J.A.J.; Perea-Torres, F.; Martínez, J.R.F. Bioenergy farming using woody crops. A review. Agron. Sustain. Dev. 2015, 35, 95–119. [Google Scholar] [CrossRef]

- Pereira, S.; Costa, M. Short rotation coppice for bioenergy: From biomass characterization to establishment–A review. Renew. Sustain. Energy Rev. 2017, 74, 1170–1180. [Google Scholar] [CrossRef]

- Dikemann, D. Silviculture and biology of short-rotation woody crops in temperate regions: Then and now. Biomass Bioenergy 2006, 30, 696–705. [Google Scholar] [CrossRef]

- Volk, T.A.; Abrahamson, L.P.; Cameron, K.D.; Castellano, P.; Corbin, T.; Fabio, E.; Johnson, G.; Kuzovkina-eischen, Y.; Labrecque, M.; Miller, M.; et al. Yields of willow biomass crops across a range of sites in North America. Asp. Appl. Biol. 2011, 112, 67–74. [Google Scholar]

- Hinchee, M.; Rottmann, W.; Mullinax, L.; Zhang, C.; Chang, S.; Cunningham, M.; Les, P.; Nehra, N. Short-rotation woody crops for bioenergy and biofuels applications. In Global Impact on Renewable Energy, Production Agriculture, and Technological Advancements; Tunes, D., Lakshmanan, P., Songstad, D., Eds.; Springer: New York, NY, USA, 2011; pp. 139–156. [Google Scholar]

- Vance, E.D.; Loehle, C.; Wigley, T.B.; Weatherford, P. Scientific basis for sustainable management of Eucalyptus and Populus as short-rotation woody crops in the US. Forests 2014, 5, 901–918. [Google Scholar] [CrossRef]

- Zamora, D. Sustainability of SRWC for Energy. Short Rotation Woody Crops Factsheet, Series # 5; University of Minnesota: Minneapolis, MI, USA, 2015; Available online: https://www.extension.umn.edu/environment/agroforestry/docs/sustainability-of-srwc-for-energy.pdf (accessed on 30 May 2008).

- Meneses-Jácome, A.; Diaz-Chavez, R.; Velásquez-Arredondo, H.I.; Cárdenas-Chávez, D.L.; Parra, R.; Ruiz-Colorado, A.A. Sustainable Energy from agro-industrial wastewaters in Latin-America. Renew. Sustain. Energy Rev. 2016, 56, 1249–1262. [Google Scholar] [CrossRef]

- Amichev, B.Y.; Hangs, R.D.; Konecsni, S.M.; Stadnyk, C.N.; Volk, T.A.; Bélanger, N.; Vujanovic, V.; Schoenau, J.J.; Moukoumi, J.; Van Rees, K.C. Willow short-rotation production systems in Canada and Northern United States: A review. Soil Sci. Soc. Am. J. 2014, 78, S168–S182. [Google Scholar] [CrossRef]

- Baettig, R.; Yáñez, M.; Albornoz, M. Cultivos dendroenergéticos de híbridos de álamo para la obtención de biocombustibles en Chile: Estado del arte. Bosque 2010, 31, 89–99. [Google Scholar] [CrossRef]

- Tenorio, C.; Moya, R.; Arias-Aguilar, D.; Briceño-Elizondo, E. Biomass yield and energy potential of short-rotation energy plantations of Gmelina arborea one year old in Costa Rica. Ind. Crops Prod. 2016, 82, 63–73. [Google Scholar] [CrossRef]

- Tenorio, C.; Moya, R.; Arias-Aguilar, D. Evaluation of changes in tree morphology parameters, biomass yield, chemical and energy properties at three spacings of short rotation energy plantations of Gmelina arborea in Costa Rica, from one to two years of age. Waste Biomass Valori. 2018, 9, 1163–1179. [Google Scholar] [CrossRef]

- Grajales, P. Establecimiento y Evaluación de Cinco Especies Arbóreas Utilizadas para Fines Dendroenergéticos en el Campo Experimental “La Bandera”; B.S. Trabajo De Experiencia Recepcional; Universidad Veracruzana, Facultad De Ciencias Agrícolas: Xalapa, Mexico, 2012; 41p. [Google Scholar]

- Resquín, F.; Rachid, C.; Hirigoyen, A.; Scoz, R.; Doldán, J.; Lopretti, M.; Capdevielle, F.; Carrasco-Letelier, L.; De Martini, M.L. Avances en la evaluación de plantaciones forestales para producción de energía. Rev. INIA 2012, 36, 42. [Google Scholar]

- Van den Broek, R.; van den Burg, T.; van Wijk, A.; Turkenburg, W. Electricity generation from eucalyptus and bagasse by sugar mills in Nicaragua: A comparison with fuel oil electricity generation on the basis of costs, macro-economic impacts and environmental emissions. Biomass Bioenergy 2000, 19, 311–335. [Google Scholar] [CrossRef]

- Betters, D.R.; Wright, L.L.; Couto, L. Short rotation woody crop plantations in Brazil and the United States. Biomass Bioenergy 1991, 1, 305–316. [Google Scholar] [CrossRef]

- Ayling, R.D.; Martins, P.J. The growing of eucalypts on short rotation in Brazil. For. Chron 1981, 57, 9–16. [Google Scholar] [CrossRef]

- Suiter, W.; de Rezende, G.C.; Mendes, C.J. Produções de florestas de Eucalyptus de ciclo curto para fins energéticos (Production of short rotation Eucalyptus for energy sources). Sociedade de Investigações Florestais Boletin Tecnico 1980, 3, 1–9. [Google Scholar]

- Rahman, M.M.; Mostafiz, S.B.; Paatero, J.V.; Lahdelma, R. Extension of energy crops on surplus agricultural lands: A potentially viable option in developing countries while fossil fuel reserves are diminishing. Renew. Sustain. Energy Rev. 2014, 29, 108–119. [Google Scholar] [CrossRef]

- Tuskan, G.A. Short-rotation woody crop supply systems in the United States: What do we know and what do we need to know? Biomass Bioenergy 1998, 14, 307–315. [Google Scholar] [CrossRef]

- Rockwood, D.L.; Rudie, A.W.; Ralph, S.A.; Zhu, J.Y.; Winandy, J.E. Energy product options for Eucalyptus species grown as short rotation woody crops. Int. J. Mol. Sci. 2008, 9, 1361–1378. [Google Scholar] [CrossRef] [PubMed]

- Cervantes, J.M. Estudio de sobrevivencia, crecimiento inicial y aporte dendroenergético de: Perymenium grande Hemsl. y Perymenium strigillosum Robinson & Greenm; Escuela Nacional de Ciencias Forestales: Siguatepeque, Honduras, 2013; 120p. [Google Scholar]

- Portillo, S. Evaluación y determinación de la cantidad de leña producida por tres especies forestales dendroenergéticas de una plantación establecida en el bosque escolar de la ESNACIFOR; Tesis de Bachillerato; Escuela Nacional de Ciencias Forestales (ESNACIFOR): Siguatepeque, Honduras, 2013; 119p. [Google Scholar]

- Figueroa, O.A.; Alvarado, C.A.; Mejia, N. Estudio de sobrevivencia y crecimiento inicial de seis especies del bosque seco para fines dendroenergéticos en la estación experimental la soledad, Comayagua. TASCANA 2013, 25, 1–18. [Google Scholar]

- Van den Broek, R.; Vleeshouwers, L.; Hoogwijk, M.; van Wijk, A.; Turkenburg, W. The energy crop growth model SILVA: Description and application to eucalyptus plantations in Nicaragua. Biomass Bioenergy 2001, 21, 335–349. [Google Scholar] [CrossRef]

- Van den Broek, R.; Van Wijk, A.D.; Turkenburg, W. Electricity from energy crops in different settings—A country comparison between Nicaragua, Ireland and the Netherlands. Biomass Bioenergy 2002, 22, 79–98. [Google Scholar] [CrossRef]

- Reyes, F.G.; Membreño, J.J.; Chávez, Y.A. Evaluación de variables dasométricas de rebrotes en Eucalyptus camaldulensis DEHNH, en la finca El Plantel, Nindiri, Masaya. La Calera 2013, 13, 39–45. [Google Scholar]

- Foidl, N.; Makkar, H.P.S.; Becker, K. The potential of Moringa oleifera for agricultural and industrial uses. In The Miracle Tree: The Multiple Attributes of Moringa; Fuglie, L.J., Ed.; CTA Publication: Wageningen, The Netherlands, 2001; pp. 45–76. [Google Scholar]

- Salazar-Zeledón, E. Influencia de altas densidades de plantación en el poder calorífico y propiedades físicas de la madera para la especie Gmelina arborea Roxb. ex Sm. Rev. For. Mesoam. Kurú 2016, 13, 51–56. [Google Scholar] [CrossRef]

- Navarro-Camacho, R.; Esquivel-Segura, E.; Briceño-Elizondo, E.; Arias-Aguilar, D. Estimating aboveground biomass for Eucalyptus saligna Sm. and Eucalyptus camaldulensis Dehn in the center region of Costa Rica. Rev. For. Mesoam. Kuru 2014, 11, 22–33. [Google Scholar] [CrossRef]

- Müller, M.D.; Couto, L.; Leite, H.G.; Brito, J.O. Avaliação de um clone de eucalipto estabelecido em diferentes densidades de plantio para produção de biomassa e energia. Biomassa Energia 2005, 2, 177–186. [Google Scholar]

- Guerra, S.P.; Garcia, E.A.; Lanças, K.P.; Rezende, M.A.; Spinelli, R. Heating value of eucalypt wood grown on SRC for energy production. Fuel 2014, 137, 360–363. [Google Scholar] [CrossRef]

- Junior, H.J.E.; de Melo, R.X.; Sartori, M.M.P.; Guerra, S.P.S.; Ballarin, A.W. Sustainable use of eucalypt biomass grown on short rotation coppice for bioenergy. Biomass Bioenergy 2016, 90, 15–21. [Google Scholar] [CrossRef]

- Lemos, S.V.; Sartori, M.M.P.; Junior, H.D.J.E.; Ribas, L.C.; Guerra, S.P.S. Geração energética de eucalipto de curta rotação. Energia na Agric. 2015, 30, 263–268. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A. Trends and challenges of brazilian pellets industry originated from agroforestry. Cerne 2016, 22, 233–240. [Google Scholar] [CrossRef]

- Garcia, É.A.; Guerra, S.P.S.; Junior, E.; de Jesus, H.; Sansígolo, C.A.; Lanças, K.P.; Yamaji, F.M. Chemical analysis of wood with bark in short rotation forestry systems. Rev. Árvore 2016, 40, 163–171. [Google Scholar] [CrossRef]

- Lima, M.A.; Gomez, L.D.; Steele-King, C.G.; Simister, R.; Bernardinelli, O.D.; Carvalho, M.A.; Rezende, C.A.; Labate, C.A.; McQueen-Mason, S.J.; Polikarpov, I. Evaluating the composition and processing potential of novel sources of Brazilian biomass for sustainable biorenewables production. Biotechnol. Biofuels 2014, 7, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Gadelha, F.D.L.; da Silva, J.A.A.; Ferreira, R.L.C.; dos Santos, R.C.; Tavares, J.A. Productivity of clones eucalypts at different management systems for purposes of energy. Pesquisa Florestal Brasileira 2015, 35, 263–270. [Google Scholar] [CrossRef]

- Eloy, E.; Caron, B.O.; Silva, D.A.D.; Schmidt, D.; Trevisan, R.; Behling, A.; Elli, E.F. Influence of spacing on energy characteristics of tree species on short rotation planting. Rev. Árvore 2014, 38, 551–559. [Google Scholar] [CrossRef]

- Eloy, E.; Caron, B.O.; Silva, D.A.D.; Souza, V.Q.D.; Trevisan, R.; Behling, A.; Elli, E.F. Energy productivity of forest species in short rotation plantings. Ciência Rural 2015, 45, 424–1431. [Google Scholar] [CrossRef]

- Eloy, E.; Silva, D.A.D.; Schmidt, D.; Trevisan, R.; Caron, B.O.; Elli, E.F. Effect of planting age and spacing on energy properties of Eucalyptus grandis W. Hill EX Maiden. Rev. Árvore 2016, 40, 749–758. [Google Scholar] [CrossRef]

- Caron, B.O.; Eloy, E.; Souza, V.Q.; Schmidt, D.; Balbinot, R.; Behling, A.; Monteiro, G.C. Quantification of forest biomass in short rotation plantations with different spacings. Comun. Sci. 2016, 1, 106–112. [Google Scholar]

- Da Costa, K.C.P.; de Lima, R.M.B.; Ferreira, M.J. Biomass and energy yield of leguminous trees cultivated in Amazonas. Floresta 2015, 45, 705–712. [Google Scholar] [CrossRef]

- Rondon, E.V. Biomass yield and growth of Schizolobium amazonicum (Huber) Ducke under different spacing conditions in the wood region. Rev. Árvore 2002, 26, 573–576. [Google Scholar] [CrossRef]

- Morales, M.; Aroca, G.; Rubilar, R.; Acuna, E.; Mola-Yudego, B.; González-García, S. Cradle-to-gate life cycle assessment of Eucalyptus globulus short rotation plantations in Chile. J. Clean. Prod. 2015, 99, 239–249. [Google Scholar] [CrossRef]

- Faúndez, P. Potential costs of four short-rotation silvicultural regimes used for the production of energy. Biomass Bioenergy 2003, 24, 373–380. [Google Scholar] [CrossRef]

- Acuña, E.; Cancino, J.; Rubilar, R.; Parra, C. Bioethanol potential from high density short rotation woody crops on marginal lands in central Chile. Cerne 2017, 23, 133–145. [Google Scholar] [CrossRef]

- Rios-Saucedo, J.C.; Acuna-Carmona, E.; Cancino-Cancino, J.; Rubilar-Pons, R.; Corral-Rivas, J.J.; Rosales-Serna, R. Dynamics of sprouting and basic density of wood in shoots of three wood species with dendroenergy potential. Agrociencia 2017, 51, 215–227. [Google Scholar]

- Esquivel, E.; Rubilar, R.; Sandoval, S.; Acuña, E.; Cancino, J.; Espinosa, M.; Muñoz, F. Efecto de plantaciones dendroenergéticas en el carbono a nivel de suelo, en dos suelos contrastantes de la región de Biobío, Chile. Rev. Árvore 2013, 37, 1135–1144. [Google Scholar] [CrossRef]

- Sandoval, S.; Cancino, J.; Rubilar, R.; Esquivel, E.; Acuna, E.; Muñoz, F.; Espinosa, M. Probability distributions in high-density dendroenergy plantations. Forest Sci. 2012, 58, 663–672. [Google Scholar] [CrossRef]

- Acuña, E.; Espinosa, M.; Cancino, J.; Rubilar, R.; Muñoz, F. Estimating the bioenergy potential of Pinus radiata plantations in Chile. Cienc. Investig. Agrar. 2010, 37, 93–102. [Google Scholar] [CrossRef]

- Carmona, R.; Nuñez, T.; Alonso, M.F. Biomass yield and quality of an energy dedicated crop of poplar (Populus spp.) clones in the Mediterranean zone of Chile. Biomass Bioenergy 2015, 74, 96–102. [Google Scholar] [CrossRef]

- Cabrera, A.M.; Tozzini, C.; Espinoza, S.; Santelices, R.; Meza, F. Biomass production and carbon balance of a short rotation forestry of Populus deltoides (clone Lux) under two different cutting cycles. Bosque 2016, 37, 205–210. [Google Scholar] [CrossRef]

- Bustamante, J.; Perez, S.; Llera, J.; Zanetti, P. Cultivo de Sauces en Alta Densidad: Peso de Biomasa al Primer Año; Jornadas de Salicáceas: Buenos Aires, Argentina, 2006; Available online: http://www.agroindustria.gob.ar/new/00/forestacion/_archivos/_biblioteca/Bustamante1.pdf (accessed on 14 May 2017).

- Vallejos-Barra, O.; Baettig, R. Incremento volumétrico de un ensayo con híbridos de Populus spp. Sustain. Agric. Food Environ. Res. 2015, 3, 1–7. [Google Scholar] [CrossRef]

- Rubilar, R.A.; Allen, H.L.; Fox, T.R.; Cook, R.L.; Albaugh, T.J.; Campoe, O.C. Advances in silviculture of intensively managed plantations. Curr. For. Rep. 2018, 4, 23–34. [Google Scholar] [CrossRef]

- Rodríguez, A.; Cancino, J.; Acuña, E.; Rubilar, R.; Muñoz, F. Evaluación del crecimiento de plantaciones dendroenergéticas de eucalyptus globulus, según densidad de plantación y turno de rotacion en suelos contrastantes de la región del Bio Bio, Chile. Cienc. Investig. Forestal. INFOR Chile 2013, 19, 1–8. [Google Scholar]

- Guerra, S.P.S.; Oguri, G.; Spinelli, R. Harvesting eucalyptus energy plantations in Brazil with a modified New Holland forage harvester. Biomass Bioenergy 2016, 86, 21–27. [Google Scholar] [CrossRef]

- Silva, D.A.; Muller, B.V.; Kuiaski, E.C.; Eloy, E.; Behling, A.; Colaço, C.M. Propriedades da madeira de Eucalyptus benthamii para produção de energia. Pesquisa Florestal Brasileira 2015, 35, 481–485. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Steele, P.H. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Zalesny, J.A.; Zalesny, R.S., Jr.; Wiese, A.H.; Sexton, B.T.; Hall, R.B. Uptake of macro-and micro-nutrients into leaf, woody, and root tissue of Populus after irrigation with landfill leachate. J. Sustain. For. 2008, 27, 303–327. [Google Scholar] [CrossRef]

- Vanbeveren, S.P.P.; Gebauer, R.; Plichta, R.; Volařík, D.; Ceulemans, R. Nutrients and energy in proleptic branches and leaves of poplar under a short-rotation coppice. Biomass Bioenergy 2016, 85, 271–277. [Google Scholar] [CrossRef]

- Verlinden, M.S.; Broeckx, L.S.; Ceulemans, R. First vs. second rotation of a poplar short rotation coppice: Above-ground biomass productivity and shoot dynamics. Biomass Bioenergy 2015, 73, 174–185. [Google Scholar] [CrossRef]

- Wolfsmayr, U.J.; Rauch, P. The primary forest fuel supply chain: A literature review. Biomass Bioenergy 2014, 60, 203–221. [Google Scholar] [CrossRef]

- Kort, J.; Collins, M.; Ditsch, D. A review of soil erosion potential associated with biomass crops. Biomass Bioenergy 1998, 14, 351–359. [Google Scholar] [CrossRef]

- Zalesny, J.A.; Zalesny, R.S.; Wiese, A.H.; Sexton, B.; Hall, R.B. Sodium and chloride accumulation in leaf, woody, and root tissue of Populus after irrigation with landfill leachate. Environ. Pollut. 2008, 155, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Johnson, L.; Prasad, P.V.; Pei, Z.; Wang, D. Big bluestem as a bioenergy crop: A review. Renew. Sustain. Energy Rev. 2015, 52, 740–756. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Sims, R.E.; Hastings, A.; Schlamadinger, B.; Taylor, G.; Smith, P. Energy crops: Current status and future prospects. Glob. Chang. Biol. 2006, 12, 2054–2076. [Google Scholar] [CrossRef]

- Carvalho, R.L.; Ole, M.; Jensen, O.M.; Luís, A.C.; Tarelho, L.A.C. Mapping the performance of wood-burning stoves by installations worldwide. Energy Build. 2016, 127, 658–679. [Google Scholar] [CrossRef]

- Kshirsagar, M.P.; Kalamkar, V.R. A comprehensive review on biomass cookstoves and a systematic approach for modern cookstove design. Renew. Sustain. Energy Rev. 2014, 30, 580–603. [Google Scholar] [CrossRef]

- Guerrero-Lemus, R.; Shephard, L.E. Biomass for heating and power production. In Low-Carbon Energy in Africa and Latin America. Lect. Notes Energy 2017, 48, 121–148. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar]

- Chen, W.H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Ehlert, D.; Pecenka, R. Harvesters for short rotation coppice: Current status and new solutions. Int. J. For. Eng. 2013, 24, 170–182. [Google Scholar] [CrossRef]

- Pecenka, R.; Silva, J.N.; Ehlert, D.; Scholz, G.V. Mechanised harvest of energy wood: State-of-the-art and new developments. Engenharia na Agric. 2016, 24, 32–40. [Google Scholar]

- Junior, H.D.J.E.; Oguri, G.; Melo, R.X.; Ballarin, A.W.; Guerra, S.P.S. Storage of whole-tree chips from high-density energy plantations of Eucalyptus in Brazil. Biomass Bioenergy 2016, 93, 279–283. [Google Scholar] [CrossRef]

- Berhongaray, G.; El Kasmioui, O.; Ceulemans, R. Comparative analysis of harvesting machines on an operational high-density short rotation woody crop (SRWC) culture: One-process versus two-process harvest operation. Biomass Bioenergy 2013, 58, 333–342. [Google Scholar] [CrossRef]

- Vanbeveren, S.P.P.; Schweier, J.; Berhongaray, G.; Ceulemans, R. Operational short rotation woody crop plantations: Manual or mechanised harvesting? Biomass Bioenergy 2015, 72, 8–18. [Google Scholar] [CrossRef]

- Niemiec, W.; Stachowicz, F.; Trzepieciński, T.; Kępa, L.; Dziurka, M. Small-scale harvesting machinery for short rotation willow coppice. Czasopismo Inżynierii Lądowej Środowiska i Architektury 2015, 62, 315–324. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Stachowicz, F.; Niemiec, W.; Kępa, L.; Dziurka, M. Development of harvesting machines for willow small-sizes plantations in East-Central Europe. Croatian J. For. Eng. 2016, 37, 185–199. [Google Scholar]

- Manzone, M.; Balsari, P. Productivity and woodchip quality of different chippers during poplar plantation harvesting. Biomass Bioenergy 2015, 83, 278–283. [Google Scholar] [CrossRef]

- Pecenka, R.; Hoffmann, T. Harvest technology for short rotation coppices and costs of harvest, transport and storage. Agron. Res. 2015, 13, 361–371. [Google Scholar]

- Lowder, S.K.; Carisma, B.; Skoet, J. Who invests how much in agriculture in low-and middle-income countries? An empirical review. Eur. J. Dev. Res. 2015, 27, 371–390. [Google Scholar] [CrossRef]

- Durand, J.; Aysa-Lastra, M. International Migration and Employment in Latin America: Uncertain Times and Changing Conditions. In Immigrant Vulnerability and Resilience; Aysa-Lastra, M., Cachón, L., Eds.; Springer International Publishing: Berlin, Germany, 2015; pp. 183–206. [Google Scholar]

- Singh, D.; Cubbage, F.; Gonzalez, R.; Abt, R. Locational determinants for wood pellet plants: A review and case study of North and South America. BioResources 2016, 11, 7928–7952. [Google Scholar]

- ITA. Sector Snapshot: Biomass Wood Pellets, Renewable Fuels Top Market Report, International Trade Administration. Available online: http://trade.gov/topmarkets/pdf/Renewable_Fuels_Biomass_Wood_Pellets.pdf (accessed on 16 May 2016).

- Jenkins, M.; Majano, A.M.; Gutiérrez, M.J. Financing renewable energy projects in emerging economies: The expansion of Pelletics. J. Bus. Res. 2016, 69, 4507–4519. [Google Scholar] [CrossRef]

- Muñoz, E.; Vargas, S.; Navia, R. Environmental and economic analysis of residual woody biomass transport for energetic use in Chile. Int. J. Life Cycle Assess. 2015, 20, 1033–1043. [Google Scholar] [CrossRef]

- Hässig, A.G.; Ubaque, C.A.G.; Rojas, G.F.T. Estudio de planta piloto para peletización de residuos madereros y su utilización como combustible en hornos ladrilleros. Tecnura: Tecnología y Cultura Afirmando el Conocimiento 2014, 18, 62–70. [Google Scholar] [CrossRef]

- Moreno-Lopez, M.; Alarcón-Herrera, M.T.; Martin-Dominguez, I.R. Feasibility of pelletizing forest residues in Northern Mexico. Waste Biomass Val. 2017, 8, 923–932. [Google Scholar] [CrossRef]

- Felfli, F.F.; Rocha, J.D.; Filippetto, D.; Luengo, C.A.; Pippo, W.A. Biomass briquetting and its perspectives in Brazil. Biomass Bioenergy 2011, 35, 236–242. [Google Scholar] [CrossRef]

- Garcia, É.A.; Guerra, S.P.S.; Junior, J.E.; Sansígolo, C.A.; Lanças, K.P.; Yamaji, F.M. Análise química da madeira com casca em sistemas florestais de curta rotação. Rev. Árvore 2016, 40, 163–171. [Google Scholar] [CrossRef]

- Amaya, A.; Corengia, M.; Cuña, A.; De Vivo, J.; Sarachik, A.; Tancredi, N. Preparation of charcoal pellets from Eucalyptus wood with different binders. J. Energy Nat. Res. 2015, 4, 24–34. [Google Scholar] [CrossRef]

- Tenorio, C.; Moya, R.; Tomazello-Filho, M.; Valaert, J. Quality of pellets made from agricultural and forestry crops in Costa Rican tropical climates. Biorecourses 2015, 10, 482–498. [Google Scholar] [CrossRef]

- Aragón-Garita, S.; Moya, R.; Bond, B.; Valaert, J.; Tomazello Filho, M. Production and quality analysis of pellets manufactured from five potential energy crops in the Northern Region of Costa Rica. Biomass Bioenergy 2016, 87, 84–95. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Pal, K.; Rosen, M.A.; Tyagi, S.K. Recent advances in the development of biomass gasification technology: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 72, 363–384. [Google Scholar] [CrossRef]

- Cutz, L.; Haro, P.; Santana, D.; Johnsson, F. Assessment of biomass energy sources and technologies: The case of Central America. Renew. Sustain. Energy Rev. 2016, 58, 1411–1431. [Google Scholar] [CrossRef]

- Santos, D.A.; Winter, E.; Junior, S. Current overview of green gasification technology in Brazil: An approach via-patent documentation. Rev. Verde de Agroecologia e Desenvol. Sustent. 2014, 9, 26–37. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in biofuel production from gasification. Prog. Energy Comb. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- De Oliveira Resende, M.; Silva, J.N.; Dalólio, F.S.; Barbosa, R.C.; Pedruzi, G.O.L. Desenvolvimento de sistema especialista para seleção de reatores de gaseificação de biomassa. Engenharia na Agric. 2017, 25, 83–91. [Google Scholar] [CrossRef]

- Miguel, J.; Pereira, R.; Maturana, A. Biomass gasification for power generation: A comparison with steam boilers in the Brazilian scenario. Engevista 2017, 19, 306–317. [Google Scholar] [CrossRef]

- Seiffert, M.; Kaltschmitt, M.; Miranda, J.A. The biomethane potential in Chile. Biomass Bioenergy 2009, 33, 564–572. [Google Scholar] [CrossRef]

- Moreda, I.L. The potential of biogas production in Uruguay. Renew. Sustain. Energy Rev. 2016, 54, 1580–1591. [Google Scholar] [CrossRef]

- Bravo, A.R. Generación eléctrica por gasificación de biomasa sólida. Master’s Thesis, Universidad Técnica Federico Santa María Departamento De Ingeniería Mecánica, Santiago, Chile, 2014. [Google Scholar]

- Aguirre, L.A. Evaluación y Caracterización Energética del gas de Síntesis de Biomasa con Poder Calorífico alto, Medio y bajo, Producto del Proceso de Gasificación Downdraft de 10 Kw. Bachelor’s Thesis, Universidad de las Fuerzas Armadas ESPE, Carrera de Ingeniería Mecánica, Santiago, Chile, 2017. [Google Scholar]

- Gámez, J.A.L.; Alvarado, A.F.A. Energías de fuentes vegetales de desecho: Biogás y gasificación. Jóvenes en la Ciencia 2017, 2, 400–404. [Google Scholar]

- Román-Figueroa, C.; Montenegro, N.; Paneque, M. Bioenergy potential from crop residue biomass in Araucania Region of Chile. Renew. Energy 2017, 102, 170–177. [Google Scholar] [CrossRef]

- Pérez, J.F.; Barrera, R.; Ramírez, G. Integration of Colombians forest commercial crops in thermochemical biorefinery concepts: A Review. Colomb. For. 2015, 18, 273–294. [Google Scholar] [CrossRef]

- Hauk, S.; Knoke, T.; Wittkopf, S. Economic evaluation of short rotation coppice systems for energy from biomass—A review. Renew. Sustain. Energy Rev. 2014, 29, 435–448. [Google Scholar] [CrossRef]

- Costanza, J.K.; Abt, R.C.; McKerrow, A.J.; Collazo, J.A. Bioenergy production and forest landscape change in the southeastern United States. GCB Bioenergy 2017, 9, 924–939. [Google Scholar] [CrossRef]

- Don, A.; Osborne, B.; Hastings, A.; Skiba, U.; Carter, M.S.; Drewer, J.; Flessa, H.; Freibauer, A.; Hyvönen, N.; Jones, M.; et al. Land-use change to bioenergy production in Europe: Implications for the greenhouse gas balance and soil carbon. GCB Bioenergy 2012, 4, 372–391. [Google Scholar] [CrossRef]

- Acuña, E.; Rubilar, R.; Cancino, J.; Albaugh, T.J.; Maier, C.A. Economic assessment of Eucalyptus globulus short rotation energy crops under contrasting silvicultural intensities on marginal agricultural land. Land Use Policy 2018, 76, 329–337. [Google Scholar] [CrossRef]

- Souza, Q.; Nogueira, A.; Ângelo, H.; Vale, A. Custo de produção das biomassas de eucalipto e capim-elefante para energia. Cerne 2011, 17, 417–426. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).