Abstract

This paper proposes a miniature DC-DC boost converter to drive the display panel of a notebook computer. To reduce the size of the circuit, the converter was designed to operate at a switching frequency of 1 MHz. The power conversion efficiency improved using a passive snubber circuit that consisted of one inductor, two capacitors, and two diodes; it reduced the switching losses by lowering the voltage stress of the switch and increased the voltage gain using charge pumping operations. An experimental converter was fabricated at 2.5 cm × 1 cm size using small components, and tested at input voltage 5 V ≤ VIN ≤ 17.5 V and output current 30 mA ≤ IO ≤ 150 mA. Compared to existing boost converters, the proposed converter had ~7.8% higher power conversion efficiency over the entire range of VIN and IO, only ~50% as much voltage stress of the switch and diodes, and a much lower switch temperature TSW = 49.5 °C. These results indicate that the proposed converter is a strong candidate for driving the display panel of a notebook computer.

1. Introduction

Notebook or tablet computers are powered by a Li ion battery pack [1,2,3,4]. Typically, the battery pack is composed of 2–4 Li ion battery cells. Each Li ion cell has a terminal voltage of 2.6–4.2 V depending on the charging state, so the voltage of the battery pack changes in the range of 5–17 V [5,6,7]. To supply power to each part of the computer, the pack voltage is converted to several voltages by DC-DC converters.

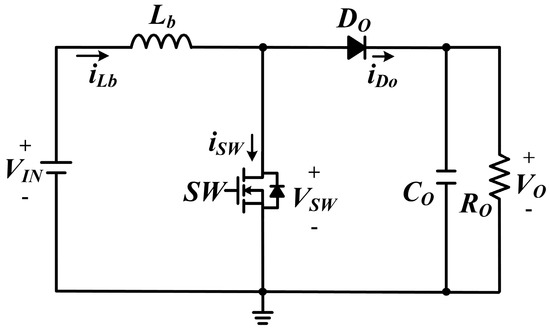

Many computers use a light-emitting diode (LED) backlight unit (BLU) for the liquid crystal display (LCD) panel. For a 17 inch panel, the voltage required to drive the LED backlight can be as high as 40 V [8]. The DC-DC boost converter for the LED BLU in a notebook or tablet computer should have a circuit topology that can reduce the overall size and weight [9,10,11,12,13,14,15,16]. The conventional boost converter (Figure 1) has the simplest structure, and can be implemented in small sizes by operating at a high switching frequency fS. However, the switching loss increases as fS increases, and thereby decreases the power conversion efficiency ηe and can cause overheating of the switch. This problem has been solved using soft-switching converters [17,18,19,20,21].

Figure 1.

Schematic of conventional DC-DC boost converter.

Soft-switching converters [17,18,19,20,21] use active snubbers to reduce switching loss. These snubbers are implemented using an auxiliary switch, diodes, and energy storage elements. The auxiliary switch requires a separate gate drive circuit that is controlled by a sophisticated algorithm. The snubber of Reference [17] discharges the drain-source capacitor CDS of the main switch before the switch turns on, so zero-voltage (ZV) turn-on of the switch is possible. The snubbers of References [18,19] force the switch current to zero before the switch turns off, so zero-current (ZC) turn-off of the switch is possible. The snubber of Reference [20] achieves ZV turn-off of the switch by reducing the rate of voltage increase during the turn-off transient, and achieves ZC turn-on of the switch by reducing the rate of current increase during the turn-on transient. However, the converters of References [17,18,19,20] have some limitations when they operate at high fS; they use a resonance between an inductor (L) and a capacitor (C) in the active snubber, the inductance L of L should be small enough to achieve ZV or ZC switching in a short time; the current peak of the switch or diodes increases as L decreases, therefore, this change increases the conduction loss and reduces the maximum output power. In the converter of Reference [21], the capacitance CDS discharges through L of the snubber when the auxiliary switch turns on. The ZV turning on of the main switch is achieved by discharging CDS completely. The L required to achieve the ZV turning on of the switch decreases as fS increases; as a consequence, the switching loss in the auxiliary switch increases. Therefore, simultaneous reduction of switching losses in the main and auxiliary switches is very difficult at high fS. The converter of Reference [9] uses a passive snubber to reduce the switching loss. The switching loss is reduced by lowering the turn-on slope of the switch current; the inductor LS that is connected in series with the switch controls the turn-on slope. However, the energy stored in LS is released as a voltage spike because the current path of LS is blocked when the switch is turned off. To ensure that this voltage spike does not exceed the maximum voltage limit of the switch, LS should be less than 50 nH at high switching frequencies; This value of LS was calculated using Equation (9) of the design guide in Reference [9]. The low value of the chip type inductor has a low maximum current limit. This low inductance also causes undesired resonance due to the parasitic inductance or capacitance of the circuit. Because of this, the converter of Reference [9] is difficult to use at high switching frequencies. Additionally, the switch current significantly increases the conduction loss in LS because the components of small size have non-negligible series resistance.

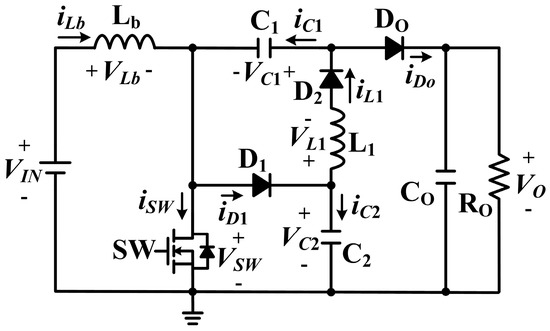

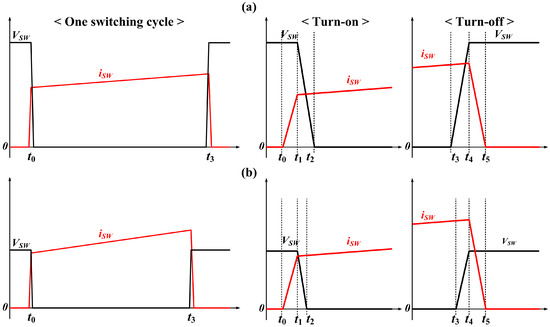

To improve upon the aforementioned drawbacks in the existing converters, this paper proposes a miniature DC-DC boost converter for the display panel of a notebook computer. The proposed converter (Figure 2) uses a passive snubber to reduce the switching loss; the capacitor C2 is connected in parallel with the switch, and the inductor L1 is connected in series with C2, and the value of L1 and C2 are large enough to prevent resonance at high fS. This lowers VSW to VO-VC1 and eliminates the switching loss. In addition, L1 is placed apart from the main current path to reduce the conduction loss in the passive snubber. The switch operates under a hard-switching condition to achieve fast switching, but the switching loss is reduced by lowering VSW (Figure 3). The switching loss PSW is calculated using the waveforms of iSW and VSW as:

Figure 2.

Schematic of proposed DC-DC boost converter.

Figure 3.

Voltage and current waveforms of the switch: (a) conventional boost converter, (b) proposed converter.

Compared with the conventional converter, the proposed converter has a similar current peak, but has VSW(t1) and VSW(t4) lowered by ~1/2, so PSW is reduced.

The proposed converter has a higher voltage conversion ratio than the conventional boost converter, and therefore has a wide range of output voltage for a given range of input voltage. Section 2 describes the circuit structure and operating principle of the proposed converter, Section 3 gives the design guidelines, Section 4 shows the experimental results, and Section 5 concludes the paper.

2. Circuit Structure and Operating Principles of the Proposed Converter

The proposed converter consists of two capacitors C1 and C2, two diodes D1 and D2, and an inductor L1, in addition to the conventional boost components Lb, DO, CO, and a switch (SW). C1 is located between boost inductor Lb and output diode DO, and acts as a charge pump capacitor to increase the voltage gain. L1 and C2 reduce the voltage stress of SW by dividing the output voltage VO. D1 and D2 provide a charging or discharging path for C2.

The operating modes (Figure 4) and key waveforms (Figure 5) of the proposed converter include three sequential modes of operation.

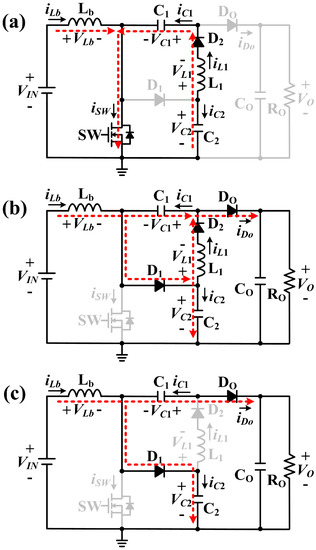

Figure 4.

Modes of operation: (a) Mode 1 (t0 < t < t1), (b) Mode 2 (t1 < t < t2), (c) Mode 3 (t2 < t < t3).

Figure 5.

Operating waveforms of the proposed DC-DC boost converter.

Mode 1 (t0~t1): The first operation (Figure 4a) starts at t = t0 by turning ON SW. During this operation, D2 turns ON, and D1 and DO turn OFF. and , so

C1 is charged and C2 is discharged when SW is turned ON. Mode 1 ends when SW is turned OFF.

Mode 2 (t1~t2): The second operation (Figure 4b) starts at t = t1 when SW turns OFF. During mode 2, D2 stays ON, and D1 and DO are turned ON. When SW is turned OFF, the anode voltage of D1 is VC2 because VLb = VC2 − VIN according to the voltage second valance law. The cathode voltage of D1 is VC2 − ΔVC2 because C2 was discharged in Mode 1, so D1 is turned ON. After D1 is turned ON, the anode voltage of DO is VC1 + VC2 and cathode voltage is VO − ΔVO because CO was discharged in Mode 1. Therefore, DO is turned ON because VC1 + VC2 = VO in steady state. In the same manner, after D1 and DO are turned ON, D2 is turned ON because the anode voltage of D2 is VC1 + VC2 and the cathode voltage is VO − ΔVO. and , so

The voltage stress of SW is VC2 because D1 is turned ON when SW is turned OFF. The output voltage VO is divided into VC1 and VC2, so the voltage stress of SW is smaller than VO, which is the voltage stress of the conventional boost converter.

Mode 3 (t2~t3): The last operation (Figure 4c) starts at t = t2 when D2 turns OFF. D1 and DO stay ON during this mode. , so

In this mode, because iL1 = 0. Mode 3 ends when SW is turned ON for the next switching cycle.

The voltage–second balance law of inductances Lb and L1 yields

where D is the duty of switching and αTS is the duration of Mode 3. Solving Equations (3) and (4) for VC1 and VC2 yields

Equation (5) and then give the voltage conversion ratio as

The average current of L1, IL1 for one switching period TS is equal to the average output current IO, so

Inserting Equation (5) into Equation (7) and solving for α yields

Combining Equations (6) and (8) yields the output voltage

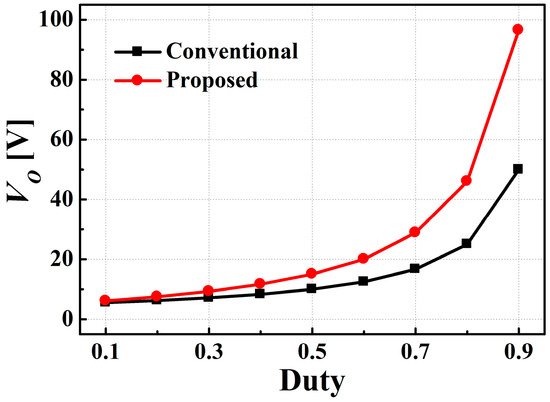

VO versus D (Figure 6) for L1 = 10 μH, fS = 1 MHz, IO = 150 mA, VIN = 5 V, and 0.1 ≤ D ≤ 0.9 was calculated using Equation (9) for the proposed converter, but the conventional boost converter was calculated using their voltage gain equations. To have VO = 40 V for given VIN, D = 0.775 was applied to the proposed converter, whereas D = 0.875 was applied to the conventional boost converter. At given VIN and D, the proposed converter had higher VO than the conventional boost converters.

Figure 6.

VO versus duty D for the experimental boost converters; VIN = 5 V, 0.1 ≤ D ≤ 0.9.

3. Design Guideline

3.1. Boost Inductor Lb

The inductance Lb of Lb should be determined so that the proposed converter operates in a continuous conduction mode (CCM). The current through Lb is minimum at t0 and maximum at t1. The following equation is obtained using the average of iLb and Equation (1),

Solving Equation (10) for iLb(t0) yields

The condition iLb(t0) > 0 should be satisfied to operate the proposed converter in CCM. This condition yields

For 5 ≤ VIN ≤ 17.5 V, VO = 40 V, fS = 1 MHz, and 30 ≤ IO ≤ 150 mA, Lb = 33 µH was determined using Equations (9) and (11).

3.2. Snubber Inductor L1

A small value of L1 causes a drastic current decrease of D2 in mode 2. Therefore, the limit of L1 is calculated using the following condition for a soft turn-off of D2.

where ID2,max is the highest diode current and tfall is the diode turn-off time; L1 ≫ 0.2 μH for ID2,max = 1 A and tfall = 10 ns. The diode turn-off loss increases as L1 decreases, so L1 = 10 µH was chosen to provide an operating margin and to reduce turn-off loss of D2.

3.3. Snubber Capacitors C1 and C2

The capacitance of C1 is determined by the condition that because VC1 should be almost constant for one switching period TS, where is the voltage ripple of C1. During Mode 1, C1 charges through L1; this results in a voltage ripple of C1; because the current through C1 decreases linearly from 0 A at t0 to at t1.

Therefore,

For VIN = 5 V, VO = 40 V, fS = 1 MHz, and L1 = 10 µH, C1 = 1 µF was determined using Equations (5) and (12). C2 has been chosen to be the same as C1 because and iC1 = −iC2 in Mode 1.

4. Experimental Results

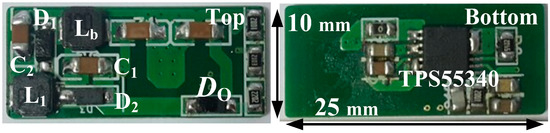

The proposed boost converter (Figure 7) was designed to operate at VIN = 5 V, VO = 40 V, 30 ≤ IO ≤ 150 mA, and fS = 1 MHz. The inductances were set at Lb = 33 µH and L1 = 10 µH. Capacitances C1 and C2 were both set at 1 µF. The experimental circuit was implemented using the following miniature components (Table 1): TPS55340 DC-DC controller (Texas Instruments Inc., Dallas, TX, USA), which has an internal n-MOS switch (40 V, 5A), RB160M-60TR diodes (Rohm Co.), IFSC-1515AH-01 (Vishay Inc.) and SSMC252008R47SC (SST Inc.) chip inductors, and multilayer ceramic chip capacitors of a size 3.2 mm × 1.6 mm. The chip inductors and capacitors have series resistances given in the parentheses. To ensure a fair comparison, the conventional boost converter used the same components.

Figure 7.

Photograph of the proposed DC-DC boost converter.

Table 1.

Component values for the experimental boost converters.

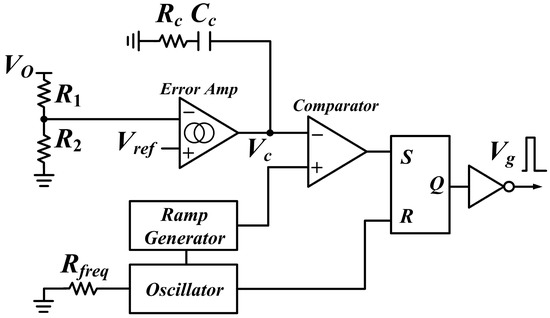

The TPS55340 regulates the output voltage with current mode PWM control, and has an internal oscillator. The pulse width modulation of the gate pulse Vg is achieved in the control circuit for the proposed converter (Figure 8) as follows; each clock pulse resets the flip-flop and the ramp generator, which sets Vg to the ‘high’ state; the output Vc of the error amplifier increases as VO increases; the comparator output changes from ‘low’ to ‘high’ when the output voltage of the ramp generator exceeds Vc, which changes the inverter output Vg to the ‘low’ state. When the output current IO increases/decreases abruptly, VO decreases/increases instantly, which increases/decreases Vc. Thus, the pulse width of Vg increases/decreases to keep VO constant.

Figure 8.

Block diagram of the control circuit for the proposed converter.

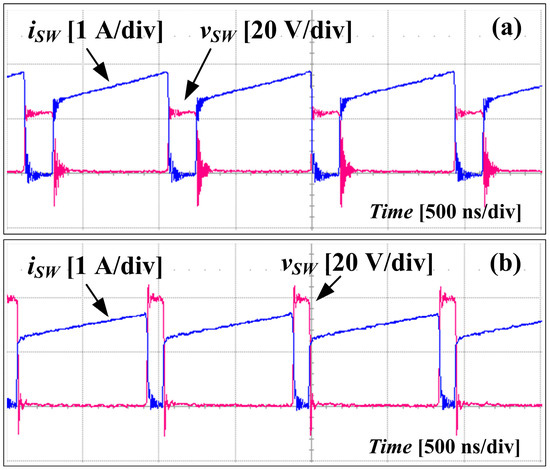

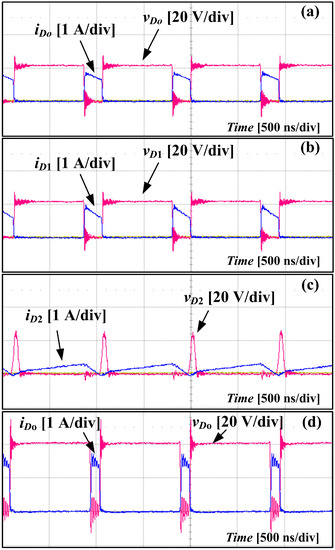

The voltage and current waveforms of SW (Figure 9) were measured at VIN = 5 V, VO = 40 V, IO = 150 mA, and fS = 1 MHz. The voltage stress of the proposed converter (Figure 9a) was lower than that of the conventional boost converter (Figure 9b) because the voltage stress was in the proposed converter but VO in the conventional boost converter. The current stresses of the proposed converter and the conventional boost converter were similar. The current waveforms of the diodes are shown in Figure 10. The diodes current stresses of the proposed converter was lower than the conventional boost converter. The time-averaged values <iD1>, <iD2>, and <iDo> were all equal to IO.

Figure 9.

Voltage and current waveforms of switch measured at VIN = 5 V, VO = 40 V, IO = 150 mA, and fS = 1 MHz. (a) Proposed converter, (b) conventional boost converter.

Figure 10.

Diode waveforms of the proposed converter. (a) Do, (b) D1, (c) D2, and diode waveform of the conventional boost converter. (d) Do measured at VIN = 5 V, VO = 40 V, IO = 150 mA and fS = 1 MHz.

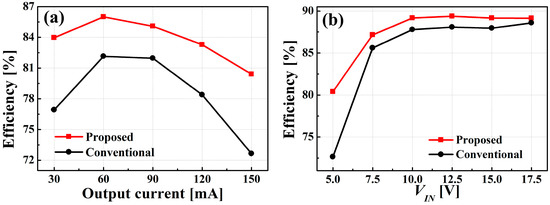

The curves of ηe on IO (Figure 11a) were measured at 30 ≤ IO ≤ 150 mA, VIN = 5 V, VO = 40 V, fS = 1 MHz. At IO = 30 mA, ηe was 84.0% for the proposed converter and 76.9% for the conventional boost converter. At IO = 150 mA, ηe was 80.4% for the proposed converter and 72.6% for the conventional boost converter. The curves of ηe on VIN (Figure 11b) were measured at 5 ≤ VIN ≤ 17.5 V, IO = 150 mA, VO = 40 V, fS = 1 MHz; ηe at VIN = 17.5 V was 89.1% for the proposed converter and 88.6% for the conventional boost converter. The ηe of the proposed converter was up to 7.8% higher than the conventional boost converter at VIN = 5 V. The proposed converter had a high ηe over the entire input voltage and output current ranges.

Figure 11.

(a) ηe versus IO at VIN = 5 V, VO = 40 V, fS = 1 MHz, and 30 ≤ IO ≤ 150 mA. (b) ηe versus VIN at IO = 150 mA, VO = 40 V, fS = 1 MHz, and 5 ≤ VIN ≤ 17.5 V.

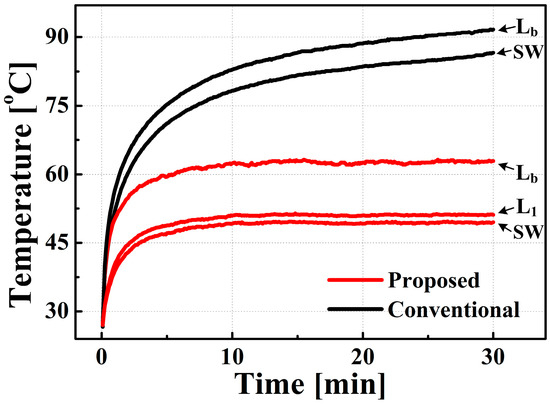

The temperatures of SW and inductors (Figure 12) were measured for 30 min using a digital temperature recorder (GL-220, GRAPHTEC), while the converters were operated at VIN = 5 V, VO = 40 V, fS = 1 MHz, and IO = 150 mA. In the conventional boost converter the switch stabilized at 86.6 °C and the inductor stabilized at 91.7 °C, but in the proposed converter, the switch stabilized at 49.5 °C and the inductor stabilized at 62.9 °C. These data indicate that the proposed converter generated less heat loss than the conventional boost converter.

Figure 12.

Temperature of switch and inductors versus operation time for the experimental converters, measured at VIN = 5 V, VO = 40 V, IO = 150 mA, and fS = 1 MHz.

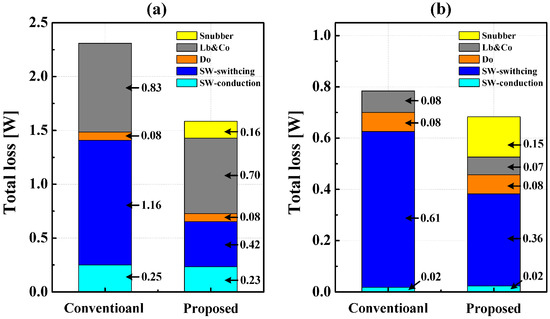

The circuit losses were calculated using a circuit simulator at VO = 40 V, IO = 150 mA, fs = 1 MHz, and VIN = 5 V (Figure 13a) and 15 V (Figure 13b). The total power losses were 1.59 W (proposed) and 2.31 W (conventional) at VIN = 5 V, and they were 0.68 W (proposed) and 0.78 W (conventional) at VIN = 15 V. These results show that the proposed converter had lower power loss than the conventional boost converter at both VIN = 5 V and 15 V. The losses in the switch were 0.65 W (proposed) and 1.41 W (conventional) at VIN = 5 V, and they were 0.38 W (proposed) and 0.63 W (conventional) at VIN = 15 V. The proposed converter reduced the switching loss by decreasing VSW. Additionally, the snubber loss of the proposed converter was 0.16 W at VIN = 5 V, and it was 0.15 W at VIN = 15 V. The proposed converter reduced the snubber losses by placing L1 at the output stage and eliminating the resonant current in the snubber circuit.

Figure 13.

Circuit losses for VO = 40 V, IO = 150 mA and fS = 1 MHz, calculated at (a) VIN = 5 V and (b) VIN = 15 V.

The voltage and current stress (Table 2) of the proposed and conventional boost converter were measured at VIN = 5 V, VO = 40 V, IO = 150 mA, and fS = 1 MHz. Without parasitic components, the voltage stress of SW and diodes were as follows: (1) in the conventional boost converter, because DO was turned ON when SW was turned OFF, and because SW was turned ON when DO was turned OFF; (2) in the proposed converter, because DO, D1, and D2 were turned ON when SW was turned OFF, because SW was turned ON when DO and D1 are turned OFF, and because D1 and DO were turned ON, and SW was turned OFF when D2 was turned OFF. The proposed converter had lower voltage stress of SW and diodes than the conventional boost converter because . The current stress of SW was similar in the conventional boost converter and the proposed converter. The current stresses of diodes were lower by half in the proposed converter than in the conventional boost converter.

Table 2.

Voltage and current stresses of components in the experimental boost converters.

The voltage stress, current stress, voltage gain, and efficiency of the existing boost converter were calculated using a circuit simulator at VIN = 5 V, VO = 40 V, IO = 150 mA, and fs = 1 MHz (Table 3). The efficiency ηe was 72.6% for the conventional boost converter, 80.4% for the proposed converter, 75.1% for the converter of Reference [12], and 76.6% for the converter of Reference [21]. The proposed converter had the highest ηe for given input and output conditions. The converters of References [12,21] had a lower efficiency than that of the proposed converter due to a high current stress and the loss of auxiliary switch, respectively. The voltage stress of the proposed converter was lower than that of the other converters because the voltage stress is VO-VC1 in the proposed converter but VO in the other converters. The current stresses of the proposed converter and the conventional boost converter were similar, but the converter of Reference [12] had a high current stress because it used resonance to reduce the switching loss at high frequency. At given VIN and VO, the proposed converter had the smallest duty, so the proposed converter had the highest voltage gain.

Table 3.

Comparison with existing boost converters.

5. Conclusions

A miniature DC-DC boost converter for driving a display panel of a notebook computer was proposed. This converter operates at a switching frequency of 1 MHz to miniaturize the circuit. The switching loss is reduced by using a passive snubber that lowers the voltage stresses of the switch. The conduction losses of the snubber and switch is also minimized by preventing high peak current due to the resonance at high fS. The experimental converter was fabricated in 2.5 cm × 1 cm size and tested at 5 ≤ VIN ≤ 17.5 V, 30 ≤ IO ≤ 150 mA. Compared to previous boost converters, the proposed converter had a higher voltage conversion ratio, ~7.8% higher power conversion efficiency over the entire range of VIN and IO, ~1/2 as much voltage stress of the switch and diodes, and a much lower switch temperature. The results indicate that the proposed converter is a strong candidate for driving the display panel of a notebook computer.

Author Contributions

S.-H.H. conceived the main idea for the proposed converter and performed overall analysis and experiment. H.-J.C. led the project and gave technical advice.

Acknowledgments

This research was supported by the Tongmyong University Research Grants 2019(2019A003-1).

Conflicts of Interest

The authors have no conflict of interest.

References

- Chen, M.; Rincón-Mora, G.A. Accurate, compact, and power-efficient Li-ion battery charger circuit. IEEE Trans. Circuits Syst. II Express Briefs 2006, 53, 1180–1184. [Google Scholar] [CrossRef]

- Zhou, S.; Rincon-Mora, G.A. A high efficiency, soft switching DC-DC converter with adaptive current-ripple control for portable applications. IEEE Trans. Circuits Syst. II Express Briefs 2006, 53, 319–323. [Google Scholar] [CrossRef]

- Salinas, F.; Krüger, L.; Neupert, S.; Kowal, J. A second life for li-ion cells rescued from notebook batteries. J. Energy Storage 2019, 24, 100747. [Google Scholar] [CrossRef]

- Nordmann, H.; Frisch, M.; Sauer, D.U. Thermal Fault-Detection method and analysis of peripheral systems for large battery packs. Measurement 2018, 114, 484–491. [Google Scholar] [CrossRef]

- Sun, J.; Xu, M.; Ying, Y.; Lee, F.C. High Power Density, High Efficiency System Two-Stage Power Architecture for laptop Computers. In Proceedings of the 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006; pp. 1–7. [Google Scholar]

- Issa, J. Display power analysis and design guidelines to reduce power consumption. J. Inf. Disp. 2012, 13, 167–177. [Google Scholar] [CrossRef]

- Tsai, Y.Y.; Tsai, Y.S.; Tsai, C.W.; Tsai, C.H. Digital noninverting-Buck–boost converter with enhanced duty-cycle-overlap control. IEEE Trans. Circuits Syst. II Express Briefs 2016, 64, 41–45. [Google Scholar] [CrossRef]

- Datasheet: STLD41 White LED Driver for Mid-Size LCD Display Backlight. Available online: http://www.st.com/resource/en/datasheet/stld41.pdf (accessed on 1 October 2018).

- Lee, S.W.; Choe, H.J.; Yun, J.J. Performance improvement of a boost LED driver with high voltage gain for edge-lit LED backlights. IEEE Trans. Circuits Syst. II Express Briefs 2017, 65, 481–485. [Google Scholar] [CrossRef]

- Wu, C.H.; Chen, C.L. High-efficiency current-regulated charge pump for a white LED driver. IEEE Trans. Circuits Syst. II Express Briefs 2009, 56, 763–767. [Google Scholar]

- Hsieh, Y.T.; Liu, B.D.; Wu, J.F.; Fang, C.L.; Tsai, H.H.; Juang, Y.Z. A high current accuracy boost white LED driver based on offset calibration technique. IEEE Trans. Circuits Syst. II Express Briefs 2011, 58, 244–248. [Google Scholar] [CrossRef]

- Choe, H.J.; Chung, Y.C.; Sung, C.H.; Yun, J.J.; Kang, B. Passive snubber for reducing switching-power losses of an IGBT in a DC-DC boost converter. IEEE Trans. Power Electron. 2014, 29, 6332–6341. [Google Scholar] [CrossRef]

- Bamgboje, D.O.; Harmon, W.; Tahan, M.; Hu, T. Low Cost High Performance LED Driver Based on a Self-Oscillating Boost Converter. IEEE Trans. Power Electron. 2019, 34, 10021–10034. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Y.; Guan, Y.; Xu, D. A High Frequency High Voltage Gain DCM Coupled-Inductor Boost LED Driver based on Planar Component. IEEE Trans. Ind. Appl. 2019, in press. [Google Scholar] [CrossRef]

- Hariharan, K.; Kapat, S. Near Optimal Controller Tuning in a Current-Mode DPWM Boost Converter in CCM and Application to a Dimmable LED Array Driving. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 7, 1031–1043. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Zhou, Q.; Xu, J. Flicker-Free Single-Switch Quadratic Boost LED Driver Compatible with Electronic Transformers. IEEE Trans. Ind. Electron. 2018, 66, 3458–3467. [Google Scholar] [CrossRef]

- Sathyan, S.; Suryawanshi, H.M.; Singh, B.; Chakraborty, C.; Verma, V.; Ballal, M.S. ZVS–ZCS high voltage gain integrated boost converter for DC microgrid. IEEE Trans. Ind. Electron. 2016, 63, 6898–6908. [Google Scholar] [CrossRef]

- Choi, H.S.; Cho, B.H. Novel zero-current-switching (ZCS) PWM switch cell minimizing additional conduction loss. IEEE Trans. Ind. Electron. 2002, 49, 165–172. [Google Scholar] [CrossRef]

- Barreto, L.H.S.C.; Coelho, E.A.A.; Farias, V.J.; de Oliveira, J.C.; de Freitas, L.C.; Vieira, J.J.B. A quasi-resonant quadratic boost converter using a single resonant network. IEEE Trans. Ind. Electron. 2005, 52, 552–557. [Google Scholar] [CrossRef]

- Elasser, A.; Torrey, D.A. Soft switching active snubbers for dc/dc converters. IEEE Trans. Power Electron. 1996, 11, 710–722. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Ding, D. Zero-voltage-and zero-current-switched PWM DC-DC converters using active snubber. IEEE Trans. Ind. Appl. 1999, 35, 1406–1412. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).