Abstract

This study investigates the potential of microalgae oil production as an alternative renewable energy source, in a pilot project located at Minamisoma City in the Fukushima Prefecture of Japan. The algal communities used in this research were the locally mixed species, which were mainly composed of Desmodesmus collected from the Minamisoma pilot project. The microalgae oil-production processes in Minamisoma consisted of three stages: cultivation, dewatering, and extraction. The estimated theoretical input-energy requirement for extracting oil was 137.25 MJ to process 50 m3 of microalgae, which was divided into cultivation 15.40 MJ, centrifuge 13.39 MJ, drum filter 14.17 MJ, and hydrothermal liquefaction (HTL) 94.29 MJ. The energy profit ratio (EPR) was 1.41. The total energy requirement was highest in the HTL process (68%) followed by cultivation (11%) and the drum filter (10%). The EPR value increased along with the yield in the cultivation process. Using HTL, the microalgae biomass could be converted to bio-crude oil to increase the oil yield in the extraction process. Therefore, in the long run, the HTL process could help lower production costs, due to the lack of chemical additions, for extracting oil in the downstream estimation of the energy requirements for microalgae oil production.

1. Introduction

Energy plays a vital role in modern society. For years, conventional energy sources, based on oil, coal, and natural gas, have been drivers for economic advancements [1]. Fossil fuel has long been used as the primary energy source in transportation. Coal and natural gas are used as fuel for electricity generation. Without fossil fuel and electricity to fuel a country, economic activity would be interrupted.

The issue of fossil-fuel depletion has recently come into debate and the rise of crude oil prices has encouraged many countries to develop alternative renewable energy sources. For example, Indonesia produces palm oil-based biodiesel because it is the most prominent producer of palm oil. Brazil produces ethanol from sugarcane as does the United States with its corn [2]. This scenario is good but can also become a problem because food crop-based biofuel can affect food availability and price, especially in developing countries [3].

Recently, algal biomass feedstock has been selected to avoid the confrontation of food vs. fuel and land-use changes [4,5,6]. Microalgae also have an advantage compared to other feedstock, with a higher oil yield/hectare. The oil palm has the highest yield of perennial crops, with 5950 L/ha, while microalgae with 30% oil (by weight) in biomass can generate 58,700 L/ha [6]. Because the land requirement for algae is one-tenth that of the oil palm, the microalgae can theoretically produce 10 times more oil than the oil palm in a same area.

Considering the advantages of microalgae, Japan has started to develop them as an energy feedstock at Minamisoma City, Fukushima Prefecture. The project location was selected in a risk-prone area after a major earthquake occurred in 2011. Because of the radioactive residue from the nuclear incident, Minamisoma may not be suitable for rehabilitation as an agricultural area. Developing microalgae as a biofuel feedstock can help restore the city as an industrial area.

1.1. Microalgae Production

Conventional microalgae oil extraction typically involves using a solvent. Therefore, only oil is used as a biofuel feedstock. However, recently, hydrothermal liquefaction (HTL) has gained more attention for its ability to process wet-algae biomass [7]. With HTL, almost all of the microalgae biomass can be converted to bio-crude oil [7,8]. The Minamisoma pilot plant is a research-based pilot plant. Its initial objective was to test a method of producing microalgae oil using HTL. The microalgae oil production started from microalgae cultivation using a raceway pond with native algal communities, with Desmodesmus as the main species with other species including Scenedesmus acumunatus, Klebsormidium sp., Dictyosphaerium sp., and other various species with small percentage. Desmodesmus as the main species proportion vary according to season but can reaches up to 24% of the total organism. The microalgae were harvested and sent to a centrifuge for the dewatering process, and a drum dryer for a second dewatering process before undergoing the HTL treatment.

The HTL process does not need to add chemicals to extract the oil; therefore, in the long run, chemical costs can be avoided. Reducing the operational costs will help lower the production cost, which is beneficial economically. The Minamisoma pilot plant uses HTL, which requires high-temperature and high-pressure systems and is expected to consume considerable energy. However, this energy requirement is expected to be offset by the increase in yield from the biomass conversion, and the omission of the energy required to dry the biomass thoroughly.

1.2. Energy Requirements

Microalgae has high potential; however, the main drawback is its size. Microalgae are small organisms; thus, to get much feedstock, water removal or drying is crucial. Drying can account for more than 80% of the energy consumption [9]. Previous researchers reported the mass balance and life-cycle assessment of microalgae; for example, using an open raceway pond for the cultivation [10,11,12] or using a photobioreactor for the cultivation stage [13]. Using the total biomass enables the utilization of fast-growing species because there is no need to wait for lipid production [14], and the HTL process utilizes biomass more efficiently than lipid extraction [15]. Minamisoma sometimes faces clogging problems in the HTL process. In the future, they must adopt a method that can resolve the clogging issue, which will successfully prolong the process time [16]. Other problems, for example, nitrogen content in the oil [17], can be resolved using two-stage HTL. In two-stage HTL, Stage 1 was pre-treatment (<200 °C) and stage 2 was the main treatment (250–350 °C). Stage 1 resulted the input nitrogen flow to the aqueous phase; following stage 2, the nitrogen reduction was up to 55% relative to direct HTL [18].

The advantages of processing various strains of microalgae are especially apparent if we consider the geographical constraints. If an area cannot grow high-lipid microalgae but is very suitable for growing high-biomass microalgae, it can still develop microalgae fuel by utilizing HTL technology. This was because HTL can process whole biomass and not only the oil in microalgae [7,8], therefore low-lipid, high-biomass microalgae still have prospects to be developed. Therefore, the HTL process in Minamisoma is projected to be developed into an industrial-sized algae oil plant. However, the energy requirement is a significant issue that must be addressed before moving from the pilot scale to the industrial scale.

Opinions are split between negative and positive energy balances, and there is still no agreement on an accurate energy balance [8]. Some studies have resulted in an energy loss [8,18] while others have resulted in an energy profit [19,20]. Energy profit ratio (EPR) is the ratio between energy produced and energy consumed, thus a positive value is preferred. Therefore, a downstream process to analyze the EPR is required for the Minamisoma project to accurately determine the energy balance through the EPR, before further establishing the plant on an industrial scale.

1.3. Objective

The objective of this research is to find the EPR, based on the energy requirements for microalgae production, involving all the stages from cultivation to extraction, to determine the feasibility of recommending an industrial-scale production from the pilot project. In this proposed analysis, the Minamisoma pilot plant was used as the ground base of development for microalgae oil production. Its potential to contribute in the rehabilitation area would be beneficial environmentally and socially.

2. Methodology

This research was based on experimental, empirical, and theoretical models. The model from [21] was mainly used in the cultivation process, while the model from [22] was mainly used in the centrifugation process. The filtration was mainly based on experimental results from [23], and the extraction was mainly based on a theoretical model from the law of thermodynamics. Figure 1 shows the analytical process of this research.

Figure 1.

Research analytical process for four stages of microalgae production at Minamisoma.

2.1. Cultivation

The production process in this study was based on the production-process layout in the Minamisoma pilot plant, which consisted primarily of four stations. Those stations were cultivation, centrifugation, drum filtration, and extraction. The cultivation station utilized an open raceway pond (ORP) with a paddlewheel acting as the mixer. The theoretical power required for a paddlewheel in cultivation was estimated using the following equation from [21]:

where Lr (m) is the channel length of the pond, w is the channel width, h is the culture depth, ρ (kg/m3) is the density of the culture broth, g (9.81 m/s2) is the gravitational acceleration, dh is the hydraulic diameter of the flow channel, fM is the Manning channel roughness factor, and e is the efficiency of the motor, drive, and paddlewheel. A typical fM value for trowel-finished concrete is 0.013 [24]. For a paddlewheel located in a channel with a flat bottom, the e value is about 0.17 [25].

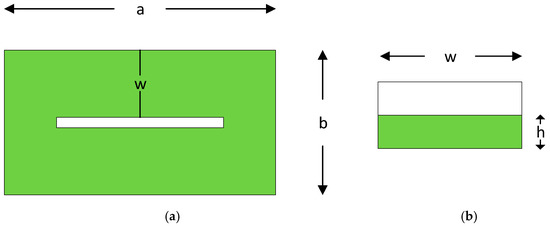

The microalgae concentration in cultivation is low. In Minamisoma, the harvest concentration was around 0.34 g/L. Therefore, the microalgae-cultivation properties, such as density and viscosity, were typically selected to closely resemble water properties at the operating temperature [21]. These parameters were later used in Equation (1) to calculate the power required for cultivation. Figure 2 shows the open-raceway pond dimensions of the Minamisoma pilot plant, where a is the length of the pond, b is the width of the pond, h is the depth of the culture, and w is the channel width.

Figure 2.

Open raceway pond: (a) top view of the open raceway pond; (b) flow channel of the open raceway pond.

Before the power calculation, the hydraulic diameter (dh) must be calculated, using the following equation from [21], where w is the width of the channel and h is the average depth of the liquid in it.

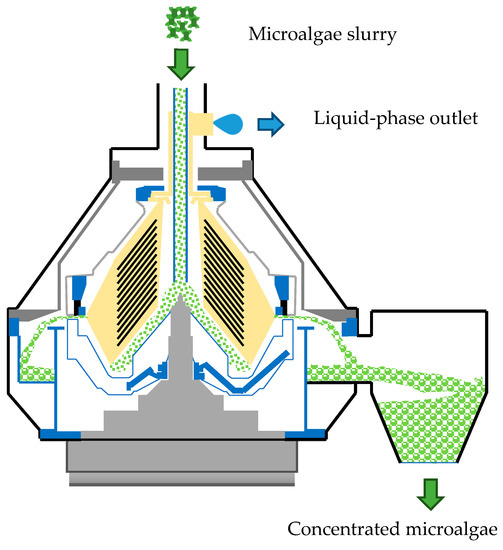

2.2. Centrifuge

The centrifuge uses centrifugal force to separate the microalgae cells from the water. The centrifuge equipment is smaller than a settling tank. The centrifuge primarily increases the gravity to accelerate the separation process. Figure 3 illustrate the disk stack centrifuge used for the experiment at the Minamisoma pilot plant.

Figure 3.

Disk-stack centrifuge used at the Minamisoma pilot plant.

The centrifuge accelerates the settling rate by increasing the gravity (G-force). The settling equation follows Stokes’ Law to calculate the terminal settling velocity (TSV). Stokes’ terminal settling velocity in gravity (1 g) can be calculated using Equation (3) from [26], where uo is the settling velocity, ρp is the particle density, ρf is the water density, g is the gravity acceleration, and d is the particle diameter. The volumetric flow rate (Q) can be calculated using Equation (4), where V is the volume and t is time.

The power is calculated using Equation (5) from [22], where Pacc is the power for the feed acceleration, sg is the specific gravity of the feed slurry, Q is the volumetric flow rate of the feed, ω is the speed, and rp is the radius of the bucket.

Pacc = 5.984(10−10)sgQ(ωrp)2

2.3. Drum Filtration

The drum-filtration energy is calculated based on the expression:

Energy = power × time.

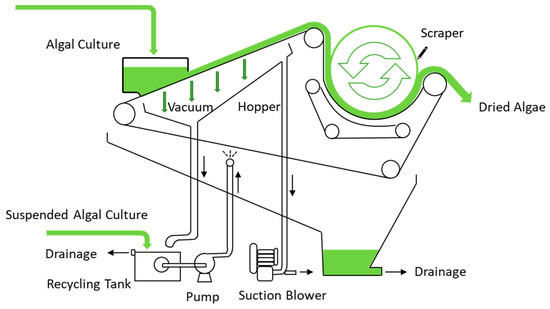

Figure 4 illustrates the drum filter used in the Minamisoma pilot plant.

Figure 4.

Drum filter installed at the Minamisoma pilot plant.

2.4. HTL

Hydrothermal liquefaction processes biomass in water at high/subcritical temperatures (below 374 °C) and high pressure (above water vapor pressure) with or without a catalyst [19,27]. HTL can process 5–20% algae concentration as input [27]; in the Minamisoma pilot plant, microalgae concentration more than 20% introduces a clogging problem. In the HTL process, microalgae biomass is broken down in water to small molecules which then can repolymerize into oily compounds. HTL therefore allows wet conversion of biomass, thus reducing the energy consumption in drying process [19,28]. In the HTL process, the primary data was obtained from the Minamisoma pilot plant, especially from [23] and from the literature review. The specific heat (Cp) for the microalgae can be determined utilizing Equation (7) from [29].

The basic equation to calculate the heat requirement for microalgae and water is as shown in equation, where m is the mass and ΔT is the temperature difference (8).

Q = m × Cp × ΔT

2.5. Energy Profit Ratio (EPR)

The final part is the energy profit ratio (EPR) calculation, which is the ratio of the energy produced to the energy consumed by an energy-production method. The EPR value can be calculated using Equation (9) as in [30].

3. Results and Discussion

3.1. Baseline

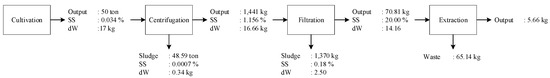

The Minamisoma pilot plant in Fukushima Prefecture, Japan was selected for its collected algal communities. The technology was implemented using four stations from cultivation to extraction. The cultivation process was carried out using an open raceway pond (ORP). The dewatering process consisted of two sub-processes: centrifugation for the first phase and a drum filter for the second phase. The last primary process was extraction, which used hydrothermal liquefaction (HTL) methods. Figure 5 shows the mass balance of the microalgae oil production at Minamisoma, SS is suspended solid and dW is dry weight.

Figure 5.

Mass balance of microalgae oil production at the Minamisoma pilot plant.

3.2. Cultivation

The pilot project in Minamisoma used an ORP to cultivate microalgae. The ORP dimensions were 20 m in width and 50 m in length (1000 m2 area). The cultivation depth was 0.2 m, which made the volume 200 m3 or 200,000 L. The ORP was constructed from concrete.

The main microalgae species cultivated in Minamisoma is Desmodesmus. The microalgae cultivation had a hydraulic retention time (HRT) of four days with an average harvest concentration of 0.034%. The harvesting volume per day was 50 m3. Therefore, the everyday cultivation had a yield of 17 kg of microalgae (dry weight) or 0.34 g/L. The primary equipment in this cultivation station was the raceway pond, which utilized an electric motor to drive the paddlewheel. Table 1 shows the parameters and value for ORP at Minamisoma pilot plant

Table 1.

Open raceway pond parameters for the pilot plant at Minamisoma.

Nagappan and Verma [31] used the same species, Desmodesmus sp., but the highest yield obtained from their laboratory was 77.73 mg/L or 0.08 g/L. The biomass yield obtained in this research was similar to the result from Ji et al., in which the biomass yield was 0.385 g/L [32]. The yield in this research can be increased by adding anaerobically digested wastewater (ADW), where the yield reached 1.039 g/L, or a more-than-250% increase in biomass; therefore, in the future, the yield potential can still be increased.

Using Equation (2), the calculated dh value was 0.77 m and, using Equation (1), the power for the paddlewheel was 0.86 MJ. The paddlewheel was operated for 24 h a day, and the energy consumption was 20.53 MJ. In addition, we could reduce the paddlewheel speed at night, when there is no photosynthesis, to further reduce the energy consumption to 15.40 MJ. Table 2 shows the energy consumption for the two scenarios.

Table 2.

Energy consumption by the paddlewheel.

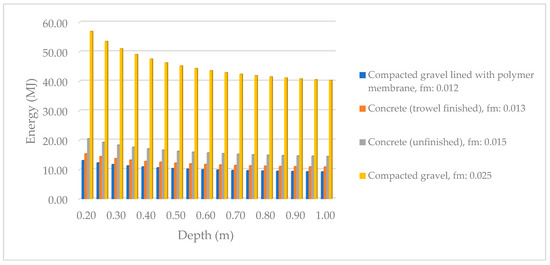

By using calculation based on Equation (1), the power consumption decreases with the increased culture depth. The power consumption is also decreased by lowering the Manning coefficient. The Manning value is related to the pond materials; a smooth surface gives a lower Manning value because the friction is lower, thereby reducing the overall power consumption. Figure 6 shows the power-consumption changes by depth and material changes.

Figure 6.

Energy requirements for operating the paddlewheel with different culture depths and pond materials (18 h).

Additional energy is required if we consider the nutrients used in the cultivation. With an initial weight of 5 kg and a harvest weight of 17 kg, approximately 12 kg of biomass was produced. Using stoichiometry from [23,33], we can estimate the nutrients needed for cultivation. The calculation based on the stoichiometry can be seen in Appendix A, and Table 3 shows the energy for the nutrients. The energy demand was estimated using the Simapro® Cumulative Energy Demand Methods, version 1.09.

Table 3.

Nutrients’ energy demand.

The nutrients’ energy demand is very high if we rely on the fertilizer. Alternatively, we can integrate the microalgae cultivation with other industries to supply nutrients for the microalgae [32,34,35,36]. If we could replace the CO2 and other nutrients, it would be beneficial for the final EPR value.

3.3. Centrifugation

A centrifuge was used to accelerate the harvesting time for microalgae cultivation compared to gravity sedimentation. With a 360-L volume and a 270-s residence time, we calculated the volumetric flow rate of 1.33 L/s. The total time to process 50 m3 input using Equation (4) results in 10.42 h. With a volumetric flow rate of 1.33 L/s, we can compare this value to the typical centrifuge setting to obtain the speed of the centrifuge and the radius of the bucket/bowl from [33]. The typical setting for a 1.33 L/s input uses a 10,000-rpm speed and a bucket radius of 0.25 m. The later power can be calculated using Equation (5), which results in a value of 4.99 HP or 13.39 MJ.

The calculated theoretical value for the centrifugal action was 13.39 MJ or 0.07 kWh/m3. This theoretical value was lower than the application in practice because of influences such as machine efficiency. A field measurement of around 1 kWh/m3 was reported; this value is the same as [37], which also gave a value of 1 kWh/m3, but higher than the value from the Alva Laval in [38], which gave a value of 0.53 kWh/m3. The parameters to calculate the centrifuge power can be seen in Table 4.

Table 4.

Energy required in the centrifuge process.

3.4. Filtration

According to the specification’s energy requirement, the drum filter equipment’s power was 1.42 kW, with a feed capacity of 520 kg/h to produce 20% microalgae. The input feed was 1441 kg, which required 2.77 h of processing time. The total energy consumption for the filtration was 14.17 MJ. This value is equal to 2.73 kWh/m3, which was slightly lower than the value obtained by [38] and Mohn in [39], both of which gave a value of 3 kWh/m3.

3.5. Extraction

The native microalgae communities cultivated in Minamisoma were mainly Desmodesmus. Theoretically, solvent extraction can only extract from fatty-acid content, which is only 13% of the total biomass. This fatty-acid value was lower than the protein and polysaccharide values, which were 45.7% and 21.1%, respectively. Hydrothermal liquefaction (HTL), on the other hand, could convert almost all the biomass into crude oil. Therefore, the yield is expected to be higher than for only oil extraction. Because the purpose is to produce energy, a higher yield is preferable. Table 5 shows the properties of the algal communities in Minamisoma [40].

Table 5.

Properties of the algal communities at the Minamisoma pilot plant.

A previous study showed a base for calculating the specific heat of the algal communities [29]. Table 6 shows the parameters used to calculate the specific heat of the algal communities with Desmodesmus as the main species.

Table 6.

Specific heat assumption.

The specific heat of the microalgae was calculated using the composition given in Table 5 and Table 6. Using Equation (7), the specific heat (Cp) of the microalgae was 1.58 kJ/(kg·°C).

The HTL input was a microalgae slurry with a microalgae concentration of 20%; therefore, for 70.81 kg of input, 56.64 kg was water and 14.16 kg was microalgae. Here, we used the average value required to heat the water from 25 °C to 350 °C. The energy required to heat 56.64 kg of water from 25 °C to 350 °C, according to Equation (8), was 87.02 MJ, and the energy required to heat 14.16 kg of microalgae from 25 °C to 350 °C was 7.28 MJ. Thus, the total energy to heat 70.81 kg of microalgae slurry from 25 °C to 350 °C was 94.29 MJ. The microalgae specific heat (Cp) value was 1.58 kJ/(kg·°C). This microalgae specific heat value was categorized as average, as [29] stated that the specific heat for microalgae ranged from 1.2–2 kJ/(kg·°C). Table 7 shows the parameters used in the theoretical calculation of the energy requirement.

Table 7.

Parameters used in the hydrothermal liquefaction (HTL) energy requirement.

3.6. Energy Profit Ratio (EPR)

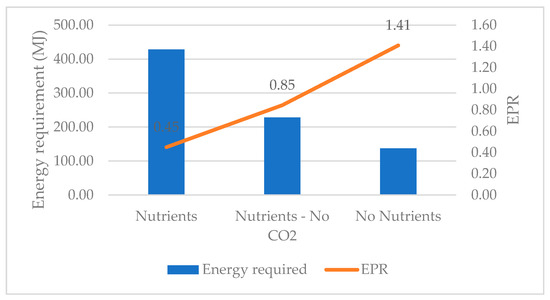

The EPR (Energy Profit Ratio) is the ratio of the energy produced to the energy consumed by an energy-production method [30]. The highest energy demand came from the nutrients, followed by the HTL process, with around 68% and 22%, respectively. Carbon dioxide from flue gas could be used as a CO2 source in microalgae cultivation [41]. If we could obtain CO2 from another industry, the nutrient percentage would decrease to around 40% of the total energy demand. Further, if we could completely substitute the nutrients, the highest energy consumption would be the HTL process with around a 68% share.

Without the nutrients, the HTL energy consumption was the highest, with 94.29 MJ or slightly more than 68%, followed by cultivation with 15.40 MJ or slightly more than 11%. The drum filtration and centrifuge contributed 14.17 MJ and 13.39 MJ or around 10% and 9%, respectively. With a microalgae-oil energy content of 193.27 MJ, the energy profit ratio was found to be 1.41.

Figure 7 shows the EPR value with nutrients, with nutrients but without CO2, and without nutrients. It was observed that with nutrients, the EPR was very low at only 0.45; the EPR value increased to 0.85 if we excluded the CO2 from the system. The EPR value would rise more if we could substitute all the needed nutrients. Therefore, an integrated system for microalgae cultivation or overall microalgae oil production is preferable. An integrated microalgae cultivation system was partially designed and a study reported on a photo-bioreactor using wastewater, which resulted in an increased yield [39,40]. We expect that the EPR value can be increased with the increased yield.

Figure 7.

Energy profit ratio with nutrients and nutrients removed.

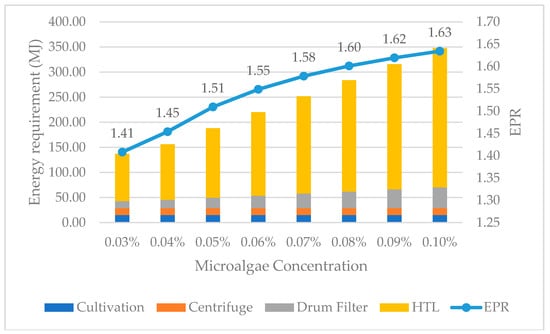

To determine the EPR value from the increase in biomass yield, we calculated different scenarios, from the existing 0.03% to a concentration of 0.1%. The other parameters are the same, with the paddlewheel running for 18 h and a culture depth of 0.2 m. The energy requirement for cultivation was mostly the same because of the constant paddlewheel operation, and the increased yield produced more energy, thereby helping to increase the EPR value. A similar scenario occurred in a centrifuge, which further increased the EPR value. The results are shown in Table 8.

Table 8.

Energy profit ratio from scenarios with a culture depth of 0.2 m.

The theoretical EPR value can reach more than 1, which indicates a positive energy balance; however, the field applications were typically lower than the theoretical value. Therefore, equipment optimization or an increased yield is still needed. The increasing yields in the scenarios showed an increase in the EPR. Desmodesmus yields reached 0.8 g/L in our experiment and [42] also achieved a yield of 0.758 g/L; several other studies were also included [34,35,36]. Figure 8 shows the EPR value increase with different yield scenarios.

Figure 8.

Energy profit ratio (EPR) for different microalgae concentrations.

Increasing the concentration in the HTL input yielded a higher EPR; however, the HTL equipment design needs further improvement. A higher concentration in the HTL input means more microalgae and less water. Because the energy required to heat water is higher compared to heating microalgae, the energy requirement is expected to decrease. However, the higher the input concentration, the more likely the equipment is to clog and disrupt the HTL process. The HTL equipment in Minamisoma sometimes clogged with a higher input concentration. Therefore, an input concentration higher than 30% in HTL equipment was suggested for future research. Another aspect that needs to be considered is the use of a heat exchanger. The pilot project in Minamisoma did not utilize a heat exchanger; therefore, the energy requirement was higher. By incorporating a heat exchanger, the energy requirement is expected to decrease.

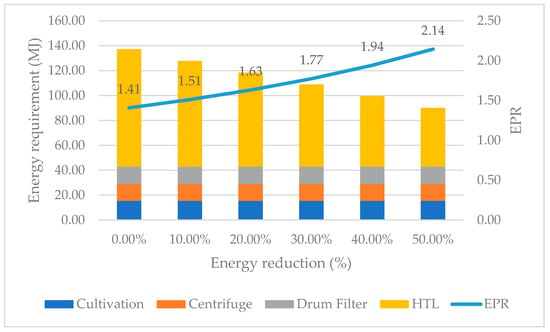

The EPR value in the system for a 0.03% microalgae concentration was 1.41. If we incorporate a heat exchanger, the EPR is expected to increase. The heat exchanger effectiveness was reported to vary between 0.6 and 1 [43]. We simulated the decreased energy requirement and assumed 10% to 50% energy reductions. Figure 9 shows the EPR by energy reduction in the four stages for the Minamisoma pilot plant.

Figure 9.

EPR status by energy reduction in the HTL process.

Before being used as a biofuel feedstock, microalgae was mostly commercially produced for its nutritional value [7]. This type of cultivation did not pose problems for energy balance because the product was mostly for food (supplements), feed, or cosmetics. When the purpose was changed to energy production, the EPR was brought into serious consideration. We need to input less energy than the energy produced to make it a sustainable option.

The disadvantage of microalgae is its small size and high water content. These constraints should be overcome through developing equipment and reducing the processing time. On the other hand, the dewatering process requires higher energy if we utilize a centrifuge and filtration, compared to gravity sedimentation. Extraction using HTL also requires higher energy, which, in turn, results in a lower EPR for the overall product line. However, in a gravity-sedimentation system, the required time is longer, and the area is significantly more extensive.

Cultivating microalgae for energy production could be optimized by using traditional methods such as gravity sedimentation to harvest the microalgae; however, the trade-off is the processing time. Time and area could be a trade-off with the energy requirement. The EPR is the decision-making benchmark for the feasibility of converting pilot-type plants to industrial-scale or integrated microalgae production systems. The EPR of this research indicates that the current level of microalgae-cultivation technology for producing bioenergy is still on the border of being feasible. More research on productivity and machine efficiency are still needed.

4. Conclusions

The EPR result from the calculated energy requirement using a downstream approach for four stages in the Minamisoma pilot plant was more than 1, which means that the amount of energy produced was higher than the energy required in the four stages of oil extraction. The EPR was found to be more than 1 with a nutrient replacement, which indicated the potential of the Minamisoma pilot plant to move to the industrial scale. On the other hand, in the scenario without nutrient replacement, the EPR was lower than 1. In such a case, integrated microalgae production systems were recommended. A supply of nutrients from external sources (e.g., waste) could help mitigate the nutrient requirement, thereby reducing the energy requirement for nutrients.

An option to switch to more gravitation settling processes could help increase the EPR; however, the trade-off was a longer processing time. The other disadvantage was the area required, which is typically larger. The EPR could be increased by increasing the yield in the cultivation station or by changing the processing method to use technology with lower energy requirements.

Another option was to increase the machine efficiency by, for example, increasing the HTL equipment input concentration or incorporating a heat exchanger. Even though increasing the concentration of the HTL input was expected to yield a higher EPR, the HTL equipment design needs to be improved accordingly, because the higher input concentration makes it more likely for clogging to occur and disrupt the HTL process. The clogging problem in the HTL process has been successfully solved by other researchers, which makes the HTL process more promising and increases the possibility for expansion to a larger scale.

By knowing the EPR value, we can determine which process needs more attention, and take the necessary precautions to minimize the energy requirements for oil extraction. Therefore, this research recommends scaling up the Minamisoma pilot project to an industrial scale, based on the EPR, as preparation for a bigger picture of ensuring energy security.

Acknowledgments

This work was supported by a grant from the Next-generation Renewable Energy Development Program for Fukushima reconstruction and revitalization, Fukushima Prefecture, for 2013–2015.

Author Contributions

This work was developed and written by Dhani S. Wibawa. Muhammad A. Nasution performed evaluation of the technical calculation. Mikihide Demura provided data for microalgae cultivation and analyzed the respective data. It was conceived with Ryozo Noguchi, Tofael Ahamed, and Makoto M. Watanabe who provided major editorial contributions and guidance. All authors contributed to the writing of the paper.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| Parameters | Value | Unit |

| Open raceway pond | ||

| Length (a) | 50 | m |

| Width (b) | 20 | m |

| Channel width (w) | 10 | m |

| Height (h) | 0.2 | m |

| Area | 1000 | m2 |

| Volume | 200 | m3 |

| HRT | 4 | days |

| Harvest | 50 | m3/d |

| Paddlewheel running time | 18 | h |

| Centrifugation | ||

| Horsepower for feed acceleration (Pacc) | 4.99 | HP |

| 13.39 | MJ | |

| Specific gravity feed slurry (sg) | 1000.02 | kg/m3 |

| Volumetric flow rate of feed (Q) | 1.33 | L/s |

| Angular speed (ω) | 10,000.00 | rpm |

| Radius of the bucket (rp) | 0.25 | m |

| Filtration | ||

| Feed capacity | 520 | kg/hr |

| Running time | 2.77 | hr |

| Extraction | ||

| Desmodesmus sp. Properties | ||

| Water | 5.70 | % |

| Fatty acids | 13.00 | % |

| Protein | 45.70 | % |

| Polysaccharide | 21.10 | % |

| Ash | 14.50 | % |

| Specific heat | ||

| Water | 4.18 | kJ/(kg·°C) |

| Fatty acids | 2.30 | kJ/(kg·°C) |

| Protein | 1.47 | kJ/(kg·°C) |

| Polysaccharides | 1.26 | kJ/(kg·°C) |

| Ash | 0.73 | kJ/(kg·°C) |

| HTL equipment | ||

| Mass | 70.81 | Kg |

| Microalgae concentration | 20 | % |

| Water concentration | 80 | % |

| Cp microalgae | 1.58 | kJ/(kg·°C) |

| Cp water (average) | 4.73 | kJ/(kg·°C) |

| Initial temperature | 25 | °C |

| Final temperature | 350 | °C |

Appendix A. Microalgae Biomass Stoichiometry

| CO2 | + | 0.148 HNO3 | + | 0.014 H2SO4 | + | 0.012 H3PO4 | + | 0.751 H2O |  | CH1.715O0.427N0.148S0.014P0.012 | + | 1.437 O2 | ||

| MW | g/mol | 44.01 | 63.01 | 98.08 | 98.00 | 18.02 | 23.47 | 32.00 | ||||||

| #mol | mol | 511.39 | 75.69 | 7.16 | 6.14 | 384.06 | 511.39 | 734.87 | ||||||

| Mass | g | 22,506.89 | 4769.36 | 702.17 | 601.38 | 6919.14 | 12,000.00 | 23,515.83 | ||||||

| kg | 22.51 | 4.77 | 0.70 | 0.60 |

References

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Wilson, T.; Baker, R.; Ricketts, M.; Roe, S.; Wilson, C.; Koehler, N. 2016 Ethanol Industry Outlook; Renewable Fuels Association: Washington, DC, USA, 2016. [Google Scholar]

- Von Braun, J. The World Food Situation: New Driving Forces and Required Actions; International Food Policy Research Institute: Washington, DC, USA, 2008. [Google Scholar]

- Baffes, J.; Haniotis, T. Placing the 2006/08 Commodity Price Boom into Perspective; Policy Research Working Papers; WPS 5371.; The World Bank: Washington, DC, USA, 2010; ISBN 5371. [Google Scholar]

- Urbanchuk, J.M. The Renewable Fuel Standard and Consumer Food Prices; ABF Economics: Washington, DC, USA, 2013. [Google Scholar]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef] [PubMed]

- Benemann, J. Microalgae for biofuels and animal feeds. Energies 2013, 6, 5869–5886. [Google Scholar] [CrossRef]

- López Barreiro, D.; Prins, W.; Ronsse, F.; Brilman, W. Hydrothermal liquefaction (HTL) of microalgae for biofuel production: State of the art review and future prospects. Biomass Bioenergy 2013, 53, 113–127. [Google Scholar] [CrossRef]

- Lardon, L.; Hélias, A.; Sialve, B.; Steyer, J.-P.P.; Bernard, O.; Helias, A.; Sialve, B.; Steyer, J.-P.P.; Bernard, O. Life-cycle assessment of biodiesel production from microalgae. Environ. Sci. Technol. 2009, 43, 6475–6481. [Google Scholar] [CrossRef] [PubMed]

- Yuan, J.; Kendall, A.; Zhang, Y. Mass balance and life cycle assessment of biodiesel from microalgae incorporated with nutrient recycling options and technology uncertainties. GCB Bioenergy 2015, 7, 1245–1259. [Google Scholar] [CrossRef]

- Woertz, I.C.; Benemann, J.R.; Du, N.; Unnasch, S.; Mendola, D.; Mitchell, B.G.; Lundquist, T.J. Life cycle GHG emissions from microalgal biodiesel - A CA-GREET model. Environ. Sci. Technol. 2014, 48, 6060–6068. [Google Scholar] [CrossRef] [PubMed]

- Passell, H.; Dhaliwal, H.; Reno, M.; Wu, B.; Ben Amotz, A.; Ivry, E.; Gay, M.; Czartoski, T.; Laurin, L.; Ayer, N. Algae biodiesel life cycle assessment using current commercial data. J. Environ. Manag. 2013, 129, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Grierson, S.; Strezov, V.; Bengtsson, J. Life cycle assessment of a microalgae biomass cultivation, bio-oil extraction and pyrolysis processing regime. Algal Res. 2013, 2, 299–311. [Google Scholar] [CrossRef]

- Jones, S.; Zhu, Y.; Anderson, D.; Hallen, R.T.; Elliott, D.C. Process Design and Economics for the Conversion of Algal Biomass to Hydrocarbons: Whole Algae Hydrothermal Liquefaction and Upgrading; Technical Report; Pacific Northwest National Lab.: Richland, WA, USA, 2014. [Google Scholar]

- Frank, E.D.; Elgowainy, A.; Han, J.; Wang, Z. Life cycle comparison of hydrothermal liquefaction and lipid extraction pathways to renewable diesel from algae. Mitig. Adapt. Strateg. Glob. Chang. 2013, 18, 137–158. [Google Scholar] [CrossRef]

- Mørup, A.J.; Becker, J.; Christensen, P.S.; Houlberg, K.; Lappa, E.; Klemmer, M.; Madsen, R.B.; Glasius, M.; Iversen, B.B. Construction and Commissioning of a Continuous Reactor for Hydrothermal Liquefaction. Ind. Eng. Chem. Res. 2015, 54, 5935–5947. [Google Scholar] [CrossRef]

- Biller, P.; Sharma, B.K.; Kunwar, B.; Ross, A.B. Hydroprocessing of bio-crude from continuous hydrothermal liquefaction of microalgae. Fuel 2015, 159, 197–205. [Google Scholar] [CrossRef]

- Jazrawi, C.; Biller, P.; He, Y.; Montoya, A.; Ross, A.B.; Maschmeyer, T.; Haynes, B.S. Two-stage hydrothermal liquefaction of a high-protein microalga. Algal 2015, 8, 15–22. [Google Scholar] [CrossRef]

- Biller, P.; Ross, A.B. Potential yields and properties of oil from the hydrothermal liquefaction of microalgae with different biochemical content. Bioresour. Technol. 2011, 102, 215–225. [Google Scholar] [CrossRef] [PubMed]

- Minowa, T.; Yokoyama, S.; Kishimoto, M.; Okakura, T. Oil production from algal cells of Dunaliella tertiolecta by direct thermochemical liquefaction. Fuel 1995, 74, 1735–1738. [Google Scholar] [CrossRef]

- Chisti, Y. Algae Biotechnology; Bux, F., Chisti, Y., Eds.; Green Energy and Technology; Springer International Publishing: Basel, Switzerland, 2016; ISBN 978-3-319-12333-2. [Google Scholar]

- Perry, R.H.; Green, D.W. Section 18: Liquid-Solid Operations and Equipment. In Perry’s Chemical Engineers’ Handbook; Perry, R.H., Green, D.W., Eds.; McGraw-Hill: New York, NY, USA, 2008; Volume 8, p. 2400. [Google Scholar]

- Demura, M.; Yoshida, M.; Yokoyama, A.; Ito, J.; Kobayashi, H.; Kayano, S.; Tamagawa, Y.; Watanobe, M.; Date, N.; Osaka, M.; et al. Biomass productivity of native algal communities in Minamisoma city, Fukushima Prefecture, Japan. Algal Res. 2018, 29, 22–35. [Google Scholar] [CrossRef]

- Te Chow, V. Open-Channel Hydraulics; McGraw-Hill: New York, NY, USA, 1959; ISBN 9780070859067. [Google Scholar]

- Borowitzka, M.A. Culturing Microalgae in Outdoor Ponds. In Algal Culturing Techniques; Andersen, R.A., Ed.; Academic Press: Amsterdam, The Netherlands, 2005; pp. 205–218. ISBN 0-12-088426-7. [Google Scholar]

- Perry, R.H.; Green, D. Section 6: Fluid and Particle Dynamics. In Perry’s Chemical Engineers’ Handbook; Perry, R.H., Green, D.W., Eds.; McGraw-Hill: New York, NY, USA, 2008; p. 2400. [Google Scholar]

- Garcia Alba, L.; Torri, C.; Samorì, C.; Van Der Spek, J.; Fabbri, D.; Kersten, S.R.A.; Brilman, D.W.F. Hydrothermal treatment (HTT) of microalgae: Evaluation of the process as conversion method in an algae biorefinery concept. Energy Fuels 2012, 26, 642–657. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.C.; Champagne, P. Overview of recent advances in thermo-chemical conversion of biomass. Energy Convers. Manag. 2010, 51, 969–982. [Google Scholar] [CrossRef]

- Yang, C.; Wu, J.; Deng, Z.; Zhang, B.; Cui, C.; Ding, Y. A Comparison of Energy Consumption in Hydrothermal Liquefaction and Pyrolysis of Microalgae. Trends Renew. Energy 2017, 3, 76–85. [Google Scholar] [CrossRef]

- Matsushima, J. Why is the energy balance ratio view important?—Reexamination of the definition and significance of EPR-. Nucl. Instrum. Methods Phys. Res. 1996, 3, 42–47. [Google Scholar]

- Nagappan, S.; Verma, S.K. Growth model for raceway pond cultivation of Desmodesmus sp. MCC34 isolated from a local water body. Eng. Life Sci. 2016, 16, 45–52. [Google Scholar] [CrossRef]

- Ji, F.; Zhou, Y.; Pang, A.; Ning, L.; Rodgers, K.; Liu, Y.; Dong, R. Fed-batch cultivation of Desmodesmus sp. in anaerobic digestion wastewater for improved nutrient removal and biodiesel production. Bioresour. Technol. 2015, 184, 116–122. [Google Scholar] [CrossRef] [PubMed]

- Perry, R.H.; Green, D.W. Perry’s Chemical Engineers’ Handbook; McGraw-Hill: New York, NY, USA, 2008; Volume 8, ISBN 9780071422949. [Google Scholar]

- Sasongko, N.A.; Noguchi, R. Comprehensive evaluation of integrated energy plantation model of palm oil and microalgae based biofuel for sustainable energy production. Energy Procedia 2015, 68, 226–235. [Google Scholar] [CrossRef]

- Mehmood, M.A.; Rashid, U.; Ibrahim, M.; Abbas, F.; Taufi, Y.H. Algal Biomass Production Using Waste Water. Biomass Bioenergy 2014, 307–327. [Google Scholar] [CrossRef]

- Cai, T.; Park, S.Y.; Li, Y. Nutrient recovery from wastewater streams by microalgae: Status and prospects. Renew. Sustain. Energy Rev. 2013, 19, 360–369. [Google Scholar] [CrossRef]

- Mohn, F.H. Experiences and strategies in the recovery of biomass from mass cultures of microalgae. Algal Biomass 1980, 471–547. [Google Scholar]

- Al Hattab, M.; Ghaly, A.; Hammoud, A. Microalgae Harvesting Methods for Industrial Production of Biodiesel: Critical Review and Comparative Analysis. J. Fundam. Renew. Energy Appl. 2015, 5, 1000154. [Google Scholar] [CrossRef]

- Borowitzka, M.A.; Borowitzka, L.J. Micro-Algal Biotechnology; Cambridge University Press: New York, NY, USA, 1988; ISBN 0521323495. [Google Scholar]

- Matsumoto, S.; Aramaki, T.; Ichikawa, S. Minamisoma Microalgae Experiment on Continuous Hydrothermal Liquefaction Treatment, Internal Report. 2017.

- Li, F.F.; Yang, Z.H.; Zeng, R.; Yang, G.; Chang, X.; Yan, J.B.; Hou, Y.L. Microalgae capture of CO2 from actual flue gas discharged from a combustion chamber. Ind. Eng. Chem. Res. 2011, 50, 6496–6502. [Google Scholar] [CrossRef]

- Ji, F.; Hao, R.; Liu, Y.; Li, G.; Zhou, Y.; Dong, R. Isolation of a novel microalgae strain Desmodesmus sp. and optimization of environmental factors for its biomass production. Bioresour. Technol. 2013, 148, 249–254. [Google Scholar] [CrossRef] [PubMed]

- Milani Shirvan, K.; Mamourian, M.; Mirzakhanlari, S.; Ellahi, R. Numerical investigation of heat exchanger effectiveness in a double pipe heat exchanger filled with nanofluid: A sensitivity analysis by response surface methodology. Powder Technol. 2017, 313, 99–111. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).