Biogas and Ethanol from Wheat Grain or Straw: Is There a Trade-Off between Climate Impact, Avoidance of iLUC and Production Cost?

Abstract

1. Introduction

2. Materials and Methods

- Inventory and analysis of statistics and data for biomass quantification and the identification of relevant regions and regional differences.

- Inventory and analysis of georeferenced data on soil properties for subsequent simulation of the effects of straw removal on soil organic carbon (SOC) content.

- Assessment of material and product flows in biofuel production using published data on the use of wheat straw and grain for ethanol and biogas production.

- Assessment of GHG emissions according to the ISO (International Organization for standardization) standard for life cycle assessment and by applying the methodology defined in the EU RED.

- Assessment of feedstock production costs using a stepwise calculation method considering field operations, transport and storage.

- Assessment of biogas and ethanol production cost using investment analysis based on the annuity method.

2.1. Feedstock Production and Transport

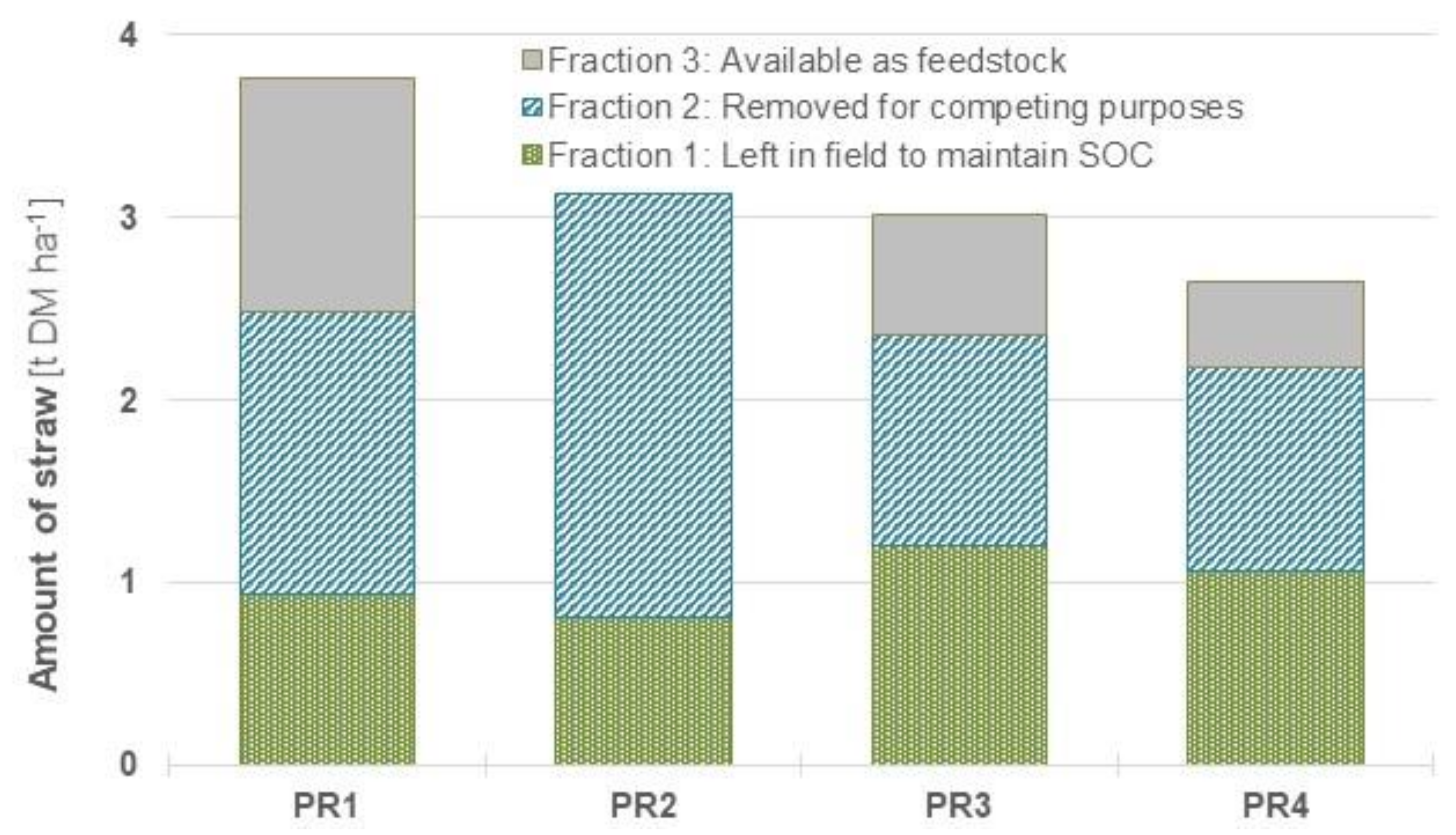

- Straw fraction 1, corresponding to the amount of SOC mineralised.

- Straw fraction 2, currently removed and used for other purposes [21].

- Straw fraction 3, available for bioenergy production without having any impact on SOC and without competing with any other uses.

2.2. Ethanol and Biogas Production and Distribution

2.2.1. Ethanol

2.2.2. Biogas

2.3. Economic Assessment

2.3.1. Capital Cost

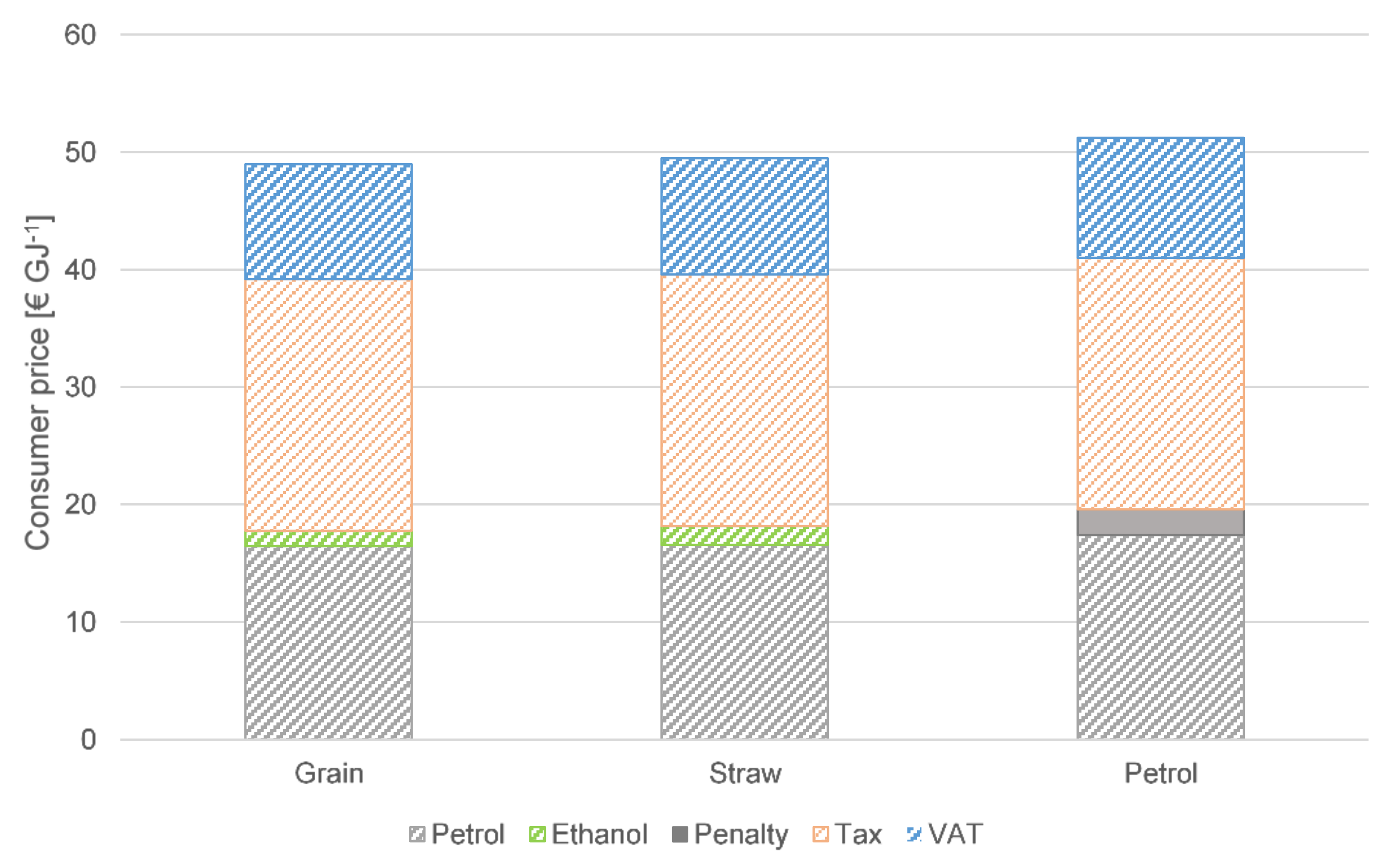

2.3.2. Current Market Price for Vehicle Fuels in Sweden

2.4. Greenhouse Gas Emissions

2.5. Sensitivity Analysis

3. Results and Discussion

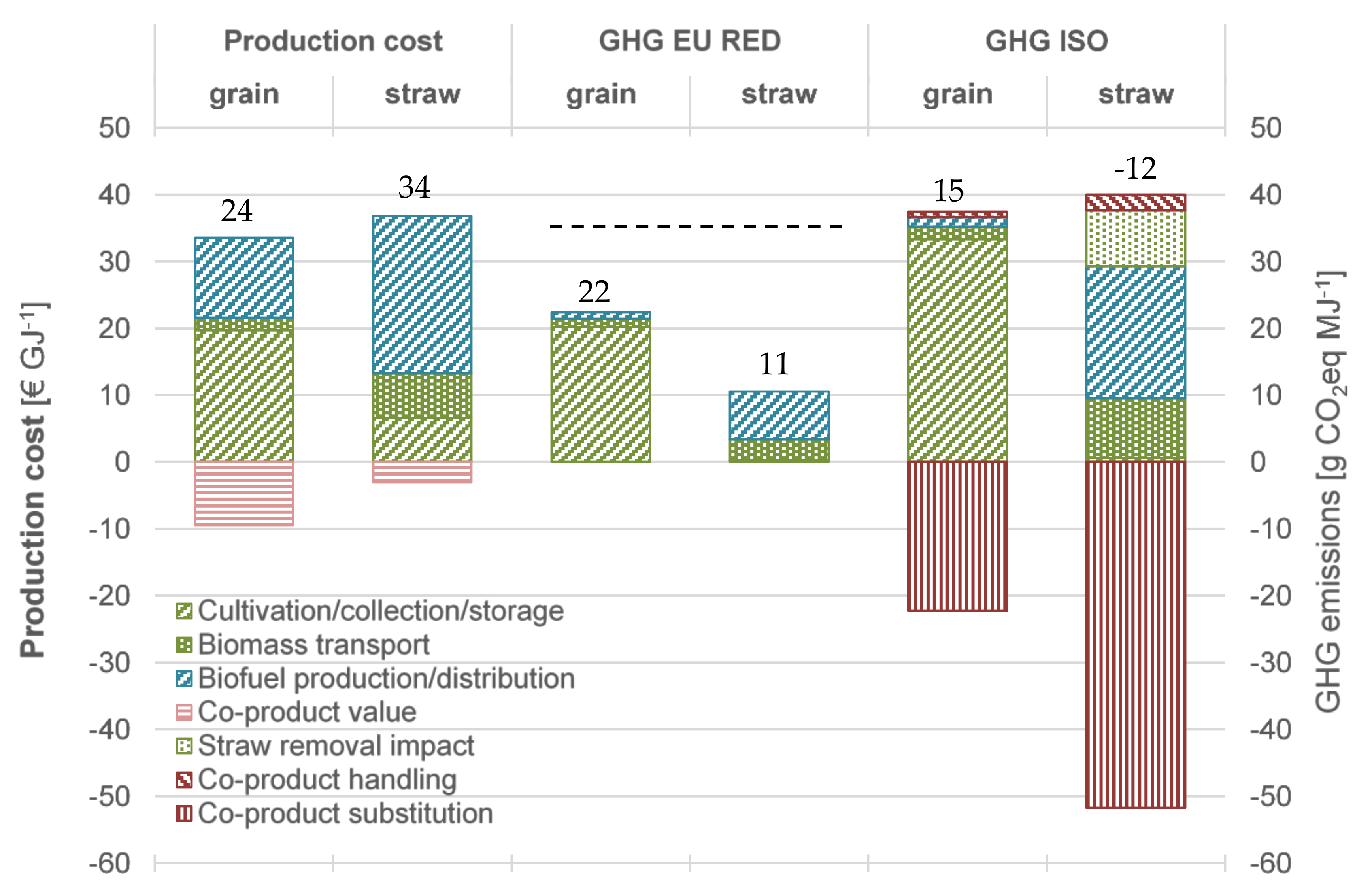

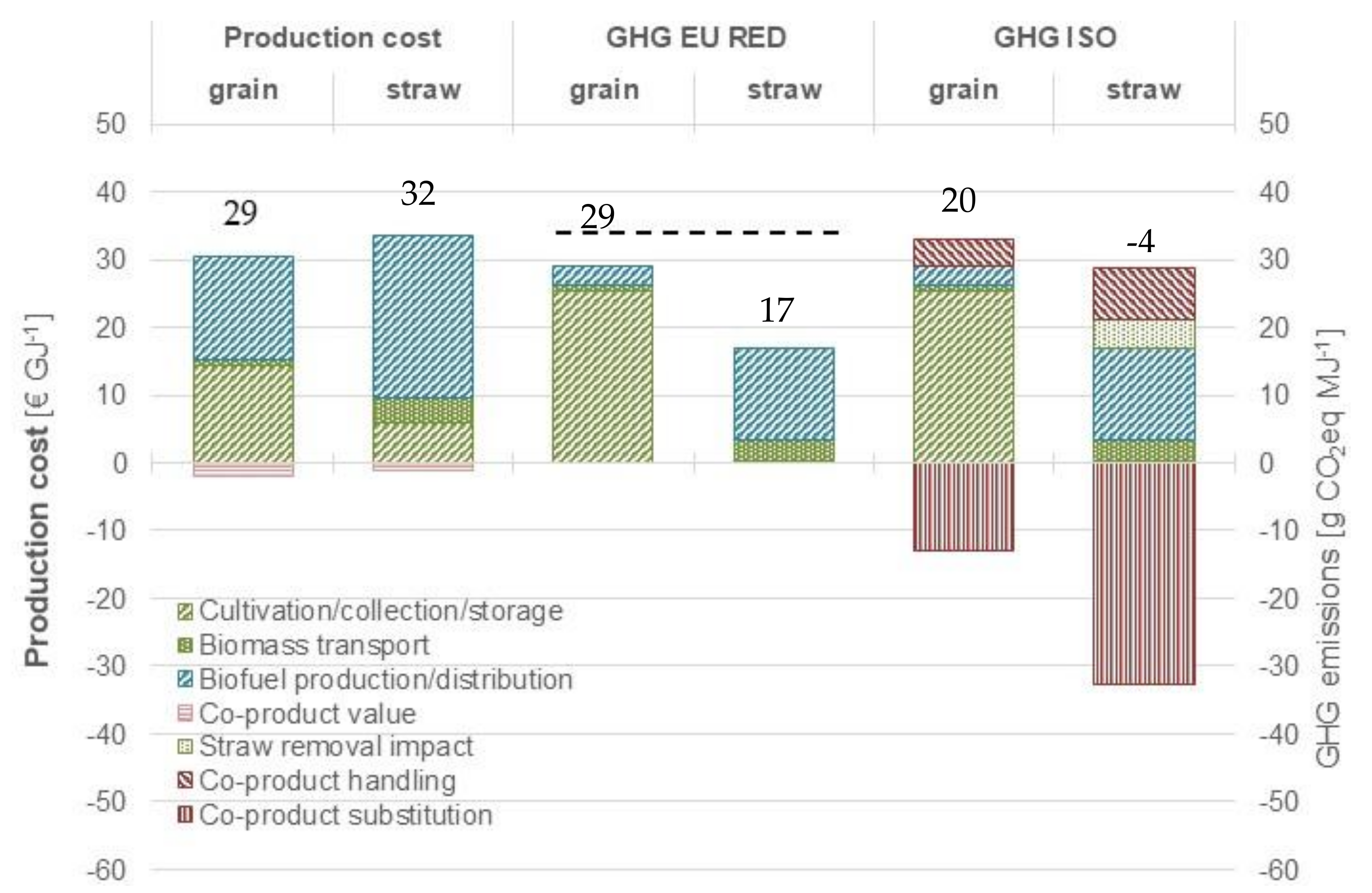

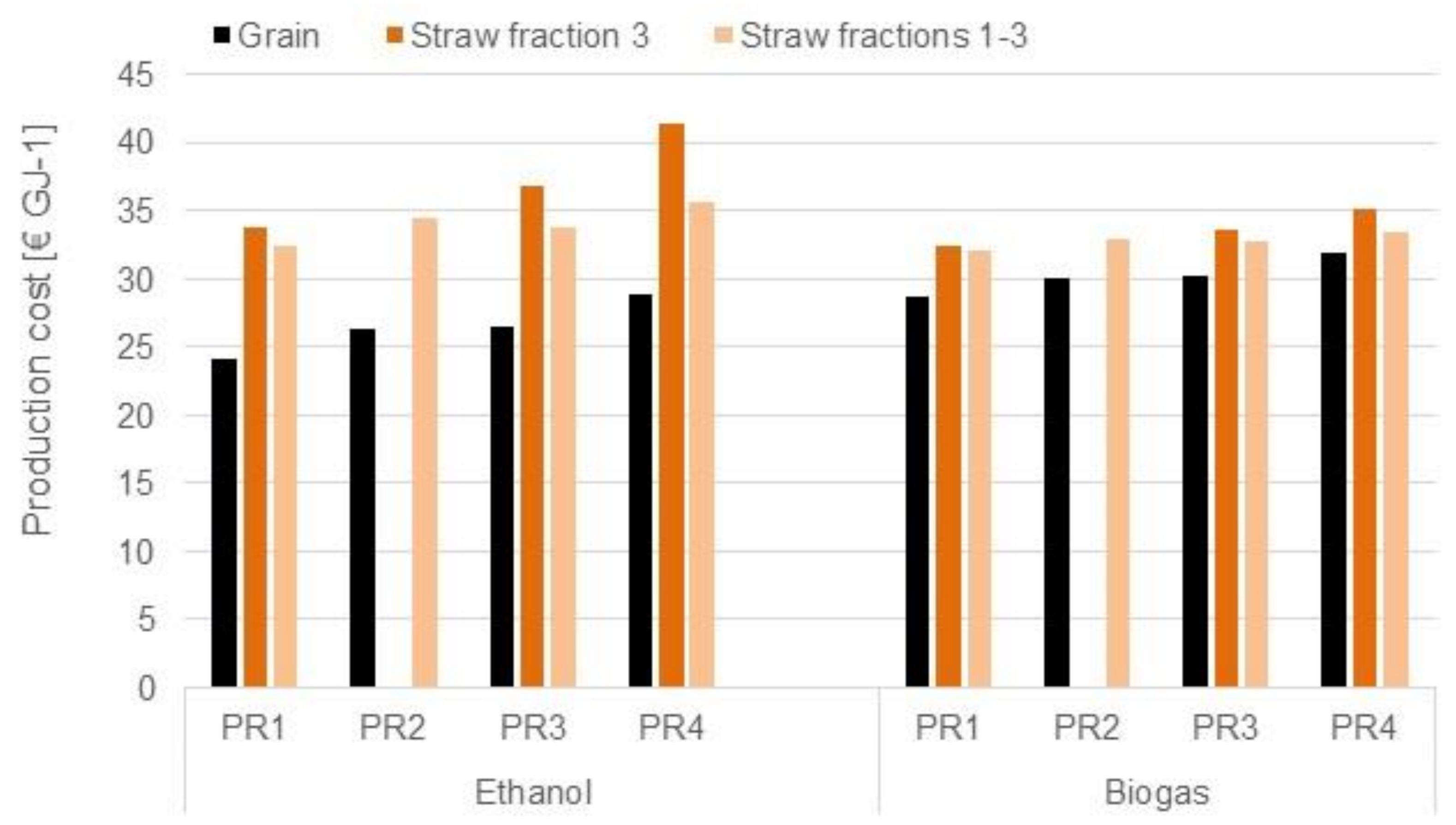

3.1. Production Cost

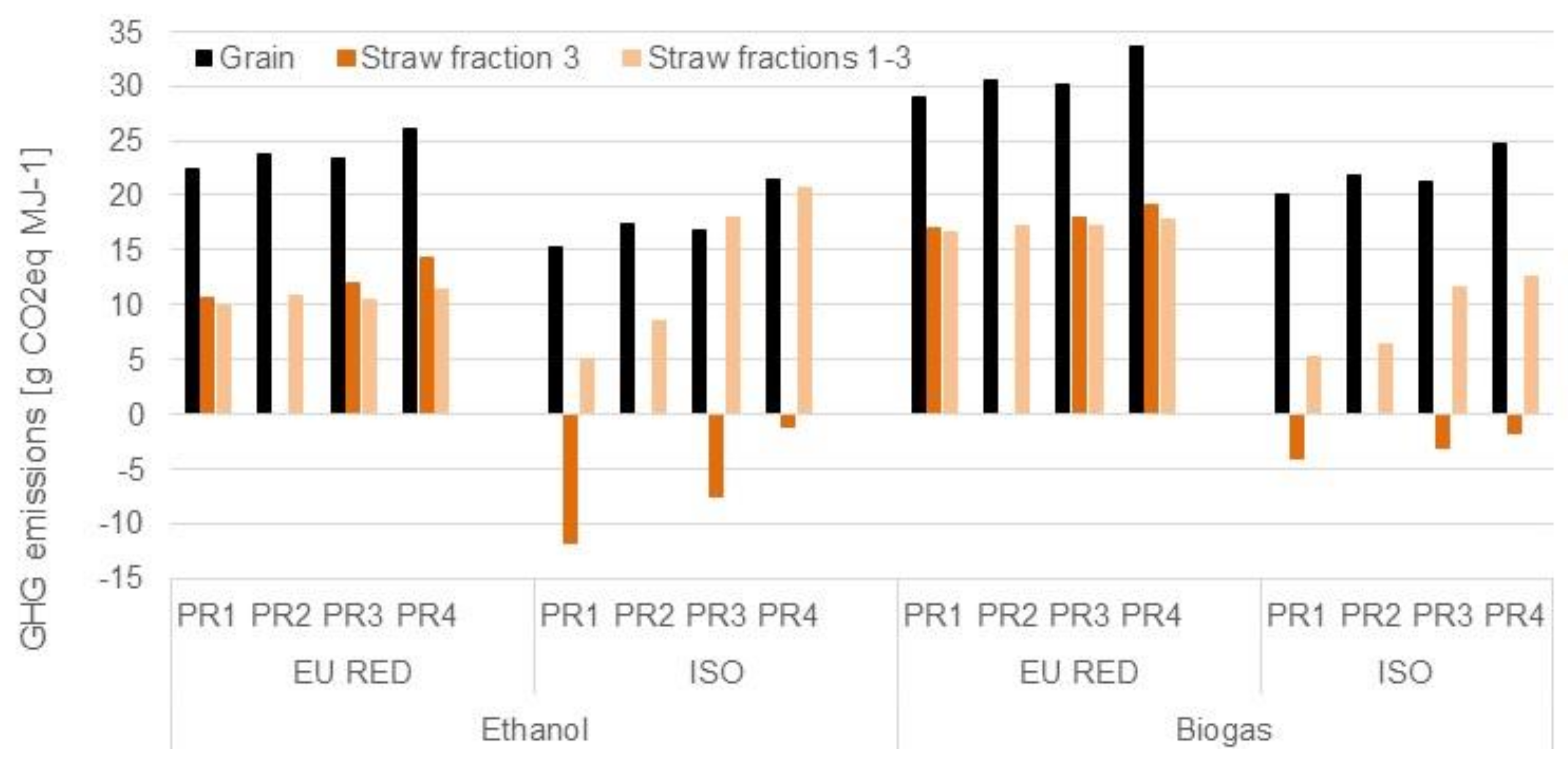

3.2. Greenhouse Gas Emissions

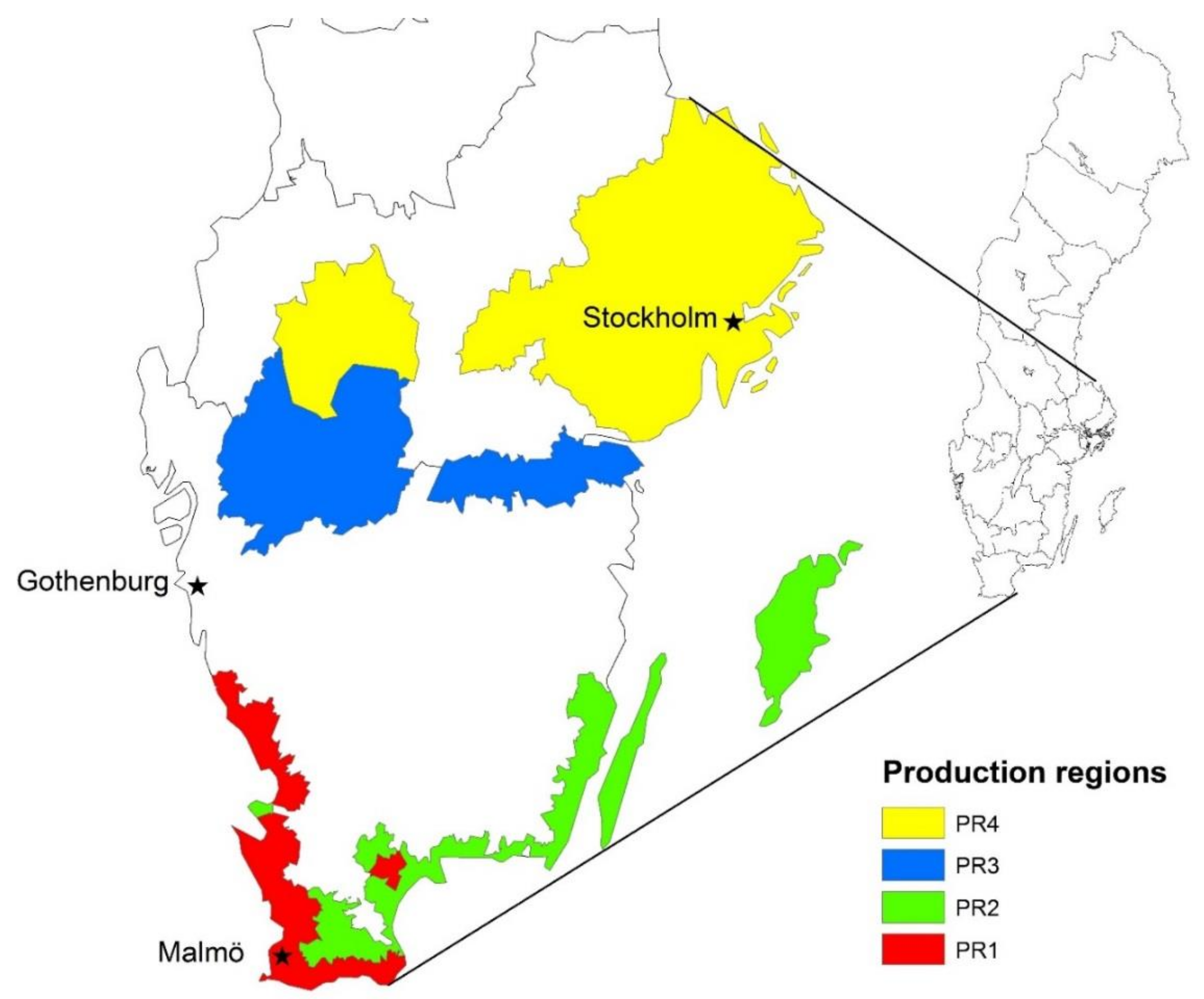

3.3. Impact of Regional Differences and Ratio of Straw Removal

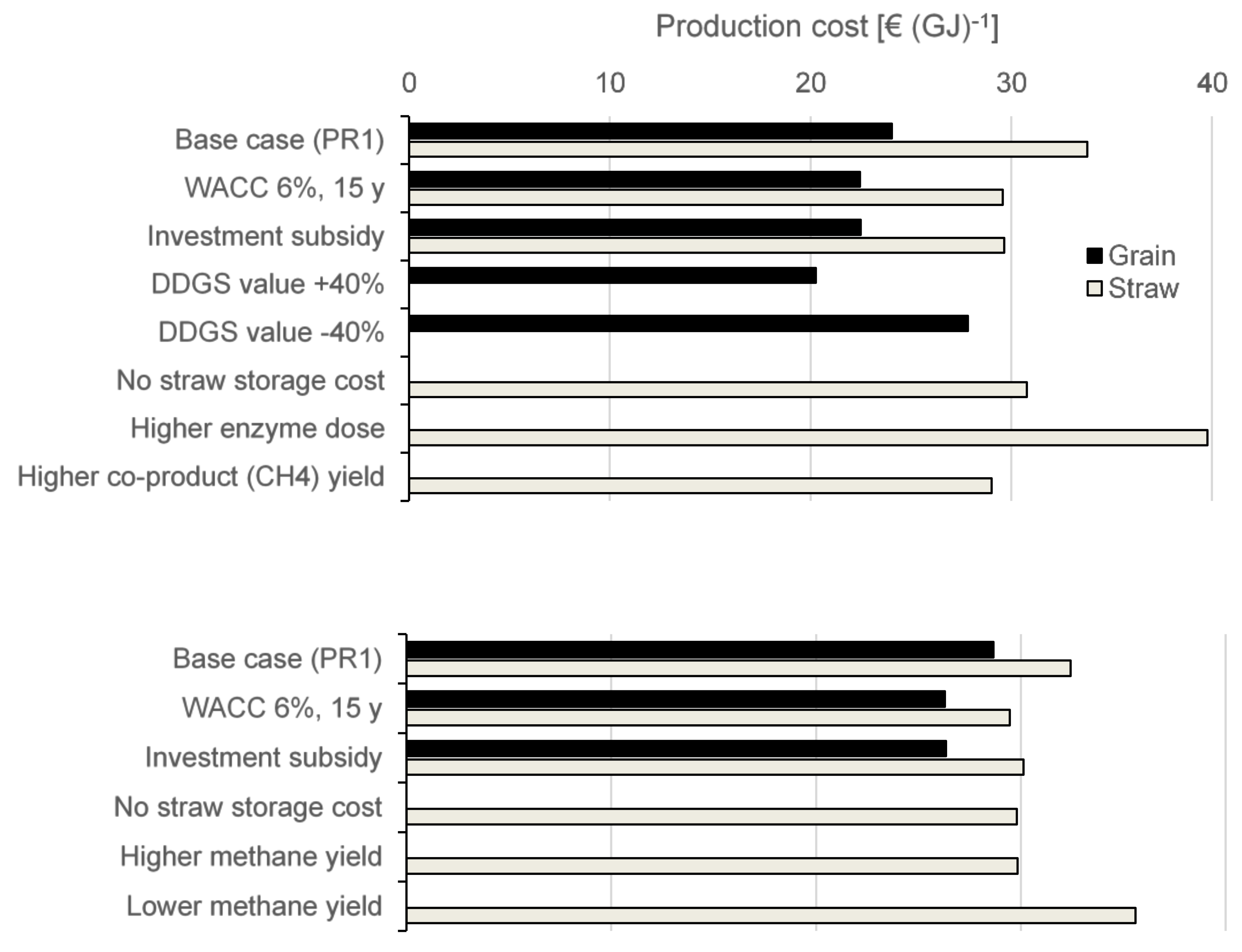

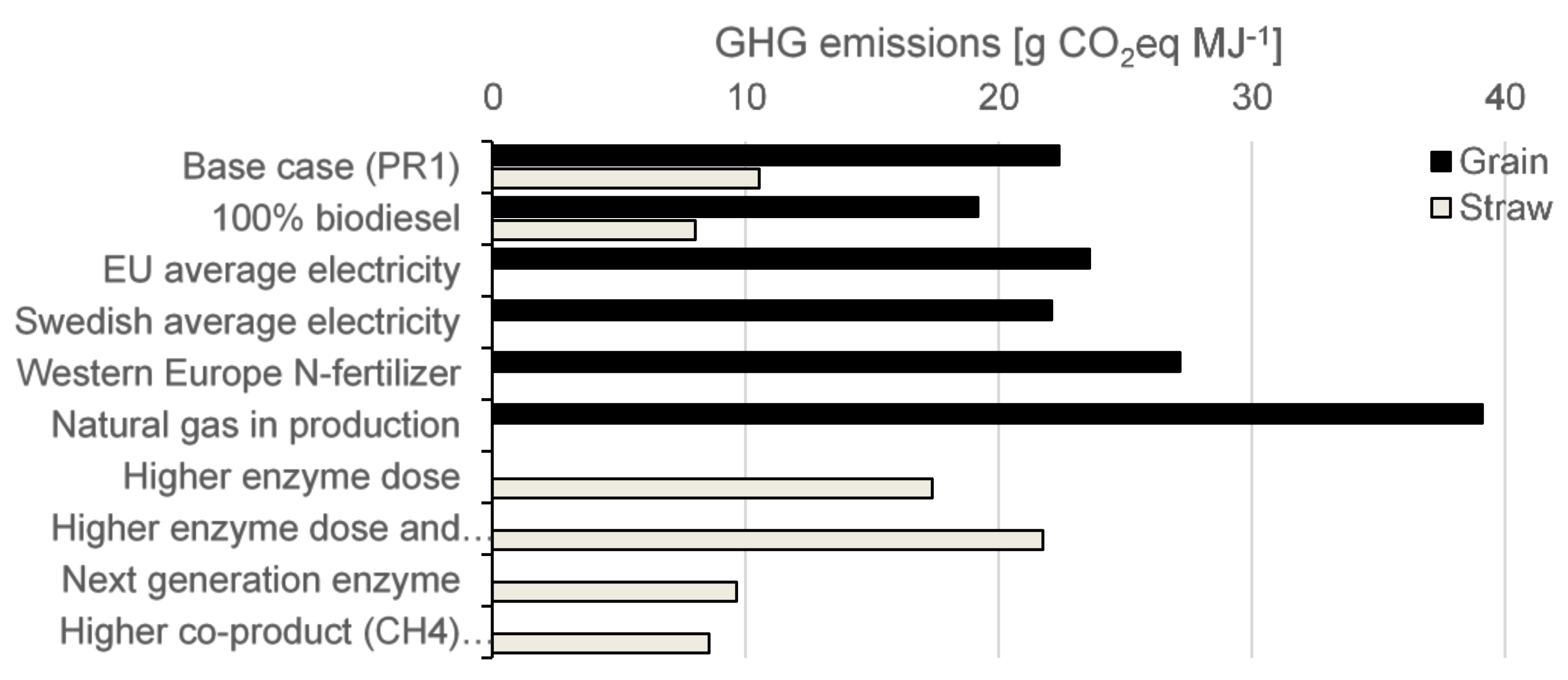

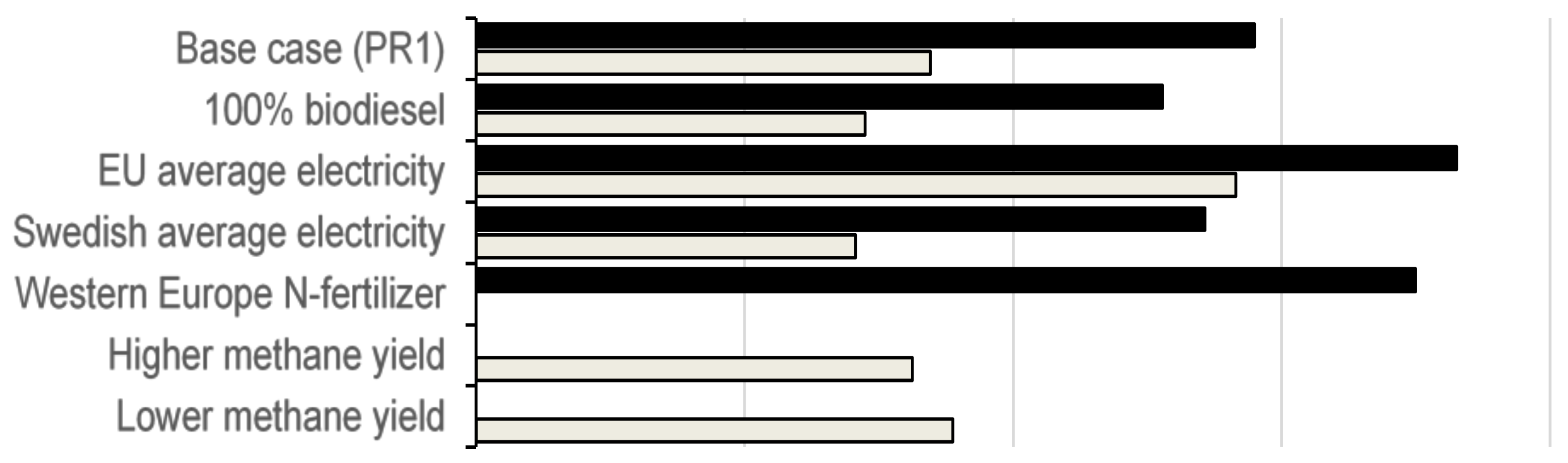

3.4. Sensitivity Analysis

3.5. Ethanol from Grain vs. Straw with a GHG Reduction Mandate

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Feedstock Production, Transport and Storage

Appendix A.1. Cultivation Input

| Production Region | Base Amount | Biomass Nutrient Content | ||

|---|---|---|---|---|

| N a | N a | P b | K b | |

| [kg ha−1] | [% of DM] | [% of DM] | [% of DM] | |

| PR1–3 | 30 | 1.81 | 0.36 | 0.50 |

| PR4 | 40 | 1.88 | 0.36 | 0.50 |

| Production Region | Biomass Nutrient Content | ||

|---|---|---|---|

| N | P | K | |

| [% of DM] | [% of DM] | [% of DM] | |

| PR1–4 | 0.57 | 0.03 | 1.06 |

Appendix A.2. Energy Inputs

| Material | Units | Energy Input | Reference |

|---|---|---|---|

| Diesel | [MJ/L] | 38.9 | - |

| Electricity | [MJ/kWh] | 3.6 | - |

| Fertilizer N | [MJ/kg] | 48.0 | [42] |

| Fertilizer P | [MJ/kg] | 18.7 | [42] |

| Fertilizer K | [MJ/kg] | 5.8 | [42] |

| Machinery | [MJ/t] | 33.8–44.2 | [43] |

| Production Region | Grain | Straw | ||||

|---|---|---|---|---|---|---|

| Technical Potential | Sustainable Potential | |||||

| Biogas | Ethanol | Biogas | Ethanol | Biogas | Ethanol | |

| PR1 | 6.1 | 35.6 | 13.5 | 41.3 | 17.8 | 54.4 |

| PR2 | 11.2 | 64.9 | 38.7 | 118.0 | n/a | n/a |

| PR3 | 8.6 | 50.2 | 18.6 | 56.8 | 31.2 | 95.4 |

| PR4 | 13.5 | 78.2 | 30.0 | 91.5 | 54.3 | 165.7 |

| Parameter | Primary Energy Input (Biogas Production) | Primary Energy Input (Ethanol Production) | ||||||

|---|---|---|---|---|---|---|---|---|

| [MJ ha−1] | [MJ ha−1] | |||||||

| PR1 | PR2 | PR3 | PR4 | PR1 | PR2 | PR3 | PR4 | |

| Material | ||||||||

| Fertilizer N | 7140 | 6181 | 6012 | 6072 | 7140 | 6181 | 6012 | 6072 |

| Fertilizer P | 444 | 369 | 356 | 313 | 444 | 369 | 356 | 313 |

| Fertilizer K | 192 | 160 | 154 | 135 | 192 | 160 | 154 | 135 |

| Seed | 1620 | 1620 | 1620 | 1620 | 1620 | 1620 | 1620 | 1620 |

| Pesticides | 518 | 518 | 518 | 518 | 518 | 518 | 518 | 518 |

| Liming | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 |

| Operation | ||||||||

| Stubble treatment | 231 | 231 | 231 | 231 | 231 | 231 | 231 | 231 |

| Ploughing | 1060 | 1060 | 1060 | 1060 | 1060 | 1060 | 1060 | 1060 |

| Harrowing | 528 | 528 | 528 | 528 | 528 | 528 | 528 | 528 |

| Sowing | 425 | 425 | 425 | 425 | 425 | 425 | 425 | 425 |

| Rolling | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 |

| Fertilizer application | 166 | 166 | 166 | 166 | 166 | 166 | 166 | 166 |

| Spraying | 241 | 241 | 241 | 241 | 241 | 241 | 241 | 241 |

| Combine harvesting | 1730 | 1434 | 1371 | 1202 | 1730 | 1434 | 1371 | 1202 |

| Transp. field–facility | 874 | 417 | 667 | 241 | 50 | 12 | 20 | 7 |

| Transp. field–farm | 0 | 410 | 35 | 489 | 1099 | 950 | 897 | 800 |

| Transp. farm–facility | 0 | 44 | 4 | 98 | 474 | 670 | 510 | 663 |

| Drying (electricity) | 1398 | 1163 | 1122 | 985 | 1398 | 1163 | 1122 | 985 |

| Drying (heat) | 3227 | 2684 | 2588 | 2273 | 3227 | 2684 | 2588 | 2273 |

| Total | 20,116 | 17,962 | 17,406 | 16,898 | 20,865 | 18,723 | 18,127 | 17,542 |

| Parameter | Primary Energy Input (Biogas Production) | Primary Energy Input (Ethanol Production) | ||||||

|---|---|---|---|---|---|---|---|---|

| [MJ ha−1] | [MJ ha−1] | |||||||

| PR1 | PR2 | PR3 | PR4 | PR1 | PR2 | PR3 | PR4 | |

| Fertilizer | ||||||||

| N | 1029 | 856 | 825 | 725 | 1029 | 856 | 825 | 725 |

| P | 17 | 21 | 18 | 17 | 21 | 18 | 17 | 15 |

| K | 233 | 194 | 187 | 164 | 233 | 194 | 187 | 164 |

| Operations | ||||||||

| Baling | 157 | 130 | 126 | 111 | 157 | 130 | 126 | 111 |

| Collection 1 | 493 | 438 | 431 | 400 | 493 | 438 | 431 | 400 |

| Transport 2 | 555/672 | 639/- | 577/787 | 646/995 | 890/1246 | 1145/- | 957/1597 | 1166/2232 |

| Total | 2488/2604 | 2274/- | 2163/2373 | 2060/2409 | 2823/3179 | 2780/- | 2543/3183 | 2580/3647 |

Appendix A.3. Feedstock Production Costs

| Material | Units | Cost | Reference |

|---|---|---|---|

| Electricity | [€-ct./kWh] | 5.72 | [47] |

| Fertilizer N | [€/kg] | 1.11 | [48] |

| Fertilizer P | [€/kg] | 2.44 | [48] |

| Fertilizer K | [€/kg] | 0.78 | [48] |

| Parameter | Feedstock Production Cost (Biogas Production) [€ ha−1] | Feedstock Production Cost (Ethanol Production) [€ ha−1] | ||||||

|---|---|---|---|---|---|---|---|---|

| PR1 | PR2 | PR3 | PR4 | PR1 | PR2 | PR3 | PR4 | |

| Fertilizer | ||||||||

| N | 24 | 20 | 19 | 17 | 24 | 20 | 19 | 17 |

| P | 3 | 2 | 2 | 2 | 3 | 2 | 2 | 2 |

| K | 31 | 26 | 25 | 22 | 31 | 26 | 25 | 22 |

| Operations | ||||||||

| Baling | 37 | 31 | 30 | 26 | 37 | 31 | 30 | 26 |

| Collection 1 | 50 | 44 | 43 | 40 | 50 | 44 | 43 | 40 |

| Transport 2 | 56/68 | 64/- | 58/79 | 65/100 | 90/125 | 115/- | 96/161 | 117/225 |

| Cultivation | 58 | 48 | 46 | 41 | 58 | 48 | 46 | 41 |

| Harvest | 37 | 31 | 30 | 26 | 37 | 31 | 30 | 26 |

| Storage | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Transport | 105/117 | 108/- | 101/122 | 105/140 | 139/175 | 159/- | 140/204 | 157/265 |

| Total | 200/212 | 187/- | 177/199 | 172/207 | 234/270 | 238/- | 216/280 | 224/332 |

| Parameter | Feedstock Production Cost (Biogas Production) | Feedstock Production Cost (Ethanol Production) | ||||||

|---|---|---|---|---|---|---|---|---|

| [€ t DM−1] | [€ t DM−1] | |||||||

| PR1 | PR2 | PR3 | PR4 | PR1 | PR2 | PR3 | PR4 | |

| Material | ||||||||

| Fertilizer N | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 |

| Fertilizer P | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Fertilizer K | 8.2 | 8.2 | 8.2 | 8.2 | 8.2 | 8.2 | 8.2 | 8.2 |

| Operations | ||||||||

| Baling | 9.9 | 9.8 | 9.9 | 9.9 | 9.9 | 9.8 | 9.9 | 9.9 |

| Collection 1 | 13.2 | 14.1 | 14.4 | 15.2 | 13.2 | 14.1 | 14.4 | 15.2 |

| Transport 2 | 14.9/18 | 20.5/- | 19.3/26.2 | 24.5/37.8 | 23.8/33.3 | 36.8/- | 31.9/53.3 | 44.3/84.8 |

| Cultivation | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 |

| Harvest | 9.9 | 9.8 | 9.9 | 9.9 | 9.9 | 9.8 | 9.9 | 9.9 |

| Storage | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Transport | 28/31.1 | 34.6/- | 33.6/40.6 | 39.7/53 | 37/46.5 | 50.9/- | 46.3/67.6 | 59.4/99.9 |

| Total | 53.2/56.3 | 59.8/- | 58.8/65.8 | 64.9/78.2 | 62.2/71.7 | 76.1/- | 71.5/92.8 | 84.7/125.2 |

| Parameter | Production Costs (Biogas Production) | Production Costs (Ethanol Production) | ||||||

|---|---|---|---|---|---|---|---|---|

| [€ ha−1] | [€ ha−1] | |||||||

| PR1 | PR2 | PR3 | PR4 | PR1 | PR2 | PR3 | PR4 | |

| Material | ||||||||

| Fertilizer N | 111 | 165 | 143 | 139 | 165 | 143 | 139 | 141 |

| Fertilizer P | 36 | 58 | 48 | 46 | 58 | 48 | 46 | 41 |

| Fertilizer K | 16 | 26 | 21 | 21 | 26 | 21 | 21 | 18 |

| Seeds | 56 | 84 | 84 | 84 | 84 | 84 | 84 | 84 |

| Pesticides | 49 | 98 | 98 | 98 | 98 | 98 | 98 | 98 |

| Liming | 17 | 17 | 17 | 17 | 17 | 17 | 17 | 17 |

| Operations | ||||||||

| Stubble treatment (cultivator) | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 |

| Ploughing | 113 | 113 | 113 | 113 | 113 | 113 | 113 | 113 |

| Harrowing | 56 | 56 | 56 | 56 | 56 | 56 | 56 | 56 |

| Sowing | 58 | 58 | 58 | 58 | 58 | 58 | 58 | 58 |

| Rolling | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Fertilizer spreading | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| Spraying | 34 | 34 | 34 | 34 | 34 | 34 | 34 | 34 |

| Combine harvest | 196 | 162 | 155 | 136 | 196 | 162 | 155 | 136 |

| Transp. field-facility | 54 | 26 | 41 | 15 | 3 | 1 | 1 | 0 |

| Transp. field-farm | 0 | 25 | 2 | 30 | 68 | 59 | 56 | 50 |

| Transp. farm-facility | 0 | 4 | 0 | 10 | 48 | 67 | 51 | 67 |

| Drying (ventilator electricity only) | 120 | 100 | 96 | 84 | 120 | 100 | 96 | 84 |

| Drying (heat production) | 118 | 98 | 94 | 83 | 118 | 98 | 94 | 83 |

| Total | 1305 | 1190 | 1157 | 1115 | 1369 | 1261 | 1221 | 1177 |

| Parameter | Production Costs (Biogas Production) | Production Costs (Ethanol Production) | ||||||

|---|---|---|---|---|---|---|---|---|

| [€ t DM−1] | [€ t DM−1] | |||||||

| PR1 | PR2 | PR3 | PR4 | PR1 | PR2 | PR3 | PR4 | |

| Material | ||||||||

| Fertilizer N | 17 | 30 | 27 | 30 | 25 | 26 | 26 | 30 |

| Fertilizer P | 5 | 11 | 9 | 10 | 9 | 9 | 9 | 9 |

| Fertilizer K | 2 | 5 | 4 | 4 | 4 | 4 | 4 | 4 |

| Seeds | 9 | 15 | 16 | 18 | 13 | 15 | 16 | 18 |

| Pesticides | 8 | 18 | 19 | 21 | 15 | 18 | 19 | 21 |

| Liming | 3 | 3 | 3 | 4 | 3 | 3 | 3 | 4 |

| Operations | ||||||||

| Stubble treatment (cultivator) | 4 | 5 | 5 | 6 | 4 | 5 | 5 | 6 |

| Ploughing | 17 | 21 | 21 | 24 | 17 | 21 | 21 | 24 |

| Harrowing | 9 | 10 | 11 | 12 | 9 | 10 | 11 | 12 |

| Sowing | 9 | 11 | 11 | 13 | 9 | 11 | 11 | 13 |

| Rolling | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 |

| Fertilizer spreading | 3 | 3 | 3 | 4 | 3 | 3 | 3 | 4 |

| Spraying | 5 | 6 | 7 | 7 | 5 | 6 | 7 | 7 |

| Combine harvest | 30 | 30 | 29 | 29 | 30 | 30 | 29 | 29 |

| Transp. field-facility | 8 | 5 | 8 | 3 | 0 | 0 | 0 | 0 |

| Transp. field-farm | 0 | 5 | 0 | 7 | 10 | 11 | 11 | 11 |

| Transp. farm-facility | 0 | 1 | 0 | 2 | 7 | 12 | 10 | 14 |

| Drying (ventilator electricity only) | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| Drying (heat production) | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| Total | 198 | 218 | 219 | 241 | 208 | 231 | 232 | 254 |

Appendix B. Biofuel Production Cost

| System Components | Biogas | Ethanol | ||

|---|---|---|---|---|

| Grain | Straw | Grain | Straw 1 | |

| Biogas plant | 3 | 4 | ||

| Ethanol plant | 174 | 131 | ||

| Upgrading of biogas | 2 | 2 | 7 | |

| Compression and distribution of biogas | 0.1 | 0.1 | 2 | |

| Digestate storage | 1 | 3 | ||

| Filling stations | 4 | 4 | 14 | |

| Total investment cost | 10 | 13 | 174 | 154 |

| Operational Cots | Cost | Reference |

|---|---|---|

| Process energy | ||

| Electricity from the grid for biofuel production 1 | €57/MWh | [47] |

| Natural gas 2 | €37/MWh | [47] |

| Heat from external supplier | €26/GJ | [27] |

| Additives and chemicals | ||

| Acetic acid | €0.2/kg3 | |

| Enzymes (ethanol from grain) | €3.3/kg enzyme solution | [22] |

| Enzymes (ethanol from straw) | €3.0/FPU | [26] |

| N | €1.1/kg | [48] |

| P | €2.4/kg | [48] |

| FeSO4 | €4.1/kg | [27] |

| Trace elements for biogas production | €21,600 | [27] |

| Ammonia (25%) | €0.2/kg | 3 |

| Phosphoric acid (50%) | €0.6/kg | 3 |

| Antifoam | €2.2/kg | 3 |

| (NH4) 2HPO4 | €0.7/kg | 3 |

| MgCl2/MgSO4 | €0.2/kg | 3 |

| Molasses | €0.1/kg | 3 |

| Cooling water | €0.02/m3 | [49] |

| Processing water | €0.2/m3 | [49] |

| Maintenance | ||

| Biogas plant | 5% of investment | [27] |

| Digestate storage | 0.5% of investment | [27] |

| Upgrading plant | 3% of investment | [27] |

| Vehicle gas filling stations | 3% of investment | [27] |

| Services | ||

| Digestate transport - Fixed cost - Transport cost | €0.95/t €0.04/t | [50] [50] |

| Digestate application | €2/t | [27] |

| Distribution of biogas | €8.9/MWh | [51] |

| Distribution of ethanol | €0.01/dm3 | [52] |

| Storage of grain 3 | €0.01/kg | [53] |

| Storage of straw | €0.02/kg | [48] |

| Co-Product | Unit | Reference |

|---|---|---|

| Macro-nutrients in digestate N P K | €1.1/kg €2.4/kg €0.8/kg | [48] [48] [48] |

| DDGS 1 | €0.24/kg DM | [54] |

| Electricity 2 | €27/MWh | [55] |

| Electricity certificates 3 | €15/MWh | [56] |

| Lignin pellets 4 | €0.09/kg DM | [26,57] |

| Carbon dioxide | €0.003/kg | [26] |

Appendix C. Greenhouse Gas Emissions

| Energy Source | Emission [g CO2eq MJ−1] | Ref. | Comment |

|---|---|---|---|

| Fossil fuel reference | 83.8 | [8] | Comparator when calculating the GHG emission saving according to the EU RED |

| Diesel | 80.4 | [59] | Average Swedish fossil diesel blend in 2016, containing 21% (vol.) biodiesel |

| HVO | 14.0 | [59] | Swedish biodiesel consisting of hydrogenated vegetable oil (HVO), average emission in 2016 |

| FAME | 32.3 | [59] | Swedish biodiesel consisting of fatty acid methyl ester (FAME), average emission in 2016 |

| 100% biodiesel | 23.2 | The alternative value for 100% biodiesel, calculated assuming a 50/50 blend of HVO and FAME | |

| Electricity, Nordic mix | 34.9 | [60] | Currently used in Swedish reporting of GHG emissions for biofuels according to the EU RED |

| Electricity, Swedish mix | 13.1 | [61] | Suggested future emission in Swedish reporting of GHG emissions for biofuels according to the EU RED |

| Electricity, EU28 mix | 124.2 | [61] | Alternative value for evaluating the impact of EU average electricity in calculations of GHG emissions for biofuels according to the EU RED |

| Wood chips | 3.4 | [62] | Used together with a heat conversion efficiency of 85% |

| Natural gas | 69 | [63] | Used together with a heat conversion efficiency of 90% |

| Cultivation Input | Emission [kg CO2eq kg−1] | Ref. | Comment |

|---|---|---|---|

| Mineral fertilizer N | 4.5 | Swedish average mineral N utilization 2016 1 | |

| Mineral fertilizer N | 7.8 | [64] | Western European production |

| Mineral fertilizer P | 2.3 | [65] | |

| Mineral fertilizer K | 0.7 | [65] | |

| Seeding material | 0.3 | [65] | |

| Lime | 0.1 | [66] | |

| Pesticides | 11 | [65] | Per kg active substance |

| Process Additive | Emission [kg CO2eq kg−1] | Ref. | Comment |

|---|---|---|---|

| Acetic acid | 0.6 | [69] | |

| Ammonia | 3.2 | [65] | Per kg N |

| Phosphoric acid | 3.0 | [65] | |

| Antifoam | 1.3 | [70] | |

| (NH4) 2HPO4 | 3.3 | [65] | |

| MgSO4 | 0.1 | [69] | |

| Molasses | 0.1 | [24] | |

| Enzymes | 5.5 | [70] | Revised based on reduced fossil energy input in the production of Cellic CTec3 (Novozymes) |

| Enzymes | 8.0 | [24,70] | 2014 emission data for Cellic Ctec3 |

| Trace minerals | 0.4 | [69] | Yeast extract 1 |

| CH4 from biogas production | 0.5 2 | [27] | |

| CH4 from biogas upgrading | 0.2 2 | [27] | Includes emission from flare 3 |

Appendix C.1. Co-Product Substitution

| Co-Product Amounts (Underlined) and Emissions | ||

|---|---|---|

| Grain-based ethanol | ||

| DDGS | 0.34 | [t DM (t DM)−1] |

| Transport to feed production plant | 7.7 | [kg CO2eq (t DM)−1] |

| Substitution of soybean meal & rape meal | −192 | [kg CO2eq (t DM)−1] |

| Straw-based ethanol | ||

| Upgraded methane | 2780 1 | [MJ (t DM)−1] |

| Input upgrading/distribution electricity | 5.6 | [kg CO2eq (t DM)−1] |

| Input upgrading/distribution heat | 1.3 | [kg CO2eq (t DM)−1] |

| Methane losses | 2.6 | [kg CO2eq (t DM)−1] |

| Substitution of natural gas | −193 | [kg CO2eq (t DM)−1] |

| Fibre pellets | 4320 | [MJ (t DM)−1] |

| Substitution of wood pellets | −14.8 | [kg CO2eq (t DM)−1] |

| Grain-based biogas | ||

| Biofertilizer containing: | ||

| NH4-N | 12.4 2 | [kg (t DM)−1] |

| P | 5.2 | [kg (t DM)−1] |

| K | 5.5 | [kg (t DM)−1] |

| C | 108 | [kg (t DM)−1] |

| Transport and field application | 5.8 5 | [kg CO2eq (t DM)−1] |

| Biofertilizer storage 3 | 6.8 | [kg CO2eq (t DM)−1] |

| N2O emission at application 4 | 39 | [kg CO2eq (t DM)−1] |

| NPK substitution | −71 | [kg CO2eq (t DM)−1] |

| SOC benefit | −92 | [kg CO2eq (t DM)−1] |

| Straw-based biogas | ||

| Biofertilizer containing: | ||

| NH4-N | 7.5 2 | [kg (t DM)−1] |

| P | 0.6 | [kg (t DM)−1] |

| K | 10 | [kg (t DM)−1] |

| C | 247 | [kg (t DM)−1] |

| Transport and field application | 6.9 6 | [kg CO2eq (t DM)−1] |

| Biofertilizer storage 3 | 20 | [kg CO2eq (t DM)−1] |

| N2O emission at application 4 | 30 | [kg CO2eq (t DM)−1] |

| NPK substitution | −42 | [kg CO2eq (t DM)−1] |

| SOC benefit | −210 | [kg CO2eq (t DM)−1] |

| Emission | Reference | ||

|---|---|---|---|

| Nitrogen loss | |||

| Ammonia losses | |||

| Biofertilizer storage | 1 | [%] (NH3-N of N-tot) | [75] |

| Mineral fertilizer field application | 0.91 | [%] NH3-N of N-tot?) | [76] |

| Biofertilizer field application | 10 | [%] (NH3-N of NH4-N) | [77] |

| N2O emissions at field application | |||

| All N in field (mineral N, biofertilizer N, N in crop residues) | 1 | [%] (N2O-N of N-tot) | [58] |

| Indirect N2O emission | |||

| Leakage to water 1 | 0.75 | [%] (N2O-N of NO3-N) | [58] |

| Emission to air | 1 | [%] (N2O-N of NH3-N) | [58] |

Appendix C.2. SOC Simulation

| PR | SOC Content (%) | Mean Bulk Density (t/m3) | Mean Clay Density (%) | Field Experiment | Reaction Coefficient |

|---|---|---|---|---|---|

| 1 | 1.77 (1.25–2.98) | 1.38 | 13.8 | Ekebo | 0.0089 |

| 2 | 1.97 (1.25–2.95) | 1.16 | 12.9 | Orupsgården | 0.0081 |

| 3 | 2.06 (1.45–2.99) | 1.22 | 19.9 | Högaså | 0.0102 |

| 4 | 2.08 (1.48–5.55) | 1.06 | 18.7 | Kungsängen | 0.0070 |

References

- European Commission (EC). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A Policy Framework for Climate and Energy in the Period from 2020 to 2030; COM (2014) 15 Final; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Environment Agency (EEA). Key Trends and Drivers in Greenhouse Gas Emissions in the EU in 2015 and Over the Past 25 Years; European Environment Agency: Copenhagen, Denmark, 2017. [Google Scholar]

- The Government of Sweden. The Climate Policy Framework. Available online: http://www.government.se/articles/2017/06/the-climate-policy-framework/ (accessed on 29 September 2018).

- Trafikverket. Åtgärder för att Minska Transportsektorns Utsläpp av Växthusgaser—Ett Regeringsuppdrag; Trafikverket 2016:111; Trafikverket: Boren, Sweden, 2016. [Google Scholar]

- European Union (EU). Directive 2009/28/EC of the european parliament and of the council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. Off. J. Eur. Union 2009, L140, 16–62. [Google Scholar]

- Eurostat. Share of Renewable Energy in Fuel Consumption of Transport. Available online: http://ec.europa.eu/eurostat/web/products-datasets/-/tsdcc340 (accessed on 1 November 2017).

- Energimyndigheten. Drivmedel 2016 Mängder, Komponenter och Ursprung Rapporterade Enligt Drivmedelslagen och Hållbarhetslagen; ER 2017:12; Energimyndigheten: Eskilstuna, Sweden, 2017. [Google Scholar]

- European Union (EU). Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015 Amending Directive 98/70/EC Relating to the Quality of Petrol and Diesel Fuels and Amending Directive 2009/28/EC on the Promotion of the Use of Energy from Renewable Sources; European Union: Brussels, Belgium, 2015. [Google Scholar]

- Ahlgren, S.; Di Lucia, L. Indirect land use changes of biofuel production—A review of modelling efforts and policy developments in the European Union. Biotechnol. Biofuels 2014, 7, 10. [Google Scholar] [CrossRef] [PubMed]

- Popp, J.; Kot, S.; Lakner, Z.; Oláh, J. Biofuel use: Peculiarities and implications. J. Secur. Sustain. Issues 2018, 7, 477–493. [Google Scholar] [CrossRef]

- De Rosa, M.; Knudsen, M.T.; Hermansen, J.E. A comparison of Land Use Change models: Challenges and future developments. J. Clean. Prod. 2016, 113, 183–193. [Google Scholar] [CrossRef]

- Ahlgren, S.; Björnsson, L.; Prade, T.; Lantz, M. Biofuels from Agricultural Biomass—Land Use Change in a Swedish Perspective; 2017:13; f3 The Swedish Knowledge Centre for Renewable Transportation Fuels: Göteborg, Sweden, 2017. [Google Scholar]

- Tonini, D.; Hamelin, L.; Astrup, T.F. Environmental implications of the use of agro-industrial residues for biorefineries: Application of a deterministic model for indirect land-use changes. Glob. Chang. Boil. Bioenergy 2016, 8, 690–706. [Google Scholar] [CrossRef]

- Prade, T.; Björnsson, L.; Lantz, M.; Ahlgren, S. Can domestic production of iLUC-free feedstock from arable land supply Sweden’s future demand for biofuels? J. Land Use Sci. 2017, 12, 407–441. [Google Scholar] [CrossRef]

- Svensk Författningssamling (SFS). Lag (2017:1201) om Reduktion av Växthusgasutsläpp Genom Inblandning av Biodrivmedel i Bensin och Dieselbränslen; The Swedish Code of Statutes, Uppdaterad t.o.m. SFS 2017:1233; Svensk Författningssamling: Stockholm, Sweden, 2017. [Google Scholar]

- Larsson, S. Sveriges Jordbruksområden—En Redovisning av Jordbruksområden och Växtzoner i Svenskt Jord- och Trädgårdsbruk; Field Research Unit, Swedish University of Agriculutural Sciences: Uppsala, Sweden, 2004; p. 13. [Google Scholar]

- European Commission (EC). Agriculture in the European Union—Market Statistical Information; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Henriksson, A.; Stridsberg, S. Möjligheter att Använda Halmeldning Till Energiförsörjningen i Södra SVERIGE; Department of Agricultural Engineering, Swedish University of Agricultural Sciences: Uppsala, Sweden, 1992. [Google Scholar]

- Kätterer, T.; Bolinder, M.A.; Andrén, O.; Kirchmann, H.; Menichetti, L. Roots contribute more to refractory soil organic matter than above-ground crop residues, as revealed by a long-term field experiment. Agric. Ecosyst. Environ. 2011, 141, 184–192. [Google Scholar] [CrossRef]

- Poeplau, C.; Kätterer, T.; Bolinder, M.A.; Börjesson, G.; Berti, A.; Lugato, E. Low stabilization of aboveground crop residue carbon in sandy soils of Swedish long-term experiments. Geoderma 2015, 237–238, 246–255. [Google Scholar] [CrossRef]

- Statistiska Centralbyrån (SCB). Odlingsåtgärder i Jordbruket 2012. Träda, Slåttervall, vårkorn, Höstspannmål samt Användning av Halm och Blast; Statistics Sweden: Stockholm, Sweden, 2013; p. 44.

- Joelsson, E.; Borbála, E.; Galbe, M.; Wallberg, O. Techno-economic evaluation of integrated first- and second generation ethanol production from grain and straw. Biotechnol. Biofuels 2016, 9. [Google Scholar] [CrossRef] [PubMed]

- Ekman, A.; Wallberg, O.; Joelsson, E.; Börjesson, P. Possibilities for sustainable biorefineries based on agricultural residues—A case study of potential straw-based ethanol production in Sweden. Appl. Energy 2013, 102. [Google Scholar] [CrossRef]

- Karlsson, H.; Börjesson, P.; Hansson, P.-A.; Ahlgren, S. Ethanol production in biorefineries using lignocellulosic feedstock—GHG performance, energy balance and implications of life cycle calculation methodology. J. Clean. Prod. 2014, 83, 420–427. [Google Scholar] [CrossRef]

- Pål, B.; Ahlgren, S.; Barta, Z.; Björnsson, L.; Ekman, A.; Erlandssson, P.; Hansson, P.-A.; Hanna, K.; Kreuger, E.; Lindstedt, J.; et al. Sustainable Performance of Lignocellulose-Based Ethanol and Biogas Co-Produced in Innovative Biorefinery Systems; Environmental and Energy System Studies, LTH: Lund, Sweden, 2013. [Google Scholar]

- Joelsson, E.; Dienes, D.; Kovacs, K.; Galbe, M.; Wallberg, O. Combined production of biogas and ethanoil at high solids loading from wheat straw impegrenated with acetic acid: Experimental study and techno-economic evaluation. Sustain. Chem. Process. 2016, 4, 14. [Google Scholar] [CrossRef]

- Lantz, M.; Kreuger, E.; Björnsson, B. An economic comparison of dedicated crops vs agricultural residues as feedstock for biogas of vehicle fuel quality. AIMS Energy 2017, 5, 28. [Google Scholar] [CrossRef]

- Energimyndigheten. Produktion och Användning av Biogas och Rötrester år 2016; ES 2017:07; Energimyndigheten: Eskilstuna, Sweden, 2017. [Google Scholar]

- Lantz, M. Hållbarhetskriterier för Biogas—En Översyn av Data och Metoder; Report 100; Environmental and Energy System Studies, Lund University: Lund, Sweden, 2017. [Google Scholar]

- Petersson, A.; Wellinger, A. Biogas Upgrading Technologies—Development and Innovations; IEA Bioenergy Task 37; European Commission Joint Research Centre: Petten, The Netherlands, 2009. [Google Scholar]

- International Energy Agency (IEA). Biogas Upgrading Plant List, Data Up to the End of 2015; IEA Bioenergy Task 37; European Commission Joint Research Centre: Petten, The Netherlands, 2016. [Google Scholar]

- Svenska Petroleum och Biodrivmedel Institutet (SPBI). Priser och skatter [Prices and Taxes]. Available online: http://spbi.se/statistik/priser/ (accessed on 17 November 2017).

- CircleK. Drivmedelspriser för privatkunder [Vehicle Fuel Prices]. Available online: https://www.circlek.se/sv_SE/pg1334072467111/privat/drivmedel/Priser/Priser-privatkund.html (accessed on 17 November 2017).

- Skatteverket. Skattesatser på Bränslen Och el 2017 [Tax on Fuel and Electricity 2017]. Available online: https://www.skatteverket.se/foretagochorganisationer/skatter/punktskatter/energiskatter/skattesatser.4.77dbcb041438070e0395e96.html (accessed on 17 November 2017).

- International Organization for Standardization (ISO). ISO 14044:2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Hansson, P.; Saltzman, I.-L.; Bååth Jacobsson, S.; Petersson, P. Produktionsgrenskalkyler för Växtodling—Efterkalkyler för år 2014—Södra Sverige; Hushållningssällskapen Kalmar-Kronoberg-Blekinge, Krisitanstad, Malmöhus och Halland: Kalmar, Sweden, 2014; p. 62. [Google Scholar]

- Green, M.B. Energy in pesticide manufacture, distribution and use. In Energy in Plant Nutrition and Pest Control; Helsel, Z.R., Ed.; Elsevier: New York, NY, USA, 1987; Volume 2, pp. 165–178. [Google Scholar]

- BCS. Chapter 9—Limestone and crushed rock. In Energy and Environmental Profil of the U.S. Mining Industry; U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy: Washington, DC, USA, 2002; p. 12. [Google Scholar]

- Statens Jordbruksverk (SJV). Riktlinjer för Gödsling och Kalkning 2017; Swedish Board of Agriculture: Jönköping, Sweden, 2016; p. 100.

- Statens Jordbruksverk (SJV). Jordbruksverkets Produktlista. Available online: http://www.jordbruksverket.se/download/18.773c089e128e1620fa5800087307/1370041066727/Produktlista100610.pdf (accessed on 8 August 2014).

- Engquist, M.; Jansson, S.; Johansson, C.; Algerbo, P.-A.; Johnson, F.; Neuman, L. Maskinkostnader 2016; LRF Konsult: Linköping, Sweden, 2016; p. 48. [Google Scholar]

- Berglund, M.; Börjesson, P. Assessment of energy performance in the life-cycle of biogas production. Biomass Bioenergy 2006, 30, 254–266. [Google Scholar] [CrossRef]

- Börjesson, P. Energianalyser av Biobränsleproduktion i Svenskt Jord- och Skogsbruk - idag och kring 2015; Department of Technology and Society, Lund University: Lund, Sweden, 1994; p. 67. [Google Scholar]

- Overend, R.P. The Average Haul Distance and Transportation Work Factors for Biomass Delivered to a Central Plant. Biomass 1982, 2, 75–79. [Google Scholar] [CrossRef]

- Börjesson, P.; Gustavsson, L. Regional production and utilization of biomass in Sweden. Energy 1996, 21, 747–764. [Google Scholar] [CrossRef]

- HIR Maskinkostnader 2016; Swedish Rural Economy and Agricultural Societies: Bjärred, Sweden, 2016.

- Statistiska Centralbyrån (SCB). Energipriser på Naturgas och el [Energy Prices for Natural Gas and Electricity]. Available online: http://www.scb.se/EN0302 (accessed on 23 September 2017).

- Rosenqvist, H. Kalkyler för Energigrödor 2017—Fastbränsle, Biogas, Spannmål och Raps; Jordbruksverket: Jönköping, Sweden, 2017. [Google Scholar]

- Seider, W.D.; Seader, J.D.; Lewin, D.R.; Widagdo, S. Product and Process Design Principles-Synthesis, Analysis, and Evaluation; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Lantz, M.; Björnsson, L. Biogas från Gödsel och Vall—Analys av Föreslagna Styrmedel; LRF—The Federation of Swedish Farmers: Stockholm, Sweden, 2011. [Google Scholar]

- Börjesson, P.; Lantz, M.; Andersson, J.; Björnsson, L.; Fredriksson Möller, B.; Fröberg, M.; Hanarp, P.; Hulteberg, C.; Iverfeldt, E.; Lundgren, J.; et al. Methane as Vehicle Fuel—A Well-to-Wheel Analysis (Metdriv); Report 2016:06; f3 The Swedish Knowledge Centre for Renewable Transportation Fuels: Göteborg, Sweden, 2016. [Google Scholar]

- Energimyndigheten. Övervakningsrapport Avseende Skattefbefrielse för Flytande Biodrivmedel under 2016; Energimyndigheten: Eskilstuna, Sweden, 2017. [Google Scholar]

- Agriwise. Områdeskalkyler 2017—lagring av spannmål. 2017, Database for economic planning and analysis, Swedish Agricultural University. Available online: www.agriwise.org (accessed on 23 September 2017).

- Biggs, C.; Edward, O.; Valin, H.; Peters, D.; Spoettle, M. Decomposing Biofuel Feedstock Crops and Estimating Their ILUC Effects; Ecofys: Utrecht, The Netherlands, 2016. [Google Scholar]

- Nordpool. System Price. Available online: http://www.nordpoolspot.com/Market-data1/Dayahead/Area-Prices/SYS1/Yearly/?view=table (accessed on 28 December 2017).

- Energimyndigheten. En Svensk-Norsk Elcertificatsmarknad—Årsrapport för 2016; Report ET 2017:9; Energimyndigheten and Norges Vassdrag- och Energidirektorat: Eskilstuna, Sweden, 2017. [Google Scholar]

- Statistiska Centralbyrån (SCB). Trädbränsle och torvpriser nr 3 2017, Sveriges Officiella Statistik; EN 0307 SM 1703; Statistics Sweden: Stockholm, Sweden, 2017.

- Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories; Eggleston, S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Prepared by the National Greenhouse Gas Inventories Programme; The Intergovernmental Panel on Climate Change, Institute for Global Environmental Strategies: Kamiyamaguchi Hayama, Japan, 2006; Volume 4. [Google Scholar]

- Energimyndigheten. Drivmedel 2016; The Swedish Energy Agency: Eskilstuna, Sweden, 2017. [Google Scholar]

- Energimyndigheten. Vägledning Till Regelverket om Hållbarhetskriterier för Biodrivledel och Flytande Biobränslen; The Swedish Energy Agency: Eskilstuna, Sweden, 2012. [Google Scholar]

- Moro, A.; Lonza, L. Electricity carbon intensity in European Member States: Impacts on GHG emissions of electric vehicles. Transp. Res. Part D Transp. Environ. 2017. [Google Scholar] [CrossRef]

- Börjesson, P.; Tufvesson, L.; Lantz, M. Livscykelanalys av Svenska Biodrivmedel; Environmental and Energy Systems Studies, Lund University: Lund, Sweden, 2010; pp. 1102–3651. [Google Scholar]

- Edwards, R.; Larive, J.-E.; Rickeard, D.; Weindorf, W. Well to tank Appendix 2—Version 4a Summary of Energy and GHG Balance of Individual Pathways; Joint Research Center, Institute for Energy and Transport: Ispra, Italy, 2014. [Google Scholar]

- Fossum, J.P. Calculation of Carbon Footprint of Fertilizer Production; Yara HESQ: Oslo, Norway, 2014. [Google Scholar]

- Biograce. Biograce Version 4d 2015 ed. 2015. Available online: http://www.biograce.net/home (accessed on 29 September 2018).

- Kool, A.; Marinussen, M.; Blonk, H. LCI Data for the Calculation Tool -Feedprint for Greenhouse Gas Emissions of Feed Production and Utilization GHG EMISSIONS of N, P and K Fertilizer Production; Blonk Consultants: Gouda, The Netherlands, 2012. [Google Scholar]

- Ahlgren, S.; Röös, E.; Di Lucia, L.; Sundberg, C.; Hansson, P.-A. EU sustainability criteria for biofuels: Uncertainties in GHG emissions from cultivation. Biofuels 2012, 3, 399–411. [Google Scholar] [CrossRef]

- Statistiska Centralbyrån (SCB). Statistics Sweden Database. Varuimport från Avsändningsland, ej Bortfallsjusterat, ton efter Handelspartner, varugrupp SITC och år, 5621 Mineral or Chemical Fertilizers, Nitrogenous, 2016; Statistics Sweden: Örebro, Sverige, 2017.

- Adom, F.; Dunn, J. Material and Energy Flows in the Production of Macro and Micronutrients, Buffers, and Chemicals used in Biochemical Processes for the Production of Fuels and Chemicals from Biomass; Argonne National Laboratory: Argonne, IL, USA, 2015. [Google Scholar]

- Olofsson, J.; Barta, Z.; Börjesson, P.; Wallberg, O. Integrating enzyme fermentation in lignocellulosic ethanol production: life-cycle assessment and techno-economic analysis. Biotechnol. Biofuels 2017, 10, 51. [Google Scholar] [CrossRef] [PubMed]

- Novozymes. Novozymes Cellic® CTec3 Application Sheet; Novozymes A/S: Bagsvaerd, Denmark, 2012. [Google Scholar]

- Karlsson, H.; Ahlgren, S.; Sandgren, M.; Passoth, V.; Wallberg, O.; Hansson, P.-A. Greenhouse gas performance of biochemical biodiesel production from straw: Soil organic carbon changes and time‑dependent climate impact. Biotechnol. Biofuels 2017, 10, 2017. [Google Scholar] [CrossRef] [PubMed]

- Jordbruksverket. Marknadsöversikt-Vegetabilier; The Swedish Board of Agriculture: Jönköping, Sweden, 2012. [Google Scholar]

- Flysjö, A.; Cederberg, C.; Strid, I. LCA-Databas för Konventionella Fodermedel; SIK Rapport; SIK Institutet för Livsmedel och Bioteknik: Göteborg, Sweden, 2008. [Google Scholar]

- Björnsson, L.; Prade, T.; Lantz, M. Grass for Biogas-Arable Land as Carbon Sink. An Environmental and Economic Assessment of Carbon Sequestration in Arable Land through Introduction of Grass for Biogas Production; Energiforsk: Stockholm/Malmö, Sweden, 2016. [Google Scholar]

- Swedish environmental Protection Agency (SEPA). National Inventory Report Sweden 2015. Greenhouse Gas Emission Inventiories 1999–2013; Swedish Environmental Protection Agency: Stockholm, Sweden, 2015.

- Karlsson, S.; Rodhe, L. Översyn av Statistiska Centralbyråns Beräkning av Ammoniakavgången i Jordbruket—Emissionsfaktorer för Ammoniak vid Lagring och Spridning av Stallgödsel; JTI—Institutet för Jordbruks- och Miljöteknik: Uppsala, Sweden, 2002. [Google Scholar]

- Carlsson, C.; Kyllmar, K.; Ulén, B. Typområden på Jordbruksmark—Växtnäringsförluster i små Jordbruksdominerade Avriningsområden 2001/2002; Division of water Quality Management, Swedish University of Agricultural Sciences: Uppsala, Sweden, 2003. [Google Scholar]

- Andren, O.; Katterer, T. ICBM: The introductory carbon balance model for exploration of soil carbon balances. Ecol. Appl. 1997, 7, 1226–1236. [Google Scholar] [CrossRef]

- Kungl. Skogs- och Lantbruksakademiens (KSLA). Success Stories of Agricultural Long-term Experiments; Åke Barklund, General Secretary and Managing Director; KSLA: Stockholm, Sweden, 2007; p. 108. [Google Scholar]

- Petersen, J.; Mattsson, L.; Riley, H.; Salo, T.; Thorvaldsson, G.; Christensen, B.T. Long Continued Agricultural Soil Experiments: Nordic Research Platform—A Catalog; Norden: Hellerup, Denmark, 2008; p. 103. [Google Scholar]

| Production Region | Total Land Area | Arable Land | Fraction of Total Arable Land Sweden | Average Grain Yield | Average Area under Winter Wheat Production |

|---|---|---|---|---|---|

| (ha) | (%) | (%) | (kg DM ha−1) | (ha) | |

| PR1—Gothenland southern plainsslättbygder | 552,021 | 48.5 | 10.2 | 6573 | 93,293 |

| PR2—Gothenland central plains | 967,796 | 30.1 | 11.1 | 5468 | 33,293 |

| PR3—Gothenland northern plains | 1,203,550 | 32.5 | 14.9 | 5273 | 99,177 |

| PR4—Svealands plains | 2,963,151 | 19.5 | 22.1 | 4631 | 90,017 |

| Material and Energy Flows | Grain | Straw | Reference |

|---|---|---|---|

| Feedstock demand (t DM/y) | 440,000 | 200,000 | [24,25] |

| Energy input—process (MWh/t DM) | |||

| Natural gas a | 1.05 | [24] | |

| Wood chips | 0.11 b | [27] | |

| Electricity | 0.04 c | [27] | |

| Energy input—distribution (MWh/t DM) | |||

| Diesel (truck transport) | 0.004 | 0.002 | Present work |

| Electricity (filling station) | 0.006 | [27] | |

| Additives/Chemicals (kg/t DM) | |||

| Acetic acid | 1.1 | [25] | |

| Ammonia (25%) | 40 | [25] | |

| Antifoam | 0.4 | [25] | |

| Enzyme, 1 g | 1.1 | ||

| Enzyme, 2 g | 5.6 | [25] | |

| H2SO4 | 7.3 | [24] | |

| MgCl2/MgSO4 | 0.1 | [25] | |

| Molasses | 26 | [25] | |

| NaOH | 7.3 | [24] | |

| (NH4)2HPO4 | 1.1 | [25] | |

| NH4OH | 7.3 | [24] | |

| Phosphoric acid | 3.5 | [25] | |

| Yeast | 0.002 | [24] | |

| Water | 2200 | 55,900 | [26] |

| Main product (MWh/t DM) | |||

| Ethanol | 2.67 | 1.1 | |

| Methane | 0.8 | [24,25] | |

| Co-products (MWh/t DM) | |||

| Electricity, incl. internal use | 0.25 | 0.09 | [24,25] |

| Electricity, net output | 0.18 | 0.05 | [24,25] |

| Lignin pellets (at product humidity) d | 1.2 | [24,25] | |

| DDGS (at product humidity) e | 1.55 | [24] |

| Material and Energy Flows | Grain | Straw |

|---|---|---|

| Feedstock demand (t DM/y) | 13,100 | 21,500 |

| Energy input—process (MWh/t DM) | ||

| Wood chips | 0.48 | 0.29 |

| Electricity | 0.21 | 0.26 |

| Energy input—distribution (MWh/t DM) | ||

| Electricity (filling station) | 0.03 | 0.03 |

| Additives/Chemicals (kg/t DM) | ||

| FeSO4 | 0.03 | |

| N | 8.69 | |

| P | 0.25 | |

| Trace elements | 0.12 | 0.07 |

| Process water | 3200 | 4200 |

| Main product | ||

| Methane (LHV) (MWh/t DM) | 3.5 | 2.1 |

| Co-products | ||

| Biofertilizer (kg/t DM) | 145 | 479 |

| whereof | ||

| NH4-N | 14 | 8.3 |

| P | 5.2 | 0.6 |

| K | 5.5 | 10 |

| C | 108 | 247 |

| Market Price | Diesel | Petrol | CNG |

|---|---|---|---|

| Fuel price | 17.4 | 17.4 | 25.5 |

| Energy and CO2 tax | 14.3 | 21.4 | 6.8 |

| Total price | 31.7 | 38.8 | 32.3 |

| Input—Production | Units | Value | Description |

|---|---|---|---|

| Energy supply—electricity | g CO2eq MJ−1 | 34.9 | Nordic mix |

| 124 | EU28 mix | ||

| 13.1 | Swedish mix | ||

| Energy supply—heat | g CO2eq MJ−1 | 4.0 | Wood chips |

| 77 | EU mix natural gas | ||

| Fuel for crop production and transport | g CO2eq MJ−1 | 80.4 | Diesel with low-blend biodiesel |

| 23.2 | Biodiesel | ||

| Mineral N manufacture | kg CO2eq kg N−1 | 4.45 | Average use Sweden |

| 7.8 | Western European average | ||

| Enzyme dose | g enzyme (100 g cellulose)−1 | 1.7 | Used in techno-economic study |

| 6.0 | Max. trial dose recommended | ||

| 6.8 | Next-generation enzymes | ||

| Enzyme manufacture emissions | kg CO2eq kgenzyme−1 | 5.5 | |

| 8.0 | |||

| 0.9 | Next-generation enzymes | ||

| Methane yield—straw | m3 (t DM)−1 | 224 | |

| 202 | |||

| 247 | |||

| Straw storage cost | € (t DM)−1 | 0.02 | Indoor |

| 0 | Outdoor | ||

| Capital cost | |||

| - Depreciation | years | 20 | |

| - Depreciation | 15 | ||

| - WACC | % | 11 | |

| - WACC | 6 | ||

| Investment subsidy | % | 0 | |

| 30 | |||

| Co-products | |||

| DDGS—sales price | € (t DM)−1 | 0.24 | |

| 0.34 | |||

| 0.14 | |||

| Methane yield (straw ethanol process) | MJ (t DMstraw)−1 | 2900 | Experimentally derived |

| 6666 | Theoretically calculated |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lantz, M.; Prade, T.; Ahlgren, S.; Björnsson, L. Biogas and Ethanol from Wheat Grain or Straw: Is There a Trade-Off between Climate Impact, Avoidance of iLUC and Production Cost? Energies 2018, 11, 2633. https://doi.org/10.3390/en11102633

Lantz M, Prade T, Ahlgren S, Björnsson L. Biogas and Ethanol from Wheat Grain or Straw: Is There a Trade-Off between Climate Impact, Avoidance of iLUC and Production Cost? Energies. 2018; 11(10):2633. https://doi.org/10.3390/en11102633

Chicago/Turabian StyleLantz, Mikael, Thomas Prade, Serina Ahlgren, and Lovisa Björnsson. 2018. "Biogas and Ethanol from Wheat Grain or Straw: Is There a Trade-Off between Climate Impact, Avoidance of iLUC and Production Cost?" Energies 11, no. 10: 2633. https://doi.org/10.3390/en11102633

APA StyleLantz, M., Prade, T., Ahlgren, S., & Björnsson, L. (2018). Biogas and Ethanol from Wheat Grain or Straw: Is There a Trade-Off between Climate Impact, Avoidance of iLUC and Production Cost? Energies, 11(10), 2633. https://doi.org/10.3390/en11102633