Musculoskeletal Health Effects of Manual Sandcrete Block Handling Among Construction Artisans: Implications for Industry Practice and Training

Abstract

1. Introduction

- What types of musculoskeletal health issues are commonly experienced by construction artisans engaged in manual sandcrete block handling?

- What specific manual handling practices contribute to these musculoskeletal health issues?

- How do artisan weight and block weight affect musculoskeletal disorders among construction artisans handling sandcrete blocks?

2. Literature Review

2.1. Overview of Construction Artisans

2.2. Occupational Health Risks Faced by Artisans in Standardised Block Usage

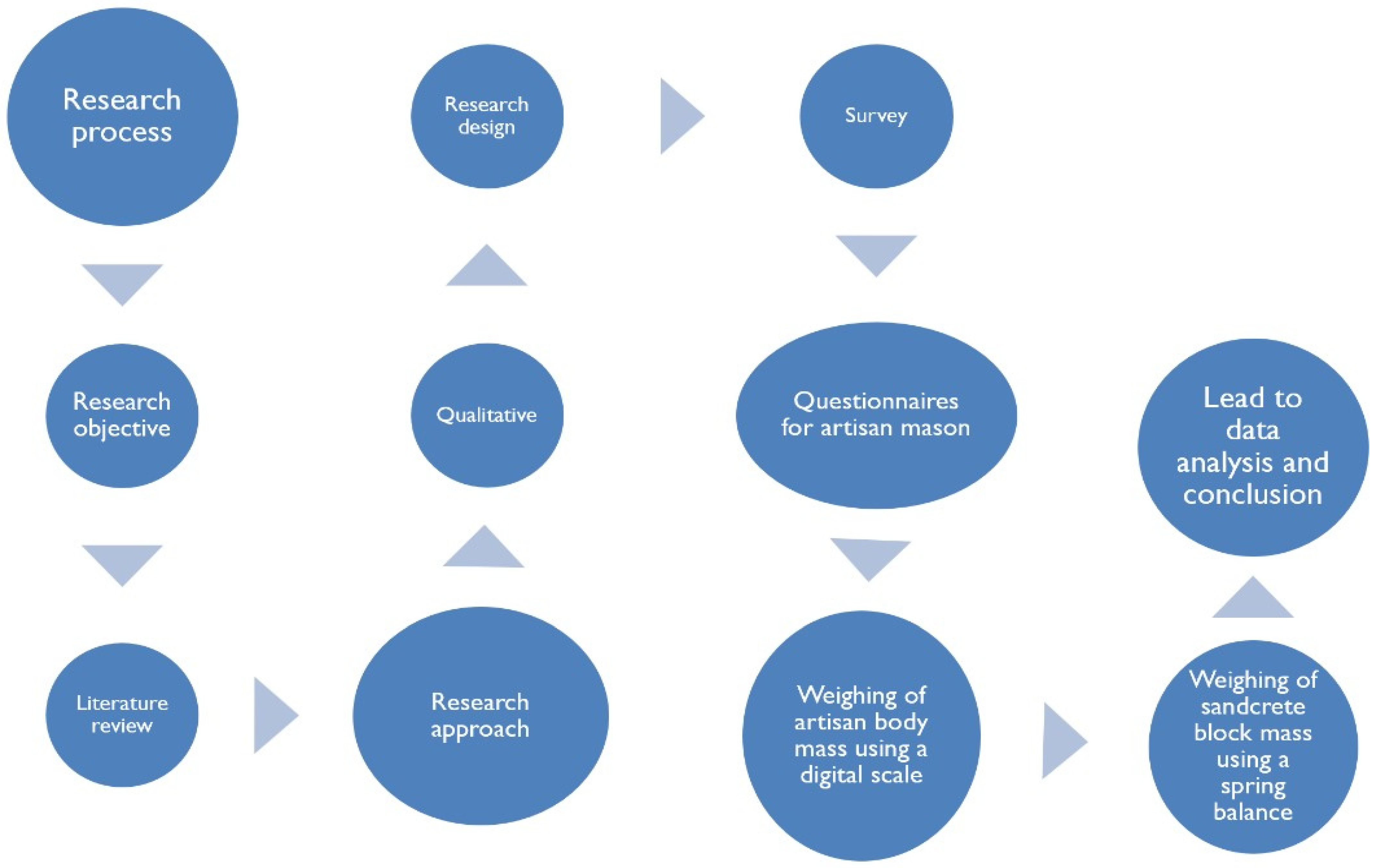

3. Research Methods

3.1. Research Approach

3.2. Data Collection Instruments and Procedure

- Demographic Information: This section gathered data on their gender, qualifications, years of experience, nature of work, and work hours.

- Work Practices and Manual Handling Activities: This section included questions on how often artisans lift sandcrete blocks, typical postures used, lifting techniques, and work durations.

- Musculoskeletal Health Symptoms: This section used closed-ended Likert-scale items to capture the presence and severity of musculoskeletal symptoms (e.g., lower back pain, joint pain, muscle fatigue) and how these symptoms impact work life. A 5-point Likert scale was used: 1 = Strongly Agree; 2 = Agree; 3 = Neutral; 4 = Disagree and 5 = Strongly Disagree.

- Primary engagement in walling/blockwork using sandcrete units;

- A minimum of ten years of experience in the construction industry.

3.3. Study Area and Population

3.4. Data Analysis

- Descriptive statistics (frequencies, percentages, means, and standard deviations) were used to summarise demographic data and responses related to work practices and health symptoms.

- Mean Item Scores were calculated to determine the severity and frequency of musculoskeletal symptoms.

- Pearson’s Correlation Coefficient was used to test the relationship between variables such as years of experience, frequency of block lifting, and reported musculoskeletal symptoms.

- Standard deviation was used to assess variability in responses and body mass measurements.

3.5. Ethical Considerations

4. Results

4.1. Background Characteristics

4.2. Working Conditions of the Artisan Mason

4.3. Descriptive Statistics of the Problems Faced by the Artisans

4.4. Relationship Between Background Characteristics and the Working Problem

4.5. Relationship Between Background Characteristics and Working Problems

5. Discussion of Results

5.1. Discussion on Background Characteristics

5.2. Discussion on the Working Conditions of Artisans

5.3. Discussion on the Health Problems Faced by Artisans

5.4. Discussion on the Relationship Between Background Characteristics and Health Problems

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Halabi, Y.; Xu, H.; Long, D.; Chen, Y.; Yu, Z.; Alhaek, F.; Alhaddad, W. Causal factors and risk assessment of fall accidents in the US construction industry: A comprehensive data analysis (2000–2020). Saf. Sci. 2022, 146, 105537. [Google Scholar] [CrossRef]

- Eze, E.C.; Nwaki, W.N.; Obonadhuze, B.I. Construction tradespeople’s perception of the factors motivating labour productivity on construction projects. J. Technol. Manag. Bus. 2020, 7, 50–68. Available online: https://penerbit.uthm.edu.my/ojs/index.php/jtmb/article/view/7235 (accessed on 16 August 2024). [CrossRef]

- Boadu, E.F.; Wang, C.C.; Sunindijo, R.Y. Characteristics of the construction industry in developing countries and its implications for health and safety: An exploratory study in Ghana. Int. J. Environ. Res. Public Health 2020, 17, 4110. [Google Scholar] [CrossRef]

- Boakye, M.K.; Adanu, S.K.; Adzivor, E.K.; Coffie, G.H.; Ayimah, J.C. Factors influencing health and safety performance at construction sites in Ghana: The perspective of building artisans. Int. J. Occup. Saf. Ergon. 2023, 29, 1121–1127. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Chen, C.; Li, X.; Yao, W.; Wang, Z.; Zhu, H. Analysis of the impact of construction robots on workers’ health. Build. Environ. 2022, 225, 109595. [Google Scholar] [CrossRef]

- Ifeanyi, A.C. Assessment of Occupational Health Safety Compliance in the Nigerian Construction Industry; University of Johannesburg: Johannesburg, South Africa, 2017. [Google Scholar]

- Koc, K.; Ekmekcioğlu, Ö.; Gurgun, A.P. Determining susceptible body parts of construction workers due to occupational injuries using inclusive modelling. Saf. Sci. 2023, 164, 106157. [Google Scholar] [CrossRef]

- Amusan, L.M.; Oluwatobi, O.; Dalshe, C.; Ezenduka, J.; Emetere, M.; Owolabi, J.D.; Tunji-Olayeni, P.F. Towards improving artisan and craftsmen productivity. IOP Conf. Ser. Earth Environ. Sci. 2021, 655, 012083. [Google Scholar] [CrossRef]

- Afolabi, F.J. We can regulate ourselves’: Exploring the artisans’ trade associations’ contributions to occupational safety and health problem prevention. Saf. Sci. 2022, 154, 105836. [Google Scholar] [CrossRef]

- Ryu, J.; Banting, B.; Abdel-Rahman, E.; Haas, C.T. Ergonomic characteristics of expert masons. J. Constr. Eng. Manag. 2023, 149, 04022150. [Google Scholar] [CrossRef]

- Tao, Y.; Hu, H.; Xu, F.; Zhang, Z. Ergonomic Risk Assessment of Construction Workers and Projects Based on Fuzzy Bayesian Network and DS Evidence Theory. J. Constr. Eng. Manag. 2023, 149, 04023034. [Google Scholar] [CrossRef]

- Okereke, G.K.O.; Omeje, H.O.; Nwaodo, S.I.; Chukwu, D.U.; Asogwa, J.O.; Obe, P.I.; Uwakwe, R.C.; Uba, M.B.I.; Edeh, N.C. Reducing burnout among building construction and mechanical trade artisans: The role of rational emotive behaviour intervention. J. Ration. Emot. Cogn. Behav. Ther. 2022, 40, 61–74. [Google Scholar] [CrossRef]

- Lebechukwu, I.R.; Peter, A.A. Assessing skill capability of artisans and craftsmen in Nsukka industrial market, Enugu State, Nigeria. Ianna J. Interdiscip. Stud. 2021, 3, 26–35. Available online: https://iannajournalofinterdisciplinarystudies.com/index.php/1/article/view/70 (accessed on 16 August 2024).

- Tweneboah-Koduah, I.; Adusei, C. Entrepreneurship determinants of artisans/craftsmen in Kumasi Metropolis, Ghana. Am. J. Ind. Bus. Manag. 2016, 6, 163. [Google Scholar] [CrossRef][Green Version]

- Andohful, K.F.; Mensah, C.E.; Bamfo-Agyei, E. Understanding the compressive strength of commercially produced sandcrete blocks using the Ghana building code. Afr. J. Appl. Res. 2021, 7, 155–174. [Google Scholar][Green Version]

- Abudu, H.D.; Mewomo, C.M.; Bondinuba, F.K.; Liphadzi, M.; Adjei, K.O. PLS-SEM assessment of the effect of using standardized blocks on artisans’ health in the construction industry. J. Asian Archit. Build. Eng. 2025, 1–17. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Oguntayo, D.O.; Babalola, O.E.; Oke, O.L.; Akinkurolere, O.O. Investigation of micronised laterite sandcrete block compressive strength. Case Stud. Constr. Mater. 2021, 14, e00530. [Google Scholar] [CrossRef]

- Robert, U.W.; Etuk, S.E.; Agbasi, O.E.; Okorie, U.S.; Lashin, A. Hygrothermal properties of sandcrete blocks produced with raw and hydrothermally-treated sawdust as partial substitution materials for sand. J. King Saud Univ. Eng. Sci. 2021. [CrossRef]

- Isaksson, R.; Buregyeya, A. Understanding sustainability–the case of building blocks in Tanzania and Uganda. TQM J. 2020, 36, 1900–1916. [Google Scholar] [CrossRef]

- Onyia, M.E.; Ikeagwuani, C.C.; Egbo, M.C. Effect of pressed palm oil fruit fibre on mechanical properties of sandcrete masonry blocks using Taguchi-grey relational analysis optimization technique. Clean. Mater. 2022, 5, 100124. [Google Scholar] [CrossRef]

- Akorli, K.S.; Aigbavboa, C.O.; Ametepey, S.O.; Gyamfi, T.A. The influence of partially replacing pit sand with quarry dust on the compressive strength of sandcrete blocks. Mater. Today Proc. 2023, 93, 422–427. [Google Scholar] [CrossRef]

- Alejo, A.O. Comparison of strength of sandcrete blocks produce with fine aggregate from different sources. Niger. J. Technol. 2020, 39, 332–337. [Google Scholar] [CrossRef]

- Girish, N.; Iqbal, R.; Khanzode, V.; De, A. Manual material handling and occupational low back disorders: A narrative literature review emphasising maximum acceptable weight of load. Int. J. Hum. Fac. Ergon. 2015, 3, 376–392. [Google Scholar] [CrossRef]

- Sobeih, T.; Salem, O.; Genaidy, A.; Abdelhamid, T.; Shell, R. Psychosocial factors and musculoskeletal disorders in the construction industry. J. Constr. Eng. Manag. 2009, 135, 267–277. [Google Scholar] [CrossRef]

- Chaudhary, H.; Jaswinder Singh, J.S. A literature review on MSDS using ergonomic body assessment tools: RULA and REBA. Int. J. Sci. Res. 2012, 2, 147–149. [Google Scholar] [CrossRef]

- Obeidat, M.S.; Abbasi, D.B.; Alzoubi, K.M.; Alyahya, L.A. Postural Modeling of Palletizing Workers via Simulation based on RULA, NMQ, and NIOSH. Ind. Eng. Manag. Syst. 2024, 23, 18–34. [Google Scholar] [CrossRef]

- Xiang, Y.; Arora, J.S.; Rahmatalla, S.; Marler, T.; Bhatt, R.; Abdel-Malek, K. Human lifting simulation using a multi-objective optimisation approach. Multibody Syst. Dyn. 2010, 23, 431–451. [Google Scholar] [CrossRef]

- Lavender, S.A.; Li, Y.C.; Andersson, G.B.J.; Natarajan, R.N. The effects of lifting speed on the peak external forward bending, lateral bending, and twisting spine moments. Ergonomics 1999, 42, 111–125. [Google Scholar] [CrossRef]

- Blache, Y.; Dal Maso, F.; Desmoulins, L.; Plamondon, A.; Begon, M. Superficial shoulder muscle co-activations during lifting tasks: Influence of lifting height, weight and phase. J. Electr. Kines. 2015, 25, 355–362. [Google Scholar] [CrossRef]

- Joshi, M.; Deshpande, V. Application of interpretive structural modelling (ISM) for developing ergonomic workstation improvement framework. Theor. Issues Ergon. Sci. 2023, 24, 88–110. [Google Scholar] [CrossRef]

- Gonsalves, N.; Akanmu, A.; Shojaei, A.; Agee, P. Factors influencing the adoption of passive exoskeletons in the construction industry: Industry perspectives. Int. J. Ind. Ergon. 2024, 100, 103549. [Google Scholar] [CrossRef]

- Ghafoori, M.; Clevenger, C.; Abdallah, M.; Rens, K. Heart rate modelling and prediction of construction workers based on physical activity using deep learning. Autom. Constr. 2023, 155, 105077. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Anwer, S.; Li, D.; Yu, Y.; Mi, H.Y.; Wuni, I.Y. Assessment of a passive exoskeleton system on spinal biomechanics and subjective responses during manual repetitive handling tasks among construction workers. Saf. Sci. 2021, 142, 105382. [Google Scholar] [CrossRef]

- Kisi, K.P.; Kayastha, R. Analysis of musculoskeletal pains and productivity impacts among Hispanic construction workers. Heliyon 2024, 10, e24023. [Google Scholar] [CrossRef]

- Pistolesi, F.; Baldassini, M.; Lazzerini, B. A human-centric system combining smartwatch and LiDAR data to assess the risk of musculoskeletal disorders and improve ergonomics of Industry 5.0 manufacturing workers. Comput. Ind. 2024, 155, 104042. [Google Scholar] [CrossRef]

- Yu, Y.; Umer, W.; Yang, X.; Antwi-Afari, M.F. Posture-related data collection methods for construction workers: A review. Autom. Constr. 2021, 124, 103538. [Google Scholar] [CrossRef]

- Mary, A.M. Occupational hazards among health care workers in Nigeria. Afr. J. Biomed. Res. 2023, 26, 319–326. [Google Scholar]

- Gupta, A.H.; Kaur, H. Occupational health problems of phulkari artisans. Int. J. Res. Soc. Sci. 2019, 9, 697–710. Available online: http://www.ijmra.us/ (accessed on 15 July 2024).

- Ibrahim, A.; Nnaji, C.; Namian, M.; Koh, A.; Techera, U. Investigating the impact of physical fatigue on construction workers’ situational awareness. Saf. Sci. 2023, 163, 106103. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiang, T.; Guo, H.; Ma, L.; Guan, Z.; Fang, Y. Impact of physical and mental fatigue on construction workers’ unsafe behaviour based on physiological measurement. J. Saf. Res. 2023, 85, 457–468. [Google Scholar] [CrossRef]

- Naoum, S.G. Dissertation Research and Writing for Construction Students; Routledge: Abingdon, UK, 2012. [Google Scholar]

- Fobiri, G.; Abaitey, B.A.; Attimah, B.; Ofori, G.; Nana-Addy, E. An investigation into the working conditions of informal construction artisans in the Ghanaian construction industry. In Proceedings of the 8th International Conference on Infrastructure Development in AfricaInt (ICIDA), Kumasi, Ghana, 19–23 November 2023. [Google Scholar]

- Pandey, P.; Pandey, M.M. Research Methodology Tools and Techniques; Bridge Center: Tokyo, Japan, 2021. [Google Scholar]

- Shahu, R. The NIOSH lifting equation for manual lifting and its applications. J. Ergon. 2016, 6, 1–10. [Google Scholar] [CrossRef]

- Coenen, P.; Kingma, I.; Boot, C.R.; Twisk, J.W.; Bongers, P.M.; van Dieën, J.H. Cumulative low back load at work as a risk factor of low back pain: A prospective cohort study. J. Occup. Rehabil. 2013, 23, 11–18. [Google Scholar] [CrossRef]

- Soares, C.O.; Pereira, B.F.; Gomes, M.V.P.; Marcondes, L.P.; de Campos Gomes, F.; de Melo-Neto, J.S. Preventive factors against work-related musculoskeletal disorders: Narrative review. Rev. Bras. Med. Trab. 2020, 17, 415. [Google Scholar] [CrossRef] [PubMed]

- Walker-Bone, K.; Thomsen, J.F. Musculoskeletal Disorders. In Textbook of Occupational Medicine Practice; World Scientific Publishing: Singapore, 2022; pp. 197–243. [Google Scholar] [CrossRef]

- Punnett, L.; Wegman, D.H. Work-related musculoskeletal disorders: The epidemiologic evidence and the debate. J. Electromyogr. Kinesiol. 2004, 14, 13–23. [Google Scholar] [CrossRef]

- Marras, W.S.; Allread, W.G.; Burr, D.L.; Fathallah, F.A. Prospective validation of a low-back disorder risk model and assessment of ergonomic interventions associated with manual materials handling tasks. Ergonomics 2000, 43, 1866–1886. [Google Scholar] [CrossRef]

- Kudlinski, D. Assessing safety programs and strategies to prevent heavy equipment struck-by incidents in construction. In Proceedings of the IISE Annual Conference and Expo, Montreal, QC, Canada, 18–21 May 2024. [Google Scholar]

- Da Costa, B.R.; Vieira, E.R. Risk factors for work related musculoskeletal disorders: A systematic review of recent longitudinal studies. Am. J. Ind. Med. 2010, 53, 285–323. [Google Scholar] [CrossRef]

- DiDomenico, A.; Nussbaum, M.A. Effects of different physical workload parameters on mental workload and performance. Int. J. Ind. Ergon. 2011, 41, 255–260. [Google Scholar] [CrossRef]

- Perry, C.M.; Sheik-Nainar, M.A.; Segall, N.; Ma, R.; Kaber, D.B. Effects of physical workload on cognitive task performance and situation awareness. Theor. Issues Ergon. Sci. 2008, 9, 95–113. [Google Scholar] [CrossRef]

- MacDonald, W. The impact of job demands and workload on stress and fatigue. Aust. Psychol. 2003, 38, 102–117. [Google Scholar] [CrossRef]

- Kermavnar, T.; de Vries, A.W.; de Looze, M.P.; O’Sullivan, L.W. Effects of industrial back-support exoskeletons on body loading and user experience: An updated systematic review. Ergonomics 2021, 64, 685–711. [Google Scholar] [CrossRef]

- Castellucci, H.I.; Viviani, C.; Hernández, P.; Bravo, G.; Martínez, M.; Ibacache, J.; Bartsch, Á. Developing countries and the use of ISO Standard 11228-3 for risk management of work-related musculoskeletal disorders of the upper limbs (WRMSDs-ULs): The case of Chile. Appl. Ergon. 2021, 96, 103483. [Google Scholar] [CrossRef]

- Lowe, W.; Ballinger, C.; Protheroe, J.; Lueddeke, J.; Nutbeam, D.; Armstrong, R.; Adams, J. Suggestions for a research agenda for health literacy and musculoskeletal health—Reflections following a qualitative evidence synthesis. Work. Pap. Health Sci. 2014, 1, 1–8. [Google Scholar]

- Odebiyi, D.O.; Okafor, U.A.C. Musculoskeletal disorders, workplace ergonomics and injury prevention. In Ergonomics—New Insights; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Gallagher, S.; Heberger, J.R. Examining the interaction of force and repetition on musculoskeletal disorder risk: A systematic literature review. Hum. Factors 2013, 55, 108–124. [Google Scholar] [CrossRef]

- Hunter, D.; Silverstein, B. Perceptions of risk from workers in high risk industries with work related musculoskeletal disorders. Work 2014, 49, 689–703. [Google Scholar] [CrossRef]

| S/No | Health Risks | Causes | |||||

|---|---|---|---|---|---|---|---|

| Lifting of Blocks | Fall of Blocks | Pushing and Pulling of Blocks | Bending and Twisting | Weather Conditions | References | ||

| 1 | Abdominal pain | x | x | x | [17,32,33] | ||

| 2 | Headache | x | x | x | [30] | ||

| 3 | Numbness | x | x | [12] | |||

| 4 | Joint pain | x | x | x | [24] | ||

| 5 | Waist pain | x | x | x | [34] | ||

| 6 | Muscles pain | x | [34] | ||||

| 7 | Low-back pain | x | x | x | [35] | ||

| 8 | Chronic pain | x | x | x | [36] | ||

| 9 | Hernias | x | x | x | [37] | ||

| 10 | Cuts | x | [38] | ||||

| 11 | Bruises | x | x | [39] | |||

| 12 | Sprains | x | x | x | x | [40] | |

| 13 | Tears | x | x | x | [41] | ||

| 14 | Small fractures | x | x | x | [38,39] | ||

| 15 | Muscle strains | x | x | x | x | [37,38] | |

| Background Characteristics | Frequency | Percent |

|---|---|---|

| Gender | ||

| Male | 402 | 100.00 |

| Female | 0 | 0.00 |

| Total | 402 | 100.0 |

| Highest qualification | - | |

| No formal education | 160 | 39.8 |

| Basic education level | 202 | 50.2 |

| Junior high-level | 40 | 10.0 |

| Total | 402 | 100.0 |

| Years of working experience | - | |

| 10–15 years | 180 | 44.8 |

| 16–20 years | 215 | 53.5 |

| 21–25 years | 4 | 1.0 |

| 26 years and above | 3 | 0.7 |

| Total | 402 | 100.0 |

| Working Conditions | Mean | Std. Deviation |

|---|---|---|

| Weight of the artisan Mason | 61.53 | 7.55 |

| Weight of the 125 mm block | 25.39 | 0.82 |

| Weight of the 150 mm block | 30.29 | 0.77 |

| The number of 125 mm blocks you laid in a day | 106.84 | 20.22 |

| The number of 150 mm blocks you laid in a day | 82.65 | 10.27 |

| The number of hours you work in a day | 7.70 | 0.62 |

| Frequency | Percent | |

| The number of resting hours per day | - | |

| 30 min | 101 | 25.1 |

| 1 h | 301 | 74.9 |

| Total | 402 | 100.0 |

| Number of working days in the week | - | |

| 5 days | 71 | 17.7 |

| 6 days | 313 | 77.9 |

| 7 days | 18 | 4.5 |

| Total | 402 | 100.0 |

| Problems | General Problem | Lifting | Pulling and Pushing | Bending and Twisting | Falling | Weather Conditions | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean (SD) | Rank | Mean (SD) | Rank | Mean (SD) | Rank | Mean (SD) | Rank | Mean (SD) | Rank | Mean (SD) | Rank | |

| Abdominal pain | 3.73 (1.111) | 9 | 3.89 (0.972) | 6 | 3.93 (1.058) | 9 | 4.02 (0.894) | 5 | 4.02 (0.967) | 6 | 3.00 (1.521) | 10 |

| Headache | 3.96 (0.993) | 3 | 3.24 (0.680) | 10 | 3.94 (0.869) | 8 | 3.72 (0.783) | 12 | 3.99 (0.927) | 7 | 4.11 (0.990) | 1 |

| Numbness (shaking) | 3.75 (0.978) | 8 | 3.15 (0.839) | 12 | 4.28 (0.894) | 2 | 3.75 (0.823) | 10 | 4.05 (0.946) | 5 | 2.97 (1.495) | 11 |

| Joint Pain | 3.65 (1.044) | 13 | 4.71 (0.674) | 2 | 4.00 (0.862) | 5 | 3.49 (0.883) | 14 | 3.87 (0.868) | 14 | 2.90 (1.476) | 14 |

| Waist Pain | 3.91 (1.045) | 5 | 4.71 (0.670) | 3 | 3.61 (0.795) | 13 | 3.70 (0.824) | 13 | 3.88 (0.943) | 13 | 3.01 (1.524) | 9 |

| Muscles Pain | 3.69 (0.915) | 12 | 4.62 (0.652) | 4 | 3.60 (0.940) | 14 | 4.26 (0.821) | 1 | 3.95 (0.858) | 9 | 3.15 (1.581) | 3 |

| Low-Back Pain | 3.88 (0.993) | 6 | 4.74 (0.639) | 1 | 3.77 (0.877) | 10 | 4.11 (0.854) | 2 | 3.91 (0.877) | 11 | 3.09 (1.550) | 4 |

| Chronic Pain | 3.73 (0.962) | 10 | 2.46 (1.071) | 14 | 4.28 (0.964) | 1 | 4.02 (0.749) | 6 | 4.22 (0.926) | 3 | 3.06 (1.510) | 7 |

| Hernia | 4.06 (1.002) | 1 | 3.71 (1.155) | 7 | 3.94 (0.960) | 7 | 3.88 (1.121) | 7 | 3.89 (0.854) | 12 | 2.95 (1.524) | 13 |

| Muscles Strains | 3.98 (0.943) | 2 | 3.66 (1.113) | 8 | 4.13 (0.927) | 3 | 4.06 (1.025) | 3 | 3.93 (0.865) | 10 | 2.97 (1.501) | 12 |

| Cut | 3.73 (0.917) | 11 | 3.17 (0.922) | 11 | 4.03 (1.011) | 4 | 3.85 (0.942) | 8 | 3.96 (0.937) | 8 | 3.03 (1.545) | 8 |

| Sprain | 3.94 (0.877) | 4 | 3.26 (0.860) | 9 | 3.74 (0.932) | 11 | 3.80 (0.978) | 9 | 4.25 (0.811) | 2 | 3.09 (1.578) | 5 |

| Bruises (scratches) | 3.81 (0.816) | 7 | 3.91 (0.747) | 5 | 3.99 (1.046) | 6 | 4.03 (1.011) | 4 | 4.46 (0.850) | 1 | 3.16 (1.619) | 2 |

| Small Fractures | 3.64 (0.954) | 14 | 2.59 (1.185) | 13 | 3.66 (0.809) | 12 | 3.74 (0.932) | 11 | 4.15 (0.839) | 4 | 3.07 (1.547) | 6 |

| RWeight | Weight 125 mm Blocks | Weight 150 mm Blocks | No. 125 mm Blocks | No. 150 mm Blocks | Workers | NRHD | NWDW | ||

|---|---|---|---|---|---|---|---|---|---|

| RWeight | Coeff. | 1 | |||||||

| p-value | |||||||||

| Weight 125 mm blocks | Coeff. | −0.202 ** | 1 | ||||||

| p-value | 0.000 | ||||||||

| Weight 150 mm blocks | Coeff. | −0.248 ** | 0.919 ** | 1 | |||||

| p-value | 0.000 | 0.000 | |||||||

| No. 125 mm blocks | Coeff. | −0.115 * | −0.178 ** | −0.208 ** | 1 | ||||

| p-value | 0.021 | 0.000 | 0.000 | ||||||

| No. 150 mm blocks | Coeff. | −0.166 ** | 0.151 ** | 0.148 ** | 0.331 ** | 1 | |||

| p-value | 0.001 | 0.002 | 0.003 | 0.000 | |||||

| Workers | Coeff. | −0.133 ** | 0.709 ** | 0.628 ** | −0.174 ** | 0.093 | 1 | ||

| p-value | 0.008 | 0.000 | 0.000 | 0.000 | 0.063 | ||||

| NRHD | Coeff. | −0.217 ** | 0.644 ** | 0.489 ** | −0.111 * | −0.004 | 0.881 ** | 1 | |

| p-value | 0.000 | 0.000 | 0.000 | 0.027 | 0.934 | 0.000 | |||

| NWDW | Coeff. | −0.070 | 0.722 ** | 0.626 ** | −0.183 ** | 0.051 | 0.796 ** | 0.732 ** | 1 |

| p-value | 0.162 | 0.000 | 0.000 | 0.000 | 0.306 | 0.000 | 0.000 | ||

| N | 402 | 402 | 402 | 402 | 402 | 402 | 402 | 402 | |

| Relationship Between Background Characteristics and Working Problems | Pearson Correlation | p-Value | 95% CI | |

|---|---|---|---|---|

| Lower | Upper | |||

| Highest qualification—General problem | 0.092 | 0.064 | −0.005 | 0.189 |

| Highest qualification—Lifting | 0.259 | 0.000 ** | 0.165 | 0.348 |

| Highest qualification—Pulling and Pushing | 0.083 | 0.097 | −0.015 | 0.179 |

| Highest qualification—Bending and Twisting | 0.067 | 0.178 | −0.031 | 0.164 |

| Highest qualification—Falling | 0.005 | 0.923 | −0.093 | 0.103 |

| Highest qualification—Weather Conditions | −0.154 | 0.002 ** | −0.248 | −0.057 |

| Years of working experience—General problem | 0.099 | 0.047 * | 0.001 | 0.195 |

| Years of working experience—Lifting | 0.245 | 0.000 ** | 0.151 | 0.335 |

| Years of working experience—Pulling and Pushing | 0.041 | 0.413 | −0.057 | 0.138 |

| Years of working experience—Bending and Twisting | 0.021 | 0.678 | −0.077 | 0.118 |

| Years of working experience—Falling | −0.012 | 0.818 | −0.109 | 0.086 |

| Years of working experience—Weather Conditions | −0.123 | 0.013 * | −0.219 | −0.026 |

| RWeight—General problem | −0.015 | 0.768 | −0.112 | 0.083 |

| RWeight—Lifting | −0.077 | 0.124 | −0.173 | 0.021 |

| RWeight—Pulling and Pushing | −0.073 | 0.146 | −0.169 | 0.025 |

| RWeight—Bending and Twisting | −0.084 | 0.093 | −0.180 | 0.014 |

| RWeight—Falling | −0.010 | 0.847 | −0.107 | 0.088 |

| RWeight—Weather Conditions | 0.129 | 0.010 * | 0.031 | 0.224 |

| Weight 150 mm block—General problem | 0.063 | 0.209 | −0.035 | 0.160 |

| Weight 150 mm block—Lifting | 0.207 | 0.000 ** | 0.112 | 0.299 |

| Weight 150 mm block—Pulling and Pushing | 0.103 | 0.039 * | 0.005 | 0.199 |

| Weight 150 mm block—Bending and Twisting | 0.073 | 0.142 | −0.025 | 0.170 |

| Weigh 150 mm block—Falling | 0.019 | 0.709 | −0.079 | 0.116 |

| Weight 150 mm block—Weather Conditions | −0.199 | 0.000 ** | −0.291 | −0.103 |

| Workers—General problem | 0.048 | 0.335 | −0.050 | 0.145 |

| Workers—Lifting | 0.346 | 0.000 ** | 0.257 | 0.429 |

| Workers—Pulling and Pushing | 0.079 | 0.116 | −0.019 | 0.175 |

| Workers—Bending and Twisting | 0.063 | 0.211 | −0.035 | 0.159 |

| Workers—Falling | 0.095 | 0.056 | −0.003 | 0.191 |

| Workers—Weather Conditions | −0.104 | 0.036 * | −0.200 | −0.007 |

| Number of days of work in the week—General problem | 0.071 | 0.157 | −0.027 | 0.167 |

| Number of days of work in the week—Lifting | 0.270 | 0.000 ** | 0.177 | 0.359 |

| Number of days of work in the week—Pulling and Pushing | 0.114 | 0.022 * | 0.017 | 0.210 |

| Number of days of work in the week—Bending and Twisting | 0.070 | 0.164 | −0.028 | 0.166 |

| Number of days of work in the week—Falling | 0.125 | 0.012 * | 0.028 | 0.220 |

| Number of days of work in the week—Weather Conditions | −0.113 | 0.023 * | −0.208 | −0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adjei, K.O.; Liphadzi, M.; Bondinuba, F.K.; Mewomo, C.M.; Abudu, H.D. Musculoskeletal Health Effects of Manual Sandcrete Block Handling Among Construction Artisans: Implications for Industry Practice and Training. Int. J. Environ. Res. Public Health 2025, 22, 1689. https://doi.org/10.3390/ijerph22111689

Adjei KO, Liphadzi M, Bondinuba FK, Mewomo CM, Abudu HD. Musculoskeletal Health Effects of Manual Sandcrete Block Handling Among Construction Artisans: Implications for Industry Practice and Training. International Journal of Environmental Research and Public Health. 2025; 22(11):1689. https://doi.org/10.3390/ijerph22111689

Chicago/Turabian StyleAdjei, Kofi Owusu, Murendeni Liphadzi, Francis Kwesi Bondinuba, Cecilia Modupe Mewomo, and Haruna Domanamwin Abudu. 2025. "Musculoskeletal Health Effects of Manual Sandcrete Block Handling Among Construction Artisans: Implications for Industry Practice and Training" International Journal of Environmental Research and Public Health 22, no. 11: 1689. https://doi.org/10.3390/ijerph22111689

APA StyleAdjei, K. O., Liphadzi, M., Bondinuba, F. K., Mewomo, C. M., & Abudu, H. D. (2025). Musculoskeletal Health Effects of Manual Sandcrete Block Handling Among Construction Artisans: Implications for Industry Practice and Training. International Journal of Environmental Research and Public Health, 22(11), 1689. https://doi.org/10.3390/ijerph22111689