Abstract

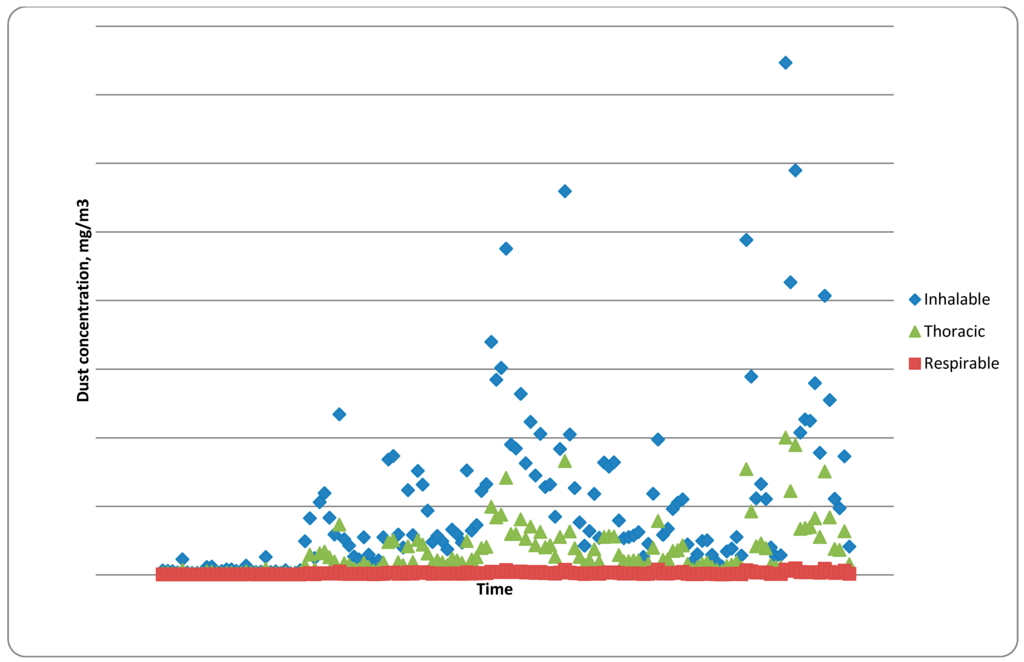

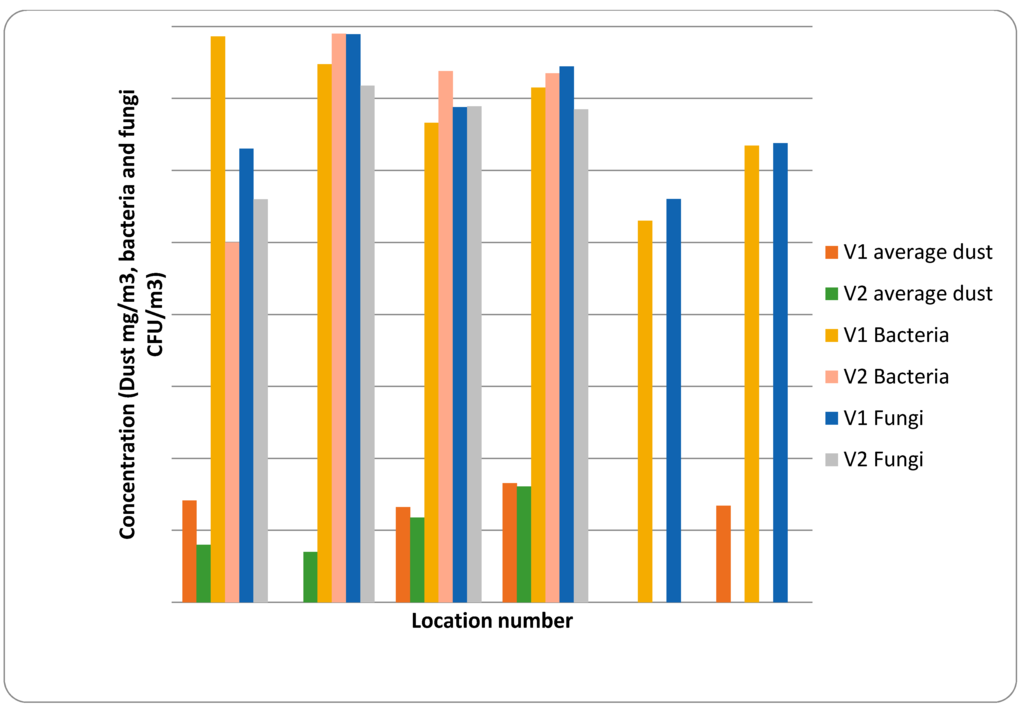

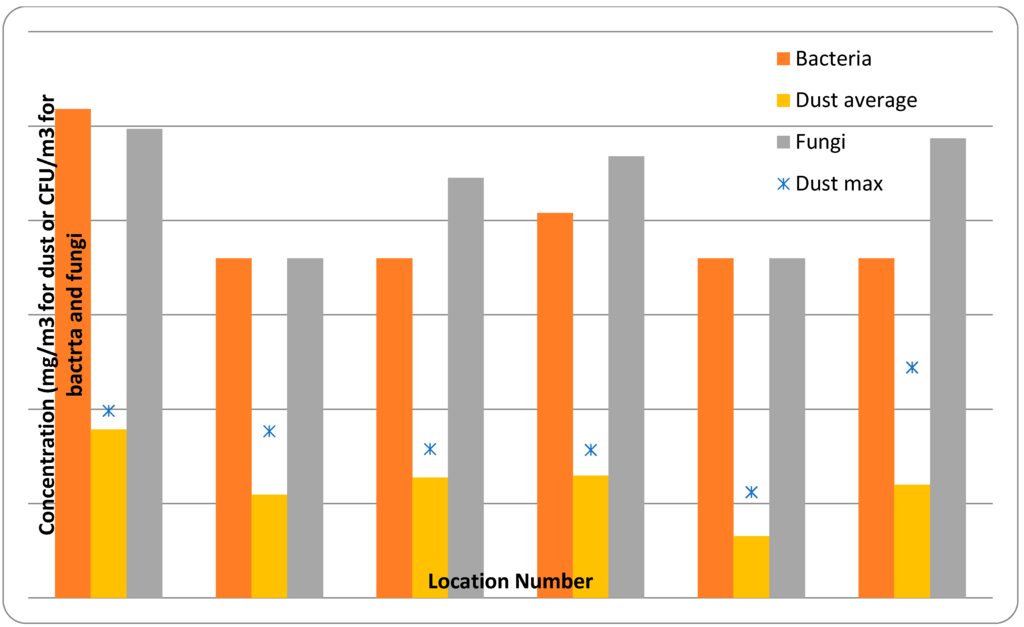

Biomass is increasingly being used for power generation; however, assessment of potential occupational health and safety (OH&S) concerns related to usage of biomass fuels in combustion-based generation remains limited. We reviewed the available literature on known and potential OH&S issues associated with biomass-based fuel usage for electricity generation at the utility scale. We considered three potential exposure scenarios—pre-combustion exposure to material associated with the fuel, exposure to combustion products, and post-combustion exposure to ash and residues. Testing of dust, fungal and bacterial levels at two power stations was also undertaken. Results indicated that dust concentrations within biomass plants can be extremely variable, with peak levels in some areas exceeding occupational exposure limits for wood dust and general inhalable dust. Fungal spore types, identified as common environmental species, were higher than in outdoor air. Our review suggests that pre-combustion risks, including bioaerosols and biogenic organics, should be considered further. Combustion and post-combustion risks appear similar to current fossil-based combustion. In light of limited available information, additional studies at power plants utilizing a variety of technologies and biomass fuels are recommended.

1. Introduction

Biomass-fueled power generation will contribute to reaching international targets for renewable production of electricity and related greenhouse gas emissions reductions through new construction or re-powering of existing coal-fired units [1]. Biomass combustors, common in small scale, industrial boiler, or cogeneration (heat/power) applications, have now been developed for electricity generation at a larger utility scale (over 50 megawatts (MW) thermal input) [2]. As with other solid fuel power plants, facilities using biomass as the primary combustion source can provide a reliable source for base load, cycling, and on-demand situations. However, as with any emerging or scaled-up technology, evaluation of environmental and occupational health impacts requires an understanding of the properties and characteristics of the fuel, as well as consideration of plant design, fuel processing, handling and storage [3].

In the case of occupational health and safety (OH&S), biomass combustion may result in several unique worker exposures relative to petroleum or coal-based fuels. These differences may be due both to the combustion process itself and the introduction of new occupational tasks related to biomass handling, storage and processing. Though extensive data from utility-scale operations are limited, occupational information can be gleaned from small-scale biomass technologies or related industries, such as waste handling and forestry [4,5]. This review focuses on the potential for occupational exposure and related health risks specific to biomass-based electricity generation, primarily for direct-fired, stand-alone technologies. It should, however, be noted that other biomass energy conversion processes, such as co-firing with coal, gasification, pyrolysis and anaerobic digestion have similar OH&S issues around biomass handling and, where available, experiences from these systems have been drawn upon. This review does not discuss the potential for health effects at the population level due to ambient emissions, or residential in-home exposures due to wood or other biomass burning (see [6] for a good review of this topic).

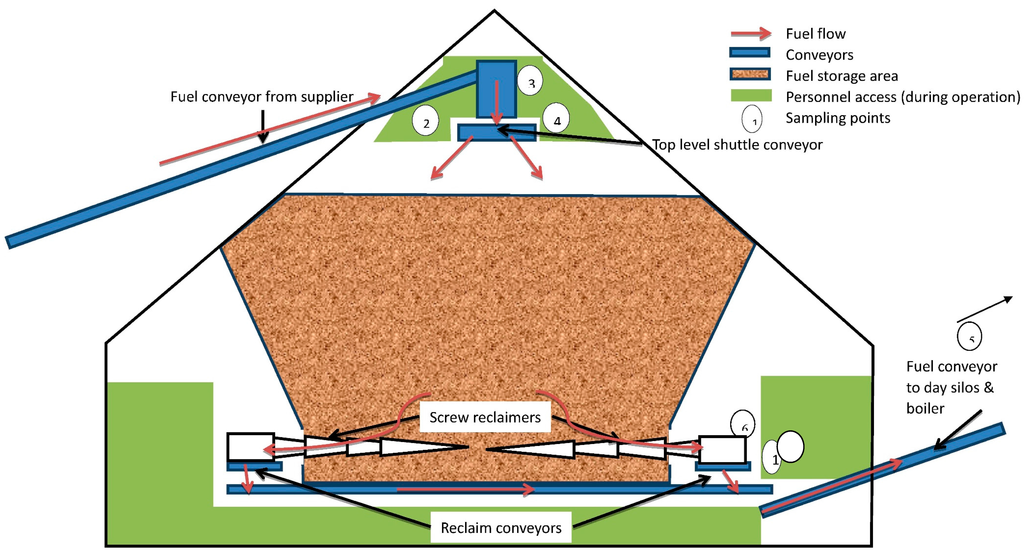

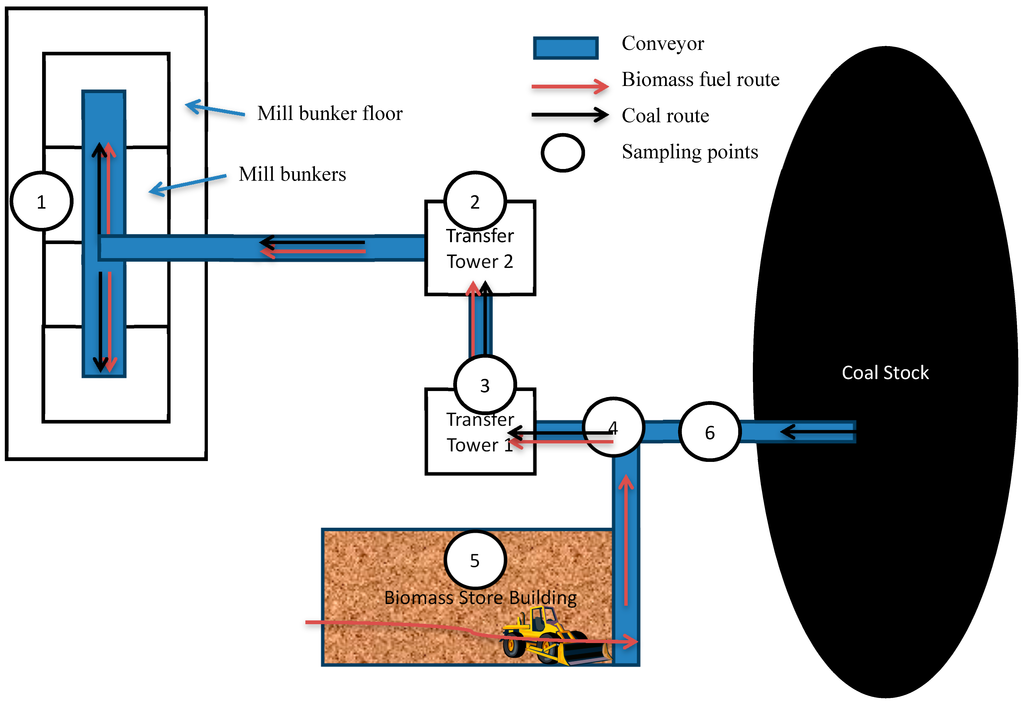

For the most part, it is possible to separate processes at power plants into three groups: pre-combustion (handling, storage, fuel preparation), combustion (including flue gas treatment), and post-combustion (ash and by-product handling). Each of these groups has its own inherent OH&S issues and hence this review follows a similar categorization. Following a discussion of the literature, testing results for dust, fungal and bacterial levels at two power stations are presented.

2. Summary of Available Technologies and Fuel Types

Combustion technologies used (or proposed) for modern biomass-fueled, direct-fired power plants vary by design, fuel flexibility, and environmental considerations. As such, the degree and type of emissions control technologies required to meet any required emission limits for pollutants of regulatory concern also influence OH&S issues. Biomass varies substantially in composition and fuel characteristics, so some combustion technologies may be more suitable than others for a particular biomass feedstock, depending on factors such as availability, composition and moisture content. The combination of fuel and boiler type chosen establishes the relative combustion efficiency, temperature range, and other combustion characteristics that influence the quantities, types and chemical composition of the solid waste to be handled post-combustion (ash and air pollution control residues). These factors, along with influences such as local pollution control regulations, also govern the choice of control technologies and ultimately the relative risks associated with worker exposure to potentially hazardous substances from combustion and post-combustion handling processes [2,3,7,8]. In direct-fired, 100% biomass combustion for power generation, combustion within a given boiler produces high-pressure steam for driving a turbine [9]. Table 1 provides a summary of the major types of stand-alone, direct-fired biomass technologies; the two most common combustion boiler types for dedicated biomass combustion are generally of a stoker (grate) or fluidized bed design. Table 2 provides a summary of available emission control technologies and related environmental exposures of potential concern for these two common designs; it should be noted, however, that not all technologies can be used with all biomass fuels.

In addition to these stand-alone technologies, a number of large (up to 660 MWe) pulverized coal units in Europe have recently been converted to combust 100% biomass, although this type of boiler is not generally considered the most suitable for a new build biomass plant due to the high level of biomass pre-processing required (such as drying and pelletizing).

A wide variety of biomass fuels are in current use for electricity generation. These include agricultural residues, such as straw, olive cake, and palm kernels, wood chip and wood residues, and specially grown “energy crops” such as miscanthus and switchgrass. The choice of the fuel (or mixture of fuels) used in a particular boiler depends on a number of factors, including availability of sufficient quantities (taking into account seasonality), fuel quality, potential negative impacts on the boiler, and price. In some countries, the definition of biomass also includes waste materials such as sewage sludge and post-consumer wood (including panel products such as particleboard). Levels of contaminants such as heavy metals can be significantly higher in these waste materials than for “clean” biomass types (e.g., see the Phyllis2 database [10]. As a result, their use is often subject to tighter regulatory controls. For example, the EU’s Industrial Emissions Directive includes emission limits for biomass combustion in the same section as fossil fuels, but plants using demolition wood must meet the stricter waste incineration limits [11].

Table 1.

Summary of available large-scale, standalone biomass combustion technologies for electricity generation.

| Direct Fired Technology | Common Fuel Types | Biomass Feed Size (cm) | Moisture Content (%) | Generation Capacity (MW) |

|---|---|---|---|---|

| Pile burners | Wood or agricultural residues (excl. wood flour) | Limited by grate size and feed opening | <65 | 4 to 110 |

| - with underfire stoker | Sawdust, select bark (“non-stringy”), shavings, chips, “hog” fuel | 0.6–5 | 10–30 | 4 to 110 |

| Stoker grate boilers | Sawdust, select bark (“non-stringy”), shavings, end cuts, chips, “hog” fuel, sander dust | 0.6–5 | 10–50 | 4 to 300 |

| Suspension boilers | ||||

| - Cyclonic | Sawdust, select bark (“non-stringy”), shavings, wood flour, sander dust | <0.6 | <15 | <30 |

| - Air spreader-stoker | Wood flour, sander dust, processed sawdust, shavings | 0.1–0.15 | <20 | 1.5 to 30 |

| Fluidized-bed combustor | Low alkali fuels: wood residues or peat | <5 | <60 | Up to 300 |

| - with underfire stoker | Sawdust, select bark (“non-stringy”), shavings, chips, “hog” fuel | 0.6–5 | 10–30 | 4 to 110 |

| - with underfire stoker | Sawdust, select bark (“non-stringy”), shavings, chips, “hog” fuel |

Summarized from [2] and [12].

Table 2.

Substances of significance for health and corresponding emission control options for stoker or fluidized bed boilers.

| Air Pollution Control or Environmental Target | Emission Control Options | |

|---|---|---|

| Stoker Boiler | Fluidized Bed Boiler | |

| Typical post-combustion air pollution control | PM—Cyclones, ESP, FF NOx—SNCR, SCR (only applicable for low alkali fuels) CO—oxidation catalysis SOx/HCl—IDSIS, SDA, DS (with FF), FGDw | PM—ESP and FF NOx—SNCR, SCR (only applicable for low alkali fuels) CO—generally absent SOx/HCl—In furnace injection, IDSIS, SDA, DS, FGDd (with FF) |

| Low sulfur oxide (SOx) combustion | Not possible (in furnace) | Some reduction possible through limestone addition to bed material |

| Low NOx combustion | Air staging | Generally low inherent NOx (due to lower temperature), air staging, flue gas recirculation |

| Low CO formation | Difficult (lower combustion efficiency) | Generally low due to higher combustion efficiency |

Summarized from: [2,7,8,13]; CO = Carbon Monoxide; DS = Dry sorbent; ESP = Electrostatic Precipitator; FF = Fabric Filter or Baghouse; FGDd = Dry Flue Gas Desulfurization; FGDw = Wet Flue Gas Desulfurization; HCl = Hydrogen Chloride; IDSIS = In Duct Sorbent Injection System; NOx = Nitrogen Oxides; PM = Particulate Matter; SCR = Selective Catalytic Reduction; SDA = Spray Dryer Absorber; SNCR = Selective Non-Catalytic Reduction; SOx = Sulfur dioxide.

3. Potential Occupational Exposures

Evaluating potential occupational exposures at biomass-fueled power generation facilities is complicated not only by the wide variety (and mixtures) of fuel types, but also by the variety of facility designs and lack of detailed exposure monitoring data reported in the literature. The focus of this section is on exposures associated with fuels used at these facilities (pre-combustion, stack emissions, and post-combustion), as opposed to other secondary occupational exposures (i.e., forklift/truck traffic, diesel generators, etc.). Evaluation of a biomass feedstock generally includes analyses for energy content, fuel properties (including moisture and ash content), and major fuel elements (carbon, hydrogen, nitrogen, sulfur, chlorine) [14], as well as more minor components capable of influencing plant operations, including the main mineral components of the ash and levels of heavy metals [15,16]. These physiochemical properties also influence the type of emissions (air, water and solids), environmental impacts, and plant control requirements. Just as the availability and type of the source fuel(s) influences the ability to design, site, and operate a large-scale biomass combustion plant [17], it also determines the nature of the operational waste streams and the associated potential for worker exposure. As with other combustion-based power plants, biomass-fueled facilities produces emissions to air and water, as well as solid byproducts such as ash and pollution control residues.

Due to the limited data regarding occupational biomass exposures in the power generation sector, potential worker exposures—particularly those unique to biomass versus other fuels—are described from similar occupational exposures as needed, such as wood pellet or other biomass waste management. Exposed populations of interest are identified, and relevant exposure sources and routes are discussed. The section also identifies substances of significance to health (SSHs) at these facilities, and further discuss SSHs that may have different exposure profiles than at traditional fossil fuel power generation facilities.

3.1. Overview of Exposure Sources and Routes

In general, three primary sources of exposure should be considered for an occupational risk assessment of a biomass-fueled generation facility: the biomass fuel itself (pre-combustion), biomass combustion emissions (usually associated with the boiler or stack), and exposure to the resulting ash residue (post-combustion). Some exposures may be common to multiple stages. For example, workers may be exposed to gaseous pollutants and particulate matter (PM) generated from biomass handling, transport, storage, and agitation, as well as from post-combustion ash. Numbers of workers and their typical tasks vary between installations, but a basic overview is provided in Table 3.

The inherent physiochemical characteristics, including the amount of cellulose, hemicelluloses, and volatile organics, in common biomass sources such as straw, wood pellets and chips, may be expected to influence pre-combustion exposures. As well as dust from the material itself, biomass may contain an inhalable bioaerosol component, comprised of microorganisms and endotoxins [18]; these materials may be released during industrial handling [19,20,21]. In general, exposure levels in wood handling industries differ substantially by the type and size of biomass, by temperature and humidity, and by the specific task (e.g., transport, shredding, agitation) [20]. Primary exposure routes are likely to be through inhalation of particulate, bioaerosols and volatile compounds and dermal contact, although there is also the risk of mechanical irritation of the eyes. Ingestion is a less likely route of exposure, although contamination of welfare areas with biomass may be an issue in some cases where controls are inadequate.

For onsite personnel, the primary exposure route is likely to be associated with the pre-combustion release of PM, bioaerosols, and volatile organics from the biomass during storage and handling operations. Although combustion of biomass produces pollutant gases and PM, exposure to these is considered to be a risk mainly at the very small scale (such as in domestic heating and cooking); at the utility scale, plant design and control should minimize the risk of worker exposure to combustion products.

For some plant workers, there is also the potential for exposure to post combustion products, particularly ash. Different combustion technologies produce ash with differing characteristics, which are further modified by emissions control systems. At the utility scale, it is usual for different ashes to be handled separately, with streams labeled as “bottom ash” and “fly ash” most commonplace. The bottom ash, removed from the bottom of the boiler, is primarily composed of relatively unreactive, high melting point materials such as aluminosilicates; with fluidized bed boilers there is also a contribution from the bed material (often sand), as well as any limestone used for acid gas control. In contrast, the fly ash consists of those inorganic components that have volatilized in the furnace before condensing as the gas cools, as well as fine non-volatile ash that has become entrained in the flue gas before being collected in control devices such as filters and electrostatic precipitators (ESPs). Many of the volatile trace elements contained in the fuel are concentrated in this fly ash. Where dry sorbents are added to the flue gas for pollutant control (e.g., lime for acid gas abatement or activated carbon for heavy metal control), these are also removed with the fly ash. Some plants may have multiple ash capture stages to reduce the proportion of the ash contaminated with air pollution control sorbents.

Although it may be assumed that the highest risk of exposure to ash is among those personnel involved in its handling and storage, there are other groups of workers who may also be at risk. Where ash handling systems are not fully enclosed, airborne ash releases may affect all personnel, while those workers working on repair and maintenance within the boiler are likely to be exposed to ash in the form of furnace deposits. It should be noted that these boiler deposits could have different chemical characteristics to the bulk ash; for example, they could be enriched in those metals that preferentially condense into the deposit at particular furnace temperatures [22]. While potential exposure to ash should be limited by process controls (such as enclosure of handling systems) wherever possible, with Personal Protective Equipment (PPE) used by workers to reduce any residual risk, the efficiency of these controls can vary widely. The effectiveness of PPE in particular is heavily influenced by factors including training, proper fit (a particular issue with respiratory protection), safety culture, management enforcement, and workers’ own perception of risk. Exposure routes of interest for ash include inhalation and dermal contact during transfer and transport processes, with incidental ingestion of ash or dust comparatively less important. Biomass ash can also be highly alkaline, presenting a risk of irritation and corrosiveness due to pH alone, particularly in contact with skin and eyes.

3.2. Substances of Significance to Health

3.2.1. Pre-Combustion Exposures

Pre-combustion exposure to biomass materials is influenced by the unique physiochemical properties of the fuel. A limited number of European studies have reported ambient PM concentrations within facilities associated with biomass combustion, processing or handling; these have often focused on bioaerosols, including bacteria, fungi, endotoxin, and other related markers [4,5,23,24,25]. There has also been significant interest in exposure to gaseous species, mainly carbon monoxide (following a number of fatal incidents during transport and storage of wood pellets), but also volatile organics [26,27,28,29,30]. In general, these studies have focused on area monitoring or overall personnel exposure assessment, with minimal or no worker task specification. Table 4 summarizes the SSHs identified from the literature for biomass handling, processing (e.g., wood pellets), and storage at either biomass power facilities or related industries such as wood pellet production.

3.2.2. Combustion-Related Exposures

The major combustion SSHs emitted from biomass-fueled power generation facilities are similar to those from traditional fossil fuel generation facilities. Concentrations of these substances in the flue gas can be influenced by factors such as fuel chemical composition, boiler design, pollutant control systems, and combustion conditions, and so can vary considerably between different facilities. In addition to criteria pollutants such as PM, carbon monoxide (CO), sulfur oxides (SOx), and nitrogen oxides (NOx), a number of different volatile organic compounds (acrolein, aldehydes) and some associated persistent semi-volatile compounds (PAHs, dioxins/furans) may also be present, although data regarding their presence—and more especially their concentrations—in the flue gas are often limited. Emitted PM also contains mineral and metal species. The US EPA AP-42 guidance does provide emission factors for a large number of organic species from wood residue combustion in boilers; these factors were last updated in 2001 [31]. The boilers which have provided the data used to generate these factors are generally industrial-scale rather than utility-scale units, being primarily used to utilize residues from wood processing facilities and pulp mills. In many cases, emission factors presented are derived from only one or two measurements. Where there are multiple measurements available, the range of values often spans several orders of magnitude. As a result, these factors may not reflect current practice at the utility scale, particularly in terms of boiler design (most tests were undertaken on stoker or Dutch Oven-type boilers) and flue gas clean up. Non-woody biomass fuels are not considered in AP-42, with the exception of a limited amount of data provided for bagasse use in sugar mills. It should be noted that as the size of the installation increases, there is greater scope for optimization of the combustion system, improving efficiency and reducing air emissions associated with poor combustion. In many countries, there are also legally mandated emission limits on major pollutants to air for plants over a specified thermal input, and these limits often decrease as plant size increases (see for example [11]). The controls required to meet the limits for major pollutants often also provide a co-benefit removal of minor species (for example, systems for sulfur oxide reduction can also reduce other acidic gases) [13]. Emission rates (per unit of output) for large-scale generation plants can therefore be significantly lower than for smaller industrial units. Table 5 provides a summary of the types of substances that may be of interest to occupational health in this industry; however, it should be noted that many of these substances are associated with combustion processes in general, not biomass combustion specifically.

Although few quantitative data on SSHs at biomass combustion facilities exist, a number of studies provide information on the relative stack emissions at biomass facilities compared to traditional fossil-fueled facilities. For example, biomass fuels generally have lower levels of mercury and sulfur than coal, and thus mass emissions of SOx and mercury from these facilities would likely be lower (assuming similar control technologies) [32]. Chlorine levels in biomass are more variable, but for wood (the most common biomass fuel used for large-scale generation) chlorine content is typically very low, which may lead to low emissions of chlorinated dioxins and furans. However, on the other hand, the heterogeneous nature of biofuels (as compared to coal) might lead to less efficient combustion and possibly the formation of proportionately more of these chemicals for the same chlorine content in the two fuels [32,33,34]. Emissions of PM and NOx depends on the levels of ash and nitrogen in the fuel, the combustion system, and the emissions control technologies used. At the utility scale it could be expected that PM and NOx emissions would be lower than for coal combustion (except for those coal plants fitted with selective catalytic reduction systems for NOx), but higher than for light oil or natural gas combustion [5,36].

While the types of SSHs emitted are fairly well understood, there are very few data on concentrations that might be relevant to assessing occupational risks versus concentrations related to ambient releases. The design and operation of modern biofuel plant is such that the probability of release of flue gas into the plant itself should be low, and therefore assessment of risk of worker exposure to combustion products based on composition of stack emissions is likely to overestimate risk.

3.2.3. Post-Combustion Related Exposures

The majority of inorganic material associated with the biomass fuel is recovered from the boiler as ash. As the composition of mineral matter in different biomass fuel varies, so does the ash, with additional variability introduced by the use of non-fuel materials, such as sand or other minerals, as the bed material in fluidized bed boilers, along with the use of sorbents for flue gas treatment. In large-scale boilers, multiple ash streams are often produced with different chemical properties. For example, in fluidized bed boilers the bottom, or bed, ash consists of a mixture of fuel ash, bed material, and coarse contaminants of biomass (such as stones). Certain volatile elements, including sulfur, chlorine, alkali metals, and some heavy metals, are depleted in the bottom ash, as the temperatures in the boiler are sufficient to vaporize them and they exit the boiler in the flue gas. In contrast, the fly ash (or filter ash) consists of material fine enough to be carried by the flue gas and can be enriched in the volatile elements as they condense out onto the ash as the flue gas cools.

Table 3.

Typical power plant tasks and exposures.

| Job Type | Tasks | Potential Exposures |

|---|---|---|

| Trucker | Transport of biomass to site (road/rail) Loading and discharge of material Transport of ash | Biomass dust and bioaerosols generated during biomass loading and discharge Ash dust generated during loading and discharge Diesel exhaust from vehicles |

| Fuel Handling Plant operative | Transport of biomass through the site Storage of biomass Fuel preparation (milling etc.) | Biomass dust and bioaerosols generated during biomass handling and milling Off-gases from storage Direct contact with moldy biomass |

| Cleaner | Removal of dust deposits from plant | Generation of airborne biomass dust, bioaerosols and ash through disturbance of deposits Potential for direct contact with moldy biomass |

| Maintenance engineer | Maintenance of plant equipment during normal operation | Generation of airborne biomass dust, bioaerosols and ash through disturbance of deposits Potential for exposure to combustion gases |

| Outage contractor | Repair of plant items during shutdown periods (particularly within the boiler) | Generation of airborne biomass dust, bioaerosols and ash through disturbance of deposits Direct contact with ash deposits within the boiler (often confined spaces) |

| Ash handling plant operative | Removal of ash from the boiler Transport to storage | Direct contact with ash |

| Other plant personnel | Various | Fugitive dusts from fuel and ash handling plants Combustion gases |

Table 4.

Identified substances of significance to health (SSHs): pre-combustion.

| SSH Class | COI | Source | Industry | Reference(s) |

|---|---|---|---|---|

| Particulate Matter | Wood dust | Raw or processed material Straw, wood chips, pellets | Forestry Wood pellet production Biomass generation Biomass laboratory | [25,37,38,39,40] |

| Bioaerosols | Microbial (Fungi/Bacteria) | Component of PM Wood chips or pellets | Biomass power generation Fuel processing and handling | [23,40,41,42,43] |

| Endotoxin | Component of PM Straw, grain, hay, organic waste | Biomass power generation | [21] | |

| Volatile Organics (VOCs) | Aldehydes Total VOCs | Off gassing from sawdust Auto-oxidation of unsaturated fatty acids | Wood pellet production | [5,26] |

| Organics | Monoterpenes Resin acids | Components of PM, off gassing from sawdust | Wood pellet production Forestry, milling | [5,26,44] |

| Inorganic Gases | Carbon monoxide | Off gassing from raw materials | Wood pellet production, transport, storage | [28,29,30] |

Table 5.

Identified substances of significance for health (SSHs) and potential health effects: combustion and post-combustion.

| SSH Class | SSH | Source | Refs | Health Effects Associated with Exposure Route | Refs | |

|---|---|---|---|---|---|---|

| Inhalation | Dermal/Eye | |||||

| Inorganic Gases | Carbon monoxide | Combustion | [45] | CNS; Miscarriage; Carboxylhemoglobinemia | [45,46] | |

| Nitrogen oxides | Combustion | [45] | URT and LRT | Irritation (Skin and Eye) | [45,48] | |

| Sulfur oxides | Combustion | [46] | Pulmonary function; LRT | [45,49] | ||

| Acid aerosols (e.g., H2SO4) | Combustion | [47] | Pulmonary function | Irritation (Skin and Eye) | [45,49] | |

| Hydrocarbons | 1,3-Butadiene | Combustion | [45] | CNS; Stomach, Respiratory and Hematolymphopoietic Cancers | [45,50] | |

| n-Hexane | Combustion | [45] | CNS; Peripheral Neuropathy | Irritation (Eye) | [45] | |

| PAHs a | Combustion, Ash | [45,48,49] | Lung Cancer | Skin Cancer * | [51] | |

| Benzene | Combustion | [45] | Leukemia; Anemia; CNS | [45,52] | ||

| Styrene | Combustion | [45] | CNS | [45] | ||

| Oxygenated organics | Acrolein | Combustion | [45] | URT; Pulmonary edema; Pulmonary emphysema | Irritation (Skin and Eye) | [45] |

| Formaldehyde | Combustion | [45] | URT; Nose Cancer * | Irritation (Skin and Eye) | [45,53] | |

| Methanol | Combustion | [45] | CNS; URT | Eye Damage | [45,54] | |

| Acetic acid | Combustion | [45] | URT; Pulmonary function | Irritation (Eye) | [45] | |

| Catechol | Combustion | [45] | URT | Dermatitis; Irritation (Eye) | [45] | |

| Cresol (methylphenols) | Combustion | [45] | URT; Kidney; Liver | Skin Damage | [45,55] | |

| Hydroquinone | Combustion | [45] | CNS | Irritation (Eye) | [45,56] | |

| Fluorenone | Combustion | [45] | URT | Irritation (Eye) | [57] | |

| Anthraquinone | Combustion | [45] | Respiratory | Irritation (Skin and Eye) | [58] | |

| Chlorinated organics b | Methylene chloride | Combustion | [45] | CNS; Peripheral Neuropathy; Liver and Lung Cancer * | Irritation (Skin and Eye) | [59,60] |

| Methyl chloride | Combustion | [45] | CNS; Liver; Kidney; CNS *; Testicular *; Teratogenic * | [45,61] | ||

| Dioxins/furans | Combustion | [45,48] | URT; Chloracne; Liver; Glucose metabolism | Chloracne | [62,63] | |

| Particulate matter (PM) | PM10 | Combustion/Condensation | [45] | Pulmonary function; URT | Irritation (Eye) | [64] |

| PM2.5 | Combustion/Condensation | [45] | Pulmonary function; URT | Irritation (Eye) | [22] | |

| Inorganics | Aluminum (Al) c | Combustion | [45] | Pneumoconiosis; LRT | [45,66] | |

| Arsenic (As) e | Ash | [48,49] | URT and LRT; Lung Cancer | [45,67] | ||

| Beryllium (Be) d | Ash | [48] | Beryllium disease; | Irritation (Skin) | [45,68,69] | |

| Cobalt (Co) d,e | Ash | [48] | Pulmonary function; Myocardial effects | [45,70] | ||

| Magnesium (Mg) d | Combustion | [45] | URT; Pulmonary function; Metal fume fever | Irritation (Eye) | [71] | |

| Iron (Fe) d | Combustion | [45,49] | Pneumoconiosis; URT | Irritation (Skin and Eye) | [45,72] | |

| Manganese (Mn) f | Combustion | [45] | Neurobehavioral | [73,74] | ||

| Zinc (Zn) h | Combustion | [45,49] | Metal fume fever; LRT and URT | Irritation (Skin and Eye) | [45,75,76] | |

| Nickel (Ni) d | Combustion, Ash | [45,48,49] | Pneumoconiosis; Nasal and Lung Cancer | Dermatitis | [45,77,78] | |

| Copper (Cu) d | Combustion | [45,49] | URT; Metal fume fever | Irritation (Eye) | [45,79] | |

| Lead (Pb) f,g,h,i | Combustion | [45,49] | CNS and PNS; Hematologic; Nephropathy | [45,80] | ||

| Mercury (Hg) d,f | Ash | [48] | CNS and PNS; Kidney | [45,81] | ||

| Chromium (Cr) d | Combustion, Ash | [45,48,49] | Pulmonary function; Lung Cancer | Irritation (Skin) | [45,82] | |

| Cadmium (Cd) d,i | Combustion | [45] | Pulmonary function; Kidney | [45,83,84] | ||

| Quartz | Ash | [48] | Pulmonary fibrosis; Chronic silicosis; Lung cancer * | [45,85] | ||

CNS—central nervous system; LRT—lower respiratory tract; PNS—peripheral nervous system; URT—upper respiratory tract; * Endpoints derived from animal studies; a Oral exposure—Animal bioassays positive for reproductive/developmental effects and stomach cancer; b Assumes chlorine in fuel; c Oral exposure—Animal bioassay positive neurotoxicity; d Oral exposure—Human gastrointestinal toxic effects observed for Be, Co, Mg, Fe, Ni, Cu, Hg, Cr, Cd; e Oral exposure—Human skin toxicity observed for As (and cancer) and Co; f Oral exposure—Human CNS effects observed for Mn and Pb; g Oral exposure—Human PNS effects observed for Pb; h Oral exposure—Human hematologic effects observed for Zn and Pb; i Oral exposure—Human kidney toxicity observed for Pb and Cd.

Two studies provide information on levels of SSHs in biomass boiler room dust (likely to consist of a mixture of pre-combustion and post-combustion material), and others have reported qualitative aspects of exposure. Cohn et al. [23] reported levels of PAHs and selected trace metals in three dust samples collected from the boiler room at a straw-burning biomass generation facility in Denmark (Table 6). Madsen and Sharma [18] performed an analysis on a single sample of dust collected in the boiler room of a straw-fueled biomass plant and found that the primary inorganic elements present were potassium, calcium, and sodium. Other elements included aluminum, magnesium, iron, manganese, phosphorus, zinc, nickel, copper, lead, chromium, and cadmium (Table 6). Although different analytes were targeted in each study, the overlapping analyzed components were roughly similar with respect to concentration, with the exception of nickel, which was higher in the Madsen and Sharma study than the Cohn et al. study. It should be noted that the number of samples was extremely low in both studies, limiting interpretability of the findings.

Table 6.

SSHs in biomass power generation boiler room dust.

| SSH | Madsen et al. [18] N = 1 Concentration (ppm) | Cohn et al. [23] N = 3 Concentration Range (ppm) |

|---|---|---|

| K | 303,154 | − |

| Ca | 53,061 | − |

| Na | 44,266 | − |

| Al | 6789 | − |

| Mg | 5892 | − |

| Fe | 16,434 | 8100–28,000 |

| Mn | 361 | − |

| P | 1890 | − |

| Zn | 1770 | 1050–15,700 |

| Ni | 568 | 30–125 |

| Cu | 530 | 300–525 |

| Pb | 127 | 115–150 |

| Cr | 38 | 20–50 |

| Cd | 5 | − |

| Li | − | 4.8–15 |

| As | − | 5–15 |

| PAH | − | 145–880 |

− not analyzed.

4. Potential Occupational Risks

The potential occupational health impacts of biomass combustion in power generation remain poorly defined, and as a result, there is limited guidance available to inform monitoring and health surveillance best practice guidance. The following section classifies potential occupational risks related to biomass into pre-combustion, combustion, and post-combustion categories. Because of the limited availability of sector-specific studies, information from related industries, uncontrolled combustion, or ambient-focused studies is utilized. Unfortunately, these studies cannot be relied upon to provide specific information related to occupational scenarios using controlled generation technologies, but can serve as a guide for future worker health and safety research.

4.1. Pre-Combustion Risks

In combination with the sparse information regarding exposures of biomass-based generation workers, a lack of epidemiologic studies limits the ability to establish potential associations or speculate on the role of biomass in any potential adverse health effects in workers. However, ancillary data from related industries can help to define constituents of potential concern for future study.

4.1.1. Bioaerosols

A number of case studies have associated occupational health effects with exposure to microorganisms in wood chip dust. Exposure to fungi from stored chipped wood used for heating has been linked to respiratory allergies and hypersensitivity pneumonitis [41,42,43,86]. In the wood-processing industry, dose-response relationships have been reported between endotoxin levels and respiratory symptoms [87], with significantly higher prevalence of respiratory symptoms such as cough and chronic bronchitis among woodworkers than in the control group. However, the microbial content of fuel biomass used in large-scale power generation has not been extensively reported, making it difficult to extrapolate to potential exposure levels of concern. Cases of extrinsic allergic alveolitis (EAA) have been identified in connection with the use of wood chips for heating. van Assendelft et al. [42] reported that EAA was associated with endotoxins for Penicillium in two farmers, the first of whom used green pine and alder chips, and the second who used birch, osier, and alder woods. Both cases reported respiratory symptoms and malaise after handling wood chips. Furthermore, in the second case levels of molds, including Penicillium and Aspergillus, were high on the surface of the wood chip, despite the storage area being cleaned and no visible signs of mold growth in the material. EEA was also diagnosed in the case of a maintenance worker in a sawmill which processed spruce and Douglas fir woods [88]. Immunological testing suggested sensitization of the worker to Trichoderma konigii, exposure to which was believed to be associated with the use of damp logs in the sawmill.

Ławniezek-Wałczyk et al. [89] reported the results of bioaerosol sampling at a coal-fired power plant that was also co-firing sunflower seed pellets and wood chips. Analysis of samples collected from nine plant locations plus an outdoor reference location with MAS (N = 4 per location) and Andersen six-stage (N = 20) impactors showed that both bacterial and fungal spore levels were significantly higher within the plant than the reference case (all t-test p values < 0.05). Levels of airborne bacterial spores varied from 5.1 × 102 cfu/m3 to 2.0 × 104 cfu/m3 while fungal spore levels varied between 2.2 × 102 cfu/m3 and 2.3 × 104 cfu/m3. Levels were highest in the areas around the conveyor system, particularly where the biomass was in free-fall, such as during conveyor loading and transfer. Species analysis showed that fungal types included Aspergillus species (including A. fumigatus), Mucor spp., Penicillium spp., Rhizopus stolnifer, and a number of yeasts. Gram-negative rods identified included Citrobacter spp., Pseudomonas spp. (including P. aeruginosa, which can cause severe lung and urinary tract infections), and Rahnella aquatilis, while various Gram-positive Bacillus, Micrococcus and Staphylococcus species and thermophilic and mesophilic actinomycetes were also identified. The Polish Ministry of Health [90] classifies nine of the species identified as a “group 2” infection risk. Analysis of fresh samples of the biomass types used at the plant showed a similar mix of genus types, although the number of species identified was smaller.

Madsen et al. [25] examined the levels of different microbial indicators, including bacteria, actinomycetes, fungi, lipopolysaccharide, endotoxin, and muramic acid for various biomass stock (straw, wood chips, wood pellets, and wood briquettes) handling on a small pilot scale (particulate generated via rotating drum). Both the microbial content and overall “dustiness” varied by fuel type, analytical method, and biochemical indicator. Overall, straw generated more respirable particles (both by number and mass), total bacteria, and endotoxin versus wood chips, pellets or briquettes. Not unexpectedly, moisture content influenced particle generation, with higher moisture decreasing overall particle release. However, wood chips generated as much or more respirable PM than straw during initial handling (e.g., early generation rate in rotating drum test). By comparison, wood pellets and briquettes (both processed biomass stock) generated the lowest amount of microbial components, potentially indicating that non-microbial particles may be a greater concern for this type of biofuel. The densification process usually requires heat, and sometimes steam, decreasing the inherent microbial content of the material, while the low moisture content of the product (<10% is typical; higher moisture levels cause pellets to swell and break up into dust and so are avoided) limits its suitability as a growth medium for opportunistic microorganisms. However, these fuels may be prone to break-up during transport and handling, particularly if this involves multiple stages as in the case in large-scale supply, potentially releasing fine dust.

A follow-up study measured fungi, bacteria, actinomycetes, endotoxin, and n-acetyl-beta-d-glucoaminidase at five Danish biomass-fueled plants (straw and/or wood chips) at different seasonal time points [20]. Both personal worker and stationary area monitors were utilized to determine inhalable bioaerosols for an approximately 5- to 7-h window in fuel areas (e.g., storage), non-fuel areas (e.g., offices), and outdoors (e.g., local background). In total, 32 personal exposure measurements and 108 area samples were taken across the five plants over four days of monitoring (two in spring, two in autumn). Personal levels were converted to a time-weighted average (TWA). In summary, the authors considered levels of endotoxin (median personal exposure 55 EU/m3), bacteria (4.8 × 105 cells/m3) thermophilic actinomycetes (1.3 × 104 cfu/m3), and fungi (2.1 × 105 spores/m3) to be high at all five biomass-fueled plants. As with the laboratory tests, the highest levels of endotoxin exposure were associated with straw (although Aspergillus fumigatus levels were highest at the wood chip plant). Work related to the straw shredder produced levels up to 119,000 EU·m−3. For perspective, this is orders of magnitude higher than the levels reported by Zock et al. [91] to affect lung function in potato processing workers (53 EU·m−3). In these Danish plants, 34% of workers handling straw or wood chips had exposure levels above 150 EU·m−3, and the overall median personal exposure of 55 EU·m−3 was higher than that observed by Rongo et al. [92] in small-scale wood industries. Levels of bacteria and fungi were also high in this study. For example, in 81% of study workers, personal exposures to mesophilic fungi were higher than levels previously reported to be associated with eye, nose and respiratory irritation (>104 colony forming units (cfu) per m3 ) [93]. These levels are higher than previously reported in the wood processing [87] and milling [4] industries.

In further work, levels of fungal and bacterial components in PM1 were analyzed in samples taken from 14 Danish biofuel plants principally utilizing straw [95]. N-acetyl-β-d-glucosaminidase and (1→3)-β-d-glucans, both associated with fungi, were found in all PM1 samples (N = 29) at higher concentrations than in total dust, while cultivatable fungal spores were present in 6 of the samples and thermophilic actinomycetes in 23. Some research suggests a relationship between (1→3)-β-d-glucan and airway inflammation [96]. Few occupational exposure limits exist for bioaerosols, although the Dutch Expert Committee on Occupational Safety has recommended a health-based limit for endotoxin of 90 EU/m3 [97]. Recommended reference values of 1.0 × 105 cfu/m3 for bacteria and 5 × 104 cfu/m3 for fungi in industrial settings where organic dusts are present have also been proposed [89]. Eduard [93] identified a lowest observed effect level (LOEL) for diverse fungal species of 105 spores/m3 in non-sensitized populations; however, for asthmatic patients with pre-existing allergy to Penicillium sp. or Alternaria alternate, LOELs to the sensitizing agent of 1 × 104 spores/m3 and 2 × 104 spores/m3 respectively were identified for reduced airway conductance.

Wouters et al. [98] reported on results from personal monitoring of workers for exposure to dust, endotoxin, and (1→3)-β-d-glucan in both waste management and power generation industries. Four power plants were studied; one was a dedicated wood pellet boiler, while the other three co-fired a number of different biomass types with coal. A wood pellet manufacturer was also included in the study. Large variations in exposure were observed both between and within worker tasks. The highest average exposures to inhalable dust, (1→3)-β-d-glucan, and endotoxin occurred during wood pellet production (9.6 mg/m3 inhalable dust, 12.07 µg/m3 glucan and 200 EU/m3), but exposures of up to 2104 EU/m3 and 290.9 µg/m3 glucan were seen in the power plants. Average levels of endotoxin and glucan were lower in the co-firing plants than in the dedicated biomass plant (26.1 EU/m3 vs. 32 EU/m3 and 2.1 µg/m3 vs. 8.4 µg/m3 glucan) but inhalable dust levels were higher (1.3 mg/m3 vs. 0.48 mg/m3).

Madsen et al. [99] reported a significant inflammatory response among mice exposed to airborne dust collected from either a combined straw-feeding/boiler room (termed the “boiler room”) or a combined straw-receiving/storage hall (termed the “straw storage hall”). Mice were exposed via intratracheal instillation to either a single dose of dust (18 or 54 µg) from either the boiler room or straw storage hall, or four doses (each 54 µg) on consecutive days. The greatest inflammatory responses were observed in the mice exposed to dust from the straw storage hall, including 30 to 60-fold elevations in mRNA expression in lung tissue for interleukin-6 (IL-6), monocyte chemoattractant protein-1 (MCP-1), and macrophage inflammatory protein-2 (MIP-2) compared to controls. Levels of mRNA for these cytokines were increased about 10-fold in mice exposed to dust from the boiler room. The study authors hypothesized that the inflammatory response was linked with microbial components in the dust, which were generally present at higher concentrations in the dust from the straw storage hall than from the boiler room. Importantly, the study reported a lack of significant increases in DNA strand breaks in bronchoalveolar lavage (BAL) samples, and thus no evidence of DNA damage, for either dust type. Madsen et al. [99] cautioned that “more data are needed for an understanding of how the data should be interpreted in a comprehensive risk assessment of exposure at biofuel plants.”

Cohn et al. [23] characterized PM components from source biomass (straw and wood pellets), including microbial components and mutagenic activity, from area-level particle samples at the same Danish plant. PM generated via agitation from the source material (pre-combustion) was larger in diameter than PM collected within the facility from the straw storage hall and the boiler room, the latter of which likely included post-combustion ash. Particle diameter ranged from 3.5–5 µm for pure straw biomass, 5.0–7.5 µm for wood pellet samples, and 0.77–0.97 µm for samples from the area of the biomass facility. A large portion of the biomass facility PM was of respirable size, but less so for the raw samples (30%–58% vs. 98%). A number of different factors were identified as potential contributors to this difference, including the greater distance from source to measurement in the biomass plant allowing the larger particles to sediment and the presence of combustion PM from biomass and vehicle emissions. PM generated from the raw biomass differed from facility biomass in terms of composition, reactivity (generation of reactive oxygen species), and mutagenicity (Salmonella mutagenicity assay). Specifically, biomass facility PM samples were higher in metal content, polyaromatic hydrocarbons, reactivity potential, thermophilic bacteria (actinomycetes), fungi (A. fumigatus) and mutagenic activity, as compared to source-specific biomass generated PM. However, facility samples were collected using a high throughput area sampler potentially contaminated with additional exposure sources (e.g., diesel fumes or other vehicular emissions, welding fumes, etc.). As reported by Madsen [20], facility area samples related to straw handling or storage did have high levels of fungal spores and endotoxin, again raising concerns that high pre-combustion exposure may put workers at risk for irritation or inflammatory responses [100,101].

A recent published report from Denmark [102] investigated bioaerosol exposure levels in relation to respiratory symptom and asthma prevalence at a straw and wood chip-fueled power plant. The worker population was compared to a similar occupational group at a more conventional fuel facility. No increased prevalence of pneumonitis symptoms was observed among the biomass facility workers; however, higher asthma symptoms were reported among non-smokers exposed to straw (OR 7.6, 95% C.I. 1.4–12.8) and to lesser extent wood chips. A logistical data analysis reported increased asthma symptoms and work-related respiratory symptoms related to increased endotoxin exposure (OR 1.5, 95% C.I. 1.1–44.4). No statistical associations with endotoxin exposure were observed for rhinitis, conjunctivitis, current asthma, coughing, flu-like symptoms, or diarrhea. Similar associations appeared to be related to fungal exposure. No associations were found between lung function indices and bioaerosol exposure indicators. Albeit a cross-sectional study which lacks the ability to demonstrate causality, this first study adds to the knowledge of exposure methodology, measured levels of bioaerosols, and respiratory symptoms in an industry-specific cohort.

4.1.2. Wood Dust

Wood dust has been recognized as an irritant, sensitizer, respiratory toxicant, and, for a limited number of species, a potential carcinogen [103,104]. The UK Government’s Health and Safety Executive (UK HSE) has also issued guidance on the health risks associated with particular species, as shown in Table 7 [105]; this information was targeted primarily at the wood-working industry and so contains a large number of “unusual” woods, but some species also have relevance in the biomass power generation industry. Mandatory or recommended OELs have been established in a number of regions, including Europe, Canada, and the United States, based on either total inhalable or respirable wood dust, with some authorities specifying lower limits for some wood groups, based on their carcinogenic or allergenic potential, as shown in Table 8 [106,107]. Although the current European Union OEL for hardwood dust is 5 mg/m3 of inhalable dust, the EU’s Scientific Committee for OELs has reported that exposure to wood dust at levels of 0.5 mg/m3 can induce measurable health effects in the human respiratory system [108]. In a small Swedish study, worker exposure to wood dust ranged from 0.16 to 19 mg/m3 (total dust) in a wood pelleting facility, with levels varying across the processing facility [26]. Many of the levels observed were higher than the concurrent Swedish OEL and some studies in other Swedish woodworking industries [103,109]. In a more detailed follow up study by Hagstrom et al. [5,24], 35% of inhalable dust samples were above the Swedish OEL. Additionally, larger variation existed between shifts versus between workers, indicating that day-to-day temporal variation was higher than inter- individual worker variability.

Table 7.

Reported health effects associated with wood species (adapted from [105]). Species in bold are known to be in current use as biomass fuels.

| Wood Name | Classification | Reported Health Effects |

|---|---|---|

| Abura/bahia | Hardwood | vomiting |

| Afrormosia | Hardwood | skin irritation, splinters go septic, nervous system effects |

| Afzelia/doussie | Hardwood | dermatitis, sneezing |

| Agba/tola | Hardwood | skin irritation |

| Alder | Hardwood | dermatitis, rhinitis, bronchial effects |

| Andiroba/crabwood | Hardwood | sneezing, eye irritation |

| Ash | Hardwood | decrease in lung function |

| Avodire | Hardwood | dermatitis, nose bleeds |

| Ayan/movingui | Hardwood | dermatitis |

| Basralocus/angelique | Hardwood | general unspecific effects |

| Beech | Hardwood | dermatitis, decrease in lung function, eye irritation (possibly from bark lichens) |

| Birch | Hardwood | dermatitis on sawing lumber |

| Bubinga | Hardwood | dermatitis, skin lesions possible |

| Cedar of Lebanon | Softwood | respiratory disorders, rhinitis |

| Cedar (Cent/S American) | Hardwood | allergic contact dermatitis |

| Cedar (Western Red) | Softwood | asthma, rhinitis, dermatitis, mucous membrane irritation, central nervous system effects |

| Chestnut (sweet) | Hardwood | dermatitis (possibly from bark lichens) |

| Douglas fir | Softwood | dermatitis, splinters go septic, rhinitis, bronchial effects |

| Ebony | Hardwood | mucous membrane irritation, dermatitis, possibly a skin sensitizer |

| Freijo/cordia | Hardwood | possibly a skin sensitizer |

| Gaboon/okoume | Hardwood | asthma, cough, eye irritation, dermal effects (hands, eyelids) |

| Gedu nohor/edinam | Hardwood | dermatitis (rare) |

| Greenheart | Hardwood | splinters go septic, cardiac and intestinal disorders, severe throat irritation |

| Guarea | Hardwood | skin and mucous membrane irritation |

| Gum (southern blue) | Hardwood | dermatitis |

| Hemlock (western) | Softwood | bronchial effects, rhinitis |

| Idigbo | Hardwood | possible irritant |

| Iroko | Hardwood | asthma, dermatitis, nettle rash |

| Larch | Softwood | nettle rash, dermatitis (possibly from bark lichens) |

| Limba | Hardwood | splinters go septic, nettle rash, nose and gum bleeding, decrease in lung function |

| Mahogany | Hardwood | dermatitis, respiratory disorders, mucous membrane irritation |

| Makore | Softwood | dermatitis, mucous membrane and respiratory tract irritation, central nervous system and blood effects |

| Mansonia | Hardwood | splinters go septic, skin sensitization, irritation, respiratory disorders, nose bleeds, headache, cardiac disorders |

| Maple | Hardwood | decrease in lung function |

| Meranti/lauan (various) | Softwood | skin irritation |

| Oak (various) | Hardwood | asthma, sneezing, eye irritation |

| Obeche | Softwood | skin and respiratory tract irritation, nettle rash, dermatitis (handling articles), feverish, sneezing, wheezing |

| Opepe | Hardwood | dermatitis, mucous membrane irritation, central nervous system effects (e.g., giddiness, visual effects), nose bleeds and blood spitting |

| Padauk | Hardwood | species-dependent: itching, eye irritation, vomiting, swelling (e.g., eyelids) |

| Peroba | Hardwood | skin and mucous membrane irritation, systemic effects (e.g., headache, nausea, stomach cramp, weakness), blisters |

| Pine (many species) | Softwood | skin irritation (may cause photosensitization) decrease in lung function |

| Poplar | Hardwood | sneezing, eye irritation, may cause blisters |

| Ramin | Hardwood | dermatitis (possibly from bark) |

| Rosewood (many species) | Hardwood | dermatitis, respiratory disorders. Effects may arise from handling wood |

| Sapele | Hardwood | skin irritation |

| Spruce (several species) | Softwood | respiratory disorders, possible photosensitization |

| Teak | Hardwood | dermatitis (potent, even after seasoning), nettle rash, respiratory disorders |

| Utile | Hardwood | skin irritation |

| Walnut (not African) | Hardwood | sneezing, rhinitis, dermatitis from nut shells and roots |

| Wenge | Hardwood | splinters go septic, dermatitis, central nervous system effects (e.g., giddiness, drowsiness, visual disturbance), abdominal cramps |

| Whitewood (American) | Hardwood | dermatitis |

The link between wood dust exposure and nasal cancer has been explored in a number of studies, led by Macbeth [110] and Acheson et al. [111], with a number of studies in the 1980s and 1990s providing evidence of a relationship between wood dust and sinonasal adenocarcinoma (e.g., [112,113,114,115,116,117]). In 1995, IARC issued guidance that “there is sufficient evidence in humans for the carcinogenicity of wood dust”, with a clear association between adenocarcinoma of the nasal cavities and paranasal sinuses and exposure to hardwood dust [104]. A link with softwood dust is less clear. Identification of specific wood species implicated is problematic, since most of the research has been based on the lumber and furniture making industries, where exposure to a variety of tree species is likely. In Germany, dusts from beech and oak have been classified as carcinogenic since 1985 [118]. Links between wood dust exposure and other cancers are less conclusive, although studies have also indicated higher rates of lung, nasal cavity, nasopharynx, larynx, and prostate cancers with exposure to wood dust, particularly hardwood dusts [117,119,120,121].

Table 8.

Occupational exposure limits (legal and recommended) for biomass-relevant substances in various countries.

| Country/Region | Dust Type | Limits mg/m3 | Additional comments | Health Endpoint/Comments |

|---|---|---|---|---|

| Short-term (15 min) | Long-term (8 h. Time Weighted Average) | |||

| Wood dusts | ||||

| US (OSHA) | Particulate not otherwise regulated (includes wood dust)—inhalable—respirable | 15 5 | Throat, skin, eye irritation, upper respiratory problems | |

| US (NIOSH recommended) | Wood dust | 1 | Pulmonary Function, Carcinogen | |

| European Union (applies to all member countries) | Hardwood (inhalable fraction) | 5 | Carcinogenic, sensitizer | |

| UK | Softwood (inhalable fraction) | 5 | Sensitizer | |

| Australia | Hardwood | 1 | ||

| Australia | Softwood | 5 | ||

| Ontario, Canada | Certain hardwoods such as beech and oak | 1 | ||

| Ontario, Canada | Softwood | 10 | 5 | |

| Sweden | Inhalable non-impregnated wood dust | 2 | Carcinogen | |

| Sweden | Impregnated wood | 0.05 | Applies if levels of impregnating substances (with their own OELs) are unknown | |

| Australia | Softwood | 10 | 5 | Sensitizer |

| Australia | Certain hardwoods such as beech and oak | 1 | Sensitizer | |

| Germany | Respirable wood dust | 2 | Selected species identified as carcinogenic and/or sensitizing | |

| Russia | Wood dust | 6 | Maximum allowable concentration, sensitizer, fibrogenic action | |

| US (OSHA/California) | Wood dust, all soft and hard woods except Western red cedar | 10 | 5 | |

| US (OSHA/California) | Wood dust, Western red cedar | 2.5 | ||

| Other biomass dusts | ||||

| US (OSHA) | Grain dust (oat, wheat, barley) | 10 | ||

| UK | Grain dust (inhalable fraction) | 10 | Sensitizer | |

| Trace metals in biomass ash | ||||

| UK | Cadmium and Cadmium compounds (as Cd) | 0.025 | Carcinogenic (selected compounds) | |

| UK | Cobalt and Cobalt compounds (as Co) | 0.1 | Carcinogenic (selected compounds), sensitizer | |

| UK | Manganese and inorganic manganese compounds (as Mn) | 0.5 | ||

| US (OSHA) | Cadmium dust | 0.5 | 0.2 | |

| US (OSHA) | Cobalt metal, dust, and fume (as Co) | 0.1 | ||

| US (OSHA/California) | Cadmium | 0.005 | ||

| US (California) | Manganese and compounds, as Mn | 0.2 | ||

| US (OSHA/California) | Cobalt metal, dust, and fume (as Co) | 0.02 | ||

The association between exposure to wood dust and asthma symptoms was reported in the 1940s [122] and has repeatedly been identified since (e.g., [123,124,125,126]). A meta-analysis of the data by Pérez-Rios et al. [127] suggested that exposure to wood dust could increase the risk of work-related asthma by 50%. In a number of these studies, sensitization to specific wood species has been identified. In the De Zotti and Gubian study [123], bronchial provocation tests identified obeche, chestnut, acacia, and iroko woods as being likely to cause asthma symptoms in four cases, while oak, beech, and pine woods triggered rhinitis in three cases. Positive responses to respiratory provocation and skin challenge tests and specific IgE antibodies to ash wood were found by Fernández-Rivas [124] in the case of a furniture factory worker suffering rhinitis and asthma symptoms. In the UK, physicians report cases of occupational asthma to the SWORD database [128], with estimates given for the number of diagnoses linked to different potential causative agents. Between 1998 and 2012, wood dust was ranked as the third most common causative agent in terms of the average number of cases of occupational asthma linked to exposure reported each year (15 cases), behind isocyanates (49 cases) and flour (29 cases). Note that incidence rates are not reported for individual causative agents. As these data rely on both a positive diagnosis of occupational asthma and identification of the causative agent by a respiratory specialist, these figures may be underestimated.

4.1.3. Volatile Organic Compounds (VOCs)

Monoterpenes, such as α-pinene, β-pinene, and Δ3-carene, are derived from biomass and may be of concern due to their ability to irritate eyes, skin, and mucous membranes [26,109]. The previously mentioned small study among Swedish wood pellet workers (5) reported personal exposures to monoterpenes in the range of 0.64 to 28 mg/m3, below the Swedish occupational exposure limit of 150 mg/m3 (total or individual monoterpene, 8-h TWA. However, intercompany variation appeared to be substantial, potentially due to variable moisture content or wood type. The correlation between wood dust and monoterpenes was moderate (0.44). A related concern has been raised regarding oxidization of monoterpenes to form both particle- and gas-phase reaction products that may induce respiratory effects [129].

In the Swedish wood pellet production study [5] measurements also included resin acids, α-pinene, and total VOCs. Resin acids ranged from <0.33–10 µg/m3 and α-pinene from <0.23–25 mg/m3 (β-pinene and Δ3-carene were below detection limits for the majority of samples). Workers were exposed to multiple resin acids; although no OELs exist for these compounds, exposure in other industries to colophony (a resin-containing compound also known as rosin, and used in soldering flux, adhesives, and polishes among other products) has been associated with occupational asthma and contact dermatitis [130]. The correlation between total dust and resin acids was moderate. Monoterpene levels varied by location and relative age of the raw material, with newer raw material associated with higher measurements. The VOC analysis identified a range of compounds including terpenes, C6-C11 aldehydes (e.g., hexanal, heptanal and nonanal), and other hydrocarbons (e.g., ethylacetate, propionic acid, 1-pentanol, and 2-butanone), all of which have been identified as irritant chemicals [131].

Svedberg et al. [28] investigated levels of a number of organic gases during storage at three pellet production plants, both in warehouses containing pellets and in domestic storage rooms. The principle organic compounds identified at two of the warehouses were aldehydes (50%–60% w/w), acetone (30%–40% w/w), and methanol (10% w/w) (the third warehouse had an ambient temperature of −10 °C and levels were below detection limits). In one warehouse, a peak aldehyde reading of 457 mg/m3 was recorded at the surface of the pellet pile, with hexanal (70%–80%wt) and pentanal (10%–15%wt) predominating. Auto-oxidation of fatty acids in the wood was proposed as the mechanism of formation of these compounds, the rate of which increases with temperature. Hexanal and carbon monoxide were also present in the emissions from pine lumber drying at these plants. Human exposure studies indicate that hexanal concentrations of 10 ppm are sufficient to invoke symptoms of mild irritation [132].

4.1.4. Carbon Monoxide (CO)

Carbon monoxide exposure, such as that which could occur in confined or enclosed spaces where wood pellets are stored or transported, has resulted in accidents and fatalities [28,133]. In the Hagstorm et al. study [5], all CO levels remained below 1.6 mg/m3. In an earlier Swedish report, air sampling in one warehouse containing freshly produced wood pellets showed CO levels of 54 mg/m3 at the ceiling [28]. In 2012, Gauthier et al. reviewed the deaths of two people, one in Germany in 2010 and the other in Switzerland in 2011, both of which were linked to CO exposure in storage rooms of multi-household wood pellet heating systems [30]. These systems consist of an airtight storage room (filled pneumatically from the outside) which feeds a boiler supplying hot water to the surrounding houses. In normal operation, the storage room is not entered—both casualties were investigating faults in the pellet handling system at the time. In the Swiss case, CO measurements of 7500 ppm were recorded several days after the event, with 2 h of ventilation only reducing this to 2000 ppm (note the system guidelines recommended 15 min of ventilation prior to accessing the storage area). Subsequent experiments confirmed that the CO was likely generated from the wood pellets rather than a fault in the combustion system, and that the area was also likely to be oxygen deficient. A third fatality was reported in Ireland after a householder entered his 7-ton capacity pellet storage room [134]. Two deaths in different wood pellet silos have been reported in Finland [30]. Ship holds appear to be particularly susceptible to the buildup of lethal levels of CO, coupled with oxygen depletion, with six deaths during wood pellet transport and at least three during transport of other woody materials reported since 2002 [27,28,29,30,135]. This is most likely due to the gradual decomposition of biomass and release of CO and CO2 [136]. High oxygen and temperature can accelerate this process [27].

Emissions from off-gassing have also been recorded during storage of non-pelletized wood material. He et al. [137] stored logging residues in sealed containers at 15 °C and 35 °C. At 35 °C, after 10 days, oxygen levels in the headspace of the containers had decreased to near-zero, while CO2 was present at 13.8%, CO at 0.16%, and CH4 at 0.15%. Also detected in the headspace were numerous volatile organic compounds (total concentration 85 ppm), including alcohols, aldehydes, acids, acetone, benzene, ethers, esters, and terpenes. High product turnover, good ventilation and high oxygen levels may be expected to decrease the likelihood of off gassing [27]; however, at biomass-fueled generation facilities a number of different storage systems are in use, and so the effectiveness of these cannot be guaranteed. Biomass may also be stored for significant periods of time, e.g., during an unplanned shutdown, which increases the risk of off-gas accumulation.

4.2. Combustion-Associated Risks

Occupational studies focusing on the potential health risks posed by exposures to biomass combustion products at large scale biomass power plants are lacking, with minimal data on potential SSHs and their exposure levels relative to facility, worker tasks, working environment, and biofuel stock. Because there remains uncertainty regarding the specific components, concentrations, and related nature of the health risks posed by specific biomass combustion products from modern power plants, this section must rely on identifying the potential for adverse OH&S effects based on data from other biomass exposures scenarios, including poorly- or uncontrolled biomass combustion such as wildfires. However, given the greater degree of control over both combustion quality and specific pollutants as well as the high level of dispersion from the stacks of utility scale power plants, data from these less-controlled sources should be considered worst-case. Although occupational exposure of power plant workers to combustion gases is expected to be low during normal operation, self-heating and spontaneous combustion of stored biomass (due to biological and chemical oxidation reactions) is a recognized issue in many industries, including the power sector [9]. Under these situations, there is a risk of worker exposure to products from incomplete biomass combustion and smoldering. However, the frequency of such exposures is expected to be low and the size of the affected population limited.

4.2.1. Health Effect Studies of Relevance and Uncertainties in the Available Studies

A wide range of literature exists on exposure to smoke from residential wood burning, prescribed burning, and wildfires, as well as resultant health effects (see reviews by e.g., [6,138,139]). Therefore, this section relies on data from these alternate combustion technologies (e.g., small domestic woodburning appliances such as woodstoves, wood log boilers, and fireplaces, and also forest and brush fires) to explore the potential health risks posed by the occupational exposure to biomass combustion products within commercial biomass power plants.

It is important to emphasize the large uncertainties associated with the consideration of health effects data from these studies. Major factors leading to differences in occupational exposures at power plants versus uncontrolled ambient exposures include variability in the composition and physicochemical properties of the combustion gases from biomass, and thus the potential toxicity of the mixture, based on biomass fuel type and properties, boiler type, and combustion conditions. In particular, the completeness of the combustion process is a key determinant of the levels and composition of biomass emissions [140]. In general, concentrations of CO, VOCs such as acrolein, formaldehyde, and benzene, gaseous and particulate PAHs, and other organic species are enriched in emissions from incomplete biomass combustion [141]. With incomplete combustion, particle emissions are dominated by condensable organic particles, soot, and char [33]. In contrast, large-scale boilers, representative of a modern biomass-fueled power plants, generally operate under more controlled and stable combustion conditions that favor quasi-complete combustion [33,138]. Under such optimal combustion conditions, organic carbon content of particle emissions can be negligible, and inorganic ash can dominate particle emissions [33,140]. Combustion conditions are more variable in domestic wood-burning appliances such as woodstoves and fireplaces, typically yielding emissions rich in both soot and organic carbon particles and containing lesser amounts of inorganic ash [140]. Incomplete combustion, and thus emissions dominated by organic carbon particles and hydrocarbons, appear more prevalent for prescribed burning and wildfire events where low temperatures and smoldering conditions prevail [140,142].

Another source of information on the impact of biomass combustion on health is research on household biomass combustion for heating and cooking purposes in developing countries. These studies illustrate the significant public health burden of indoor biomass combustion in these populations, including an estimated 1 to 2 million premature deaths per year due to chronic obstructive pulmonary disease (COPD), acute and chronic respiratory disease, tuberculosis, and lung cancer [6]. Given that unvented stoves continue to have widespread usage in developing countries, often discharging emissions directly into the living space, such exposures and related health risks for these biomass combustion scenarios are unlikely to reflect occupational exposure at electricity-generating biofuel power plants. Therefore, particularly large uncertainties exist regarding the relevance of health effects findings from studies either based on wildfires or prescribed agricultural or wild land burning or from studies of the effects of indoor household combustion relative to biomass combustion sources favoring more efficient and complete combustion, such as modern biofuel plants. Nonetheless, despite these uncertainties, findings from such epidemiologic studies do have the statistical power to detect possible biomass combustion product-related health outcomes.

Finally, given the scarcity of relevant studies, both on health effects and exposure data specific to occupational environments at biofuel plants, it is not feasible to quantify biomass-specific risks posed to workers. Instead, assessments of potential adverse occupational effects are currently limited to qualitative extrapolation of findings from controlled exposure studies and epidemiologic studies in populations exposed to uncontrolled biomass smoke. Furthermore, while experimental animal data exist describing the toxicity of various types of biomass combustion products (as reviewed by [6,139]), until better sector-specific occupational exposure characterization becomes available for biofuels of concern, these data are of limited quantitative value.

4.2.2. Studies of Occupational Exposures and Potential Health Risks at a Large-Scale Danish Biofuel Plant

To date, only the research group based at the Danish National Research Centre for the Working Environment has reported on potential occupational exposures and related toxicities at a large-scale biofuel plant, specifically a straw-fueled 8.3 MW electricity-generating facility in Zealand, Denmark [23,25]. Studies have addressed pre-combustion emissions such as organic dust and bioaerosols (e.g., [20,25,95]), with more recent limited data related to combustion-related PM [23].

As discussed earlier, Cohn et al. [23] investigated the mutagenicity and generation of highly reactive oxygen species (hROS) of respirable PM samples collected from the boiler room of a Danish biofuel facility (as well as PM samples reflecting pre-combustion materials from the straw storage hall at the same facility, as well as test samples of biomass-derived PM obtained by placing straw (n = 9) and wood pellets (n = 1) in a rotating drum). Using a Salmonella mutagenicity assay, they reported evidence of mutagenicity for the majority of the PM samples collected from the boiler room. In addition, they observed higher hROS generation in a cell-free chemical assay for the boiler room PM samples than for the biomass stock-derived PM samples. As discussed by the study authors, these findings suggest greater biological activity of biomass-combustion PM versus biomass-derived PM (e.g., pre-combustion biomass fuel), although they note that boiler room PM likely consists of a complex combustion mixture of both biomass and vehicular emissions (e.g., trucks and diesel-powered forklifts), thereby limiting the biomass-specific apportionment of both exposure and risk. Overall, these findings provide limited evidence of the potential toxicity of biomass combustion PM from a modern biofuel facility, primarily using straw-based stock fuel. Additionally, the limited number of sites sampled indicates the potential difficulty in apportioning the portion of combustion PM due to biomass stock or other facility sources.

4.2.3. Controlled Human Exposure Studies of Small-Scale Biomass Combustion

Controlled exposure studies, or chamber studies, are considered to provide some of the more useful data for assessing the potential health risks of inhaled pollutants due to the use of human subjects, well-defined exposure concentrations and durations, and precise measures of biological responses [143]. As summarized in Table 9, a number of controlled exposure studies have utilized biomass smoke generated from domestic wood burning appliances, including woodstoves and wood pellet boiler systems. These small combustion appliances are less efficient and more poorly controlled than large boilers in biomass fueled power plants, thereby contributing to differences in emissions (e.g., higher organic carbon and soot content) relative to biofuel plants, as discussed previously. As a result, these results are only briefly discussed and reference is made to the source material cited for further details of the testing undertaken.

Despite the use of highly elevated exposure levels of biomass smoke, as reflected by PM2.5 concentrations in the range of 150 to >600 µg/m3, these studies have generally reported evidence of fairly mild and readily reversible biological responses (Table 9). Observed effects include relatively small increases in some biomarkers of lung and systemic inflammation, airway oxidative response, blood coagulation response, or lipid peroxidation, including changes in several biological markers achieving statistical significance. As shown in Table 9, many of these studies reported inconsistent findings for some types of biological responses, or a greater number of negative findings (i.e., no changes compared to control) than statistically significant positive findings.

Human controlled exposure studies of healthy adult volunteers thus provide some evidence of statistically significant, but generally mild, biological responses to elevated smoke exposures from uncontrolled biomass combustion, in particular lung and systemic inflammation and an airway oxidative response. While the physiological significance of some of the observed responses is ambiguous, they provide evidence of potential respiratory and cardiovascular health risks from elevated exposures to biomass smoke. However, it is again important to emphasize the uncertainties regarding the relevance of these findings to the biomass combustion gas at modern biofuel plants.

4.2.4. Epidemiologic Investigations of Uncontrolled Ambient Biomass Smoke

Epidemiologic studies of populations affected by biomass smoke are more numerous than human controlled exposure studies. None are currently available for workers or communities impacted by biomass combustion emissions from a modern biofuel plant, and findings from the available studies of wildfires and prescribed burning are of uncertain relevance to occupationally exposed workers at modern biofuel plants due to potential differences in combustion conditions and the properties of combustion emissions (as discussed earlier). In addition, it is important to note that epidemiologic studies have a variety of other general limitations and uncertainties that contribute to the difficulty in making causal conclusions based on this type of health effects evidence only, including model selection and specification, treatment of co-pollutants, control of potential confounders (e.g., smoking, seasonal effects), and exposure misclassification. A particular advantage of epidemiological studies compared to human controlled exposure studies, however, involves their frequent study of large populations and thus increased statistical power to detect rare health outcomes.

Overall, epidemiological findings regarding smoke from uncontrolled biomass combustion are mixed. Table 10 summarizes the epidemiologic literature related to short-term studies of exposures to biomass smoke in areas impacted by large-scale biomass combustion events. These studies show a range of outcomes, from increased emergency department visits to mortality. There is now a consistent body of epidemiologic evidence linking elevated short-term exposure to biomass smoke with increased risk of a variety of respiratory-related health impacts. Despite a growing number of studies, there is little epidemiologic evidence linking biomass smoke exposure to either cardiovascular-related health outcomes or mortality. In addition, the epidemiologic evidence linking biomass smoke exposure and cardiovascular health outcomes is significantly weaker than that linking urban PM2.5 with cardiovascular morbidity and mortality [144].

4.2.5. Regulatory Consideration of Biomass Combustion Emissions and Cancer Risk