Abstract

Over the past 18 months, we have performed hundreds of temperature characterizations of fiber Bragg gratings inscribed in different germanium-doped silica glass fibers. Under experimental conditions, the main conclusions are as follows: the temperature dependence of the “temperature gauge factor” or the normalized temperature sensitivity, KT, was found to be quadratic in the −50–200 °C range, while it may be considered linear for the −20–100 °C range; KT values at 20 °C vary from 5.176 × 10−6 K−1, for a B/Ge co-doped fiber up to 6.724 × 10−6 K−1, for a highly Ge-doped fiber; KT does not depend on the hydrogen-loading process or the gratings coupling strength; KT is essentially independent of wavelength in the 1500–1600 nm range, its value being accurately determined with a relative error ~0.2%; based on the accurate value of KT = 6.165 × 10−6 K−1, at 20 °C, obtained for gratings inscribed in the SMF-28 fiber, we calculated a value of 19.4 × 10−6 K−1 for the thermo-optic coefficient of bulk germanium glass; and gratings produced by femtosecond-laser radiation and UV-laser radiation exhibit comparable values of KT. The previous achievements allow, by having knowledge of KT for a single grating, the accurate determination of the temperature dependence of the Bragg wavelength for any other grating inscribed in the same fiber; the presented methodology enables one to determine the “unknown” gratings’ temperature sensitivity, typically with an error of 0.01 pm/°C, being, therefore, very useful in research labs and computer simulations. Thus, expressions for the temperature dependence of KT for gratings inscribed in several fibers are given, as well as an expression for KT as a function of the effective refractive index. We have also fully analyzed the potential sources of error in KT determination.

1. Introduction

For more than three decades, temperature sensing has probably been the most well-known application of fiber Bragg gratings (FBG) [1,2,3,4,5,6]. Independently of the physical parameter under measurement, temperature discrimination is required [7,8,9,10,11,12,13]. In particular, the development of optical fiber sensors for harsh environments [14], such as high temperature [15,16] and cryogenic applications [17,18,19], is a demanding task. In the latter context and based on our experience with arc-induced gratings [20], we recently discussed their use as high-sensitivity cryogenic temperature sensors [18]. However, some limitations in the presented model were pointed out, mainly concerning the lack of accurate values for fiber parameters, such as the temperature dependence of the glass thermo-optic coefficients. Therefore, in recent years, we have been gathering accurate data on that topic. First, on synthetic fused silica glass [21], based on the work of Leviton and colleagues [22], and then on germanium-doped silica glass [23] relying on the temperature behavior of FBGs, where the requirement for more precise measurements was identified. Thus, in comparison to the number of publications related to FBG theory, applications and simulations, only a few acknowledge the fact that the Bragg wavelength shifts nonlinearly with temperature, even for a limited temperature range, such as 120 °C, and that the thermo-optic coefficient of silica-doped glass fibers depends on temperature and wavelength [21,23,24,25,26]. Recently [25], preliminary results pointed toward the independence of wavelength of the “temperature gauge factor” KT = (1/λ)(dλ/dT) [3,27] or the normalized temperature sensitivity, in the 1500–1600 nm range. However, we recognize that definite conclusions require higher stability, accuracy and resolution of the equipment used. Therefore, in this paper, we compare the normalized temperature sensitivity of fs-FBGs and UV-FBGs, and we discuss the potential effect of the hydrogen-loading process and of the initial grating coupling strength on KT values. We demonstrate that KT is, essentially, independent of wavelength in the 1500–1600 nm wavelength range, even for highly germanium-doped silica glass fibers. The KT expressions for FBGs inscribed in silica fibers with distinct concentrations of GeO2 are also given. Based on the previous results, we also demonstrate that the temperature dependence of the Bragg wavelength of a second FBG can be accurately predicted through the integration of the KT expression obtained previously for a former FBG, in an approach that resembles recently published work [28,29]. A thorough discussion of the experimental errors that can affect the determination of the FBG temperature sensitivity is also presented.

2. Gratings Fabrication

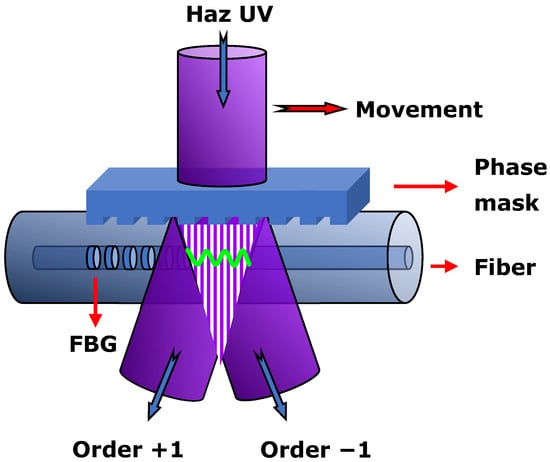

The UV-FBGs were inscribed in six different fibers, their properties being presented in Table 1. Gratings were made by scanning a doubled argon laser UV-laser (λlaser = 244 nm, nominal power = 100 mW, laser beam cross section = 0.9 × 0.9 mm2) over the fibers through a phase mask Ibsen Photonics® (period = 1063.50 ± 0.01 nm and length = 10 mm), as depicted in Figure 1. Different grating strengths were achieved by changing several parameters. The fluence on the fiber was controlled by reducing the beam power, by focusing the beam by a cylindric lens if necessary and, mainly, by accurate control of the scan speed. The fluence was reduced so that the gratings had an index change below 10−5 (1 cm long gratings with reflectivity below 1%) [30]. The reflectivity was measured taking as reference the reflection from a fiber tip cut at 0°. For the specific gratings produced (PS1250/1500 and SM1500 fibers), the laser power had been in the range 10 mW to 70 mW, and the beam scanning speed in the range 0.01685 mm/s to 1.348 mm/s. Gratings in the PS 1250/1500 fiber and grating of 33% reflectivity (R) in the SM1500 fiber were made without a focusing lens. Gratings with R = 12%, 2.8% and 0.7% in SM1500 fiber (NA = 0.30) were made with a divergent cylindric lens (intensity in the fiber decreased by a factor of 10), and the phase mask period was 1056.50 nm (Table 1). The estimated fluence, F (J/mm2), is also given in Table 2. It should be stressed that the choice of the phase mask period, Λ, was such that the Bragg wavelength (λB = neffΛ, neff being the effective refractive index) would be in the 1500–1600 nm range. For instance, for the SMF-28 fiber, a λB ~1539 nm @20 °C was measured (used in the thermal characterization in the next section). Note also that the exact value depends on the fiber strain during inscription and on the grating’s reflectivity [30].

Table 1.

Properties of the fibers used in this work.

Figure 1.

Schematic of the fiber Bragg grating recording system based on the phase mask method.

Table 2.

Gratings reflectivity and UV fluence for the gratings inscribed in six different fibers.

3. Gratings Thermal Characterization

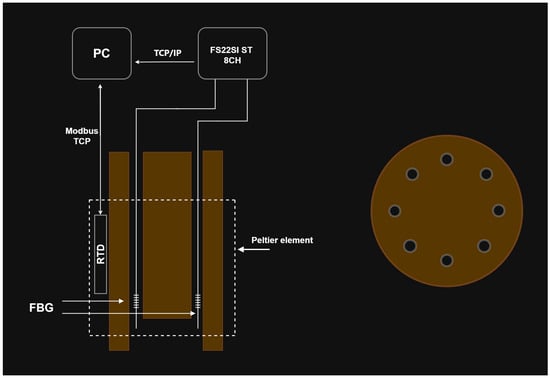

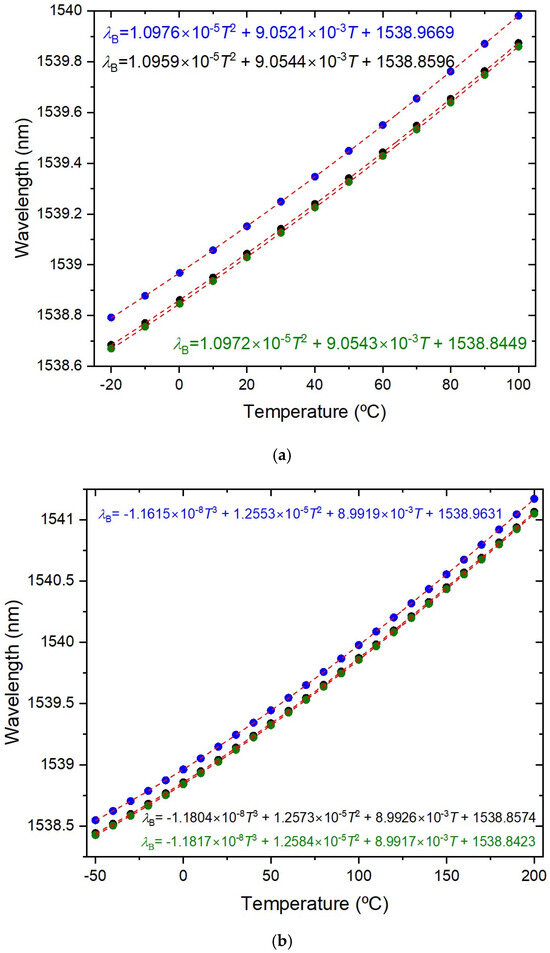

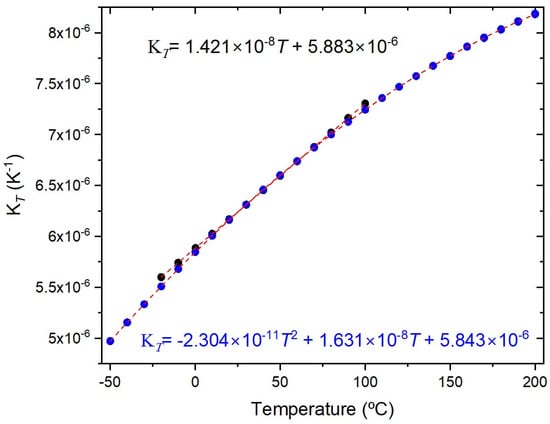

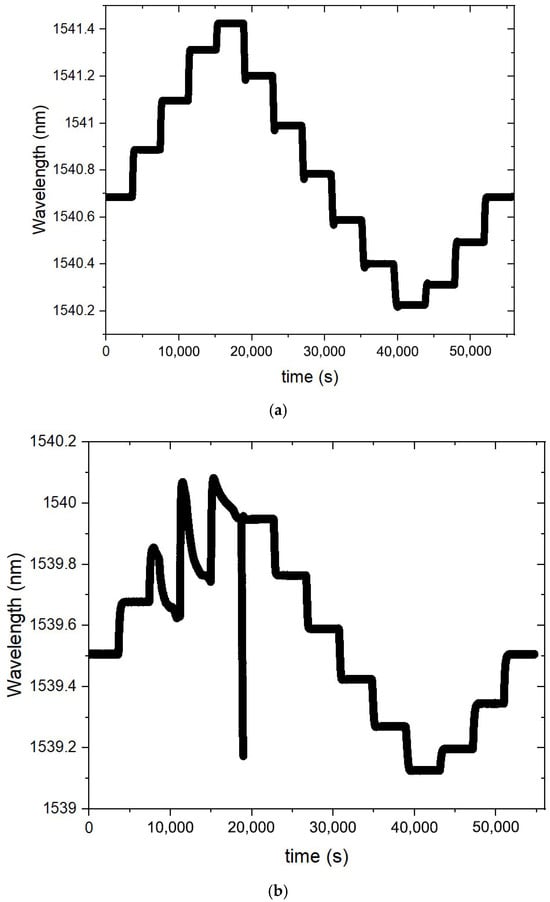

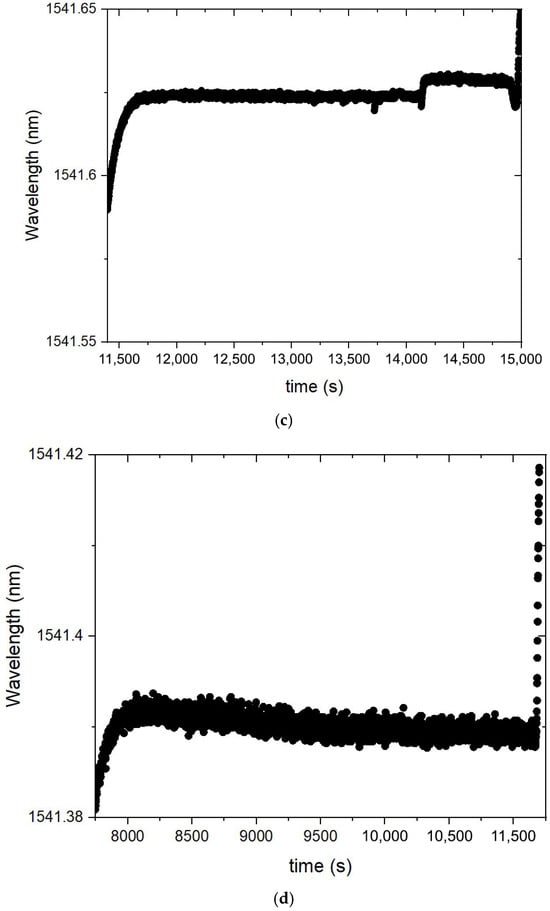

The temperature characterization was performed using a Dry block-temperature calibrator from Sika, model type TP17200S, allowing measurements between −55 °C and 200 °C with 0.01 °C resolution and an accuracy of 0.2 °C. Gratings were mounted inside the insert blocks, keeping them stress-free. Bragg wavelengths were measured, after ~1 h stabilization, using an optical interrogator FS22SI BraggMeter ST (with eight channels), with an acquisition rate of 1 sample/s, which enables resolution/stability better than 0.5 pm/1 pm. Figure 2 shows that a PC collects the temperature measurements from the Dry block and the wavelength readings from the optical interrogator. Also shown is the position of the FBGs inside the insert block (eight holes). It should be stressed that each value communicated by Sika is an average of 20 temperature measurements (each registered 130 ms). The temperature range was from −20 °C up to 100 °C (cycle: 30 °C up to 90 °C, followed by 100 °C down to −20 °C, and finally −10 up to 30 °C, all in steps of 20 °C). At each temperature step, the Bragg wavelength was determined by averaging 2500 data points and the standard deviation was lower than 0.7 pm, with a typical value of 0.4 pm. The fitting to the experimental data followed the standard procedure of analyzing the coefficient of determination (R2~1), the residuals of the wavelength fitting and the residual sum of squares (RSSs) [24,28]. Therefore, the order of the polynomial fitting was determined by R2 having essentially a value of 1 (R2 ≥ 0.99999), and when the RSSs did not reduce substantially by performing a higher order fitting. A quadratic fitting was applied to the temperature dependence of the Bragg wavelength and it was observed that KT shifted linearly with temperature. Similarly, gratings inscribed in the SMF-28 fiber were submitted to four heating cycles from −50 °C up to 200 °C. A cubic fitting was applied to the temperature dependence of the Bragg wavelength and KT shifted quadratically with temperature. Figure 3 shows the temperature dependence of the Bragg wavelength for both temperature cycles. The comparison between the fitting of KT is presented in Figure 4, where it can be observed that a divergence occurs as one approaches the limits of the temperature interval [−20, 100] °C. This divergence can be explained by the fact that, at room temperature, KT = ((1/neff)(dneff/dT) + αSiO2) (the normalized thermo-optic coefficient and the thermal expansion coefficient, respectively) is essentially determined by the temperature behavior of the thermo-optic coefficient (dneff/dT), a cubic temperature dependence [21,23,31,32,33,34,35]. The calibrations were repeated with all fiber gratings, as shown in Table 2, and the results are summarized in Table 3. It can be observed that KT increases with the fiber GeO2 content, being lower for the B/Ge fiber. The absolute values of KT for the SMF-28 fiber and Leoni SMF with an Ormocer coating differs from the ones previously measured [25]. Therefore, we performed a reanalysis of those experiments and the results will be discussed in the next section. The possible effect of the hydrogen-loading process or the grating coupling strength (reflectivity) on KT values was studied using gratings in the SMF-28e+ fiber. The results have shown that up to a reflectivity of 15% there is no impact on the determination of the normalized temperature sensitivity. Similar results were obtained for the other fibers, namely, a grating induced in the PS1500 (NA = 0.29) fiber with a reflectivity as high as 33% was tested, and gratings inscribed in a batch of the Leoni SMF with an Ormocer coating, having reflectivity ranging from 1% up to a saturated level, were also used.

Figure 2.

Schematic of the fiber Bragg grating temperature measurements calibration. The drawing on the right represents the cross section of the insert block (not in scale).

Figure 3.

Bragg wavelength temperature dependence for the three UV-FBGs induced in the SMF-28 fiber: (a) four heating cycles −20–100 °C and (b) four heating cycles −50–200 °C (average values for each FBG).

Figure 4.

KT versus temperature (average values) considering the three FBGs for both temperature cycles.

Table 3.

KT expressions for FBGs inscribed in different fibers, in the temperature range [−20, 100] °C.

4. Error Analysis Related to FBG Thermal Characterization

This section, besides its scientific content, also intends to be a pedagogical one in an era of unprecedent exponential increase in “insufficiently mature” published data. The initial thermal characterizations were performed using a customized oven, as described in [36] (although with shorter dimensions) and the thermal bath described in [25]. However, both heating apparatuses exhibited errors in the absolute temperature measurements. We realized that a 5 pm difference (or equivalently a temperature difference of 0.5 °C) on each temperature step led, after fitting the temperature dependence of the Bragg wavelength, to values of KT at room temperature (20 °C) that were expected for 29.4 °C, clearly being not sufficient for the precision required [23]. Therefore, all further characterizations were performed using the calibrated Dry block described in the previous section, and, using this new setup (Dry block + optical interrogator), we have investigated the potential source of errors in the determination of the temperature dependence of the Bragg wavelength, for which hundreds (above 750) of independent temperature measurements were performed over the last 18 months.

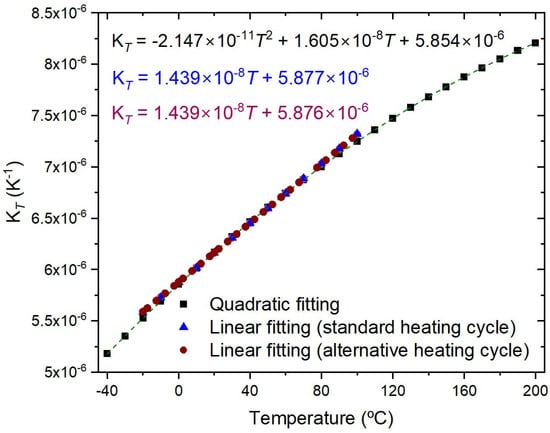

The potential effect of using different optical interrogators (comparison with a FS22SI with four channels) was analyzed. We have tested three FBGs (λB~1543 nm) inscribed in the SM1500 (NA = 0.20) and another three FBGs (λB~1541 nm) induced in the Leoni SMF fiber (with an Ormocer coating). Three heating cycles were performed in the temperature interval: −20–100 °C, using the eight channels unit and four more for the four channels unit, for a total of 34 tests. All KT values at 20 °C were in the interval ±0.004 K−1; therefore, both interrogators register the same values of Bragg wavelengths and, consequently, lead to the same KT values. We have identified another source of error related to a temperature gradient inside the calibration inserts (15.0 cm long) containing the FBG, which was estimated to be ~0.3 °C/cm outside the homogeneous temperature region. For instance, by using an array of two gratings inscribed in the SM1500 (NA = 0.30) fiber, separated by 6.0 cm, a difference in KT value of 0.006 K−1 was obtained, which corresponds to 0.5 °C. Therefore, one grating being 2.0 cm outside the uniform region yields a temperature gradient of 0.25 °C/cm. Values ranging from 0.25 up to 0.35 °C/cm were obtained by using different arrangements: gratings inserted at different depths (5 to 15 cm) and an array with five 4.5 mm gratings separated by ~10 mm. The Sika manual states that the homogeneous temperature zone is limited to 4.0 cm; therefore, the FBG should be well inside that region at the bottom of the insert. Since the temperature stability is very important to obtain good measurements, for each temperature step we analyzed the standard deviation, which was typically better than 0.4 pm, and we calculated the average of the resonance wavelength, typically using 2500 data points. When we closed the cycle, returning to the initial temperature, we also checked the resonance wavelength; the difference should be lower than 1 pm. Sometimes, the device loses stability, probably associated with condensation, which is observed in Figure 5b–d (wavelength vs. time), which also impacts the values obtained for KT. In such extreme cases, the measurements were discarded and only those exhibiting standard deviations lower than 1.0 pm were considered. It should be stressed that we have tried to minimize the occurrence of condensation inside the Dry block by increasing the temperature above 100 °C in the first step before decreasing to 30 °C, but the improvement is not always clear, nor is it uniform for all channels. The frequency of instability events seems to be associated with changes in temperature and humidity in the lab room throughout the year. As an example, it was difficult to reach stable values of temperature at −50 °C during summer and, therefore, we limited measurements down to −40 °C.

Figure 5.

(a) Stable measurements corresponding to the raw data (wavelength) from the optical interrogator during a temperature cycle (from 30 °C up to 100 °C, down to −20 °C and up to 30 °C) for ~16 h; (b) instability at 70 °C, 90 °C and 100 °C steps; (c,d) instability at single temperature steps (initially checked by the larger values of standard deviation).

When the above sources of error are controlled, we still have to deal with the curve fitting. A thorough study on the measurements’ repeatability was performed by using three gratings inscribed in the SMF-28 fiber. Four heating cycles (−20–100 °C) followed by another four heating cycles (−50–200 °C) were performed. Recently (6-month interval), five heating cycles (−40–200 °C) were also performed to compare reproducibility (measurements were limited to −40 °C, as mentioned above). For the former, a 2nd order polynomial fitting was applied to the temperature dependence of the Bragg wavelength, while a wider temperature range demands a higher polynomial fitting (Figure 3). As can be observed in Figure 4 and Figure 6, the normalized temperature sensitivity value is slightly lower for the latter. Nevertheless, a similar value is obtained when restricted to the same temperature range. It should be mentioned that KT values at 20 °C do not differ by more than 0.01 in each temperature range, totaling 39 independent measurements. We have also analyzed the influence of decreasing the temperature step, by performing three tests between −40 °C and 100 °C such that, when merged with previous tests, it results in temperature steps of about 2.5 °C. The KT values are similar to the ones obtained in previous tests (Linear-alternative in Figure 6). In general, gratings in other fibers show similar behavior.

Figure 6.

KT obtained for different temperature ranges and temperature steps.

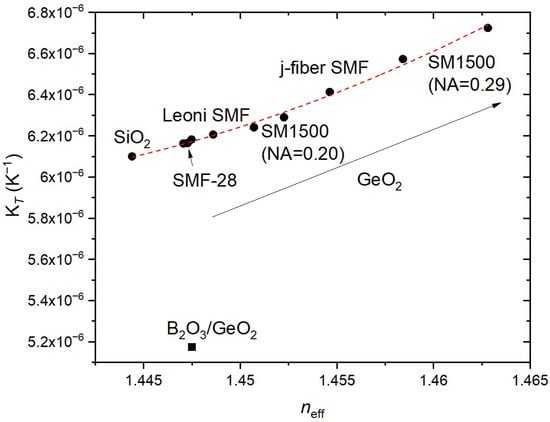

The last source of error, and one of the most important, is the homogeneity of the fiber itself, that is, the uniform distribution of the germanium concentration along the fiber core. As mentioned previously, we found values for fs-FBGs ranging from 6.175 × 10−6 K−1 up to 6.224 × 10−6 K−1, and from 6.153 × 10−6 K−1 up to 6.213 × 10−6 K−1 for UV-FBGs. The lack of uniformity was pointed out in the past during the fabrication of mechanically induced gratings in the SMF-28 fiber [37] and arc-induced gratings in the B/Ge co-doped fiber [20]. In this work, we have used the Leoni SMF fiber as a reference, since we had commercially available fs-FBGs on it, and, therefore, we could make comparisons between FBGs produced under different fabrication techniques and parameters, such as reflectivity. Initially we attributed the differences to the fs inscription [38], but, after a comparison of UV-FBGs produced in the SMF-28 fiber and in the Leoni SMF fiber using different setups ([25] and current work), we noticed that, while the ones inscribed in the SMF-28 fiber show similar values of KT, the same did not happen for FBGs induced in the Leoni SMF fiber. Moreover, recently we have inscribed FBGs in two new commercially available batches of SM1500 fiber (both NA = 0.20 and NA = 0.30), and, not only is the Bragg wavelength much higher (Δncore = 1.555 × 10−3 and 4.390 × 10−3, which corresponds to an estimated increase in GeO2 concentration, Δn = 1.464 × 10−3 × [GeO2(mol%)], of 1.1 and 3.0 mol%, respectively [23]), but KT is also higher for FBGs induced in both fibers: from 6.238 × 10−6 K−1 to 6.290 × 10−6 K−1 and from 6.574 × 10−6 K−1 to 6.724 × 10−6 K−1, respectively. Therefore, we have used 18 m of the Leoni SMF fiber containing two fs-FBGs (~19%; (6.182 ± 0.001) × 10−6 K−1) to inscribe UV-FBGs with different reflectivity (<1%, 18.9%, 98.8% and saturated), using both setups and all values of KT falling in the range (6.186 ± 0.006) × 10−6 K−1. It should be highlighted that peak detection for the high reflectivity gratings is also a demanding task (and the values of R2 of the fitting are lower for these gratings). Therefore, since we cannot guarantee that there is a uniform distribution of germanium in the core of the 18 m length of the Leoni SMF fiber, under the experimental conditions, we may conclude that KT is similar for fs-FBGs and UV-FBGs and that the coupling strength has a negligible influence on the determination of KT. For the sake of illustration, and since we do not know the fiber parameters in order to determine germanium concentration, we present KT as a function of neff in Figure 7. We have also included the KT value (KT = 1.418 × 10−8 T + 6.130 × 10−6 K−1; 6.413 × 10−6 K−1 @20 °C) obtained using three gratings (λB~1540, 1547 and 1554 nm) inscribed in another high Ge-doped fiber (j-fiber SMF: NA = 0.26 and MFD = 5.5 ± 0.4). It is clearly shown that KT increases with the increase in GeO2 concentration and decreases with B2O3 concentration. For FBGs inscribed in Ge-doped fibers, the expression KT = 4.472 × 10−4 neff2 − 1.270 × 10−3 neff + 9.075 × 10−4 (red line in Figure 7) can be used to estimate the KT value at 20 °C, as a function of the effective refractive index, with a typical error of 1 × 10−8 K−1 being the worst-case scenario, for highly Ge-doped fibers, of 7 × 10−8 K−1 (a “KT” value of 19.84 × 10−6 K−1, for bulk germanium glass was also considered [23]; shown in Supplementary Materials).

Figure 7.

KT vs. neff @20 °C, obtained for various gratings inscribed in fibers with different germanium concentration. The red line is the fitting of the KT vs. neff (expression given in the text) as the GeO2 concentration increase (pointed by the arrow).

5. Prediction of the Temperature Dependence of the Bragg Wavelength

Assuming that we know K(T) for one UV-FBG and λ(T0) for a second FBG inscribed in the same fiber, we can determine λ(T) for the latter, through the integration of K(T) and by applying a 3rd order Taylor expansion to the exponential function. Thus,

or

and therefore,

and

where Ki (i = 0, 1, 2) are coefficients. From the previous sections, it is clear that a quadratic polynomial fits, with high correlation, the temperature dependence of the Bragg wavelength in the [−20, 100] °C temperature range. Furthermore, increasing the polynomial order would result in a negligible reduction in the RSSs. Thus, a linear behavior for KT is adequate, and therefore, K2 = 0. We demonstrate the applicability by using five gratings written in the SM1500 (NA = 0.20) fiber with a reflectivity of about 0.5%. Table 4 summarizes the average values of KT at 20 °C for four tests in the [−40, 200] temperature range, limited to the [−20, 100] °C, and also three tests in the [−20, 97.5] °C, in steps of 10 °C, but at different temperature plateaus. For each grating, the absolute error of KT is within 0.002 K−1. Therefore, there is a slight dependence of KT on wavelength (in a range that exceeds 50 nm) that was averaged in the subsequent calculations. Thus, by fitting all experimental data, for the first temperature range, we obtained KT = −2.197 × 10−11T2 + 1.669 × 10−8T + 5.919 × 10−6, for the second, we obtained KT = 1.500 × 10−8T + 5.941 × 10−6 and for the last, we obtained KT = 1.512 × 10−8T + 5.936 × 10−6 (R2 = 0.9999). Table 5 summarizes the results obtained by comparison of the Bragg wavelengths and temperature sensitivity (dλ/dT) values from direct calibration (dλ_dir2/dT and dλ_dir3/dT, for quadratic and cubic fitting, respectively) and by following Equations (1)–(4), where we have assumed KT through the fitting of all experimental data of the five FBGs (λ_int2 and dλ_dint2/dT, for quadratic fitting and λ_int3 and dλ_dint3/dT, for cubic fitting). In each temperature range, the difference in wavelength is lower than 3 pm and the calculated temperature sensitivity differs by ~0.01 pm/°C. It should be noted that the differences in the temperature sensitivity near the limits of the temperature range (0.1 pm/°C) are essentially due to the dependence of KT on temperature (which goes from quadratic to cubic dependence for larger temperature interval), despite its slight dependence on wavelength for the five FBGs inscribed in this fiber with high GeO2 dopant concentration (as observed in Table 4 and with impact on the fitting: R2 = 0.9999). Concerning the [−20, 97.5] °C temperature range, the values of KT at 20 °C have lower dispersion (Table 4), and similar results were obtained when applying the method to estimate the wavelength and temperature sensitivity of the “unknown” grating.

Table 4.

KT values at 20 °C obtained using five FBGs induced in the SM1500 (NA_0.20).

Table 5.

Calculated Bragg wavelength and temperature sensitivity for the “unknown” grating.

A similar analysis was performed using five gratings inscribed in the SMF-28 fiber and KT was calculated in the −20–100 °C temperature range. Table 6 summarizes the average values of dλ/dT and KT for four independent measurements. Note that the dependence of the temperature sensitivity on wavelength is well-expressed in Equation (4). All results are within 6.165 ± 0.004 K−1, being more stable than the ones obtained for the previous gratings inscribed in the SM1500 fiber. Table 7 shows the results of considering the methodology by using KT = 1.424 × 10−8T + 5.883 × 10−6 obtained for all FBGs and by applying it to the FBGs at 1561.6 nm. The largest difference, 2.4 pm, occurs at −20 °C, but the sensitivity is always within 0.01 pm/°C. It should be stressed that we analyzed the independence of wavelength using gratings inscribed in other fibers and the results were even more constant, within 0.001, although for shorter wavelength ranges: SM1500_NA = 0.30 (two FBGs; 10 nm), j-fiber SMF (three FBGs; 14 nm) and Leoni SMF (five gratings; 27 nm).

Table 6.

dλ/dT and KT values at 20 °C obtained using five FBGs inscribed in the SMF-28 fiber and Bragg wavelengths fitted in the [−20, 100] °C temperature range.

Table 7.

Calculated Bragg wavelength and temperature sensitivity for the “unknown” grating.

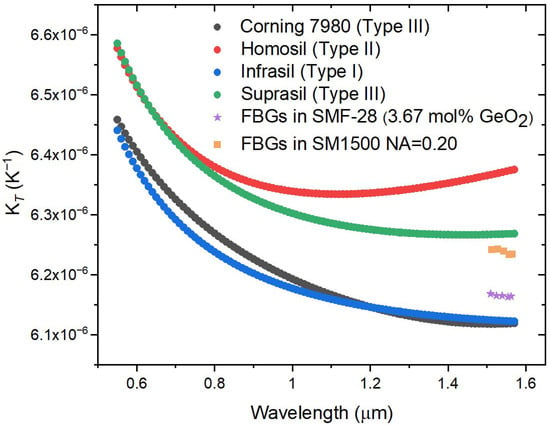

Figure 8 shows the wavelength dependence of “KT” for four silica glasses and KT for five FBGs inscribed in the SMF-28 Corning fiber and in the SM1500 fiber (NA = 0.20). As can be observed, the wavelength dependence of KT is negligible for the FBGs in the SMF-28 fiber (and also resembles the “KT” behavior of the Corning glass). On the other hand, KT seems to have a slight dependence on wavelength for FBGs in the SM1500 fiber.

Figure 8.

“KT” for four silica glasses [21,22,39,40,41] and KT for UV-FBGs inscribed in the SMF-28 Corning fiber and in FiberCore SM1500 fiber (NA = 0.20).

6. Discussion of the Results

The results obtained depend on the stability and resolution of the devices used. The optical interrogator has a sub-picometer resolution (wavelength is determined with eight digits) and the Dry block has a temperature resolution of 0.01 °C (four digits). However, the temperature registered every second is an average of 20 measurements and, therefore, we have assumed five digits for intermediate calculations. On the other hand, it is important to recognize that, sometimes, we are comparing results for the same gratings obtained with intervals of several months, and not only do the environmental conditions change, but both devices require calibration at least every year. In fact, it should be highlighted that the requirement for calibration was the main cause of the recent instability measurements discussed previously, since the replacement for another optical interrogator surpasses that event. Despite the good results obtained overall, there is room for improvement, and not only will the Dry-block be placed in a space with a controlled environment (temperature and humidity), but also an external calibrated temperature sensor with higher resolution will be inserted in a hole to be drilled in the center of the insert block containing the FBG (Figure 2), in order to guarantee higher temperature accuracy and resolution.

Concerning the polynomial fitting to the temperature dependence of the Bragg wavelength, from the theoretical point of view, the higher the order of the polynomial, the better the fitting, at least up to the fourth order, since, as discussed, the thermo-optic coefficient follows a cubic temperature dependence. However, depending on the temperature interval, and based on the coefficient of determination, residuals and RSSs, we assumed for the Bragg wavelength a quadratic and a cubic dependence for the temperature range −20–100 °C and −50–200 °C, respectively. In general, for each temperature step, we used an average of 2500 data points and the standard deviation was much lower than 1 pm (error bars in the figures would be smaller than the dimensions of the data points). Typically, for FBGs inscribed in the SMF-28 fiber, the error in KT @20 °C is of the order of 2 × 10−9 K−1 when considering different gratings but the same wavelength; it duplicates by taking into account different wavelengths, and including the fitting and tests over time, it is 5 × 10−9 K−1. This value may duplicate for FBGs inscribed in high Ge-doped fibers, as observed in the previous section.

Different fibers were used in this study in order to measure the impact of GeO2 concentration (or, at least, of neff) on KT values, and also to understand if the potential dependence of KT on wavelength would differ from the “KT” behavior of bulk SiO2 glass, as the GeO2 concentration increases. Apparently, some dependence may exist for high Ge-doped fibers, but care should be taken, since these fibers are more temperature-sensitive, and, therefore, more prone to temperature measurement errors. A comparison of the KT values obtained for FBGs inscribed in the SMF-28 fiber (probably the most well-known fiber and the one exhibiting more stable parameters over time) is presented in Table 8. As can be seen, the value obtained in this work has higher accuracy and compares well with the value determined by Flockhart et al. [24], where they have also used a quadratic fitting, and with the one achieved by Imas et al. [27], taking into account that they have used a linear fitting for a temperature interval above 20 °C. Moreover, the value of KT = 6.165 × 10−6 K−1, at 20 °C, obtained accurately for FBGs inscribed in the SMF-28 fiber, allowed us to recalculate, following the methodology presented in [23], the thermo-optic coefficient of bulk germanium glass to be 19.4 × 10−6 K−1, being, therefore, in excellent agreement with the published literature [42]. Finally, the approach that we presented in the preceding section to estimate the wavelength dependence of the “unknown” FBGs by considering the KT from another grating also reinforces the accuracy of the experimental results.

Table 8.

KT values obtained for FBGs inscribed in the SMF-28/SMF-28e+ fibers.

In [43], a much higher value of KT = (7.19 ± 0.16) × 10−6 K−1 was also presented for an FBG inscribed in a SM1500 fiber (the conditions were the same as those described in the table above). KT values of 5.86 × 10−6 K−1 and 5.95 × 10−6 K−1 (standard deviation for temperature and wavelength were 0.6–0.9 °C and 5–8 pm, respectively) were also obtained for FBGs inscribed in a PS1250/1500 fiber [44]. In this case, a quadratic fitting was used from 22 °C up to 250 °C and, therefore, the uncertainty is very high to extrapolate the correct value at 20 °C, these values also being much higher than the one obtained in this work.

7. Conclusions

We have shown that the temperature dependence of the normalized temperature sensitivity, KT, was found to be quadratic in the −50–200 °C range while it is linear for the −20–100 °C range. KT values at 20 °C range from 5.176 × 10−6 K−1, for a B/Ge co-doped fiber up to 6.724 × 10−6 K−1, for a highly Ge-doped fiber. We have demonstrated that KT does not depend on the hydrogen-loading process, nor on the gratings coupling strength, and that is independent of wavelength in the 1500–1600 nm range. Furthermore, gratings produced by femtosecond-laser radiation and UV-laser radiation exhibit comparable values of KT. The KT expressions for FBGs inscribed in silica fibers with distinct concentrations of GeO2 were given. A KT = 6.165 × 10−6 K−1, at 20 °C, was accurately obtained for FBGs inscribed in the SMF-28 fiber, which allowed us to calculate the thermo-optic coefficient of bulk germanium glass to be 19.4 × 10−6 K−1. A discussion of the potential sources of error on KT determination was presented. We have introduced a methodology that allows the accurate determination of the temperature dependence of the Bragg wavelength of any grating, as far as one has knowledge of KT for a single grating inscribed in the same fiber. This methodology is very useful in research labs and computer simulations, being a step further towards the determination of the thermo-optic coefficient of ternary glasses, such as the B/Ge co-doped silica glass fiber (FiberCore PS125/1500). Therefore, by also having knowledge of the fiber parameters (namely, the refractive index profile), we expect to estimate the temperature dependence of the thermo-optic coefficient of such glass and accurately determine the dispersion turning points of arc-induced gratings at cryogenic temperatures. This would be the ultimate corner to be turned towards the development of high-sensitivity cryogenic temperature sensors based on arc-induced gratings.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/s26020435/s1, Figure S1: KT vs. neff from SiO2 up to GeO2.

Author Contributions

Conceptualization, methodology and data analysis, G.M.R.; experimental work, J.L.C., M.C., F.M.A., J.P., R.O., R.N., M.P. and P.C.; writing—review and editing, G.M.R., J.L.C. and R.O. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financed by national funds through the Portuguese funding agency, FCT—Fundação para a Ciência e a Tecnologia, I.P., under the support of INESC TEC through FCT within project 10.54499/UID/50014/2025 and supported by The Applied Digital Transformation Laboratory (ADiT-LAB), through FCT within project 10.54499/UIDP/06121/2025. This work was also funded by FCT—Fundação para a Ciência e a Tecnologia, I.P., and, when eligible, co-funded by EU funds under project/support UID/50008/2025—Instituto de Telecomunicações, with DOI identifier https://doi.org/10.54499/UID/50008/2025. R. Oliveira acknowledges the FCT contract CEECIND2021.01066 with DOI identifier 10.54499/2021.01066.CEECIND/CP1653/CT0004. J. L. Cruz acknowledges the grant through project PROMETEO:CIPROM/2022/30, funded by the Generalitat Valenciana, Spain.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data segments can be obtained by contacting the corresponding author.

Conflicts of Interest

Authors Miguel Cosme and Francisco M. Araújo were employed by the company HBK FiberSensing, S. A. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Meltz, G.; Morey, W.W.; Glenn, W.H. Formation of Bragg gratings in optical fibers by a transverse holographic method. Opt. Lett. 1989, 14, 823–825. [Google Scholar] [CrossRef]

- Hill, K.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Light. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; LeBlanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber grating sensors. J. Light. Technol. 2002, 15, 1442–1463. [Google Scholar] [CrossRef]

- Hill, K.O.; Malo, B.; Bilodeau, F.; Johnson, D.C.; Albert, J. Bragg gratings fabricated in monomode photosensitive optical fiber by UV exposure through a phase mask. Appl. Phys. Lett. 1993, 62, 1035–1037. [Google Scholar] [CrossRef]

- Rao, Y.J. In-fibre Bragg grating sensors. Meas. Sci. Technol. 1997, 8, 355. [Google Scholar] [CrossRef]

- Xu, M.G.; Archambault, J.L.; Reekie, L.; Dakin, J.P. Discrimination between strain and temperature effects using dual-wavelength fibre grating sensors. Electron. Lett. 1994, 30, 1085–1087. [Google Scholar] [CrossRef]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Iadicicco, A.; Campopiano, S.; Cutolo, A.; Giordano, M.; Cusano, A. Self temperature referenced refractive index sensor by non-uniform thinned fiber Bragg gratings. Sens. Actuators B Chem. 2006, 120, 231–237. [Google Scholar] [CrossRef]

- Lobry, M.; Fasseaux, H.; Loyez, M.; Chah, K.; Goormaghtigh, E.; Wattiez, R.; Chiavaioli, F.; Caucheteur, C. Plasmonic Fiber Grating Biosensors Demodulated Through Spectral Envelopes Intersection. J. Light. Technol. 2021, 39, 7288–7295. [Google Scholar] [CrossRef]

- Feng, D.; Gao, Y.; Zhu, T.; Deng, M.; Zhang, X.; Kai, L. High-Precision Temperature-Compensated Magnetic Field Sensor Based on Optoelectronic Oscillator. J. Light. Technol. 2021, 39, 2559–2564. [Google Scholar] [CrossRef]

- Zhao, Y.; Liao, Y. Discrimination methods and demodulation techniques for fiber Bragg grating sensors. Opt. Lasers Eng. 2004, 41, 1–18. [Google Scholar] [CrossRef]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg Grating Sensors toward Structural Health Monitoring in Composite Materials: Challenges and Solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef]

- Gangwar, R.K.; Kumari, S.; Pathak, A.K.; Gutlapalli, S.D.; Meena, M.C. Optical Fiber Based Temperature Sensors: A Review. Optics 2023, 4, 171–197. [Google Scholar] [CrossRef]

- Deng, Y.; Jiang, J. Optical Fiber Sensors in Extreme Temperature and Radiation Environments: A Review. IEEE Sens. J. 2022, 22, 13811–13834. [Google Scholar] [CrossRef]

- Ma, S.; Xu, Y.; Pang, Y.; Zhao, X.; Li, Y.; Qin, Z.; Liu, Z.; Lu, P.; Bao, X. Optical Fiber Sensors for High-Temperature Monitoring: A Review. Sensors 2022, 22, 5722. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Bian, Q.; Liang, J.; Wang, Z.; Yu, Y.; Meng, Z. Recent advances in optical fiber high-temperature sensors and encapsulation technique [Invited]. Chin. Opt. Lett. 2023, 21, 090007. [Google Scholar] [CrossRef]

- Martins, R.; Caldas, P.; Teixeira, B.; Azevedo, J.; Monteiro, J.; Belo, J.H.; Araujo, J.P.; Santos, J.L.; Rego, G. Cryogenic Temperature Response of Reflection-Based Phase-Shifted Long-Period Fiber Gratings. J. Light. Technol. 2015, 33, 2511–2517. [Google Scholar] [CrossRef]

- Ivanov, O.V.; Caldas, P.; Rego, G. High Sensitivity Cryogenic Temperature Sensors Based on Arc-Induced Long-Period Fiber Gratings. Sensors 2022, 22, 7119. [Google Scholar] [CrossRef] [PubMed]

- Haneef, S.M.; Ludbrook, B.M.; Davies, M.; Siamaki, M.; Gonzalas, J.; Huang, X.; A Moseley, D.; A Badcock, R. Cryogenic optical fiber sensors for superconducting system protection in cryo-electric aircraft. Supercond. Sci. Technol. 2025, 38, 085008. [Google Scholar] [CrossRef]

- Colaco, C.; Caldas, P.; Del Villar, I.; Chibante, R.; Rego, G. Arc-Induced Long-Period Fiber Gratings in the Dispersion Turning Points. J. Light. Technol. 2016, 34, 4584–4590. [Google Scholar] [CrossRef]

- Rego, G. Temperature Dependence of the Thermo-Optic Coefficient of SiO2 Glass. Sensors 2023, 23, 6023. [Google Scholar] [CrossRef] [PubMed]

- Leviton, D.B.; Frey, B.J. Temperature-dependent absolute refractive index measurements of synthetic fused silica. In Proceedings of the Optomechanical Technologies for Astronomy, Orlando, FL, USA, 24–31 May 2006; SPIE—The International Society for Optical Engineering: Bellingham, WA, USA, 2006. [Google Scholar]

- Rego, G.M. Temperature Dependence of the Thermo-Optic Coefficient of GeO2-Doped Silica Glass Fiber. Sensors 2024, 24, 4857. [Google Scholar] [CrossRef]

- Flockhart, G.M.H.; Maier, R.R.J.; Barton, J.S.; MacPherson, W.N.; Jones, J.D.C.; Chisholm, K.E.; Zhang, L.; Bennion, I.; Read, I.; Foote, P.D. Quadratic behavior of fiber Bragg grating temperature coefficients. Appl. Opt. 2004, 43, 2744–2751. [Google Scholar] [CrossRef] [PubMed]

- Preizal, J.; Cosme, M.; Pota, M.; Caldas, P.; Araújo, F.M.; Oliveira, R.; Nogueira, R.; Rego, G.M. Normalized temperature sensitivity of fiber Bragg gratings inscribed under different conditions. In Proceedings of the 29th International Conference on Optical Fiber Sensors, Porto, Portugal, 25–30 May 2025; SPIE: Bellingham, WA, USA, 2025. [Google Scholar]

- Yoffe, G.W.; Krug, P.A.; Ouellette, F.; Thorncraft, D.A. Passive temperature-compensating package for optical fiber gratings. Appl. Opt. 1995, 34, 6859–6861. [Google Scholar] [CrossRef]

- Imas, J.J.; Bai, X.; Zamarreño, C.; Matias, I.; Albert, J. Accurate compensation and prediction of the temperature cross-sensitivity of tilted FBG cladding mode resonances. Appl. Opt. 2023, 62, E8–E15. [Google Scholar] [CrossRef]

- Buchfellner, F.; Stadler, A.; Bian, Q.; Hennesen, M.; Zeisberger, A.; Koch, A.W.; Roths, J. Generalized and wavelength-dependent temperature calibration function for multipoint regenerated fiber Bragg grating sensors. Opt. Express 2022, 30, 44769–44784. [Google Scholar] [CrossRef] [PubMed]

- Lerner, A.; Cotillard, R.; Blanchet, T.; Roussel, N.; Bouwmans, G.; Laffont, G. An intrinsic sensitivity calibration scheme for high temperature measurements using femtosecond point-by-point written fiber Bragg gratings. Opt. Laser Technol. 2024, 170, 110278. [Google Scholar] [CrossRef]

- Cruz, J.L.; Barmenkov, Y.O.; Díez, A.; Andres, M.V. Measurement of phase and group refractive indices and dispersion of thermo-optic and strain-optic coefficients of optical fibers using weak fiber Bragg gratings. Appl. Opt. 2021, 60, 2824–2832. [Google Scholar] [CrossRef]

- Wang, W.; Yu, Y.; Geng, Y.; Li, X. Measurements of thermo-optic coefficient of standard single mode fiber in large temperature range. In Proceedings of the 2015 International Conference on Optical Instruments and Technology: Optical Sensors and Applications, Beijing, China, 17–19 May 2015; SPIE: Bellingham, WA, USA, 2015. [Google Scholar]

- Tan, C.Z. Dependence of the refractive index on density, temperature, and the wavelength of the incident light. Eur. Phys. J. B 2021, 94, 139. [Google Scholar] [CrossRef]

- Yang, N.; Qiu, Q.; Su, J.; Shi, S.-J. Research on the temperature characteristics of optical fiber refractive index. Optik 2014, 125, 5813–5815. [Google Scholar] [CrossRef]

- Shen, X.; Song, C.; Shi, F.; Tian, Y.; Tie, G.; Qiao, S.; Peng, X.; Zhang, W.; Hou, Z. Research on Laser-Induced Damage Post-Restoration Morphology of Fused Silica and Optimization of Patterned CO2 Laser Repair Strategy. Micromachines 2023, 14, 1359. [Google Scholar] [CrossRef]

- Sharp, D.E.; Ginther, L.B. Effect of Composition and Temperature on the Specific Heat of Glass. J. Am. Ceram. Soc. 1951, 34, 260–271. [Google Scholar] [CrossRef]

- Rego, G.M. Arc-Induced Long-Period Fibre Gratings: Fabrication and Their Applications in Optical Communications and Sensing. Ph.D. Thesis, Engineering Faculty, Porto University, Porto, Portugal, 2006. [Google Scholar]

- Rego, G.; Fernandes, J.R.A.; Santos, J.L.; Salgado, H.M.; Marques, P.V.S. New technique to mechanically induce long-period fibre gratings. Opt. Commun. 2003, 220, 111–118. [Google Scholar] [CrossRef]

- Jovanovic, N.; Thomas, J.; Williams, R.J.; Steel, M.J.; Marshall, G.D.; Fuerbach, A.; Nolte, S.; Tünnermann, A.; Withford, M.J. Polarization-dependent effects in point-by-point fiber Bragg gratings enable simple, linearly polarized fiber lasers. Opt. Express 2009, 17, 6082–6095. [Google Scholar] [CrossRef] [PubMed]

- Leviton, D.B.; Frey, B.J.; Madison, T.J. Temperature-dependent refractive index of CaF2 and Infrasil 301. In Proceedings of the Cryogenic Optical Systems and Instruments XII, San Diego, CA, USA, 26–27 August 2007; SPIE—The International Society for Optical Engineering: Bellingham, WA, USA, 2007. [Google Scholar]

- Leviton, D.B.; Miller, K.H.; Quijada, M.A.; Grupp, F.U. Temperature-dependent refractive index measurements of CaF2, Suprasil 3001, and S-FTM16 for the Euclid near-infrared spectrometer and photometer. In Proceedings of the Current Developments in Lens Design and Optical Engineering XVI, San Diego, CA, USA, 10–11 August 2015; SPIE—The International Society for Optical Engineering: Bellingham, WA, USA, 2015. [Google Scholar]

- Miller, K.H.; Quijada, M.A.; Leviton, D.B. Cryogenic refractive index of Heraeus homosil glass. In Proceedings of the Current Developments in Lens Design and Optical Engineering XVIII, San Diego, CA, USA, 7–8 August 2017; SPIE—The International Society for Optical Engineering: Bellingham, WA, USA, 2017. [Google Scholar]

- Uhlmann, D.R.; Kreidl, N.J. Optical Properties of Glass; The American Ceramic Society: Westerville, OH, USA, 1991. [Google Scholar]

- Osuch, T.; Anuszkiewicz, A.; Zakrzewski, D.; Filipkowski, A.; Olszewski, J.; Mergo, P.; Pysz, D.; Kasztelanic, R.; Buczyński, R. Enhancement of spectral response of Bragg gratings written in nanostructured and multi-stepped optical fibers with radially shaped GeO2 concentration. Opt. Express 2020, 28, 14774–14787. [Google Scholar] [CrossRef] [PubMed]

- Pal, S.; Sun, T.; Grattan, K.T.; Wade, S.A.; Collins, S.F.; Baxter, G.W.; Dussardier, B.; Monnom, G. Non-linear temperature dependence of Bragg gratings written in different fibres, optimised for sensor applications over a wide range of temperatures. Sens. Actuators A Phys. 2004, 112, 211–219. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.