Abstract

Food quality and safety are essential for ensuring public health, preventing foodborne illness, reducing food waste, maintaining consumer confidence, and supporting regulatory compliance and international trade. This has led to the emergence of many research works that focus on automating and streamlining the assessment of food quality. Electronic noses have become of paramount importance in this context. We analyze the current state of research in the development of electronic noses for food quality and safety. We examined research papers published in three different scientific databases in the last decade, leading to a comprehensive review of the field. Our review found that most of the efforts use portable, low-cost electronic noses, coupled with pattern recognition algorithms, for evaluating the quality levels in certain well-defined food classes, reaching accuracies exceeding 90% in most cases. Despite these encouraging results, key challenges remain, particularly in diversifying the sensor response across complex substances, improving odor differentiation, compensating for sensor drift, and ensuring real-world reliability. These limitations indicate that a complete device mimicking the flexibility and selectivity of the human olfactory system is not yet available. To address these gaps, our review recommends solutions such as the adoption of adaptive machine learning models to reduce calibration needs and enhance drift resilience and the implementation of standardized protocols for data acquisition and model validation. We introduce benchmark comparisons and a future roadmap for electronic noses that demonstrate their potential to evolve from controlled studies to scalable industrial applications. In doing so, this review aims not only to assess the state of the field but also to support its transition toward more robust, interpretable, and field-ready electronic nose technologies.

1. Introduction

The development of the electronic nose started in the 1960s when researchers began exploring artificial olfaction systems capable of mimicking the human sense of smell. In 1964, Wilkens and Hartman introduced the idea of simulating olfactory processes electronically, contributing to the theoretical groundwork for artificial odor recognition systems []. In 1965, Buck et al. explored how chemical compounds could be detected through surface effects on metals and semiconductors, laying the principles that underpin modern gas sensor technology []. Around the same time, Dravnieks and Trotter developed a polar vapor detector based on contact potential modulation, an early precursor to volatile organic compounds’ (VOCs) sensing mechanisms []. In the early 1980s, Persaud and Dodd proposed a system designed to replicate the mechanisms of human smell perception using an array of gas sensors combined with a pattern recognition algorithm []. A few years later, Ikegami and Kaneyasu expanded upon this idea by applying an array of semiconductor gas sensors to distinguish the freshness of food products []. The concept of an electronic nose (e-nose) as we know it today is considered to be an intelligent system that integrates an array of chemical or gas sensors with signal processing and pattern recognition mechanisms capable of identifying both simple and complex odors [,]. Early e-nose models relied on metal oxide semiconductors and conducting polymer sensors, which, despite their limitations, demonstrated the potential for detecting and discriminating complex odor patterns associated with VOCs. Over time, advancements in sensor technology, nanomaterials, and machine learning have significantly improved the performance of e-nose devices, enabling applications in various industries. Today, modern e-noses incorporate biosensors, artificial intelligence, and miniaturized designs, making them more sensitive, selective, and appropriate for real-world applications.

E-noses play an important role in improving quality control, safety, and efficiency in various sectors, making them an indispensable technological advancement. Studies [,] emphasize that e-noses are crucial for the following:

- Ensuring food quality and safety: E-noses help detect spoilage, contamination, and adulteration in food products, ensuring freshness and quality control.

- Advancing medical diagnostics: E-noses are used in disease detection by analyzing breath, sweat, or urine to identify biomarkers associated with conditions like diabetes, cancer, and infections.

- Enhancing environmental monitoring: E-noses detect pollutants, hazardous gases, and air quality changes, aiding in environmental protection and public health.

- Improving industrial process control: E-noses help monitor manufacturing processes, detect leaks, and ensure consistent product quality in industries such as pharmaceuticals, perfumes, and beverages.

- Strengthening security and defense: E-noses are used in explosive and drug detection, helping in law enforcement and military and border security operations.

- Boosting agriculture and farming: E-noses assist in monitoring soil conditions, plant health, and pest infestations by detecting VOCs released by plants to improve crop yields and reduce reliance on harmful pesticides.

- Ensuring workplace safety: E-noses help prevent occupational hazards by detecting toxic or flammable gases in industrial and laboratory environments.

1.1. Research Questions and Contributions

Ensuring food quality and safety is vital for protecting public health, preventing foodborne illness, reducing food waste, maintaining consumer confidence, and supporting regulatory compliance and international trade. In this context, a timely review of e-noses is essential to capture recent innovations, discuss their advantages and limitations, and summarize the key research directions in order to enhance food quality and safety assurance.

1.1.1. Research Questions

The research questions we explore in this survey include the following:

- Research Question 1 (RQ1): What are the state-of-the-art research results over the last decade in the field of e-nose systems aimed at food quality and safety?

- Research Question 2 (RQ2): What lessons have been learned from the design and deployment of e-nose systems in laboratory and industrial settings?

- Research Question 3 (RQ3): What research gaps exist in the application of e-noses for food quality and safety, and what are the future research directions that we must explore to address these gaps?

1.1.2. Research Contributions

We summarize the main research contributions of this work that address the research questions above as follows:

- We present an in-depth analysis of research results over the past decade in the e-nose field designed for food quality and safety. We concluded the analysis based on a proposed taxonomy, which we developed through a comprehensive examination of peer-reviewed research papers from three scientific databases. We highlight key technological advances, practical implementations, and performance results obtained across various food sectors.

- We identify critical lessons learned, such as the importance of e-nose components selection (sensors, signal processing unit, data pattern recognition model) according to the type of food and the need to develop suitable data pattern recognition models, as well as new sensors tailored to food quality and safety assessment.

- We identify current research gaps, such as the lack of real-world validation and limited sensor sensitivity, and we discuss future research opportunities that will improve the reliability, scalability, and industrial applicability of e-nose technologies in food systems.

1.1.3. Organization of This Paper

We organize the rest of the paper as follows: Section 2 introduces the main components of an electronic nose. Section 3 outlines our review methodology, introduces the final dataset of documents selected for analysis, and presents relevant statistical information. Section 4 analyzes the selected research works based on our proposed taxonomy and discusses lessons learned. Section 5 addresses research gaps and recommends future research directions. Finally, in Section 6, we make some concluding remarks.

2. E-Nose Components

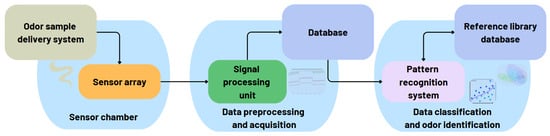

The definition of an electronic nose presented in [] highlights the key components of such a system that work together to detect, analyze, and interpret odors: the sensor array, the signal processing unit, and the pattern recognition system.

The sensor array is the core component of the e-nose, comprising multiple chemical or gas sensors that respond differently to various VOCs, creating a unique pattern for different odors. To provide a clearer understanding of sensor technologies, we adopted a classification based on the way each type of sensor operates. Common categories include the following:

- Chemiresistive sensors, such as metal oxide semiconductor (MOS) sensors [] and carbon nanotube (CNT) sensors [], detect gases through changes in electrical resistance upon exposure to VOCs.

- Conductometric sensors, including conducting polymer (CP) sensors [], alter their conductivity in the presence of gas molecules.

- Mass-sensitive sensors, such as quartz crystal microbalance (QCM) sensors [] and surface acoustic wave (SAW) sensors [], detect gas adsorption by measuring shifts in resonant frequency.

- Electrochemical sensors [] convert chemical reactions at the electrode surface into electrical signals.

- Optical sensors [] monitor changes in light absorption, fluorescence, or scattering in response to gas exposure.

- Field-effect transistor (FET)-based sensors [,], a growing category often involving nanomaterials or 2D materials, modulate current flow through a semiconductor channel when exposed to target VOCs.

- Bioelectronic sensors [] integrate biological recognition elements to selectively detect specific VOCs.

Table 1 presents the advantages and application domains of the types of sensors that can be used in the e-nose development process.

Table 1.

E-nose sensor array types, their advantages, and application sectors.

The signal processing unit transforms sensor outputs into digital electronic signals for further analysis. It includes amplifiers, analog-to-digital converters (ADC), and noise filters to refine the data.

The pattern recognition system uses machine learning, artificial intelligence, or statistical algorithms to analyze the sensor data and identify unique odor patterns by comparing against a database of known smells. The most commonly used approaches include principal component analysis (PCA) [] (reduces the dimensionality of sensor data while retaining key information), linear discriminant analysis (LDA) [] (classifies odors by maximizing the separation between different groups), artificial neural networks (ANNs) [] (mimics brain-like processing to learn and recognize odors patterns), support vector machines (SVMs) [] (separate odor data into different classes using an optimal decision boundary), and k-nearest neighbors (KNNs) [] (classify odors based on similarity to known reference samples). Within an e-nose, the sensor type determines the data characteristics, which in turn influence the pattern recognition technique needed for effective odor analysis. Therefore, MOS and CP sensors require fast, efficient recognition methods like PCA, ANNs, and SVMs due to large sensor response variations; QCM and SAW sensors produce high-precision frequency-based data, making ANNs and SVMs ideal for classification; optical and electrochemical sensors work well with PCA and LDA for chemical discrimination; and bioelectronic sensors use advanced techniques like ANNs to handle complex biological interactions in odor detection. Table 2 presents the advantages of each pattern recognition technique that can be used in the e-nose development process, the relation between these techniques and sensor types, and also the areas where they can be used.

Table 2.

Pattern recognition technique, their advantages, related sensor type, and application areas.

We found that the results of the odor classification and analysis should be presented in a more user-friendly manner (i.e., mobile and web-based interfaces), making them easily accessible to e-nose end-users. This approach enhances efficient user interaction, enables real-time monitoring, and improves data visualization.

In addition to the previously discussed components, an e-nose should include a sample delivery system to ensure consistent, controlled, and repeatable exposure of VOCs to the sensor array. This component plays a key role in enhancing the accuracy and dependability of odor detection. It can include a sampling port to collect the gas sample, pre-concentrators to enhance sensitivity by capturing and releasing VOCs, filters to remove unwanted contaminants, flow controllers to regulate the gas rate and pressure, temperature and humidity controllers to maintain optimal conditions to prevent variations in sensor responses, a sample chamber to hold the gas sample for uniform interaction with the sensor array, and pumps to facilitate the movement of the gas sample through the system, and a ventilation system to ensure safe disposal of the analyzed gas after detection [].

Figure 1 presents an overview of the e-nose components, highlighting the key elements we have discussed above and their interconnections.

Figure 1.

The main components of e-nose and their interactions.

3. Review Methodology

3.1. Criteria for Selecting Relevant Research Papers Used in This Review

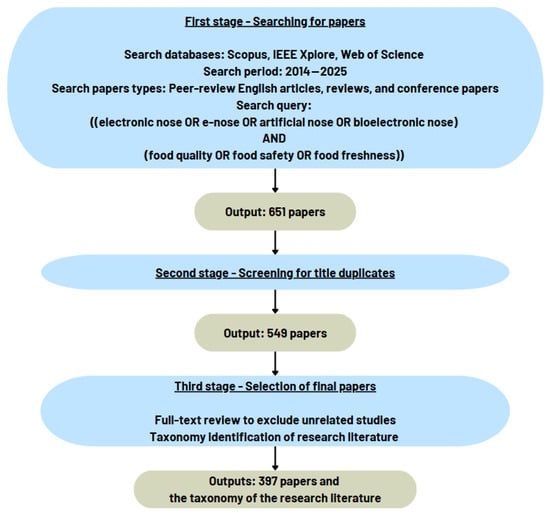

To select the most relevant research papers used in this review, we adopted the strategy in Figure 2.

Figure 2.

The three stages of the review methodology.

- In the first stage, we used the Scopus, IEEE Xplore, and Web of Science (WoS) electronic databases to search for final peer-review English-language documents published between 2014 and 2025. We considered only documents of type articles, reviews, and conference papers. We conducted the search using the following words appearing in the title or abstract of the documents: electronic nose, e-nose, artificial nose, bioelectronic nose, food quality, food safety, and food freshness.

- In the second stage, we reviewed the titles of the documents retrieved from the search query to remove duplicates.

- In the third stage, we thoroughly reviewed the full text of the remaining documents (after removing duplicates) before making the final selection, excluding unrelated studies, highlighting the key sections relevant to our review, and identifying the taxonomy of the research literature on the development of e-nose technology/applications in the field of food quality and safety.

3.2. Preliminary Results Obtained

The search query results from the Scopus electronic database, retrieved on 6 March 2025, yielded a total of 69 peer-reviewed documents. These include 40 journal articles (58%), 11 reviews (15.9%), and 18 conference papers (26.1%).

The search results from the IEEE Xplore database, retrieved on 6 March 2025, reveal a total of 117 peer-reviewed documents. These include 21 journal/magazine articles (18%), 2 reviews (1.7%), and 94 conference papers (80.3%).

The search results from the Web of Science database, retrieved on 6 March 2025, indicate a total of 465 peer-reviewed documents. These include 298 journal articles (64.1%), 120 reviews (25.8%), and 47 conference papers (10.1%).

After removing the duplicates, the preliminary documents dataset consists of 314 journal/magazine articles, 122 reviews, and 113 conference papers.

Table 3 presents an overview of the preliminary search results for the documents.

Table 3.

Preliminary search results.

3.3. Final List of Selected Papers and Taxonomy of the Research Literature on E-Nose for Food Quality and Safety

After a comprehensive analysis of the publications obtained in the second stage of the selection process, we excluded those that (a) do not have food quality and safety as their main research objectives (with terms like food, food quality, food safety, or food freshness appearing only in the abstract); (b) primarily review the food quality and safety field, presenting only general information about e-nose, such as definitions and descriptions of basic components, alongside other systems, devices, or techniques for this purpose; (c) rely only on the gas chromatography technique; (d) address food quality for animals; and (e) do not show promising results in terms of performance metrics.

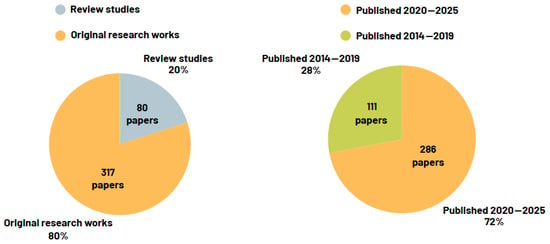

As a result, the final list of publications includes 397 documents, which include 241 journal/magazine articles, 80 reviews from journals and conferences, and 76 conference papers from all the three electronic databases previously mentioned. Table 4 presents a summary of the final list of publications.

Table 4.

Final search results.

Figure 3 presents an additional analysis of the data, which reveals that approximately 20% of the papers in the final dataset are review studies, and most of the original research results have been published in journals/magazines. Additionally, 72% of the papers were published in the past 5 years, which demonstrates the growing interest of the scientific community in this topic.

Figure 3.

Statistics from the final list of publications.

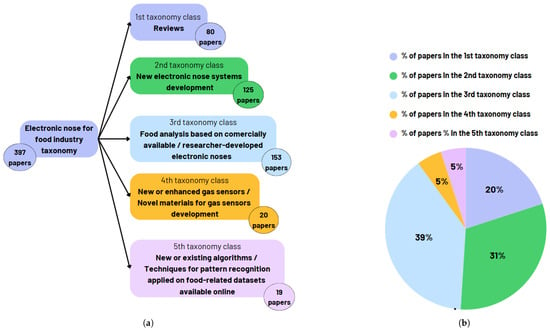

During this stage, we classified the documents in the final dataset into five distinct classes. The first category covers review studies that focus on the application of e-nose technology in the food industry. The second category includes papers that present the development of new electronic noses for food quality and safety. The third category comprises papers that use commercially available or researcher-developed electronic noses, either alone or in combination with other techniques, for food analysis. The fourth category includes research studies that introduce new/enhanced gas sensors or novel materials for gas sensor development with applicability in the food industry. The last category includes papers that present the outcomes of applying existing algorithms or techniques for pattern recognition or their fusion, on food-related datasets available online. Figure 4a illustrates the taxonomy of the research literature on e-nose technology for food quality and safety based on these categories. Figure 4b presents the distribution of papers in the final list of publications belonging to each identified category.

Figure 4.

(a) Taxonomy of the research literature on electronic nose for food quality and safety. (b) The distribution (by categories) of papers in the final list of publications.

As Figure 4 shows, most of research efforts have focused on analyzing food data from commercial or laboratory-based e-nose systems, followed closely by studies dedicated to developing new electronic nose systems. There are also several reviews that have been published that cover the latest advancements in the field. Studies concerning the development of new gas sensors and new algorithms/techniques for pattern recognition using existing datasets have also attracted some interest.

4. Analysis of the Research Works from the Final List of Selected Publications

In this section, we emphasize the novel contribution of our review when compared with existing reviews that we selected in our taxonomy. Additionally, we present the most promising research works from the final selection, encompassing the remaining four categories of the taxonomy, and we highlight the key lessons learned from these past studies.

4.1. Reviews

As Figure 4 shows, we identified several review articles in our final selection of papers. These published reviews covered several aspects on the topic of electronic nose.

4.1.1. Reviews on Advancements in Electronic Nose Systems for Food Industry Applications

One category of review papers explored recent advancements in electronic nose systems and their applications in the food industry. The studies [,,,,,,,,,,,] describe the technologies used to develop each of the e-nose components and discuss some proposed solutions of this type of systems. Some reviews focus on the advancement of electronic nose technology in relation to a specific food category: meat [,,,], berries [], oils [,], fruits and vegetables juice [], milk and dairy [,], tea [], and wine [,].

4.1.2. Reviews on Sensor Development and Pattern Recognition Techniques in Electronic Nose Systems

Reviews such as [,,,,,,,] investigate the progress made in the development of sensors with high sensitivity and selectivity for detecting VOCs emitted from food, and highlight the challenges related to sensor stability, cross-sensitivity, environmental interference, and also their integration into e-nose-based applications. The authors of [,,,] reviewed pattern recognition techniques that can be applied to electronic nose systems. In addition, they also discussed current challenges and potential future directions of these methods.

4.1.3. Reviews on Recent Sensing Technologies for Food Quality Assessment

Another category of reviews focuses on recent sensing technologies for food quality assessment. For example, refs. [,,,,,,,,,,] present comprehensive reviews of electronic sensing technologies (e-nose, e-tongue, e-eye) and their applications. Similarly, refs. [,] highlight electronic noses as intelligent detection tools in the food industry, along with technologies such as computer vision, intelligent tracing systems, intelligent colorimetric films, and near-infrared spectroscopy.

4.1.4. Our Review on Sensor-Based Electronic Nose for Food Quality and Safety

Our review offers a comprehensive and structured examination of the past decade’s research on sensor-based e-nose devices for ensuring food quality and safety. In contrast with earlier efforts and past publications mentioned in Section 4.1.2, which focus on the technologies used to develop e-nose components and explore proposed solutions, the novelty of our contributions includes the following:

- Development and application of a unique taxonomy ensuring broad coverage and reduced selection bias: We conducted an extensive analysis of peer-reviewed studies across three major scientific databases, the taxonomy. The taxonomy enables a systematic evaluation of technological advancements (both sensors and pattern recognition techniques), practical implementations, and performance outcomes across the following food and beverage sectors: meat, seafood, vegetables and fruits, spices, oils, coffee, tea, diary, and alcoholic beverages.

- Decade-long coverage of research results: By capturing trends over an extended period, our review offers an up-to-date perspective on technological evolution and trends.

- Lessons-learned synthesis: Our review identifies critical lessons learned from the existing literature in each category from the taxonomy we developed. The lessons learned will help guide both future academic research and practical development of e-nose systems for food quality and safety.

- Identification of unresolved research gaps: Our review reveals notable gaps that must be addressed in the future. These gaps include the lack of e-nose real-world validation, limitations in sensor sensitivity and stability, challenges in achieving miniaturize and portable e-noses, lack of standardized testing protocols, limited real-time processing capabilities, and insufficient support for user-friendly visualization of odor classification and identification outcomes.

Our review serves as a valuable resource for researchers, especially those new to the field of electronic noses for food quality and safety, because it provides a comprehensive foundation and state-of-the-art, in-depth information on current technologies, applications, and research directions in this area.

4.2. Electronic Nose Systems for Food Quality and Safety

Thirty-one percent of the journal/magazine articles and conference papers in the final list of selected publications present electronic nose systems for odor authentication and recognition, for quality assessment, and for quality monitoring of various food and beverage products, including meat (i.e., chicken, beef, pork), seafood (i.e., fish, prawn), vegetables and fruits (i.e., tomato, broccoli, banana, avocado), spices, oils (i.e., palm, olive, sunflower, essential oils), coffee, tea, diary (i.e., milk), and alcoholic beverages (i.e., rice wine, beer, scotch, whiskey, liquor). These papers describe the physical components of the e-noses developed, along with the data analysis approaches used for odor classification and identification. Table 5 briefly presents the analysis of these e-noses from the following perspectives: design architecture (sensor array and signal processing unit), data analysis techniques, evaluation and performance metrics, and application area.

Table 5.

Summary of electronic nose systems for food quality and safety.

Lessons Learned

Based on the detailed analysis of electronic nose-type systems for food quality and safety that we performed above in Table 5, we found that most of these systems are homemade, low-cost, using commercial MOS sensors and simple microcontroller boards in the Arduino and ESP32 range (Arduino Uno R3, Arduino Mega 2560, Arduino Uno, ATmega8, Arduino Due, PIC, PIC18F45K22, Arduino Nano, Gizduino, ESP32, and the Node MCU IoT platform) or single-board computers such as Raspberry Pi (Raspberry Pi 3 and 4, S3C6410-based Linux platform), or data acquisition cards like NI DAQ card—USB-6009 and PCI6035E, available on the market. Table 6 provides a complete list of all the gas sensors used in e-nose solutions from Table 5 along with their key characteristics. The characteristics presented are important because sensor range defines e-nose sensitivity, and power and response time are critical for portable or multi-sensor systems. For example, heater-based sensors need long startup or preheat times, which limits portability. Table 5 and Table 6 offer researchers a comprehensive overview of the most commonly used sensors in the development of the e-nose system, their corresponding application areas, and the algorithms that achieve good performance levels. These tables provide practical insights and recommendations that will significantly reduce the efforts of designers and implementors required for sensor selection. Creating such selection tables is a crucial preliminary step in the sensor selection process.

Table 6.

Summary of gas sensors used in e-nose systems and their key features (response time—the time a sensor takes to reach a certain percentage of its final output signal after exposure to a target gas; resume time—the time the sensor takes to return to its baseline signal after the removal of the target gas).

For the classification of the acquired data, Table 5 reveals that the main techniques presented in Table 2 (PCA, LDA, ANNs, SVM, KNN) and variations of those (i.e., CNN, PNN, LSTM, MLP, SVR) are the most used. Current trends focus on implementing machine learning technologies, such as CNN and LSTM, and general AI solutions, because processing platforms have become more accessible, affordable, and powerful. Although these solutions involving AI methods and algorithms are not novel, researchers can now truly benefit from their use, thanks to the emergence of cost-effective and high-performance hardware platforms. The use of other models, such as Linear Regression, k-Means, Random Forest, Stochastic Gradient Descent, Naïve Bayes, Fuzzy logic, Discrete Fourier Transformation, Quadratic Discriminant Analysis, and Extreme Gradient Boosting, also yielded results with an accuracy of over 80%, as reported by the authors. Some research works combined PCA with other techniques (i.e., SVN, LDA, PNN, KNN, k-Means) for the following reasons: (a) it reduces the number of features of the acquired data while retaining the most relevant information; (b) it helps filter out sensor noise and irrelevant variations in the data; (c) it pre-processes the data, which results in faster training times, better generalization, higher accuracy, especially when the raw sensor data are noisy or redundant; and (d) it reduces data to two or three dimensions, guiding researchers in the selection of the appropriate pattern recognition technique. In these cases, the performance metrics yield highly encouraging results. We can conclude that PCA acts as a smart pre-processing step that makes the data more manageable and informative for learning tasks.

Most proposed e-nose solutions lack support for the user-friendly visualization of the odor classification and the identification of the results. It is important to ensure that the analysis results are effectively communicated to end users in real time through software applications and easy-to-use graphical user interfaces.

Our in-depth analysis of the research studies also reveals that the developed e-nose systems do not target the achievement of high-performance measurement prototypes or products; rather, the authors focused on concept validation with their prototype systems. This is supported by the following conclusions:

- Cost: The sensors used in the experiments belong to the cheap components’ class, usually included in gas measurement systems, where their main feature is the detection of the presence of a certain gas component. Another characteristic of such systems is the low manufacturing cost. The documentation that comes with the sensors used is brief, containing little relevant information, omitting aspects like the manufacturer-recommended schematics, calibration and compensation methods depending on temperature and relative humidity values, or formulas for converting the voltage or resistance measured by the microcontroller back into the actual physical quantity measured by the sensor. In many cases, the datasheets do not include important characteristics such as precision, accuracy, repeatability, stability over time, or startup periods. Most sensors used are analog, and they do not integrate calibration circuits, drift, compensation or control mechanisms, or an ADC within the same package. As a result, their overall measurement performance is typically poor, and they are further affected by the required external electronics. The BME688 [] sensor used in [,] stands out in a positive way because it includes important circuitry besides the sensing element, which supports advanced functions such as filtering, signal conditioning, the ADC, the compensation table and algorithm, and digital communication with the processing unit, ESP32. The BME688 development kit uses eight sensors instead of one to form a sensor array, which enhances detection performance, especially for low-cost setups. Though calibrated, sensors differ slightly, and tracking signal trends over time across multiple sensors improve reliability. Additionally, free gas flow causes variations in individual sensor responses before steady state, making arrays beneficial.

- Power usage: The energy consumption required by the sensors used is high, and they are suitable for integration with systems powered permanently from the main power outlet. Sensors with heaters that are common in most studies have long response times, between 10 and 300 s, and operate at 200–400 °C. This leads to high power consumption unsuitable for portable devices and faster aging that requires frequent recalibrations. The recommended preheating time, or sensor warm-up time, until the first correct measurements can be extensively long, up to 2 to 7 days in some cases. The power consumed during measurement ranges from 0.3 to 1.0 W, and the continuous operation of the heating element in some sensors makes them unsuitable for use in portable electronic nose systems.

- Data collection: The data acquisition platforms are not designed for instrumentation systems. Most of the proposed solutions use low-resolution ADCs (10- or 12-bit), typically with a 0 to 5 V input range. This leads to an effective resolution per bit of 5 to 10 mV. Temperature and relative humidity compensation are generally based on low-accuracy T and RH sensors (±1 °C for temperature and ±4% for relative humidity), with a few exceptions. In platforms based on ESP32, measurement performance in terms of used digits is further limited by the built-in ADC, which typically offers an effective resolution of only 8 bits. Some proposed electronic nose systems utilize industrial-grade measurement platforms (i.e., PCI6035E, AD7606) and compensation sensors (sensors helping in adjusting the measurement depending on ambient parameters such as temperature, humidity, or pressure) for temperature and relative humidity (i.e., SHT15), which outperform those commonly used in standard gas detectors.

- Portability: Very few papers focus on low-power or portable systems. However, the question of whether a measurement system can be powered from the main outlet is a valid one. In this case, what are the time and logistical efforts required to make the system operational at a different location? For example, when considering the BME688 sensor, a system using it requires 30 min to reach maximum accuracy after power cycling. Other manufacturers do not specify this time requirement, but in some cases, it could require days.

- Data processing: Generally, the accuracy of measurement data is verified through thousands of hours of operation and repeated measurements, ideally conducted on multiple similar devices operating in parallel. Some past research solutions [,,,,,] used professional techniques (i.e., Gas Chromatography–Mass Spectrometry (GC–MS) []) to compare their experimental results with reference ones. In all the papers that we reviewed, the number of samples collected by the sensor arrays and used by the machine learning algorithms is rather small (<300 samples). In these conditions, expecting authors to validate their work with equipment that has been running for a full year is not feasible. This raises questions regarding the performance metrics obtained. To validate the results obtained, standard test/evaluation scenarios should be run, not just particular test sets created by the authors of the papers.

4.3. Food Analysis Based on Previously Developed/Commercial Electronic Nose Systems

Thirty-nine percent of the publications in the final set of selected publications present food and beverage quality assessment and quality monitoring solutions that integrate commercial e-noses or electronic nose systems developed by other research labs. The research works in this taxonomy category perform some sort data acquisition based on these devices, followed by, in the majority of cases, different data processing and prediction algorithms.

4.3.1. Commercial Electronic Nose Systems

Our analysis found that the most used commercial e-noses are PEN3 [] from Airsense Analytics Inc., Fox 3000 [] from Alpha MOS, Fox 4000 [] from Alpha MOS, FOODsniffer [], NeOse Pro [] from Aryballe Technologies, and Cyranose@ 320 [] produced by Sensigent. Table 7 summarizes their main characteristics, along with a few promising papers that employed them, considering aspects such as data analysis techniques, evaluation and performance metrics, and application domains.

Table 7.

Summary of commercial electronic nose systems for food quality and safety.

4.3.2. Electronic Noses Developed by Academic Research Groups

Our analysis reveals that several academic research groups developed electronic noses that other researchers later employed them in their own studies. For instance, research groups from the University of Rome Tor Vergata developed LibraNose [] and also other prototypes [,], very similar to LibraNose. Researchers from the Industrial Engineering School of the University of Extremadura, Spain, designed a low-cost, high-accurate electronic nose [], and those from the Institute of Agrophysics PAS in Lublin, Poland, created the Agrinose [] system. In the Department of Biosystems Engineering, Faculty of Agriculture, Bu-Ali Sina University, Hamedan, Iran, researchers designed an e-nose [] that has been successfully used in several studies regarding garlic quality assessment. Table 8 summarizes the main characteristics of these e-noses, along with a few promising papers that employed them, considering aspects such as data analysis techniques, evaluation and performance metrics, and application domains.

Table 8.

Summary of electronic noses developed by academic research groups for food quality and safety.

Lessons Learned

Numerous research studies use commercial electronic nose instruments, like those mentioned in Table 7, because of their user-friendly operation and dependable performance. These instruments allow researchers to save time, ensure consistent reliability, and focus on more advanced research questions. Additionally, commercial e-noses facilitate the generation of reproducible and comparable results, all without the need to navigate the challenges of developing custom hardware.

Our analysis highlights several ways in which the research community adopted commercial electronic noses, as follows:

- To apply well-known pattern recognition techniques to assess the quality and safety of different types of food: Studies such as [,,,,] used PEN3, Fox 3000, and Fox 4000 commercial electronic noses to apply algorithms such as PCA, Random Forest, and ANNs to evaluate the quality of various food categories (meat, fruits, jams, milk). In [,,], the researchers applied well-known pattern recognition techniques (PCA, PLS-DA, Partial Least Squares regression) to both e-nose data (PEN3, Fox 4000) and chromatography analysis results (GC–MS), leveraging the complementary strengths of these methods in chemical analysis and pattern recognition.

- To develop novel models or algorithms for odor identification and classification: Studies such as [,,,] used data collected from commercial electronic nose devices (PEN3, Cyranose@ 320) to develop novel data models for the identification and classification of odors, demonstrating strong performance.

- To confirm the ability of commercial e-noses to recognize and classify aromas: Studies such as [,] proved that the FOODsniffer e-nose can accurately classify meat based on its data analysis, with results validated against GC–MS analysis and physicochemical measurements. The authors of [] validated NeOse Pro to evaluate the quality of the plant-based beverage by applying PCA and LDA to the e-nose data and comparing the results with those obtained using the same algorithms on GC–MS data.

The previous classification also applies to electronic noses developed by research groups. Table 8 shows that the e-nose designed within the Department of Biosystems Engineering, Bu-Ali Sina University, can successfully assess the quality of garlic by applying well-known pattern recognition techniques (PCA, LDA, SMV, Backpropagation Neural Network) [], and the e-noses developed by the University of Rome Tor Vergata work well with PLS-DA, PCA, and LDA to identify bacteria in food and beverage [,,]. In [,,], researchers applied techniques such as PCA, Random Forest regression, PLS-DA, and Partial Least Squares to data collected from LibraNose and the e-nose developed by the Industrial Engineering School of the University of Extremadura to assess the quality of meat, roasted coffee, and almonds. The authors of these studies validated the obtained results using GC–MS and High Performance Liquid Chromatography. Studies [,,] used LibraNose data in the development of novel models or algorithms for meat quality assessment, while other studies [,] used Agrinose to implement models for the assessment of the suitability of bread for consumption after storage and to identify rapeseed spoilage. These last two studies validated their results by comparing them with those obtained from GC–MS and Fourier Transform Infrared Spectroscopy analysis.

During our analysis, we identified new sensors integrated into e-noses developed by research groups. Table 9 completes the list of sensors presented in Table 6 by including the new ones mentioned in Section 4.3.2 of this review.

Table 9.

Summary of gas sensors used in e-nose systems and their key features.

An in-depth analysis of the research studies reveals that these instruments can accurately detect certain types of food, but this does not necessarily imply they are suitable for detecting all food classes. The selection of such instruments should not be arbitrary; the selected sensors must be carefully evaluated based on the primary VOCs present in the target sample. Comparing the results obtained from using e-nose data and various algorithms with those from chromatography analyses, which are highly accurate in the identification of VOCs in food, serves to validate the findings. Chromatography provides precise, specific chemical data, but is time-consuming, expensive, and requires skilled operators. E-noses may be more advantageous over GC–MS in distinguishing the integral aroma profile, although they cannot identify the explicit VOCs of different samples. Combining e-noses data analysis with complementary technologies analysis, such as human sensory evaluation, GC–MS, or e-tongue to assess food quality can achieve high detection accuracy. However, this approach often involves significant time due to data fusion processes and incurs substantial costs.

Similar to the approaches analyzed in the first category of our taxonomy, those in the second category also focus on concept validation conducted at the laboratory level.

4.4. Gas Sensors for Electronic Nose Systems

In the final set of selected publications, we also found several research efforts that focus on the development of new gas sensors for the food industry. Table 10 summarizes the key results from the selected articles.

Table 10.

Summary of new gas sensors for the food industry.

Lessons Learned

Recent advancements in e-nose technologies demonstrate that sensor performance can be significantly improved through material innovation and system integration.

Surface and chemical modifications, such as those applied to Silicon NanoWires or graphene, enhance sensitivity and selectivity, which is critical for detecting specific analyses in complex environments. The use of advanced materials like graphene and graphene with Metal Phthalocyanines enables precise gas discrimination, expanding the applicability of e-noses in food quality and safety.

Bio-inspired approaches, particularly those mimicking the diversity of biological olfactory systems, show strong potential when combined with AI and machine learning for analyzing multi-dimensional VOCs data. Moreover, the integration of e-nose systems with compact, low-power computing architectures, such as memristor-based accelerators, addresses challenges in energy efficiency and real-time data processing, essential for portable devices.

Efforts toward miniaturization, including the use of Film Bulk Acoustic Resonator sensors and reference drift compensation, have made portable e-noses more viable for field deployment. Colorimetric and bioelectronic sensor innovations, leveraging either chemical complexes or olfactory receptors, offer energy-independent or ultra-sensitive detection, pushing the boundaries of low-resource and high-precision sensing.

These developments show that future e-nose systems will increasingly rely on the synergy of novel materials, bio-inspired sensing strategies, smart signal processing, and system-level integration to meet the demands of next-generation applications in food quality and safety assessment.

4.5. Food-Related Datasets and Algorithms/Techniques for Pattern Recognition Used on Them

Several publications in the final collection of articles emphasize the use of available food-related databases, which various algorithms/techniques for pattern recognition used. Table 11 summarizes the e-nose datasets and the related studies that utilized them, as well as the methods and performance metrics reported.

Table 11.

Summary of datasets used in e-nose research for food quality and safety.

Lesson Learned

Our analysis reveals the following results:

- Public datasets provide a valuable foundation for developing and testing new models or algorithms for odor identification and classification.

- Public datasets accelerate comparative research. The availability of well-structured datasets has enabled researchers to benchmark different models, promoting transparency and repeatability. As Table 11 shows, deep learning models outperform traditional classifiers in some cases. Additionally, approaches that combine multiple classifiers tend to boost accuracy and model stability. Such comparisons are possible because the researchers employed the same dataset.

- Diverse model strategies provide complementary insights. The use of a wide range of algorithms across datasets shows that no single approach performs best across all datasets and applications. Different algorithms excel under specific data characteristics and task requirements.

- Model performance is dataset dependent. Even if the authors of the cited research efforts reported high accuracies, these are heavily influenced by the specific dataset, number of classes, sensor types, and experimental conditions.

5. Research Gaps and Future Research Opportunities

Despite promising progress, a significant gap remains between lab scale e-nose prototypes and practical, market-ready solutions for food quality and safety monitoring. Current limitations include insufficient sensor sensitivity and stability, challenges in device miniaturization and portability, lack of standardized testing protocols, limited real-time processing capabilities, and lack of support for the user-friendly visualization of the odor classification and identification results. Furthermore, there is a lack of robust data fusion strategies and comprehensive odor reference datasets to support reliable decision making in diverse real-world scenarios.

To address these gaps, future research should focus on the following areas:

- Sensor technology: We must develop novel gas-sensitive materials with enhanced selectivity and sensitivity for food VOCs, new gas sensors with fast response time, adaptive calibration methods, and sensor baseline correction techniques to improve the stability of the gas sensors and integrate bio-inspired or biomimetic sensors.

- Data processing: We must implement deep learning algorithms for pattern recognition and VOC classification. We must develop and implement efficient multi-sensor (e-nose, e-tongue, e-eye) data fusion algorithms for a more holistic food profiling approach. Additionally, we must also develop standardized odor databases and reference libraries and real-time data analysis platforms for on-site decision making.

- Miniaturization and portability: We must integrate micro-electro-mechanical systems/ nano-electro-mechanical systems technology for compact and low-power devices. We must also develop reliable wireless and IoT-enabled e-noses for remote monitoring.

- Standardization: We must develop standardized testing protocols across different food types and storage conditions.

To consolidate the practical contributions of this review, Table 12 summarizes the key research gaps identified in current electronic nose applications and the corresponding solutions proposed in this work.

Table 12.

Summary of gaps and corresponding solutions in this work.

6. Conclusions

The application of electronic noses in the food industry has witnessed significant growth over the past decade, demonstrating considerable potential in monitoring food quality and safety, detecting spoilage, assessing freshness, and verifying food authenticity across a wide range of products, including meat, seafood, fruits and vegetables, spices, oils, dairy, and beverages. We arrive at this conclusion based on our analysis of more than 350 peer-reviewed documents retrieved from three scientific databases (Scopus, IEEE Xplore, WoS) using a targeted keyword search. This analysis followed a proposed taxonomy that categorized the publications into five distinct classes: (1) publications that present the development of new electronic noses; (2) publications that use commercially available or researcher-developed electronic noses, either alone or in combination with other techniques; (3) publications that introduce new/enhanced gas sensors or novel materials for the development of gas sensors; (4) publications that present the outcomes of applying existing algorithms or techniques for pattern recognition, or their fusion, on food-related datasets available online; and (5) review studies. Moreover, the analysis revealed that, despite notable progress, several challenges remain. E-nose systems still rely on general-purpose sensor arrays, limiting their adaptability to diverse types of food. In addition, issues related to sensor noise, drift, calibration, temperature, or modularization continue to hinder widespread industrial adoption. Moreover, while many studies report high classification accuracy, there is often a lack of standardization in methodologies/protocols for data pre-processing, feature selection, model deployment, and testing, along with limited application in real-world scenarios. Future research directions must focus on gas sensor technology, data processing, miniaturization and portability, and standardization.

Author Contributions

Conceptualization, T.S. and G.D.M.; methodology, T.S. and G.D.M.; investigation, T.S., G.D.M., T.C.R. and E.A.A.-S.; writing—original draft preparation, T.S., G.D.M., S.F. and T.C.R.; writing—review and editing, S.Z. and S.F.; supervision, S.Z. and S.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was achieved through the FoodNose project, ctr. no. 4/01.07.2024, funded by the Technical University of Cluj-Napoca through the GNaC ARUT 2023 Program.

Acknowledgments

We thank the anonymous reviewers for their valuable comments, which helped us improve the organization, content, and presentation of this paper.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ADC | analog-to-digital converters |

| ANNs | artificial neural networks |

| CNN | Convolutional Neural Network |

| CNT | carbon nanotube |

| CP | conducting polymer |

| GC–IMS | Gas Chromatography with Ion Mobility Spectrometry |

| GC–MS | Gas Chromatography–Mass Spectrometry |

| KNNs | k-nearest neighbors |

| LDA | linear discriminant analysis |

| LSTM | Long Short-Term Memory |

| MLP | Multilayer Perceptron |

| MOS | metal oxide semiconductor |

| MSE | Mean Squared Error (MSE) |

| PCA | principal component analysis |

| PIC | Programmable Interface Controller |

| PLS-DA | Partial Least Squares-Discriminant Analysis |

| PNN | Probabilistic Neural Network |

| PPM | Parts per Million |

| QCM | quartz crystal microbalance |

| R2 | R-squared |

| RMSE | Root Mean Square Error |

| SAW | surface acoustic wave |

| SVMs | support vector machines |

| SVR | Support Vector Machine Regression Technique |

| VOCs | volatile organic compounds |

| WoS | Web of Science |

References

- Wilkens, W.F.; Hartman, J.D. An electronic analog for the olfactory processes. Ann. N. Y. Acad. Sci. 1964, 116, 608–612. [Google Scholar] [CrossRef] [PubMed]

- Buck, T.; Allen, F.; Dalton, J. Detection of Chemical Species by Surface Effects on Metals and Semiconductors; Bell Telephone System Technical Publications; Bell Telephone Laboratories: Murray Hill, NJ, USA, 1965; Available online: https://books.google.ro/books?id=08s_mwEACAAJ (accessed on 7 July 2025).

- Dravnieks, A.; Trotter, P. Polar vapour detector based on thermal modulation of contact potential. J. Sci. Instruments 1965, 42, 624. [Google Scholar] [CrossRef]

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352–355. [Google Scholar] [CrossRef] [PubMed]

- Ikegami, A.; Kaneyasu, M. Olfactory detection using integrated sensors. Dig. Tech. Pap. Transducers 1985, 85, 136–139. [Google Scholar]

- Gardner, J.W.; Bartlett, P.N. A brief history of electronic noses. Sens. Actuators B Chem. 1994, 18, 210–211. [Google Scholar] [CrossRef]

- Yu, X.; Fu, L.; Wang, T.; Liu, Z.; Niu, N.; Chen, L. Multivariate chemical analysis: From sensors to sensor arrays. Chin. Chem. Lett. 2024, 35, 109167. [Google Scholar] [CrossRef]

- Freddi, S.; Sangaletti, L. Trends in the Development of Electronic Noses Based on Carbon Nanotubes Chemiresistors for Breathomics. Nanomaterials 2022, 12, 2992. [Google Scholar] [CrossRef] [PubMed]

- Furizal, F.; Ma’arif, A.; Firdaus, A.; Rahmaniar, W. Future Potential of E-Nose Technology: A Review. Int. J. Robot. Control Syst. 2023, 3, 449–469. [Google Scholar] [CrossRef]

- Goel, N.; Kunal, K.; Kushwaha, A.; Kumar, M. Metal oxide semiconductors for gas sensing. Eng. Rep. 2023, 5, e12604. [Google Scholar] [CrossRef]

- Luo, K.; Peng, H.; Zhang, B.; Chen, L.; Zhang, P.; Peng, Z.; Fu, X. Advances in carbon nanotube-based gas sensors: Exploring the path to the future. Coord. Chem. Rev. 2024, 518, 216049. [Google Scholar] [CrossRef]

- Abdel-Hakim, M.; Sayed, M.M. Conducting Polymers Sensor. In Handbook of Nanosensors: Materials and Technological Applications; Ali, G.A.M., Chong, K.F., Makhlouf, A.S.H., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 229–262. [Google Scholar] [CrossRef]

- Johannsmann, D.; Langhoff, A.; Leppin, C. Studying Soft Interfaces with Shear Waves: Principles and Applications of the Quartz Crystal Microbalance (QCM). Sensors 2021, 21, 3490. [Google Scholar] [CrossRef] [PubMed]

- Mandal, D.; Banerjee, S. Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications. Sensors 2022, 22, 820. [Google Scholar] [CrossRef] [PubMed]

- Williams, D.E. Electrochemical sensors for environmental gas analysis. Curr. Opin. Electrochem. 2020, 22, 145–153. [Google Scholar] [CrossRef]

- Mishra, V.; Rashmi, R.; Khera, S. Optical Gas Sensors; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Salaün, A.C.; Le Bihan, F.; Pichon, L. Field Effect Transistor Technologies for Biological and Chemical Sensors. In Smart Sensors for Environmental and Medical Applications; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2020; Chapter 2; pp. 11–41. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Z.; Chan, C.L.J.; Wan, Z.A.; Ye, W.; Tang, W.; Ma, Z.; Ren, B.; Zhang, D.; Song, Z.; et al. Biomimetic olfactory chips based on large-scale monolithically integrated nanotube sensor arrays. Nat. Electron. 2024, 7, 157–167. [Google Scholar] [CrossRef]

- Balasurya, S.; Kokilavani, S.; Janani, B.; Sudheer Khan, S. 5–Recent advances in bioelectronic noses based on olfactory receptors. In Nanotechnology-Based E-Noses; Gupta, R.K., Nguyen, T.A., Bilal, M., Ahmadi, M., Eds.; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Sawston, UK, 2023; pp. 125–141. [Google Scholar] [CrossRef]

- Jolliffe, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef] [PubMed]

- Xanthopoulos, P.; Pardalos, P.M.; Trafalis, T.B. Linear Discriminant Analysis. In Robust Data Mining; Springer: New York, NY, USA, 2013; pp. 27–33. [Google Scholar] [CrossRef]

- Walczak, S.; Cerpa, N. Artificial Neural Networks. In Encyclopedia of Physical Science and Technology, 3rd ed.; Meyers, R.A., Ed.; Academic Press: New York, NY, USA, 2003; pp. 631–645. [Google Scholar] [CrossRef]

- Wang, L. Support Vector Machines: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Zhang, Z. Introduction to machine learning: K-nearest neighbors. Ann. Transl. Med. 2016, 4, 218. [Google Scholar] [CrossRef] [PubMed]

- Borowik, P.; Grzywacz, T.; Tarakowski, R.; Tkaczyk, M.; Ślusarski, S.; Dyshko, V.; Oszako, T. Development of a Low-Cost Electronic Nose with an Open Sensor Chamber: Application to Detection of Ciboria batschiana. Sensors 2023, 23, 627. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Z.; Liu, Y.; Li, C.; Wang, D.; Wu, H. Electronic Noses: From Gas-Sensitive Components and Practical Applications to Data Processing. Sensors 2024, 24, 4806. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, Z.; Zhao, T.; Li, H.; Jiang, J.; Ye, J. Electronic nose for the detection and discrimination of volatile organic compounds: Application, challenges, and perspectives. TrAC Trends Anal. Chem. 2024, 180, 117958. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y. Electronic nose and its application in the food industry: A review. Eur. Food Res. Technol. 2024, 250, 21–67. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, Y.; Zhang, B.; Upadhyay, A.; Xiao, Z.; Luo, Y. Machine learning-supported sensor array for multiplexed foodborne pathogenic bacteria detection and identification. Trends Food Sci. Technol. 2024, 154, 104787. [Google Scholar] [CrossRef]

- Ali, A.; Mansol, A.S.; Khan, A.A.; Muthoosamy, K.; Siddiqui, Y. Electronic nose as a tool for early detection of diseases and quality monitoring in fresh postharvest produce: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2023, 22, 2408–2432. [Google Scholar] [CrossRef] [PubMed]

- Roy, M.; Yadav, B. Electronic nose for detection of food adulteration: A review. J. Food Sci. Technol. 2022, 59, 846–858. [Google Scholar] [CrossRef] [PubMed]

- Al-Dayyeni, W.S.; Al-Yousif, S.; Taher, M.M.; Al-Faouri, A.W.; Tahir, N.M.; Jaber, M.M.; Ghabban, F.; Najm, I.A.; Alfadli, I.M.; Ameerbakhsh, O.Z.; et al. A Review on Electronic Nose: Coherent Taxonomy, Classification, Motivations, Challenges, Recommendations and Datasets. IEEE Access 2021, 9, 88535–88551. [Google Scholar] [CrossRef]

- Mohd Ali, M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci. Technol. 2020, 99, 1–10. [Google Scholar] [CrossRef]

- Bonah, E.; Huang, X.; Aheto, J.H.; Osae, R. Application of electronic nose as a non-invasive technique for odor fingerprinting and detection of bacterial foodborne pathogens: A review. J. Food Sci. Technol. 2020, 57, 1977–1990. [Google Scholar] [CrossRef] [PubMed]

- Sanaeifar, A.; ZakiDizaji, H.; Jafari, A.; de la Guardia, M. Early detection of contamination and defect in foodstuffs by electronic nose: A review. TrAC Trends Anal. Chem. 2017, 97, 257–271. [Google Scholar] [CrossRef]

- Gliszczyńska-Świgło, A.; Chmielewski, J. Electronic Nose as a Tool for Monitoring the Authenticity of Food. A Review. Food Anal. Methods 2017, 10, 1800–1816. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Sun, X.; Wang, S.; Jia, W. Research Progress of Electronic Nose and Near-Infrared Spectroscopy in Meat Adulteration Detection. Chemosensors 2024, 12, 35. [Google Scholar] [CrossRef]

- Khaled, A.Y.; Parrish, C.A.; Adedeji, A. Emerging Nondestructive Approaches for Meat Quality and Safety Evaluation—A Review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3438–3463. [Google Scholar] [CrossRef] [PubMed]

- Zaukuu, J.L.Z.; Bazar, G.; Gillay, Z.; Kovacs, Z. Emerging trends of advanced sensor based instruments for meat, poultry and fish quality—A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 3443–3460. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Liang, G.; Wang, Y.; Wang, J. Electronic Noses as a Powerful Tool for Assessing Meat Quality: A Mini Review. Food Anal. Methods 2018, 11, 2916–2924. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Mujumdar, A.S.; Yu, D. Advanced Detection Techniques Using Artificial Intelligence in Processing of Berries. Food Eng. Rev. 2022, 14, 176–199. [Google Scholar] [CrossRef]

- Modesti, M.; Taglieri, I.; Bianchi, A.; Tonacci, A.; Sansone, F.; Bellincontro, A.; Venturi, F.; Sanmartin, C. E-Nose and Olfactory Assessment: Teamwork or a Challenge to the Last Data? The Case of Virgin Olive Oil Stability and Shelf Life. Appl. Sci. 2021, 11, 8453. [Google Scholar] [CrossRef]

- Majchrzak, T.; Wojnowski, W.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic noses in classification and quality control of edible oils: A review. Food Chem. 2018, 246, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Osmólska, E.; Stoma, M.; Starek-Wójcicka, A. Juice Quality Evaluation with Multisensor Systems—A Review. Sensors 2023, 23, 4824. [Google Scholar] [CrossRef] [PubMed]

- Nagraik, R.; Sharma, A.; Kumar, D.; Chawla, P.; Kumar, A.P. Milk adulterant detection: Conventional and biosensor based approaches: A review. Sens. Bio-Sens. Res. 2021, 33, 100433. [Google Scholar] [CrossRef]

- Yakubu, H.G.; Kovacs, Z.; Toth, T.; and, G.B. Trends in artificial aroma sensing by means of electronic nose technologies to advance dairy production—A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 234–248. [Google Scholar] [CrossRef] [PubMed]

- Kaushal, S.; Nayi, P.; Rahadian, D.; Chen, H.H. Applications of Electronic Nose Coupled with Statistical and Intelligent Pattern Recognition Techniques for Monitoring Tea Quality: A Review. Agriculture 2022, 12, 1359. [Google Scholar] [CrossRef]

- Alfieri, G.; Modesti, M.; Riggi, R.; Bellincontro, A. Recent Advances and Future Perspectives in the E-Nose Technologies Addressed to the Wine Industry. Sensors 2024, 24, 2293. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Méndez, M.L.; De Saja, J.A.; González-Antón, R.; García-Hernández, C.; Medina-Plaza, C.; García-Cabezón, C.; Martín-Pedrosa, F. Electronic Noses and Tongues in Wine Industry. Front. Bioeng. Biotechnol. 2016, 4, 81. [Google Scholar] [CrossRef] [PubMed]

- Shuba, A.; Umarkhanov, R.; Bogdanova, E.; Anokhina, E.; Burakova, I. Possibilities of an Electronic Nose on Piezoelectric Sensors with Polycomposite Coatings to Investigate the Microbiological Indicators of Milk. Sensors 2024, 24, 3634. [Google Scholar] [CrossRef] [PubMed]

- Nemufulwi, M.I.; Swart, H.C.; Mhlongo, G.H. Advances of Nano-Enabled ZnFe2O4 Based-Gas Sensors for VOC Detection and Their Potential Applications: A Review. Processes 2023, 11, 3122. [Google Scholar] [CrossRef]

- Kumar, A.; Castro, M.; Feller, J.F. Review on Sensor Array-Based Analytical Technologies for Quality Control of Food and Beverages. Sensors 2023, 23, 4017. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Debliquy, M.; Zhang, C. Metal–oxide–semiconductor resistive gas sensors for fish freshness detection. Compr. Rev. Food Sci. Food Saf. 2023, 22, 913–945. [Google Scholar] [CrossRef] [PubMed]

- Chia, M.R.; Phang, S.W.; Ahmad, I. Emerging Applications of Versatile Polyaniline-Based Polymers in the Food Industry. Polymers 2022, 14, 5168. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Chan-Park, M.B.; Wang, M. Functional Polymers and Polymer–Dye Composites for Food Sensing. Macromol. Rapid Commun. 2020, 41, 2000279. [Google Scholar] [CrossRef] [PubMed]

- He, S.; Yuan, Y.; Nag, A.; Feng, S.; Afsarimanesh, N.; Han, T.; Mukhopadhyay, S.C.; Organ, D.R. A Review on the Use of Impedimetric Sensors for the Inspection of Food Quality. Int. J. Environ. Res. Public Health 2020, 17, 5220. [Google Scholar] [CrossRef] [PubMed]

- Ponzoni, A.; Baratto, C.; Cattabiani, N.; Falasconi, M.; Galstyan, V.; Nunez-Carmona, E.; Rigoni, F.; Sberveglieri, V.; Zambotti, G.; Zappa, D. Metal Oxide Gas Sensors, a Survey of Selectivity Issues Addressed at the SENSOR Lab, Brescia (Italy). Sensors 2017, 17, 714. [Google Scholar] [CrossRef] [PubMed]

- Ji, H.; Pu, D.; Yan, W.; Zhang, Q.; Zuo, M.; Zhang, Y. Recent advances and application of machine learning in food flavor prediction and regulation. Trends Food Sci. Technol. 2023, 138, 738–751. [Google Scholar] [CrossRef]

- Lin, Y.; Ma, J.; Wang, Q.; Sun, D.W. Applications of Machine Learning Techniques for Enhancing Nondestructive Food Quality and Safety Detection. Crit. Rev. Food Sci. Nutr. 2023, 63, 1649–1669. [Google Scholar] [CrossRef] [PubMed]

- Salehi, F. Recent Advances in the Modeling and Predicting Quality Parameters of Fruits and Vegetables during Postharvest Storage: A Review. Int. J. Fruit Sci. 2020, 20, 506–520. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, M.; Mujumdar, A.S. Recent developments of artificial intelligence in drying of fresh food: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2258–2275. [Google Scholar] [CrossRef] [PubMed]

- Gil, M.; Rudy, M.; Duma-Kocan, P.; Stanisławczyk, R. Electronic Sensing Technologies in Food Quality Assessment: A Comprehensive Literature Review. Appl. Sci. 2025, 15, 1530. [Google Scholar] [CrossRef]

- Tibaduiza, D.; Anaya, M.; Gómez, J.; Sarmiento, J.; Perez, M.; Lara, C.; Ruiz, J.; Osorio, N.; Rodriguez, K.; Hernandez, I.; et al. Electronic Tongues and Noses: A General Overview. Biosensors 2024, 14, 190. [Google Scholar] [CrossRef] [PubMed]

- Grassi, S.; Benedetti, S.; Casiraghi, E.; Buratti, S. E-sensing systems for shelf life evaluation: A review on applications to fresh food of animal origin. Food Packag. Shelf Life 2023, 40, 101221. [Google Scholar] [CrossRef]

- Poeta, E.; Liboà, A.; Mistrali, S.; Núñez-Carmona, E.; Sberveglieri, V. Nanotechnology and E-Sensing for Food Chain Quality and Safety. Sensors 2023, 23, 8429. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Hu, Z.; Hu, X.; Li, D.; Tian, S. Electronic tongue and electronic nose for food quality and safety. Food Res. Int. 2022, 162, 112214. [Google Scholar] [CrossRef] [PubMed]

- Modesti, M.; Tonacci, A.; Sansone, F.; Billeci, L.; Bellincontro, A.; Cacopardo, G.; Sanmartin, C.; Taglieri, I.; Venturi, F. E-Senses, Panel Tests and Wearable Sensors: A Teamwork for Food Quality Assessment and Prediction of Consumer’s Choices. Chemosensors 2022, 10, 244. [Google Scholar] [CrossRef]

- Calvini, R.; Pigani, L. Toward the Development of Combined Artificial Sensing Systems for Food Quality Evaluation: A Review on the Application of Data Fusion of Electronic Noses, Electronic Tongues and Electronic Eyes. Sensors 2022, 22, 577. [Google Scholar] [CrossRef] [PubMed]

- Aouadi, B.; Zaukuu, J.L.Z.; Vitális, F.; Bodor, Z.; Fehér, O.; Gillay, Z.; Bazar, G.; Kovacs, Z. Historical Evolution and Food Control Achievements of Near Infrared Spectroscopy, Electronic Nose, and Electronic Tongue—Critical Overview. Sensors 2020, 20, 5479. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Son, M.; Park, T.H. The bioelectronic nose and tongue using olfactory and taste receptors: Analytical tools for food quality and safety assessment. Biotechnol. Adv. 2018, 36, 371–379. [Google Scholar] [CrossRef] [PubMed]

- Peris, M.; Escuder-Gilabert, L. Electronic noses and tongues to assess food authenticity and adulteration. Trends Food Sci. Technol. 2016, 58, 40–54. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Jiang, Q.; Mujumdar, A.S. Intelligent System/Equipment for Quality Deterioration Detection of Fresh Food: Recent Advances and Application. Foods 2024, 13, 1662. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Jiang, H.; Adade, S.Y.S.S.; Kang, W.; Xue, Z.; Zareef, M.; and, Q.C. Overview of advanced technologies for volatile organic compounds measurement in food quality and safety. Crit. Rev. Food Sci. Nutr. 2023, 63, 8226–8248. [Google Scholar] [CrossRef] [PubMed]

- Amalia, A.; Rivai, M.; Purwanto, D. Indoor Beef Quality Identification Using Gas Sensor Array and Probabilistic Neural Network Method. In Proceedings of the 2024 IEEE International Conference on Artificial Intelligence and Mechatronics Systems (AIMS), Virtual, 22–23 February 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Hanwei Electronics Co., Ltd. MQ Series Gas Sensors. Available online: https://www.hwsensor.com/ (accessed on 14 March 2025).

- Figaro Engineering Inc. TGS Series Gas Sensors. Available online: https://www.figaro.co.jp/en/product/sensor/ (accessed on 14 March 2025).

- Mohebali, B.; Tahmassebi, A.; Meyer-Baese, A.; Gandomi, A.H. Chapter 14–Probabilistic neural networks: A brief overview of theory, implementation, and application. In Handbook of Probabilistic Models; Samui, P., Tien Bui, D., Chakraborty, S., Deo, R.C., Eds.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 347–367. [Google Scholar] [CrossRef]

- Damdam, A.N.; Ozay, L.O.; Ozcan, C.K.; Alzahrani, A.; Helabi, R.; Salama, K.N. IoT-Enabled Electronic Nose System for Beef Quality Monitoring and Spoilage Detection. Foods 2023, 12, 2227. [Google Scholar] [CrossRef] [PubMed]

- Aosong Electronics Co., Ltd. AM2302 (DHT22) Temperature and Humidity Sensor. Available online: https://cdn.sparkfun.com/assets/f/7/d/9/c/DHT22.pdf (accessed on 14 March 2025).

- Winsen Electronics Technology Co., Ltd. MH-Z19C–NDIR CO2 Sensor Module. Available online: https://www.winsen-sensor.com/sensors/co2-sensor/mh-z19c.html (accessed on 14 March 2025).

- Winsen Electronics Technology Co., Ltd. Electrochemical Gas Detection Module. User’s Manual V2.8. Model: ZE03. Available online: https://www.winsen-sensor.com/d/files/ze03-electrochemical-module-manualv2_8(3).pdf (accessed on 14 March 2025).

- Espressif Systems. ESP32-S3–Wi-Fi and Bluetooth Microcontroller. Available online: https://www.espressif.com/en/products/socs/esp32-s3 (accessed on 14 March 2025).

- Draper, N.R.; Smith, H. Applied Regression Analysis, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- Mada Sanjaya, W.S.; Roziqin, A.; Purnama Sari, N.A.M.; Sintia, P.; Alamsyah, F.; Putra, T.F.; Taqwim, A.; Mubasyir, F.H.; Temiesela, A.W.; Zaman, M.F.B.; et al. Chicken Meat Freshness Evaluation using Support Vector Machine Method and Raspberry Pi 4 based Electronic Nose. In Proceedings of the 2023 IEEE 9th Information Technology International Seminar (ITIS), Batu Malang, Indonesia, 18–20 October 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Arduino. Arduino Mega 2560 Rev3–Microcontroller Board. Available online: https://docs.arduino.cc/hardware/mega-2560/?_gl=1*11yinyr*_up*MQ..*_ga*MTQyNTM5MTk0NC4xNzQyMTI2Mzk4*_ga_NEXN8H46L5*MTc0MjEyNjM5Ni4xLjAuMTc0MjEyNjM5Ni4wLjAuMjAwODkwNTQ4NQ (accessed on 14 March 2025).

- The Raspberry Pi Foundation. Raspberry Pi 4 Model B–Single Board Computer. Available online: https://www.raspberrypi.com/products/raspberry-pi-4-model-b/ (accessed on 14 March 2025).

- Anwar, H.; Anwar, T. Quality assessment of chicken using machine learning and electronic nose. Sens. Bio-Sens. Res. 2025, 47, 100739. [Google Scholar] [CrossRef]

- Kuongshun Electronic, Ltd. DHT22/AM2302 Digital Temperature Humidity Sensor. Available online: https://www.kuongshun-ks.com/uno/uno-sensor/dht22-am2302-digital-temperature-humidity-sensor.html (accessed on 14 March 2025).

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Ren, X.; Wang, Y.; Huang, Y.; Sun, D.; Xu, L.; Wu, F. E-nose System using CNN and Abstract Odor Map to Classify Meat Freshness. In Proceedings of the 2023 IEEE 6th Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 24–26 February 2023; Volume 6, pp. 1200–1204. [Google Scholar] [CrossRef]

- Hefei Micro Nano Sensing Technology Co., Ltd. HGS1000, HGS1001, HGS1002 MEMS Gas Sensors. Available online: https://www.pilotagemicrosystem.com/ (accessed on 14 March 2025).

- O’Shea, K.; Nash, R. An Introduction to Convolutional Neural Networks. arXiv 2015. [Google Scholar] [CrossRef]

- Li, L.; Wu, Y.; Ou, Y.; Li, Q.; Zhou, Y.; Chen, D. Research on machine learning algorithms and feature extraction for time series. In Proceedings of the 2017 IEEE 28th Annual International Symposium on Personal, Indoor, and Mobile Radio Communications (PIMRC), Montreal, QC, Canada, 8–13 October 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Laga, S.A.; Sarno, R. Optimal Sample Temperature of Electronic Nose For Detecting Beef and Pork Mixture. In Proceedings of the 2019 International Conference on Information and Communications Technology (ICOIACT), Yogyakarta, Indonesia, 24–25 July 2019; pp. 398–402. [Google Scholar] [CrossRef]

- Zakaria, E.; Wijaya, D.R.; Gunawan, T. Predicting Microbial Populations in Seafood using Support Vector Regression Algorithms and Electronic Nose. In Proceedings of the 2023 International Conference on Artificial Intelligence Robotics, Signal and Image Processing (AIRoSIP), Yogyakarta, Indonesia, 9–10 August 2023; pp. 280–284. [Google Scholar] [CrossRef]

- Drucker, H.; Burges, C.J.C.; Kaufman, L.; Smola, A.; Vapnik, V. Support Vector Regression Machines. Adv. Neural Inf. Process. Syst. (NIPS) 1997, 9, 155–161. Available online: https://proceedings.neurips.cc/paper_files/paper/1996/file/d38901788c533e8286cb6400b40b386d-Paper.pdf (accessed on 16 March 2025).

- Wang, X.; Yu, G.; Liu, R.P.; Zhang, J.; Wu, Q.; Su, S.W.; He, Y.; Zhang, Z.; Yu, L.; Liu, T.; et al. Blockchain-Enabled Fish Provenance and Quality Tracking System. IEEE Internet Things J. 2022, 9, 8130–8142. [Google Scholar] [CrossRef]

- Hermawan, L.M.; Novamizanti, L.; Wijaya, D.R. Crab Quality Detection with Gas Sensors Using a Machine Learning. In Proceedings of the 2024 IEEE International Conference on Internet of Things and Intelligence Systems (IoTaIS), Bali, Indonesia, 28–30 November 2024; pp. 270–275. [Google Scholar] [CrossRef]

- Duda, R.O.; Hart, P.E. Pattern Classification and Scene Analysis; John Wiley & Sons: New York, NY, USA, 1973. [Google Scholar] [CrossRef]

- Astuti, S.D.; Isyrofie, A.I.F.A.; Nashichah, R.; Kashif, M.; Mujiwati, T.; Susilo, Y.; Winarno.; Syahrom, A. Gas Array Sensors based on Electronic Nose for Detection of Tuna (Euthynnus Affinis) Contaminated by Pseudomonas aeruginosa. J. Med. Signals Sens. 2022, 12, 306–316. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Ning, J.; Mei, Z.; Chen, J.; Gao, Y.; Yi, X.; Wu, P. Development of food electronic nose for prawn (macrobrachium rosenbergii) quality rapid assessment and their relationship with the physicochemical index. Int. J. Food Prop. 2021, 24, 346–353. [Google Scholar] [CrossRef]

- Padilla, D.A.; Krystine, D.; Anticuando, M.; Directo, C.K.R. An Electronic Nose Approach in Identifying Ripe Tomato Fruit Using LeNet-5 Structure. In Proceedings of the 2024 7th International Conference on Information and Computer Technologies (ICICT), Honolulu, HI, USA, 15–17 March 2024; pp. 223–227. [Google Scholar] [CrossRef]

- Anticuando, M.K.D.; Directo, C.K.R.; Padilla, D.A. Electronic Nose and Deep Learning Approach in Identifying Ripe Lycopersicum esculentum L. TomatoFruit. In Proceedings of the 2022 13th International Conference on Computing Communication and Networking Technologies (ICCCNT), Kharagpur, India, 3–5 October 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Affognon, L.; Diallo, A.; Diallo, C.; Ezin, E.C. Supervised Learning Models for Tomato Quality Prediction Using Electronic Nose Data. In Proceedings of the 2023 International Conference on Electrical, Computer and Energy Technologies (ICECET), Cape Town, South Africa, 16–17 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Concepcion, R.S.; Sybingco, E.; Lauguico, S.C.; Dadios, E.P. Implementation of Multilayer Perceptron Neural Network on Quality Assessment of Tomato Puree in Aerobic Storage using Electronic Nose. In Proceedings of the 2019 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), Bangkok, Thailand, 18–20 November 2019; pp. 65–70. [Google Scholar] [CrossRef]

- Concepcion, R.S.; Bandala, A.A.; Bedruz, R.A.R.; Dadios, E.P. Fuzzy Classification Approach on Quality Deterioration Assessment of Tomato Puree in Aerobic Storage using Electronic Nose. In Proceedings of the 2019 IEEE 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Laoag, Philippines, 29 November–1 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- e Gizmo Mechatronix Central. Gizduino: Arduino Compatible Kit. 2011. Available online: https://www.e-gizmo.net/oc/kits%20documents/Gizduino/Gizduino%20manual.pdf (accessed on 16 March 2025).

- Yen, J. Fuzzy logic-a modern perspective. IEEE Trans. Knowl. Data Eng. 1999, 11, 153–165. [Google Scholar] [CrossRef]

- Ebenezer L, B.; A, S.; Baskar, C. Freshness Monitoring of Broccoli Using Intelligent Electronic Nose Systems for Sustainability in Food Supply Chains. In Proceedings of the 2024 International Conference on Smart Electronics and Communication Systems (ISENSE), Kottayam, India, 6–7 December 2024; pp. 1–6. [Google Scholar] [CrossRef]

- van der Maaten, L.; Hinton, G. Visualizing Data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. Available online: http://jmlr.org/papers/v9/vandermaaten08a.html (accessed on 16 March 2025).

- MacQueen, J.B. Some Methods for Classification and Analysis of Multivariate Observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability; University of California Press: Berkeley, CA, USA, 1967; Volume 1, pp. 281–297. Available online: https://projecteuclid.org/euclid.bsmsp/1200512992 (accessed on 16 March 2025).

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Ezhilan, M.; Nesakumar, N.; Babu, K.J.; Srinandan, C.; Rayappan, J.B.B. Freshness Assessment of Broccoli using Electronic Nose. Measurement 2019, 145, 735–743. [Google Scholar] [CrossRef]

- Microchip Technology Inc. ATmega8. Available online: https://www.microchip.com/en-us/product/atmega8 (accessed on 18 March 2025).

- Rana, S.; Bisht, Y.; Tyagi, G.; Badoni, A. FruitfulInsight: IOT and ML-Based System to Predict Expiry of Fruits. In Proceedings of the 2024 2nd International Conference on Device Intelligence, Computing and Communication Technologies (DICCT), Dehradun, India, 15–16 March 2024; pp. 148–153. [Google Scholar] [CrossRef]