Numerical Study of Bubble Breakup in Fractal Tree-Shaped Microchannels

Abstract

:1. Introduction

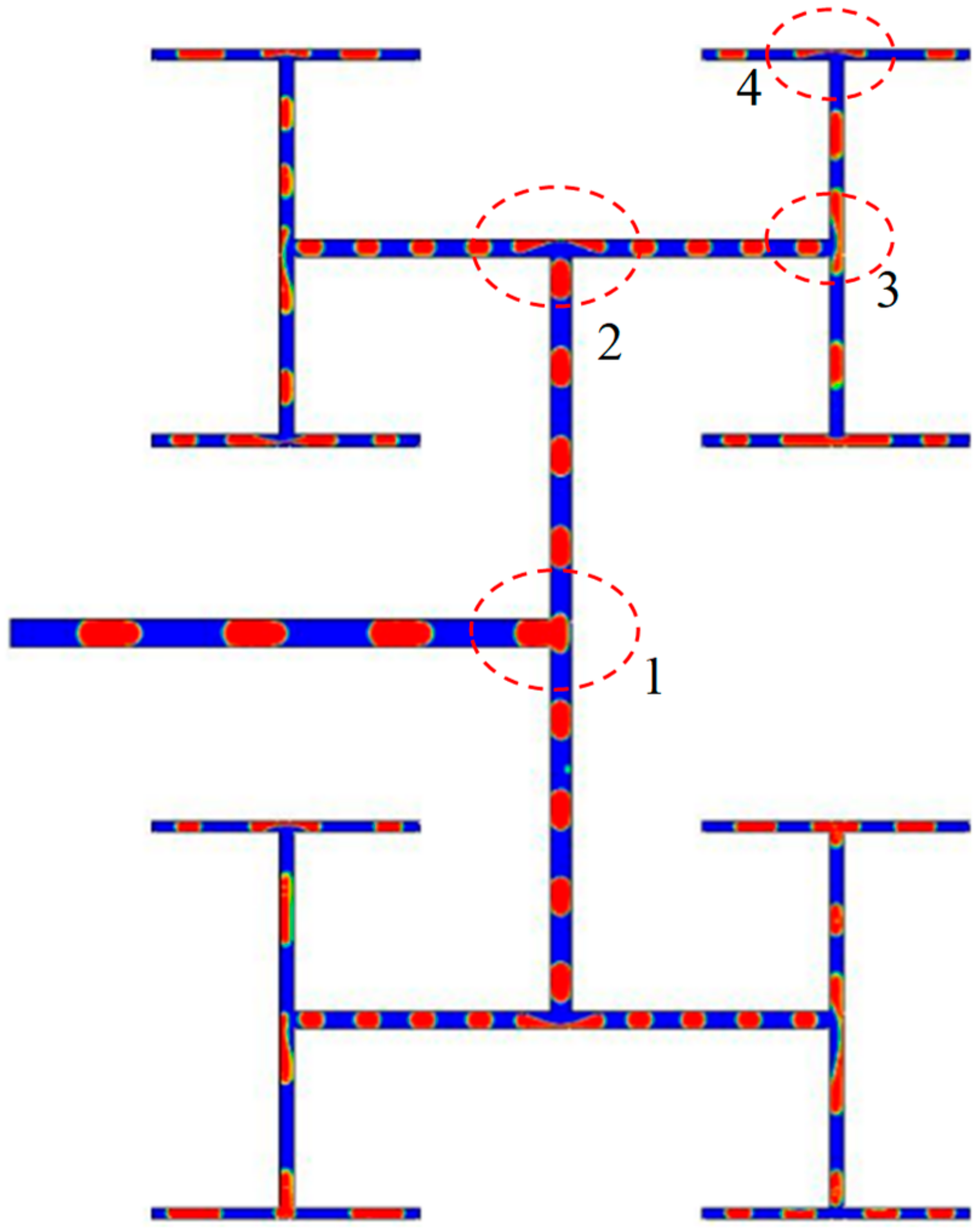

2. Results and Discussions

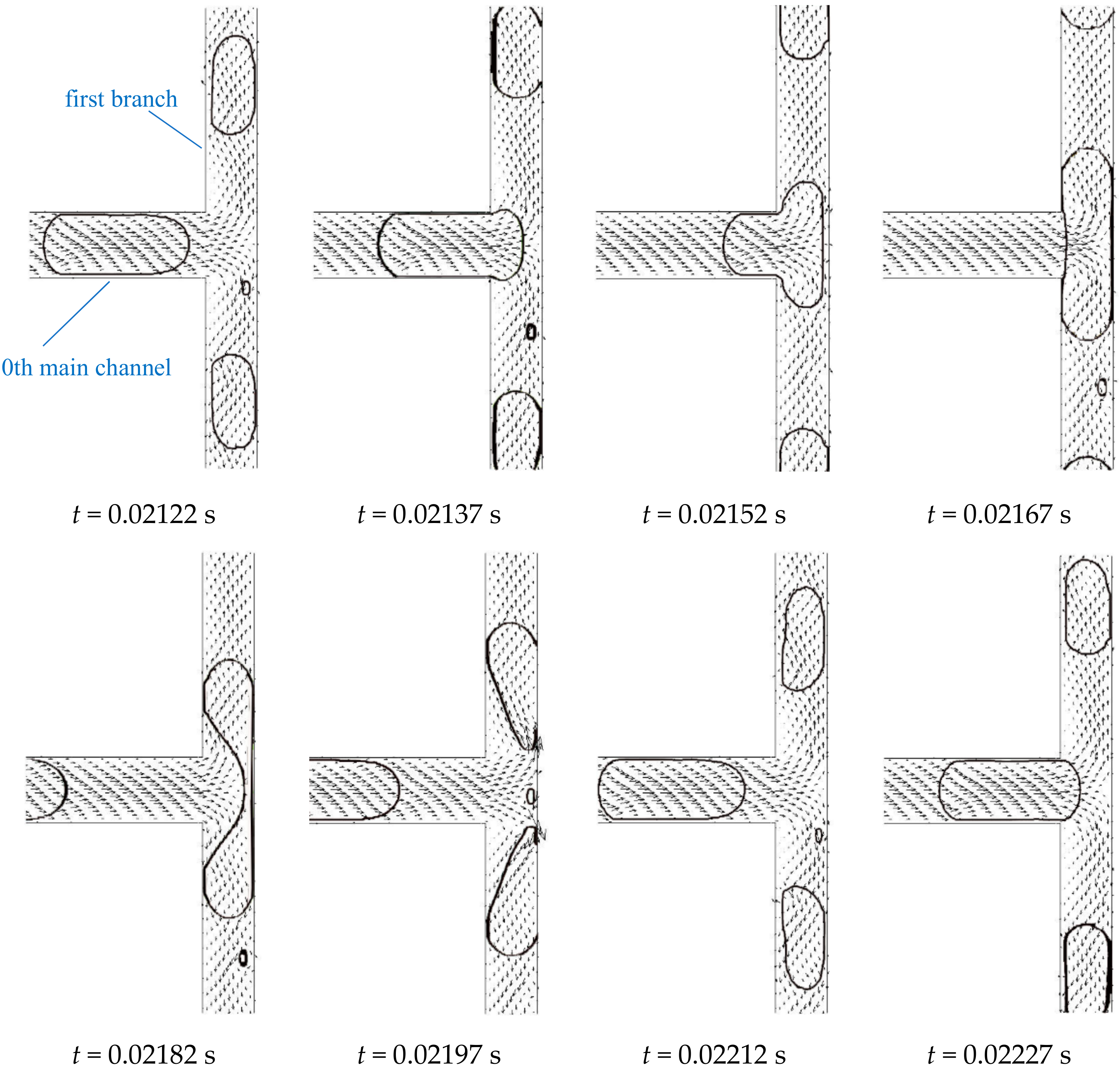

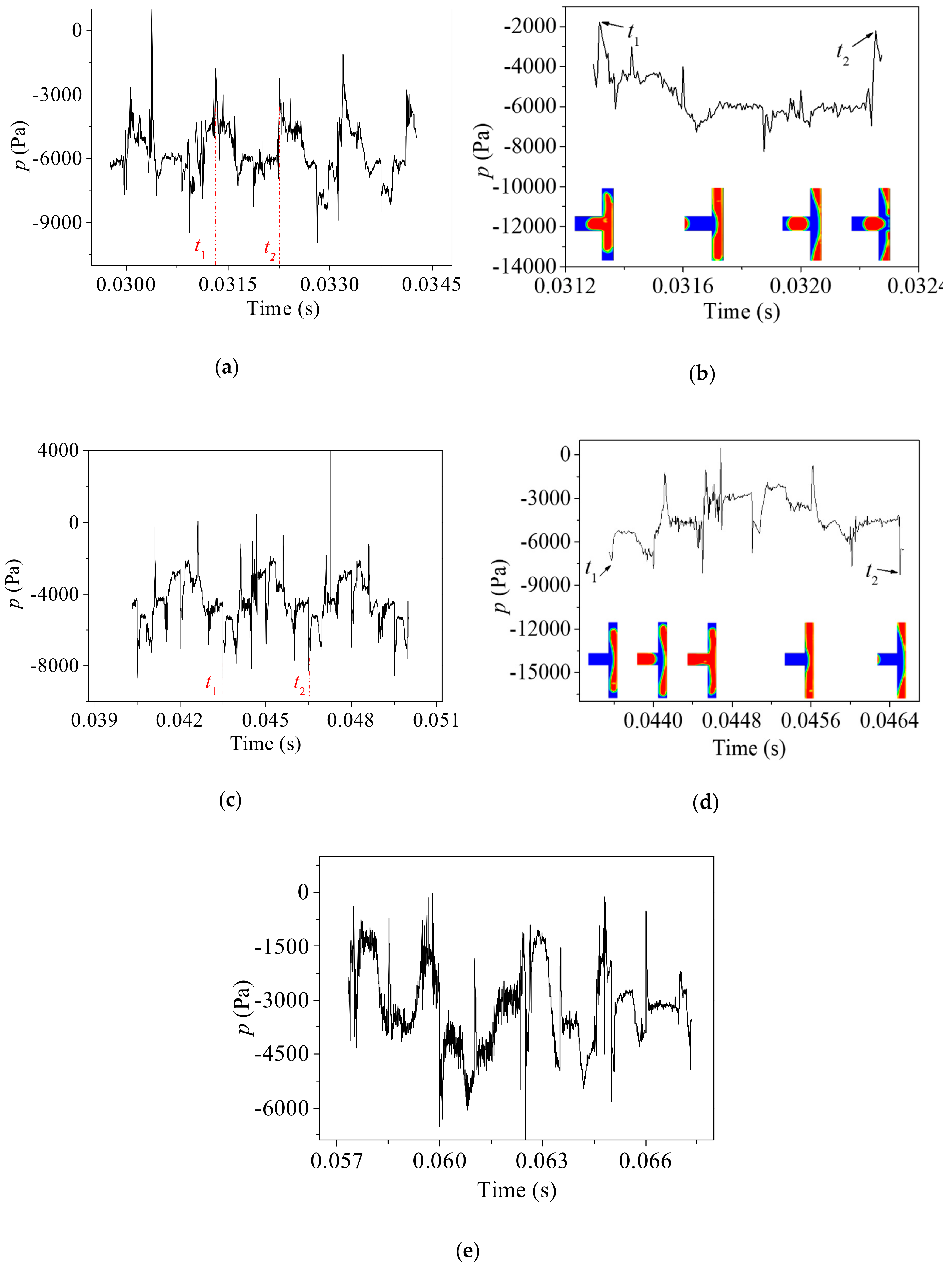

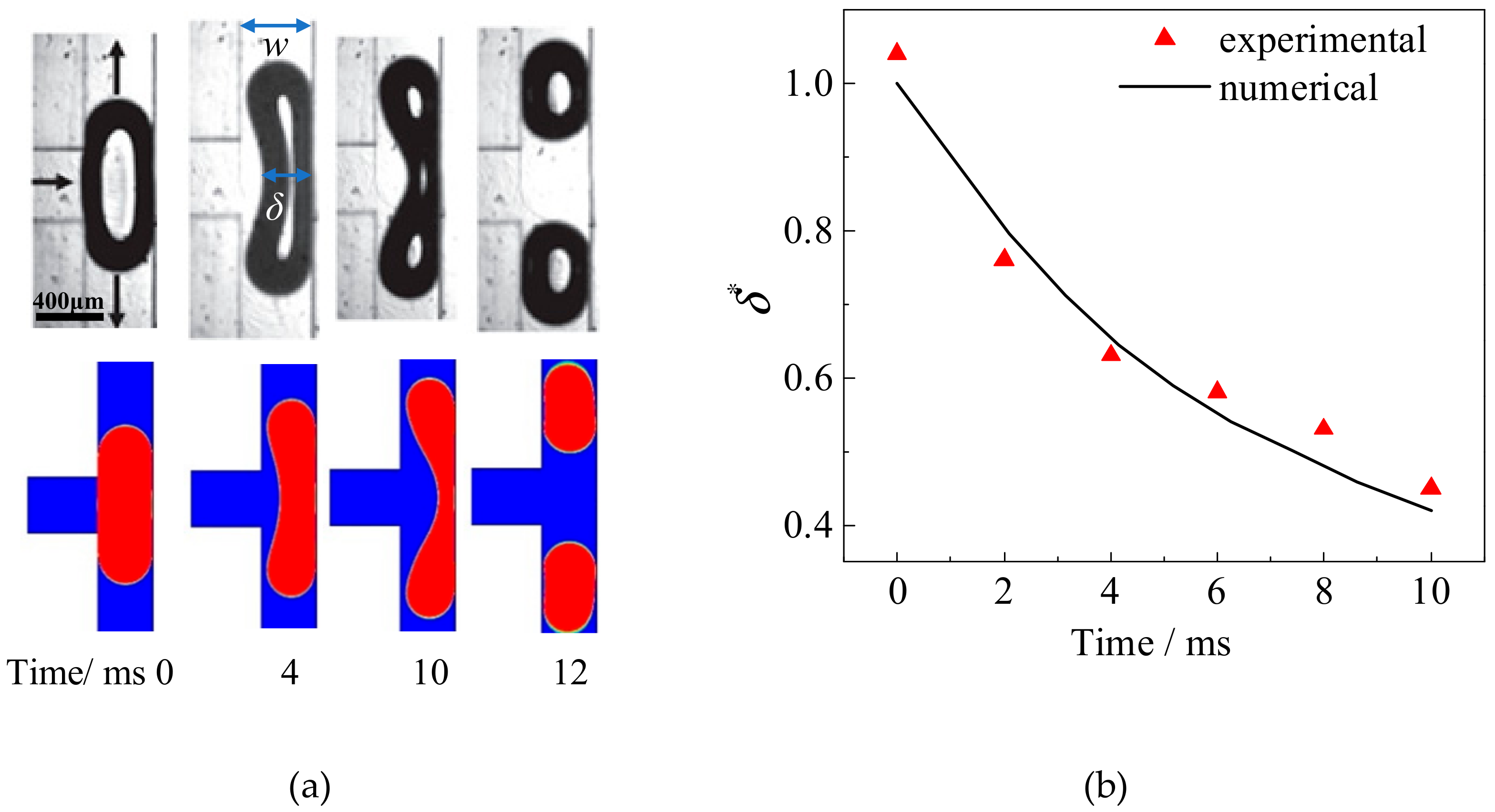

2.1. Obstructed Breakup at the First Bifurcation

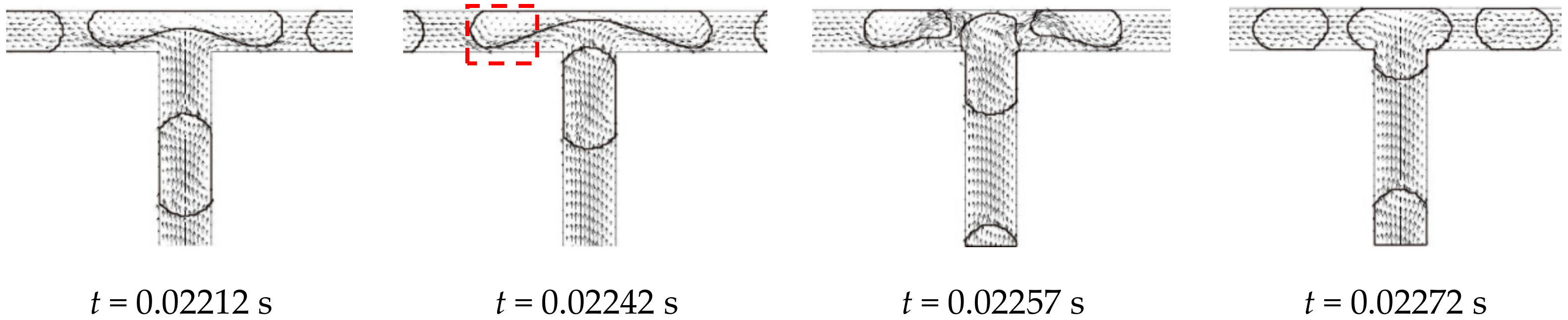

2.2. Obstructed-Tunnel Combined Breakup at the Second Bifurcation

2.3. Coalesced Breakup at the Third Bifurcation

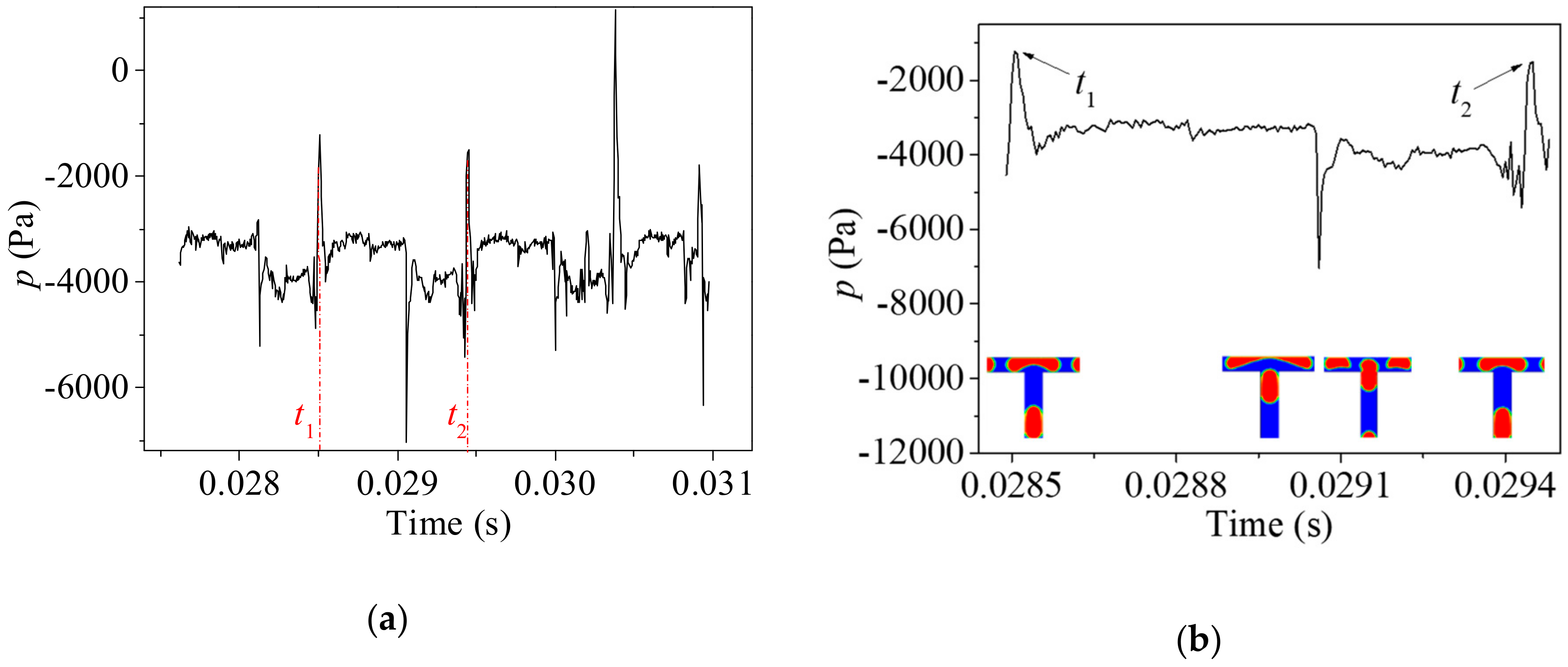

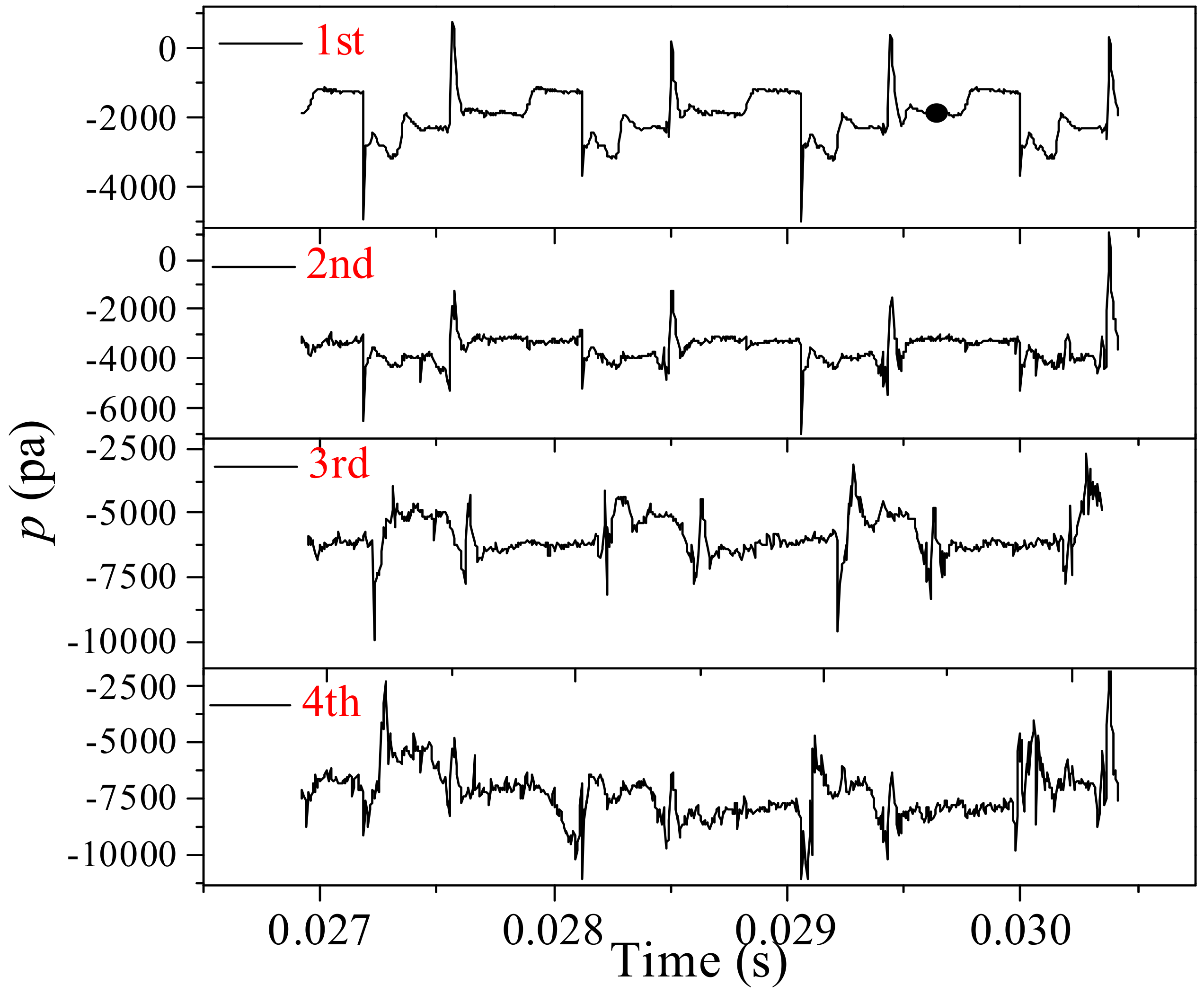

2.4. Pressure Variation at Different Levels of Bifurcation

3. Mathematical Model

4. Numerical Solution

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kreutzer, M.T.; Günther, A.; Jensen, K.F. Sample dispersion for segmented flow in microchannels with rectangular cross section. Anal. Chem. 2008, 80, 1558–1567. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Gao, W.; Zhang, H.; Zou, M.H.; Chen, Y.P.; Zhao, Y.J. Programmable wettability on photocontrolled graphene film. Sci. Adv. 2018, 4, 7392. [Google Scholar] [CrossRef]

- De Jong, J.; Verheijden, P.W.; Lammertink, R.G.H.; Wessling, M. Generation of local concentration gradients by gas−liquid contacting. Anal. Chem. 2008, 80, 3190–3197. [Google Scholar] [CrossRef]

- Kok, M.P.; Segers, T.; Versluis, M. Bubble sorting in pinched microchannels for ultrasound contrast agent enrichment. Lab. Chip 2015, 15, 3716–3722. [Google Scholar] [CrossRef]

- Ozcelik, A.; Ahmed, D.; Xie, Y.; Nama, N.; Qu, Z.; Nawaz, A.A.; Huang, T.J. An acoustofluidic micromixer via bubble inception and cavitation from microchannel sidewalls. Anal. Chem. 2014, 86, 5083–5088. [Google Scholar] [CrossRef]

- Cooke, D.; Kandlikar, S.G. Effect of open microchannel geometry on pool boiling enhancement. Int. J. Heat Mass Transf. 2012, 55, 1004–1013. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Shi, M. Dynamic performance analysis on start-up of closed-loop pulsating heat pipes (clphps). Int. J. Therm. Sci. 2013, 65, 224–233. [Google Scholar] [CrossRef]

- Nisar, A.; Afzulpurkar, N.; Mahaisavariya, B.; Tuantranont, A. Mems-based micropumps in drug delivery and biomedical applications. Sens. Actuators B Chem. 2008, 130, 917–942. [Google Scholar] [CrossRef]

- Kooiman, K.; Vos, H.J.; Versluis, M.; de Jong, N. Acoustic behavior of microbubbles and implications for drug delivery. Adv. Drug Deliv. Rev. 2014, 72, 28–48. [Google Scholar] [CrossRef]

- Wang, J.; Sun, L.; Zou, M.; Gao, W.; Liu, C.; Shang, L.; Gu, Z.; Zhao, Y. Bioinspired shape-memory graphene film with tunable wettability. Sci. Adv. 2017, 3, e1700004. [Google Scholar] [CrossRef]

- Jackson, J.; Chen, A.; Zhang, H.; Burt, H.; Chiao, M. Design and near-infrared actuation of a gold nanorod–polymer microelectromechanical device for on-demand drug delivery. Micromachines 2018, 9, 28. [Google Scholar] [CrossRef]

- Cristini, V.; Tan, Y.-C. Theory and numerical simulation of droplet dynamics in complex flows—A review. Lab. Chip 2004, 4, 257–264. [Google Scholar] [CrossRef]

- Fu, T.; Ma, Y.; Funfschilling, D.; Li, H.Z. Dynamics of bubble breakup in a microfluidic t-junction divergence. Chem. Eng. Sci. 2011, 66, 4184–4195. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, X.; Shi, M. Hydrodynamics of double emulsion droplet in shear flow. Appl. Phys. Lett. 2013, 102, 051609. [Google Scholar] [CrossRef]

- Chung, C.; Lee, M.; Char, K.; Ahn, K.H.; Lee, S.J. Droplet dynamics passing through obstructions in confined microchannel flow. Microfluid Nanofluid 2010, 9, 1151–1163. [Google Scholar] [CrossRef]

- Anna, S.L. Droplets and bubbles in microfluidic devices. Annu. Rev. Fluid Mech. 2016, 48, 285–309. [Google Scholar] [CrossRef]

- Leshansky, A.M.; Pismen, L.M. Breakup of drops in a microfluidic t junction. Phys. Fluids 2009, 21, 023303. [Google Scholar] [CrossRef]

- Liu, H.; Ju, Y.; Wang, N.; Xi, G.; Zhang, Y. Lattice boltzmann modeling of contact angle and its hysteresis in two-phase flow with large viscosity difference. Phys. Rev. E 2015, 92, 033306. [Google Scholar] [CrossRef]

- Cheng, W.L.; Sadr, R.; Dai, J.; Han, A. Prediction of microdroplet breakup regime in asymmetric t-junction microchannels. Biomed. Microdevices 2018, 20, 72. [Google Scholar] [CrossRef]

- He, K.; Wang, S.; Zhang, L.-Z. Transient split features of slug flow at an impacting micro-t-junction: A numerical study. Int. J. Heat Mass Transf. 2017, 112, 318–332. [Google Scholar] [CrossRef]

- Yang, S.; Fu, H.; Yu, B. Fractal analysis of flow resistance in tree-like branching networks with roughened microchannels. Fractals 2017, 25, 1750008. [Google Scholar] [CrossRef]

- Li, T.; Jiang, K.; Xi, L. Average distance of self-similar fractal trees. Fractals 2018, 26, 1850016. [Google Scholar] [CrossRef]

- Yang, S.; Paik, K. New findings on river network organization: Law of eigenarea and relationships among hortonian scaling ratios. Fractals 2017, 25, 1750029. [Google Scholar] [CrossRef]

- Chen, Y.P.; Deng, Z.L. Gas flow in micro tree-shaped hierarchical network. Int. J. Heat Mass Transf. 2015, 80, 163–169. [Google Scholar] [CrossRef]

- Choi, W.; Hashimoto, M.; Ellerbee, A.K.; Chen, X.; Bishop, K.J.M.; Garstecki, P.; Stone, H.A.; Whitesides, G.M. Bubbles navigating through networks of microchannels. Lab. Chip 2011, 11, 3970–3978. [Google Scholar] [CrossRef] [Green Version]

- Hoang, D.A.; Haringa, C.; Portela, L.M.; Kreutzer, M.T.; Kleijn, C.R.; van Steijn, V. Design and characterization of bubble-splitting distributor for scaled-out multiphase microreactors. Chem. Eng. J. 2014, 236, 545–554. [Google Scholar] [CrossRef]

- Yen, T.H. Effects of wettability and interfacial nanobubbles on flow through structured nanochannels: An investigation of molecular dynamics. Mol. Phys. 2015, 113, 3783–3795. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Yu, W.; Deng, Z.; Chen, Y. Bubble breakup in a microfluidic t-junction. Sci. Bull. 2016, 61, 811–824. [Google Scholar] [CrossRef]

- Chen, Y.P.; Deng, Z.L. Hydrodynamics of a droplet passing through a microfluidic t-junction. J. Fluid Mech. 2017, 819, 401–434. [Google Scholar] [CrossRef]

- Leshansky, A.M.; Afkhami, S.; Jullien, M.C.; Tabeling, P. Obstructed breakup of slender drops in a microfluidic $t$ junction. Phys. Rev. Lett. 2012, 108, 264502. [Google Scholar] [CrossRef]

- Link, D.R.; Anna, S.L.; Weitz, D.A.; Stone, H.A. Geometrically mediated breakup of drops in microfluidic devices. Phys. Rev. Lett. 2004, 92, 054503. [Google Scholar] [CrossRef] [PubMed]

- Fu, T.; Ma, Y.; Li, H.Z. Hydrodynamic feedback on bubble breakup at a t-junction within an asymmetric loop. AIChE J. 2014, 60, 1920–1929. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface-tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhang, X.; Li, Q.; Wu, L. Numerical Study of Bubble Breakup in Fractal Tree-Shaped Microchannels. Int. J. Mol. Sci. 2019, 20, 5516. https://doi.org/10.3390/ijms20215516

Zhang C, Zhang X, Li Q, Wu L. Numerical Study of Bubble Breakup in Fractal Tree-Shaped Microchannels. International Journal of Molecular Sciences. 2019; 20(21):5516. https://doi.org/10.3390/ijms20215516

Chicago/Turabian StyleZhang, Chengbin, Xuan Zhang, Qianwen Li, and Liangyu Wu. 2019. "Numerical Study of Bubble Breakup in Fractal Tree-Shaped Microchannels" International Journal of Molecular Sciences 20, no. 21: 5516. https://doi.org/10.3390/ijms20215516

APA StyleZhang, C., Zhang, X., Li, Q., & Wu, L. (2019). Numerical Study of Bubble Breakup in Fractal Tree-Shaped Microchannels. International Journal of Molecular Sciences, 20(21), 5516. https://doi.org/10.3390/ijms20215516