Comparative Study of the Efficiency of Additives in the Extraction of Phycocyanin-C from Arthrospira maxima Using Ultrasonication

Abstract

1. Introduction

2. Results

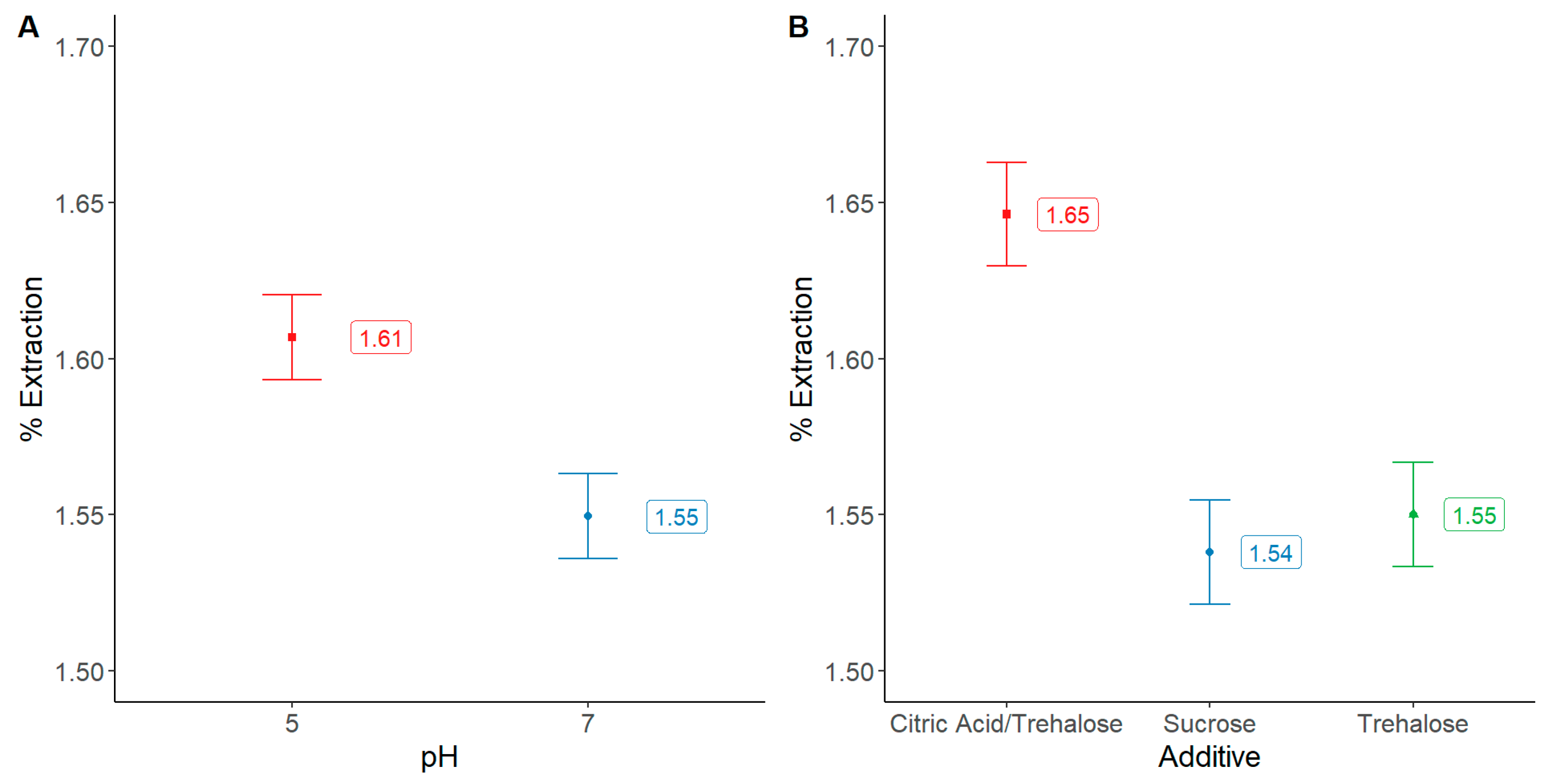

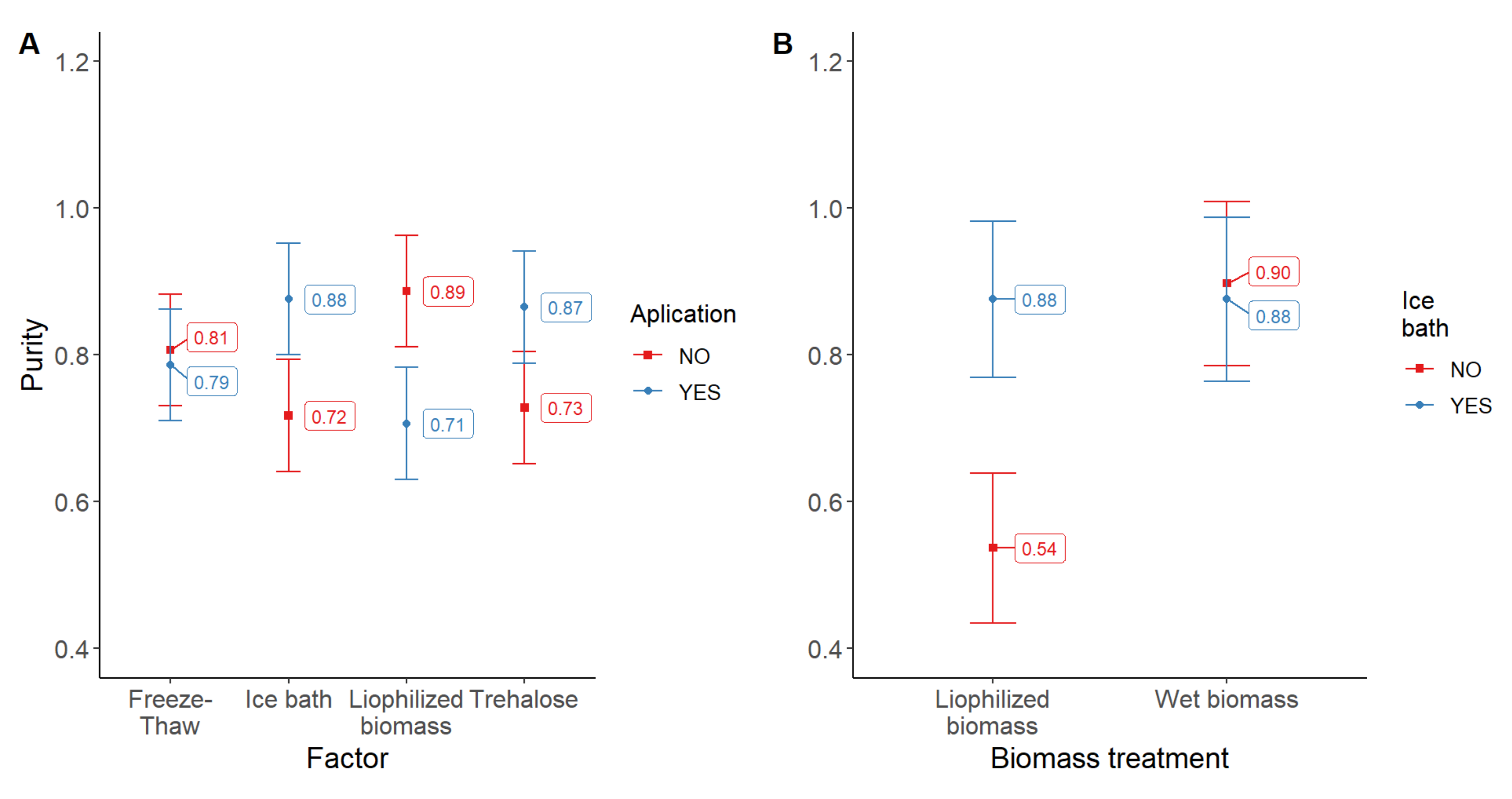

2.1. Screening of Factors with Impact on Phycocyanin Extraction Yield Using Sonication as a Cell-Disruption Method

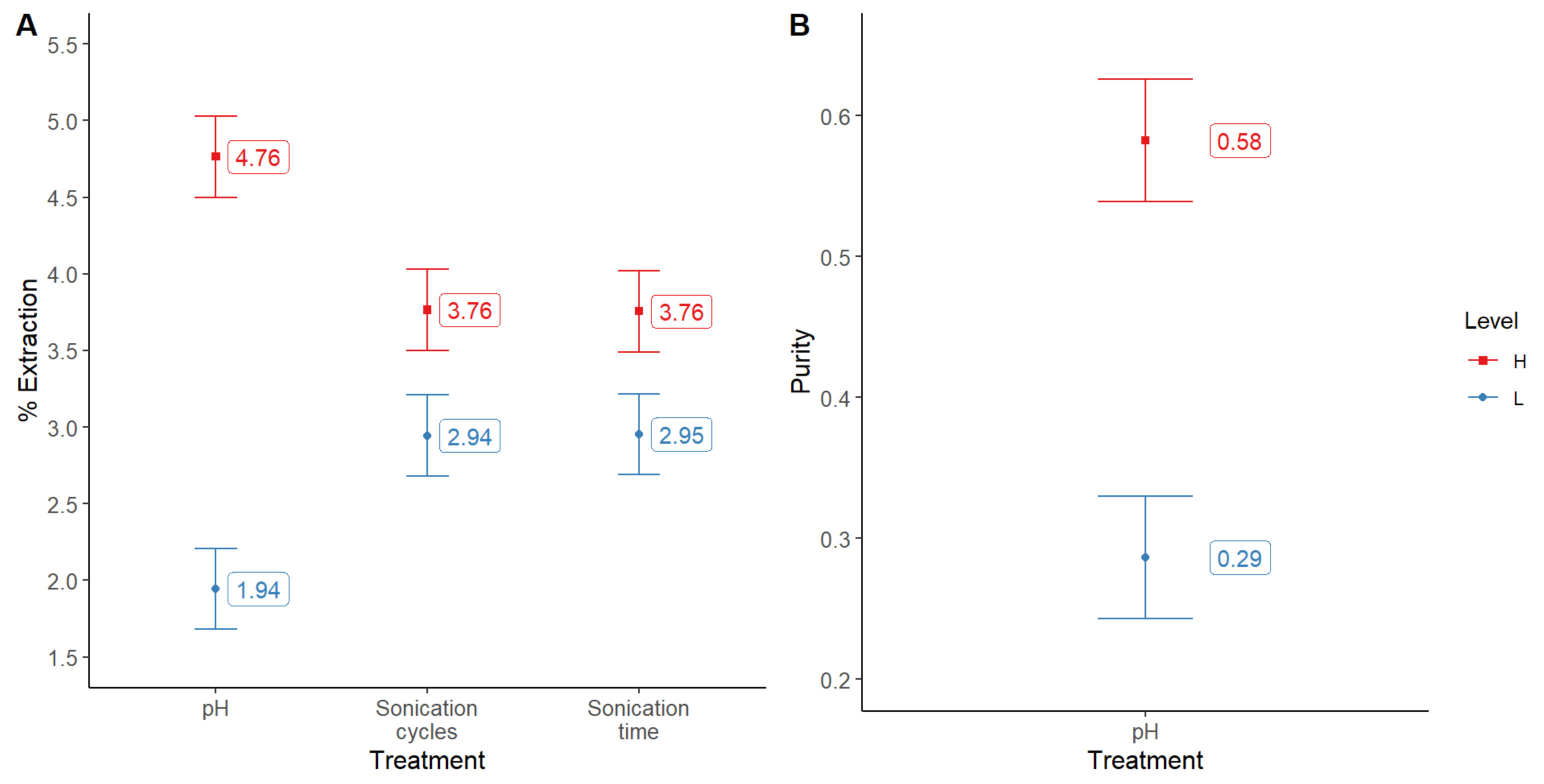

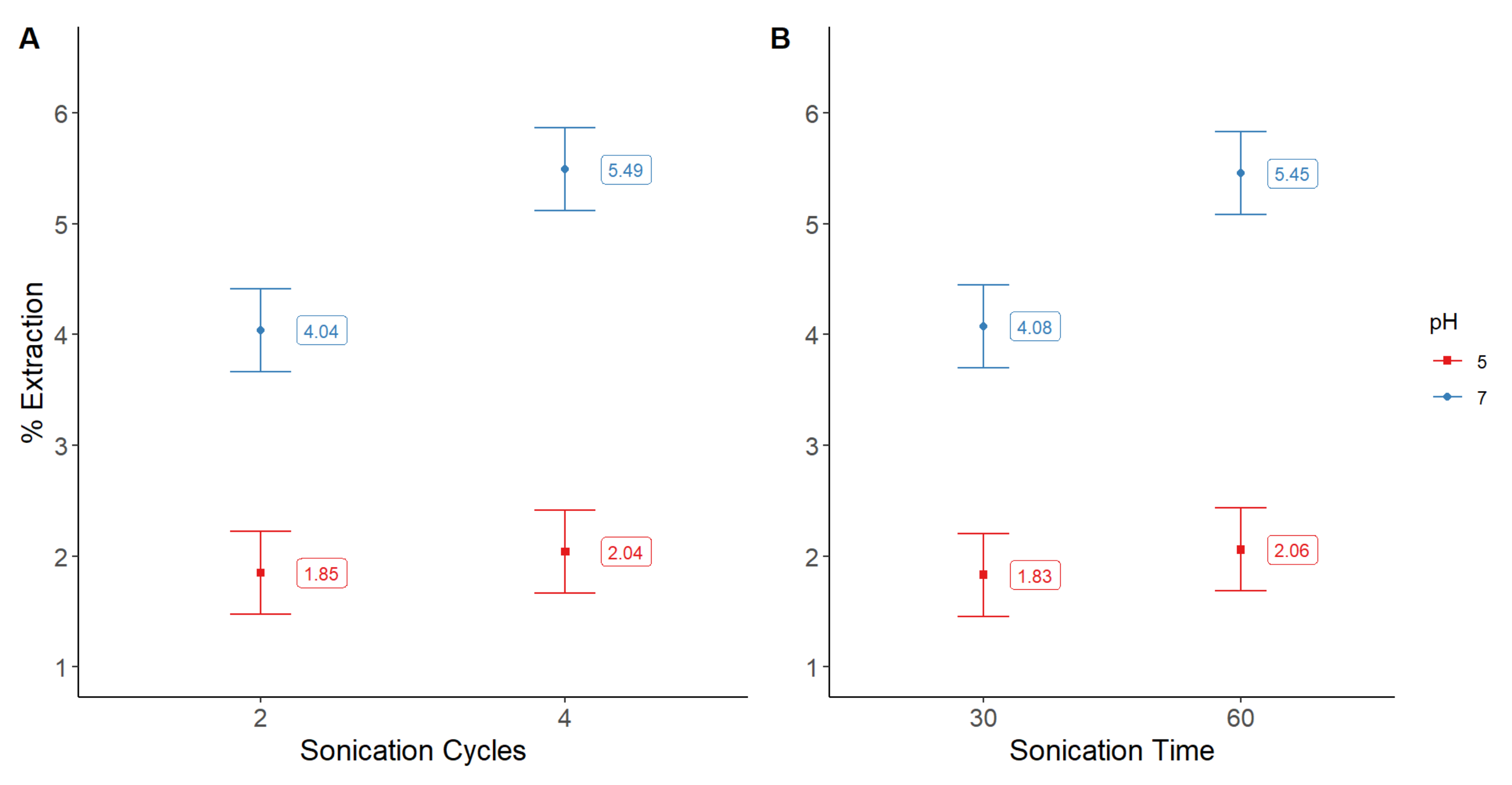

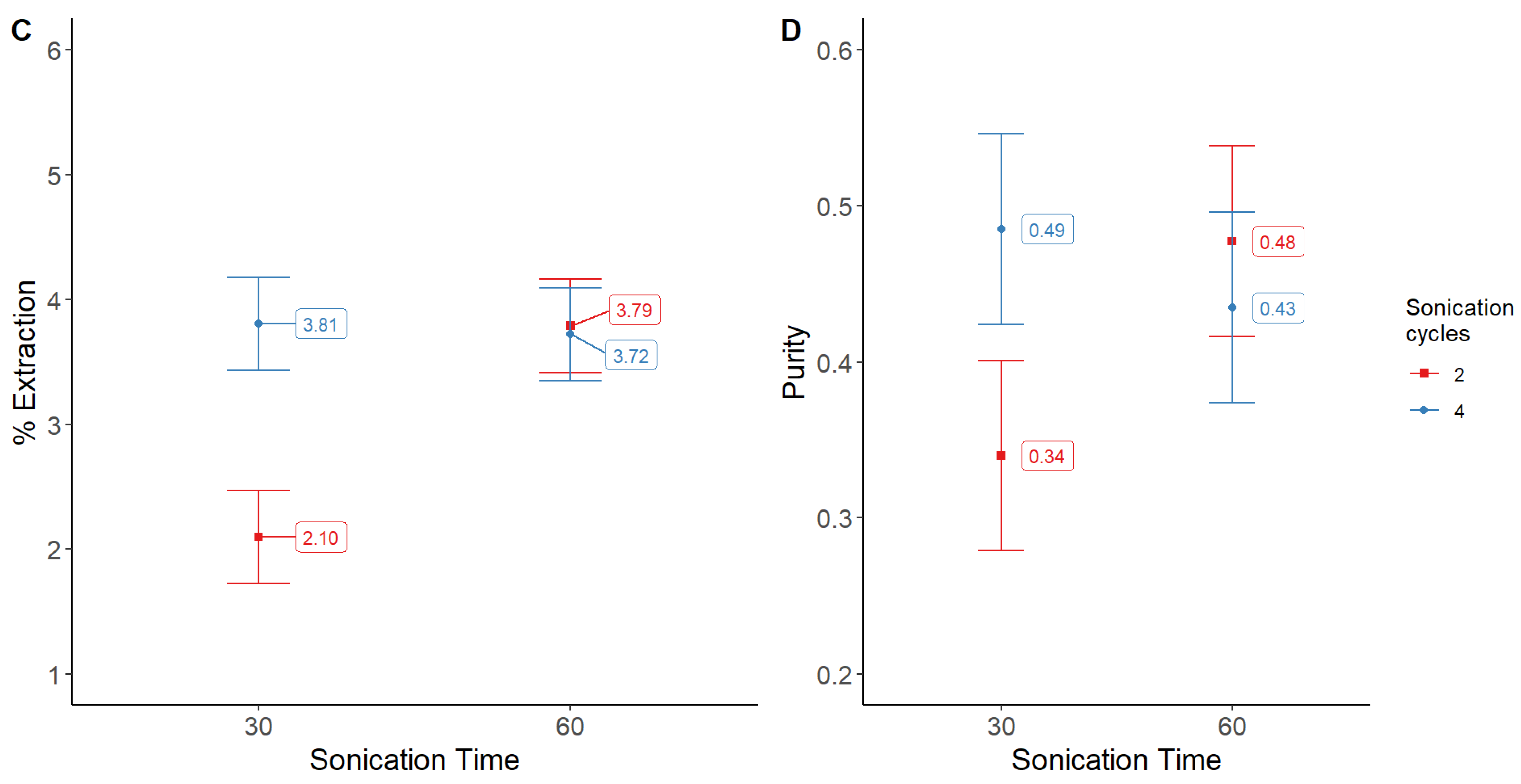

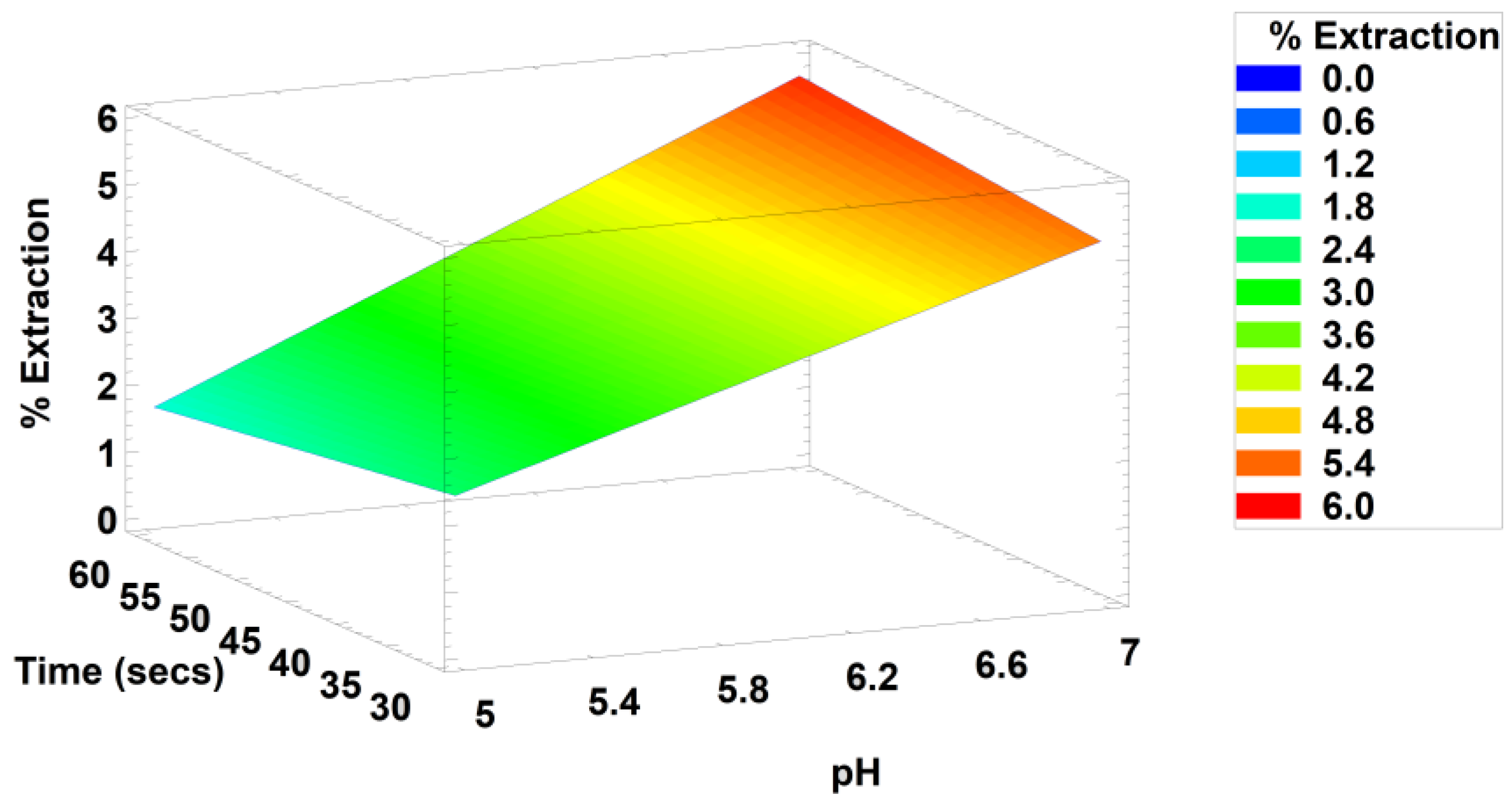

2.2. Analysis of the Effect of Sonication Parameters in Phycocyanin Extraction Yield and Purity

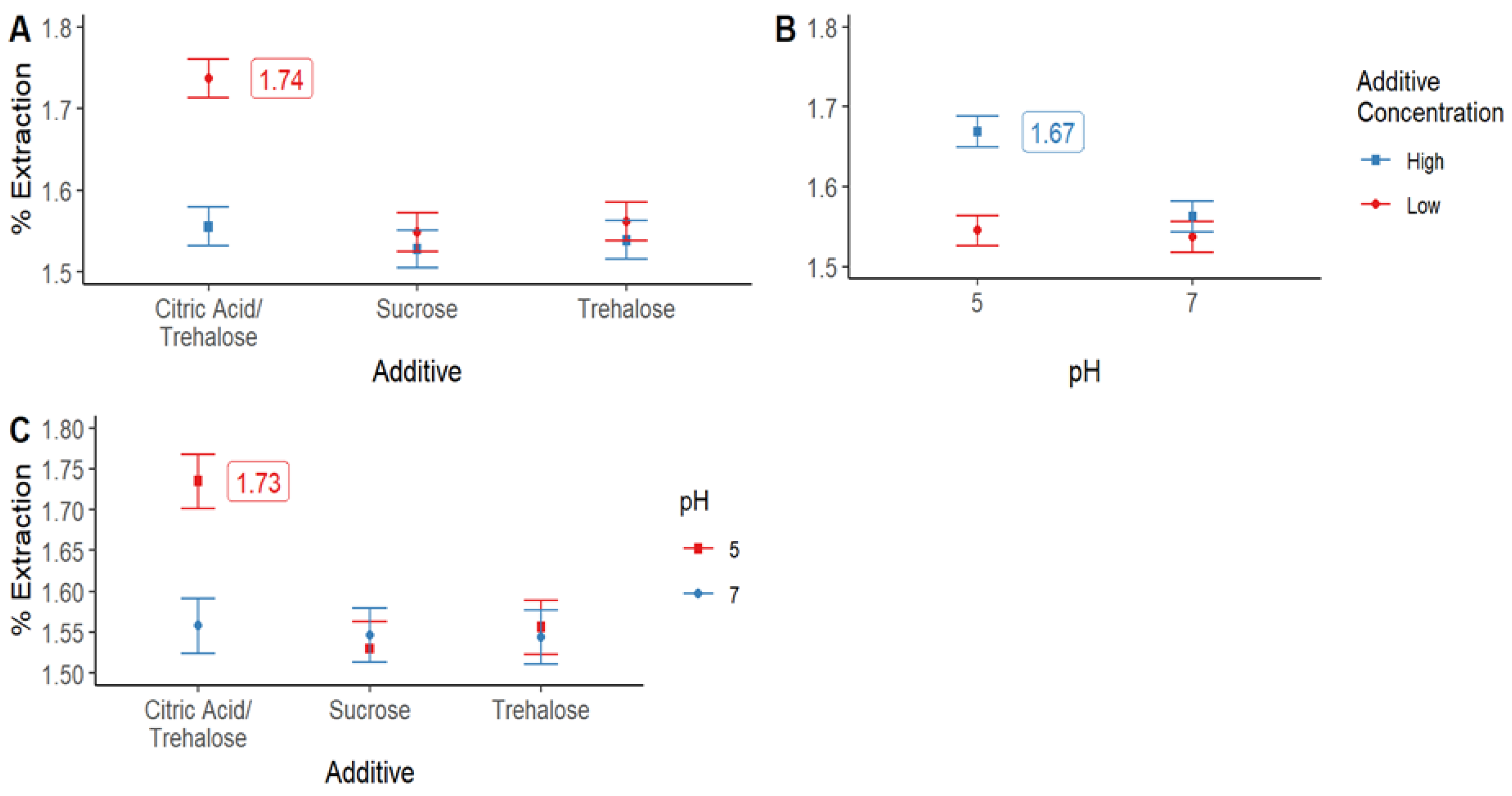

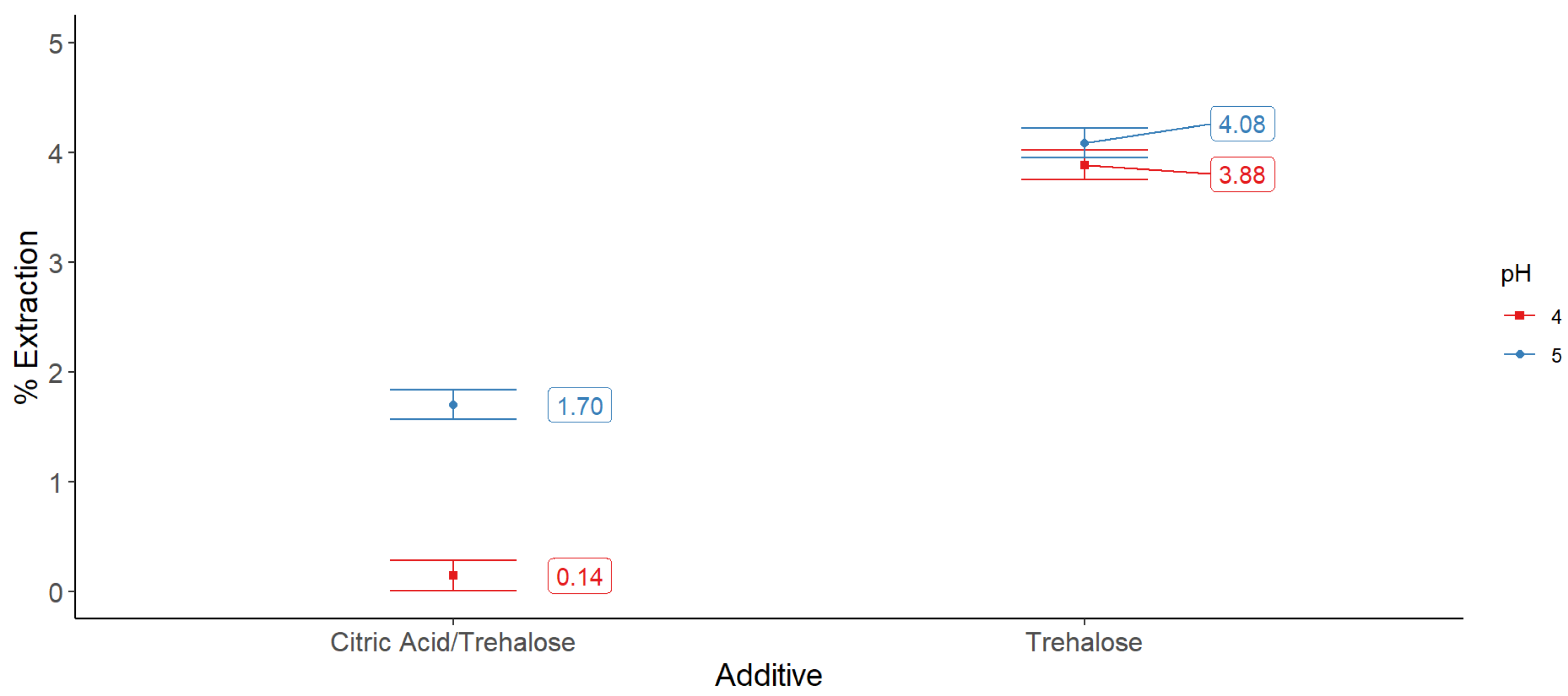

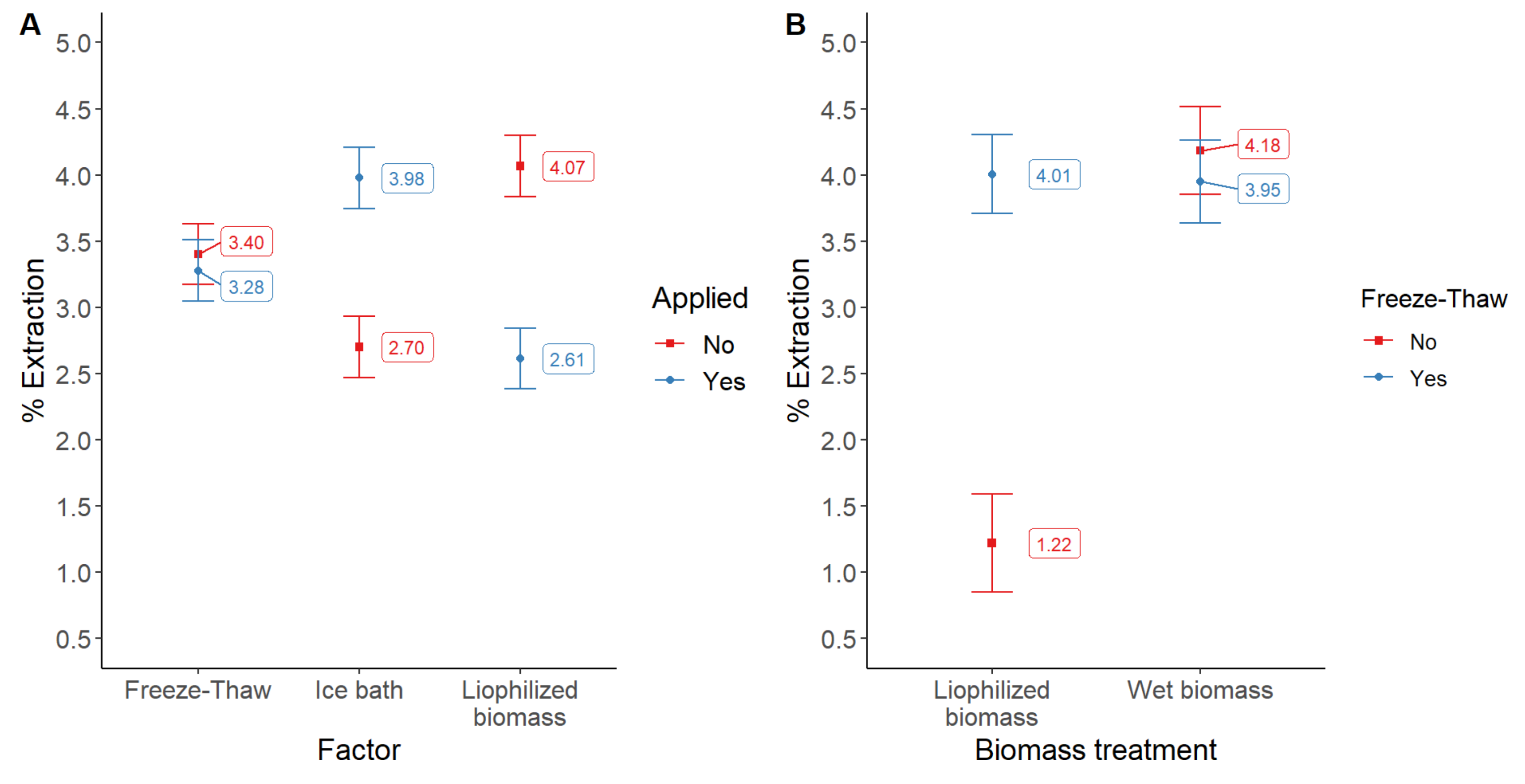

2.3. Analysis of the Phycocyanin Extraction Yield and Purity when Combining Sonication with Other Operation Parameters

3. Discussion

3.1. Screening of Factors with Impact on Phycocyanin Extraction Yield Using Sonication as a Cell-Disruption Method

3.2. Analysis of the Effect of Sonication Parameters in Phycocyanin Extraction Yield and Purity

3.3. Analysis of the Phycocyanin Extraction Yield and Purity when Combining Sonication with Other Operation Parameters

4. Materials and Methods

4.1. Cyanobacteria Growth Conditions

4.2. Experimental Designs and Processing Conditions

4.3. Analytical Methods

4.4. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Escalante, F.M.E.; Pérez-Rico, D.A. Advancements in Algae in Nutraceutical and Functional Food. In Recent Advances in Micro and Macroalgal Processing: Food and Health Perspectives; Rajauria, G., Yuan, Y.V., Eds.; John and Wiley and Sons: Hoboken, NJ, USA, 2021; pp. 506–536. [Google Scholar]

- Ahuja, K.; Mamtani, K. Phycocyanin Market Analysis 2019–2025 Growth Statistics Report. Available online: https://www.gminsights.com/industry-analysis/phycocyanin-market (accessed on 31 March 2021).

- Escalante, F.M.E.; Pérez-Rico, D.A.; Alarcón-Jiménez, J.L.; González-Morales, E.; Guerra-Álvarez, L.F.; Ramírez-Vázquez, J.C.; Gutiérrez-Pulido, H. Phycocyanin Thermo-Photostability: An Accelerated Life-Test Analysis. J. Mex. Chem. Soc. 2020, 64, 218–229. [Google Scholar] [CrossRef]

- Rahman, D.Y.; Sarian, F.D.; van Wijk, A.; Martinez-Garcia, M.; van der Maarel, M.J.E.C. Thermostable Phycocyanin from the Red Microalga Cyanidioschyzon Merolae, a New Natural Blue Food Colorant. J. Appl. Phycol. 2017, 29, 1233–1239. [Google Scholar] [CrossRef] [PubMed]

- Antecka, A.; Klepacz-Smółka, A.; Szeląg, R.; Pietrzyk, D.; Ledakowicz, S. Comparison of Three Methods for Thermostable C-Phycocyanin Separation and Purification. Chem. Eng. Process Process Intensif. 2022, 171, 108563. [Google Scholar] [CrossRef]

- Vernès, L.; Granvillain, P.; Chemat, F.; Vian, M. Phycocyanin from Arthrospira Platensis. Production, Extraction and Analysis. Curr. Biotechnol. 2015, 4, 481–491. [Google Scholar] [CrossRef]

- Adjali, A.; Clarot, I.; Chen, Z.; Marchioni, E.; Boudier, A. Physicochemical Degradation of Phycocyanin and Means to Improve Its Stability: A Short Review. J. Pharm. Anal. 2022, 12, 406–414. [Google Scholar] [CrossRef]

- Böcker, L.; Ortmann, S.; Surber, J.; Leeb, E.; Reineke, K.; Mathys, A. Biphasic Short Time Heat Degradation of the Blue Microalgae Protein Phycocyanin from Arthrospira Platensis. Innov. Food Sci. Emerg. Technol. 2019, 52, 116–121. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Paciulli, M.; Abbaspourrad, A. Extraction of Phycocyanin—A Natural Blue Colorant from Dried Spirulina Biomass: Influence of Processing Parameters and Extraction Techniques. J. Food Sci. 2020, 85, 727–735. [Google Scholar] [CrossRef]

- Patil, G.; Chethana, S.; Sridevi, A.S.; Raghavarao, K.S.M.S. Method to Obtain C-Phycocyanin of High Purity. J. Chromatogr. A 2006, 1127, 76–81. [Google Scholar] [CrossRef]

- Choi, W.Y.; Lee, H.Y. Effect of Ultrasonic Extraction on Production and Structural Changes of C-Phycocyanin from Marine Spirulina Maxima. Int. J. Mol. Sci. 2018, 19, 220. [Google Scholar] [CrossRef]

- Aoki, J.; Sasaki, D.; Asayama, M. Development of a Method for Phycocyanin Recovery from Filamentous Cyanobacteria and Evaluation of Its Stability and Antioxidant Capacity. BMC Biotechnol. 2021, 21, 40. [Google Scholar] [CrossRef]

- Mishra, S.K.; Shrivastav, A.; Mishra, S. Effect of Preservatives for Food Grade C-PC from Spirulina Platensis. Process Biochem. 2008, 43, 339–345. [Google Scholar] [CrossRef]

- Eriksen, N.T. Production of Phycocyanin—A Pigment with Applications in Biology, Biotechnology, Foods and Medicine. Appl. Microbiol. Biotechnol. 2008, 80, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.-L.; Wang, G.-H.; Xiang, W.-Z.; Li, T.; He, H. Stability and Antioxidant Activity of Food-Grade Phycocyanin Isolated from Spirulina Platensis. Int. J. Food Prop. 2016, 19, 2349–2362. [Google Scholar] [CrossRef]

- Kumar, D.; Dhar, D.W.; Pabbi, S.; Kumar, N.; Walia, S. Extraction and Purification of C-Phycocyanin from Spirulina Platensis (CCC540). Indian J. Plant Physiol. 2014, 19, 184–188. [Google Scholar] [CrossRef] [PubMed]

- Chaiklahan, R.; Chirasuwan, N.; Triratana, P.; Loha, V.; Tia, S.; Bunnag, B. Polysaccharide Extraction from Spirulina Sp. and Its Antioxidant Capacity. Int. J. Biol. Macromol. 2013, 58, 73–78. [Google Scholar] [CrossRef]

- Pan-utai, W.; Kahapana, W.; Iamtham, S. Extraction of C-Phycocyanin from Arthrospira (Spirulina) and Its Thermal Stability with Citric Acid. J. Appl. Phycol. 2018, 30, 231–242. [Google Scholar] [CrossRef]

- Vali Aftari, R.; Rezaei, K.; Mortazavi, A.; Bandani, A.R. The Optimized Concentration and Purity of Spirulina PlatensisC-Phycocyanin: A Comparative Study on Microwave-Assisted and Ultrasound-Assisted Extraction Methods. J. Food Process. Preserv. 2015, 39, 3080–3091. [Google Scholar] [CrossRef]

- Chaiklahan, R.; Chirasuwan, N.; Bunnag, B. Stability of Phycocyanin Extracted from Spirulina Sp.: Influence of Temperature, PH and Preservatives. Process Biochem. 2012, 47, 659–664. [Google Scholar] [CrossRef]

- Chaiklahan, R.; Chirasuwan, N.; Loha, V.; Tia, S.; Bunnag, B. Separation and Purification of Phycocyanin from Spirulina Sp. Using a Membrane Process. Bioresour. Technol. 2011, 102, 7159–7164. [Google Scholar] [CrossRef]

- Silveira, S.T.; Burkert, J.F.M.; Costa, J.A.V.; Burkert, C.A.V.; Kalil, S.J. Optimization of Phycocyanin Extraction from Spirulina Platensis Using Factorial Design. Bioresour. Technol. 2007, 98, 1629–1634. [Google Scholar] [CrossRef]

- Moraes, C.C.; Sala, L.; Cerveira, G.P.; Kalil, S.J. C-Phycocyanin Extraction from Spirulina Platensis Wet Biomass. Braz. J. Chem. Eng. 2011, 28, 45–49. [Google Scholar] [CrossRef]

- Corrêa, P.S.; Morais Júnior, W.G.; Martins, A.A.; Caetano, N.S.; Mata, T.M. Microalgae Biomolecules: Extraction, Separation and Purification Methods. Processes 2020, 9, 10. [Google Scholar] [CrossRef]

- Sarada, R.; Pillai, M.G.; Ravishankar, G.A. Phycocyanin from Spirulina Sp: Influence of Processing of Biomass on Phycocyanin Yield, Analysis of Efficacy of Extraction Methods and Stability Studies on Phycocyanin. Process Biochem. 1999, 34, 795–801. [Google Scholar] [CrossRef]

- Faieta, M.; Neri, L.; Sacchetti, G.; Di Michele, A.; Pittia, P. Role of Saccharides on Thermal Stability of Phycocyanin in Aqueous Solutions. Food Res. Int. 2020, 132, 109093. [Google Scholar] [CrossRef] [PubMed]

- Bennett, A.; Bogorad, L. Complementary Chromatic Adaptation in a Filamentous Blue-Green Alga. J. Cell Biol. 1973, 58, 419–435. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Vega, J.E.; Villafaña-Estarrón, E.; Escalante, F.M.E. Comparative Study of the Efficiency of Additives in the Extraction of Phycocyanin-C from Arthrospira maxima Using Ultrasonication. Molecules 2023, 28, 334. https://doi.org/10.3390/molecules28010334

Martínez-Vega JE, Villafaña-Estarrón E, Escalante FME. Comparative Study of the Efficiency of Additives in the Extraction of Phycocyanin-C from Arthrospira maxima Using Ultrasonication. Molecules. 2023; 28(1):334. https://doi.org/10.3390/molecules28010334

Chicago/Turabian StyleMartínez-Vega, Jorge Eugenio, Erika Villafaña-Estarrón, and Froylán M. E. Escalante. 2023. "Comparative Study of the Efficiency of Additives in the Extraction of Phycocyanin-C from Arthrospira maxima Using Ultrasonication" Molecules 28, no. 1: 334. https://doi.org/10.3390/molecules28010334

APA StyleMartínez-Vega, J. E., Villafaña-Estarrón, E., & Escalante, F. M. E. (2023). Comparative Study of the Efficiency of Additives in the Extraction of Phycocyanin-C from Arthrospira maxima Using Ultrasonication. Molecules, 28(1), 334. https://doi.org/10.3390/molecules28010334