Safety, Resilience and Sustainability of Industrial Processes and Chemical Plants

A topical collection in Sustainability (ISSN 2071-1050). This collection belongs to the section "Sustainable Chemical Engineering and Technology".

Viewed by 60795Editor

Interests: environmental protection and engineering; human factor; inherent safety; nanomaterials, occupational accidents; safety and loss prevention in the process industries

Topical Collection Information

Dear Colleagues,

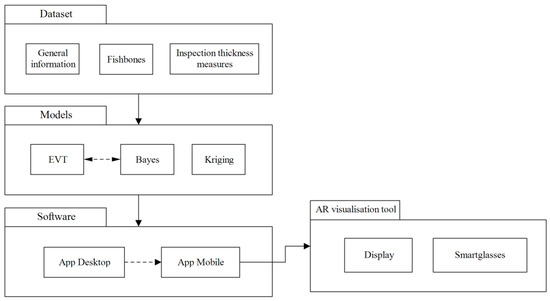

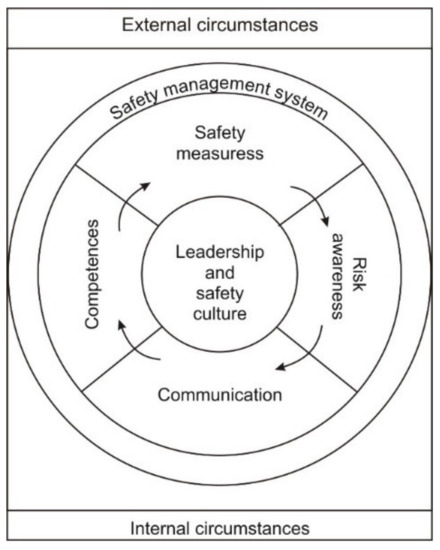

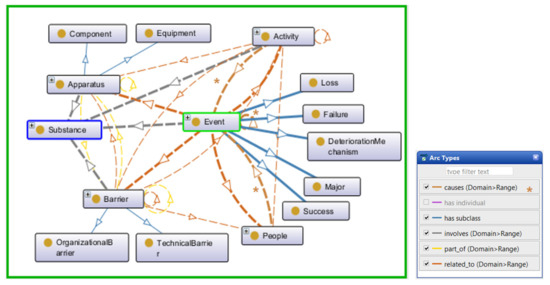

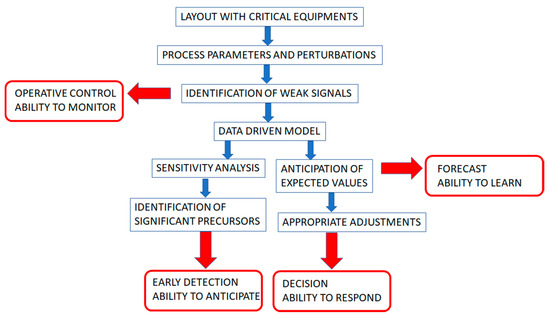

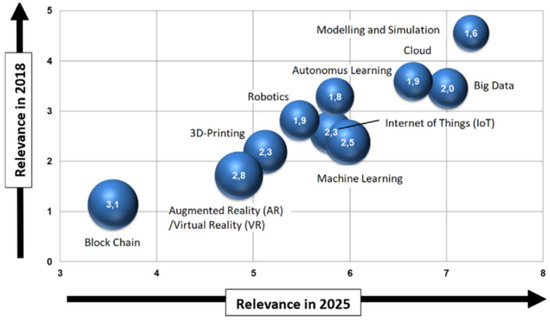

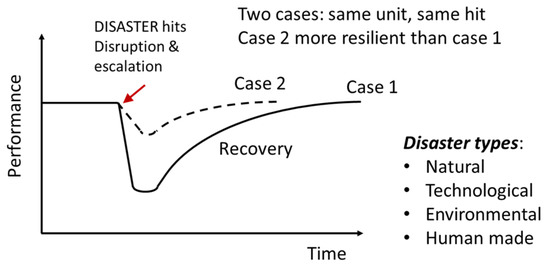

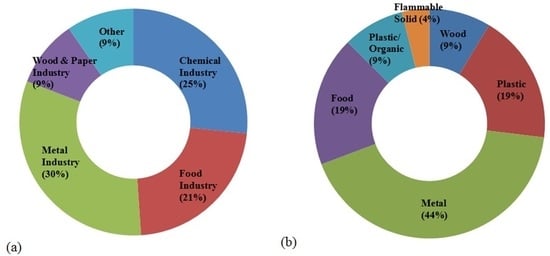

In these last years, the industrial world has on the one hand experienced radical technological advances in connection with communication and fast-developing societal developments requiring further research and applications for sustainability and process safety improvement. On the other hand, especially in Europe, facilities date back to several decades and due to economic crises, aging has become a major concern in the process industry, due to the high cost of investing in new equipment and consequences associated with failure. Many challenges still need to be addressed in order to make further progress in the safety and sustainability of plants and processes towards Safety 4.0, including the development and employment of user-friendly and effective risk assessment models, development of the resilience engineering approach, harmonized education of process safety, and using economic theories and dynamic models in safety and sustainability decision making. Big data, expert elicitation, Bayesian statistics and networks, and knowledge of human error provide the challenge of improving the management of risk and sustainability by the better determination of the effect of risk reducing measures, of their cost/benefit and budget allocation, but also, in an operational sense, the possibility of continuous risk level monitoring. Notwithstanding noteworthy advancements, inherent safety and resilience are still common sense rather than common practice, so that risk mitigation techniques and modelling remain up-to-date research topics in the field of process sustainability and safety.

In light of the above, Sustainability is publishing a Special Issue on “Safety, resilience and sustainability of industrial processes and chemical plants”. Theoretical, experimental research, numerical analysis, and management or engineering applications related to both occupational and process safety items in industrial plants are welcome.

We are pleased to receive all submissions to this Special Issue including research papers, case studies and comprehensive reviews related but not limited to the following topics:

- accidental and environmental risk mitigation

- consequence modelling;

- designing for safety and sustainability

- hazards from novel or emerging technologies

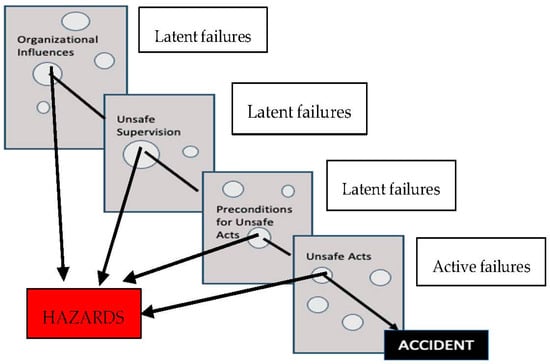

- human and organizational factors

- integration of safety and sustainability

- loss prevention and safety in SMEs

- management of plant aging

- new approaches towards “Safety 4.0”

- occupational and process safety

- preventive and mitigation measures

- resilient process

- risk and hazard analysis

- safety and sustainability indicators

- simulation and modelling

- sustainability and safety economics

Dr. Bruno Fabiano

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Sustainability is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- modelling

- process and personnel safety

- preventive and protective measures

- risk assessment

- sustainability