Process Control and Optimization in the Era of Industry 5.0

A special issue of Processes (ISSN 2227-9717). This special issue belongs to the section "Process Control and Monitoring".

Deadline for manuscript submissions: 27 March 2026 | Viewed by 2467

Special Issue Editors

Interests: artificial intelligence control technology; industrial process advanced control and optimization control technology

Interests: reinforcement learning; model predictive control; human–machine augmentation; human–machine cooperative game theory

Special Issues, Collections and Topics in MDPI journals

Interests: model predictive control; process control; optimization; learning based model predictive control

Special Issue Information

Dear Colleagues,

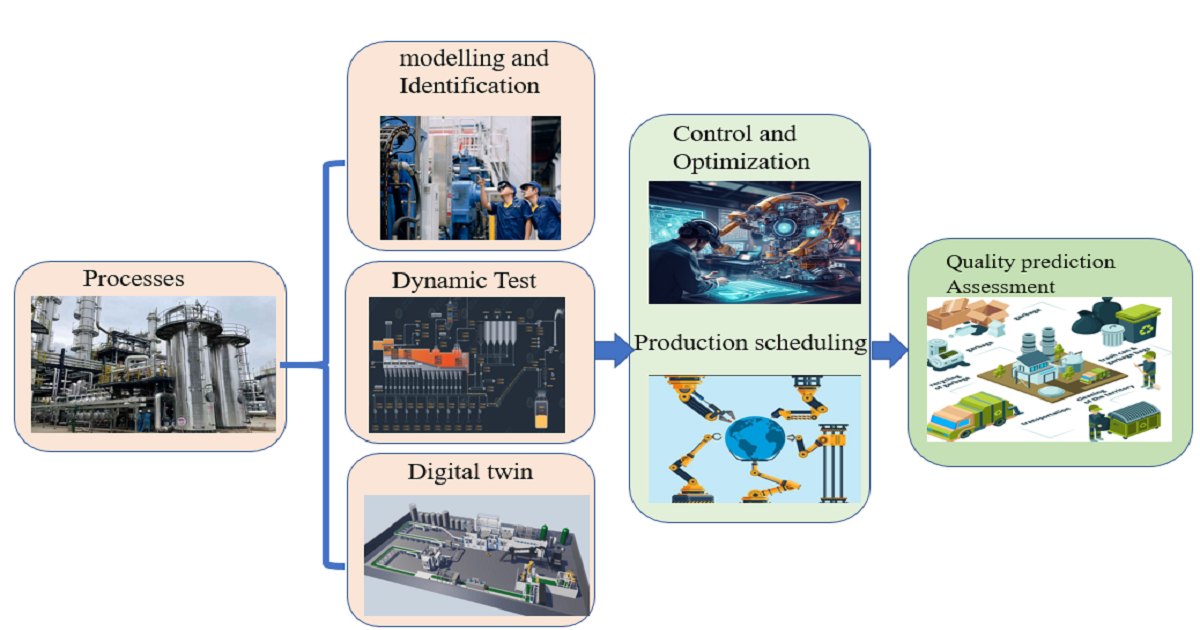

We invite you to submit papers to this Special Issue of Processes on “Process Control and Optimization in the Era of Industry 5.0”. Ensuring production stability, reducing production costs, and energy consumption of industrial processes have become increasingly critical as industries adopt more automated, digital, and complex processes in the era of Industry 5.0. The integration of advanced control and optimization technologies offers new opportunities to enhance the production stability of industrial operations while improving efficiency and resource utilization and reducing production costs and energy consumption.

The rapid progress in fields such as artificial intelligence (AI), machine learning, and the Industrial Internet of Things (IIoT) is transforming industrial process modeling and control systems. These advancements allow for more intelligent control and predictive control techniques, enabling accurately identifying the dynamics of the process, optimizing control strategies, and ensuring production stability. With the ability to deal with vast operational data, modern industrial systems can be more robust and adaptable, leading to improved operational stability and reduced production costs and energy consumption.

Given these developments, this Special Issue aims to highlight the latest trends, research, applications, and challenges in advanced process control and optimization for industrial processes in the era of Industry 5.0. We invite both theoretical and application-oriented contributions, as well as review articles that explore innovations in these areas. All submissions will undergo peer review and be evaluated for their originality, relevance, and contribution to the field.

Potential topics of interest include, but are not limited to, the following:

- Advanced modeling and control methods for the process;

- Application of AI, machine learning, and data analytics in process modeling;

- IIoT-based data-driven modeling for processes;

- Collaborative and distributed control in industrial processes;

- Parameter estimation and system identification based on machine learning;

- Performance evaluation for industrial control systems;

- Nonlinear and coupled process control using model predictive control techniques;

- Digital twin applications for process simulation;

- Industrial intelligent control and intelligent optimization.

Prof. Dr. Aimin An

Prof. Dr. Shuyou Yu

Dr. Langwen Zhang

Prof. Dr. Zhonggai Zhao

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Processes is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- process data analysis and modeling

- intelligent information perception and data processing

- data-driven modeling

- parameter estimation and system identification

- system simulation and dynamic simulation

- digital twin of industrial process equipment

- machine learning algorithms and applications

- industrial intelligent control and intelligent optimization

- data-driven model-based predictive control

- advanced control theory and methods

- data drive and control in the process industry

- servo-drive control

- engineering equipment modeling and intelligent control

- smart factories in the era of Industry 5.0

- optimization and production scheduling

- quality prediction of industrial process products

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- Reprint: MDPI Books provides the opportunity to republish successful Special Issues in book format, both online and in print.

Further information on MDPI's Special Issue policies can be found here.