Feature Paper Collection in Plasma Coatings, Surfaces & Interfaces

Share This Topical Collection

Editors

Dr. Bocong Zheng

Dr. Bocong Zheng

Dr. Bocong Zheng

Dr. Bocong Zheng

E-Mail

Website

Collection Editor

Fraunhofer Center for Coatings and Diamond Technologies, East Lansing, MI 48824, USA

Interests: plasma simulation; plasma surface engineering; gas discharge physics; physical vapor deposition; radio frequency discharges; magnetized plasmas

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

You are invited to submit your work to this Feature Paper Collection on Plasma, which focuses on low-temperature plasma theory and applications. Low-temperature plasmas are widely used for manufacturing semiconductor devices, tribological coatings, displays, solar panels, and many more technical products. On one hand, fully understanding plasma behavior requires the combined effort of simulation and diagnostics. Accurate simulation of plasmas, especially at low pressures (<100 mTorr), is computationally extensive due to the requiements to resolve the fastest temporal process and the finest spatial behavior of electrons. On the other hand, industry production has continuously driven the development of more efficient plasma sources and processes. Some particular challenges include large-area coatings at high frequencies, material-induced restriction to the process temperature, and capability to tune coatings’ microstructures. This feature Paper Collection aims to introduce the latest experimental, computational, and theoretical developments in the field of low-temperature plasma, through a series of original work and review articles from leading researchers around the world.

Potential topics include but are not limited to:

- Modeling and diagnostic methods of plasma discharges;

- Fundamental understanding of plasma behavior;

- Plasma-enhanced coatings and structures;

- Plasma-surface interactions;

- Novel plasma-based thin film deposition and material synthesis technology;

- Implementation of plasma processing for research and industrial applications.

Dr. Qi Hua Fan

Dr. Bocong Zheng

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Coatings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Published Papers (6 papers)

Open AccessArticle

APDBD Plasma Polymerized PNIPAm Coatings with Controlled Thickness via Spin Coating Technique

by

Hakim Ssekasamba, Xinwang Chen, Haodong Cui, Xiaoliang Tang, Gao Qiu, Xihua Lu and Qingsong Yu

Viewed by 596

Abstract

Thermosensitive Poly(N-isopropylacrylamide) (PNIPAm) films were synthesized via atmospheric pressure dielectric barrier discharge (APDBD) plasma polymerization. In order to control the thickness of the films, a spin coating technique was used during the deposition of N-isopropylacrylamide (NIPAM) monomer solution onto several glass substrates. We

[...] Read more.

Thermosensitive Poly(N-isopropylacrylamide) (PNIPAm) films were synthesized via atmospheric pressure dielectric barrier discharge (APDBD) plasma polymerization. In order to control the thickness of the films, a spin coating technique was used during the deposition of N-isopropylacrylamide (NIPAM) monomer solution onto several glass substrates. We used the coefficient of determination (R-square value) in linear regression to investigate the significance and optimize spin coating parameters during the fabrication of NIPAM coatings before exposure to APDBD plasma to ensure reproducible and uniform film properties. The spin coating parameters investigated in this study include spin speed, spin time, and NIPAM solution concentration with R-square values of 0.978, 0.946, and 0.944, respectively. Also, as a result of the thermosensitive nature of NIPAM, the spin coating operating conditions of temperature and humidity were maintained at 39.0 °C and 15%, respectively. During the APDBD plasma polymerization, argon was used as the discharge gas, and the distance between the two parallel electrodes and plasma frequency were maintained at 5.0 mm and 17 kHz, respectively. The plasma exposure time required for polymerization of PNIPAm coatings was optimized to 60 s. Also, the results showed that a coating with minimal defects had an optimal thickness of 5.18 μm, fabricated under conditions of 90 wt.% NIPAM concentration, spin speed of 4000 rpm, and total spin time of 7 s.

Full article

►▼

Show Figures

Open AccessArticle

Effect of Si and HA on the Mechanical Characteristics of Spark-Plasma-Sintered Mg–Zn–Mn–(Si–HA) Composites

by

Abdulaziz Kurdi, Doaa Almalki, Sayan Sarkar, Alaa Aldurihem, Ahmed Degnah and Animesh Kumar Basak

Viewed by 1057

Abstract

Mg–Zn–Mn-based biocomposites hold prospects as potential orthopedic material. The composition of these composites can be modulated, based on applications, by selective elemental alloying. Towards that, the addition of silicon (Si), hydroxyapatite (HA), or both is considered, followed by the consolidation method, such as

[...] Read more.

Mg–Zn–Mn-based biocomposites hold prospects as potential orthopedic material. The composition of these composites can be modulated, based on applications, by selective elemental alloying. Towards that, the addition of silicon (Si), hydroxyapatite (HA), or both is considered, followed by the consolidation method, such as spark plasma sintering (SPS). In this study, the micro-mechanical properties of Mg–Zn–Mn–(Si–HA) composites were investigated through the micro-pillar compression method. The effect of Si and HA incorporation on the mechanical characteristics and deformation mechanism was also elucidated. The microstructure of the composite presents porosity, together with different bioactive phases, such as Mg–Zn, CaMg, Mn–P, MgSi

2, Mn–Si, Mn–CaO, CaMgSi, and Ca–Mn–O. Such porous structures were determined to facilitate cell growth when used as an implant, particularly for musculoskeletal-related disabilities. The yield stress (YS) and compressive stress of the Mg–Zn–Mn–Si–HA were about 1543 ± 99 MPa and 1825 ± 102 MPa, respectively. These values were about 5.8 and 4.8 times higher, respectively, than those of Mg–Zn–Mn–HA composites (266 ± 42 MPa and 380 ± 10 MPa, respectively), and the same was observed for the elastic modulus. Besides that, alloying with HA and Si alters the deformation mechanism from brittle (for Mg–Zn–Mn–Si composites) or ductile (for Mg–Zn–Mn–HA composites) to predominant ductile failure without compromising the attained mechanical properties.

Full article

►▼

Show Figures

Open AccessReview

Modern Innovations and Applications in Plasma Electrolytic Oxidation Coatings on Aluminum, Magnesium, and Titanium

by

Angus G. McCarroll and Pradeep L. Menezes

Cited by 3 | Viewed by 2887

Abstract

Plasma electrolytic oxidation (PEO) is an electrochemical surface modification technique for producing dense oxide layers on valve metals. This review compiles the various modifications to the PEO process that have been used to improve the produced coatings and make them suitable for specific

[...] Read more.

Plasma electrolytic oxidation (PEO) is an electrochemical surface modification technique for producing dense oxide layers on valve metals. This review compiles the various modifications to the PEO process that have been used to improve the produced coatings and make them suitable for specific applications, with a focus on examples of aluminum, magnesium, and titanium substrates. An overview of the PEO process is given, highlighting the various process parameters and their effects on the final surface. The challenges with light metals that motivate the use of surface modifications are summarized, along with some of the other modifications that attempt to overcome them. Two broad categories of modifications to the PEO process are presented: in situ modifications, influencing the properties of the coating during its formation, and ex situ modifications, augmenting the properties of an already-formed coating. Finally, specific examples of applications for modified PEO processes are discussed, including battery, biomedical, water treatment, and energy production applications.

Full article

►▼

Show Figures

Open AccessArticle

Feasible Exploration Study of Anti-Silicon Element Corrosion Coating for C/C Composites

by

Haijiang Yu, Huiyong Yang, Deteng Wang, Yixin Xiao, Lianyi Wang, Zhi Chen, Wei Li, Ruiying Luo and Juntong Huang

Viewed by 666

Abstract

This study investigates the fabrication of a ZrSiO

4-based coating (ZSO coating) on substrate surfaces using atmospheric plasma spraying (APS) technology, with ZrSiO

4 as the feedstock material. A comprehensive characterization of the coating systems was conducted, including an in-depth analysis of

[...] Read more.

This study investigates the fabrication of a ZrSiO

4-based coating (ZSO coating) on substrate surfaces using atmospheric plasma spraying (APS) technology, with ZrSiO

4 as the feedstock material. A comprehensive characterization of the coating systems was conducted, including an in-depth analysis of phase composition and a systematic evaluation of the effects of spray thickness and heat treatment temperature on phase evolution, microstructural development, and the resulting properties. The coatings’ resistance to silicon corrosion and the associated failure mechanisms were thoroughly examined. The key findings reveal that the plasma-sprayed coatings form a multiphase system composed of ZrSiO

4, along with the decomposition products of ZrO

2 and SiO

2. Optimal performance was observed within a critical thickness range of 154–240 μm. Post-deposition heat treatment at 1500 °C significantly improved the integrity of the coatings, as evidenced by a marked reduction in crack density and porosity, leading to substantial enhancement in densification. The coatings demonstrated outstanding performance in the high-temperature silicon corrosion tests, maintaining structural integrity after 4 h of exposure to molten silicon and its oxides at 1500 °C. Notably, the coatings effectively prevented the penetration of silicon into the C/C substrate, preserving strong interfacial adhesion without the formation of permeable cracks. Furthermore, post-corrosion analysis showed that the surface reaction products could be easily removed, underscoring the coatings’ exceptional protective capability for the underlying C/C substrate.

Full article

►▼

Show Figures

Open AccessArticle

The Effects of Surface Plasma Carburization on the Microstructure and Molten Salt Corrosion Resistance of Ta

by

Xuming Lv, Dongbo Wei, Xianpu Huang, Zeyu Gao and Pingze Zhang

Cited by 2 | Viewed by 1258

Abstract

In order to enhance the corrosion resistance of tantalum, the double-glow plasma (DGP) metallurgy technique was used to prepare TaC coatings on the tantalum. The morphology, microstructure, and phase constituents of TaC were examined by scanning electron microscopy (SEM) and X-ray diffraction (XRD).

[...] Read more.

In order to enhance the corrosion resistance of tantalum, the double-glow plasma (DGP) metallurgy technique was used to prepare TaC coatings on the tantalum. The morphology, microstructure, and phase constituents of TaC were examined by scanning electron microscopy (SEM) and X-ray diffraction (XRD). Nano-indentation tests were used to evaluate the mechanical properties of the coatings. The specimens were immersed in NaCl-KCl molten salt at 830 °C to evaluate their corrosion resistance. The results showed that the coating prepared by the DGP technique has a thickness of approximately 5 µm, the diffusion layer has a thickness of 2.5 µm, and the nano-indentation hardness is measured to be 17.27 GPa. The high-temperature stable ceramic phase enhances the high-temperature oxidation resistance of pure tantalum (Ta), while the dense corroded surface and oxidation products improve the anti-corrosion property of TaC coatings.

Full article

►▼

Show Figures

Open AccessEditor’s ChoiceArticle

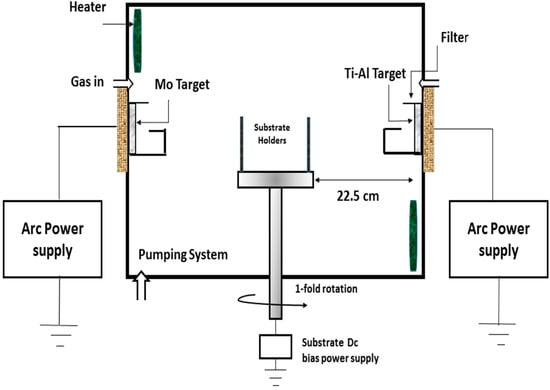

Influence of Bilayer Thickness on Mechanical and Tribological Properties of (Ti-Al)N/MoN Nanostructured Hard Coatings Deposited by Cathodic Arc Ion Plating

by

Muhammad I. Yousaf, Tushagu Abudouwufu, Bing Yang, Alexander Tolstoguzov and Dejun Fu

Cited by 3 | Viewed by 1825

Abstract

Deposition of (Ti-Al)N/MoN multilayered coatings was carried out through a cathodic ion-plating system in an argon and then nitrogen atmosphere. Bilayer thickness (Λ) of all the samples were achieved, from 22 to 104 nm, by organizing substrate holder rotational speed (SRS). To obtain

[...] Read more.

Deposition of (Ti-Al)N/MoN multilayered coatings was carried out through a cathodic ion-plating system in an argon and then nitrogen atmosphere. Bilayer thickness (Λ) of all the samples were achieved, from 22 to 104 nm, by organizing substrate holder rotational speed (SRS). To obtain the optimum properties of the (Ti-Al)N/MoN coatings, the Ti and Al ratio was maintained at a level of 1:1. X-ray diffraction (XRD), high-resolution transmission electron microscopy (HRTEM), X-ray photoelectron spectroscopy (XPS), and Raman spectroscopy were utilized to analyze the crystal structure and morphology of the coatings. Mechanical and tribological properties were examined by nanohardness and atomic force microscopy (AFM). The preferred orientation of the (Ti-Al)N/MoN nanoscale multilayer films was TiAlN (200) and MoN (200), which had face centered cubic (fcc) and hexagonal structures, respectively. The hardness increased with the decrease in Λ (104 nm to 26 nm), and then it increased. The highest hardness of 37 GPa was revealed at Λ = 26 nm, whereas the least wear rate of 8.09 × 10

−7 mm

3/N.m was attained at Λ = 22 nm. Wear rate, roughness, and coefficient of friction were decreased with decreasing bilayer period. EDS results showed that Al and Ti contents were almost the same in all samples, as per design of the experiment.

Full article

►▼

Show Figures