In Vitro Comparative Study of Microhardness and Flexural Strength of Acrylic Resins Used in Removable Dentures †

Abstract

:1. Introduction

2. Materials and Methods

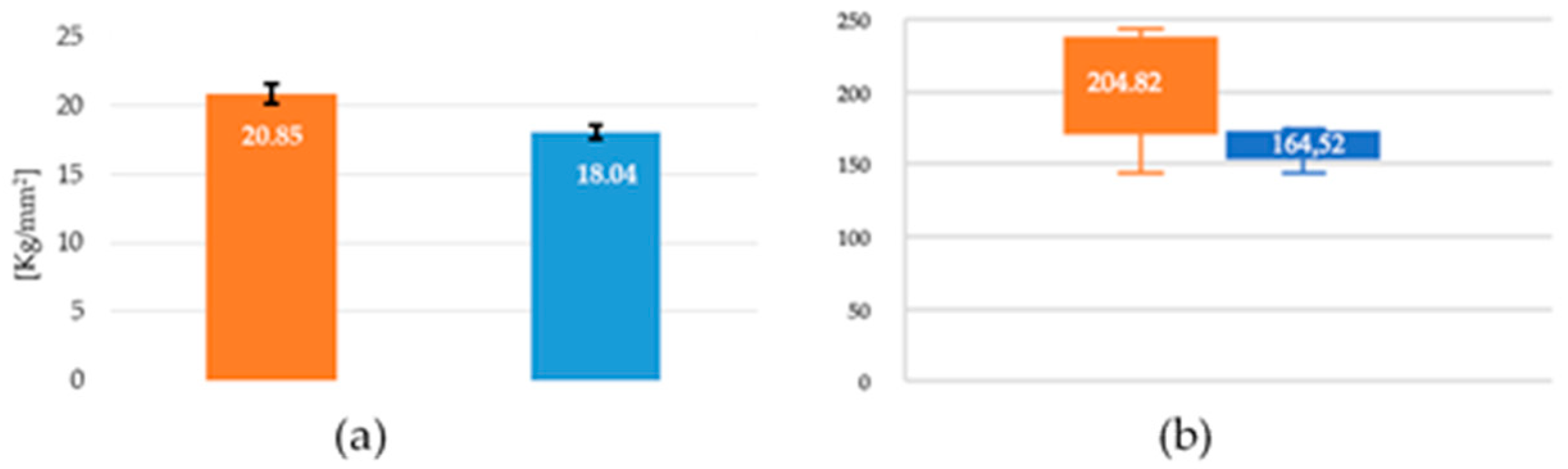

3. Results and Discussion

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cervino, G.; Cicciù, M.; Herford, A.S.; Germanà, A.; Fiorillo, L. Biological and Chemo-Physical Features of Denture Resin. Materials 2020, 13, 3350. [Google Scholar] [CrossRef] [PubMed]

- Ozkir, S.E.; Yilmaz, B.; Unal, S.M.; Culhaoglu, A.; Kurkcuoglu. Effect of heat polymerization conditions and microwave on the flexural strength of polymethylmethacrylate. Eur. J. Dent. 2018, 12, 116–119. [Google Scholar] [CrossRef] [PubMed]

- Camacho, D.; Svidzinki, T.; Furlaneto, M.; Lopes, M.; Corrêa, G. Acrylic resins for dental use based polymethylmethacrylate. Braz. J. Surg. Clin. Res. 2014, 6, 63–72. [Google Scholar] [CrossRef]

- ISO 20795-1. Dentistry—Base Polymers—Part 1: Denture Base Polymers; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Kostic, M.; Petrovic, M.; Krunic, N.; Igic, M.; Janosevic, P. Comparative analysis of water sorption by different acrylic materials. Acta Med. Median. 2014, 53, 5–9. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, M.; Neves, S.; Carvalho, J.; Arantes-Oliveira, S.; Félix, S. In Vitro Comparative Study of Microhardness and Flexural Strength of Acrylic Resins Used in Removable Dentures. Med. Sci. Forum 2021, 5, 45. https://doi.org/10.3390/msf2021005045

Costa M, Neves S, Carvalho J, Arantes-Oliveira S, Félix S. In Vitro Comparative Study of Microhardness and Flexural Strength of Acrylic Resins Used in Removable Dentures. Medical Sciences Forum. 2021; 5(1):45. https://doi.org/10.3390/msf2021005045

Chicago/Turabian StyleCosta, Marta, Sara Neves, Joana Carvalho, Sofia Arantes-Oliveira, and Sérgio Félix. 2021. "In Vitro Comparative Study of Microhardness and Flexural Strength of Acrylic Resins Used in Removable Dentures" Medical Sciences Forum 5, no. 1: 45. https://doi.org/10.3390/msf2021005045

APA StyleCosta, M., Neves, S., Carvalho, J., Arantes-Oliveira, S., & Félix, S. (2021). In Vitro Comparative Study of Microhardness and Flexural Strength of Acrylic Resins Used in Removable Dentures. Medical Sciences Forum, 5(1), 45. https://doi.org/10.3390/msf2021005045