Abstract

The utilization of sugarcane molasses (SCM), a byproduct of sugar refining, offers a promising bio-based alternative to conventional chemical admixtures in cementitious systems. This study investigates the effects of SCM at five dosage levels, 0.25%, 0.50%, 0.75%, 1.00%, and 1.25% by weight of cement, on cement mortar performance across fresh, mechanical, thermal, durability, and density criteria. A comprehensive experimental methodology was employed, including flow table testing, compressive strength (7, 14, and 28 days) and flexural strength measurements, embedded thermal sensors for real-time hydration monitoring, water absorption and chloride ion penetration tests, as well as 28-day density determination. Results revealed clear dose-dependent behavior, with SCM enhancing mortar flowability proportional to dosage, raising the spread diameter from 11.5 cm (control) to 20 cm at 1.25%. At 0.25% SCM, compressive strength (47.5 MPa at 28 days) and flexural strength (~2.9 MPa) were higher than those of the remaining SCM dosages, supported by sustained heat release and positive temperature differentials. However, dosages ≥ 0.5% drastically suppressed hydration kinetics and mechanical performance, with compressive strength falling below 10 MPa. Furthermore, high SCM content led to increased water absorption (up to 10.6%) and chloride permeability (CIP above 5100 C), while bulk density declined from 2250 kg/m3 to 2080 kg/m3 at 1.25% SCM. Statistical validation using one-way ANOVA confirmed that these differences across dosage levels were significant (p < 0.05), underscoring the importance of dosage optimization. This investigation confirms that low-dosage SCM (≤0.25%) can be an effective bio-additive, providing improved workability with negligible compromise in strength and durability. In contrast, higher dosages undermine matrix integrity and performance. Future work is recommended to assess long-term microstructural evolution, field exposure durability, and adaptability across diverse cementitious systems.

1. Introduction

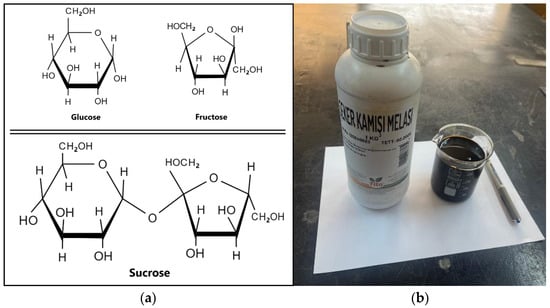

In the quest for more sustainable and environmentally friendly construction practices, the search for viable bio-based alternatives to traditional chemical admixtures in cementitious materials has gained significant momentum [1,2]. Among these alternatives, sugarcane molasses (SCM) has emerged as a promising eco-efficient additive, primarily due to its organic composition, wide availability, and economic value [3]. SCM is a viscous, dark brown byproduct derived from the final stage of sugar extraction in the sugar refining industry [4]. Chemically, SCM consists of approximately 76% dry matter, with major constituents including sucrose (42.4–55.2%), glucose (2.6–8%), fructose (5.3–10.9%), ash (10–16%), and smaller quantities of organic acids, polysaccharides, oligosaccharides, crude protein, potassium, and nitrogen compounds [5]. This composition imparts multifunctional behavior, enabling SCM to serve as a water-reducing, set-retarding, or accelerating agent based on its dosage and interaction with cement hydration products [6,7,8,9].

Numerous studies have explored the performance of SCM in modifying fresh and hardened properties of mortar and concrete. At lower dosages, SCM acts predominantly as a dispersant and hydration modulator. For instance, Yousif et al. [10] reported a 41.4% increase in 7-day compressive strength and a peak strength of 40 MPa at 28 days with 0.25% SCM. Weifeng et al. [11] demonstrated a 12% strength improvement at 3 days with just 0.04% molasses, along with delayed C3S hydration and enhanced fluidity. In another study, Ali et al. [12] found that incorporating 0.25–0.50% sugarcane molasses into recycled aggregate concrete improved both workability and compressive strength, particularly at a 0.50 W/C ratio, reinforcing the efficacy of low SCM dosages for enhancing fresh and hardened properties. These enhancements are typically attributed to the presence of sugars and organic acids, which modulate the formation and growth of hydration products such as ettringite and calcium silicate hydrates.

The retarding effects of SCM have been extensively documented. Khan & Baradan [13] found a setting time delay of up to 255 min with 0.04% molasses, a behavior that proves especially valuable in hot weather concreting. Yildrim and Altun examined three molasses types sourced from different factories and found that molasses significantly prolonged both the initial and final setting times of mortar [14]. Similarly, Kassa observed increased setting times with 0.075–0.1% molasses, while a higher dosage of 0.3% led to a reduction in setting time [15]. Conversely, Juneja et al. reported that molasses accelerates setting at lower dosages (up to 0.5%) but delays it when used at higher levels (0.75–2.0%) [16]. Mohammed & Kadhim [17] utilized SCM in lightweight concrete, achieving 42.2 MPa compressive strength with a 19.31% reduction in density, highlighting its effectiveness even in alternative aggregate systems. From a durability perspective, Akar & Canbaz [18] reported an increase in 28-day strength by 20% and improved resistance to alkali-silica reaction when SCM was incorporated at optimal levels. Similar findings were echoed by Dias et al. [19], who studied hydration chemistry alterations due to the presence of molasses. These benefits underscore SCM’s potential to improve both the service life and the mechanical performance of cement-based materials. Despite its advantages, the performance of SCM is highly dosage sensitive. Exceeding optimal limits can result in excessive retardation or adverse effects on early-age strength. For instance, Odal [20] demonstrated that incorporating 1.5% sugarcane molasses by weight of cement resulted in a marked reduction in compressive strength and a prolonged final setting time of 270 min, emphasizing the detrimental effects of excessive SCM dosage on early-age performance. Thus, determining the optimal dosage is critical for balancing workability, setting time, and mechanical performance.

Given this context, the present study aims to systematically assess the performance of SCM as a bio-based additive in cement mortar. Five dosage levels of 0.25%, 0.50%, 0.75%, 1.00%, and 1.25% by weight of cement were selected to explore the dosage-dependent effects of SCM on both fresh and hardened properties. The experimental program encompasses the following: (i) workability characterization via flow table testing; (ii) mechanical evaluation through compressive strength testing at 7, 14 and 28 days, as well as flexural strength testing of prisms; and (iii) hydration behavior monitoring using embedded thermal sensors to capture real-time internal temperature evolution concerning ambient conditions. Additionally, the study investigates durability attributes, including water absorption and chloride ion penetration, alongside density measurements to assess the influence of SCM on pore structure and matrix compactness. Collectively, these assessments aim to deliver a comprehensive understanding of the role of SCM in influencing hydration kinetics, microstructural development, and performance outcomes in cement-based systems.

The novelty of this study lies in the comprehensive evaluation of SCM’s performance across fresh, mechanical, durability, density and thermal properties. In contrast to the previous limited investigations, this study utilizes real-time thermal monitoring linking SCM dosage with hydration kinetics and performance results.

To support the scientific rationale and contextual relevance of this study, Table 1 offers a chronological summary of key investigations into the use of SCM in cementitious systems. It provides a structured comparison of experimental approaches, dosage levels, testing protocols, and resultant performance metrics. This summary consolidates current understanding while highlighting areas where further research is needed, offering valuable context for the objectives and direction of the present study. It is worth mentioning that each of the studies mentioned in Table 1 has its own unique SCM composition, however they do not vary drastically from the limits given earlier.

Table 1.

Summary of research on SCM in cementitious mixes.

2. Materials and Mix Design

2.1. Materials

A total of five basic mortar mixes were used throughout this research that had the following constituents.

2.1.1. Cement

The cement used in this research is ordinary Portland cement CEM I 42.5N, which conforms to ASTM C150/C150M-20 [26]. The chemical and physical properties of the used cement are listed in Table 2 and Table 3, respectively.

Table 2.

Chemical Composition and Main Compounds of OPC.

Table 3.

Physical Properties of OPC.

2.1.2. Sand

The fine aggregate used in this research is classified as zone 2, which agrees with ASTM C33/C33M-18 [27]. The grading for the fine aggregate was determined by sieve analysis, and the results are listed in Table 4. Physical and chemical properties are listed in Table 5.

Table 4.

Sieve analysis of sand used in this study according to ASTM C33.

Table 5.

Physical and chemical properties for the sand used in this study.

2.1.3. Water

Clean, potable water was employed in the preparation of the mortar mixes, exhibiting a neutral pH of 7.0, a chloride concentration of 0.04%, and a sulfate content of 0.08%, all within acceptable limits for construction applications.

2.1.4. Sugar Cane Molasses

The sugar cane molasses (SM) was obtained from Al-Etihad Co. Ltd. in Babylon, Iraq. Molasses from sugarcane is a residual product obtained during sugar processing. As sugarcane juice is boiled to form crystals, the leftover dense, dark syrup that remains after extracting the sugar is known as molasses. Properties of the SCM used are listed in Table 6. Figure 1 exhibits the SM used in this study.

Table 6.

Sugar Cane Molasses properties.

Figure 1.

Sugar Cane Molasses used in this study, (a) molecular structure of SCM, (b) SCM photograph.

2.2. Mixing Procedure and Curing Method

The mixing procedure adopted in this study conforms to ASTM C109 specifications [28]. The mortar mix comprised one part cement to 2.75 parts sand by mass, with a constant water-to-cement (W/C) ratio maintained at 0.45. Sugar cane molasses was used as an additive at levels of (0, 0.25, 0.5, 0.75, 1.00, 1.25%) by weight of cement. Figure 2a shows the mixer with a capacity of five liters that was used in preparing the mixes. The dry constituents were mixed before adding the water with the percentage of sugar cane molasses until a homogeneous mix was obtained. The mix’s consistency was determined using the flow table test according to ASTM C1437 [29] in which its apparatus is shown in Figure 2b. Then, the mortar mix was placed in clean and oiled moulds to prepare the specimen shown in Figure 3. 50 mm cubic specimens were cast and compacted in two layers for compressive strength testing. In addition, prism specimens measuring 40 mm × 40 mm × 160 mm were prepared for flexural strength testing. A single 150 mm cube was prepared for each mix to determine the hydration temperature of each mix. Specimens, for the compressive and flexural strengths, after demolding were left in the laboratory for 24 h to totally dry, then placed in water until the day of testing.

Figure 2.

(a) The mortar mixer, (b) apparatus for the flow table test according to ASTM C1437.

Figure 3.

Mortar moulds for preparing the specimens.

3. Testing Program

For compressive strength evaluation, The 50 mm cubes were tested at the ages of 7, 14, and 28 days according to ASTM C109/C109M [28]. The specimens were demolded after 24 h and cured in lime-saturated water until the designated testing ages. Testing was performed using a TC-B001 universal testing machine with a compressive strength capacity of 3000 kN, operated at a constant loading rate of 0.3 MPa/s. For each age and dosage, three replicate samples were tested, and the average value was reported.

Flexural strength was determined on prism specimens (40 × 40 × 160 mm) at 7, 14, and 28 days according to ASTM C348 [30]. The specimens were tested under three-point loading with a span length of 100 mm, and the applied load was recorded until failure. Similarly to compressive testing, the mean of three prisms was calculated for each age and SCM dosage. Thermal behavior during hydration was monitored by embedding calibrated electronic temperature sensors at the center of selected mortar cubes. Temperature readings were automatically logged at hourly intervals for the first 72 h of hydration, along with simultaneous ambient temperature measurements. Figure 4 illustrates the thermometer and sensor arrangement. These measurements allowed for assessing the internal exothermic activity associated with hydration reactions and the influence of SCM dosage. Additional testing included flow table measurements for workability assessment (ASTM C230) [31], water absorption (ASTM C642) [32], and rapid chloride ion penetration (ASTM C1202) [33]. Density was determined by oven-drying the specimens at 105 ± 5 °C to constant mass and dividing by their respective volumes. Each test was performed in triplicate, and averages are reported to ensure consistency and reliability.

Figure 4.

Thermometers used in determining both the mortar’s and ambient temperatures.

4. Results and Discussion

4.1. Workability (Flow Table Test Results)

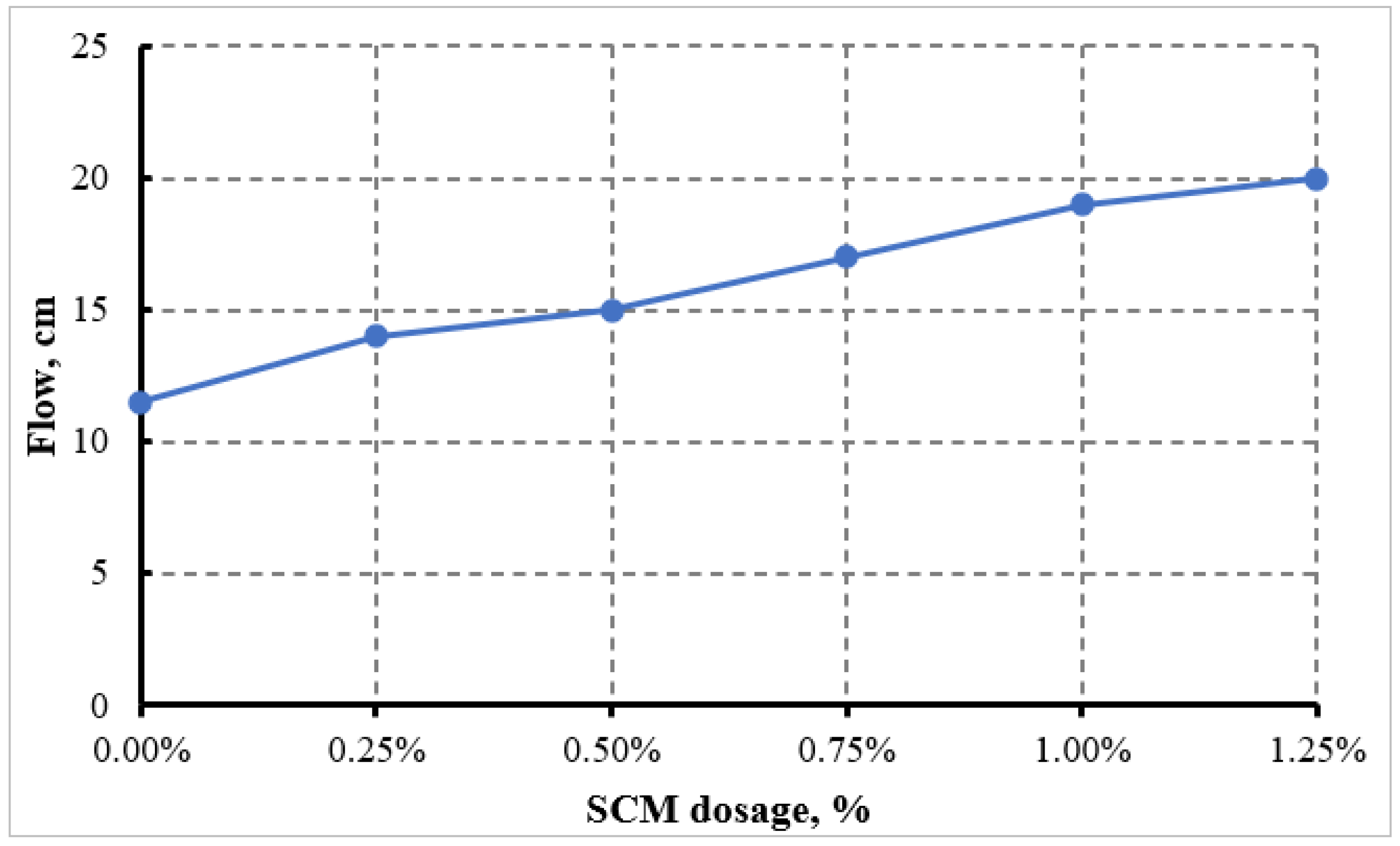

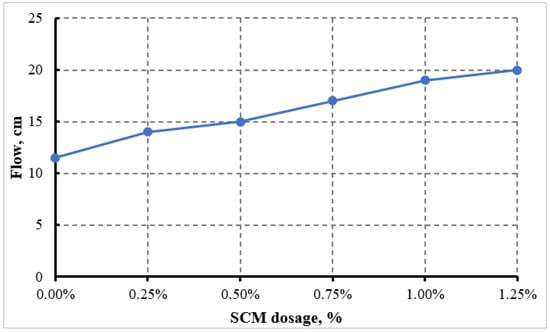

Figure 5 illustrates the flow diameter of cement mortar mixtures containing various dosages of sugarcane molasses (SCM), demonstrating a progressive increase in workability with higher SCM content.

Figure 5.

Workability test results.

The control mix exhibited a flow diameter of 11.5 cm, while the mix with 1.25% SCM achieved the highest diameter of 20 cm, marking a 74% enhancement in flow. The increase was approximately linear, with increments of 2–3 cm observed between each dosage step. This improved workability can be attributed to the plasticizing effect of SCM components, particularly the high sugar content (sucrose, glucose, fructose), which adsorb on cement particle surfaces and promote dispersion by breaking down agglomerates and reducing water demand. Additionally, the acidic nature of molasses (pH ~4.7) may delay early hydration, reducing the formation of stiffening hydrates in the fresh state and further enhancing flowability. These observations are consistent with findings from [24], who reported a slump increase from 4.9 cm to 18.6 cm upon the addition of 0.3% SCM, and [34], who observed improved surface smoothness and workability at higher dosages. Similarly [17] linked increased fluidity to organic dispersants present in molasses, which facilitate better particle rearrangement in the mix. However, it is worth noting that while enhanced flow is advantageous for workability and compaction, excessive dosage may impact setting behavior and early strength development, necessitating a balanced optimization in practical applications. Overall, the flow table data affirm the potential of SCM as an effective bio-based plasticizer, offering significant improvements in mortar rheology without reliance on synthetic chemical admixtures.

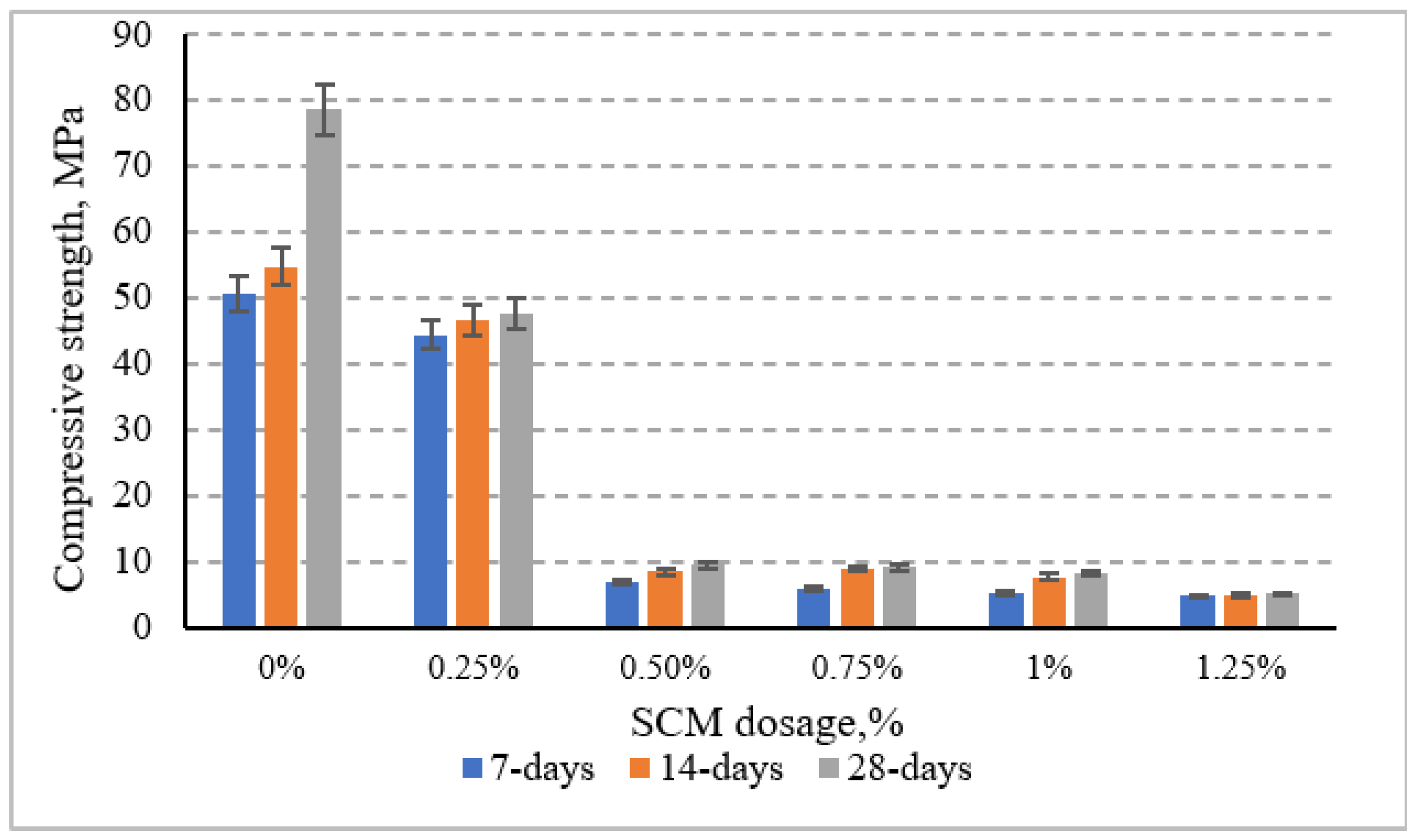

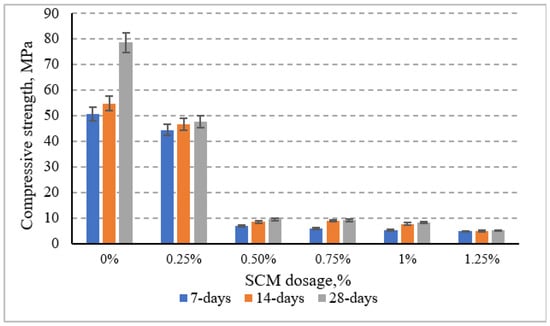

4.2. Compressive Strength

As illustrated in Figure 6, the compressive strength of mortar mixes exhibited a pronounced sensitivity to the dosage of SCM, with strength trends varying significantly across the evaluated curing ages (7, 14, and 28 days). The control mix (0% SCM) demonstrated the highest compressive strength, reaching approximately 52 MPa at 7 days, 55 MPa at 14 days, and peaking near 80 MPa at 28 days. Upon incorporating 0.25% SCM, a moderate strength reduction was observed, with 28-day compressive strength decreasing to around 48 MPa, representing a ~40% drop compared to the control mix. Despite this reduction, the 0.25% mix still retained reasonable strength development, suggesting partial compatibility of low SCM dosages with the hydration process. However, further increases in SCM content (≥0.25%) led to a sharp and consistent decline in compressive strength at all curing ages. At 0.50%, the 28-day strength fell below 10 MPa, and continued to decline slightly with 0.75%, 1.0%, and 1.25% dosages, exhibiting strengths of 9.1, 8.21 and 5.04 MPa, respectively. This pronounced drop can be attributed to excessive retardation of cement hydration caused by high concentrations of sugars and organic compounds in molasses, which interfere with the formation of calcium silicate hydrate (C–S–H) and delay the setting and strength gain processes. This behavior aligns with findings reported by [34], who noted that high SCM dosages suppress early hydration kinetics and adversely affect long-term mechanical development.

Figure 6.

Compressive strength results at different ages.

These results underscore the critical dosage threshold of SCM in cementitious systems, where low additions (<0.5%) may provide limited benefits or minimal compromise, while higher dosages (>0.5%) significantly disrupt structural integrity. Thus, for compressive strength enhancement or preservation, careful optimization of SCM dosage is essential.

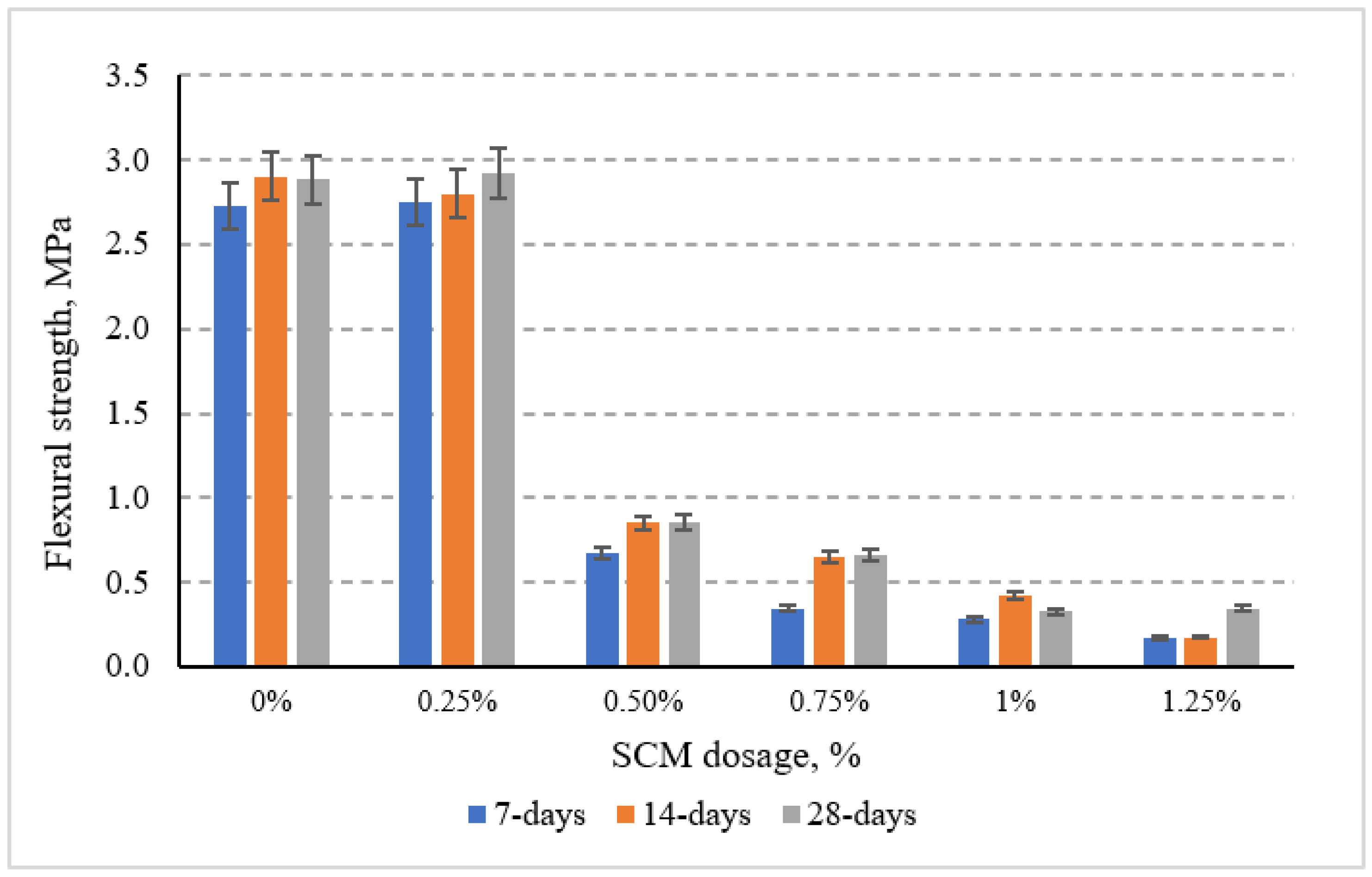

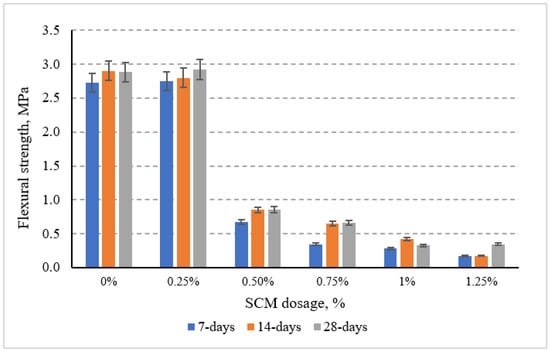

4.3. Flexural Strength Results

Figure 7 presents the evolution of flexural strength for mortar mixes incorporating various dosages of SCM at 7, 14, and 28 days. The control mix (0% SCM) achieved the highest flexural performance, with values of approximately 2.8 MPa at 7 days and rising marginally to about 3.0 MPa at 28 days. Incorporating 0.25% SCM resulted in negligible reduction in strength, maintaining values close to the control (≈2.7–2.9 MPa), suggesting that low concentrations of SCM do not significantly compromise the mortar’s tensile load-bearing capacity. However, at dosages ≥ 0.25%, flexural strength declined sharply. Mortars with 0.50% SCM reached a maximum of only ~0.9 MPa at 28 days, while those with 1.25% showed flexural strength below 0.4 MPa—an overall drop of nearly 85% compared to the control. This trend is consistent with the observed reduction in compressive strength and can be attributed to disrupted hydration kinetics and impaired microstructural development at higher molasses dosages. The excessive sugar content likely hinders the formation and interlinking of calcium silicate hydrate (C–S–H) gel and ettringite, which are vital for tensile stress transfer within the matrix.

Figure 7.

Flexural strength results at different ages.

These results reaffirm the dosage-sensitive nature of SCM as a bio-admixture, emphasizing that although small additions may preserve or marginally affect flexural performance, higher dosages significantly weaken the mortar’s flexural response, potentially compromising durability and crack resistance.

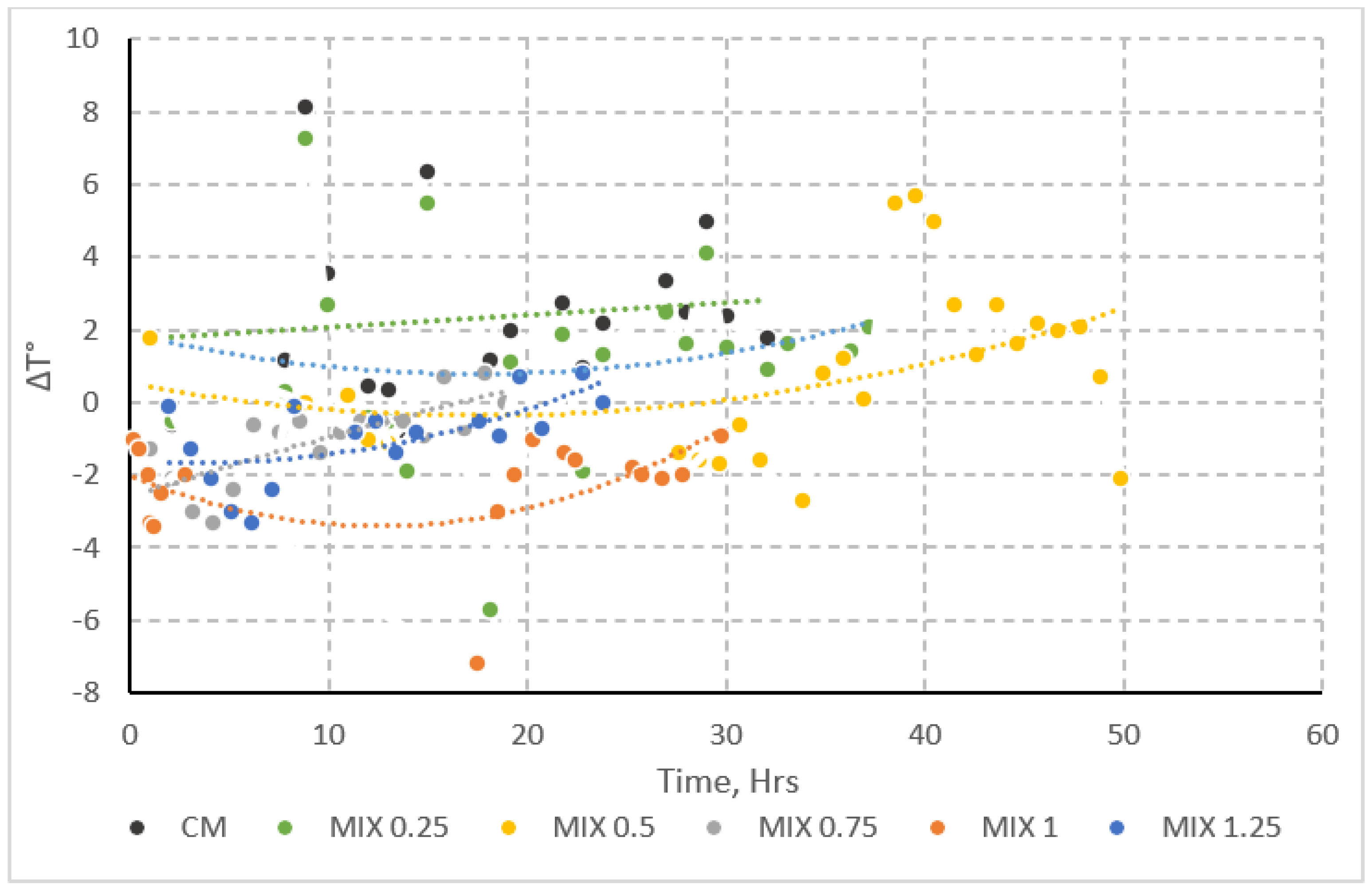

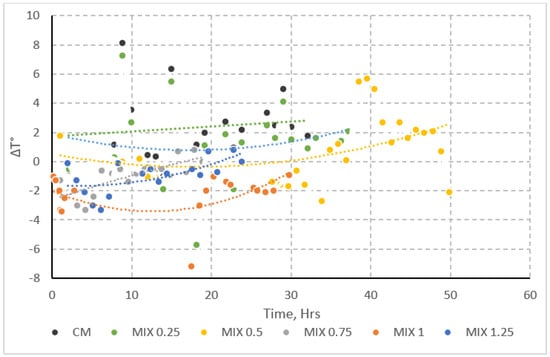

4.4. Thermal Behavior During Hydration

Figure 8 illustrates the evolution of temperature differentials (ΔT) over time for mortar mixes containing varying dosages of sugarcane molasses (SCM), relative to the control mix (CM). The ΔT represents the internal exothermic response subtracted from ambient conditions, offering a sensitive proxy for tracking the hydration heat released as a function of time.

Figure 8.

Thermal profile for varying cement mortars.

The control mix (CM) exhibited a steady linear increase in temperature, indicating uninterrupted hydration and typical exothermic progression associated with the formation of calcium silicate hydrate (C–S–H) and other hydration products. Among the SCM-modified mortars, the 0.25% dosage demonstrated the most active exothermic behavior, with ΔT rising positively over time and showing consistent upward deviation after 24 h. This profile implies enhanced hydration kinetics likely due to the catalytic effect of low sugar concentrations in promoting early nucleation and accelerating the formation of hydration products.

Conversely, higher dosages of SCM (0.75%, 1.0%, and 1.25%) showed flatter or even initially negative ΔT profiles during the first 24 h, suggesting delayed or suppressed exothermic activity. Notably, the 1.0% mix exhibited the most pronounced thermal depression (ΔT as low as −4 °C), with only gradual recovery after 30 h. These subdued profiles align with the significantly lower mechanical strengths observed for these mixes, reinforcing the notion that high concentrations of sugars interfere with early-age hydration, possibly via chelation of calcium ions and inhibition of C–S–H growth [19,34]. Overall, thermal monitoring confirms the dosage-sensitive dual role of SCM: a hydration facilitator at low contents and a retardant at higher levels. This underscores the value of in situ thermal analysis in optimizing SCM dosages for performance enhancement in cementitious systems.

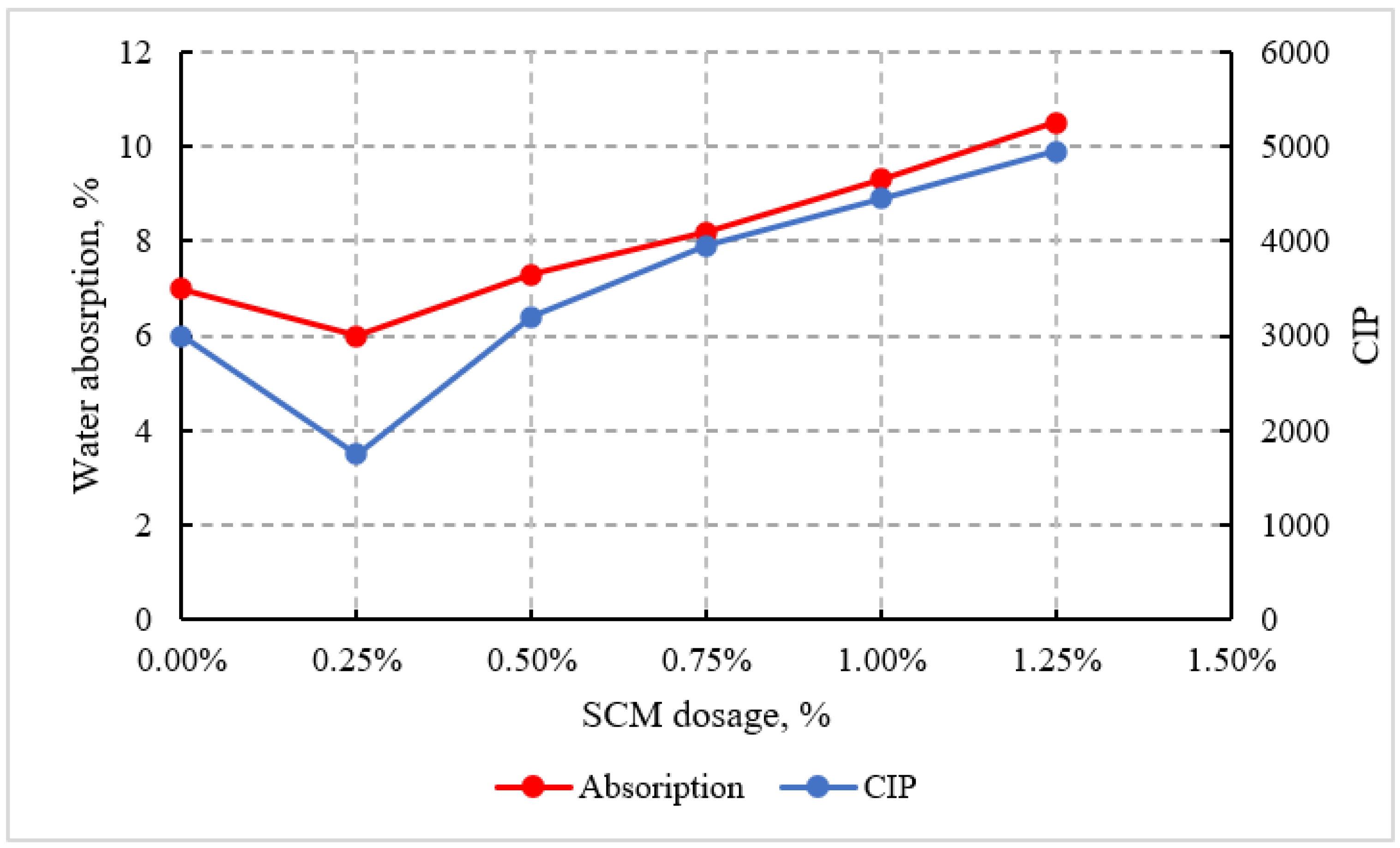

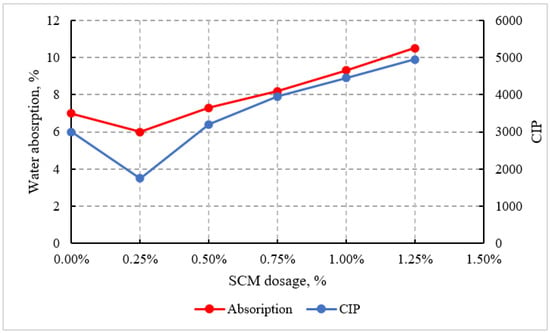

4.5. Durability Results

Durability of the SCM-modified mortars was evaluated through two key indicators: water absorption and chloride ion penetration (CIP), both presented in Figure 9. Water absorption results demonstrated that incorporating 0.25% SCM reduced absorption from 7.1% in the control mix to 6.2%, indicating improved compactness and reduced pore connectivity. This enhancement can be attributed to better particle dispersion and possibly denser early hydration products facilitated by low sugar concentrations. However, as the SCM dosage increased beyond 0.25%, water absorption rose progressively, reaching 10.6% at 1.25%. This suggests that higher organic and sugar content interfered with normal hydration processes, leading to increased capillary porosity. A similar trend was observed in CIP measurements: chloride penetration declined at 0.25% SCM to 3500 C, reflecting enhanced resistance to ionic ingress, but increased steadily at higher dosages, peaking at 5100 C for 1.25% SCM. The correlation between elevated absorption and CIP underscores the negative impact of excessive SCM on the microstructural integrity of the mortar. These findings align with prior studies [19,24], which reported that elevated sugar concentrations can delay hydration and promote a looser pore structure, ultimately compromising durability.

Figure 9.

Durability results for varying cement mortars.

Overall, the data support the hypothesis that low dosages of SCM can be beneficial for enhancing durability, while higher concentrations induce adverse effects due to poor microstructural integrity. The trends observed reinforce the critical importance of dosage optimization when incorporating bio-based admixtures like sugarcane molasses in cementitious systems.

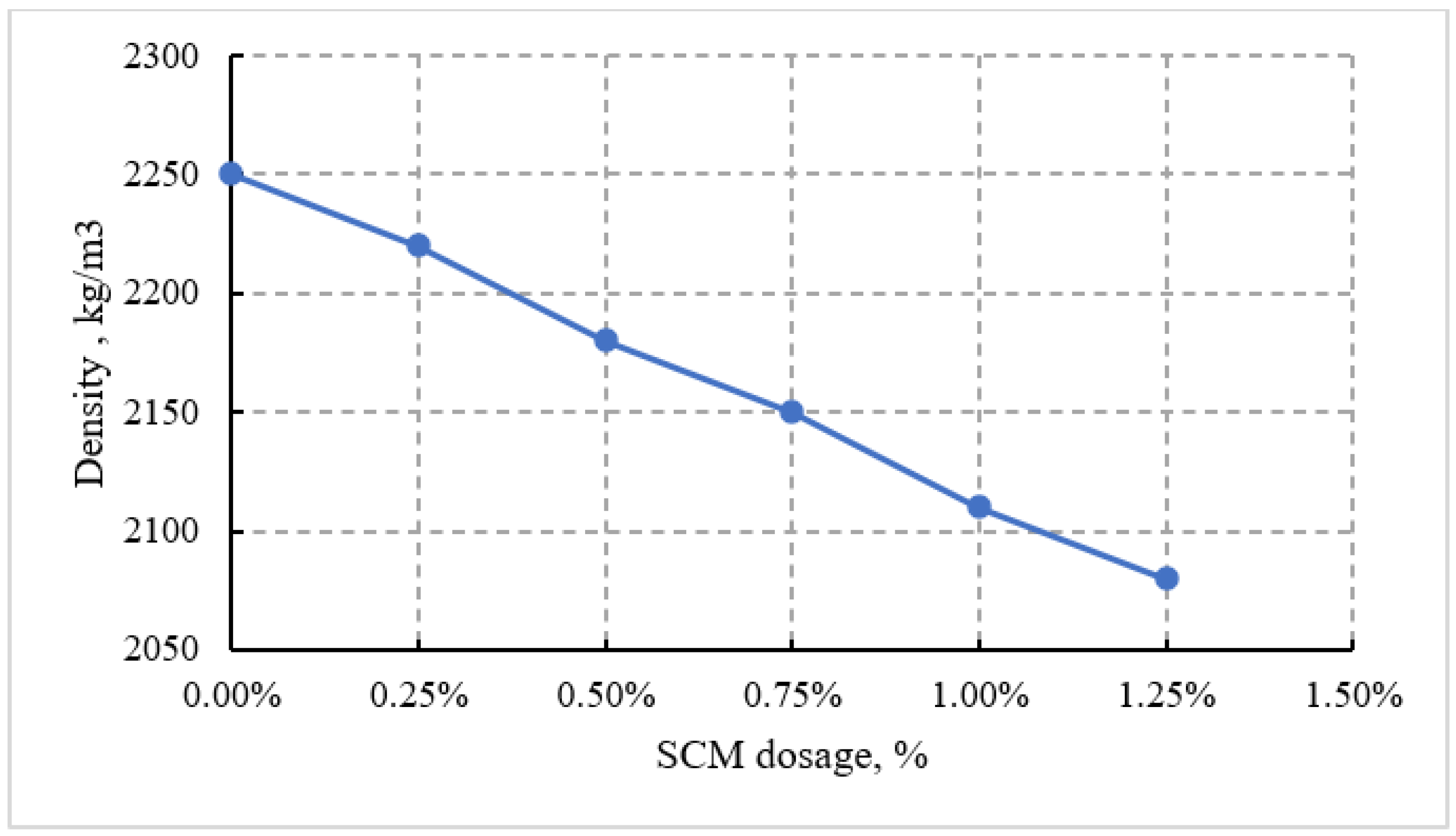

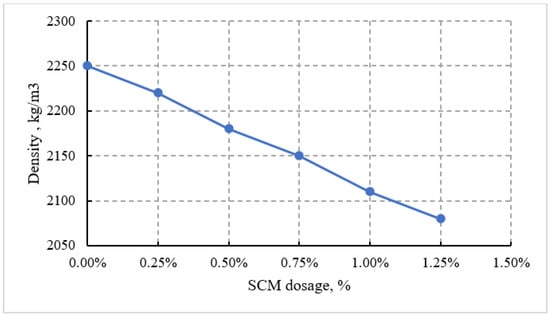

4.6. Density Results

The influence of sugarcane molasses (SCM) on the density of cement mortars at 28 days is illustrated in Figure 10. The results indicate a clear decreasing trend in density with increasing SCM dosage. The control mix recorded the highest density at 2250 kg/m3. Incorporating 0.25% and 0.5% SCM led to moderate reductions, lowering density to approximately 2220 kg/m3 and 2180 kg/m3, respectively. Further increases in SCM content resulted in more pronounced declines, reaching 2150 kg/m3 at 0.75%, 2110 kg/m3 at 1.0%, and a minimum of 2080 kg/m3 at 1.25%. This progressive reduction is likely linked to two main factors: the lower specific gravity of the SCM additive itself and the disruption of cement hydration at higher dosages, which can produce a more porous and less compact microstructure. These trends are consistent with the findings of [17], who observed similar reductions in density in lightweight concrete containing SCM, attributing it to reduced solid phase development and increased entrapped air or capillary porosity. Thus, while low SCM dosages may retain acceptable mass-to-volume ratios, excessive inclusion compromises the matrix compactness and bulk density of the hardened mortar.

Figure 10.

Density results for varying cement mortars.

5. Statistical Insight

To complement the experimental findings, regression and ANOVA analyses were conducted using Minitab 17 to statistically validate the effect of sugarcane molasses (SCM) dosage on cement mortar performance. The null hypothesis (H0) assumed that no significant differences exist among the tested dosage levels, while the alternative hypothesis (H1) posited that SCM content produces measurable changes in fresh, mechanical, thermal, durability, and density properties. A 95% confidence level was adopted, whereby a p-value < 0.05 necessitates rejection of H0, confirming that the observed variations are statistically significant. As summarized in Table 7, the results demonstrated clear evidence of significance across multiple parameters. Compressive strength at 28 days showed a strong negative correlation with dosage (p = 0.027), confirming that higher SCM levels reduce strength beyond random variation. Similarly, flexural strength decreased systematically with dosage (p = 0.015), reflecting the same sensitivity. Workability, on the other hand, improved markedly with increasing SCM, and the regression model explained nearly all the variance (R2 = 98.8%, p < 0.001), highlighting a consistent and statistically robust trend. Durability indicators also reached significance: water absorption rose with dosage (p = 0.009), and chloride ion penetration correlated strongly with SCM content (p = 0.026), underscoring the negative durability implications of overdosing. Finally, density exhibited the most significant response, with R2 = 99.8% and p < 0.001, confirming that the observed reductions cannot be attributed to chance.

Table 7.

Summary of Regression and ANOVA Results.

Overall, the statistical analyses conducted in Minitab 17 provide robust evidence that SCM dosage exerts a decisive effect on mortar performance. With all key performance indicators returning p-values below 0.05, the null hypothesis was consistently rejected. These findings reinforce the experimental observations and confirm that dosage optimization is critical: while low SCM levels enhance workability without major performance penalties, higher dosages significantly compromise strength, durability, and density. This statistical validation therefore justifies restricting SCM incorporation to ≤0.25% by cement weight for practical applications, beyond which adverse effects become both experimentally evident and statistically significant.

6. Conclusions

This study comprehensively investigated the effects of incorporating sugarcane molasses (SCM) as a sustainable bio-additive into cement mortar at varying dosages (0.25% to 1.25% by weight of cement). The experimental program encompassed fresh properties, mechanical performance, thermal behavior during hydration, durability characteristics, and density evaluations. Based on the results obtained, the following conclusions can be drawn:

- Incorporating SCM increased mortar workability and increased the flow diameter from 11.5 cm (control) to 20 cm at the dosage of 1.25%. This behavior is attributed to the dispersing action of sugar-based compounds in molasses, which reduces interparticle friction and enhances paste fluidity.

- Mortar workability improved progressively, as indicated by the increase in flow diameter from 11.5 cm (control) to 20 cm at 1.25% SCM.

- At 0.25% SCM, compressive (47.5 MPa at 28 days) and flexural (~2.9 MPa) strengths were lower than the control mix but higher than the strengths exhibited by the remaining dosages, demonstrating minimal interference with hydration. However, higher dosages (≥0.25%) led to drastic reductions in both strengths (compressive < 10 MPa), confirming that SCM’s effect is highly dosage-dependent and detrimental beyond optimal levels.

- Thermal monitoring results showed that 0.25% SCM exhibited the strongest sustained heat release and hence enhanced hydration. At 0.75% SCM showed suppressed temperatures due to sugar–calcium complexation inhibiting C-S-H and delayed setting time.

- Durability assessments showed increasing water absorption and chloride ion penetration with rising SCM content. The control mix had the lowest values (~7% absorption, ~6000 C CIP), while the 1.25% SCM mix exceeded 10% absorption and approached 5300 C. These results indicate deterioration in pore structure and increased permeability at high SCM levels.

- Mortar density steadily declined from 2250 kg/m3 (control) to ~2080 kg/m3 at 1.25% SCM. This trend likely results from a more porous matrix and entrapped air associated with delayed setting and altered hydration, especially at higher sugar concentrations.

- At a low dosage (0.25%), SCM can be considered a useful, effective, and sustainable admixture. It improves workability while maintaining acceptable strength and durability, offering a bio-based alternative to chemical admixtures. However, higher dosages (>0.25%) undermine mechanical and durability performance, limiting practical applicability.

- The present findings are specific to the cement type, curing regime, and testing program employed. Future research should aim to (i) link SCM’s chemical composition more directly to performance, (ii) evaluate long-term durability under field exposure, and (iii) extend investigations to other binders and concrete systems. Such work will clarify SCM’s broader role in sustainable construction and its potential to complement or partially substitute conventional admixtures.

Author Contributions

Investigation, A.H.A., Z.S.A. and M.Z.A.-M.; resources, A.H.A., Z.S.A., M.Z.A.-M. and T.H.I.; supervision, A.H.A.; validation, A.H.A., Z.S.A. and M.Z.A.-M.; visualization, A.H.A., Z.S.A. and M.Z.A.-M.; analysis, A.H.A., Z.S.A. and M.Z.A.-M.; writing—original draft, A.H.A., M.Z.A.-M. and T.H.I.; writing—review and editing, A.H.A. and T.H.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The support provided by the Department of Civil Engineering at the University of Baghdad is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ferrándiz-Mas, V.; Bond, T.; García-Alcocel, E.; Cheeseman, C.R. Lightweight mortars containing expanded polystyrene and paper sludge ash. Constr. Build. Mater. 2014, 61, 285–292. [Google Scholar] [CrossRef]

- Cardinale, T.; D’Amato, M.; Sulla, R.; Cardinale, N. Mechanical and physical characterization of papercrete as new eco-friendly construction material. Appl. Sci. 2021, 11, 1011. [Google Scholar] [CrossRef]

- Albayati, A.H.; Mohammed, A.M.; Al-Kheetan, M.J.; Al-ani, A.F.; Oukaili, N.K.; Moudhafar, M.M.; Sukhija, M.; Jweihan, Y.S.; Ghaffar, S.H. Performance enhancement of natural asphalt using waste-derived modifiers: Sugarcane molasses and waste engine oil. Clean. Waste Syst. 2025, 11, 100261. [Google Scholar] [CrossRef]

- Saboo, N.; Sukhija, M.; Mehta, D.; Haswanth, K.; Srivastava, A.; Patil, A. Use of raw sugarcane molasses as a partial replacement of asphalt binder: An experimental investigation. Constr. Build. Mater. 2023, 369, 130541. [Google Scholar] [CrossRef]

- Mehta, D.; Saboo, N. Use of sugarcane molasses for preparation of bio-asphalt: Effect of source. Constr. Build. Mater. 2024, 421, 135691. [Google Scholar] [CrossRef]

- Acharya, D.P.; Gyawali, T.R. Investigation of the performance of natural molasses on physical and mechanical properties of cement mortar. Ain Shams Eng. J. 2024, 15, 102355. [Google Scholar] [CrossRef]

- Thomas, N.L.; Birchall, J. The retarding action of sugars on cement hydration. Cem. Concr. Res. 1983, 13, 830–842. [Google Scholar] [CrossRef]

- Gao, X.; Yang, Y.; Deng, H. Utilization of beet molasses as a grinding aid in blended cements. Constr. Build. Mater. 2011, 25, 3782–3789. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Jennings, H.M. New insights into the effects of sugar on the hydration and microstructure of cement pastes. Cem. Concr. Res. 2002, 32, 393–399. [Google Scholar] [CrossRef]

- Yousaf, M.; Usama, M.; Yousaf, M.U.; Ali, M.U.; Zafar, M.S.; Vocciante, M. Performance of Molasses Waste as a Cement Replacement to Study Concrete Compressive Strength. Appl. Sci. 2024, 14, 10102. [Google Scholar] [CrossRef]

- Weifeng, L.; Suhua, M.; Shengbiao, Z.; Xiaodong, S. Physical and chemical studies on cement containing sugarcane molasses. J. Therm. Anal. Calorim. 2014, 118, 83–91. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Baig, H.S.; Malik, S.; Din, M.; Aslam, H.M.U. Effect of molasses and water–cement ratio on properties of recycled aggregate concrete. Arab. J. Sci. Eng. 2020, 45, 3455–3467. [Google Scholar] [CrossRef]

- Khan, B.; Baradan, B. The effect of sugar on setting-time of various types of cements. Sci. Vis. 2002, 8, 71–78. [Google Scholar]

- Altun, H.y.a.b. Use of Molasses in Concrete as a Water Reducing and Retarding Agent. Indian J. Eng. Mater. Sci. 2012, 19, 421–426. [Google Scholar]

- Kassa, Y. Application of cane molasses as concrete retarder admixture. SN Appl. Sci. 2019, 1, 1547. [Google Scholar] [CrossRef]

- Juneja, A.; Singh, E.; Bhardwaj, A.; Kataria, V. To study accelerating and retarding behaviors of molasses in cement mortar and concrete. Int. Res. J. Eng. Technol. 2017, 4, 362–366. [Google Scholar]

- Mohammed, T.A.; Kadhim, H.M. Effect of pumice stone and sugar molasses on the behavior of reinforced concrete one-way ribbed slabs. Civ. Eng. J. 2022, 8, 334–347. [Google Scholar] [CrossRef]

- Akar, C.; Canbaz, M. Effect of molasses as an admixture on concrete durability. J. Clean. Prod. 2016, 112, 2374–2380. [Google Scholar] [CrossRef]

- Dias, M.O.; Ensinas, A.V.; Nebra, S.A.; Maciel Filho, R.; Rossell, C.E.; Maciel, M.R.W. Production of bioethanol and other bio-based materials from sugarcane bagasse: Integration to conventional bioethanol production process. Chem. Eng. Res. Des. 2009, 87, 1206–1216. [Google Scholar] [CrossRef]

- Odal, A.J.S. Impact of Sugar Cane Molasses to Concrete Strength and Concrete Retardation. Int. J. Membr. Sci. Technol. 2023, 10, 2815–2828. [Google Scholar] [CrossRef]

- Serte, A.T. Impact of Sugarcane Molasses in Concrete as Time Retarding and Water Reducing Admixture. Master’s Thesis, Addis Ababa Science And Technology University, Addis Ababa, Ethiopia, 2019. [Google Scholar]

- Ali, B.; Qureshi, L.A. Durability of recycled aggregate concrete modified with sugarcane molasses. Constr. Build. Mater. 2019, 229, 116913. [Google Scholar] [CrossRef]

- Harriet, N.; Joel, M.; George, I.; Jonas, B. Effect of Molasses on the Strength and Workability of Concrete with Cement Partially Replaced by Saw Dust Ash (SDA). Eur. J. Eng. Sci. Technol. 2021, 4, 43–56. [Google Scholar] [CrossRef]

- Agarwal, V.B.a.P. Effect of Addition of Sugarcane Molasses in Structural Concrete. Int. Res. J. Eng. Technol. 2022, 9, 3986–3989. [Google Scholar]

- Hussein, M.J.; Naser, M.H.; Naser, F.H.; Almamoori, A.H.N.; Hussien, M.L. Performance of sugarcane molasses in concrete under hot weather. Pollack Period. 2024, 19, 68–75. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C109/C109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C230/C230M; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2022.

- Rashid, K.; Tariq, S.; Shaukat, W. Attribution of molasses dosage on fresh and hardened performance of recycled aggregate concrete. Constr. Build. Mater. 2019, 197, 497–505. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).