Abstract

Proper and uniform seed depth within the optimum range increases crop germination rate, which directly affects yield. Seed depth mainly depends on seed placement techniques. In conventional seed drill and planters, variations and fluctuations in seeding depth were recorded. This issue can be resolved by adaption of intelligent crop sowing machinery. A real-time seed depth control system was designed and developed to monitor and maintain the required seed depth. The developed system was installed on a tractor-mounted conventional seed drill. The materials used were ultrasonic sensors, a micro-controller, an RTC module, buzzers, an LCD, an SD card module, a power battery, and switch buttons. The system read height difference as a reference value. The seeding depth data was stored in the SD card. The results showed by introducing real time depth control system in existing seeders, it is possible to achieve desired plant population and homogeneous germination. The average cumulative germination rate (GR) of wheat with the seed depth control system was 126 plants/m2, and with a conventional seed drill (without SDCS) 117 plants/m2. The yield of wheat with the seed depth control system was 1225 kg/acre, and with the conventional seed drill (without SDCS) 1124 kg/acre in an arid region. Result shows that the crop yield could be enhanced by proper seed placement at the required seed depth by using the seed depth control system. Further field trials on different soils, regions and environmental conditions could improve the results.

1. Introduction

Food security is a major concern in third-world countries. Considering these countries’ continuously expanding populations, expanding industry, and expanding economy, agriculture must develop. The most widely produced cereal crop, and a key source of food in Pakistan, is wheat. It has a yield average of 2600 kg/ha and is grown on a little over 9 million hectares. However, progressive farmers can achieve up to 5000 kg/ha [1]. The low yield is the consequence of several factors. It is primarily caused by low-quality seed, broadcast sowing techniques, late sowing, and insufficient irrigation water. The recommended seed sowing depth for wheat is 3 to 6 cm.

Wheat is sown by five methods: broadcasting, sown behind a local plough, drilling, dibbling and the zero tillage method. These methods result in improper and non-uniform seed distribution. Although drilling can resolve this problem to some extent, it is not fully appropriate. Seed drills are useful for sowing crops such as wheat, barley, sorghum, and maize where there is no need to maintain a certain distance between plants in the same row, while a seed planter is helpful for groundnut [2].

In all the sowing methods for wheat, seeding depth has a great impact on plant height, seed germination rate and yield [3]. If seed depth is in the optimum range, height and seed germination rate should be uniform and homogeneous [4]. This uniform germination rate directly affects the yields of the crops. Therefore, we developed a system that attaches to a conventional seed drill to monitor and maintain the seeding depth and affects plant height, germination rate and yield.

2. Material and Methods

The system was designed and developed at a farm machinery workshop, (33.6492° N, 73.0815° E) FAE&T and tested at Koont Research Farm, (33.1166° N, 73.0111° E) Chakwal. The developed real-time monitoring system program was integrated with all components, i.e., RTC (Real Time clock) module, SD card module, buzzers, LCD, and switch buttons that were electronically connected with a microcontroller through electronic circuits. Ultrasonic sensors were also integrated for measuring depth [5]. After the integration of the microcontroller, the whole system was installed on a tractor-propelled conventional seed drill. Metal plates were used for reference points for the sensors. Tines of a conventional seed drill were placed on the soil surface related to the ON switch of the system. The LCD showed sensor reading as reference values, with respect to the metal plate. Height difference readings were compared, one measured manually from the sensor to metal plates and the other with the sensor. If both values were same, sowing was started, this error was corrected by adjusting the height difference. The system read the height difference as a reference value. The seed depth data were stored on an SD card, inserted into the system. The seed depth control system was tested, and various parameters were monitor and measured i.e., seeding depth with and without the control system on a conventional seed drill, germination rates, and yields.

3. Results and Discussion

3.1. Seeding Depth

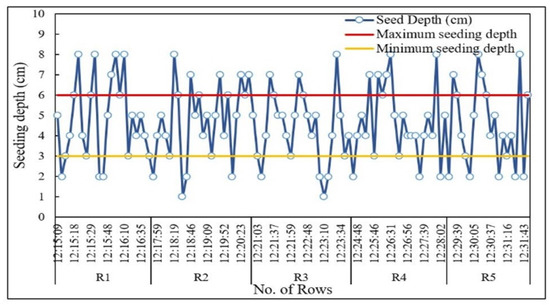

Figure 1 shows seeding depth fluctuations in rows during conventional seed drilling without the seed depth control system. The red line represents the maximum permissible seeding depth, while the yellow line shows the minimum permissible seeding depth. As per data collected from five different rows, each row shows a different trend of seeding depth. Seeding depth in these fields were not uniform or homogeneous. In row 1, 2, many seeds were planted too deeply (above 6 cm), and in row 3 and row 5 most of the seed were planted too shallowly (below 3 cm). Overall, 64% of seeds were planted with a permissible seeding depth, while 24% were planted either too deeply (19%) or too shallowly (17%).

Figure 1.

Seeding depth range without SDCS during wheat sowing 2021.

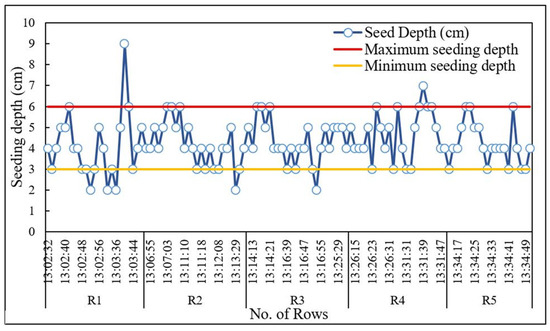

Seeding depth directly affects germination rate, as well as yield. Figure 2 shows the trend of seeding depth in different rows using the seed depth control system. Most of the seeds were planted within the permissible range. Using this system, 94% of seeds were planted within the permissible seeding depth while 6% were planted either too deeply (1.7%) or too shallowly (4.3%).

Figure 2.

Seeding depth range with SDCS during wheat sowing 2021.

At the maximum value of seeding depth recorded (9 cm), the seed was too deep in the soil, needing more energy to germinate. A minimum value of 2 cm was found at five different positions. Shallow seeds are exposed more to the sunlight, and do not get enough moisture to germinate. These shallow seeds are attacked by birds and rats because they are not placed at the desired depth. By introducing SDCS, most seeds were sown at the proper depth. Figure 1 shows that except R1, the remaining rows (R2, R3, and R4) show homogeneous seeding depth within the required range. These results are in line with the literature [6], and the variation in the seeding depth was quite similar [7].

3.2. Germination Rate

The germination rate data in both plots were analyzed. The data were collected on the 7th, 10th, 13th, 16th, 19th, 22nd and 25th day after sowing in both fields. The average accumulative germination rate of wheat without and with the SDCS of 25 samples were 57.17% and 63.04%, respectively The germination rates using SDCS system were significantly improved. Better results could be attained by using hybrid or high-quality seed.

3.3. YIELD

The wheat yield was 1225 kg/acre with SDCS, and 1124 kg/acre with the conventional seed drill. Wheat production with SDCS in one hectare was 3028 kg, and with the conventional seed drill was 2778 kg/ha. In last year it was observed 2339 kg/ha. There was a significantly 8% increase in yield achieved by controlling the seeding depth at uniform level.

4. Conclusions

In Pakistan, proper seed depth and uniform distribution of seeds are major problems. Although conventional drills have been introduced to solve these problems, optimum seed depth cannot be maintained. Our seed depth control system (SDCS) maintains seeding depth at the desired range. To validate this system a study was conducted at the University Research Farm to sow wheat seeds with and without SDCS. The average cumulative germination rate of wheat with SDCS was 126 plants/m2, and with the conventional drill was 117 plants/m2. The wheat yield with the SDCS drill was 1225 kg/acre and with the conventional drill was 1124 kg/acre. The crop yield increased 8% by placement of seeds at the recommended depth. In Pakistan an estimated 22 million acres of wheat are sowed per year. This represents 40% of the country's total cultivated land during winter. By adopting this system and optimizing seeding depth, around 2.2 million tons more wheat can be produced, which would directly reduce food shortage and minimize the import of wheat.

Author Contributions

Conceptualization, T.I. and U.u.R.; methodology, T.I. and M.A.; software, Y.S., M.A. and F.I.; validation, A.M.G., S.R.S. and Y.S.; formal analysis, T.I.; investigation, A.M.G.; writing—original draft preparation, T.I. and A.M.G.; writing—review and editing, T.I., S.R.S. and M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Center for Industrial Biotechnology, and Data Driven Smart Decision Platform, PMAS-Arid Agriculture University, Rawalpindi, Pakistan.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are very thankful to the Faculty of Agricultural Engineering and Technology and Univ. Research Farm Administration of PMAS Arid Agriculture University Rawalpindi, Pakistan for providing the platform for this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Finance Division Government of Pakistan. Pakistan Economic Survey 2019-20. In Economic Survey. Islamabad: Economic Advisor’s Wing, Ministry of Finance.; 2020. Available online: https://www.finance.gov.pk/survey/chapter_20/PES_2019_20.pdf (accessed on 13 March 2022).

- Sarker, T.R.; Alam, M.; Ali, M.R.; Saha, C.K.; Haque, M.A. Design and development of a multi-crop manual seed drill. CIGR J. 2019, 21, 51–60. [Google Scholar]

- Sedara, A.; Ibrahim, Y.; Manuwa, S.; Sedara, O. Development of a Low-Cost Seed Drill for Sowing Amaranth Seed Development of a Low-Cost Seed Drill for Sowing Amaranth Seed. World Acad. J. Eng. Sci. 2020, 7, 39–45. [Google Scholar]

- Nielsen, S.K.; Munkholm, L.J.; Lamandé, M.; Nørremark, M.; Edwards, G.T.C.; Green, O. Seed drill depth control system for precision seeding. Comput. Electron. Agric. 2017, 144, 174–180. [Google Scholar] [CrossRef]

- Dvorak, J.S.; Stone, M.L.; Self, K.P. Object detection for agricultural and construction environments using an ultrasonic sensor. J. Agric. Saf. Health. 2016, 22, 107–119. [Google Scholar] [CrossRef] [PubMed]

- Suomi, P.; Oksanen, T. Automatic working depth control for seed drill using ISO 11783 remote control messages. Comput. Electron. Agric. 2015, 116, 30–35. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Munkholm, L.J.; Lamandé, M.; Nørremark, M.; Skou-Nielsen, N.; Edwards, G.T.C.; Green, O. Seed drill instrumentation for spatial coulter depth measurements. Comput. Electron. Agric. 2017, 141, 207–214. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).