Abstract

Shortly, the demand for food production will increase, and the challenges to agriculture, including climate change, land degradation, farmable land availability and labor effort, will be resolved by applying precision agriculture techniques. In modern precision agriculture, variable rate (VR) technology is one of the key research areas. This technology provides an improved adjustment of agrochemical dosage to the trees by applying pesticide spraying to only areas where trees are detected based on their heights. This paper presents the testing results of an indigenously developed spot-specific sprayer for orchards based on tree detection through ultrasonic sensors. Lab Results show that spot-specific spraying provides 40% of agrochemical savings for an area of 100 acres compared with traditional spraying for the citrus orchard. Such technology can facilitate the farmers by automatic pesticide sprayers and economically protect the plants.

1. Introduction

Today agricultural industries are adopting both primitive and modern sensors and controller-based technologies to tackle these issues, each having advantages and disadvantages. Modern technologies are also judged based on their impact on the global environment and ecosystem. In most parts of the world, uniform spraying of pesticides is practiced by the use of pesticide-filled tanks and nozzles for spraying. Mainly it is carried by a single person who sprays it across the field [1]. This method also has many disadvantages because uniform spraying does not consider plant size, and farmers rush mostly without proper protection, which may result in many health hazards. Such uniform spraying is primarily manual, which works on the hydraulics principle, which is exhausting. This spraying technique uses more pesticide than the required amount for the crop, which is expensive and time-consuming [2].

In the early 2000s, this manual spaying was replaced with electric pump spraying; it had reduced the human effort, but the rest was the same; for example, this electric pump spraying technique also used more pesticides than actually required for crops, which was the core problem [3].

Researchers have attempted to develop variable rate (VR) technologies for various crops. To date, less attention has been given to the economical use of ultrasonic sensors in variable rate (VR) systems. S. Gangadharan et al. conducted a comparative analysis between a LIDAR sensor and an ultrasonic sensor [4]. Sensors were tested in such a way that enabled the process of an automated shaker system and controlled its working. Both sensors were tested in an outdoor and indoor environment with accuracy factors of 10.16 and 5.08, respectively. The sensor was mounted in vertical and horizontal setups to develop a 3D canopy profile for a citrus tree groove. They also worked on volume estimation with the LIDAR sensor in their study. However, very little work has been performed to incorporate an ultrasonic sensor for tree detection in the intelligent sprayer [5].

In this paper, using an ultrasonic sensor integrated into a local boom sprayer that avoids unnecessary usage of expensive chemicals is presented that will not only reduce the cost of production but reduce environmental pollution. The boom sprayer provides better penetration of agrochemicals without damaging leaves and thus protects from various insects/diseases.

2. Methodology

The system is powered by a 12 V battery connected to a solar panel for automatic charging from sunlight. The system consists of 4 modules that are centrally controlled by a microcontroller. After boom selection, the sensors will start detecting objects at a certain distance, which can be altered according to a user’s requirements.

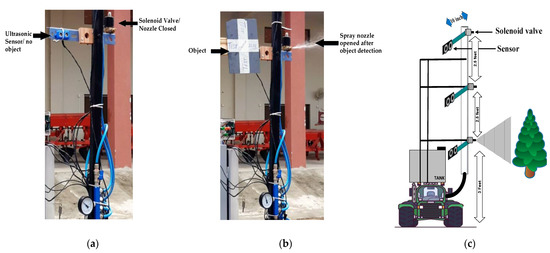

The ultrasonic sensor will send a high flag signal to the microcontroller if a tree or object is detected within the sensing range of the sensor. The controller in the system will decide which relay to operate attached to that particular sensor’s output. The relay will switch ON the solenoid valves connected to that specific relay, as shown in Figure 1b. The system is mounted on a metal frame boom 3 feet above the ground. The distance between each sensor is 2.5 feet, and the distance between the sensor and solenoid value is 10 inches during lab testing.

Figure 1.

Laboratory testing of system and design frame. (a). No object; hence solenoid valve is closed (b). Object detected and solenoid spraying in action (c). Design of Spot-Specific sprayer, spraying only when trees are detected, based on their height.

Ultrasonic Sensor

The working of ultrasonic sensors is based on the principle of the Doppler Effect. The Ultrasonic transmitter transmits an ultrasonic sound wave, the signal travels in the air, and when it acquires objected by some material, it gets reflected near the device; this reflected wave is detected through the ultrasonic receiver module [6]. Now, to analyze the distance, we use equation 1; the speed of sound in air is (330 m/s) and the time when the signal is transmitted.

Distance = speed × time

This principle is widely used for object detection, obstacle avoidance and depth measurements [7]. Ultrasonic sensors are of two types that are HC-SR04 and JSN-SR04. HR-SR04 has high speed with less distance accuracy, it can detect the object fast, but the measuring distance has (<5%>) error. While the JSN-SR04 has a percentage distance measuring error (<2%>), its detecting speed is slow [8].

The spot-specific sprayer with three solenoid valves and three ultrasonic sensors on a single boom is shown in Figure 1c. This system can be attached to any tractor or small farm vehicle. The ultrasonic sensor will detect the trees, and nozzles attached to the solenoid valves will spray whenever the trees are in the sensing range. Three sensors are attached to 10 feet boom at the height of the citrus tree. If the tree’s height is 3 feet, then only the bottom nozzle will start spraying; if the height is 6 feet, then the bottom and middle nozzle will start spraying; and if the tree’s height is 9 feet tall, then all three nozzles will start spraying.

3. Results and Discussions

Testing of spot-specific sprayers is divided into two categories. In the first category, the opening and closing intervals of the solenoid valves are calculated for one, two and three sensors separately. The switching interval of the class B (coil insulation) relay is 10 ms, while the power transistor has a 0.1 ms switching interval; both the results of relay and transistor-based switching are shown in Table 1. Due to the fast switching of power transistors, the solenoid valves operate fast, and no part of the tree canopy is missed during spraying.

Table 1.

Lab testing results for nozzle opening and closing.

The above results show that the power transistor performs better than relay-based switching as there is a time lag between the opening and closing of solenoid values through the relay, which misses the target tress spraying. The excess amount of agrochemicals is wasted.

Comparison of Uniform Spraying and Spot-Specific Spraying

Spot-specific sprayer provides agrochemical savings of up to 40% for citrus trees. The detail for different agrochemical for citrus and their saving for a 100-acre area is given in Table 2.

Table 2.

Amount of different agrochemicals and their savings for spot-specific spraying.

4. Conclusions

The developed prototype of a spot-specific spraying system efficiently detected the objects in laboratory settings through the ultrasonic sensors-based central control system. Before commercialization, field testing is required to fully assess the capability of spotting specific sprayers in tree detection and agrochemical spraying in different orchards. Such a system saves up to 40% of agrochemicals through sensor-based automation, which is economical and easy to implement. All the components are easily available in the market at low prices.

Author Contributions

Conceptualization, S.R.S. and M.N.T.; methodology, S.H. and A.A.; investigation, M.N.T. and S.R.S.; resources, M.N.T.; data curation, S.H. and A.A.; writing—original draft preparation, S.H. and A.A.; writing—review and editing, R.A. and A.A.; visualization, S.H. and R.A.; supervision, S.H. and A.A. All authors have read and agreed to the published version of the manuscript.

Funding

The study is a part of a pilot project for the Data-Driven Smart Decision Platform for Increased Agriculture Productivity (DDSDP) PSDP-funded project No. 332.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data can be available on request.

Acknowledgments

The authors would like to acknowledge all funding agencies and the scientific and support staff of DDSDP and NCIB projects.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Waqas, M.S.; Cheema, M.J.M.; Hussain, S.; Ullah, M.K.; Iqbal, M.M. Delayed irrigation: An approach to enhance crop water productivity and to investigate its effects on potato yield and growth parameters. Agric. Water Manag. 2021, 245, 106576. [Google Scholar] [CrossRef]

- Xiao, K.; Ma, Y.; Gao, G. An intelligent precision orchard pesticide spray technique based on the depth-of-field extraction algorithm. Comput. Electron. Agric. 2017, 133, 30–36. [Google Scholar] [CrossRef]

- Gonzalez-de-soto, M.; Emmi, L.; Perez-ruiz, M.; Aguera, J.; Gonzalez-de-santos, P. ScienceDirect Special Issue: Robotic Agriculture Autonomous systems for precise spraying e Evaluation of a robotised patch sprayer. Biosyst. Eng. 2016, 146, 165–182. [Google Scholar] [CrossRef]

- Gangadharan, S.; Burks, T.F.; Schueller, J.K. A comparison of approaches for citrus canopy profile generation using ultrasonic and Leddar® sensors. Comput. Electron. Agric. 2019, 156, 71–83. [Google Scholar] [CrossRef]

- Hussain, S.; Cheema, M.J.M.; Arshad, M.; Ahmad, A.; Latif, M.A.; Ashraf, S.; Ahmad, S. Spray uniformity testing of unmanned aerial spraying system for precise agro-chemical applications. Pakistan J. Agric. Sci. 2019, 56, 897–903. [Google Scholar] [CrossRef]

- Kelemen, M.; Virgala, I.; Kelemenová, T.; Miková, Ľ.; Frankovský, P.; Lipták, T. Distance Measurement via Using of Ultrasonic Sensor. J. Autom. Control 2015, 3, 71–74. [Google Scholar] [CrossRef]

- Derkach, M.; Skarga-bandurova, I. Obstacle Avoidance Algorithm for Small Autonomous Mobile Robot Equipped with Ultrasonic Sensors. In Proceedings of the 2020 IEEE 11th International Conference on Dependable Systems, Services and Technologies (DESSERT), Kyiv, Ukraine, 14–18 May 2020; pp. 236–241. [Google Scholar]

- Moussa, M.; Moussa, A. Ultrasonic based heading estimation for aiding land vehicle navigation in gnss denied environment. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, XLII, 10–12. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).