Abstract

Energy Performance Contracting (EPC) can help the European Union (EU) in accelerating the cost-effective renovation of existing building stock. However, there are many risks and barriers that can inhibit the application of EPC. These barriers include uncertainty about building data, lack of quality assurance regarding the post-renovation energy performance, and process complexity. In order to cross these barriers, this paper presents ModSCO. ModSCO is a web application based on a Reduced Order grey-box Model (ROM) able to systematically quantify the energy savings achieved through Energy Conservation Measures (ECMs) utilising the schema of the International Performance Measurement and Verification Protocol (IPMVP). The benefits of utilising ModSCO in terms of accuracy and time savings are demonstrated with a comparison with a whole building energy model developed with IES-VE.

1. Introduction

Buildings are responsible for approximately 40% of European Union (EU) energy consumption and 36% of the greenhouse gas emissions. Buildings are therefore the single largest energy consumer in Europe. To increase the building’s energy performance, the EU has established a legislative framework with the scope of achieving a highly energy efficient and decarbonised building stock by 2050. To do so, it needs to create a stable environment for investment decisions and enable consumers and businesses to make more informed choices to save energy and money [1].

One of the potential measures to target these objectives is Energy Performance Contracting (EPC) [2]. EPC is a mechanism for organising energy efficiency financing with the scope of reducing the building energy consumption. The company involved in EPC is usually an Energy Service Company (ESCO).

In this mechanism, the ESCO enters agreements with property owners to improve the energy efficiency of their property by implementing various Energy Conservation Measures (ECMs). The ESCO ensures energy savings in comparison to a historical (or calculated) energy baseline. In relation to the savings achieved by the implementation of ECMs, the ESCO receives performance-based remuneration.

To be more competitive during the audit, the ESCO must: (i) define valid energy conservation measures, (ii) predict the thermal behaviour of the future building, and (iii) correctly determine and adjust the energy baseline for the estimation of the energy savings due to the ECMs installed.

The third point is one of the main challenges and a potential crucial issue in the EPC business model as it can generate a considerable degree of insecurity and monetary risks.

The Measurement and Verification (M&V) and in particular the International Performance Measurement and Verification Protocol (IPMVP) [3] provides an important framework to help quantify the energy savings of retrofit measures.

However, the application of the IPMVP framework in the retrofitting contest is often complex due to limited and uncertain information about the buildings. In order to address this challenge and enhance the uptake of EPC, this paper presents ModSCO. ModSCO is a web application based on a Reduced Order grey box Model (ROM) that can be used for systematic quantification of energy savings (avoided energy consumption) achieved through ECMs utilising information data available for existing buildings.

2. ModSCO Web Application

2.1. ModSCO Core Platform

The core of the ModSCO web application is a Python script [4] based on a long open-source stack (PyFMI [5] and dependencies) that is stored in a server. The Python script runs a Functional Mock-up Unit (FMU) [6], generated using an open-source software called Jmodelica [7]. The FMU file contains the Reduced Order grey-box Model (ROM). The ROM is based on the RC-Network that was developed using the Modelica language programming [8] within the Dymola Environment [9]. A detailed description of the ROM and its parameter calculation was presented in [10].

To make accessible the Python script and, thus, to simplify the use of ROM, a web based Graphical User Interface (GUI) was created by using the bubble.io platform [11]. The GUI uses an Application Programming Interface (API) to send and receive information from the Python script stored in the server.

2.2. ModSCO Work-Flow

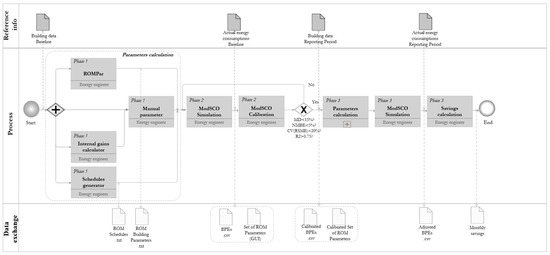

Figure 1 shows the framework for the utilisation of the ModSCO web application represented with the Business Process Model Notation (BPMN) v2.0 [12]. BPMN provides an intuitive and easy way for non-expert users to understand the workflow. It represents the semantics of complex processes easily and in an intelligible form [13].

Figure 1.

ModSCO workflow represented with the Business Process Model Notation v2.0.

The utilisation of the web application is defined by three phases.

Phase 1 calculates the 28 parameters needed to run the ModSCO application. The calculus of the parameters is based on formulae and methods defined by standards, which are implemented in three MS Excel based tools: ROMPar, schedule generator, and internal gain calculator, which are downloadable in the web application. During Phase 1, the energy engineer plays with the MS Excel tools using building information. The tools generate the parameters (ROM Schedules.txt, building parameters.txt files of Figure 1) that are fundamental to build and run the simulations. The ModSCO GUI allows for the upload of the generated text files and, once the energy engineer manually fulfils the remaining inputs (Manual parameters of Phase 1 (Figure 1)), the application is ready to perform the ModSCO simulation.

Phase 2 of the workflow shows in Figure 1, regard the ModSCO simulation which output is the calibrated IPMVP Baseline Period Energy consumptions (BPEs) for the building under analysis. Therefore, the parameters outlined in Phase 1 are simulated and sent by the API to the Python script. The Python script produces the BPEs in .csv format that are compared with the actual consumption of the building for the calibration of the model. The ModSCO ROM’s structure and its low number of parameters helps in reducing the degree of freedom of the calibration phase, thus reducing the possibility of over-fitting issues [14]. For this reason, a knowledge-based calibration procedure, based on the method described by Giretti [15], was adopted to select the group of model parameters more affected by the uncertainty. The calibration phase focuses on iteratively optimising the values of the selected group of uncertain parameters in order to increase the accuracy of the BPEs. During Phase 2, the user runs a simulation for every iteration and the resulting BPEs are compared with the actual measured energy consumptions (e.g. energy bills). This comparison is performed utilising a dedicated MS Excel Tool (calibration and saving estimation tool) that is downloadable from the application. The MS Excel Tool calculates the calibration error and accuracy by using the following indices and their IPMVP acceptable limits [16]:

- Normalised Mean Biased Error → NMBE < 5%

- Coefficient of Variation of Root Mean Square Error → CV(RMSE) < 20%

- Coefficient of Determination → R2 > 0.75

- Monthly Deviation < 15%

The BPEs generated by ModSCO are considered accepted and calibrated if all the values are within the IPMVP acceptance criteria range.

The last phase of Figure 1 uses the calibrated ModSCO model to generate the Adjusted BPEs, allowing for the calculation of the energy savings due to the adoption of the ECMs.

In order to create the Adjusted BPEs, the calibrated ROM has to be updated with the data referred to in the reporting period. These data include all the independent variables such as the weather file, occupancy schedules, equipment schedules, HVAC set points, and HVAC heating/cooling ON-OFF. Furthermore, other ROM’s inputs can be adjusted if the static factors are modified in the reporting period. These may include people heat gains (occupancy type, density), significant equipment problems or lighting levels, etc. Finally, the energy engineer calculates the energy savings using the same MS Excel Tool calibration and saving estimation tool. The tool allows us to compare the adjusted BPEs with the Reporting Period Energy consumption (RPEs) and the savings are calculated using the following formula:

where the calibration error is based on the accuracy achieved during the model calibration phase.

Savings = (Adjusted BPE − RPE) ± Calibration Error

3. The ModSCO Test Case

The previous section described the entire workflow to calculate energy savings for the implementation of ECMs in a building using the ModSCO web application. This section reports a real test case, where two different workflows to calculate the IPMVP BPEs are compared in terms of accuracy and time. The first was done by using the ModSCO web application while, for the second, a whole building energy model was developed with the IES-VE software [17].

The test case is a university building (i.e., Áras de Brún) constructed in 1960 and located in the campus of the National University of Ireland Galway. The building is constituted by a standalone concrete post and beam construction with extensive glazing to the east and west facades. The heating system is provided by two gas condensing boilers located in the plant room, each providing a thermal output of 107 kW. In 2019, the building had an annual electrical consumption of 338 MWh and a further 94 MWh for natural gas. All these measured data plus a series of interviews with the building manager supported the development, validation, and calibration of both the ModSCO and IES-VE models. However, different uncertain and missing information was present in the building (e.g., system schedules, equipment data). Table 1 shows a comparison of the ModSCO and IES-VE statistical indices after the calibration phase. The calibrated ModSCO model satisfied all the IPMVP calibration criteria for both natural gas and electricity consumption. Similarly, the IES-VE Model satisfied all the calibration criteria.

Table 1.

Comparison of the IPMVP® statistical indices of the calibrated 2019 ModSCO Model and the IES-VE model.

In terms of time, the workflow of ModSCO required 6 h in total, which includes the parameters calculation and 28 simulations for the calibration, while the development and calibration of the IES-VE model took 40 h. The higher amount of time to develop the whole building energy model was due to collecting the extensive number of inputs parameters needed to perform the simulations. The estimation of these parameters required a dedicated building survey and increased the difficulties of the calibration.

4. Conclusions

This paper presents a novel web application, called ModSCO, that enhance the uptake of EPC for the quantification of energy savings achieved through Energy Conservation Measures (ECMs). The ModSCO web application was compared with a whole building energy model developed using IES in a campus building located in Galway, Ireland. Calibration results of both energy models were in the acceptance range of IPMVP for monthly energy consumption prediction. However, time savings were demonstrated in the utilisation of the ModSCO model where limited building information and uncertain data are present.

Funding

This research work was funded by the Irish Research Council (IRC)—R2M Solution S.r.l Enterprise Partnership Scheme Postgraduate Scholarship 2017 under project ID EPSPG/2017/359 and by the European Union H2020 program under the Sphere project with Grant agreement No. 820805.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy issues.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kranzl, L.; Toleikyte, A.; Müller, A.; Hummel, M.; Heiskanen, E.; Marschoss, K.; Rohde, C.; Kockat, J.; Steinbach, J.; Regodón, I.D.; et al. Laying Down the Pathways to Nearly Zero-Energy Buildings. A Toolkit for Policy Makers. Available online: https://www.entranze.eu/files/downloads/D6_11/entranze_report_final.pdf (accessed on 25 September 2021).

- Augustins, C.; Jaunzems, E.; Rochas, D. Managing energy efficiency of buildings: Analysis of ESCO experience in Latvia. Energy Procedia 2018, 147, 614–623. [Google Scholar] [CrossRef]

- Efficiency Valuation Organization. International Performance Measurement and Verification Protocol Core Concepts. Available online: https://evo-world.org/en/products-services-mainmenu-en/protocols/ipmvp (accessed on 25 September 2021).

- Python.org. Available online: https://www.python.org/ (accessed on 25 September 2021).

- Andersson, C.; Akesson, J.; Fuhrer, C. PyFMI: A Python Package for Simulation of Coupled Dynamic Models with the Functional Mock-up Interface. Tech. Rep. Math. Sci. 2016, 2, 1–40. [Google Scholar]

- Functional Mock-Up Interface. Available online: https://fmi-standard.org/ (accessed on 23 September 2021).

- JModelica.org. Available online: https://jmodelica.org/ (accessed on 23 September 2021).

- Fritzson, P.; Engelson, V. Modelica—A unified object-oriented language for system modeling and simulation. Lect. Notes Comput. Sci. 1998, 1445, 67–90. [Google Scholar]

- Dymola by Dassault Systèmes®. 2021. Available online: https://www.3ds.com/it/prodotti-e-servizi/catia/prodotti/dymola/ (accessed on 20 September 2021).

- Piccinini, A.; Hajdukiewicz, M.; Keane, M.M. A novel reduced order model technology framework to support the estimation of the energy savings in building retrofits. Energy Build. 2021, 244, 110896. [Google Scholar] [CrossRef]

- Bubble.io. Available online: https://bubble.io/ (accessed on 11 September 2021).

- Business Process Model and Notation (BPMN), Version 2.0. 2010. Available online: https://www.omg.org/spec/BPMN/2.0/PDF (accessed on 25 September 2021).

- D’Angelo, L.; Piccinini, A.; Seri, F.; Sterling, R.; Costa, A.; Keane, M.M. BIM-based business process model to support systematic deep renovation of buildings. Build. Simul. Conf. Proc. 2019, 1, 137–144. [Google Scholar] [CrossRef]

- Drgoňa, J.; Arroyo, J.; Figueroa, I.C.; Blum, D.; Arendt, K.; Kim, D.; Ollé, E.P.; Oravec, J.; Wetter, M.; Vrabie, D.L.; et al. All you need to know about model predictive control for buildings. Annu. Rev. Control 2020, 50, 190–232. [Google Scholar] [CrossRef]

- Giretti, A.; Vaccarini, M.; Casals, M.; Macarulla, M.; Fuertes, A.; Jones, R.V. Reduced-order modeling for energy performance contracting. Energy Build. 2018, 167, 216–230. [Google Scholar] [CrossRef] [Green Version]

- Piccinini, A.; D’Angelo, L.; Seri, F.; Deane, C.; Sterling, R.; Costa, A.; Giretti, A.; Keane, M.M. Development of A Reduced Order Model for Standard-Based Measurement and Verification to Support ECM. In Proceedings of the 16th IBPSA Conference, Rome, Italy, 2–4 September 2019; pp. 4180–4187. [Google Scholar] [CrossRef]

- Integrated Environmental Solutions|IES-VE. Available online: https://www.iesve.com/ (accessed on 11 September 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).