Abstract

Growth in the advancement of 3D printing technology has made it easy to fabricate complicated bio-inspired structures (BISs). In this paper, the sandwich structure of the beetle elytron structure (BES) hollow cylinder, influencing every corner of the honeycomb structure, is designed by considering parameters like the thickness, length, and diameter of the hollow cylinder, with the different ranges taken giving minimum and maximum values in the response surface methodology (RSM). Sandwich structures are fabricated using VAT polymerization technology. A Universal Testing Machine (UTM) tests the fabricated structures for compression, and results are recorded from the tests of each specimen. All specimens’ compressive strength (CS) and energy absorptions (EA) values are calculated. Design parameters at which the energy absorbed and the compression strength are high are evaluated and considered optimal parameters for a specific range of values.

1. Introduction

High-performance materials and structures are now being designed quickly due to the intense need for components and devices with specialized qualities [1]. High-performance structures may be created for various applications by drawing inspiration from these geometrical shapes. It is well realized that the accessibility of lightweight designs with brilliant energy ingestion limits is fundamental for various design applications. BISs have been proven to significantly improve conventional designs regarding energy intake limit. They are motivated by several organic patterns seen in nature. As a result, the use of the biomimetic method for designing areas has been growing for revolutionary lightweight designs with excellent energy intake limitations [2].

Beetle Elytra Structure (BES) and Honeycomb Structure (HCS)

Zhang et al. [3] investigated bionic multi-cell tubes (BMCTs) modeled after beetle forewings’ structure. The crashworthiness of various MCTs and BMCTs concerning impact axial loads were compared to FE models of quadrilateral, hexagonal, and octagonal sections. The mechanical components of the EBEP crash box may be modified by varying the amplitude of the deformation lines, according to CS tests and simulation reports, to satisfy the design requirements for diverse engineering applications [4]. In addition to this work, Xiang et al. [5] fabricated a bi-tubular thin-walled structure (BBTS) by modeling hollow cylindrical structures with colorful cross-sectional polygons motivated by the internal architecture of lady beetle wings. The study articles [2,6,7] thoroughly review the aforementioned literature while comparing beetle forewing structures with other biomimetic structures. Zhang x et al. [8] generated the lightweight and high-strength material in the bio-inspired material, a honeycomb (HP) structure. It has the high compression strength required to increase the compression strength in that structure, adding the beetle elytra structure to HP at every corner of the hexagonal shape. There was an increment in the compression strength above 50%, and the energy absorbing capacity also increased in the BEP. Wang et al. [9] also investigated the mechanical performance of the honeycomb structures under low and medium strain rates. Both yield and plateau stress were estimated under dynamic compression tests. The prediction of the output results are also good for this type of bio-inspired structure, using an artificial intelligence technique in the latest research [10,11].

2. Materials and Methods

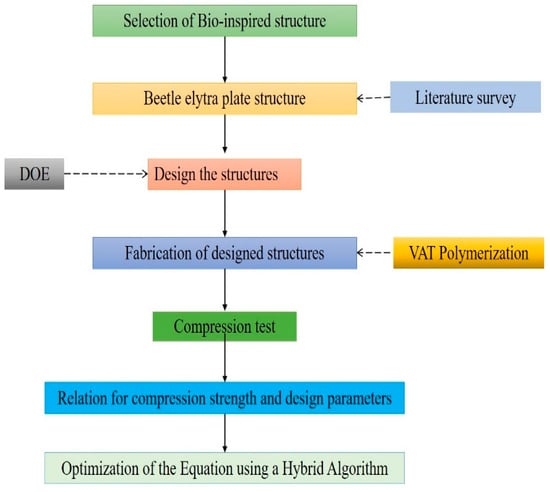

The design methodology followed in this study is shown in the flow chart in Figure 1. The experimental sandwich structure of the BES design included the below parameters. From the literature survey, the range of the design parameters was selected, as described below.

Figure 1.

A flow chart for the design methodology.

- ❖

- Length of the wall [L] =

- ❖

- Diameter of hollow cylinder[D] =

- ❖

- Thickness of both wall cylinders [T] =

- ❖

- Height[H] = 10 mm

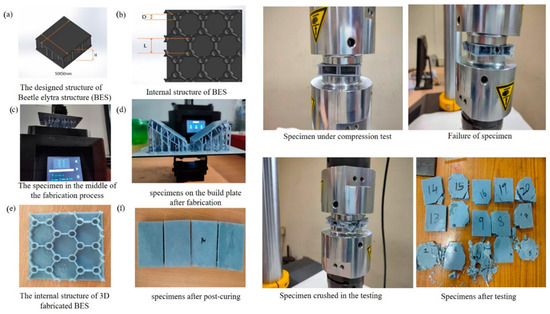

After finalizing the range of the design parameters, the module design of experiments (DOEs) in MINITAB 19 software was used to create the set of specimens. Once the set of design parameters was known, Fusion 360 2.0.15775 CAD software calculated specimens and converted the CAD file into an STL file. The slicing, fabrication, and testing processes of all specimens were carried out as mentioned in the research study [10]. The total procedure carried during the current research is visualized in Figure 2.

Figure 2.

The design, fabrication, and testing processes of the 3D-printed specimens.

3. Results and Discussion

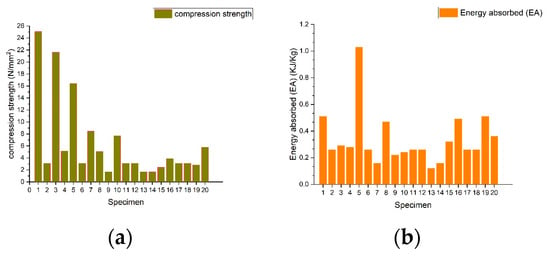

After testing all specimens, the compression strength values were recorded for each specimen, and the variations in all specimens are shown in Figure 3a. The area calculated for the energy absorption values of each specimen under the stress–strain curves was recorded through Blue Hill V 4.42 software connected to UTM. The formula used to calculate the EA values is given by Equation (1)

where is the specimen absorbing the energy, is the average crushing load, and is the difference between the final and initial crushing distance, respectively.

Figure 3.

Specimens showing variations in (a) compression strength and (b) energy absorption.

The variations in the EA values of all tested specimens are graphically represented, as shown in Figure 3b. Specimens 1, 3, and 5 are the structures that show good CSs as per the material used for the fabrication. The design sets of parameters of specimens 1 and 3 were the best performers among all 20 specimens. It was quite interesting that specimen 5 is in third place in terms of CS, but it was shown to have a highly reliable performance in terms of energy absorption. It was clear that specimen 1 showed a better CS but did not absorb that much energy after a failure. This is due to the internal failure of the honeycomb structures, which could not take the further load. By observing the graphs, it was noted that the EA capacity of the specimens was good even after the initial failure points are recorded. The main reason for these results was a perfect set of the diameter of the circle arranged at six corners like a hexagon pattern and the distance between them. The best performed specimens in terms of energy absorption values are shown in Table 1. The results seen in EA values of all specimens are interesting in terms of studying the bio-inspired BES and HCS, which may give new drive to the development of the lightweight high-strength components, a crucial need in the engineering sector.

Table 1.

The best specimens with parameters.

4. Conclusions and Future Scope

This paper investigates the effects of design parameters, namely the thickness, length, and diameter of the hollow cylinder of the BES structures. It was observed that specimens 1 and 3 showed good compressive behavior among all specimens, and specimen 5 had the best value of EA due to its internal honeycomb integrated sandwich structure. Designs need to be developed with other geometries replacing the circular shapes, and we need to conduct different mechanical tests on specimens in the future.

Author Contributions

Conceptualization, methodology, and writing—original draft preparation; writing—review and editing validation; software; and validation—R.D. and K.S.H. Supervision and project administration—B.M.G. and G.S.M. All authors have read and agreed to the published version of the manuscript.

Funding

We acknowledge the Science and Engineering Research Board, Grant No. TAR/2021/000343, for their extended support to carry the research work.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, J.; Liu, W.; Pantula, A.; Wang, Z.; Gracias, D.H.; Nguyen, T.D. Periodic buckling of soft 3D printed bioinspired tubes. Extrem. Mech. Lett. 2019, 30, 100514. [Google Scholar] [CrossRef]

- Ramakrishna, D.; Bala Murali, G. Bio-inspired 3D-printed lattice structures for energy absorption applications: A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 237, 503–542. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, Z.; Bai, F. Crashworthiness design for bio-inspired multi-cell tubes with quadrilateral, hexagonal and octagonal sections. Thin-Walled Struct 2018, 122, 42–51. [Google Scholar] [CrossRef]

- Yu, X.; Pan, L.; Chen, J.; Zhang, X.; Wei, P. Experimental and numerical study on the energy absorption abilities of trabecular–honeycomb biomimetic structures inspired by beetle elytra. J. Mater. Sci. 2019, 54, 2193–2204. [Google Scholar] [CrossRef]

- Xiang, J.; Du, J.; Li, D.; Scarpa, F. Numerical analysis of the impact resistance in aluminum alloy bi-tubular thin-walled structures designs inspired by beetle elytra. J. Mater. Sci. 2017, 52, 13247–13260. [Google Scholar] [CrossRef]

- Doodi, R.; Balamurali, G. Experimental and analytical investigation of bio-inspired lattice structures under compressive loading. Eng. Res. Express 2023, 5, 035035. [Google Scholar] [CrossRef]

- Chouhan, G.; Gunji, B.M.; Bidare, P.; Ramakrishna, D.; Kumar, R. Experimental and numerical investigation of 3D printed bio-inspired lattice structures for mechanical behaviour under quasi-static loading conditions. Mater. Today Commun. 2023, 35, 105658. [Google Scholar] [CrossRef]

- Zhang, X. Influence of honeycomb dimensions and forming methods on the compressive properties of beetle elytron plates. J. Sandw. Struct. Mater. 2020, 22, 28–39. [Google Scholar] [CrossRef]

- Wang, D.; Bai, Z. Mechanical property of paper honeycomb structure under dynamic compression. Mater. Des. 2015, 77, 59–64. [Google Scholar] [CrossRef]

- Doodi, R.; Gunji, B.M. Prediction and experimental validation approach to improve performance of novel hybrid bio-inspired 3D printed lattice structures using artificial neural networks. Sci. Rep. 2023, 13, 7763. [Google Scholar] [CrossRef] [PubMed]

- Panda, B.N.; Biswal, B.B.; Deepak, B.B.L.V. Integrated AHP and fuzzy TOPSIS Approach for the Selection of a Rapid Prototyping Process under Multi-Criteria Perspective. In Proceedings of the 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati, Assam, India, 12–14 December 2014. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).