Abstract

Concrete pavement growth can cause blow-ups and other pressure-related issues, such as concrete buckling and crushing at the transverse cracks or joints. In addition, these issues result in damaged to adjoining structures, such as bridge abutments, decks, and access structures in the pavement. However, available theoretical solutions and methods for evaluating pavement growth and predictions of concrete pavement blow-up are considerably limited. In this study, therefore, the pavement growth and blow-up analysis model was developed to predict the blow-up potential due to concrete pavement growth. This model considered factors such as the pavement structure and materials, climatic conditions, configuration of expansion joint, base friction characteristics, geometric imperfection, rotational stiffness of joints, and design reliability. In addition, the pavement growth and blow-up analysis model can be used to predict the service life of expansion joints and the blow-up occurrence time by considering the factors affecting it. Using the developed model, various sensitivity analysis was performed to investigate the factors affecting the potential concrete pavement growth and blow-up occurrence. It was found that the factors of substrate type, coefficient of thermal expansion, precipitation, and alkali–silica reaction had a significant effect on pavement growth and blow-up occurrence times.

1. Introduction

Concrete pavement performance is typically impaired by pavement growth, which is a phenomenon that increases pavement length. Pavement growth is caused by several factors, such as increases in the pavement’s temperature and moisture, infiltration of incompressible particles into cracks and joints, pumping of base material into cracks and joints beneath the concrete slab, and concrete expansion caused by the alkali–silica reaction (ASR) in concrete [1]. This issue can cause concrete pavement blow-up and other pressure-related issues, such as concrete crushing and damage to adjoining structures (e.g., bridge abutments, decks, drainage, manholes, and access structures in the pavement). The cumulative pavement growth in concrete pavements increases the probability of blow-up distress [1,2,3]. Ref. [3] presumed that most of these blow-ups were due to the generation of a high pavement pressure (this study took place before the use of pressure-relief joints was introduced). There is also a report that blow-ups occurred in the USA during a heatwave in the summer of 2016. In South Korea, numerous blow-ups and other pressure-related distresses occurred in many areas in the summer of 2018, when the air temperature and moisture levels were extremely high.

When a concrete pavement is newly constructed, the joint seals are intact and function well, reducing the probability of pressure generation in the pavement. However, as the pavement ages, the joint sealant fails owing to repeated joint movements, stiffening, traffic abrasion, etc. [4]. This failure accelerates the infiltration of incompressible particles into the joints, increasing the probability of pressure generation. This outcome is explained as a cyclical pressure-generation process caused by the infiltration of incompressible particles [2,5]. The process of a joint completely closing is referred to as joint closure (JC); in this case, the faces of adjacent slabs in the joint come into contact either with each other or the incompressible particles [6]. This contact generally occurs because of concrete slab expansion resulting from the increases in temperature and moisture. The temperature at which a joint closes is called the JC temperature (Tc); we note that Tc may be low if there are incompressible particles in the joint.

For years, pavement growth and blow-up have been major problems for highway and airport engineers, as well as for road users, because they directly impact the performance of concrete pavements and adjacent or nearby structures, such as bridge abutments. If the contact concrete slabs can move freely in the spacing of the expansion joints, blow-up does not occur. Therefore, controlling and maintaining the widths of functioning expansion joints during their service lives is crucial. The objective of this study was to develop a reproducible methodology for estimating pavement growth and predicting the time of blow-up occurrence. Blow-up and pavement growth are affected by the complex interactions of numerous factors, such as the climatic conditions, the quantity of incompressible particles infiltrating the joints, the pavement structure and materials, and the joint systems of the concrete pavement sections.

2. Descriptions of Pavement Growth and Blow-Up Analysis Model

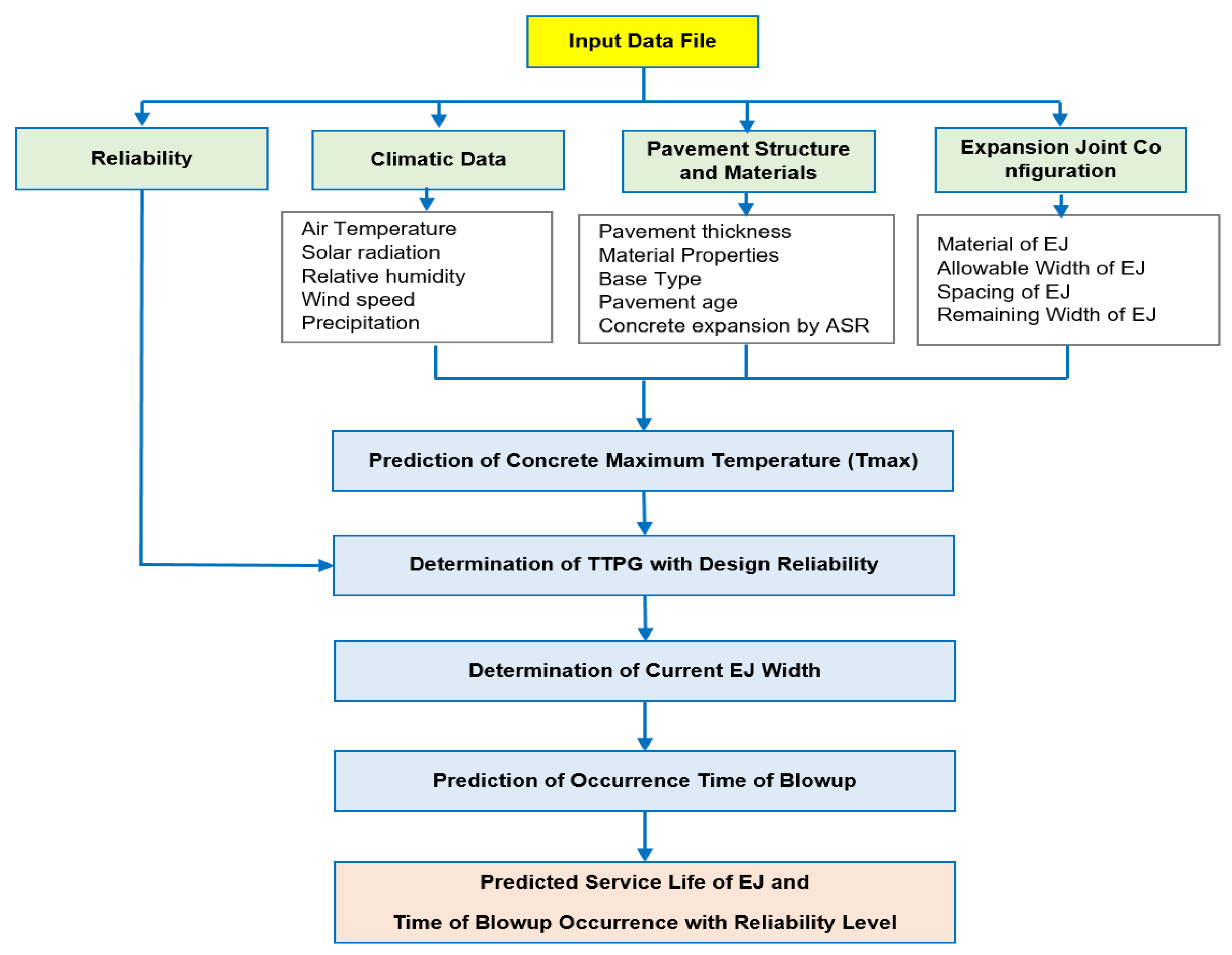

In this study, a user-friendly tool called the pavement growth and blow-up analysis (PGBA) model was developed using MATLAB to estimate the service life of expansion joint and blow-up occurrence time. Figure 1 illustrates the overall framework for the PGBA model. For the input file, there are four groups of input data, which are climatic data, pavement structures and materials, configuration of the expansion joint, and design reliability. The backbone of the run file consists of the prediction of maximum concrete temperature (Tmax), the prediction of the trigger temperature for pavement growth (TTPG), the prediction of alkali–silica reaction (ASR), the prediction of the current width of expansion (W_EJ) and the service life of expansion joint, and the prediction of concrete pavement blow-up after the closing of expansion joints.

Figure 1.

Overall framework for the PGBA program.

To predict the annual maximum concrete temperature (Tmax), a numerical predictive model for the concrete pavement temperature was established using the 1D finite difference method [7]. As previously mentioned, the TTPG is the temperature at which all transverse cracks and contraction joints among the expansion joints begin to come into contact and generate an axial compressive force in the pavement section. To estimate the magnitude of TTPG for a given concrete pavement section, [7] developed a statistical regression equation, which is in function with the concrete pavement age, transverse joint spacing, and maximum annual precipitation, using the Long-Term Performance Pavement Seasonal Monitoring Program (LTPP SMP) database.

3. Sensitivity Analysis of PGBA Model

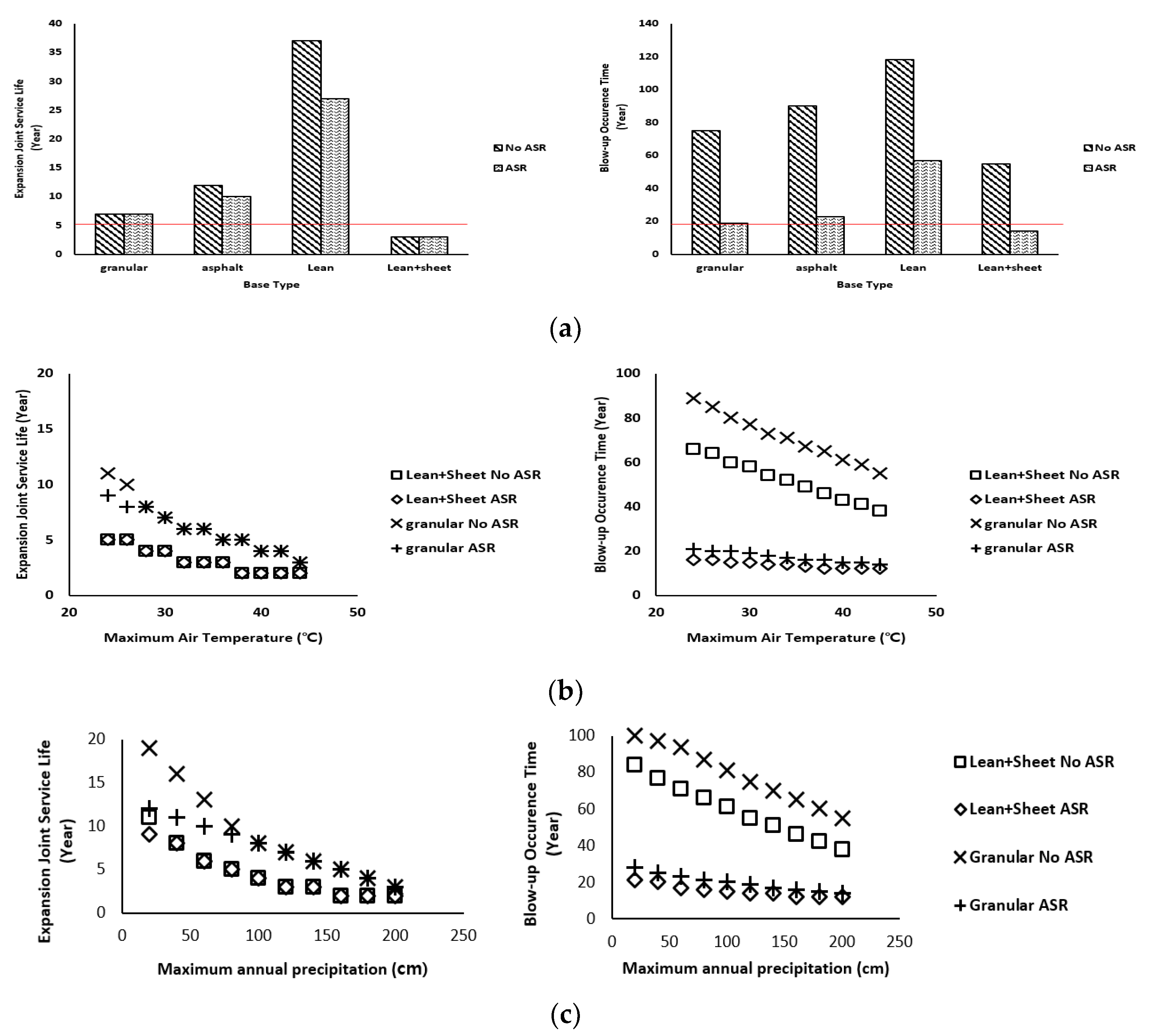

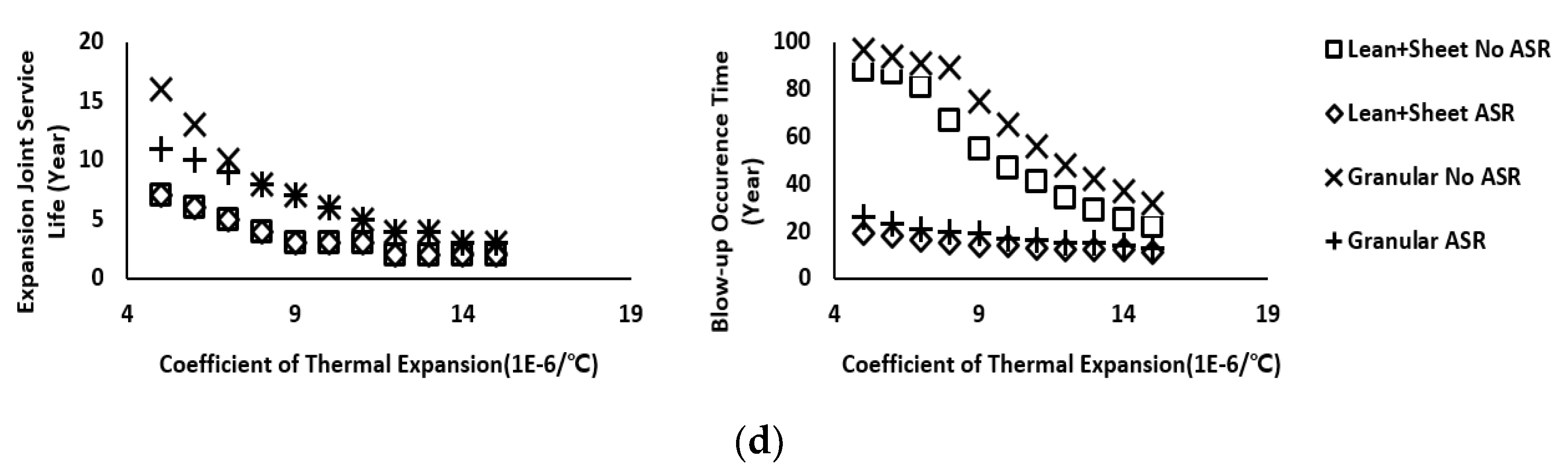

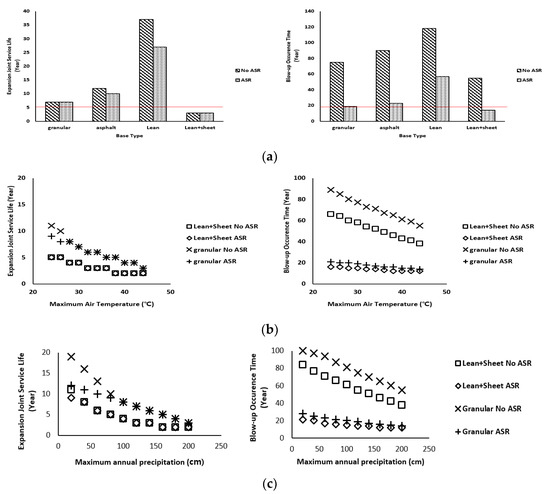

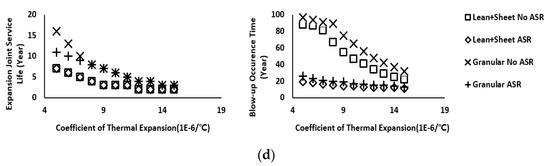

Various sensitivity analyses were performed to investigate the factors affecting the potential of pavement growth and blow-up, as shown in Figure 2. In the case of the lean concrete base using a plastic sheet with low frictional resistance, the service life of expansion joint is less than 5 years (Figure 2a). The maximum temperature is reported as an influence factor in the thermal expansion of concrete. In the case of lean concrete using a plastic sheet, as shown in Figure 2b, there is a very short service life of less than 5 years for the expansion joint, even at normal temperatures of about 23 °C. In addition, if ASR does not occur, blow-up occurs within 40 years in extreme conditions with maximum air temperatures exceeding 40 °C. On the other hand, blow-up occurs within 20 years in ASR conditions. As shown in Figure 2c,d, the service life of the expansion joint decreased as the precipitation and CTE of concrete increased. The probability of blow-up occurrence increased when precipitation and CTE increased.

Figure 2.

Sensitivity analysis results used to predict the service life of the expansion joint and blow-up occurrence times: (a) various base types, (b) the maximum temperature in the summer season, (c) annual average precipitation, and (d) the coefficient of thermal expansion.

4. Conclusions

In this study, the pavement growth and blow-up analysis model was developed to predict the blow-up potential due to the concrete pavement growth. This PGBA model considered factors such as the pavement structure and materials, climatic conditions, configuration of the expansion joint, base friction characteristics, geometric imperfection, rotational stiffness of joints, and design reliability. In addition, the PGBA model can be used to predict the service life of expansion joints and the blow-up occurrence time by considering the factors affecting it. Using the developed model, various sensitivity analyses were performed to evaluate the factors affecting the potential of concrete pavement growth and blow-up occurrence. It was found that the factors of substrate type, coefficient of thermal expansion, precipitation, and alkali–silica reaction had a significant effect on pavement growth and blow-up occurrence. In a further study, it will be necessary to verify the PGBA model by comparing it to previous research.

Author Contributions

Conceptualization, S.L. and Y.K.; methodology, H.A. and Y.K.; investigation and H.A.; original draft preparation, Y.K.; writing—review and edition, S.L. and Y.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF), which is funded by the Ministry of Education (2021R1A6A1A03044326).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the research team members at the Institute for Disaster Prevention, GWNU, for their guidance and support throughout the project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Smith, K.D.; Snyder, M.B.; Darter, M.I.; Reiter, M.J.; Hall, K.T. Pressure Relief and Other Joint Rehabilitation Techniques; RES Consultants: Champaign, IL, USA, 1987. [Google Scholar]

- Rogers, C.E.; Bouvy, A.; Schiefer, P. Alleviating the Effects of Pavement Growth on Structures; MDOT Division of Operation: Lansing, MI, USA, 2012.

- Burke, M.P., Jr. Intergral & Semi-Intergral Bridges. In Bridge Damage and the Pavement G/P Phenomenon; Wiley-Blackwell: Hoboken, NJ, USA, 2009; pp. 21–39. [Google Scholar]

- Yang, G.; Bradford, M.A. A refined modelling for thermal-induce upheaval buckling of continuously reinforced concrete pavements. Eng. Struct. 2017, 150, 256–270. [Google Scholar] [CrossRef]

- Kerr, A.D. Blowup of a concrete pavement adjoining a rigid structure. Int. J. Non-Linear Mech. 1994, 29, 387–396. [Google Scholar] [CrossRef]

- Lee, S.W.; Stoffels, S.M. Analysis of In Situ Horizontal Joint Movements in Rigid Pavements. Transp. Res. Rec. 2002, 1778, 9–16. [Google Scholar] [CrossRef]

- Chhay, L.; Kim, Y.K.; Lee, S.W. Evaluation of temperature for pavement growth potential of concrete pavement. Constr. Build. Mater. 2021, 278, 121790. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).