Abstract

The production of biodiesel from microalgae presents a sustainable and renewable solution to the growing global energy demands, with catalysts playing a critical role in optimizing the transesterification process. This study examines the emerging catalysts and innovative techniques utilized in converting microalgal lipids into fatty acid methyl esters, emphasizing their impact on reaction efficiency, yield, and environmental sustainability. Sulfuric acid demonstrates excellent performance in in situ transesterification, while NaOH/zeolite achieves high biodiesel yields using ultrasound- and microwave-assisted methods. Metal oxides such as CuO, NiO, and MgO supported on zeolite, as well as ZnAl-layered double hydroxides (LDHs), further enhance reaction performance through their high activity and stability. Enzymatic catalysts, particularly immobilized lipases, provide a more environmentally friendly option, offering high yields (>90%) and the ability to operate under mild conditions. However, their high cost and limited reusability pose significant challenges. Ionic liquid catalysts, such as tetrabutylphosphonium carboxylate, streamline the process by eliminating the need for drying and lipid extraction, achieving yields as high as 98% from wet biomass. The key novelty of this work lies in its detailed focus on the use of ionic liquids and nanocatalysts in microalgae-based biodiesel production, which are often underrepresented in previous reviews that primarily discuss homogeneous and heterogeneous catalysts.

1. Introduction

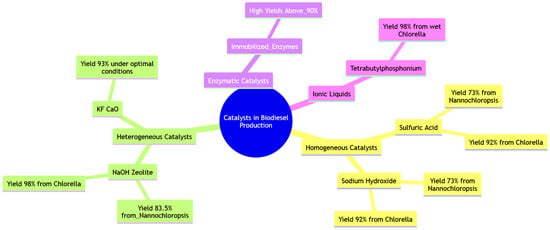

The production of biodiesel from microalgae is a multifaceted process encompassing cultivation, harvesting, drying, lipid extraction, and transesterification. Microalgae are regarded as an attractive feedstock due to their high lipid yields, rapid growth cycles, and their ability to grow on non-arable land [1,2]. Microalgae are cultivated using open raceway ponds, photobioreactors, or hybrid systems. While open ponds are more cost-effective, they are vulnerable to contamination and environmental variability. Photobioreactors, on the other hand, allow for higher productivity due to controlled conditions [3,4,5]. Efficient harvesting is essential for reducing energy input. Common techniques include centrifugation, filtration, and flocculation [6,7]. Lipids can be extracted using various techniques, including transesterification, Soxhlet extraction, ultrasonic- or microwave-assisted extraction, and supercritical CO2 extraction. Among these, supercritical CO2 offers notable advantages due to its environmental compatibility and efficiency [8,9]. Traditional methods of transesterification utilize acidic, alkaline, or enzymatic catalysts. Although enzymes offer superior selectivity and milder processing conditions, their high cost remains a major limitation [10]. Advanced techniques such as supercritical alcohol transesterification, the BIOX (Biological Oxidation) method, and the use of nanocatalysts are being developed to enhance conversion rates and accommodate lower-quality lipid feedstocks [8,10,11]. Catalysts play a pivotal role in converting microalgal lipids into fatty acid methyl esters (FAMEs) through transesterification. Their application significantly enhances reaction efficiency, reduces processing time, and supports more environmentally friendly and cost-effective biodiesel production processes. Heterogeneous catalysts such as potassium-promoted Fe2O3–Al2O3 magnetic nanocatalysts have shown high stability and reusability, making them viable for large-scale processes [12]. Graphene-based catalysts, with their high surface area and functional groups, provide excellent efficiency, easy recovery, and environmental benefits [13]. Metal oxides supported on zeolite, including CuO/Zeo, NiO/Zeo, and MgO/Zeo, have been explored for microalgal oil conversion, showing promising yields under optimized conditions [14]. Additionally, carbon-based solid acid catalysts derived from microalgae residues serve as sustainable and regenerable options for both esterification and transesterification [15]. Enzymatic catalysts, particularly immobilized enzymes, are effective for oils with high free fatty acid content and offer clean processing with reusability benefits [16,17,18]. Nanocatalysts, known for their high surface area and catalytic activity, are increasingly applied to optimize reaction parameters in biodiesel synthesis. Lastly, ionic liquids such as tetrabutylphosphonium carboxylate have been successfully used for direct transesterification of wet microalgae, eliminating the need for prior drying or lipid extraction and offering a recyclable, green alternative [19]. Catalysts in microalgae-based biodiesel production can be classified in various classifications, as shown in Figure 1.

Figure 1.

Catalysts in microalgae-based biodiesel production.

Table 1 shows some important studies on the use of catalysts in biodiesel production. Unlike previous reviews that primarily focus on homogeneous and heterogeneous catalysts, this study places special emphasis on emerging catalytic systems such as nanocatalysts, carbon-based materials, and ionic liquids. This review aims to contribute by offering a comprehensive and updated synthesis of advanced catalytic strategies, emphasizing their sustainability, reusability, and industrial scalability, which are critical for the future of green biofuel technologies.

Table 1.

Overview of catalyst studies in microalgae-derived biodiesel production.

2. Use of Homogeneous Catalysts in Microalgae-Based Biodiesel Production

Homogeneous catalysts, such as sulfuric acid, sodium hydroxide, and sodium methoxide, are among the most commonly used due to their high efficiency in the transesterification process. Sulfuric acid and sodium hydroxide have demonstrated excellent yields, with sulfuric acid achieving FAME yields of 73% from Nannochloropsis oculata and 92% from Chlorella sp. [29]. Homogeneous catalysts, primarily strong acids (e.g., HCl and H2SO4) and bases (e.g., NaOH and KOH), are widely utilized in the transesterification of microalgal lipids into fatty acid methyl esters (FAMEs), the primary constituents of biodiesel. Their widespread application is attributed to their high catalytic activity, fast reaction rates, and ability to effectively convert both triglycerides and free fatty acids (FFAs) into biodiesel [21,30]. Acid catalysts like H2SO4 are particularly effective in processing microalgae oils with high FFA content and can be combined with dimethyl carbonate to enhance biodiesel yields [21]. On the other hand, base catalysts such as NaOH and KOH are preferred for oils with low FFA concentrations due to their higher reaction rates and lower operating temperatures. Despite their efficiency and ability to produce high yields, homogeneous catalysts present several limitations that hinder their sustainability and scalability. Chief among these is the difficulty of separating the catalyst from the final biodiesel product, which complicates purification, reduces product purity, and increases the likelihood of soap formation [30,31]. Furthermore, homogeneous catalysts are typically non-recyclable and generate hazardous waste streams, raising environmental and disposal concerns [23,32]. Compared to heterogeneous catalysts, homogeneous systems are less environmentally benign and offer limited opportunities for catalyst recovery and reuse [12,14,31]. Heterogeneous catalysts such as metal oxides, zeolites, and supported alkaline earth metals not only simplify the post-reaction separation process but also exhibit strong potential for repeated use, improving economic and environmental performance [23,33]. In addition, heterogeneous catalysts like CaO and zeolite-based materials have demonstrated excellent activity in transesterifying microalgal lipids, narrowing the performance gap with their homogeneous counterparts [14,27]. While homogeneous catalysts remain effective for lab-scale or small-batch biodiesel synthesis due to their simplicity and reactivity, large-scale industrial applications may benefit more from heterogeneous systems or hybrid approaches that blend catalytic efficiency with sustainability. To bridge the gap, ongoing research is focusing on minimizing the environmental drawbacks of homogeneous catalysts and enhancing their compatibility with green solvents and integrated bioprocesses [33,34].

3. Use of Heterogeneous Catalysts in Microalgae-Based Biodiesel Production

The application of heterogeneous catalysts in biodiesel production from microalgae has gained significant traction due to their operational and environmental advantages over homogeneous catalysts. These solid-phase catalysts facilitate easier separation from the reaction mixture, allowing for simplified purification and reduced post-processing steps [16,23,31]. Their reusability across multiple cycles not only lowers production costs but also minimizes catalyst waste, enhancing the overall sustainability of the process [35,36]. Furthermore, heterogeneous catalysts mitigate several environmental issues associated with homogeneous systems, such as toxic waste generation and the need for neutralization and washing, making them a greener alternative for large-scale biodiesel synthesis [16,23]. Various types of heterogeneous catalysts have been explored, including metal oxides like CaO and Fe2O3–Al2O3, which are effective for transesterification reactions due to their strong basicity and thermal stability [12,23]. Zeolite-based catalysts, particularly NaOH/zeolite composites, have shown high biodiesel yields when used with microalgal species such as Nannochloropsis oculata and Chlorella vulgaris [31]. Biochar derived from agricultural residues or fermentation byproducts, such as spent rootlets, has also emerged as a promising low-cost catalyst, with unmodified biochar often outperforming acid-modified variants in conversion efficiency [35]. Additionally, composite catalysts like KF/CaO and LiOH–pumice have demonstrated high effectiveness in microalgae transesterification, offering potential for both catalytic efficiency and structural robustness [36,37]. Optimization of process parameters such as reaction temperature, methanol-to-biomass ratio, catalyst loading, and reaction time is critical to achieving high conversion rates. For instance, magnetic Fe2O3–Al2O3 supported with KOH has proven highly effective under optimized thermal and mixing conditions [12]. Despite these advantages, challenges remain, particularly concerning the scalability, production cost, and regeneration efficiency of heterogeneous catalysts. Research continues to focus on developing more cost-effective, reusable catalysts derived from abundant natural resources or industrial waste materials [38]. To ensure commercial viability, further advancements are needed in catalyst durability, resistance to deactivation, and compatibility with wet or unrefined algal biomass [33]. Overall, heterogeneous catalysis represents a promising route toward greener and more sustainable biodiesel production from microalgae, provided current technological and economic barriers can be addressed through continued innovation and process integration.

4. Use of Enzymatic Catalysts in Microalgae-Based Biodiesel Production

The application of enzymatic catalysts in microalgae-based biodiesel production has emerged as a promising and eco-friendly alternative to conventional chemical catalysis. Enzymatic transesterification, primarily driven by lipase enzymes, enables the conversion of microalgal lipids into biodiesel under mild and environmentally benign conditions. One of the main benefits of enzymatic catalysts is their high specificity, which facilitates simultaneous esterification and transesterification of triglycerides and free fatty acids without the formation of undesirable byproducts [17,39]. This makes enzymatic catalysis particularly suitable for microalgae oils, which often contain high levels of free fatty acids. Moreover, enzymes function under relatively mild conditions—typically between 30 °C and 50 °C and at atmospheric pressure—leading to significant energy savings during processing [16,40]. Under optimized conditions, enzymatic transesterification has demonstrated high conversion efficiencies, often exceeding 90% ester yield, particularly when using optimal alcohol-to-oil molar ratios in the range of 3:1 to 4.5:1 [16,41]. Another key advantage is the reusability of enzymes, especially when immobilized on solid supports. Immobilized enzymes enhance operational stability and enable multiple usage cycles, thereby helping to reduce the overall cost of the process [17,42]. However, the commercial-scale application of enzymatic biodiesel production still faces several challenges. The high initial cost of enzymes remains a major constraint, although advancements in enzyme immobilization, recycling, and novel reactor configurations are gradually addressing this issue [16,17,43]. Reaction times in enzymatic processes are generally longer than in chemical catalysis, sometimes requiring between 12 and 48 h to achieve maximum yields [16]. Additionally, careful optimization of factors such as enzyme concentration, temperature, pH, alcohol type, and alcohol-to-oil ratio is essential to maximize reaction efficiency [43]. Recent technological developments have introduced innovative methods to enhance enzymatic catalysis. For example, studies using propane as a pressurized solvent system have demonstrated increased lipid accessibility and reaction rates [40]. The combination of different lipase systems, such as Novozym435 and lipase NS81006, has been shown to enhance both yield and polyunsaturated fatty acid (PUFA) enrichment in biodiesel products [41]. Furthermore, emerging solvent systems including ionic liquids and thermoresponsive solvents have been explored to improve enzyme stability and reduce processing time [17,42]. Overall, enzymatic catalysis offers a green, efficient, and technically flexible route for biodiesel production from microalgae. With ongoing advancements in enzyme engineering, immobilization techniques, and integrated process development, enzymatic methods are becoming increasingly feasible for scalable and sustainable biodiesel manufacturing [33,39].

5. Use of Ionic Liquids in Microalgae-Based Biodiesel Production

Ionic liquids (ILs) have gained increasing attention as effective and environmentally friendly catalysts in the production of biodiesel from microalgae. Their unique physicochemical properties—such as low vapor pressure, thermal stability, and tunable polarity—make them particularly advantageous for green chemical processes. One of the most notable benefits of ILs is their ability to catalyze direct transesterification of wet microalgae biomass, thereby eliminating the need for energy-intensive drying and lipid extraction steps traditionally required in biodiesel production. This significantly reduces both processing time and energy consumption [19,44]. Different types of ILs—acidic, basic, and supported forms—have been developed to enhance catalytic activity and broaden applicability. Acidic ILs are particularly advantageous for processing feedstocks with high free fatty acid content, as they catalyze both esterification and transesterification without pretreatment [45,46]. Basic ILs, on the other hand, offer high reactivity under relatively mild conditions [47]. The incorporation of ILs into hybrid systems, including IL–enzyme conjugates and supported ionic liquid phases, has further improved biodiesel yields and catalyst reusability [48]. In addition to IL formulation, process enhancements like ultrasonication and microwave-assisted transesterification have significantly accelerated biodiesel synthesis and improved reaction kinetics [44,49]. These approaches facilitate better mass and heat transfer, leading to higher biodiesel productivity. Optimization studies have also focused on identifying ideal conditions—including methanol-to-oil molar ratio, catalyst loading, and reaction time—to maximize biodiesel output [50,51].

6. Use of Nanocatalysts in Microalgae-Based Biodiesel Production

The application of nanocatalysts in biodiesel production from microalgae has garnered significant attention in recent years due to their exceptional catalytic properties and potential to improve process efficiency. Nanocatalysts are characterized by a high surface area-to-volume ratio, which enhances their reactivity and facilitates faster and more efficient transesterification reactions [25]. These catalysts exhibit excellent thermal stability and high activity, enabling effective conversion of microalgal lipids into fatty acid methyl esters (FAMEs), the main component of biodiesel. Additionally, nanocatalysts are often reusable over multiple cycles without significant loss of catalytic performance, which supports more sustainable and cost-effective production [25,52]. Calcium-based nanocatalysts, such as calcium methoxide and calcium oxide, have been particularly effective, achieving biodiesel yields up to 99% under optimized conditions. Similarly, magnetic nanocatalysts—like SO42−/Fe3O4–Al2O3—offer the advantage of easy separation from the reaction mixture and have demonstrated yields as high as 87.6% [52]. In addition, carbon-based catalysts such as graphene oxide have shown promise under microwave irradiation, delivering high biodiesel yields while minimizing the environmental impact associated with metal-based systems [26]. Nanocatalysts have also been utilized in innovative approaches like direct or in situ transesterification, where the extraction of lipids and their conversion to biodiesel occur in a single step. This integration reduces energy consumption and simplifies the overall process [53,54,55]. For instance, bio-nanoparticles derived from bio-waste have been applied in whole-biomass transesterification, significantly enhancing biodiesel yields from Coelastrella sp. [54]. Optimization studies have emphasized the importance of key parameters such as the methanol-to-oil molar ratio, catalyst loading, temperature, and reaction time in maximizing yield [25,56]. Table 2 shows catalyst types, performance, and environmental implications in microalgae-based biodiesel production.

Table 2.

Catalyst types, performance, environmental impact in microalgae-based biodiesel production.

7. Environmental Sustainability

The environmental sustainability of catalysts in biodiesel production from microalgae is a multifaceted issue that encompasses catalyst selection, energy efficiency, lifecycle emissions, and waste management. Catalysts play a central role in enhancing the conversion efficiency of microalgal lipids into biodiesel, but their environmental performance varies significantly depending on their type, regeneration potential, and compatibility with green processing methods. Traditional acid and base catalysts such as hydrochloric acid (HCl) and sodium hydroxide (NaOH) are widely used for transesterification and esterification due to their high reactivity [64,65]. However, these catalysts pose challenges in terms of corrosiveness, difficulty in recovery, and production of wastewater. More sustainable alternatives include metal-based catalysts, such as Cu/HZSM-5, Ni–Mg/ZSM-5, CaO, and Ce, which have been shown to improve bio-oil quality by reducing the nitrogen and oxygen content in co-pyrolysis, enhancing energy density while lowering pollutant formation [66,67]. Ionic liquids (ILs) have emerged as a particularly eco-friendly catalyst group due to their low volatility, recyclability, and ability to catalyze transesterification under mild conditions without pretreatment steps, leading to significant energy savings and reduced emissions [45]. From an environmental perspective, lifecycle assessment (LCA) provides a robust framework for evaluating the sustainability of catalytic biodiesel production. LCA studies indicate that biodiesel derived from microalgae generally demonstrates a favorable energy balance, often producing more energy than it consumes, especially when using energy-efficient or recyclable catalysts [68,69]. Furthermore, biodiesel production systems that incorporate CO2 sequestration by microalgae can result in net reductions in carbon emissions over their entire lifecycle [70,71]. Waste utilization also enhances environmental sustainability—using wastewater as a nutrient source not only reduces the need for synthetic fertilizers but also minimizes eutrophication risks when integrated with nutrient-recycling biocatalysts [72,73]. Advanced catalysts such as ILs and enzyme-immobilized systems also contribute to reducing the global warming potential (GWP) and photochemical oxidation by operating under milder conditions and generating fewer volatile organic compounds [44,74]. Technological advancements further support sustainability. For example, the integration of hybrid cultivation systems with genetically engineered microalgae can increase biomass productivity, thereby reducing the land and resource footprint of feedstock cultivation [73]. In addition, methods such as ultrasound-assisted enzymatic extraction and microwave transesterification have shown the potential to reduce energy use while improving lipid recovery rates [75]. However, despite these promising strategies, economic feasibility remains a limiting factor for large-scale implementation. Studies suggest that while microalgae biodiesel has significant environmental advantages, optimizing process economics—especially related to catalyst costs and their recovery or regeneration—is essential for commercial scalability [76,77]. Consequently, the development of low-cost, durable, and reusable catalysts remains a high priority for ensuring long-term sustainability.

8. Challenges and Future Directions

The production of biodiesel from microalgae using catalytic processes presents significant opportunities for sustainable energy development but is accompanied by a number of critical challenges and potential future directions. One of the most persistent issues is the high production cost associated with multistage processing steps, including cultivation, harvesting, drying, lipid extraction, and conversion [33]. These stages are energy-intensive and contribute substantially to the overall economic burden, limiting the scalability of the technology [7,17,34,78]. Catalysts themselves also introduce challenges. Enzymatic catalysts, while environmentally friendly and efficient, are expensive and require improvements in stability and reusability to be considered economically viable on a commercial scale [17,33].

Homogeneous catalysts, such as sodium or potassium hydroxide, often suffer from difficult separation procedures and produce environmentally harmful waste, raising sustainability concerns [32]. Another significant challenge is the optimization of reaction conditions, which play a crucial role in influencing yield and efficiency. Factors like reaction time, temperature, and the presence of water in wet microalgae biomass complicate transesterification and reduce overall efficiency [79,80]. Additionally, traditional solvent-based methods, such as those employing hexane, have been criticized for their adverse environmental impact, prompting calls for greener alternatives in catalyst systems [81]. Furthermore, catalysts themselves can contribute to pollution if not properly recovered or recycled [34].

The application of ionic liquids (ILs) as catalysts in microalgae-based biodiesel production is constrained by several limitations. The foremost challenge is their high production cost, which undermines economic viability, especially at industrial scales [42]. Additionally, the recovery and reuse of ILs involve complex and often costly separation processes. Their compatibility with wet biomass is not universal—while some ILs are optimized for in situ reactions, many still exhibit reduced efficiency in the presence of water. Reaction kinetics can also be sluggish due to mass transfer limitations, lowering the overall process throughput. Although ILs are touted as green alternatives, concerns remain regarding their environmental impact, particularly their toxicity and biodegradability. Technically, the process often requires the integration of microwave or ultrasound assistance, adding complexity and energy demand. Moreover, effective disruption of microalgal cell walls—critical for lipid extraction—remains a challenge for many ILs. Lastly, achieving optimal reaction conditions such as IL-to-biomass ratio, temperature, and reaction time demands precise control, which may not be feasible in scaled-up operations. These limitations highlight the need for further optimization and innovation to fully leverage ILs in sustainable biodiesel production [49,82].

In response to these challenges, research is moving toward future-oriented solutions that promise to improve both economic and environmental viability. A major avenue of exploration involves the development of cost-effective and recyclable heterogeneous catalysts, including bio-derived and metal–organic framework (MOF) catalysts, which offer advantages in separation and reuse [32,33]. Additionally, in situ transesterification techniques, which combine lipid extraction and transesterification into a single step, are being explored to reduce energy usage and streamline production. Innovations such as microwave irradiation and supercritical methanol processing are being applied to enhance these integrated reactions [79,83]. Another area receiving significant attention is the enhancement of enzymatic catalyst performance through immobilization technologies, which extend enzyme lifetimes and improve reusability [15]. Moreover, integrating biodiesel production with environmental co-benefits, such as CO2 capture and wastewater treatment, represents a sustainable pathway that could offset operational costs while supporting environmental objectives [84]. Genetic engineering and metabolic pathway optimization of microalgae are also being explored to improve lipid accumulation and biomass productivity, which are critical for feedstock availability [34,85].

9. Conclusions

The advancement of catalyst technologies in biodiesel production from microalgae presents a transformative opportunity for renewable energy development. Homogeneous catalysts, including acids and bases, continue to be widely applied due to their strong reactivity and cost-efficiency. Acid catalysts such as sulfuric acid effectively support in situ transesterification by breaking down microalgal cell walls and enabling direct lipid conversion. Base catalysts like sodium hydroxide are known for their rapid reaction kinetics and high efficiency under optimized conditions. Among heterogeneous catalysts, those supported on zeolite have demonstrated excellent performance with various microalgal species. Metal oxides on zeolite—such as copper, nickel, and magnesium oxides—have also shown promising results under specific process parameters. In addition, innovative catalysts like KF/CaO and ZnAl-layered double hydroxides (LDHs) have proven highly effective, especially when combined with advanced techniques like ultrasound and microwave irradiation. These developments underscore the potential of refining catalyst selection, reaction conditions, and process integration to significantly improve biodiesel production efficiency. Future research should emphasize enhancing catalyst durability, environmental sustainability, and industrial scalability to unlock the full potential of microalgae-based biodiesel as a viable renewable fuel source.

Author Contributions

Conceptualization, P.P.B. and P.S.; methodology, P.P.B. and P.S.; validation, P.S.; formal analysis, P.P.B.; investigation, P.P.B. and P.S.; data curation P.S.; writing—original draft preparation, P.P.B.; writing—review and editing, P.S.; visualization, P.S.; supervision, P.P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available within this manuscript.

Acknowledgments

The authors gratefully acknowledge the support of Dibrugarh University in this study. The authors also wish to extend their sincere thanks to the academic editor and the chair of the conference for the opportunity to present this work at the 3rd International Electronic Conference on Catalysis Sciences (ECCS 2025), held from 23 to 25 April 2025.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vijayalakshmi, S.; Anand, M.; Ranjitha, J. Microalgae-based biofuel production using low-cost nanobiocatalysts. In Microalgae Cultivation for Biofuels Production; Academic Press: Cambridge, MA, USA; Elsevier: London, UK, 2020; pp. 251–263. [Google Scholar] [CrossRef]

- Rawat, I.; Ranjith Kumar, R.; Mutanda, T.; Bux, F. Biodiesel from microalgae: A critical evaluation from laboratory to large scale production. Appl. Energy 2013, 103, 444–467. [Google Scholar] [CrossRef]

- Rahul, S.M.; Sundaramahalingam, M.A.; Shivamthi, C.S.; Shyam Kumar, R.; Varalakshmi, P.; Karthikumar, S.; Kanimozhi, J.; Vinoth Kumar, R.; Sabarathinam, S.; Ganesh Moorthy, I.; et al. Insights about sustainable biodiesel production from microalgae biomass: A review. Int. J. Energy Res. 2021, 45, 17028–17056. [Google Scholar] [CrossRef]

- Kim, K.; Yoo, J.; Lee, W.G. Recent advances in photobioreactor systems for sustainable and enhanced microalgal biofuel production. Sustain. Energy Fuels 2022, 6, 5459–5473. [Google Scholar] [CrossRef]

- Zhu, L.D.; Hiltunen, E.; Antila, E.; Zhong, J.J.; Yuan, Z.H.; Wang, Z.M. Microalgal biofuels: Flexible bioenergies for sustainable development. Renew. Sustain. Energy Rev. 2014, 30, 1035–1046. [Google Scholar] [CrossRef]

- Singh, B.; Liu, Y.; Sharma, Y.C. Synthesis of biodiesel/bio-oil from microalgae. In Biotechnological Applications of Microalgae: Biodiesel and Value-Added Products; CRC Press: Boca Raton, FL, USA, 2013; pp. 99–112. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Ong, H.C.; Cheah, M.Y.; Chen, W.-H.; Yu, K.L.; Mahlia, T.M.I. Sustainability of direct biodiesel synthesis from microalgae biomass: A critical review. Renew. Sustain. Energy Rev. 2019, 107, 59–74. [Google Scholar] [CrossRef]

- Banerjee, S.; Atta, A. Lipid extraction and biodiesel production from microalgae: Recent advances. In An Integration of Phycoremediation Processes in Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–16. [Google Scholar] [CrossRef]

- Santana, A.; Jesus, S.; Larrayoz, M.A.; Filho, R.M. Supercritical carbon dioxide extraction of algal lipids for the biodiesel production. Procedia Eng. 2012, 42, 1755–1761. [Google Scholar] [CrossRef]

- Srivastava, G.; Maravi, D.K.; Singh, A. Biodiesel production from algae through catalytic transesterification. In Algal Biorefinery: Developments, Challenges and Opportunities; Routledge: London, UK; Taylor & Francis Group: Abingdon, UK, 2021; pp. 85–109. ISBN 9781003100317. [Google Scholar]

- Borthakur, P.P. Nanoparticle enhanced biodiesel blends: Recent insights and developments. Hybrid Adv. 2025, 10, 100442. [Google Scholar] [CrossRef]

- Kazemifard, S.; Nayebzadeh, H.; Saghatoleslami, N.; Safakish, E. Application of magnetic alumina-ferric oxide nanocatalyst supported by KOH for in-situ transesterification of microalgae cultivated in wastewater medium. Biomass Bioenergy 2019, 129, 105338. [Google Scholar] [CrossRef]

- Nazloo, E.K.; Moheimani, N.R.; Ennaceri, H. Graphene-based catalysts for biodiesel production: Characteristics and performance. Sci. Total Environ. 2023, 859, 160000. [Google Scholar] [CrossRef]

- Ariffin, M.I.; Abdullah, N.; Bahruji, H.; Mohd Kasim, N.A.; Abdul Halim, N.; Yun Hin, T.Y. Optimization of biodiesel production from Chlorella Vulgaris using CuO, NiO, and MgO on zeolite 4A catalysts. J. Phys. Conf. Ser. 2019, 1349, 012065. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.; Chen, J.; Zhang, Y.; Huang, W.; Zhu, Y.; Yang, J.; Zhang, C. A microalgae residue based carbon solid acid catalyst for biodiesel production. Bioresour. Technol. 2013, 146, 767–770. [Google Scholar] [CrossRef]

- Makareviciene, V.; Sendzikiene, E.; Gaide, I. Application of heterogeneous catalysis to biodiesel synthesis using microalgae oil. Front. Environ. Sci. Eng. 2021, 15, 97. [Google Scholar] [CrossRef]

- Sowan, E.; Mozumder, M.S.; Taher, H.; Al-Zuhair, S. Innovative approaches to enhanced enzymatic microalgae-to-biodiesel production. ChemBioEng Rev. 2023, 10, 860–883. [Google Scholar] [CrossRef]

- Devi, T.; Baskar, G.; Pravin, R. Process optimization and kinetics of biodiesel production from microalgal oil using potassium doped biochar heterogeneous catalyst. Energy Environ. 2025, 36, 2087–2110. [Google Scholar] [CrossRef]

- Malekghasemi, S.; Kariminia, H.-R.; Plechkova, N.K.; Ward, V.C.A. Direct transesterification of wet microalgae to biodiesel using phosphonium carboxylate ionic liquid catalysts. Biomass Bioenergy 2021, 150, 106126. [Google Scholar] [CrossRef]

- Brar, P.K.; Örmeci, B.; Dhir, A. Parametric optimization of rice bran-based bi-functional catalyst in the one-pot conversion of indigenous algal biomass into biodiesel using response surface methodology. Biomass Convers. Biorefinery 2024, 14, 1481–1493. [Google Scholar] [CrossRef]

- Mansur, D.; Fitriady, M.A.; Susilaningsih, D.; Simanungkalit, S.P. Production of biodiesel from Coelastrella sp. microalgae. AIP Conf. Proc. 2017, 1904, 020068. [Google Scholar] [CrossRef]

- Pradana, Y.S.; Masruri, W.; Azmi, F.A.; Suyono, E.A.; Sudibyo, H.; Rochmadi. Extractive-transesterification of Microalgae Arthrospira sp. using methanol-hexane mixture as solvent. Int. J. Renew. Energy Res. 2018, 8, 1499–1507. [Google Scholar]

- Ferreira, G.F.; Pinto, L.F.R.; Filho, R.M.; Fregolente, L.V.; Hayward, J.; Bartley, J.K. Ethanol-based transesterification of rapeseed oil with CaO catalyst: Process optimization and validation using microalgal lipids. Catal. Lett. 2025, 155, 84. [Google Scholar] [CrossRef]

- Musavi, S.A.; Bakhshi, H.; Khoobkar, Z. Biodiesel production from Chlorella sp. microalgae using new derived calcium methoxide-microalgae based catalyst. Fuel 2025, 387, 134459. [Google Scholar] [CrossRef]

- Mittal, V.; Talapatra, K.N.; Ghosh, U.K. A comprehensive review on biodiesel production from microalgae through nanocatalytic transesterification process: Lifecycle assessment and methodologies. Int. Nano Lett. 2022, 12, 351–378. [Google Scholar] [CrossRef]

- Kam, Y.L.; Agutaya, J.K.C.N.; Quitain, A.T.; Ogasawara, Y.; Sasaki, M.; Lam, M.K.; Yusup, S.; Assabumrungrat, S.; Kida, T. In-situ transesterification of microalgae using carbon-based catalyst under pulsed microwave irradiation. Biomass Bioenergy 2023, 168, 106662. [Google Scholar] [CrossRef]

- Dianursanti, S.; Sistiafi, A.G.; Putri, D.N. Biodiesel synthesis from Nannochloropsis oculata and Chlorella vulgaris through transesterification process using NaOH/zeolite heterogeneous catalyst. IOP Conf. Ser. Earth Environ. Sci. 2018, 105, 012053. [Google Scholar] [CrossRef]

- De Jesus, S.S.; Ferreira, G.F.; Moreira, L.S.; Filho, R.M. Biodiesel production from microalgae by direct transesterification using green solvents. Renew. Energy 2020, 160, 1283–1294. [Google Scholar] [CrossRef]

- Velasquez-Orta, S.B.; Lee, J.G.M.; Harvey, A.P. Evaluation of FAME production from wet marine and freshwater microalgae by in situ transesterification. Biochem. Eng. J. 2013, 76, 83–89. [Google Scholar] [CrossRef]

- Hartono, R.; Wijanarko, A.; Hermansyah, H. Synthesis of biodiesel using local natural zeolite as heterogeneous anion exchange catalyst. IOP Conf. Ser. Mater. Sci. Eng. 2018, 345, 012002. [Google Scholar] [CrossRef]

- Dianursanti Delaamira, M.; Bismo, S.; Muharam, Y. Effect of reaction temperature on biodiesel production from Chlorella vulgaris using CuO/zeolite as heterogeneous catalyst. IOP Conf. Ser. Earth Environ. Sci. 2017, 55, 012033. [Google Scholar] [CrossRef]

- Javed, F.; Zimmerman, W.B.; Fazal, T.; Hafeez, A.; Mustafa, M.; Rashid, N.; Rehman, F. Green synthesis of biodiesel from microalgae cultivated in industrial wastewater via microbubble induced esterification using bio-MOF-based heterogeneous catalyst. Chem. Eng. Res. Des. 2023, 189, 707–720. [Google Scholar] [CrossRef]

- Neag, E.; Stupar, Z.; Maicaneanu, S.A.; Roman, C. Advances in Biodiesel Production from Microalgae. Energies 2023, 16, 1129. [Google Scholar] [CrossRef]

- Liu, H.; Liu, T.-J.; Guo, H.-W.; Wang, Y.-J.; Ji, R.; Kang, L.-L.; Wang, Y.-T.; Guo, X.; Li, J.-G.; Jiang, L.-Q.; et al. A review of the strategy to promote microalgae value in CO2 conversion-lipid enrichment-biodiesel production. J. Clean. Prod. 2024, 436, 140538. [Google Scholar] [CrossRef]

- Tsavatopoulou, V.D.; Vakros, J.; Manariotis, I.D. Lipid conversion of Scenedesmus rubescens biomass into biodiesel using biochar catalysts from malt spent rootlets. J. Chem. Technol. Biotechnol. 2020, 95, 2421–2429. [Google Scholar] [CrossRef]

- De Luna, M.D.G.; Doliente, L.M.T.; Ido, A.L.; Chung, T.-W. In situ transesterification of Chlorella sp. microalgae using LiOH-pumice catalyst. J. Environ. Chem. Eng. 2017, 5, 2830–2835. [Google Scholar] [CrossRef]

- Ma, G.; Hu, W.; Pei, H.; Jiang, L.; Song, M.; Mu, R. In situ heterogeneous transesterification of microalgae using combined ultrasound and microwave irradiation. Energy Convers. Manag. 2015, 90, 41–46. [Google Scholar] [CrossRef]

- Jeremiah, P.A.; Jalil, A.A.; Olutoye, M.A. Heterogeneous catalyst application in biodiesel production: Needs to focus on cost effective and reusable catalysts. IOP Conf. Ser. Mater. Sci. Eng. 2020, 808, 012013. [Google Scholar] [CrossRef]

- Nasya binti Ramlee, N.; Mahdi, H.I.; Wan Azelee, N.I. Biodiesel production using enzymatic catalyst. In Biofuels and Bioenergy: Opportunities and Challenges; Elsevier: Amsterdam, The Netherlands, 2022; pp. 133–169. [Google Scholar] [CrossRef]

- Marcon, N.S.; Colet, R.; Balen, D.S.; Pereira de Pereira, C.M.; Bibilio, D.; Priamo, W.; Bender, J.P.; Steffens, C.; Rosa, C.D. Enzymatic biodiesel production from microalgae biomass using propane as pressurized fluid. Can. J. Chem. Eng. 2017, 95, 1340–1344. [Google Scholar] [CrossRef]

- Tian, X.; Dai, L.; Liu, M.; Liu, D.; Du, W.; Wu, H. Lipase-catalyzed methanolysis of microalgae oil for biodiesel production and PUFAs concentration. Catal. Commun. 2016, 84, 44–47. [Google Scholar] [CrossRef]

- Hossain, S.M.Z.; Razzak, S.A.; Al-Shater, A.F.; Moniruzzaman, M.; Hossain, M.M. Recent advances in enzymatic conversion of microalgal lipids into biodiesel. Energy Fuels 2020, 34, 6735–6750. [Google Scholar] [CrossRef]

- Oliveira, J.; Costa, E.; Maia Dias, J.; Pires, J.C. Biodiesel production by biocatalysis using lipids extracted from microalgae oil of Chlorella vulgaris and Aurantiochytrium sp. Bioenergy Res. 2024, 17, 1080–1089. [Google Scholar] [CrossRef]

- Miao, C.; Li, H.; Lü, P.; Wang, Z.; Zhuang, X.; Yuan, Z. Preparation of biodiesel from microalgae by direct transesterification under ultrasonic-assisted ionic liquid composite conditions. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2017, 33, 248–254. [Google Scholar] [CrossRef]

- Ong, H.C.; Tiong, Y.W.; Goh, B.H.H.; Gan, Y.Y.; Mofijur, M.; Fattah, I.M.R.; Chong, C.T.; Alam, M.A.; Lee, H.V.; Silitonga, A.S.; et al. Recent advances in biodiesel production from agricultural products and microalgae using ionic liquids: Opportunities and challenges. Energy Convers. Manag. 2021, 228, 113647. [Google Scholar] [CrossRef]

- Han, B.Y.; Zhang, W.D.; Chen, Y.B.; Yin, F.; Liu, S.Q.; Zhao, X.L. A review on biodiesel synthesis using catalyzed transesterification base ionic liquids as catalyst. Adv. Mater. Res. 2013, 772, 303–308. [Google Scholar] [CrossRef]

- Andreani, L.; Rocha, J.D. Use of ionic liquids in biodiesel production: A review. Braz. J. Chem. Eng. 2012, 29, 1–13. [Google Scholar] [CrossRef]

- Sangeetha, B.; Baskar, G. Biodiesel production using ionic liquid-based catalysts. In Biodiesel Production: Feedstocks, Catalysts, and Technologies; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2022; pp. 249–267. [Google Scholar] [CrossRef]

- Shrikhande, S.; Deshpande, G.; Sawarkar, A.N.; Ahmad, Z.; Patle, D.S. Design and retrofitting of ultrasound intensified and ionic liquid catalyzed in situ algal biodiesel production. Chem. Eng. Res. Des. 2021, 171, 168–185. [Google Scholar] [CrossRef]

- Gautam, A.; Pandey, A.; Balinge, K.R.; Khajone, V.B.; Bhagat, P.R.; Ahmad, Z.; Kumar, S.; Patle, D.S. Optimization, kinetics and thermodynamics of ultrasound assisted and ionic liquid catalyzed in-situ biodiesel synthesis from wet microalgae. AIP Conf. Proc. 2023, 2785, 030014. [Google Scholar] [CrossRef]

- Ding, D.; Shen, Z.; Ma, T.; Sun, Y.; Shi, M.; Lu, T.; Wu, B.; Luque, R.; Sun, Y. Competition of dual roles of ionic liquids during in situ transesterification of wet algae. ACS Sustain. Chem. Eng. 2022, 10, 13692–13701. [Google Scholar] [CrossRef]

- Safakish, E.; Nayebzadeh, H.; Saghatoleslami, N.; Kazemifard, S. Comprehensive assessment of the preparation conditions of a separable magnetic nanocatalyst for biodiesel production from algae. Algal Res. 2020, 49, 101949. [Google Scholar] [CrossRef]

- Im, H.; Lee, H.; Park, M.S.; Yang, J.-W.; Lee, J.W. Concurrent extraction and reaction for the production of biodiesel from wet microalgae. Bioresour. Technol. 2014, 152, 534–537. [Google Scholar] [CrossRef]

- Karpagam, R.; Rani, K.; Ashokkumar, B.; Ganesh Moorthy, I.; Dhakshinamoorthy, A.; Varalakshmi, P. Green energy from Coelastrella sp. M-60: Bio-nanoparticles mediated whole biomass transesterification for biodiesel production. Fuel 2020, 279, 118490. [Google Scholar] [CrossRef]

- Saikia, M.; Sarmah, P.; Borthakur, P.P. A review of challenges to adoption of biodiesel as a diesel substitute in India. Renew. Energy Res. Appl. 2024, 5, 221–227. [Google Scholar]

- Borthakur, P.P.; Sarma, G.; Hazarika, H.; Bhattacharyya, S.; Hazarika, T. Microalgae Asterarcys sp.: A potential source for biodiesel production. Indian J. Nat. Sci. 2021, 12, 35547–35555. [Google Scholar]

- Kibar, M.E.; Hilal, L.; Çapa, B.T.; Bahçıvanlar, B.; Abdeljelil, B.B. Assessment of homogeneous and heterogeneous catalysts in transesterification reaction: A mini review. ChemBioEng Rev. 2023, 10, 412–422. [Google Scholar] [CrossRef]

- MacArio, A.; Giordano, G. Catalytic conversion of renewable sources for biodiesel production: A comparison between biocatalysts and inorganic catalysts. Catal. Lett. 2013, 143, 159–168. [Google Scholar] [CrossRef]

- Reza Talaghat, M.; Mokhtari, S.; Saadat, M. Modeling and optimization of biodiesel production from microalgae in a batch reactor. Fuel 2020, 280, 118578. [Google Scholar] [CrossRef]

- Zhu, L.; Huo, S.; Qin, L. A microalgae-based biodiesel refinery: Sustainability concerns and challenges. Int. J. Green Energy 2015, 12, 595–602. [Google Scholar] [CrossRef]

- Li, Y.-R.; Shue, M.-F.; Hsu, Y.-C.; Lai, W.-L.; Chen, J.-J. Application of factorial design methodology for optimization of transesterification reaction of microalgae lipids. Energy Procedia 2014, 52, 377–382. [Google Scholar] [CrossRef][Green Version]

- Bello, B.Z.; Nwokoagbara, E.; Wang, M. Comparative techno-economic analysis of biodiesel production from microalgae via transesterification methods. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2012; Volume 30, pp. 132–136. [Google Scholar] [CrossRef]

- Gouda, S.P.; Dhakshinamoorthy, A.; Rokhum, S.L. Metal-organic framework as a heterogeneous catalyst for biodiesel production: A review. Chem. Eng. J. Adv. 2022, 12, 100415. [Google Scholar] [CrossRef]

- Carvalho Júnior, R.M.; Vargas, J.V.C.; Ramos, L.P.; Marino, C.E.B.; Torres, J.C.L. Microalgae biodiesel via in situ methanolysis. J. Chem. Technol. Biotechnol. 2011, 86, 1418–1427. [Google Scholar] [CrossRef]

- Ramadhani, A.P.; Prashantyo, M.H.; Soedarmodjo, T.P.; Widjaja, A. The effect UV-B mutation on biodiesel from microalgae Botryococcus braunii using esterification, transesterification and combination of esterification-transesterification. AIP Conf. Proc. 2020, 2217, 030021. [Google Scholar] [CrossRef]

- Razzak, S.A.; Khan, M.; Irfan, F.; Shah, M.A.; Nawaz, A.; Hossain, M.M. Catalytic co-pyrolysis and kinetic study of microalgae biomass with solid waste feedstock for sustainable biofuel production. J. Anal. Appl. Pyrolysis 2024, 183, 106755. [Google Scholar] [CrossRef]

- Raheem, A.; Abbasi, S.A.; Mangi, F.H.; Ahmed, S.; He, Q.; Ding, L.; Memon, A.A.; Zhao, M.; Yu, G. Gasification of algal residue for synthesis gas production. Algal Res. 2021, 58, 102411. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, X.; Yuan, X. Energy and carbon balances in microalgae biodiesel. Qinghua Daxue Xuebao/J. Tsinghua Univ. 2018, 58, 324–329. [Google Scholar] [CrossRef]

- Lardon, L.; Hélias, A.; Sialve, B.; Steyer, J.-P.; Bernard, O. Life-cycle assessment of biodiesel production from microalgae. Environ. Sci. Technol. 2009, 43, 6475–6481. [Google Scholar] [CrossRef] [PubMed]

- Saranya, G.; Ramachandra, T.V. Life cycle assessment of biodiesel from estuarine microalgae. Energy Convers. Manag. X 2020, 8, 100065. [Google Scholar] [CrossRef]

- Peccia, J.; Haznedaroglu, B.; Gutierrez, J.; Zimmerman, J.B. Nitrogen supply is an important driver of sustainable microalgae biofuel production. Trends Biotechnol. 2013, 31, 134–138. [Google Scholar] [CrossRef]

- Zhou, S.; Lin, M.; Zhang, X.; Zhan, L.; Li, R.; Wu, Y. Study of life cycle assessment: Transforming microalgae to biofuel through hydrothermal liquefaction and upgrading in organic or aqueous medium. J. Clean. Prod. 2024, 444, 140942. [Google Scholar] [CrossRef]

- Ajala, E.O.; Ajala, M.A.; Akinpelu, G.S.; Akubude, V.C. Cultivation and processing of microalgae for its sustainability as a feedstock for biodiesel production. Niger. J. Technol. Dev. 2021, 18, 322–343. [Google Scholar] [CrossRef]

- Parvatker, A.G.; Prashant, K. Environmental sustainability analysis tool for biodiesel from microalgae. In Proceedings of the CHISA 2012—20th International Congress of Chemical and Process Engineering and PRES 2012—15th Conference PRES, Prague, Czech Republic, 25–29 August 2012; Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84874845270 (accessed on 13 May 2025).

- Cancela, Á.; Maceiras, R.; Sánchez, Á.; Alfonsin, V.; Urrejola, S. Transesterification of marine macroalgae using microwave technology. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 1598–1603. [Google Scholar] [CrossRef]

- Patnaik, R.; Mallick, N. Microalgal biodiesel production: Realizing the sustainability index. Front. Bioeng. Biotechnol. 2021, 9, 620777. [Google Scholar] [CrossRef]

- Kazemi Shariat Panahi, H.; Tabatabaei, M.; Aghbashlo, M.; Dehhaghi, M.; Rehan, M.; Nizami, A.-S. Recent updates on the production and upgrading of bio-crude oil from microalgae. Bioresour. Technol. Rep. 2019, 7, 100216. [Google Scholar] [CrossRef]

- Mondal, A.S.; Sharma, R.; Trivedi, N. Cutting-edge approaches for overcoming challenges in microalgal biodiesel production. In Microalgal Biomass for Bioenergy Applications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 355–394. [Google Scholar] [CrossRef]

- Fazril, I.; Shamsuddin, A.H.; Nomanbhay, S.; Kusomo, F.; Hanif, M.; Ahmad Zamri, M.F.M.; Akhiar, A.; Ismail, M.F. Microwave-assisted in situ transesterification of wet microalgae for the production of biodiesel: Progress review. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012078. [Google Scholar] [CrossRef]

- Soares, A.T.; D’Alessandro, E.B.; Lopes, R.G.; Derner, R.B.; Antoniosi Filho, N.R. Optimization of biodiesel production by in situ transesterification from dry biomass of Choricystis minor var. minor via response surface methodology. Biofuels 2021, 12, 1301–1307. [Google Scholar] [CrossRef]

- Salam, K.A.; Velasquez-Orta, S.B.; Harvey, A.P. Algal FAME production with a novel surfactant based catalyst in a reactive extraction. In Process Development Division 2013—Core Programming Area at the 2013 AIChE Annual Meeting: Global Challenges for Engineering a Sustainable Future; 2014; pp. 65–70. Available online: https://proceedings.aiche.org/conferences/aiche-annual-meeting/2013/proceeding/paper/220j-algal-fame-production-novel-surfactant-based-catalyst-reactive-extraction-1 (accessed on 13 May 2025).

- Matchim Kamdem, M.C.; Lai, N. Alkyl carbamate ionic liquids for permeabilization of microalgae biomass to enhance lipid recovery for biodiesel production. Heliyon 2023, 9, e12754. [Google Scholar] [CrossRef]

- Han, F.Y.; Komiyama, M.; Uemura, Y.; Rabat, N.E. One-path catalytic supercritical methanothermal production of fatty acid methyl ester fractions from wet microalgae Chlorella vulgaris. Biomass Bioenergy 2020, 143, 105834. [Google Scholar] [CrossRef]

- Zhang, X.; Rong, J.; Chen, H.; He, C.; Wang, Q. Current status and outlook in the application of microalgae in biodiesel production and environmental protection. Front. Energy Res. 2014, 2, 32. [Google Scholar] [CrossRef]

- Garlapati, V.K.; Gour, R.S.; Sharma, V.; Roy, L.S.; Prashant, J.K.S.; Kant, A.; Banerjee, R. Current status of biodiesel production from microalgae in India. In Advances in Biofeedstocks and Biofuels: Production Technologies for Biofuels; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2016; Volume 2, pp. 129–154. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).