1. Introduction

Globally, facility managers make complex decisions that enhance infrastructure inspections and maintenance across different industries [

1,

2]. Engineering decisions are expected to be data-driven to sustain facilities for critical inspection operations. Due to the considerable cost of engineering facilities, data-driven decisions are expected to be not only technical but also economically oriented to improve facility sustainability [

3,

4]. Techno-economic-driven decisions provide facility managers with a better understanding of inspection and maintenance methods for critical infrastructure in most industries, including the oil and gas industry. In the oil and gas industry, testing is a major activity required to improve equipment efficiency [

5,

6].

In this industry, non-destructive testing (NDT) methods play a critical role in the inspection and maintenance of equipment [

7]. This study presents a three-stage framework for carrying out testing operations within the oil and gas industry. Radiographic testing, ultrasonic testing, magnetic particle testing, liquid penetrant testing, eddy current testing, visual testing, acoustic emission testing, and thermography are among the widely used NDT methods in the oil and gas industry. Each NDT method has its distinct advantages in terms of detection sensitivity, depth penetration, and defect characterization. Also, they provide a reliable approach for assessing the integrity of infrastructure without causing damage [

8]. In addition, they ensure safety, regulatory compliance, and operational efficiency during infrastructure inspection and maintenance.

Currently, there is a gap in the literature regarding the simultaneous consideration of both technical and economic factors when selecting optimal inspection strategies in the oil and gas industry. In the literature, studies have focused on the technical performance of NDT methods while limited emphasis has been given to the economic considerations of NDT methods in terms of equipment costs, operational expenses, and personnel requirements [

9,

10,

11]. Consequently, inspection engineers and asset integrity managers rarely balance decisions that align with safety, efficiency, and cost-effectiveness objectives.

The aerospace industry is among the industries that have used NDT to improve inspection quality and maintains some of the most stringent inspection requirements [

12]. NDT has been used to detect impact damage and delaminations in carbon fiber-reinforced polymers [

13]. However, this application requires appropriate technique selection based on specific damage mechanisms common in aerospace components. The applications of NDT for additive-manufactured aerospace components show the importance of the NDT technique in the aerospace industry [

14]. Additive manufacturing allows the development of specific protocols for detecting unique defect types associated with metal 3D printing processes.

The above-mentioned knowledge serves as the motivation of this study, which presents a decision support framework that integrates technical and economic factors to guide optimal inspection decisions in the oil and gas industry. The framework uses a multi-criteria decision-making (MCDM) approach, specifically Fuzzy Analytic Hierarchy Process (FAHP), TOPSIS (Technique for Order Preference by Similarity to Ideal Solution), PROMETHEE (Preference Ranking Organization Method for Enrichment of Evaluations), and VIKOR (VIseKriterijumska Optimizacija I Kompromisno Resenje)—i.e., Multi-criteria Optimization and Compromise Solution and CRITIC (CRiteria Importance Through Intercriteria Correlation) to rank the NDT methods for analyzing and optimizing welding and coating inspection processes. The framework has a structured methodology to handle the complexity of decision-making under fuzzy conditions.

This study conducted an empirical analysis using data collected from six oil and gas industry practitioners through a questionnaire. The questionnaire captured insights on the performance of selected NDT methods across seven technical (e.g., detection sensitivity, depth penetration, and defect characterization) and seven economic factors, including equipment costs and operational expenses. The application of the framework facilitated the systematic evaluation of these factors, revealing its potential to manage vagueness and uncertainty in expert responses effectively. The findings of this study contribute to the body of knowledge on NDT applications by providing a decision support tool for inspection engineers and asset integrity managers. Also, the framework enhances decision-making processes regarding the integrity and safety of pressure equipment management in the oil and gas industry.

This study’s remaining sections are organized as follows:

Section 2 contains a literature review of related studies on NDT, while

Section 3 contains the Materials and Methods.

Section 4 and

Section 5 contains the case study and discussion of results. The last section of this study presents its conclusions and directions for further studies.

2. Literature Review

Several studies have shown that NDT allows the evaluation of materials, components, or systems properties without causing damage to them [

8,

9,

14]. NDT allows for inspection, monitoring, and evaluation while maintaining the integrity and usability of the tested objects [

15]. These benefits have led to the growth of NDT across industries including oil and gas, aerospace, civil infrastructure, manufacturing, and energy production [

16]. Most applications of NDT methods are driven by industrial needs and technological innovations [

17]. The applications start from simple visual inspection methods to sophisticated computer-aided techniques. According to the literature, NDT prominence began during World War II in the area of quality control for military goods manufacturing [

18]; after this war, NDT applications have expanded to countless civilian applications [

12].

Modern NDT applications are characterized by an integration of multiple testing methodologies. Contemporary NDT applications combine traditional techniques with advanced computational methods to enhance detection accuracy and efficiency. NDT evolution is supported by innovations and developments in materials science, computer technology, and sensor development. One of such development is the introduction of phased array ultrasonic testing for improved detection capabilities for complex geometries. Ultrasonic testing (UT) has enhanced signal processing algorithms. An enhanced UT significantly reduce noise in ultrasonic imaging, improving defect detection reliability in composite materials [

19]. Artificial intelligence (AI) has been used to automate defect detection and classification in ultrasonic inspection data, reducing human error and increasing inspection speed [

20,

21].

Using digital technologies to replace traditional film-based methods during the radiographic testing application is another innovation in NDT. The frontier of knowledge in radiographic testing has been improved through AI integration with this testing technique [

22]. It has been used to automatically identify and classify weld defects with accuracy rates exceeding 95%.

Sensors’ incorporation into electromagnetic testing methods has expanded NDT applications across different industries, including the aerospace industry [

19,

23]. For example, the development of multi-frequency array probes capable of simultaneously inspecting multiple layers of material has been used to enhance Eddy’s current testing, especially where composite and multi-layered structures exist [

24]. Sensor-enhanced NDT techniques have improved detection capabilities for subsurface defects in ferromagnetic materials. These techniques have found application in pipeline inspection and structural health monitoring applications. Sensor networks have been developed to enable continuous structural health monitoring using ultrasonic and acoustic emission sensors [

25]. The sensors are connected through IoT frameworks that provide real-time condition assessment of critical infrastructure [

26].

The incorporation of infrared thermography into NDT techniques is another emerging trend in infrastructure inspection [

9]. This incorporation enhanced the detection of delamination and internal defects in composite materials. Advances in quantitative thermography have also aided calibration procedures that transformed thermographic imaging from primarily qualitative to increasingly quantitative analysis [

27]. One benefit of this technique is accurate depth estimation and sizing. The use of AI for processing thermographic data has led to the development of algorithms that automatically identify defect types and severity in composite materials during inspection. AI application has, therefore, led to proper defect characterization and prediction. Acoustic emission testing has been identified as a tool for assessing the structural integrity of infrastructure [

28]. This technique generates information about acoustic emission parameters and damage mechanisms, including crack propagation in concrete structures under loading conditions.

3. Materials and Methods

The evaluation of the NDT techniques was performed based on technical, economic, and techno-economic analysis using different MCDM methods, including TOPSIS and VIKOR methods. MCDM methods are selected because the NDT techniques evaluation is a decision-making problem that has criteria and alternatives (i.e., techniques). Other justifications for using MCDM methods to solve the NDT evaluation problem are presented as follows:

- •

These methods allow decision-makers to participate directly in the evaluation of the NDT techniques thereby eliminating the concept of Blackbox associated with machine learning algorithms.

- •

MCDM methods handles uncertainty, vagueness, and limited data better than machining learning algorithms.

- •

These methods guide choices among alternatives while ML algorithms are used to predict outcomes or classify data points.

This study used fuzzy logic to process data that serves as inputs for the MCDM methods. Fuzzy logic was implemented based on fuzzy arithmetic operations on fuzzy numbers, including triangular fuzzy numbers (TFNs) [

29]. TFNs were used to analyze data about NDT desirability for welding inspection in the oil and gas industry. Equation (1) gives the expression of a TFN

where

denote the lower bound, modal value and upper bound, respectively.

Let

and

be two TFNs. The following mathematical operations can be performed on these two numbers when they are independent and have no interaction:

ii. Subtraction operation

iii. Multiplication operation

(all the TFNs are positive)

(

v. Scalar multiplication

if

λ ∈

R, then:

where

λ is a scalar value.

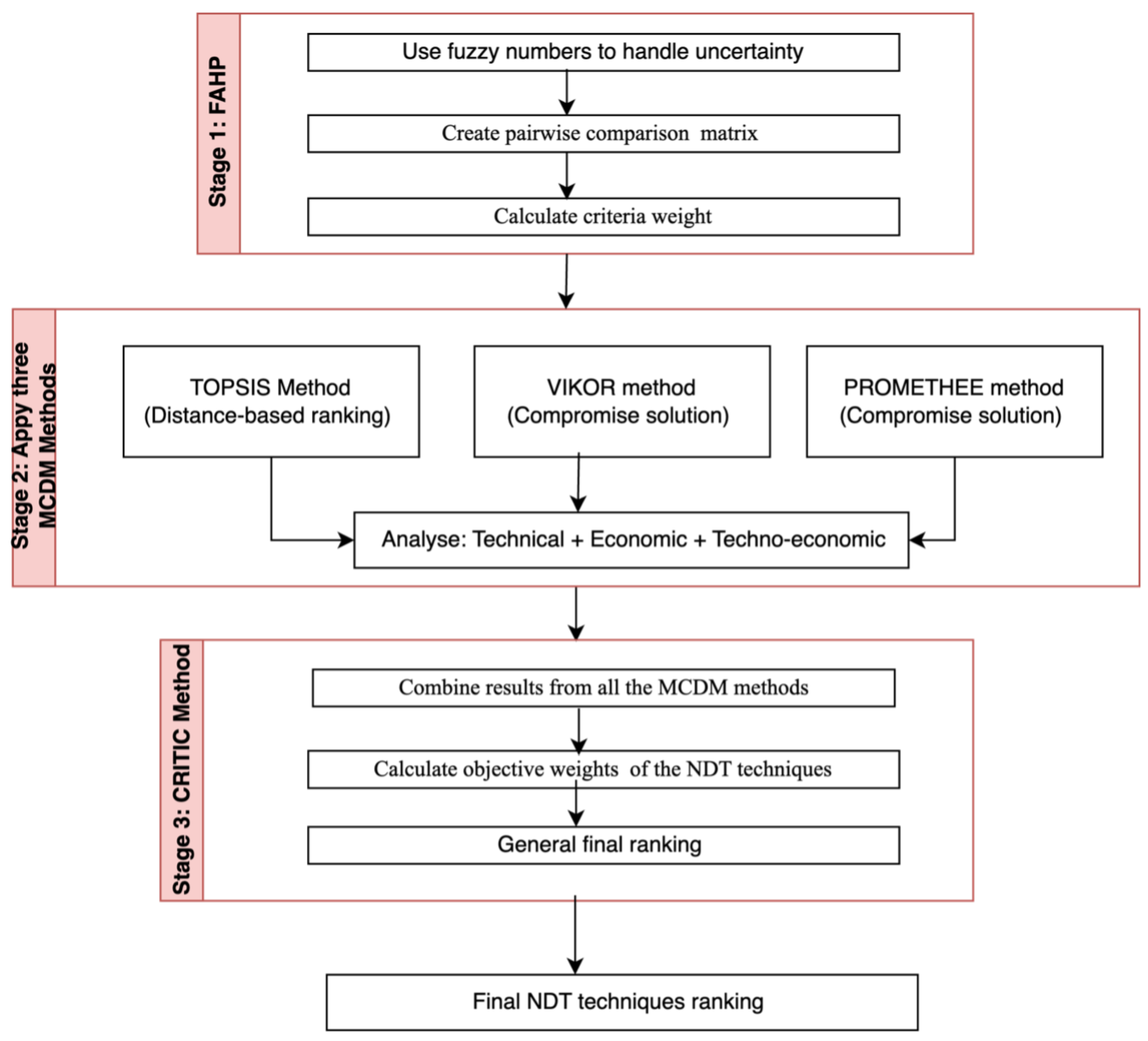

This study presents a three-stage framework that generates information about the suitability of NDT techniques for welding inspection in the oil and gas industry (

Figure 1). The first stage contains information about the determination of the importance of selected technical and economic criteria using FAHP method FAHP has the capacity to analyze complex decisions by breaking them down into a hierarchy of more easily understood sub-problems [

30,

31]. When implementing FAHP, the following steps are required:

Construct a fuzzy pairwise comparison matrix for the decision-making problem [

30]. This involves comparing criterion

i with criterion

j. The reciprocal property of Equation (7) is given as Equation (8).

Next, the criteria fuzzy synthetic extent value is computed using fuzzy arithmetic—i.e., addition and multiplication (Equation (9)).

Next, the degree of possibility of the criteria is computed using Equation (10).

The minimum values of each criterion are used to generate its normalized weight (Equation (11)).

where

where

represents the performance of alternative

for criterion

.

The second stage involves the implementation of the following three MCDM methods:

TOPSIS is an MCDM method that ranks alternatives by measuring their relative distance from ideal solutions. It works on the principle that the best alternative should be closest to the positive ideal solution (best possible outcome) and farthest from the negative ideal solution [

32,

33,

34].

PROMETHEE is an MCDM method that uses two performance measures to determine alternatives ranks [

35,

36].

VIKOR is a multi-criteria decision-making method that focuses on finding compromise solutions [

31,

37].

Table 1 summarizes the strength and limitations of the three MCDM methods and the contributions of the CRITIC method in complementing MCDM limitations.

These methods were used to analyze data about NDT techniques from technical, economic, and techno-economic perspectives. The discussion of these methods is presented as follows:

3.1. TOPSIS Method

Given that m and n represent alternatives and criteria, respectively, the decision matrix for the NDT selection is expressed as Equation (13) [

38].

where the

denotes the actual values of a criterion

j regarding alternative

i.

The decision matrix’s information is normalized using Equation (14), and then the normalized values are processed to generate a weighted normalized decision matrix (Equation (15)).

where

and

denote normalized and weighted values, respectively, of a criterion

j regarding alternative

i, and

denotes the weight of criterion

.

The weighted normalized decision matrix identifies the ideal and non-ideal solutions for the criteria based on criteria desirability as benefit or cost.

where

and

denote the ideal and non-ideal values, respectively, of criterion

j.

The alternatives’ separation measures are generated from the ideal and non-ideal solutions. These measures are obtained as distances from ideal and non-ideal solutions using Equations (21) and (22).

where

and

denote the ideal and non-ideal distance, respectively, of alternative

i.

Equation (23) is used to determine the alternative’s relative closeness to the ideal solution. The desirability of an alternative is based on the higher this solution the more desire the alternative.

where

denotes the closeness coefficient of alternative

i.

3.2. VIKOR Method

VIKOR method is the relationship between the best and worst solutions to determine the desirability of alternatives in a decision matrix [

31]. If

represents the value of the

ith alternative regarding the

jth criterion, the best value for the

jth criterion is calculated using Equation (24).

where

denotes the best value of criterion

j and

denotes the actual values of a criterion

j regarding alternative

i.

Similarly, Equation (25) is used to calculate the worst value for the

jth criterion.

where

denotes the worst value of criterion

j.

The best and worst values are used to determine the alternatives’ utility measures. Equation (26) gives the expression for calculating the alternatives’ utility measure.

where

denotes the utility value of alternative

i.

Equation (27) is used to compute the alternative regret values.

where

denotes the regret value of alternative

i.

The relationship between the utility and regret measures is used to generate the VIKOR index for alternatives (Equation (28)). The desirability of the VIKOR index is the lower the better.

where

denotes the VIKOR value of alternative

i.

where

v denotes strategy weight for combining utility and regret values for the alternatives. It is commonly taken as 0.5.

3.3. PROMETHEE Method

This method implementation begins with determining the degree to which alternative

a is preferred over alternative

b (Equation (31)) [

39].

where

denoted the global preference index of alternative

a over alternative

b regarding criterion

j.

=

denotes the performance difference between alternative a and b regarding criterion j.

denotes preference functions such as linear and Gaussian functions [

40].

The outputs from Equation (31) are combined to generate the aggregated preference index of alternatives by considering all the criteria (Equation (33)).

where

denoted the global preference index of alternative

a over alternative

b.

Next, the positive and negative preference flows of alternatives. The positive preference measures how alternative

a outranks other alternatives (Equation (34)).

where

denotes the positive flow of alternative

i.

Equation (35) measures how much alternative a is outranked by other alternatives—this gives the negative preference flow of alternative

a.

where

denotes the negative flow of alternative

i.

The combination of the positive and negative preference flows of alternatives gives their net flow (Equation (36)).

where

denotes the net flow of alternative

i.

3.4. CRITIC Method

The last stage of the methodology involves using the CRITIC method to aggregate the results from the TOPSIS, PROMETHEE, and VIKOR methods. The CRITIC method is an objective weighting method used to determine criterion weights in multi-criteria decision analysis [

41]. This method generates the parameters’ importance using the information in a decision matrix (Equation (1)). The information in Equation (13) is normalized in order to generate the normalized values for the parameters (Equation (37)). This expression is a max-min normalization scheme [

42].

The standard deviation of the

jth parameter is expressed as Equation (38).

where

denotes the mean value of the normalized score for the

jth criterion.

The correlation between two parameters (

j and

k) is computed using the Pearson correlation coefficient (Equation (39)).

where

denotes the correlation between criteria

i and

j.

The combination of the parameter’s standard deviation and correlation coefficient gives their information content (Equation (40)).

where

denotes the information content for criterion

j.

The computed normalized weight of the

jth parameter is expressed in Equation (41).

4. Case Study

A structured questionnaire was used to obtain information about selected NDT techniques in the oil and gas industry. The first section of the question contained information about the importance of technical and economic criteria with respect to welding operation inspection in the oil and gas industry (

Table 2). The information about the suitability of selected NDT techniques regarding the technical and economic criteria was contained in the second section of the questionnaire (

Table 3). This study collected information from six industry experts during the implementation of the FAHP and the other MCDM methods that were discussed in

Section 3; the details of the experts are presented in

Table 4.

This study used the information in

Table 5 to generate data about the technical and economic criteria and to generate data on the impacts of NDT techniques on welding inspection in the oil and gas industry.

5. Results and Discussion

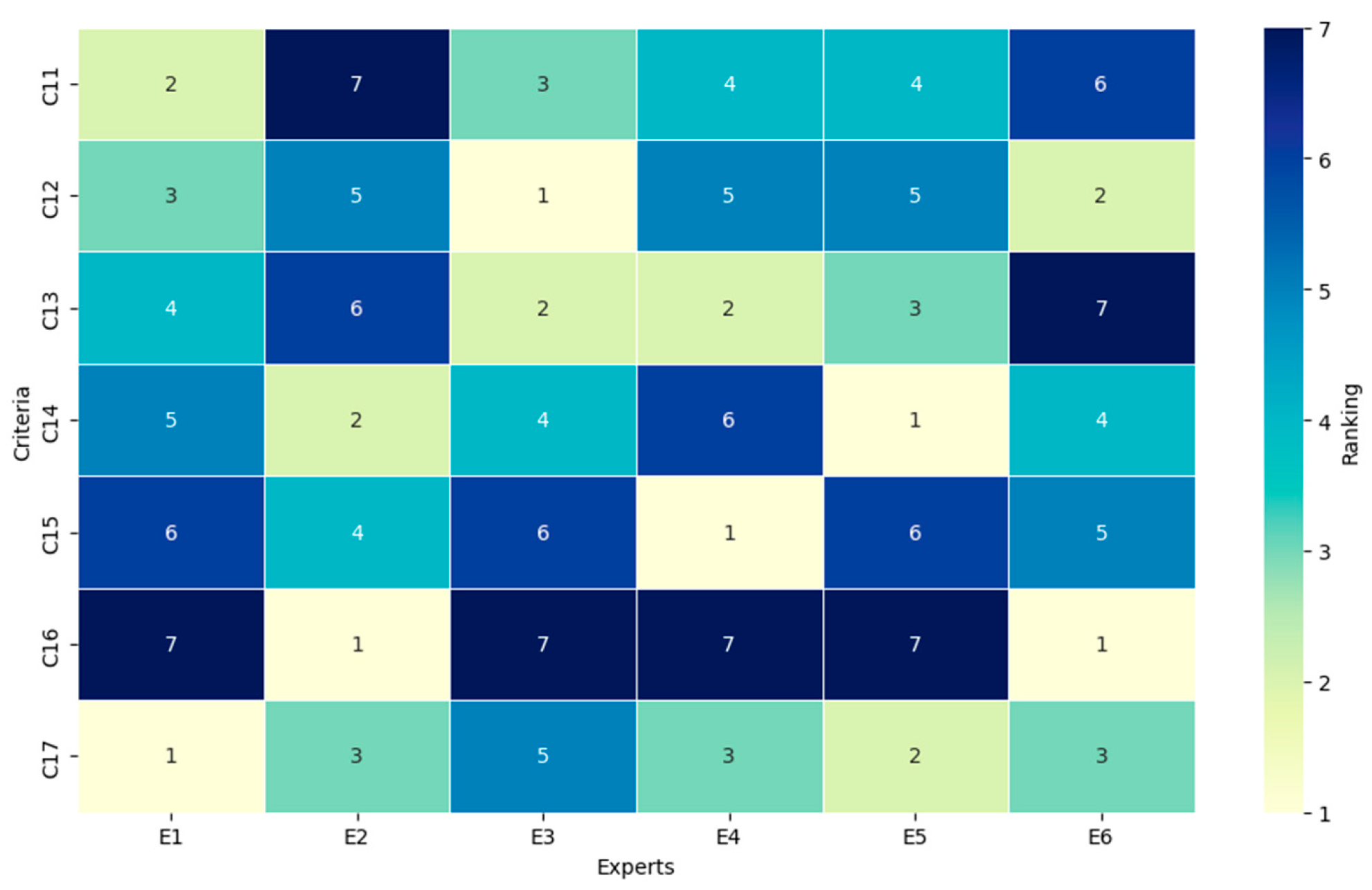

FAHP was used to generate the criteria importance from an expert-wise perspective. The results obtained are presented in

Table 6 and

Table 7.

This study used the information in

Table 6 and

Table 7 to generate heatmaps for the ranking of the technical and economic criteria (

Figure 2). The heatmap showed that C17 (spatial resolution) had the best ranking, for example, it was ranked 1st by E1, 2nd by E5, and 3rd by E2 and E4. Its rankings were never ranked below 5th. C12 (depth penetration) had moderate to good rankings across the board. It was ranked 1st by E3, 2nd by E6, and 3rd by E1.

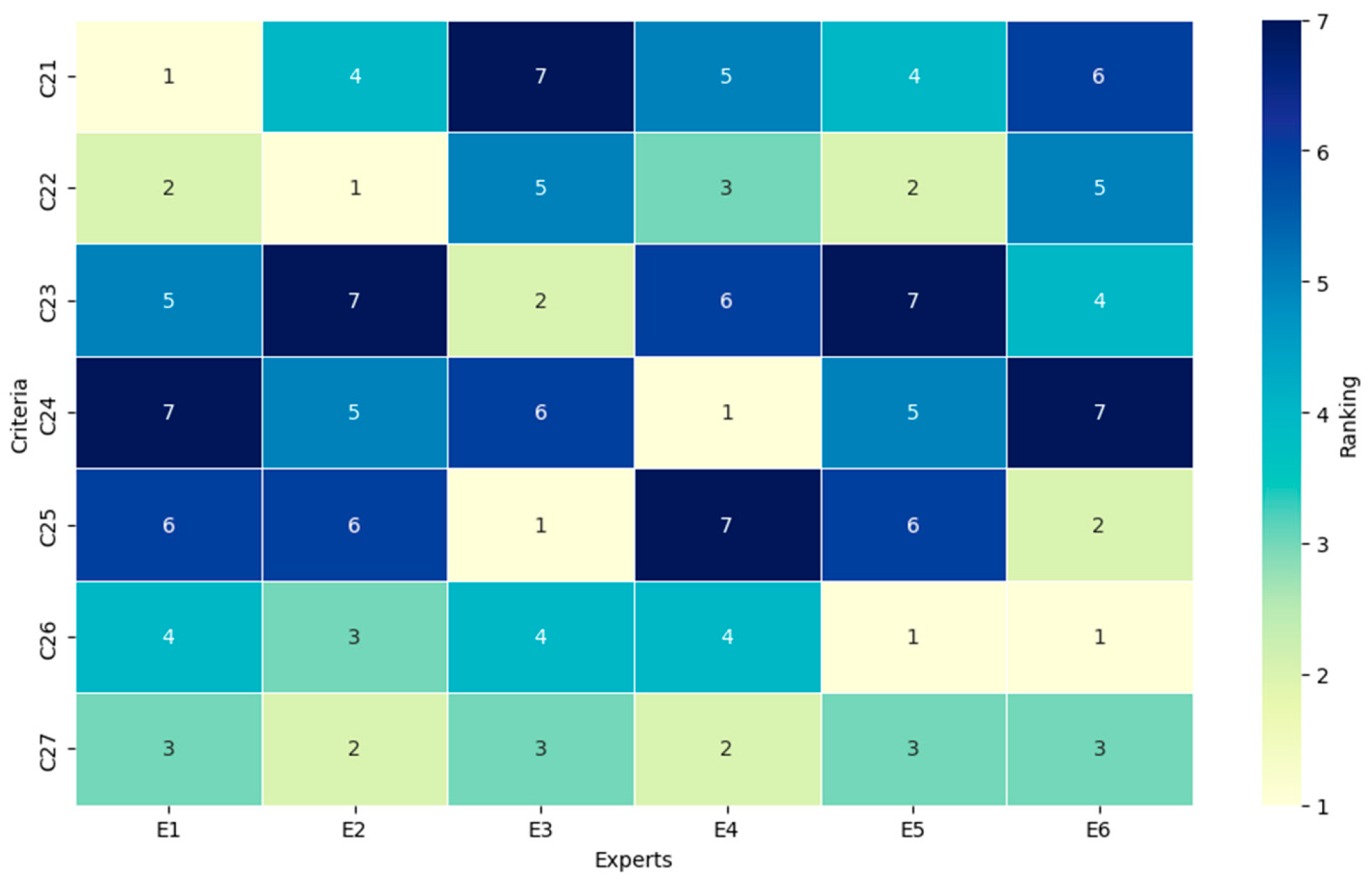

Figure 3 shows the heatmap for the economic criteria ranking by the experts. This map showed that the rank of C22 (operational cost) across most experts’ judgments (especially E2 and E1) was consistently high. C26 (recalibration costs) performed very well according to E5 and E6 (both ranked 1st). C25 (training investment) had a top rank in E3, but lower rankings in others, while C24 (inspection time) was top-ranked by E4. The results for C23 (personnel requirements) and C27 (downtime costs) were moderately ranked overall. Lastly, C21 (equipment capital cost) was highest by E1 but much lower in E3.

This study computed the consistency ratio of the criteria and presented the results in

Table 8. The pairwise comparison matrices have acceptable consistency ratios because their consistency ratios are less than 0.1. This study, therefore, generates the expert’s ratings of the technical and economic criteria (

Table 9).

Due to discrepancies in the criteria ranking, this study computed the aggregated values of the criteria importance. The results for the technical criteria showed that spatial resolution was the most important criterion for evaluating the suitability of NDT techniques for oil and gas facilities. Next, penetration depth and defect characterization had a high impact on the evaluation of the technique. On the other hand, the impact of detection sensitivity and sign-to-noise ratio were low when compared to the other technical criteria. Material compatibility and portability had a medium impact on decisions regarding the NDT techniques evaluation for oil and gas industries.

The results showed that the prioritization of equipment C27 and C22 are more critical than the other economic criteria during the analysis of NDT method suitability for off-shore welding operations. This reflects the experts’ opinions on the system’s productivity and recurring expenses that are associated with using NDT methods. On the other hand, the results revealed that C3 is the least important economic criterion for evaluating NDT suitability for offshore welding operations. The importance of the criterion could be associated with automation trends in NDT.

Table 10 shows the aggregated fuzzy numbers for the different MCDM methods, i.e., the NDT techniques TOPSIS, PROMETHEE, and VIKOR methods, which were used to analyze the results. During these MCDM method implementations, Equation (42) was used to generate the crisp values for the techniques (

Table 11).

This study combined defuzzified values with the technical criteria weights during the implementation of the MCDM methods.

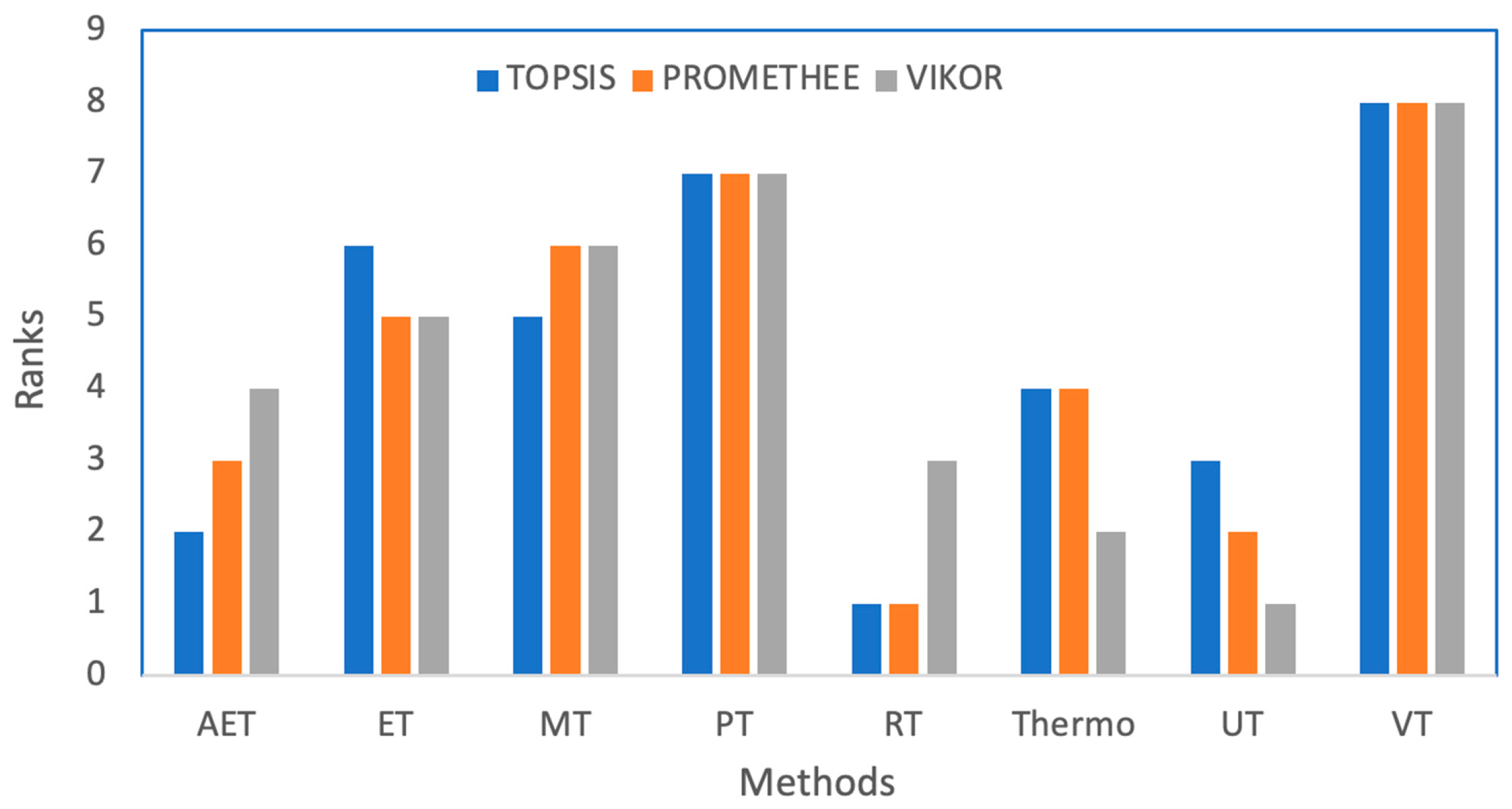

Table 12 shows the results obtained for the techniques. The results in this table were used to generate the ranking in

Figure 4.

The results in this figure showed inconsistencies in the techniques’ ranking among the MCDM methods. For example, TOPSIS and PROMETHEE ranked RT as the most suitable NDT technique, while it was ranked 3rd by the VIKOR method. UT ranks vary across the MCDM methods—ranked 1st by the VIKOR method, 2nd by the PROMETHEE method, and 3rd by the TOPSIS method. Thermo was ranked 2nd by the VIKOR method, and 4th by the TOPSIS and PROMETHEE methods.

Due to the inconsistency in the ranking, this study used the CRITIC method to aggregate the outputs MCDM method outputs.

Table 13 shows the CRITIC method’s outputs. This research used Equations (35)–(39) to generate the scores in

Table 13. According to the CRITIC method principle, a method with a high score is more suitable than a method with a lower score. Therefore, it could be deduced that RT is the most suitable technique—this result is consistent with the TOPSIS and PROMETHEE methods’ results in

Figure 4. The CRITIC method ranks for VT and the other MCDM methods’ results for VT are the same. VT was ranked as the least suitable technique. The difference in the MCDM method’s results is due to the computational approach employed by each method for ranking.

Based on the information in

Table 5, this research converted the experts’ ratings of the NDT methods to TFNs. The TFNs were aggregated and presented in

Table 14.

Table 15 shows the normalized values of the NDT. The TOPSIS, PROMETHEE, and VIKOR methods were used to process the information in the NDT techniques obtained using Equation (40). The TOPSIS, PROMETHEE, and VIKOR methods were used to process the information in

Table 15; the results obtained are presented in

Table 16. The NDT methods are arranged from the most preferred to the least preferred in

Table 16. Since the ranking of the NDT methods is the same, there is no need for further analysis of the results from the MCDM methods.

The CC, Φ, and Q values in

Table 12 and

Table 16 were used to create a techno-economic decision matrix for evaluating the suitability of the NDT methods. The CRITIC method was used to process the information in the techno-economic decision matrix—the results obtained are presented in

Table 17. From the results

Table 17, the CRITIC method identified RT as the most suitable NDT method for facility maintenance. Furthermore, VT was the least suitable NDT method for the oil and gas facility from a techno-economic perspective.

Practical Implications of This Study

The following are the implications of the results presented in this study for industrial practitioners:

The developed framework offers a systematic, transparent, and repeatable approach for NDT method selection, reducing subjective bias and improving decision quality in critical maintenance operations.

The identification of RT as the optimal technique for oil and gas applications provides direct guidance for facility managers and maintenance engineers. The comprehensive ranking of all eight methods enables informed selection based on specific operational requirements and constraints.

By explicitly considering both technical performance and economic factors, the framework enables organizations to optimize their NDT investments, potentially reducing overall maintenance costs while maintaining safety and reliability standards. Furthermore, the criteria can be increased to accommodate other criteria such as frequency of control, the sequence of application of different methods.

6. Conclusions

This study developed and implemented a fuzzy MCDM framework for evaluating and selecting optimal NDT techniques for oil and gas facility maintenance operations. The framework demonstrated the effectiveness of integrating FAHP with multiple MCDM methods to address the complex decision-making challenges inherent in industrial NDT method selection. This study systematically evaluated eight NDT techniques: radiographic testing, ultrasonic testing, magnetic testing, penetrant testing, Eddy current testing, visual testing, acoustic emission testing, and thermographic testing. The evaluation was performed through expert-driven criteria assessment.

The first assessment deals with prioritizing technical criteria using FAHP. From the results obtained, spatial resolution emerged as the most critical technical criterion (0.175), followed by depth penetration (0.155) and defect characterization (0.143). These results show this industry’s emphasis on precise defect detection and characterization capabilities. The second assessment deals with the prioritization of economic criteria. Among economic criteria, downtime costs (0.210) and operational costs (0.190) were the most significant. The third assessment deals with the ranking of the NDT techniques using MCDM methods (TOPSIS, PROMETHEE, and VIKOR). Regarding technical criteria, this study observed discrepancies in the ranking of the NDT techniques.

This study used the CRITIC aggregation method to resolve these discrepancies to provide a robust and reliable final ranking for the NDT techniques. Radiographic testing emerged as the most suitable technique (final score: 0.665). Under the economic criteria, the MCDM method generated the same rank for all the NDT techniques. Radiographic testing and visual testing were identified as the most and least suitable techniques, respectively. Techno-economic analysis of the NDT technique’s suitability was performed using the CRITIC method. The results revealed that the most and least suitable techniques were radiographic testing and visual testing, respectively.

This study focused specifically on oil and gas facilities, and findings may not directly transfer to other industrial sectors with different operational requirements and constraints. However, the method in this study can be applied in other cases by substituting the NDT methods with the methods of interest. There is a need to evaluate a combination of non-destructive testing methods, when two or more methods are used simultaneously while increasing the evaluation criteria to indicate the type of parts, material, operating conditions, and type of welding.

Author Contributions

Conceptualization, D.I., K.A. and O.B.; methodology, O.B.; software, D.I.; validation, O.B. and B.A.; formal analysis, D.I. and O.B.; investigation, O.B.; resources, K.A.; data curation, B.A.; writing—original draft preparation, O.B.; writing—review and editing, K.A.; visualization, D.I.; supervision, O.A.O.; project administration, O.A.O.; funding acquisition, O.A.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

In line with the Ethics in Health Research: Principles, Processes, and Structures (2015), Chapter 1, Sections 1.1.9 and 1.1.10, (Page 9), our study does not require ethical approval. Section 1.1.9 explicitly exempts research involving observation or questionnaires in public settings without staged intervention or privacy breaches. Additionally, Section 1.1.10 allows exemptions for studies relying solely on anonymous data where no identifiable information is generated.

Informed Consent Statement

Informed consent was obtained from all subjects involved in this study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- McDaniels, T.; Chang, S.; Cole, D.; Mikawoz, J.; Longstaff, H. Fostering resilience to extreme events within infrastructure systems: Characterizing decision contexts for mitigation and adaptation. Glob. Environ. Chang. 2008, 18, 310–318. [Google Scholar] [CrossRef]

- Barrett, P.; Baldry, D. Facilities Management: Towards Best Practice; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Bousdekis, A.; Lepenioti, K.; Apostolou, D.; Mentzas, G. A review of data-driven decision-making methods for industry 4.0 maintenance applications. Electronics 2021, 10, 828. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tran, T.P.T.; Ha, H.M.; Bui, T.-D.; Lim, M.K. Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: A data driven analysis. J. Ind. Prod. Eng. 2021, 38, 581–598. [Google Scholar] [CrossRef]

- Shafiee, M.; Animah, I.; Simms, N. Development of a techno-economic framework for life extension decision making of safety critical installations. J. Loss Prev. Process Ind. 2016, 44, 299–310. [Google Scholar] [CrossRef]

- Lovell, K.; Watson, J.; Hiteva, R. Infrastructure decision-making: Opening up governance futures within techno-economic modelling. Technol. Forecast. Soc. Change 2022, 174, 121208. [Google Scholar] [CrossRef]

- Bertovic, M. Human Factors in Non-Destructive Testing (NDT): Risks and Challenges of Mechanised NDT. Doctoral Thesis, Technische Universitaet: Berlin, Germany, 2015. [Google Scholar]

- Trampus, P.; Krstelj, V.; Nardoni, G. NDT integrity engineering—A new discipline. Procedia Struct. Integr. 2019, 17, 262–267. [Google Scholar] [CrossRef]

- El Masri, Y.; Rakha, T. A scoping review of non-destructive testing (NDT) techniques in building performance diagnostic inspections. Constr. Build. Mater. 2020, 265, 120542. [Google Scholar] [CrossRef]

- Beutel, R.; Reinhardt, H.-W.; Grosse, C.U.; Glaubitt, A.; Krause, M.; Maierhofer, C.; Algernon, D.; Wiggenhauser, H.; Schickert, M. Comparative performance tests and validation of NDT methods for concrete testing. J. Nondestruct. Eval. 2008, 27, 59–65. [Google Scholar] [CrossRef]

- Beutel, R.; Reinhardt, H.-F.; Grosse, C.U.; Glaubitt, A.; Krause, M.; Maierhofer, C.; Algernon, D.; Wiggenhauser, H.; Schickert, M. Performance demonstration of non-destructive testing methods. In Proceedings of the 9th European Conference on NDT, Berlin, Germany, 25–29 September 2006. [Google Scholar]

- Gupta, M.; Khan, M.A.; Butola, R.; Singari, R.M. Advances in applications of Non-Destructive Testing (NDT): A review. Adv. Mater. Process. Technol. 2022, 8, 2286–2307. [Google Scholar] [CrossRef]

- Han, S.; Li, Q.; Cui, Z.; Xiao, P.; Miao, Y.; Chen, L.; Li, Y. Non-destructive testing and structural health monitoring technologies for carbon fiber reinforced polymers: A review. Nondestruct. Test. Eval. 2024, 39, 725–761. [Google Scholar] [CrossRef]

- Gholizadeh, S.; Gholizadeh, S. Impact behaviours and non-destructive testing (NDT) methods in carbon fiber composites in aerospace industry: A review. Authorea Prepr. 2022, 10. [Google Scholar] [CrossRef]

- Prodhan, R.K.; Islam, M.M.; Fazle, A.B. Integration of Advanced NDT Techniques & Implementing QA/QC Programs In Enhancing Safety and Integrity in Oil & Gas Operations. Am. J. Interdiscip. Stud. 2022, 3, 1–35. [Google Scholar] [CrossRef]

- ul Hassan, I.; Panduru, K.; Walsh, J. Non-destructive testing methods for condition monitoring: A review of techniques and tools. Procedia Comput. Sci. 2025, 257, 420–427. [Google Scholar] [CrossRef]

- Kumar, S.; Mahto, D. Recent trends in industrial and other engineering applications of non destructive testing: A review. Int. J. Sci. Eng. Res. 2013, 4, 29–46. [Google Scholar]

- Vavilov, V. Thermal Non-Destructive Testing: Short History, State-of-the-Art and Trends; European Conference and Exhibition on Non-Destructive Testing: Tomsk, Russia, 2010. [Google Scholar]

- Gupta, R.; Mitchell, D.; Blanche, J.; Harper, S.; Tang, W.; Pancholi, K.; Baines, L.; Bucknall, D.G.; Flynn, D. A review of sensing technologies for non-destructive evaluation of structural composite materials. J. Compos. Sci. 2021, 5, 319. [Google Scholar] [CrossRef]

- Karthikeyan, A.; Tiwari, A.; Zhong, Y.; Bukkapatnam, S.T. Explainable AI-infused ultrasonic inspection for internal defect detection. CIRP Ann. 2022, 71, 449–452. [Google Scholar] [CrossRef]

- Sun, H.; Ramuhalli, P.; Jacob, R.E. Machine learning for ultrasonic nondestructive examination of welding defects: A systematic review. Ultrasonics 2023, 127, 106854. [Google Scholar] [CrossRef]

- Sharma, K.; Sharma, K.; Sharma, J.; Gilhotra, C. Evaluation and New Innovations in Digital Radiography for NDT Purposes. Ion Exch. Adsorpt. 2023, 1001–5493. [Google Scholar] [CrossRef]

- Mazzeschi, M. Development of Electromagnetic-Based Approaches for Non-Destructive Evaluation and Health Monitoring of Aerospace Structural Joints. Doctoral Thesis, University of Valladolid, Valladolid, Spain, 2024. [Google Scholar]

- Wang, Y.; Niu, Y.; Wei, Y.; Ye, C. Multi-frequency imaging with non-linear calibration of magnetoresistance sensors for surface and buried defects inspection. NDT E Int. 2022, 132, 102706. [Google Scholar] [CrossRef]

- Abdulkarem, M.; Samsudin, K.; Rokhani, F.Z.; Rasid, M.F.A. Wireless sensor network for structural health monitoring: A contemporary review of technologies, challenges, and future direction. Struct. Health Monit. 2020, 19, 693–735. [Google Scholar] [CrossRef]

- Smirnov, O.; Sydorenko, V.; Aleksander, M.; Zhyharevych, O.; Yenchev, S. Simulation of the cloud IoT-based monitoring system for critical infrastructures. In Proceedings of the CMiGIN 2022: 2nd International Conference on Conflict Management in Global Information Networks, Kyiv, Ukraine, 30 November 2022. [Google Scholar]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef]

- Carboni, M.; Crivelli, D. An acoustic emission based structural health monitoring approach to damage development in solid railway axles. Int. J. Fatigue 2020, 139, 105753. [Google Scholar] [CrossRef]

- Tsai, H.-C.; Lee, A.-S.; Lee, H.-N.; Hooper, H.H. Use of Similarity of Triangular Fuzzy Numbers and a Derivation Calculation Formula in Assessment of Mortise-Tenon Joints Applied in the Joinery Category of Regional Taiwan Skills Competitions. Sustainability 2022, 14, 8608. [Google Scholar] [CrossRef]

- Lyu, H.-M.; Shen, S.-L.; Zhou, A.; Yang, J. Risk assessment of mega-city infrastructures related to land subsidence using improved trapezoidal FAHP. Sci. Total Environ. 2020, 717, 135310. [Google Scholar] [CrossRef] [PubMed]

- Abdul, D.; Wenqi, J.; Tanveer, A. Prioritization of renewable energy source for electricity generation through AHP-VIKOR integrated methodology. Renew. Energy 2022, 184, 1018–1032. [Google Scholar] [CrossRef]

- Akram, M.; Dudek, W.A.; Ilyas, F. Group decision-making based on pythagorean fuzzy TOPSIS method. Int. J. Intell. Syst. 2019, 34, 1455–1475. [Google Scholar] [CrossRef]

- Ighravwe, D.E.; Oke, S.A. A multi-attribute framework for determining the competitive advantages of products using grey-TOPSIS cum fuzzy-logic approach. Total Qual. Manag. Bus. Excell. 2018, 29, 762–785. [Google Scholar] [CrossRef]

- Bouhedja, S.; Boukhaled, A.; Bouhedja, A.; Benselhoub, A. Use of the TOPSIS technique to choose the best supplier of quarry natural aggregate. Min. Miner. Deposits 2019, 14, 11–18. [Google Scholar] [CrossRef]

- Sreejith, S.S. Continuous performance evaluation of employees using AHP and modified PUGH matrix method: Contrasting with TOPSIS, PROMETHEE and VIKOR. Int. J. Anal. Hierarchy Process 2024, 16. [Google Scholar] [CrossRef]

- Tian, C.; Peng, J.; Zhang, W.; Zhang, S.; Wang, J. Tourism environmental impact assessment based on improved AHP and picture fuzzy PROMETHEE II methods. Technol. Econ. Dev. Econ. 2020, 26, 355–378. [Google Scholar] [CrossRef]

- Mehrparvar, M.; Majak, J.; Karjust, K. A comparative analysis of Fuzzy AHP and Fuzzy VIKOR methods for prioritization of the risk criteria of an autonomous vehicle system. Proc. Est. Acad. Sci. 2024, 73, 116–123. [Google Scholar] [CrossRef]

- Chatterjee, P.; Stević, Ž. A two-phase fuzzy AHP-fuzzy TOPSIS model for supplier evaluation in manufacturing environment. Oper. Res. Eng. Sci. Theory Appl. 2019, 2, 72–90. [Google Scholar] [CrossRef]

- Rafi, S.; Yu, W.; Akbar, M.A.; Alsanad, A.; Gumaei, A. Prioritization based taxonomy of DevOps security challenges using PROMETHEE. IEEE Access 2020, 8, 105426–105446. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y. Sensitivity analysis of the parameters for preference functions and rank reversal analysis in the PROMETHEE II method. Omega 2024, 128, 103116. [Google Scholar] [CrossRef]

- Mukhametzyanov, I. Specific character of objective methods for determining weights of criteria in MCDM problems: Entropy, CRITIC and SD. Decis. Mak. Appl. Manag. Eng. 2021, 4, 76–105. [Google Scholar] [CrossRef]

- Mhlanga, S.T.; Lall, M. Influence of normalization techniques on multi-criteria decision-making methods. J. Phys. Conf. Ser. 2022, 2224, 012076. [Google Scholar] [CrossRef]

Figure 1.

Steps of the proposed MCDM approach.

Figure 1.

Steps of the proposed MCDM approach.

Figure 2.

Ranking heatmap of evaluation criteria by the experts.

Figure 2.

Ranking heatmap of evaluation criteria by the experts.

Figure 3.

Ranking heatmap of cost-related evaluation criteria.

Figure 3.

Ranking heatmap of cost-related evaluation criteria.

Figure 4.

MCDM ranking of the NDT techniques using technical criteria.

Figure 4.

MCDM ranking of the NDT techniques using technical criteria.

Table 1.

Strength and limitations of the selected MCDM methods.

Table 1.

Strength and limitations of the selected MCDM methods.

| Method | Strength | Limitation | CRITIC Contribution |

|---|

| TOPSIS | Clear geometric interpretation | Rank reversal issues | Provides objective weighting |

| PROMETHEE | Flexible preference modeling | Subjective threshold setting | Reduces subjectivity bias |

| VIKOR | Compromise-oriented solution | Sensitive to v parameter | Balances different perspectives |

Table 2.

Technical and economic criteria.

Table 2.

Technical and economic criteria.

| Technical Criteria | Economic Criteria |

|---|

| Detection sensitivity (C11) | Equipment capital cost (C21) |

| Depth penetration (C12) | Operational cost (C22) |

| Defect characterization (C13) | Personnel requirements (C23) |

| Material compatibility(C14) | Inspection time (C24) |

| Signal-to-noise ratio (C15) | Training investment (C25) |

| Portability/Mobility (C16) | Recalibration/verification costs (C26) |

| Spatial resolution (C17) | Downtime impact (C27) |

Table 3.

Selected NDT techniques.

Table 3.

Selected NDT techniques.

| S/n | Technique | Description |

|---|

| 1 | Acoustic emission testing (AET) | Detects and analyses acoustic emissions from defects under stress. |

| 2 | Eddy current testing (ET) | Uses electromagnetic induction to detect surface and near-surface defects. |

| 3 | Liquid penetrant testing (PT) | Uses dye to detect surface-breaking defects. |

| 4 | Magnetic particle testing (MT) | Uses magnetic fields to detect surface and near-surface defects. |

| 5 | Radiographic testing (RT) | Uses X-rays or gamma rays to detect internal defects. |

| 6 | Thermography | Uses infrared imaging to detect temperature variations indicating defects. |

| 7 | Ultrasonic testing (UT) | Uses high-frequency sound waves to detect flaws. |

| 8 | Visual testing (VT) | Direct visual inspection, possibly aided by tools like borescopes. |

Table 4.

Experts’ details.

Table 4.

Experts’ details.

| Expert | Role | Experience | Gender | Degree |

|---|

| 1 | Precision | 6 years | Female | B.Sc. |

| 2 | Field Tech | 10 years | Male | M.Sc. |

| 3 | Deep Defects | 9 years | Male | M.Eng. |

| 4 | Quality | 8 years | Male | M.Sc. |

| 5 | R & D | 12 years | Female | M.Sc. |

| 6 | Operations | 8 years | Male | B.Sc. |

Table 5.

Linguistic variables for assessing the NDT technique suitability in the oil and gas industry.

Table 5.

Linguistic variables for assessing the NDT technique suitability in the oil and gas industry.

| Technique Impact | Criteria Importance |

|---|

| Linguistic Term | TFN | Linguistic Term | TFN |

|---|

| Very low | (0.0, 0.0, 0.25) | Equal importance | (1, 1, 1) |

| Low | (0.2, 0.35, 0.5) | Weak importance | (1, 2, 3) |

| Moderate | (0.4, 0.55, 0.7) | Moderate importance | (2, 3, 4) |

| High | (0.6, 0.75, 0.9) | Strong importance | (3, 4, 5) |

| Very high | (0.8, 0.9, 1.0) | Very strong importance | (4, 5, 6) |

Table 6.

Normalized criteria weights for technical criteria.

Table 6.

Normalized criteria weights for technical criteria.

| Criteria | E1 | E2 | E3 | E4 | E5 | E6 |

|---|

| C11: Detection sensitivity | 0.22 | 0.08 | 0.15 | 0.15 | 0.10 | 0.07 |

| C12: Depth penetration | 0.15 | 0.10 | 0.30 | 0.10 | 0.08 | 0.20 |

| C13: Defect characterization | 0.12 | 0.09 | 0.25 | 0.20 | 0.15 | 0.05 |

| C14: Material compatibility | 0.08 | 0.20 | 0.08 | 0.09 | 0.30 | 0.10 |

| C15: Signal-to-noise ratio | 0.07 | 0.12 | 0.07 | 0.25 | 0.07 | 0.08 |

| C16: Portability/Mobility | 0.06 | 0.25 | 0.05 | 0.07 | 0.05 | 0.35 |

| C17: Spatial resolution | 0.28 | 0.15 | 0.10 | 0.12 | 0.25 | 0.15 |

Table 7.

Normalized criteria weights for economic criteria.

Table 7.

Normalized criteria weights for economic criteria.

| Criteria | E1 | E2 | E3 | E4 | E5 | E6 |

|---|

| C21: Equipment capital cost | 0.28 | 0.10 | 0.05 | 0.07 | 0.15 | 0.06 |

| C22: Operational cost | 0.25 | 0.30 | 0.08 | 0.10 | 0.20 | 0.07 |

| C23: Personnel requirements | 0.07 | 0.05 | 0.25 | 0.06 | 0.05 | 0.10 |

| C24: Inspection time | 0.05 | 0.08 | 0.06 | 0.35 | 0.10 | 0.05 |

| C25: Training Investment | 0.06 | 0.07 | 0.30 | 0.05 | 0.08 | 0.25 |

| C26: Recalibration costs | 0.10 | 0.15 | 0.10 | 0.08 | 0.25 | 0.30 |

| C27: Downtime costs | 0.19 | 0.25 | 0.16 | 0.29 | 0.17 | 0.17 |

Table 8.

Consistency check for the expert’s decisions.

Table 8.

Consistency check for the expert’s decisions.

| Expert | Consistency Ratio for Technical Criteria | Consistency Ratio for Economic Criteria |

|---|

| 1 | 0.06 | 0.05 |

| 2 | 0.08 | 0.07 |

| 3 | 0.05 | 0.06 |

| 4 | 0.07 | 0.08 |

| 5 | 0.04 | 0.04 |

| 6 | 0.09 | 0.06 |

Table 9.

Aggregated criteria weights.

Table 9.

Aggregated criteria weights.

| Technical | Economic |

|---|

| Criteria | Weight | Criteria | Weight |

|---|

| C11 | 0.128 | C12 | 0.150 |

| C12 | 0.155 | C22 | 0.190 |

| C13 | 0.143 | C23 | 0.080 |

| C14 | 0.142 | C24 | 0.110 |

| C15 | 0.11 | C25 | 0.120 |

| C16 | 0.138 | C26 | 0.140 |

| C17 | 0.175 | C27 | 0.210 |

Table 10.

Aggregated fuzzy numbers for technical criteria.

Table 10.

Aggregated fuzzy numbers for technical criteria.

| Technique | C11 | C12 | C13 | C14 | C15 | C16 | C17 |

|---|

| RT | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.6, 0.75, 0.9) |

| UT | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) |

| MT | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) |

| PT | (0.2, 0.35, 0.5) | (0.0, 0.0, 0.25) | (0.2, 0.35, 0.5) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) |

| ET | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.4, 0.55, 0.7) |

| VT | (0.0, 0.0, 0.25) | (0.0, 0.0, 0.25) | (0.0, 0.0, 0.25) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.0, 0.0, 0.25) |

| AET | (0.5, 0.65, 0.8) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) |

| Thermo | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) |

Table 11.

Defuzzified values of the technical criteria.

Table 11.

Defuzzified values of the technical criteria.

| Method | C1 | C2 | C3 | C4 | C5 | C6 | C7 |

|---|

| RT | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.35 | 0.75 |

| UT | 0.75 | 0.75 | 0.75 | 0.75 | 0.55 | 0.55 | 0.55 |

| MT | 0.55 | 0.35 | 0.35 | 0.35 | 0.75 | 0.75 | 0.35 |

| PT | 0.35 | 0.063 | 0.35 | 0.55 | 0.55 | 0.75 | 0.35 |

| ET | 0.55 | 0.35 | 0.55 | 0.35 | 0.75 | 0.75 | 0.55 |

| VT | 0.063 | 0.063 | 0.063 | 0.75 | 0.75 | 0.75 | 0.063 |

| AET | 0.65 | 0.75 | 0.35 | 0.75 | 0.35 | 0.55 | 0.35 |

| Thermo | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

Table 12.

MCDM methods results using the technical criteria.

Table 12.

MCDM methods results using the technical criteria.

| | TOPSIS | PROMETHEE | VIKOR |

|---|

| Technique | S+ | S− | CC | Φ+ | Φ− | Φ | S | R | Qi |

|---|

| AET | 0.38 | 0.11 | 0.46 | 0.48 | 0.32 | 0.16 | 0.08 | 0.37 | 0.82 |

| ET | 0.36 | 0.14 | 0.59 | 0.42 | 0.45 | −0.03 | 0.25 | 0.23 | 0.49 |

| MT | 0.45 | 0.14 | 0.69 | 0.35 | 0.60 | −0.25 | 0.23 | 0.25 | 0.52 |

| PT | 0.54 | 0.16 | 0.84 | 0.28 | 0.72 | −0.44 | 0.32 | 0.19 | 0.37 |

| RT | 0.14 | 0.14 | 0.33 | 0.77 | 0.23 | 0.54 | 0.00 | 0.45 | 1.00 |

| Thermo | 0.37 | 0.07 | 0.26 | 0.49 | 0.38 | 0.11 | 0.22 | 0.29 | 0.57 |

| UT | 0.18 | 0.07 | 0.04 | 0.69 | 0.24 | 0.45 | 0.12 | 0.34 | 0.74 |

| VT | 0.60 | 0.18 | 1.00 | 0.15 | 0.90 | −0.75 | 0.45 | 0.00 | 0.00 |

Table 13.

CRITIC method outputs using the technical critical.

Table 13.

CRITIC method outputs using the technical critical.

| Method | Score | Rank |

|---|

| AET | 0.5175 | 3 |

| ET | 0.4019 | 5 |

| MT | 0.3754 | 6 |

| PT | 0.2512 | 7 |

| RT | 0.6418 | 1 |

| Thermo | 0.4750 | 4 |

| UT | 0.5646 | 2 |

| VT | 0.2301 | 8 |

Table 14.

Aggregated fuzzy numbers for economic criteria.

Table 14.

Aggregated fuzzy numbers for economic criteria.

| Technique | C21 | C22 | C23 | C24 | C25 | C26 | C27 |

|---|

| RT | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.4, 0.55, 0.7) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) | (0.6, 0.75, 0.9) |

| UT | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.6, 0.75, 0.9) | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) |

| MT | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) |

| PT | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) | (0.4, 0.55, 0.7) |

| ET | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.6, 0.75, 0.9) | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) |

| VT | (0.0, 0.0, 0.25) | (0.0, 0.0, 0.25) | (0.0, 0.0, 0.25) | (0.2, 0.35, 0.5) | (0.0, 0.0, 0.25) | (0.0, 0.0, 0.25) | (0.2, 0.35, 0.5) |

| AET | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.4, 0.55, 0.7) | (0.5, 0.65, 0.8) | (0.6, 0.75, 0.9) | (0.2, 0.35, 0.5) | (0.2, 0.35, 0.5) |

| Thermo | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) | (0.4, 0.55, 0.7) | (0.4, 0.55, 0.7) | (0.2, 0.35, 0.5) |

Table 15.

Defuzzified values of the economic criteria.

Table 15.

Defuzzified values of the economic criteria.

| Technique | C21 | C22 | C23 | C24 | C25 | C26 | C27 |

|---|

| RT | 0.75 | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 | 0.75 |

| UT | 0.55 | 0.55 | 0.75 | 0.35 | 0.75 | 0.55 | 0.35 |

| MT | 0.35 | 0.35 | 0.55 | 0.55 | 0.55 | 0.35 | 0.35 |

| PT | 0.35 | 0.35 | 0.35 | 0.75 | 0.35 | 0.35 | 0.55 |

| ET | 0.55 | 0.55 | 0.75 | 0.35 | 0.75 | 0.55 | 0.35 |

| VT | 0.063 | 0.063 | 0.063 | 0.35 | 0.063 | 0.063 | 0.35 |

| AET | 0.75 | 0.35 | 0.55 | 0.65 | 0.75 | 0.35 | 0.35 |

| Thermo | 0.55 | 0.55 | 0.55 | 0.35 | 0.55 | 0.55 | 0.35 |

Table 16.

MCDM methods results using the economic criteria.

Table 16.

MCDM methods results using the economic criteria.

| | TOPSIS | PROMETHEE | VIKOR |

|---|

| Technique | S+ | S− | CC | Φ + | Φ− | Φ | U | R | Q |

|---|

| RT | 0.00 | 0.16 | 1.00 | 0.90 | 0.10 | 0.80 | 0.12 | 0.15 | 0.00 |

| AET | 0.02 | 0.15 | 0.88 | 0.75 | 0.25 | 0.50 | 0.25 | 0.20 | 0.18 |

| UT | 0.10 | 0.12 | 0.55 | 0.60 | 0.40 | 0.20 | 0.35 | 0.30 | 0.32 |

| ET | 0.12 | 0.10 | 0.45 | 0.55 | 0.45 | 0.10 | 0.45 | 0.40 | 0.47 |

| Thermo | 0.15 | 0.09 | 0.36 | 0.50 | 0.50 | 0.00 | 0.55 | 0.50 | 0.63 |

| MT | 0.20 | 0.06 | 0.23 | 0.40 | 0.60 | −0.20 | 0.65 | 0.60 | 0.75 |

| PT | 0.25 | 0.04 | 0.14 | 0.30 | 0.70 | −0.40 | 0.75 | 0.70 | 0.89 |

| VT | 0.30 | 0.00 | 0.00 | 0.10 | 0.90 | −0.80 | 1.00 | 1.00 | 1.00 |

Table 17.

Outputs of the techno-economic analysis.

Table 17.

Outputs of the techno-economic analysis.

| Technique | Score |

|---|

| AET | 0.537 |

| ET | 0.341 |

| MT | 0.330 |

| PT | 0.288 |

| RT | 0.665 |

| Thermo | 0.366 |

| UT | 0.429 |

| VT | 0.214 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).