Abstract

The integration of sawmilling with prefabrication manufacturing presents a critical opportunity to enhance the efficiency, sustainability, and quality of timber construction in Australia. While prefabrication offers substantial benefits, including reduced waste, faster build times, and improved precision, its effectiveness is often constrained by inconsistencies and inefficiencies in upstream sawmilling processes. This state-of-the-art review examines the current structure of the Australian timber supply chain, identifies key challenges in aligning sawmill outputs with the requirements of prefabrication manufacturers, and explores enabling strategies for integration. The paper presents a comprehensive overview of integration pathways by reviewing insights from the academic literature, industry reports, national standards, and case studies from Australia and the European Union. It also proposes a priority-based implementation roadmap to guide coordinated technical, operational, and policy actions, thereby supporting the transformation toward a more connected timber sector in Australia.

1. Introduction

Timber remains a key component in sustainable construction, particularly in Australia’s housing market, where timber products dominate residential framing and structural applications [1]. Its popularity is attributed to its sustainability, local availability, high strength-to-weight ratio, workability, aesthetic appeal, and versatility in both structural and non-structural applications [2]. However, as a natural and hygroscopic material, timber presents challenges related to dimensional stability and variability. It absorbs and releases moisture according to environmental conditions, leading to shrinkage, swelling, and potential structural instability [3]. Additionally, natural defects such as knots, grain deviation, and splits further reduce uniformity, complicating its application in precision-driven construction systems.

The Australian construction sector is increasingly turning to prefabrication manufacturing. Prefabrication involves producing building components, such as wall panels, roof trusses, floor cassettes, or volumetric modules, in a factory-controlled environment, followed by on-site assembly. Around 85–90% of houses in Australia are built with timber frames [4]. Prefabrication offers numerous benefits, including improved quality control, construction speed, reduced waste, and greater cost predictability [5]. It also provides a viable path to meet the projected demand for 5.175 million additional dwellings by 2050 [4].

However, the performance and efficiency of prefabrication systems heavily depend on the consistent supply of accurately dimensioned and stable timber. Even minor deviations such as variable dimensions or off-specification material can disrupt automated assembly lines, leading to delays, rework, and productivity losses. Despite the growth of timber-based prefabrication, integration between the upstream sawmilling industry and downstream prefabrication manufacturers remains limited. Sawmills in Australia have historically operated using bulk production models focused on commodity markets. In contrast, prefabrication demands just-in-time, project-specific components with high precision and reliability. Misalignments in material properties, grading, drying quality, logistics, and communication lead to inefficiencies, increased waste, and lost opportunities for value addition.

The need for integration is particularly critical given recent developments in Australia’s building sector. Amendments to the National Construction Code (NCC) in 2016 have enabled greater use of timber in mid-rise buildings [6], and Australia’s ongoing housing shortage has accelerated the interest in prefabricated timber housing as a fast, affordable solution [7]. By 2050, Australia will need 5.175 million additional dwellings, with free-standing houses and multi-story townhouses making up nearly 75% of approvals [4]. This reinforces the ongoing need for structural timber suited to prefabricated components. These trends place increasing pressure on sawmills to deliver high-quality, consistent, and project-ready timber products suitable for prefabrication systems.

This paper presents a comprehensive review of the challenges and opportunities associated with integrating Australian softwood sawmilling and prefabrication manufacturing. The objective is to identify where current misalignments occur technically, operationally, and institutionally, and to highlight pathways for improvement. Topics include material variability, sawing techniques, grading standards, seasoning practices, supply chain dynamics, technological advancements, and regulatory frameworks. By analysing these elements, the paper aims to support better coordination between sawmill operators and prefabrication manufacturers to improve efficiency, reduce waste, and enable broader uptake of prefabricated timber construction.

2. Background

2.1. The Australian Timber Supply Chain Overview

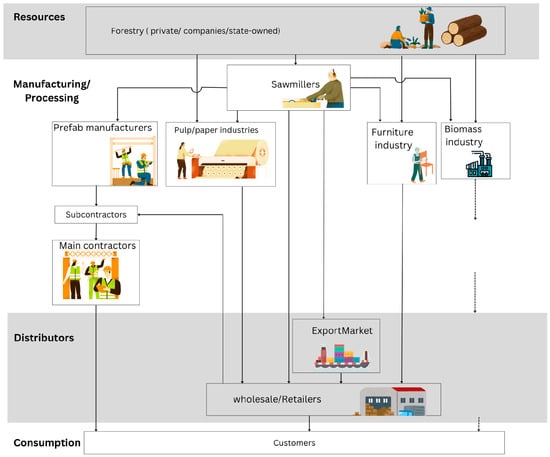

Australia’s timber supply chain is extensive and multi-tiered, encompassing forest management, harvesting, sawmilling, manufacturing, distribution, and end-use in construction (Figure 1). Forests, including extensive softwood plantations and native forests, provide the raw logs that feed the timber industry. Sawmills occupy a central role by converting logs into usable wood products and serving a wide range of customers, including truss and frame fabricators, Engineered Wood Product (EWP) manufacturers, furniture manufacturers, general construction suppliers, pulp and paper manufacturers and the biomass industry.

Figure 1.

Typical Australian timber supply chain.

According to industry reports, most softwood-sawn wood produced in Australia is consumed domestically, particularly in residential construction. In 2017–18, Australia produced about 3.9 million cubic meters of softwood-sawn wood [8]. Approximately 3.7 million m3 of sawn timber from 8.2 million m3 of processed logs in 2021–22 is consumed domestically [9]. Only a small fraction of softwood lumber output is exported, reflecting strong local demand and the economics of transporting bulky, low-value materials. According to FWPA (2022), Australia’s projected sawn softwood demand will reach 6.507 million m3 by 2050, while local production is expected to stagnate at 3.6–3.8 million m3 per annum, resulting in an implied annual supply gap of 2.638 million m3, equivalent to 40.5% of demand [4]. However, Australia also imports a significant quantity of structural timber to meet shortfalls, a reliance that became evident during recent building booms and supply disruptions.

The typical softwood sawmill recovery rate is only about 47% [9], which means that less than half of each log becomes sawn timber, with the rest being produced as residues. This highlights the supply chain’s inefficiency in raw material utilisation and underscores the importance of finding value-added uses for residues or improving processing techniques. Sawmills primarily produce structural lumber while also generating significant volumes of lower-grade by-products such as wood chips, bark, and sawdust that are sold to pulp/paper manufacturers or reprocessed into products like particleboard and landscaping mulch [10].

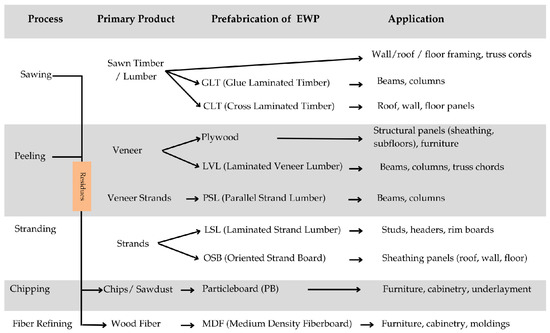

An efficient supply chain from sawmills to builders is crucial for the construction industry’s performance. Timber typically moves from sawmills to prefabrication plants either as raw kiln-dried lumber or as EWP (Figure 2). EWP might be manufactured by separate facilities, often integrated with or alongside sawmills. In Australia, about 48 softwood sawmills were in operation as of 2021–22, down from 58 five years prior [9]. Downstream, Australia has approximately 20–25 major wood-based panel and EWP mills [9], which produce items like plywood, particleboard, Laminated Veneer Lumber (LVL), Glue-Laminated Timber (GLT) and Cross-laminated timber (CLT) [6]. These are increasingly used in prefabricated timber systems that require dimensional accuracy and stability beyond what conventional sawn lumber can provide. Prefabrication plants typically source their timber from sawmills either directly or through distributors, with materials arriving as kiln-dried lumber or in the form of EWPs.

Figure 2.

Wood processing, engineered products and their applications.

2.2. Need for Integration in Timber Construction

Despite innovations in materials and systems, the vast majority of these future homes will rely on timber-based frames, placing greater pressure on upstream material accuracy, supply continuity, and moisture control [4]. Despite timber’s growing acceptance in mid-rise and sustainable construction, fragmentation persists between the timber production and construction sectors. Historically, the timber supply chain has been linear and bulk-oriented: sawmills cut logs into standard sizes and grades, stockpiling products that are then sold in volume to construction suppliers. Prefabrication manufacturers typically purchase from this stock, often through intermediaries, and then cut or assemble components as needed for specific building designs. This traditional model can lead to duplication of handling and waste. For example, a sawmill might produce 6.0 m lengths of framing timber, which a truss plant then cuts down to shorter lengths for a given house design, generating off-cuts.

From an operational standpoint, prefabrication relies on streamlined workflows and high precision. Variability in timber inputs due to inconsistent grading, moisture content, or dimensions creates bottlenecks in otherwise automated systems. If the material at jointing locations lacks sufficient quality or dimensional accuracy, it compromises connection performance and overall structural integrity, especially in prefabricated systems that rely on precision and repeatability [11].

Several sawmillers and manufacturers are unaware of the specific building types utilising their timber, relying instead on indirect feedback such as product orders, website visits, or technical queries. This disconnection limits strategic marketing, innovation, and technical support capabilities, reducing responsiveness to market demands and opportunities. Consequently, product development becomes reactive, potentially sustaining unprofitable lines while missing emerging sectoral needs, ultimately weakening timber’s competitive position in the construction sector.

Disconnect reinforces the perception of timber as a commodity rather than a high-performance construction material [12]. Integration can address these issues by aligning sawmill outputs with downstream requirements through better communication, shared digital platforms, and co-development of specifications. Aligning Australia’s sawmilling and prefabrication sectors is both a technical and economic necessity. Strategically, integration supports national goals to increase housing affordability and sustainability. Integration promises improvements in material efficiency, product reliability, and overall construction productivity, which are essential for meeting contemporary housing, sustainability, and innovation targets.

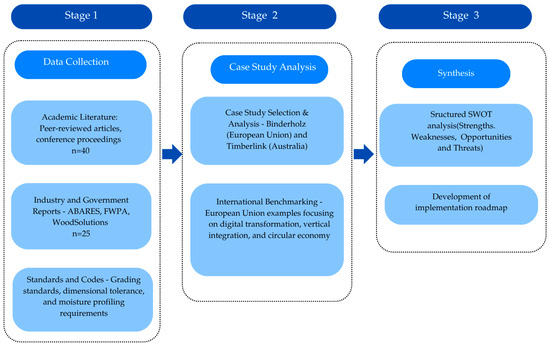

3. Methodology

This study adopts a qualitative, narrative review methodology to examine existing knowledge on the integration of sawmilling and prefabrication manufacturing in Australia. The review draws on diverse sources from academic, industry, and regulatory domains to develop a comprehensive understanding of the technical, operational, and institutional challenges associated with integration (Figure 3).

Figure 3.

Research methodology.

Stage 1: Data Collection—Building the Evidence Base

- Academic literature review: A systematic review of journal articles, conference proceedings, and scholarly reviews published between 2000 and 2025 was conducted using Scopus, Web of Science, and Google Scholar. Search terms included combinations of “sawmilling,” “prefabrication,” “engineered wood,” “digital timber supply chain,” and “integration.” Approximately 150 sources were initially screened, of which 40 were deemed directly relevant based on thematic alignment and methodological rigour.

- Industry and government reports: 25 documents published between 2000 and 2025 from key organisations, including the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES), Forest and Wood Products Australia (FWPA), and WoodSolutions, were reviewed for statistics, policy updates, and technical guidance tailored to the Australian timber sector.

- Standards and Codes: Australian standards were reviewed to understand grading, dimensional tolerance, moisture profiling, and compliance requirements that impact sawmill-prefab integration.

Stage 2: Analysis—Case Studies

- Case study selection and analysis: To complement the thematic analysis, the study incorporates two illustrative case studies—Timberlink (Australia) and Binderholz (European Union). These cases were purposefully selected based on:

- •

- The presence of vertically integrated operations spanning sawing through to engineered and prefabricated products.

- •

- The availability of publicly documented digital and operational strategies that support integration.

- International benchmarking: Comparative insights were drawn from advanced timber industries in countries such as Austria and Germany. These included technical documents and institutional reports illustrating best practices in digital transformation, vertical integration, and circular economy adoption within sawmilling and prefabricated timber systems.

Stage 3: Synthesis—SWOT Analysis and Strategic Roadmap

- A structured SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis was conducted to synthesise findings and identify the most influential internal and external factors affecting integration.

- Roadmap development: A strategic implementation roadmap was developed to translate key findings into actionable recommendations across eleven focus areas, supporting industry-wide integration between sawmilling and prefabrication.

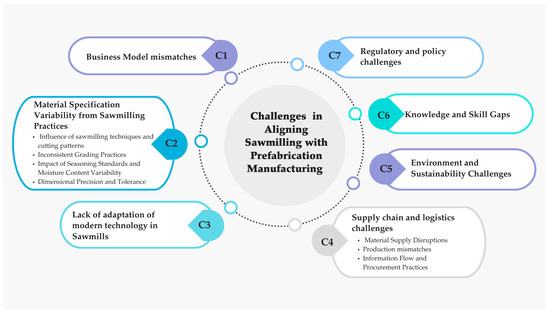

4. Results

The results from the literature review, industry reports, and case study analysis revealed multiple interrelated barriers affecting the alignment of sawmilling outputs with prefabrication manufacturing requirements. These challenges span technical, operational, and regulatory dimensions, influencing both production efficiency and product quality. To aid interpretation, the challenges have been categorised into seven main themes: business model mismatches (C1), material specification variability from sawmilling practices (C2), lack of adaptation of modern technology in sawmills (C3), supply chain and logistics challenges (C4), environment and sustainability challenges (C5), knowledge and skill gaps (C6), and regulatory and policy challenges (C7). Figure 4 presents a visual summary of these categories and their key subcomponents.

Figure 4.

Main themes of challenges in aligning sawmilling with prefabrication manufacturing.

4.1. Challenges and Enablers in Aligning Sawmilling with Prefabrication Manufacturing

4.1.1. Business Model Mismatches (C1)

One of the fundamental challenges in integrating sawmillers with prefabrication manufacturers lies in the misalignment of business models. Historically, the sawmilling industry has prioritised commodity-driven, volume-based strategies, focusing on maximising throughput and minimising production costs [13]. This production-oriented model is efficient for bulk markets but poorly suited to the evolving demands of prefabrication, which requires flexibility, customisation, and consistent quality. This mismatch often leads to supply chain instability. Prefabrication manufacturers may struggle with unreliable and inconsistent timber supply, while sawmills face irregular and unpredictable orders. As a result, both sides may see each other as commercially risky. Prefabrication firms might feel that sawmills are not responsive enough to project-specific needs, while sawmills might view prefabricators as low-volume clients who do not provide consistent demand to justify changes in production. Furthermore, maintaining buffer capacity to meet irregular or peak demand carries real and ongoing costs, and these must be recovered through pricing across the supply chain [4].

Further illustrating these challenges, a study of three Canadian forest product companies highlighted the systemic inefficiencies caused by production-focused strategies that overlook end-market demand [14]. The analysis found that companies often resorted to unplanned downtime to avoid oversupplying the market, reflecting a poor alignment between production output and customer needs. This misalignment led to higher inventory holding costs, delays in scheduling, and underutilised production capacity. Standard lumber deliveries frequently experienced lead times of over two weeks, falling short of customer expectations for rapid supply, particularly in just-in-time construction settings. Additionally, the absence of point-of-sale data sharing and the low level of trust between suppliers and customers hindered collaborative forecasting and responsiveness. These findings reinforce the need for Australia’s sawmilling industry to shift away from traditional volume-based approaches and adopt demand-responsive, collaborative models that are better suited to the precision and timing requirements of prefabrication [14].

While these structural issues are evident, Australia-specific data on costs such as delays, rework, or excess inventory is limited. Future research should model and quantify these inefficiencies.

Hansen and Juslin discuss how the traditional focus of forest product companies has been on production efficiency, cost reduction, and volume-driven strategies, rather than on value creation through market orientation or customer collaboration. They argue that many firms in the forest sector have yet to fully adopt modern marketing principles, such as customer value creation, strategic partnerships, and demand-driven production models [15]. Overcoming these challenges will likely require the development of new business models.

Collaborative partnership structures support effective supplier collaboration, co-development projects and understanding customer-specific processes, further enhancing value creation in the industry [13]. Long-term performance-based contracts can be adopted, ensuring aligned scheduling, quality criteria, and mutual responsiveness. Joint ventures, long-term supply contracts, or industry consortia allow partners to share risks and benefits. This strategic shift is essential, as it requires sawmills to transition from commodity-oriented models to collaborative strategies that not only maintain profitability but also meet the customised, demand-driven needs of prefabrication firms by supporting integrated construction workflows and enhancing supply chain resilience.

Vertical integration represents another promising solution, whereby a company owns both sawmilling and prefabrication operations, allowing for better coordination. To remain competitive, sawmills are being urged to move up the value chain by processing logs into higher-value products [16]. In the Swedish high-volume sawmill segment, forward integration or expanding into downstream activities such as secondary processing or prefabrication showed a strong positive correlation with profitability (ROI) (r ≈ 0.655, p < 0.05, where r is the correlation coefficient indicating the strength and direction of the relationship, and p is the probability value indicating statistical significance). Value added in primary production was also positively associated with ROI (r ≈ 0.533, p < 0.06), suggesting a strong tendency for higher returns when core sawmilling processes generate greater value before further integration [17]. Given that many sawmills operate on thin margins, they are often hesitant to invest in downstream manufacturing. However, vertical integration is already being pursued in Australia [9]. Millaniyage et al. (2025) identified a lack of vertical integration in Tasmania’s solid timber supply chain as a key limitation, noting that the disconnect between material suppliers and users often resulted in misaligned expectations, delays, and missed opportunities for product optimisation [18].

4.1.2. Material Specification Variability from Sawmilling Practices (C2)

Material variability remains one of the most critical challenges in aligning sawmilling operations with the requirements of prefabrication manufacturing. Timber, as a natural material, already exhibits significant variability in mechanical properties, moisture behaviour, and appearance [3]. On-site cutting of wall frames and roof trusses can result in up to 30% material waste due to mismatched lengths. Improved coordination between sawmills and frame/truss manufacturers by aligning sawmill cut lengths with design software requirements can reduce waste and improve efficiency across the supply chain [4]. This is further compounded by inconsistencies in sawmilling techniques, machinery, grading standards, seasoning methods, and dimensional precision across different mills. These variations create difficulties for prefabrication facilities, which rely on precise, standardised, and high-quality inputs to maintain the efficiency of automated manufacturing systems.

Australian Standards provide essential guidelines for the manufacturing of timber materials, ensuring standardised testing, grading methods, and minimum material property requirements such as moisture content and modulus of elasticity. All timber materials produced in Australia must comply with these standards and undergo appropriate grading before they are used in timber structure design. The relevant standards include AS 2082/2858—Visually graded sawn timber, AS/NZS 1748—Mechanically graded timber, AS 3519—Proof-graded timber, AS/NZS 2269—Structural plywood, AS/NZS 4357—Structural laminated veneer lumber, AS/NZS 1328.1—Glued laminated timber, AS 3818.3/3818.11—Round timber [19,20,21,22,23,24,25,26,27].

- (A)

- Influence of sawmilling techniques and cutting patterns

Sawing techniques and cutting patterns play a crucial role in determining the grain orientation, drying behaviour, and overall performance of timber in structural applications. These methods directly influence the structural integrity, dimensional stability, and properties of the final product [28]. Variations in cutting approaches across different sawmillers or even within different yards of the same operation can result in significant inconsistencies in timber quality, particularly in straightness, stability, and uniformity. Boards produced with certain cutting patterns may be prone to warping or distortion. Such inconsistencies pose challenges for meeting the requirements of automated prefabricating equipment, which relies on components that are dimensionally accurate and remain stable over time [29].

An Australian survey revealed that sawing accuracy is closely related to equipment setup, blade maintenance, and log handling techniques. Strategies employed to reduce distortion include log alignment to minimise stress release, the use of chipper-canter heads preceding twin-band saws, and adjustable feed pressure systems [30]. Several mills also reported modifying their sawing sequences to gradually relieve internal growth stresses, for example, by removing outer boards first. Slower feed rates and reduced pressure were used to mitigate surface checking and spring [30].

Precise guide alignment, proper saw tensioning, and frame rigidity are critical, as even minor misalignments can lead to uneven board thickness and poor surface finishes. The dimensional precision and surface quality of sawn timber are significantly influenced by the condition of green mill equipment, particularly the sharpness and alignment of saw blades and guides. Poor maintenance practices often lead to inconsistent cutting, higher kerf loss, and warped or cupped sections, all of which compromise fit-up in prefabrication workflows [31].

Moreover, the choice of sawing method across different processing stages introduces variations in timber properties. These differences are summarised in Table 1, which outlines the influence of each method on critical performance attributes relevant to prefabricated construction.

Table 1.

Different sawing processes and techniques influencing the timber product properties.

Advanced systems like twin-saw breakdown machines and multi-saw resaws have been shown to improve sawing throughput and consistency compared to conventional single-saw systems, which are slower and more prone to producing variable board dimensions due to limited control over overgrowth stress release and log movement during cutting. Trials demonstrated that using twin-saw systems for quarter-sawing and back-sawing of plantation-grown Eucalyptus globulus resulted in better dimensional performance with minimal distortion. Moreover, chipper-reducer systems integrated with twin-band saws further enhanced throughput and reduced thickness variation [34]. Outdated sawmills often rely on wider-kerf saws, which produce rough and inconsistent timber sections with higher material waste [35,36]. In contrast, modern sawmills adopt thinner-kerf saws, laser-guided cutting, and computerised profiling to ensure smoother and more uniform products suitable for automation in prefabrication processes.

The sawmill machinery market is highly fragmented, with multiple manufacturers providing a diverse selection of products (see Table 2). This fragmentation can make it challenging for buyers to identify the most appropriate machinery for their specific requirements, leading to pricing competition and complicating procurement decisions.

Table 2.

Sawmill machinery classification and applications [37].

Table 2.

Sawmill machinery classification and applications [37].

| Category | Segment | Description |

|---|---|---|

| Product Type | Fixed Sawmill | Preferred for large-scale, high-volume timber processing with automated systems for efficiency and precision. |

| Portable Sawmill | Offers mobility and flexibility, suitable for on-site or small-scale operations but with lower production capacity. | |

| Type of Head rig | Circular Saw | Efficient and fast cutting with circular rotating blades, widely used in modern sawmilling. |

| Band Saw | Highly versatile with thin kerf blades, reducing material waste and improving cutting precision. | |

| Gang Saw | A gang saw has multiple blades to cut a log into multiple pieces at once. This is a high-production method, but less common. | |

| Mounting type | horizontal | Used in high-production sawmills for large-diameter log cutting with greater stability and efficiency. |

| vertical | Ideal for precision applications and compact workspaces, often used for resawing and specialized cuts. |

- (B)

- Inconsistent Grading Practices

Timber is assigned a stress grade based on its ability to endure specific stresses, which requires evaluating its strength-related characteristics. Each piece of lumber may have natural defects, such as knots, splits, and resin pockets. Since these defects can significantly impact strength, every piece must be assessed and classified according to its structural grade. There are five grades for softwoods—Structural grade No. 1 is the strongest, and each lower grade represents a 25% reduction in strength. In Australia, stress grading is carried out through several methods defined in national standards [38].

- Visual grading: This method relies on the expertise of a trained grader who evaluates timber based on visible characteristics such as knots, grain deviations, and other defects. The Australian softwood visual grading rules are complex, specifying multiple stress grades. Due to the subjective nature of this method, variability may arise from differences in interpretation between graders.

- Machine grading: This approach uses non-destructive testing to measure timber properties such as stiffness and density. Machine grading is generally more consistent than visual grading, but results may vary due to differences in calibration, equipment type, and operational settings.

- Machine proofing grading: This method involves an initial sorting of timber into subgroups, followed by mechanical testing of each piece under a predetermined bending load (proof load). This ensures that every graded piece meets the required strength criteria.

The gradual adoption of advanced grading technologies in Australian sawmills has led to continued reliance on manual grading, resulting in errors and inconsistencies that affect timber quality and its suitability for prefabrication.

Timber structural grading in Australia follows multiple classification systems depending on the type of grading and timber species [38]:

- •

- F Grades—Used for both visually and machine-graded timber, F-grade classification is based on stress properties such as bending and tension strength.

- •

- MGP (Machine Graded Pine) Grades—Specifically assigned to machine-graded pine, focusing on modulus of elasticity (MOE) and strength properties.

- •

- A Grades—A visually graded mix of seasoned alpine and mountain ash, often used in high-strength applications.

- •

- GL Grades—Assigned to glue-laminated (glulam) timber, which consists of engineered wood products formed by bonding multiple layers of timber.

Furthermore, timber is classified not only by its strength but also by its appearance and durability. Appearance grades help consumers determine whether the visual characteristics of timber, such as colour variation, gum veins, and knots, are suitable for their project. Appearance grading is specified in AS 4785.1 [39], which provides detailed guidelines for assessing surface quality.

- •

- Appendix B of AS 4785.1 outlines permissible limits for machining imperfections and surface finish defects on exposed surfaces of softwood products.

- •

- Appendix C of AS 4785.1 defines acceptable limits for bow, spring, twist, and cup deformations.

Durability classification, as per AS 5607:2022 [40,41], categorises timber into grades 1 to 4 based on the natural durability of different species. This classification indicates the probable life expectancy of timber under specific environmental conditions.

Variations in grading standards among sawmills lead to inconsistencies in standardising raw materials and their properties [42]. Since prefabrication relies on standardised raw materials, grading inconsistencies can pose challenges in ensuring uniform structural performance. Additionally, subsequent processes such as longitudinal resawing, chemical treatments, and re-drying at the prefabrication stage can alter the initial strength properties of graded timber [43].

Several industry initiatives have been introduced to address grading inconsistencies and improve the reliability of structural timber. One such initiative is the ‘Biased Position Testing for Verification of Structural Softwood’ [44], which focuses testing efforts on defect-prone regions of timber to achieve accurate strength verification using fewer samples, thereby improving efficiency and grading reliability. Additionally, the ‘Background and Guidance Document’ [45] provides detailed guidance on compliance monitoring and verification testing to support more consistent and standardised grading practices. Incorporating the findings from these initiatives into grading protocols can significantly enhance the uniformity and predictability of timber performance, aligning sawmill outputs more effectively with the stringent requirements of prefabricated timber construction.

- (C)

- Impact of Seasoning Standards and Moisture Content Variability

Moisture content directly affects the strength, stability, and dimensional accuracy of timber components used in prefabrication. Inconsistent moisture levels can compromise product performance, leading to shrinkage, warping, bonding failure, or long-term deformation. Importantly, moisture variability is not limited to differences between boards; it can also occur within a single piece of timber. As wood dries from the outside in, the outer layers may reach the target moisture content while the inner core remains wetter. This internal variation, known as the moisture gradient, can cause internal stresses and movement if the timber is used without proper conditioning [46].

There are two main methods used to season timber:

- •

- Kiln drying employs controlled heat and airflow to remove moisture quickly and consistently. It typically results in more uniform drying outcomes but requires significant energy input.

- •

- Air seasoning involves stacking timber and allowing it to dry naturally over time. Although it is energy-efficient, the process depends on local climate conditions, which can lead to uneven or incomplete drying [39,40].

Even kiln drying has limitations. Drying rates vary depending on board thickness, initial moisture content, and position in the kiln stack. Within a single batch, some boards may become over-dried (as low as 8%) while others remain under-dried (as high as 18%) [46]. This variation is not always identified, as many sawmills rely on sampling methods rather than full batch testing. Consequently, a prefabrication manufacturer may receive timber that falls outside the acceptable moisture range.

Such variation can create several issues during the prefabrication process. If wet or unevenly dried timber is used:

- •

- Nailplates or mechanical fasteners may loosen as the timber shrinks.

- •

- Impact on adhesive performance.

- •

- Mould growth can occur when enclosed elements retain excess moisture.

- •

- Dimensional changes may cause misalignment or gaps, resulting in delays and rework.

Moisture control is especially important when adhesive bonding is involved, such as in the production of LVL, plywood, or CLT. These EWP require precise moisture conditions—typically between 8% and 12%—to ensure proper bonding and long-term structural stability [46].

‘The Australian Hardwood Drying Best Practice Manual Part 1’ [31] notes that inconsistent moisture testing methods across sawmills can result in under- or over-dried timber reaching manufacturers, adversely impacting adhesive performance and final dimensional tolerances. As visual cues are often inadequate for detecting internal drying defects, the use of mechanical moisture measurement and monitoring tools is essential for effective quality control.

While modern kilns and post-drying conditioning can help reduce internal moisture gradients, not all sawmills consistently apply these practices. High-quality producers allow timber to equalise after drying to ensure stability. However, many operations rely on partial checks instead of full-batch moisture control, increasing the risk of variation. The following are Australian standards that aim to address these issues with the following provisions:

- •

- AS/NZS 1080.1:1997 outlines the correct procedures for measuring moisture content in timber [40].

- •

- AS 4785.1:2002 defines acceptable moisture ranges for softwood timber products used in construction and prefabrication [39].

- •

- AS/NZS 4787:2001 guides assessing drying quality, including how to evaluate moisture distribution and residual drying stresses in seasoned timber [47].

Timber can reabsorb moisture during transportation and storage if not adequately protected. For example, timber seasoned in a dry inland mill may regain moisture when transported to a humid coastal prefabrication facility. Without appropriate wrapping or storage measures, this reabsorption can negate the benefits of controlled drying. Akinnawonu and Rameezdeen (2025) [48], highlight the importance of post-drying protocols such as vapour-permeable wrapping, off-ground storage, and seasonal adjustments to maintain dimensional stability and bonding performance. The study observed rapid fluctuations in moisture content (MC) across some storage facilities, indicating a need for continuous monitoring to prevent deterioration. It also identified a lack of clear guidance on best practices for the storage phase. The authors recommend the development of national guidelines covering ideal humidity conditions, recommended storage durations, and packaging integrity [48]. Without these safeguards, timber may arrive out of specification, resulting in inconsistent product quality, joint failures, and manufacturing delays.

- (D)

- Dimensional Precision and Tolerance

Prefabrication relies on components that fit together with minimal adjustment, making dimensional accuracy and tight tolerances essential. Variations in cross-section, length, bow, spring, or twist can significantly impact assembly speed, structural integrity, and finish quality [49]. Australian standards such as AS 4785.1 [39] define allowable tolerances for various timber products. For example, strip flooring and lining boards typically require tolerances within ±0.5 mm for all dimensions, with moisture content between 9 and 14%. However, adherence to these standards varies. Older equipment, operator error, and inconsistent feedstock contribute to deviations that complicate automated processes downstream.

The lack of uniform precision among different suppliers also creates difficulties in procurement and material scheduling for prefabrication yards, which must account for variability through extra labour, reprocessing, or over-ordering. Despite the clear operational impact, there is limited publicly available data on tolerance-related reject rates in the Australian timber supply chain.

Recent research by Long et al. (2023) demonstrates the significant role of tolerance accumulation in prefabricated systems, using dimensional chain theory to model whether an assembly’s cumulative deviations fall within acceptable bounds [49]. The study employs worst-case, root-sum-square (RSS), and statistical methods to assess how individual component deviations can propagate through assemblies, especially at critical junctions. These deviations, if unaccounted for, can cause installation misfits, component joint gaps, and rework, ultimately affecting efficiency, safety, and installation precision [49].

4.1.3. Lack of Adaptation of Modern Technology in Sawmills (C3)

The adoption of advanced technologies in Australian sawmills remains limited, presenting a significant challenge to integrating sawmilling operations with upstream prefabrication nodes. Technologies such as precision cutting, AI-driven optimisation, and cloud-based analytics have demonstrated potential to improve consistency in dimensions, moisture content, and grading factors vital for meeting prefabrication standards [50]. The emerging concept of Sawmill 4.0 integrates sensor-based monitoring, log-specific cutting strategies, and real-time data processing to tailor sawing and drying operations to individual logs [51]. This targeted approach significantly enhances material uniformity, reduces internal defects, and improves grading reliability. However, in Australia, adoption remains uneven, contributing to discrepancies in material quality across mills and regions. Currently, no published statistics are quantifying the adoption of AI, CT scanning, or ERP systems in Australian sawmills, indicating a need for further industry-wide research in this area. Table 3 summarises a few key modern technologies and their implications for reducing material variability.

Table 3.

Key modern technologies and their implications for reducing material variability.

The slow adoption of advanced technologies in Australian sawmills has contributed to errors and inconsistencies that compromise timber quality and reduce its suitability for prefabrication. Additionally, modernisation efforts across the sector have been uneven, resulting in mismatched production capacities between regions and mill types. For example, softwood sawmills have demonstrated higher technical efficiency (86%) compared to hardwood mills (78%); however, the additional costs associated with achieving full operational efficiency can outweigh short-term benefits.

Although the uptake of innovation remains limited, there is growing interest in technologies that offer potential improvements in quality, precision, and efficiency. In response to these challenges, the Australian Government launched the Accelerate Adoption of Wood Processing Innovation Program, committing $110 million over four years (2022–2026) to assist wood processing facilities in adopting innovative technologies that enhance the utilisation of available wood resources, material quality and production efficiency [71].

4.1.4. Supply Chain and Logistics Challenges (C4)

Beyond material inconsistencies and technological limitations, there are broader supply chain challenges that affect the smooth coordination between sawmills and prefabrication manufacturers. These include disruptions in raw material supply, suboptimal material flow and production, and fragmented communication and procurement practices. These factors prevent consistent delivery of project-specific timber, disrupt production flow, and limit the ability of sawmills and prefabricators to operate as a connected, responsive system.

- (A)

- Material Supply Disruptions

One of the biggest challenges facing the softwood sawmilling industry is securing a steady supply of raw materials. In a 2021–22 industry survey, about 40% of mills identified log supply as a major issue [9]. Timber availability and prices can be highly volatile; they fluctuate with seasonal weather patterns, regional market dynamics, geopolitical shifts, and changes in consumer demand [9]. Longer-term policy shifts have also influenced supply. In Australia, measures like expanding plantation harvests and conserving native forests under regional agreements have reshaped the supply landscape [72], promoting new investment in softwood processing capacity.

However, even with such measures, softwood supply chains remain vulnerable to unexpected disruptions. Natural disasters or global events like pandemics or trade sanctions can lead to sudden raw material shortages and logistical bottlenecks, causing mills to slow or halt production and triggering timber price spikes that ripple through domestic and international markets [9].

One notable example of a supply disruption was the 2019–20 bushfire crisis in Australia. These bushfires burned approximately 71,000 hectares of softwood plantations in New South Wales—roughly 23% of the state’s total softwood estate—creating a severe raw material shortfall [1,9]. The sudden loss of so much plantation timber generated significant uncertainty in log supply and prompted urgent salvage logging efforts. Affected regions increased harvesting rates to two or three times the normal level to recover fire-damaged pine logs before they deteriorated, since burnt trees must be processed before deterioration and pest incursions [73]. The impact will not only be immediate but long-term, as replanting the forests will create years of supply gaps, given that the new trees will take decades to reach harvestable size [73].

Global crises like the COVID-19 pandemic can trigger a sharp downturn in demand for wood products by slowing construction activity. New residential construction in Australia dropped by an estimated 37% in 2020–21, and sawn wood demand was projected to fall by up to 50% within months of the pandemic’s onset [71]. With fewer orders for timber, many sawmills scaled back operations—some mills even temporarily closed or laid off workers [8].

Sawmills are typically situated in regional areas in proximity to plantation resources, while prefabrication facilities are often located closer to urban centres to meet construction demand. As a result, transportation serves as a critical link in the supply chain [74]. Disruptions in freight logistics, such as truck shortages, increased fuel prices, or road closures, can significantly hinder the movement of materials and lead to delays, higher costs, and reduced reliability in the delivery of timber products to prefabrication manufacturers.

- (B)

- Production mismatches

Sawmills typically focus on producing standard-sized timber products, whereas prefabrication often requires custom cuts, profiles, and dimensions. This mismatch leads to additional reprocessing by manufacturers, resulting in increased costs, material waste, and inefficiencies. Prefabrication frequently demands bespoke components, such as custom lengths for panels or specific profiles for joinery applications. Traditional sawmills, which are optimised for volume-based production of standard timber sections, often struggle to deliver these non-standard elements on demand. Furthermore, many Australian sawmills operate at a smaller scale compared to international competitors, limiting their capacity to produce the high volumes of precisely cut, quality-controlled timber required by prefabrication manufacturers.

Products generally follow production models such as Make-To-Stock (MTS) and Make-To-Order (MTO), with some applications requiring Assemble-To-Order (ATO) or Engineered-To-Order (ETO) approaches [75]. Prefabricators typically require standard components on hand (MTS), while also depending on custom-made elements (MTO/ETO) for project-specific applications. Aligning production strategies with the nature of each timber component is, therefore, critical for efficient integration. Collaboration among supply chain stakeholders has been shown to improve responsiveness and competitiveness. Effective partnerships between sawmills, suppliers, and manufacturers enable shared risk, access to resources, and mutual learning, all of which enhance operational performance and market adaptability [76]. Strategies such as Collaborative Planning, Forecasting, and Replenishment (CPFR) and Vendor-Managed Inventory (VMI) are particularly suited to the timber-prefabrication interface, offering improved alignment and flexibility in managing variable demands. VMI models allow suppliers to monitor a pre-fabricator inventory in real-time and proactively manage stock levels.

- (C)

- Information Flow and Procurement Practices

The forest and timber supply chain remains highly fragmented and lacks digital integration [77], leading to significant challenges in communication, data transparency, and procurement efficiency issues. A major consequence of this fragmentation is the absence of real-time, bidirectional information flow across the chain. Prefabrication manufacturers often operate without direct contact with forest managers or sawmill operators, relying instead on intermediaries such as distributors or sales representatives who may not accurately relay upstream constraints or feedback. Similarly, sawmills typically receive aggregated market signals rather than detailed insights from individual prefab plants, limiting their ability to tailor production to specific demands. This lack of integration between the forestry and construction sectors impairs knowledge transfer and quality assurance. Studies have highlighted how inconsistent dissemination of product training and performance feedback can negatively affect outcomes across the supply chain [12].

Recent studies have explored how Enterprise Resource Planning (ERP) systems and business intelligence (BI)-driven platforms are transforming the wood industry’s supply chain coordination and digital integration. ERP systems tailored for timber operations have begun to address the complexities of fragmented workflows by streamlining information flow, procurement, and production planning across multiple stakeholders [78]. Furthermore, BI-enabled tools that link design intent with environmental performance metrics have shown promise in optimising prefabricated timber construction, particularly by aligning component manufacturing with carbon footprint targets and project schedules [79]. These innovations reinforce the potential for real-time synchronisation of sawmilling and prefabrication activities, facilitating greater transparency, reduced waste, and improved fit-up of components in industrialised house-building contexts.

Moreover, disconnected procurement practices contribute to uncertainty in lead times, supply mismatches, and operational inefficiencies. Each actor typically operates with partial information: forest growers lack clear demand forecasts, sawmills produce stock without visibility into real-time requirements, and fabricators may experience material shortages or unanticipated surpluses. Implementation of blockchain and smart contracts can significantly reduce financial challenges, including partial payments, non-payments, and prolonged payment cycles in the construction industry [80]. These technologies can enhance transparency, automate transactions, and ensure compliance with agreed terms, thereby mitigating common payment-related issues such as delays and disputes. Applying similar solutions to the timber supply chain could streamline procurement processes, foster trust among stakeholders, and improve overall operational efficiency.

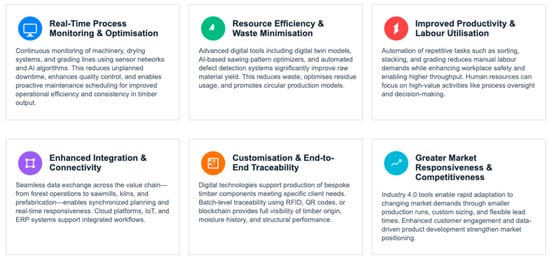

Emerging practices in international contexts show that digital collaboration, ranging from real-time inventory visibility to automated data sharing, can bridge operational gaps across fragmented timber supply chains [81]. Technologies such as Radio Frequency Identification (RFID) and digital tracking systems offer real-time traceability, inventory accuracy, and supply chain transparency (Figure 5). The shift toward Industry 4.0 practices featuring cyber-physical systems, IoT integration, and digital twins holds the potential not only for transforming sawmilling operations but also for improving integration and connectivity across the supply chain using IoT and cloud computing [82]. With the transition from Industry 4.0 to Industry 5.0, the timber and prefabrication sectors are embracing more integrated and intelligent workflows.

Figure 5.

The main benefits and key reasons for lumber manufacturers to embrace Industry 4.0.

Advanced software solutions now enable seamless integration between building design and fabrication processes (see Table 4). Tools such as Building Information Modelling (BIM) and CAD/CAM systems can generate cutting lists and machine code that are directly usable by sawmills or component manufacturers. This design-for-manufacture approach allows structural frames to be virtually modelled and then automatically translated into precision instructions for CNC routers or sawmill optimisers, significantly reducing manual adjustments and improving fit-up accuracy in prefabricated assemblies. Furthermore, the adoption of digital collaboration platforms and cloud-based common data environments is helping to overcome software fragmentation. By enabling real-time data sharing among forestry managers, sawmill operators, engineers, and builders, these platforms reduce communication gaps and promote coordinated decision-making across the supply chain, further strengthening the integration of sawmilling with prefabricated construction.

Table 4.

Digital transformation of information flow and procurement practices in the timber supply chain.

Table 4.

Digital transformation of information flow and procurement practices in the timber supply chain.

| Challenge Area | Traditional Practice | Digital-Integrated Practice | Tool/Technology |

|---|---|---|---|

| Inventory Management | Manual stocktaking; siloed data in sawmills and prefab plants | Real-time inventory visibility and automated restocking | RFID tagging, IoT sensors, cloud inventory systems |

| Procurement and Scheduling | Fragmented purchase orders and ad hoc scheduling | Coordinated demand forecasting and shared production timelines | CPFR (Collaborative Planning, Forecasting, Replenishment) |

| Communication Across the Chain | Email/phone-based updates; limited upstream-downstream visibility | Centralised, transparent communication across all supply chain actors | Common Data Environments (CDEs), BIM-based platforms |

| Quality Control and Feedback | Reactive defect reporting; no feedback loop to sawmill | Continuous monitoring of timber performance and traceability back to source | Digital twins, machine vision QC systems |

| Product Customisation | Standard bulk output disconnected from project-specific needs | Direct linking of CAD/CAM designs to sawmill sawing and treatment plans | BIM-CAM integration, digital cut lists |

| Payment and Contract Management | Paper contracts; delayed or partial payments | Real-time transaction execution with automated compliance checks | Smart contracts (Blockchain) |

| Transportation and Logistics | Manual load planning and low traceability | Route optimisation and digital tracking of timber deliveries | GPS-enabled freight, digital logistics platforms |

Efforts such as the Forest & Wood Products Australia (FWPA) “Wood Supply Chain Optimisation” initiative exemplify ongoing R&D aimed at streamlining logistics and data integration from forest to end-user. These collaborative projects have tested sensor-based traceability tools and new operational frameworks, enabling better decision-making and maximising value recovery throughout the timber value chain.

While anecdotal industry reports indicate that only a small proportion of Australian sawmills have adopted advanced technologies such as artificial intelligence (AI)-assisted grading, computed tomography (CT) scanning, or enterprise resource planning (ERP) systems, no comprehensive national statistics currently quantify this uptake. This absence of publicly available adoption data represents a significant knowledge gap and highlights the need for targeted empirical research to inform digital transformation strategies within the sector.

4.1.5. Environment and Sustainability Challenges (C5)

Material recovery in sawmills refers to the proportion of a log converted into usable timber. Recovery efficiency varies based on species, log dimensions, mill technology, and product requirements, with softwood mills generally outperforming hardwood mills. In Australian softwood sawmills, the average recovery rate was approximately 47% in 2021–22, indicating that less than half of each log was transformed into lumber [9]. In 2016–17, sawmill residues totalled an estimated 5.2 million tonnes, 78% of which originated from softwood processing [83]. Although much of this material is diverted into secondary products, the environmental benefit lies in maximising primary product yield to reduce harvesting pressure. Even though prefabrication methods can reduce on-site construction waste, they may require additional cutting or adjustment to timber, reducing overall system efficiency.

The carbon footprint of sawmilling is another critical concern. Kiln drying, which is essential for reducing timber moisture content, is a major energy-intensive process, often reliant on fossil fuels. Additionally, transportation of logs and finished products further contributes to greenhouse gas emissions. Life cycle assessment (LCA) studies reinforce the importance of improving environmental performance across both sawmilling and prefabrication stages. Life cycle assessment (LCA) studies further underscore the importance of enhancing environmental performance across the sawmilling and prefabrication chain. Australian datasets developed by Tucker (2009) provide a benchmark for softwood and engineered wood products such as LVL and plywood, identifying kiln drying, transportation, and resin use as major emission hotspots [84].

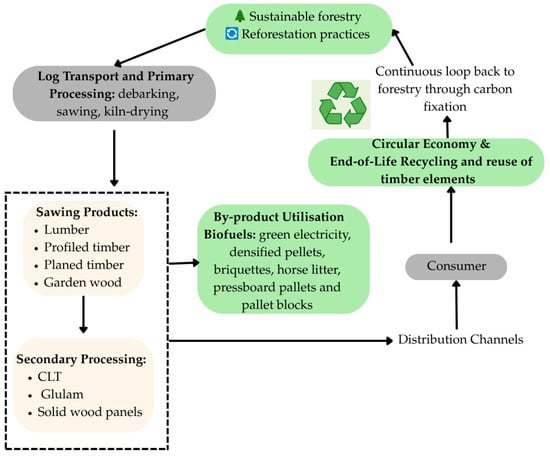

Despite these challenges, leading timber manufacturers have demonstrated that near-zero waste is achievable through fully integrated processing systems, ensuring that all parts of the log are utilised [85]. While high-grade sections are processed into structural timber, by-products such as bark, sawdust, wood chips, and shavings are converted into densified biofuels like pellets and briquettes, or used to generate thermal energy and green electricity through biomass combined heat and power systems. This approach enhances resource efficiency and supports climate-neutral energy outcomes. Table 5 summarises the key environmental and sustainability challenges in sawmilling and prefabrication, along with corresponding strategies identified in recent studies.

Table 5.

Environmental and sustainability challenges in sawmilling and prefabrication.

Table 5.

Environmental and sustainability challenges in sawmilling and prefabrication.

| Challenge | Strategy | Description | References |

|---|---|---|---|

| Waste Utilisation | Recycling residues for bioenergy, paper, and engineered wood Integrated waste management | Wood chips, sawdust, and bark are repurposed into various products like MDF, pellets, and biomass fuel. | [9,10] |

| High Carbon Footprint | Using biomass energy, solar drying, and optimising logistics | Kiln drying and transportation contribute significantly to emissions; alternative drying methods and fuel sources can reduce impact. | [50] |

| Sustainable Forestry Practices | Adopting FSC/PEFC-certified timber sourcing | Certified wood ensures responsible forest management, reducing deforestation risks and enhancing ecosystem conservation. | [13] |

| Resource Efficiency | Implementing circular economy principles in manufacturing | Prefabrication reduces material waste through precision cutting, reuse of offcuts, and waste minimization. | [5] |

| Waste Generation | Waste minimisation through precision cutting, off-site construction | Factory-based production ensures accurate cuts, reducing site-generated timber waste. | [5] |

| Energy Efficiency | Upgrading sawmill machinery and kiln drying optimisation | Installing energy-efficient sawmill motors and using heat recovery systems in kilns can significantly cut energy use. | [52] |

| Alternative Timber Utilisation | Expanding engineered wood product applications | Laminated veneer lumber (LVL) and cross-laminated timber (CLT) optimize raw material use and improve material efficiency. | [13] |

4.1.6. Knowledge and Skill Gaps (C6)

The integration of sawmilling with prefabrication manufacturing demands a skilled workforce that can bridge traditional timber processing with digital construction workflows. However, significant knowledge and competency gaps exist across the supply chain [78,79].

The Forestry Workforce Training Program—Scoping Study (DAFF, 2023) identifies wood processing and manufacturing as one of the areas with the highest current and projected workforce and training needs in the forestry sector. While formal training pathways exist, such as those delivered through TAFE (Certificate III in Sawmilling and Processing, Certificate III in Wood Machining, Certificate III in Saw Technology) and Registered Training Organisations (RTOs), the study highlights notable gaps in delivery, especially in rural and regional areas. These geographic constraints make it difficult for workers to access structured upskilling opportunities and limit industry-wide adoption of improved practices. The report also points to a shortage of suitably qualified trainers, particularly in technical and wood-processing roles, which restricts the sector’s capacity to deliver consistent, up-to-date training. This shortage is compounded by broader workforce dynamics, including the ageing profile of the current workforce and difficulties in attracting younger entrants with digital or technical competencies. These issues raise long-term concerns about knowledge transfer, workforce renewal, and the sector’s ability to keep pace with modernisation [86].

Digital illiteracy poses a key barrier to integration [79]. Traditional sawmill operators, many of whom are highly experienced in manual or semi-automated processes, often lack exposure to digital technologies, limiting their ability to adapt to advanced systems such as Building Information Modelling (BIM), CNC machining, or ERP platforms. As the timber industry transitions toward Industry 4.0 and beyond, workforce development becomes a critical enabler. Investment in targeted training covering digital tools, automation systems, and cross-sector knowledge is needed to prepare workers for integrated manufacturing models. Collaborative efforts between industry, training providers, and government (e.g., through FWPA or the Accelerate Adoption of Wood Processing Innovation Program) can help build a future-ready timber workforce capable of supporting end-to-end integration between sawmilling and prefabrication.

4.1.7. Regulatory and Policy Challenges (C7)

The integration of Australian softwood sawmilling with prefabrication manufacturing is shaped not only by technical compatibility but also by regulatory and policy frameworks. In Australia, timber production and use are governed by a complex array of national codes, grading standards, environmental regulations, and certification systems. While these aim to uphold safety and sustainability, they often slow innovation and impose additional compliance burdens, particularly when adapting traditional sawmilling practices to meet the requirements for prefabrication.

Australia’s Forest Industry in the Year 2020 report [87] underscores that the lack of national coordination is a key barrier to innovation and scalability in the timber industry. It identifies inconsistent state-level regulations on timber processing, transport, and grading as contributors to inefficiencies and elevated compliance costs. These inconsistencies disrupt supply chain uniformity and reduce interoperability with prefabrication processes. The report also notes that regulatory overlap between federal, state, and local authorities can delay the approval of modern technologies and construction systems. Addressing these challenges requires harmonised national standards, simplified approval mechanisms, and policy integration across the forestry and construction sectors.

4.2. Case Studies

The case studies were selected using purposive sampling based on their relevance to prefabrication-oriented timber supply chains, operational transparency, and contrasting levels of integration. Timberlink (Australia) represents a regionally significant firm that has recently invested in digital manufacturing and vertical integration initiatives. Binderholz (Austria), in contrast, was chosen for its advanced level of full vertical integration, from forestry through to CLT production and prefabrication, offering insights into mature international practices. Selection was not based on company size or market share but rather on their demonstrated engagement with digital transformation, vertical integration, or prefabrication alignment. This approach ensured that the cases could provide relevant qualitative insights for the research objectives.

4.2.1. Timberlink’s Integrated CLT Plant (Australia)

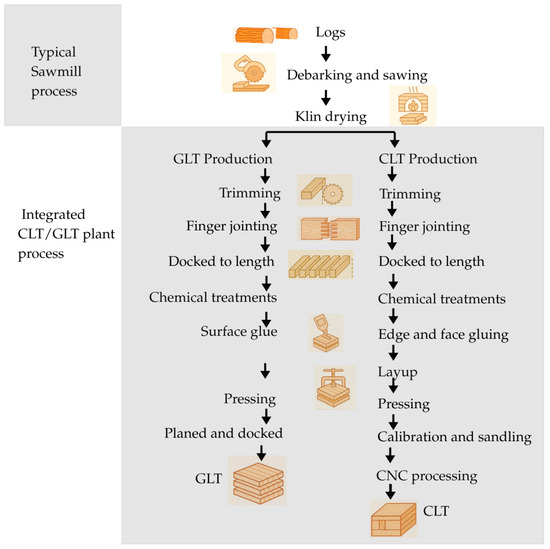

One noteworthy example of moving toward vertical integration is Timberlink’s NeXTimber facility in Tarpeena, South Australia. Timberlink, an established plantation pine sawmilling company, invested approximately $70 million to build a co-located plant that manufactures [88]. Cross-Laminated Timber (CLT) panels and Glue-Laminated Timber (GLT) beams. This facility, completed in 2023, is Australia’s first combined CLT/GLT plant integrated with a sawmill (Figure 6). The sawmill provides a steady supply of lamella (boards) cut from its Radiata pine logs, which are then finger-jointed (if needed), planed, and laminated into large structural panels and beams. By doing this on the same site, Timberlink leverages several integration advantages:

Figure 6.

Combined CLT/GLT plant integrated with a sawmill (adopted from [89]).

- (a)

- Consistent Feedstock—they control the quality of boards going into CLT, adjusting drying and grading as necessary.

- (b)

- Reduced Transportation—boards do not have to be shipped to a separate facility, saving cost and emissions.

- (c)

- Value Addition—the sawmill moves up the value chain, capturing more profit per cubic meter of wood by selling prefabricated panels instead of just sawn timber.

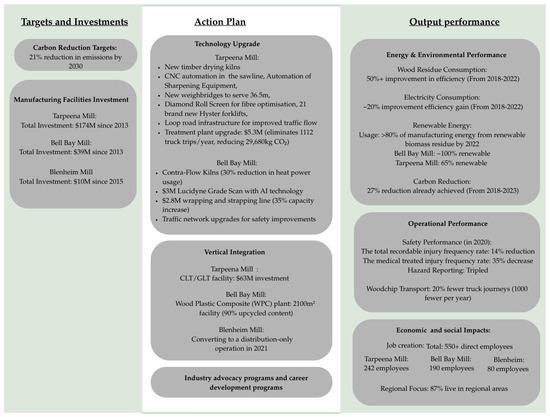

The result is products specifically designed for the construction market, focusing on prefabricated timber buildings. This integration required a significant investment and the adoption of advanced technology (Figure 7), supported by government and industry recognition of the importance of mass timber. It also had to align with standards: Timberlink must ensure its CLT meets structural design requirements. The success of this venture could serve as a model for other sawmills, demonstrating that diversifying into prefab component production is both feasible and profitable if done at scale.

Figure 7.

Targets, investments, action plans and performance of Timberlink Australia [90].

4.2.2. Technological Transformation and Vertical Integration at Binderholz (Austria-Based)

Binderholz, a leading Austrian-based timber company with operations across Europe, including Germany and Finland, exemplifies a vertically integrated enterprise that leverages Industry 4.0 innovations to transform its entire value chain, from log processing to advanced timber construction systems. The company’s strategic approach aligns smart manufacturing with sustainable practices, positioning it as a benchmark for digital transition in the sawmilling and prefabrication sectors.

- (a)

- Smart Manufacturing and Automation.

Binderholz has invested significantly in advanced production technologies to enhance product accuracy, customisation, and throughput. At its glulam plant in Jenbach, for example, the company installed a second high-frequency press and modernised its planing and sanding lines, thereby increasing production flexibility and surface quality [91]. A six-axis CNC machining centre (e.g., SCM OIKOS) enables precise, all-around timber processing for bespoke prefabricated components, demonstrating Binderholz’s capacity for batch-size-one production [92].

These operations are centrally managed by master computer systems, which coordinate the full workflow from finger-jointing to packaging, ensuring real-time optimisation and quality control. Automated high-rack warehousing solutions streamline internal logistics, enabling the efficient handling of over 2000 m3 of glulam products with minimal manual intervention [92].

- (b)

- Digital Integration and Industry 4.0 Systems

A hallmark of Binderholz’s digital transformation is the deployment of SAP S/4HANA as its core enterprise resource planning platform [93]. This supports real-time monitoring and integration across financial, logistics, procurement, and warehouse operations. Communication between staff, machines, and materials is facilitated by interconnected Industry 4.0 systems, enabling transparent data flow across all production sites [91].

- (c)

- Vertical Integration and Product Diversification

Binderholz’s vertically integrated business model spans the entire timber value chain, covering log procurement, sawmilling, and the manufacture of engineered wood products (EWP) such as CLT, glulam, and Binderholz BBS panels [94]. This structure reduces supply chain fragmentation and supports alignment with the project-specific demands of the prefabrication sector. The model also facilitates efficient reuse of production residues, reinforcing Binderholz’s commitment to value-added processing [92].

- (d)

- Sustainability and Circular Economy

Binderholz operates under a zero-waste principle, ensuring 100% utilisation of wood inputs (Figure 8) [94]. Sawmill by-products such as bark, sawdust, and wood chips are repurposed for green electricity, district heating and wood pellets. These practices reduce landfill dependency and carbon emissions while supporting global climate goals. The company’s approach exemplifies the circular economy model in timber processing [94].

Figure 8.

Binderholz’s concept of 100% all production plants.

This case study illustrates how Binderholz integrates advanced technologies, digital infrastructure, and sustainable practices to lead the timber industry’s transition to Industry 4.0. It offers a compelling precedent for Australian and global sawmilling and prefabrication sectors seeking modernisation and tighter operational alignment.

4.3. SWOT Analysis and Key Influential Factors

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis was conducted to synthesise the core internal capabilities and external pressures influencing the integration of sawmilling with prefabrication manufacturing in Australia (see Table 6). This analytical framework supports a structured understanding of where interventions are most applicable and highlights the strategic relevance of emerging solutions such as smart procurement platforms.

Table 6.

SWOT analysis.

The SWOT analysis highlights both the technical and institutional factors influencing the integration of sawmilling and prefabrication in Australia. While strengths such as established sawmilling infrastructure and government-backed innovation programs provide a solid foundation, critical weaknesses, particularly around inconsistent material accuracy and the limited adoption of digital systems, pose direct challenges to downstream prefabrication processes. Opportunities exist in harnessing emerging technologies such as BIM–ERP integration and digital twins, as well as in responding to growing demand for sustainable, low-carbon construction. However, threats such as raw material volatility, fragmented regulations, and an aging, digitally unprepared workforce may hinder progress. These insights underscore the need for coordinated, multi-level strategies that address both technical gaps and systemic barriers. Accordingly, the strategic priorities emerging from this analysis directly inform the recommended actions outlined in Section 6, particularly the proposed implementation roadmap for sector-wide integration.

5. Discussion

The integration of sawmilling with prefabrication manufacturing in Australia requires a fundamental shift from traditional volume-based operations to responsive, precision-focused supply models. Prefabrication manufacturers increasingly demand timber with consistent strength, dimensional accuracy, moisture control, and surface finish. However, many Australian sawmills continue to operate with limited grading consistency, outdated equipment, and variable moisture control, which undermines their ability to meet these performance criteria.

These technical limitations are compounded by digital gaps. The adoption of Building Information Modelling, ERP systems, and real-time quality monitoring remains low across much of the Australian sawmilling sector. This limits the ability of manufacturers and sawmills to coordinate effectively from design to delivery. In contrast, global industry leaders have integrated these systems to optimise material flow, reduce waste, and meet exact design specifications.

The SWOT analysis highlights several of these weaknesses, including inconsistent material quality, limited digital integration, and a fragmented regulatory landscape. Additionally, logistics remain a major barrier. Many sawmills located in rural regions lack the infrastructure and packaging protocols necessary to support just-in-time delivery, which is essential for efficient prefabrication workflows.

Beyond technical and logistical challenges, a lack of structured communication between sawmills and prefabrication manufacturers contributes to recurring mismatches in supply and demand. Without systematic feedback on timber performance or early engagement in design requirements, sawmills are often unaware of downstream needs and constraints. This misalignment restricts opportunities for joint optimisation and innovation.

To achieve effective integration, the focus must extend beyond upgrading machinery to developing long-term, collaborative relationships supported by shared digital tools and harmonised standards. Additionally, addressing gaps in economic and technical feasibility, such as the cost of equipment upgrades, return on investment for quality improvements, and skills development, will be critical to ensuring that integration strategies are both practical and scalable across diverse industry settings. Successful integration will rely on a supply chain that is not only technologically capable but also transparent, responsive, and strategically aligned with the evolving needs of prefabricated timber construction.

6. Conclusions and Key Recommendations

The challenges identified throughout this review underscore the need for coordinated efforts across the timber value chain. Addressing grading variability, digital fragmentation, logistical delays, and communication silos will be essential to enable successful integration between sawmilling and prefabrication in Australia. Building on the SWOT findings and industry gaps, the following recommendations outline targeted strategies to support this transformation (see Table 7).

Table 7.

Key recommendations.

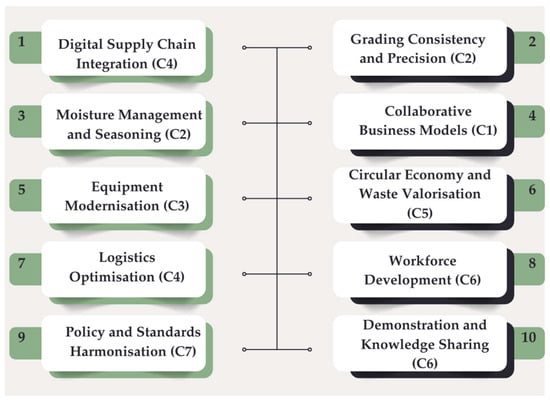

The implementation roadmap prioritises strategies based on their foundational impact on achieving integration between sawmilling and prefabrication. Digital supply chain integration is positioned as the top priority, enabling seamless data exchange and real-time coordination. This is followed by grading consistency and precision, which ensures material suitability and reduces downstream rework. Moisture management and seasoning are crucial for dimensional stability, supporting both quality and efficiency. Collaborative business models then consolidate upstream and downstream alignment. Equipment modernisation provides the technological foundation for precision and throughput. Circular economy and waste valorisation address sustainability, while logistics optimisation ensures efficient material flow. Workforce development builds the human capacity needed to operate and innovate within integrated systems. Policy and standards harmonisation supports regulatory alignment, and finally, demonstration and knowledge sharing foster industry-wide learning and adoption (Figure 9).

Figure 9.

Suggested priority-based implementation roadmap for sector integration, along with the challenge addressed.

Author Contributions

Conceptualization, H.D.; data curation, H.D.; formal analysis, H.D.; methodology, H.D.; writing—original draft preparation, H.D.; visualization, H.D.; funding acquisition, T.G. and P.M.; resources, T.G.; supervision, T.G. and P.M.; validation, T.G.; review and editing, T.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the University of Melbourne Research Scholarship and the Australian Research Council Industrial Transformation Research Program (ITRP)—Research Hub IH220100016: ARC Research Hub to Advance Timber for Australia’s Future Built Environment.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could appear to have influenced the work reported in this article.

References

- Whittle, L.; Downham, R. Upscaling the Australian softwood sawmill industry: Feasibility and implications for future plantation investment. In ABARES Research Report; Australian Government Department of Agriculture, Fisheries and Forestry: Canberra, Australia, 2019. Available online: https://www.agriculture.gov.au/abares/research-topics/forests/forest-economics/forest-economic-research/upscaling-the-australian-softwood-sawmill-industry (accessed on 1 July 2025).

- Kumar, A.; Dhiman, B.; Sharma, D. Sustainability and applications of timber as a structural material: A review. Int. Res. J. Eng. Technol. 2020, 7, 1868–1872. [Google Scholar]

- Shirmohammadi, M. Study of the hygroscopic properties of three Australian wood species used as solid wood and composite products. Eur. J. Wood Wood Prod. 2023, 81, 1495–1512. [Google Scholar] [CrossRef]

- Forest & Wood Products Australia. Future Market Dynamics and Potential Impacts on Australian Timber Imports; Available online: https://fwpa.com.au/report/future-market-dynamics-and-potential-impacts-on-australian-timber-imports-final-report/FWPA: Melbourne, Australia, 2022; (accessed on 1 August 2025).

- Rocha, P.F.; Ferreira, N.O.; Pimenta, F.; Pereira, N.B. Impacts of Prefabrication in the Building Construction Industry. Encyclopedia 2023, 3, 28–45. [Google Scholar] [CrossRef]

- Bylund, D. Enabling Prefabricated Timber Building Systems for Class 2 to 9 Buildings; Forest & Wood Products Australia (FWPA): Melbourne, Australia, 2017; Available online: https://fwpa.com.au/report/enabling-prefabricated-timber-building-systems-in-commercial-construction-pna324-1314/ (accessed on 3 July 2025).

- Woods, T.; Houghton, J. More Houses Sooner: Finding the Australian Dream; Forest & Wood Products Australia (FWPA): Melbourne, Australia, 2025; Available online: https://fwpa.com.au/report/more-houses-sooner/ (accessed on 3 July 2025).

- Whittle, L. Snapshot of Australia’s Forest Industry. In ABARES Insight; Australian Bureau of Agricultural and Resource Economics and Sciences, Department of Agriculture: Canberra, Australia, 2019. Available online: https://www.agriculture.gov.au/abares/products/insights/snapshot-of-australias-forest-industry (accessed on 7 July 2025).

- Wong, J.; Tasker, J.; Black, S. ABARES National Wood Processing Survey 2021–22. In ABARES Technical Report; Australian Bureau of Agricultural and Resource Economics and Sciences: Canberra, Australia, 2024. [Google Scholar] [CrossRef]

- Dissanayake, D.M.H.; Samarawickrama, S.; Gunewardena, T.; Mendis, P. Towards sustainable timber construction: A case study of waste generation, management, and circular strategies in Australian sawmilling and prefabrication manufacturing. In Proceedings of the 14th World Conference on Timber Engineering (WCTE 2025), Brisbane, Australia, 22–26 June 2025; pp. 2338–2346. [Google Scholar] [CrossRef]

- Dissanayake, H.; Gunawardena, T.; Mendis, P. Adaptation of connection systems for integration with engineered wood products in buildings: A systematic review. Buildings 2023, 15, 1131. [Google Scholar] [CrossRef]