Abstract

Ghana is currently facing a waste crisis that presents considerable risks to its environment, economy, and public health. This investigation evaluates four prospective waste-to-energy options—namely, incineration, anaerobic digestion, gasification, and landfill gas—with the objective of mapping out a sustainable strategy for efficient waste management. Among these solutions, anaerobic digestion stands out as a superior option, offering renewable energy production, valuable bio-product creation, and a comparatively lower greenhouse gas emission effect. A cost analysis further reveals that utilizing biogas from anaerobic digestion is not only environmentally friendly but also economically more viable than relying on light crude oil. Producing 200 MW of energy using biogas costs 36% less, potentially resulting in monthly savings of USD 5.46 million for Ghana. However, several obstacles impede the development of WtE. Inaccurate waste data and a lack of clear policies on waste-to-energy hinder the harnessing of Ghana’s WtE potential. To address this, the study recommends (1) implementing a well-defined national strategy complete with regulations and incentives to attract investments and (2) conducting specialized research to optimize WtE technologies for Ghana’s unique waste composition and context. By surmounting these challenges, Ghana stands poised to secure a sustainable future, simultaneously meeting the targets of Sustainable Development Goals 7 and 11. This entails ensuring access to affordable, reliable, sustainable, and modern energy for all (SDG 7) and fostering inclusive, safe, resilient, and sustainable cities and human settlements (SDG 11).

1. Introduction

The world faces a growing problem with waste due to improper disposal, inefficient collection, and rising populations in urban areas. Daily waste generation per person varies widely, ranging from 0.11 to 4.54 kg globally [1]. Managing this waste is complex and expensive, with significant disparities in resource allocation. While low- and middle-income countries dedicate a substantial portion of their municipal budgets to waste management, typically around 11% and 19%, respectively [2], the allocation in high-income countries remains lower, at around 4%. Furthermore, waste generation and management are intricately linked to the UN’s Sustainable Development Goals (SDGs), particularly SDGs 7, 12 and 13. Improper waste management can pollute the air and harm public health [3]. Therefore, effective waste treatment technologies and strategies are crucial to mitigate these negative impacts. In developing countries, a significant portion of waste is dumped or burned openly, leading to air pollution and health risks [4]. These practices also contribute to climate change by releasing methane and carbon dioxide [5,6,7]. To address the aforementioned environmental and health concerns associated with waste, developing countries urgently need to adopt sustainable waste management practices. The UN’s 2030 Agenda for Sustainable Development provides a roadmap for tackling this challenge. Specifically, SDG 12 aims for a significant reduction in waste generation by 2030, emphasizing prevention, reduction, recycling, and reuse as key strategies [8].

This goal aligns perfectly with SDG 7, which calls for universal access to affordable, dependable, sustainable, and modern energy by 2030 [9]. A core element of SDG 7 is to significantly increase the amount of renewable energy in the global energy mix. As a result, addressing waste management challenges through SDG 12 provides a win–win situation. This multifaceted strategy provides a possible path to a sustainable future in which responsible waste management contributes to a cleaner and greener energy environment. Waste-to-energy (WtE) technologies have received a lot of attention in industrialized countries as a realistic and promising solution to the waste crisis [10,11]. However, the use of these technologies in developing countries remains limited. Several waste treatment options are available, including composting and mass burning. However, some of the most innovative waste management strategies incorporate waste-to-energy (WtE) conversion, which provides numerous benefits [12]. This technology allows for the conversion of waste into energy through procedures such as incineration and anaerobic digestion [13]. The production of energy from waste not only reduces greenhouse gas emissions but also has the potential to create new job opportunities [14]. Furthermore, it makes trash management more effective and contributes significantly to sustainable development [14]. Despite these advantages, it is worth noting that the use of these waste treatment options is less common in underdeveloped countries [15]. The available literature provides relatively little information on how and to what extent trash is processed in these developing nations, as well as what steps might be taken to encourage sustainable waste management practices in the future. This study seeks to fill this research gap by shedding insight on the treatment approaches used in developing nations and their potential for future sustainable development. According to [16], renewable energy sources, such as hydroelectricity, even though environmentally benign, are not completely emission-free. For instance, South Africa’s 2021 electricity mix, dominated by coal-fired plants (84.4%), yielded a hefty 866.5 gCO2-e/kWh, compared to New Zealand’s 180 gCO2-e/kWh, fuelled primarily by renewables (57% hydro, 17% geothermal, 6% wind) [17,18,19,20]. As the authors of [21] point out, the increased urbanization that characterizes many developing economies exacerbates waste management concerns. However, within these problems are huge opportunities. By perceiving trash as a resource rather than a burden, emerging nations can use sustainable waste management strategies to help meet future development goals. Further, in 2017, research conducted in Korea found that waste-to-energy operations reduced greenhouse gas (GHG) emissions by 16,061 tCO2eq per year; it was projected to reduce GHG emissions even further to 33,477 tCO2eq per year by 2021 [22]. Waste-to-energy conversion techniques are broadly divided into two categories: thermochemical and biochemical [23]. Thermochemical processes employ heat to transform waste into energy, such as incineration. Biochemical processes, such as anaerobic digestion, use microbes to degrade organic waste and produce energy. Notably, the emissions from waste-to-energy (WtE) processes vary depending on the technique used. Anaerobic digestion has been shown to be more environmentally friendly than pyrolysis, gasification, and incineration [23]. The objective of this study is to conduct a systematic evaluation and identify the potential benefits and challenges of waste-to-energy (WtE) generation in developing countries, with a focus on Ghana. This will include an evaluation of the nature and features of the waste produced, its composition, present treatment technologies, the waste management sector’s opportunities and problems, and the potential for implementing or expanding WtE solutions in the country.

Research Questions

Primary Question:

- What is the most sustainable waste-to-energy (WtE) option for managing Ghana’s waste crisis, considering environmental, economic, and social factors?

Secondary Questions:

- How do the environmental impacts of incineration, anaerobic digestion, gasification, and landfill gas compare for waste management in Ghana?

- What are the characteristics of solid waste in Ghana?

- What is the economic feasibility of utilizing biogas from anaerobic digestion compared to traditional energy sources like light crude oil?

- What are the key obstacles hindering the development of WtE in Ghana?

Hypotheses:

- We hypothesize that anaerobic digestion will emerge as the most sustainable WtE option due to its potential for renewable energy production, valuable bio-product creation, and lower greenhouse gas emissions compared to other methods.

- We further hypothesize that utilizing biogas from anaerobic digestion will be more cost effective than relying on fossil fuels like light crude oil.

Overall, this article undertakes a thorough examination of various waste-to-energy (WtE) options tailored to the specific context of Ghana. Beyond merely advocating for the adoption of WtE practices, it delves deep into a critical evaluation of these options, shedding light on their environmental, social, technical and economic implications. As an additional value, the study showcases the economic feasibility of waste-to-energy in contrast to traditional energy sources, providing a compelling argument for WtE from a financial standpoint.

2. Materials and Methods

To navigate the vast body of research surrounding WtE in Ghana, the study enlisted the PRISMA framework, which stands for Preferred Reporting Items for Systematic Reviews and Meta-Analyses. This comprehensive approach guided our exploration, ensuring that we captured not only relevant studies but also the latest advancements in the field (2012–2022). This focus on recent developments enhances the transparency and accuracy of our analysis, providing a clear and up-to-date picture of WtE’s potential in Ghana. The PRISMA approach encompassed aspects such as the databases scrutinized (Web of Science and ProQuest), the criteria for inclusion and exclusion, the distinct review phases (identification, screening, and eligibility assessment), and the procedures for data extraction and analysis [24].

2.1. Eligibility and Exclusion Criteria

Eligibility criteria were established to ensure a focused and relevant selection of studies (detailed in Table 1). We exclusively included peer-reviewed journal articles published between 2012 and 2022 in English, encompassing both science and social science databases. The thematic focus centred on solid waste, waste-to-energy technologies, and associated waste management practices.

Table 1.

The inclusion and exclusion criteria.

2.2. Systematic Review Process

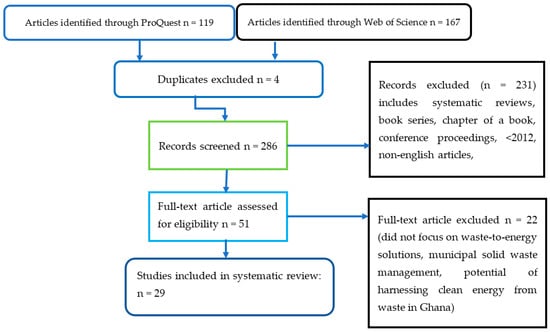

The systematic review procedure encompassed a sequence of four distinctive stages. In September 2023, we initiated the evaluation process. During the initial phase, we established a comprehensive list of pertinent terms to be employed in subsequent searches. These keywords were sourced from the existing literature and an extensive thesaurus. Upon conducting a thorough examination, four duplicate items were identified and subsequently removed. Transitioning to the subsequent steps, we engaged in a screening process, wherein 231 items were excluded from the initial pool of 286 articles based on predefined eligibility criteria. The third phase entailed accessing and scrutinizing the complete articles obtained, amounting to a total of 51 articles. Following a rigorous review, twenty-two of these articles were determined to be ineligible as they did not pertain to waste-to-energy solutions, lacked an empirical basis, failed to address municipal solid waste management, or did not explore the potential of clean energy generation from waste in Ghana. Upon concluding this final round of evaluation, a total of 29 articles met the criteria and were selected for inclusion in the review, as illustrated in Figure 1.

Figure 1.

The flow diagram of the study (author’s construct).

Summarily, we employed a rigorous systematic review methodology guided by the PRISMA framework. This ensured transparency and adherence to best practices. The PRISMA approach involved utilizing specific databases, establishing clear eligibility criteria (detailed in Table 1), and following a defined four-stage review process (depicted in Figure 1). This systematic approach yielded a final selection of 29 relevant and up-to-date studies (2012–2022) focusing on solid waste, WtE technologies, and waste management in Ghana, forming the foundation for our analysis.

3. Results and Discussions

Population-driven urbanization and increasing economic growth in developing countries necessitate effective solid waste management practices that focus on waste diversion, resource recovery, and energy generation to alleviate pressure on landfill capacity and reduce indiscriminate waste disposal and cost [25]. To accomplish this, it is crucial to explore waste-to-energy options that can contribute to the recovery of energy from waste in the metropolis while simultaneously ridding the region of filth and realizing environmental and economic benefits. This chapter delves into the generation and characteristics of solid waste in Ghana, the prospects and selection of waste-to-energy technologies, and the potential of MSW for energy recovery, adoption, and implementation in Ghana.

3.1. Solid Waste Generation and Characteristics in Ghana

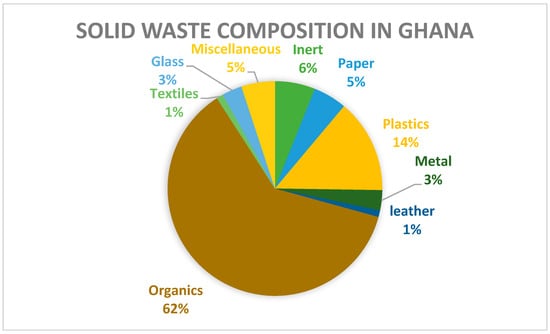

Effective waste management planning in Ghana is hampered by a lack of comprehensive national data on trash generation and composition. Numerous isolated studies have been conducted to determine the amount and composition of trash produced in the country. For instance, one study [26] found a generation rate of 0.47 kg/person/day in several Ghanaian cities. This translates to around 12,710 tonnes per day and approximately 4 million tonnes annually. This generation rate is expected to rise as population growth continues. According to [27], in Accra, Ghana, residents with greater incomes generated more trash, specifically 0.6 kg per capita per day. Middle-income groups, on the other hand, generated trash at a rate of 0.4 kg per capita per day, while low-income groups produced waste at a rate of 0.3 kg per capita per day. In a similar vein, another study [28] found that the per capita trash produced in Vittin, a high-income community in the Tamale Metropolis, is 0.33 kg per person per day. Research on trash characterization in various Ghanaian cities and towns found a considerable presence of organic components in the waste stream. Similarly, ref. [26] found that organic materials accounted for around 61% of total trash produced in Ghana (see Figure 2). The authors of [29] conducted waste characterization investigations at the Kumasi Metropolitan Assembly’s (KMA) final dump site and observed that organic waste constituted an average of 40.32% of total trash. A recent investigation conducted by [30] at Cape Coast University (UCC) found that organic waste accounted for 54.4% of total household trash in the senior and junior staff residential areas. Other waste types, such as plastics, paper, textiles, metals, and glass, have lower shares, ranging from 1.1% to 31.4%. Takoradi Sub-Metro research focused on the characterization and measurement of municipal solid trash. In their survey, they found that biodegradable materials accounted for 60.0% of solid waste, plastics for 11.5%, inert materials for 8.0%, paper and cardboard for 7.1%, miscellaneous materials for 5.0%, textiles for 2.9%, metals for 2.4%, glassware for 1.5%, and leather and rubber for 1.2% [31]. According to the findings in [32], three communities in Ghana’s Eiisu-Juaben municipality generated more than 30% of organic trash. The authors of [33] undertook a study to investigate the composition of trash found along the shores of Ghana’s coastal lagoons. The findings revealed a slightly varying distribution of litter categories, with plastics taking up 50% of the total, which was followed by organic materials at 20%, paper at 10%, textiles at 10%, and miscellaneous debris at 10%. Notably, previous research has demonstrated that seasonal fluctuations have no statistically significant effect on the nature and generation of household waste. However, seasonal variations impact the amount of outdoor trash, particularly yard waste, with trimmings being a major factor [34].

Figure 2.

Solid waste composition in Ghana (author’s construction, data source [26]).

Furthermore, some studies have found that waste generation rates vary by socioeconomic level in both urban and rural settings [35,36]. Ref. [26] reported daily waste generation rates of 0.56, 0.49, and 0.47 kg in high-, middle-, and low-income regions, respectively. According to a study undertaken by [35], the average daily trash creation in the Kumasi metropolitan area varies across socioeconomic levels. The measured values were 0.56 kg/day for high-class areas, 0.49 kg/day for middle-class areas, and 0.47 kg/day for low-class areas. The authors of [36] argue that the diversity of waste origins and volumes influences the application of solid waste management solutions. As a result, waste management solutions that work in one setting may not be effective in another. Therefore, it is critical to consider waste generation rate and characteristics when deciding on acceptable solid waste management options, such as the use of waste-to-energy (WtE) technology choices.

3.2. The State of Solid Waste Management in Ghana

The current practice in Ghana, as in many other developing countries, is to accumulate heterogeneous trash and dispose of it in designated areas without prior segregation [17]. The prevailing methodology is considered non-sustainable, contributing to the inefficiency of the already ailing waste management system in place. According to the 2013 report of the African Development Bank, Ghana generates an estimated 3.6 million tonnes of solid trash per year, with a large amount of organic biodegradable items such as food waste, yard waste, and wood waste. Unfortunately, the majority of collected trash ends up in poorly managed designated dumps or unengineered landfill sites, with minimal formal material recovery [36]. Scavengers carry out informal material recovery at houses and disposal sites, but this is insufficient to meet waste management issues. The ineffective treatment of municipal solid waste (MSW) in Ghana can be attributed to authorities’ incompetence and failure to prioritise waste management [28,36]. The problem is aggravated by insufficient waste reduction measures, weak environmental regulation enforcement, and a lack of waste management skills [31,36]. The authors of [32] found that in Ghana, the most common ways of disposing of solid waste are uncontrolled dumping, controlled dumping, sanitary landfilling, composting, and incineration. It has been noticed that unmanaged landfills are frequently found on the outskirts of cities. Nonetheless, trash collection systems and landfills are sometimes absent in rural areas and small towns. As a result, trash is disposed of in many unauthorized locations, including highly populated areas, posing possible health risks [37].

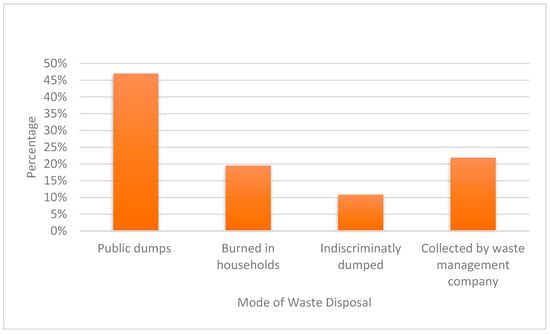

The aforementioned observation is supported by data from [38], which show that approximately 47.8% of solid waste is disposed of in public dumps, 19.5% is incinerated by households, 10.8% is indiscriminately dumped, and only 21.9% is collected by waste management companies (see Figure 3). Another study [39] also revealed that, like other developing nations, Ghana faces significant challenges in managing its municipal solid waste (MSW) due to a lack of resources and knowledge. Despite various governments implementing decentralization policies and reform projects, municipal solid waste (MSW) management remains inadequate. The current situation has resulted in inferior trash collection infrastructure in many communities around the country, including insufficient storage receptacles and illegal waste disposal activities. According to [40], in order to achieve sustainable waste management in Ghana, a comprehensive plan that includes waste analysis, reduction, valorisation, and recycling must be implemented. As a result, including waste-to-energy technologies in an integrated solid waste management (ISWM) framework would significantly contribute to waste reduction and power generation in Ghana, thus supporting sustainable development.

Figure 3.

Waste collection in Ghana (author’s construction, data source [38]).

3.3. Waste-to-Energy Technologies and Their Status in Ghana

As delineated in the preceding section, Ghana heavily depends on the practice of open dumping and landfilling as a means of waste management. Simultaneously, there is a consistent increase in waste generation within the nation, necessitating the prompt reassessment of waste management strategies by municipal authorities. The authors argue that it is time to reconsider the WtE solutions for solving Ghana’s waste problem. The technology’s current detractors, especially those who are opposed to WtE incineration plants, are acknowledged and will be addressed in the next section. Undoubtedly, Ghana stands to gain an additional advantage from waste-to-energy (WtE) technologies in the form of an augmented renewable energy resource, which can effectively mitigate its reliance on fossil fuels. According to the Ghana Energy Commission (2021), an estimated 152.34 gigawatt-hours (GWh) of electrical energy was projected to be generated from renewable energy sources in 2021. Additionally, fossil fuels are primarily responsible for electricity production in Ghana, providing energy for electricity-generating facilities such as thermal sources, which account for nearly 70% of power production in Ghana [40]. Given this context, waste presents an immensely appealing alternative fuel source due to its relatively eco-friendly nature and local availability.

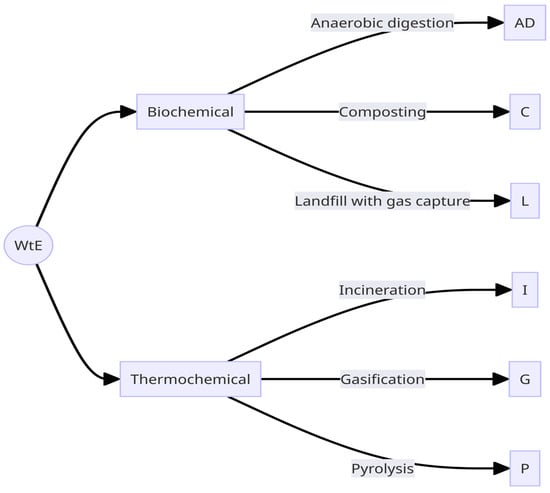

In the present investigation, we zeroed in on a few key biochemical and thermochemical processes: anaerobic digestion, incineration, gasification, and landfill gas (see Figure 4). This specific focus is driven by a profound understanding of the local Ghanaian context and a commitment to sustainable waste management. We considered the progress of these technologies in their development and the availability of data on them within the context of Ghana. Furthermore, in accordance with the literature [34,41,42], the physical and chemical characteristics of Ghana’s municipal solid waste (MSW) enable the implementation of the aforementioned waste-to-energy (WtE) conversion procedures.

Figure 4.

Waste-to-energy technologies (author’s construction, data source [43]).

Relatedly, it is crucial to acknowledge that advocating for waste-to-energy (WtE) is closely intertwined with advocating for a comprehensive, integrated waste management strategy, even though the latter encompasses a broader scope [44]. For instance, recycling—a key component of comprehensive waste management—focuses on plastic, paper, textiles, and leather as well as inert waste materials like glass and metal. In Ghana, recycling plays a pivotal role in effective waste management [44].

While the aforementioned inert materials pose minimal environmental risks when landfilled, their value becomes significant when recycled through processes such as crushing, sorting, and remelting for use in new products [45]. By embracing WtE technologies alongside robust recycling initiatives, Ghana can move toward a more sustainable waste management future—one that prioritizes environmental protection, resource recovery, and renewable energy generation.

Next, we explore the different waste-to-energy (WtE) technologies (see Figure 4) and assess their current implementation status in Ghana.

3.3.1. Incineration

Incineration is one of the oldest and most reliable methods for generating energy from municipal solid waste [46]. To do this, MSW is burned in furnaces, and the resulting heat is converted into usable electricity or thermal energy. Ash and exhaust gases are produced as a result of this procedure [46]. The ash that is left over after recycling has been carried out might be put to other uses, such as building projects. Research indicates that most current incinerators have an energy efficiency of around 30 percent [44]. Recently, there have been proposals for integrated waste-to-energy gas turbine power plants with the potential to enhance energy efficiency by over 40%. As of 2019, thirty such plants have been established in Spain, the Netherlands, and Japan [47,48]. Despite its immaturity, the integrated gas turbine system is seen as the wave of the future for WtE incineration methods [48].

One of the primary advantages of incineration, in comparison to alternative WtE methods, lies in its effectiveness in significantly reducing waste, irrespective of waste type, volume, pretreatment, or otherwise [49]. Moreover, the potential economic value of the resulting residues adds to the appeal of this technology. However, WtE incinerators do come with certain drawbacks, including their cost and associated social and environmental concerns [49]. These facilities tend to be relatively expensive to construct, and communities often display reluctance to have incinerators nearby [50]. Additionally, waste incineration releases pollutants such as metals, dioxins, and toxic gases, which can be detrimental to both human health and the environment [50]. A study by [51] examined the health impacts of waste incineration, highlighting concerns related to the emission of toxic substances such as persistent organic pollutants, NOx, SOx, and flue gasses. The results emphasized the potential for adverse health effects, including increased risks of cancers, birth defects, and other health impacts associated with proximity to waste incineration facilities. Similar findings were reported in analogous studies [47,52]. It is worth noting, however, that the quantities of these emissions have decreased in recent years due to stricter government regulations and advancements in this field [50]. Globally, Europe is a leader in the worldwide adoption of waste-to-energy incineration technology, with major investments coming from nations like Germany, the United Kingdom, France, Sweden and Italy [53]. Incineration enables these nations to reduce landfill waste volumes by as much as 90% [54]. In European Union (EU) member states, energy generation from waste accounted for 26% of the total in 2015 [55]. The energy valorisation process was responsible for 8.9% of the total heat consumption and 1.3% of the total electricity usage. By 2012, 409 waste-to-energy (WtE) facilities were operating in the European Union, burning 74 million tonnes of trash to produce 30 TWh of power and 74 TWh of heat [56].

A comprehensive study conducted in Ghana [57] revealed that the country hosts 12 controlled waste incinerators lacking energy recovery capabilities, alongside an additional 232 unregulated waste incineration facilities scattered across the nation. Furthermore, a 2020 study [41] suggests the potential for a waste incineration facility in Kumasi, with estimations projecting that it could generate approximately 30 to 52 MWh of power from 1000 tonnes of municipal solid waste (MSW). It is essential to note that there is a dearth of current information available in the literature regarding the condition of the aforementioned waste incineration plants, their locations, and their operational status. Nevertheless, according to reports by [58], the Ashanti region of Ghana is now home to a novel solar–pyrolysis–biogas hybrid waste-to-energy (WtE) plant. This groundbreaking hybrid WtE facility is estimated to have a power generation capacity of approximately 400 kW, marking it as the first of its kind in the country [58].

3.3.2. Anaerobic Digestion

Anaerobic digestion is another technology for converting waste into energy [19]. This technology involves a process in which microorganisms degrade organic materials in the absence of oxygen [59] to produce biogas, a methane-rich fuel, and digestate, a nutrient-rich fertiliser [59]. Anaerobic digestion systems typically process organic waste for 15 to 30 days per cycle [60]. The authors of [60] discovered that biogas produced in enclosed tanks has the potential to be converted into renewable energy such as heat or electricity, particularly when combined with a heat and power unit. Bio-fertiliser created from anaerobic processes can be given to agricultural lands following pasteurisation, which destroys any hazardous bacteria [61]. The anaerobic digestion process includes multiple phases. First, hydrolytic enzymes degrade complex polymers into basic amino acids, sugars, and fatty acids. Then, simple monomers go through acidogenesis, which breaks them down further into volatile fatty acids. The next step is acetogenesis, which turns acidogenesis products into acetic acid. Finally, methanogenesis generates methane and CO2 [61]. These procedures are often performed within enclosed systems known as digesters. Ref. [62] forecast that one tonne of municipal solid waste (MSW) may produce 100 m3 of biogas. Anaerobic digestion has various advantages over incineration, including fewer carbon dioxide emissions, the ability to employ organic waste as soil conditioners, and reduced odour emissions [63]. Anaerobic digestion is also more environmentally benign than incineration during its whole life cycle [63]. However, one key restriction is its slower processing pace, making it unfeasible to rely solely on it for the processing of large-scale MSW. Furthermore, it can only handle biodegradable trash or the organic component of municipal solid waste [64]. An estimated 12,000 biogas plants were operating globally in 2016, and the authors of [65] project that by 2025, there will be 15,000 such plants in operation. Despite their rarity in developing nations, AD technologies are rapidly gaining popularity in areas such as Ghana. In recent decades, a number of African countries, including Ghana, have created biogas generation efforts based on municipal solid and liquid waste. However, the majority of these plants are fairly small and are mostly used for cooking or home lighting [66]. Consider Ghana: in 2010, around 250 biogas systems were tallied, the majority of which were in domestic settings [67]. According to the Energy Commission of Ghana (2021), biogas accounts for only 0.002% of the country’s total installed capacity. Appolonia and Ashaiman are two examples of anaerobic digestion facilities in Ghana; however, they pale in comparison to the country’s enormous biogas potential. Appolonia is a 12.5 kW digester plant, while Ashaiman is a 100 kW plant.

Regarding the challenges and feasibility of anaerobic digestion (AD) in Ghana, it is necessary to effectively address prevailing drawbacks to enhance AD feasibility. Key recommendations include fostering public–private partnerships (PPPs) to address financial constraints and attract expertise often scarce in Ghana. Additionally, the reliability of energy and water supply, crucial for optimal AD operation, varies across regions in Ghana, posing potential hindrances. Ghana’s municipal solid waste (MSW) exhibits high heterogeneity, characterized by fluctuations in organic content and contamination, impacting AD efficiency and necessitating costly pre-treatment processes. Social acceptance intricacies further complicate AD implementation, with public concerns regarding odour, noise, and potential health risks potentially leading to community opposition and project failure. Mitigating these concerns requires effective community engagement and transparent communication. Furthermore, integrating biogas into the national grid requires infrastructural upgrades, particularly in rural areas, and solutions for energy storage to manage biogas production fluctuations effectively. Addressing these complexities is essential for advancing AD as a sustainable waste management solution in Ghana.

3.3.3. Gasification

The gasification process involves turning an organic substance into a synthesis gas mixture and a solid byproduct known as char. Temperatures above 650 °C are required for this transformation to occur [68]. Because of its high calorific value, synthesis gas can be used to create both electricity and biofuels [68]. Organic carbon and ash are what make char. It is important to note that the types of reactors used and the operations carried out distinguish the several gasification systems in use today [68]. Both gasification and pyrolysis can convert many forms of municipal solid waste into usable energy, and both have the ability to do so efficiently. Yet, unlike anaerobic digestion and incineration, these technologies have not yet reached full maturity [69]. Several pilot projects are now underway in Ghana to test out different gasification technologies and see which ones work best with the country’s infrastructure [70]. Papasi, in the Offinso North District of Ghana, has a gasification system that runs on an internal combustion engine, for instance. The 20 kW system uses palm kernel shells as fuel to produce power [67]. The Ghana Oil Development Company, for example, has a biomass-fired co-gasification plant in operation with an installed capacity of 2500 kW that generates an annualised average of 6.8 GWh [67]. Similarly, the Juaben Oil Mill has a capacity of 425 kW and produces an average of 1.5 GWh a year. The authors of [71] found that Benso Oil Mill’s 500 kW capacity generates an annualised average of 1.9 GWh, while Twifo Oil Palm’s 610 kW capacity generates an annualised average of 2.1 GWh.

Despite these illustrative successes, gasification in Ghana faces significant drawbacks. One major challenge is the high capital and operational costs associated with establishing gasification plants. This requirement for substantial investment surpasses the financial capacity of many municipalities in Ghana [72]. Moreover, careful financial planning and resource allocation are imperative to address the ongoing operational costs. Furthermore, the operation of gasification facilities demands specialized skills and knowledge, which are often scarce in Ghana [73]. Ensuring reliable energy supply is crucial for optimal operation, potentially posing challenges to the already burdened utility service provider in Ghana, namely the Electricity Company of Ghana [74]. Additionally, gasification efficiency is heavily contingent on the physical and chemical quality and composition of the feedstock. Ghana’s municipal solid waste (MSW) exhibits heterogeneity, including high moisture content and contamination, necessitating complex and costly pre-treatment processes such as drying, sorting, and size reduction [75]. While gasification offers cleaner emissions compared to conventional incineration, air pollution risks persist. Therefore, proper emission control technologies and stringent environmental regulations are essential to minimize harmful gas releases [67]. Addressing environmental concerns further, gasification generates ash, requiring safe and sustainable disposal solutions. Improper handling of ash can pose environmental and public health risks [76]. Thus, exploring options such as ash reuse in construction materials or secure landfills with leachate management systems is crucial to mitigate these concerns.

Recognizing these challenges and capitalizing on potential advantages is integral to determining the feasibility of gasification in Ghana. The following are key recommendations: much like anaerobic digestion, fostering public–private partnerships, involving collaboration between governmental entities, private investors, and technology providers, can alleviate financial constraints and attract expertise. Essential for ensuring efficient and sustainable gasification operations, investment in training programs for local technicians and operators is vital [77]. Enhancing gasification efficiency and optimizing synthesis gas production can be achieved by implementing source segregation and exploring cost-effective pre-treatment technologies tailored to the local waste composition. To mitigate air pollution and ensure safe ash disposal practices, it is crucial to enforce stringent environmental regulations and implement effective monitoring systems. Researching and investing in diverse applications for synthesis gas, such as electricity generation, chemical production, and transportation fuels, has the potential to maximize its economic benefits and contribute to further diversification of Ghana’s energy and industrial sectors [77].

3.3.4. Landfill Gas (LFG)

The authors of [78] likened landfills to biological reactors, where landfill gas is produced by biochemical processes when organic matter decomposes. About half of the landfill gas is carbon dioxide (CO2), and the other half is methane (CH4). According to [79], it includes NMOCs such benzene, vinyl chloride, and trichloroethylene in addition to nitrogen, ammonia, oxygen, sulphurides, carbon monoxide, and hydrogen at trace amounts. The decomposition of waste in landfills initially undergoes aerobic decomposition, resulting in small amounts of methane production. Subsequently, anaerobic conditions are established, allowing methane-producing bacteria to break down the waste and generate methane and carbon dioxide [79]. This decomposition process occurs in distinct stages, including hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Landfill gas (LFG) primarily comprises roughly 45% to 60% methane by volume, along with 40% to 60% carbon dioxide and 2% to 9% other gases such as sulphides and NMOCs [80]. During this stage, gas production remains relatively stable and can persist for approximately two decades, with the possibility of landfill gas emissions continuing for up to 50 years depending on the specific landfill’s conditions. The rate and quantity of landfill gas generated at a particular landfill site are influenced by factors such as the characteristics of the waste and environmental conditions like oxygen levels, moisture content, the age of the refuse, and temperature [81]. Landfills have commonly been regarded as one of the simplest, most cost-effective, and most widely used methods for solid waste disposal [82,83] The apparent cost-effectiveness of landfills is the main reason for their widespread use for trash disposal [84]. Inadequate maintenance and landfill operations that fall short of acceptable environmental requirements have, however, undermined this efficiency in numerous instances. But landfills have been advocated for and utilized extensively in developing nations like Ghana for the disposal of solid waste [85].

In 1994, as part of the Local Government Development Project (Urban III) [86], Ghana made its first attempt to use engineered landfills as a means of MSW disposal. Wa, Techiman, Bolgatanga, Ho, Keta/Anloga, Koforidua and Cape Coast are just a few of the medium-sized district capitals that were included in this effort; their populations range from 30,000 to 50,000. Subsequently, in 1995, the Urban Environmental Sanitation Project was implemented and focused on the five main cities in Ghana: Tamale, Tema, Accra, Sekondi-Takoradi, and Kumasi, with populations ranging from 200,000 to over 1,500,000 [84]. Tamale, Kumasi, and Sekondi-Takoradi engineered landfills were all part of this undertaking. By the year 2004, construction began on the aforesaid landfill sites. However, the effectiveness of this technology was mostly undermined by the practice of indiscriminate dumping without proper source separation. It is important to note that, currently, Ghana does not have an operational landfill gas plant but rather sanitary landfills and open dumps for waste management. Nevertheless, Armech Group, a Ghana-based company, has entered into a public–private partnership agreement with the Electricity Company of Ghana to construct a landfill gas plant in Tema [87]. This plant, estimated to cost USD 300 million, aims to generate 60 MW of clean energy. Moreover, the utilization of landfill gas in Ghana encounters notable challenges, as highlighted by [76]. One significant challenge is the lack of equipped landfills for gas capture and utilization. Addressing this limitation would require substantial investments in infrastructure upgrades and collection systems. This observation emphasizes the importance of evaluating the existing infrastructure and capabilities before assuming the full functionality of such waste-to-energy initiatives in the country. Additionally, landfills in Ghana show lower methane concentrations compared to those in developed countries, as indicated by [74], thereby affecting biogas yields and limiting the potential for energy production [74]. The efficient collection and utilization of landfill gas demand specialized skills and continuous maintenance, which are currently scarce in Ghana. This scarcity not only poses safety risks but also has the potential to contribute to greenhouse gas emissions. Consequently, there is a pressing need for the implementation of robust leak detection and mitigation strategies, as emphasized by [75].

Recognizing these challenges and leveraging potential advantages is crucial for determining the feasibility of gasification in Ghana. The following are key recommendations, akin to anaerobic digestion: firstly, prioritizing landfill upgrades and gas capture in larger, high-methane landfills with existing infrastructure can establish a foundational step for successful expansion in Ghana [86]. Secondly, evaluating and exploring innovative landfill gas (LFG) capture and utilization technologies tailored to Ghana’s specific landfill characteristics can enhance efficiency and yield. This approach also minimizes fire hazards and odour emissions, contributing to improved public health and safety near landfills, aligning with the benefits seen in other waste-to-energy (WtE) options [86]. Additionally, investing in training programs for local technicians and engineers is crucial. This investment ensures the proper operation and maintenance of the LFG system, promoting its long-term sustainability. Lastly, implementing rigorous safety protocols, regular emission monitoring, and effective leak detection systems are indispensable for mitigating environmental and public health risks associated with landfill gas utilization in Ghana [73]. These measures underscore the commitment to responsible and sustainable waste management practices in the pursuit of cleaner energy solutions in Ghana.

3.4. Energy Potential from Municipal Solid Waste in Ghana

In 2010, the capital city of Ghana, Accra, generated 950,000 tonnes of municipal waste [88]. To estimate the potential energy generation from this waste, a calculation was undertaken. Table 2 shows the amount of energy generated from each of the two broad categories of waste-to-energy technology annually in the capital city of Ghana. See Table 3 for the data used for the calculation in Table 2.

Table 2.

Energy generating potential from MSW in Accra (author’s compilation, data source [42]).

Table 3.

Data used in the biochemical and thermochemical calculation from MSW in Accra (author’s compilation, data source [42]).

In total, there is an impressive energy potential of over 147.68 kWh per tonne of municipal solid waste (tMSW) available in Accra alone. When applied to waste management in Ghana, this equates to an annual energy generation potential of 10.41 GWh via gasification, 4.63 GWh via plasma arc gasification, 3.47 GWh via pyrolysis, and 2.23 GWh via anaerobic digestion technologies [42]. To contextualise this, consider that the entire energy demand for the country in the year 2000 was 5560.1 Ktoe [89]. Therefore, the energy potential harnessed from municipal waste in Accra alone is equivalent to approximately 1.2% of the energy demand traditionally met by fossil fuels in the year 2000 [32]. Furthermore, this accounts for 6% of the expected electrical energy from renewable energy sources for the year 2021 in Ghana. More recently, a study by [32] found that at a 25% average electricity conversion ratio of waste-to-energy technology, the annual electricity generation potential from municipal solid waste in Ghana is 5827.3 GWh.

To estimate the potential energy derived from waste-to-energy (WtE) facilities, we calculate the total waste energy by factoring in the efficiencies associated with various WtE technologies, as presented in Table 3. It is essential to recognise that energy output varies among these technologies due to two primary factors: (1) differences in efficiencies and (2) the specific waste types they can effectively process. For example, anaerobic digestion, tailored for organic waste, yields a relatively lower energy output compared with thermochemical WtE technologies. This disparity arises because materials like plastic waste, constituting approximately 14% of Ghana’s waste, as indicated by [26], cannot be efficiently handled by anaerobic digestion alone. Therefore, innovative approaches, such as coupling material recycling with anaerobic digestion [57], offer a promising way to enhance its widespread adoption. Conversely, advanced pro-organic feedstock technologies like microbial electrolysis cells, microbial fuel cells, and combined dark-photo fermentation demonstrate favourable outcomes in terms of energy generation, albeit they are presently in the earlier stages of development. Further research in this domain is imperative. Additionally, Table 4 suggests that various geographic locations exhibit distinct energy potential due to variations in municipal solid waste composition. Consequently, evaluating the calorific value of MSW in a specific metropolis is a crucial step in establishing a waste-to-energy (WtE) plant.

Table 4.

Energy generating potential from municipal solid waste in Ghana using WtE technologies (author’s compilation).

Table 4 serves as a comprehensive compilation of findings from several studies regarding the energy potential of municipal solid waste (MSW) in Ghana. According to [91], crop residues and animal manure in Ghana boast an impressive energy potential of 96 PJ, primarily through biogas production. Likewise, one study [41] discovered that MSW in Kumasi has significant energy potential, with 36 MJ (equivalent to 10 kW/h) generated per 1 m3 of waste using biogas production. For other MSW management methods, another study [85] assessed the energy potential of MSW in Ghana, primarily through incineration and landfilling, and found it to be 2 GWh. On the other hand, the authors of [42] explored the energy potential through a range of techniques such as gasification, plasma arc gasification, pyrolysis, and anaerobic digestion, with respective energy potentials of 10.41, 4.63, 3.47, and 2.23 GWh. Additionally, ref. [93] highlighted the anaerobic digestion of MSW in Ghana, indicating an energy potential of 2.41 MW. Food waste in Kumasi, as per [34], demonstrated an energy potential of 775.3 l/kgVS through anaerobic digestion. In a separate study, the authors of [74] assessed the energy potential of food waste in Accra through anaerobic digestion, resulting in a substantial potential ranging from 80.43 to 300.49 GWh per year.

In essence, Table 4 and Table 5 offer valuable insights into the calorific value and energy potential of both MSW and food waste in Ghana via a diverse array of waste-to-energy technologies. These findings collectively indicate that these technologies possess the capability to produce noteworthy amounts of electricity from waste in Ghana. This not only aligns with the country’s renewable energy objectives but also provides a practical solution to the escalating waste management challenge. Nonetheless, further research is imperative to identify the most efficient and effective waste-to-energy technologies tailored to Ghana’s waste management needs.

Table 5.

Calorific value from municipal solid waste in Ghana (author’s compilation).

3.5. Adoption and Implementation of WtE Technologies

3.5.1. Socio-Economic Impact of WtE Technologies

The implementation of waste-to-energy projects results in the development of new employment opportunities in the surrounding areas [95]. The construction and operation of waste-to-energy plants can provide local communities with direct, indirect, temporary, and permanent employment opportunities [96,97].

3.5.2. Technical and Environmental Impact of WtE Technologies

The implementation of waste-to-energy (WtE) technologies offers a significant positive impact on mitigating global warming by reducing greenhouse gas emissions, including CO2, when compared to conventional methods of waste disposal like open burning and unregulated landfilling. When municipal solid waste (MSW) is incinerated in a thermal WtE plant, it prevents approximately 1010 kg of CO2 per tonne of waste from being released into the atmosphere, especially when not factoring in biogenic carbon emissions from methane gas in landfills. CO2 emissions from incinerators stand at 1.188 pounds of CO2 per kWh, while gasification plants exhibit lower emissions, approximately 0.855 pounds of CO2 per kWh. Anaerobic digestion plants contribute around 0.05–0.5 pounds of CO2 per kWh of electricity generated, and landfill gas recovery systems release 0.6 pounds of CO2 per kWh [98]. Among these WtE technologies, anaerobic digestion stands out as the most environmentally friendly. It is reported that gasification, pyrolysis, and anaerobic digestion are 33%, 65%, and 111% more environmentally sustainable, respectively, than direct combustion, according to findings by [96].

In terms of by-products, incineration facilities typically recycle the bottom ash to recover valuable metals, while the remaining ash can find use as construction materials, specifically aggregates [99]. In the case of anaerobic digestion, the primary by-product is digestate, a nutrient-rich material suitable for use as a fertilizer [100]. Gasification primarily results in ashes alongside the generated synthesis gas. The by-products of landfill gas (LFG) can exhibit considerable variability based on several specific parameters employed in the process, including feedstock type, waste age, landfill age, oxygen levels, moisture content, and temperature. Primary by-products of LFG plants typically include bottom ash and digestate. Bottom ash can undergo recycling to extract valuable metals, and the remaining ash is a viable option for construction materials, notably aggregates. Digestate, on the other hand, serves as a nutrient-rich material suitable for use as a fertiliser [100]. The authors of [101] detail the usual capacity scales for each waste treatment method, as follows: as an example, (1) incinerating waste can treat 1500 tonnes per day; (2) gasifying waste can effectively manage 10 and 100 tonnes per day; (3) anaerobic digestion can handle approximately 500 tonnes per day; and (4) it is estimated that a typical African landfill can treat approximately 8 × 10−4 tonnes of waste per day, which could be used for LFG production and utilisation. While plant size has a direct bearing on production capacity, these numbers give a rough idea of the global average for facilities that are currently available and functional. In terms of technological advancement, landfill gas and waste incineration are the most developed processes, followed by anaerobic digestion; gasification, however, is still in its nascent phase [102].

The efficiency of energy production varies across technologies due to factors such as thermodynamic cycles, plant scale, feedstock type, and optimisation techniques [103]. Using steam turbines, traditional incinerators have an electrical efficiency range of 15–30% [104]. For heating purposes, incinerators can achieve efficiencies of up to 90%, while those for combined heat and power are closer to 40% [104]. The maximum efficiency for biogas production using anaerobic digestion is 28% [105], and if the efficiency of a gas turbine is 30% to 40%, the overall efficiency range could increase by 8.4 to 11.2%. Depending on the type of turbine used, gasification technology can achieve efficiencies of 10–27%, or 30–40% for advanced gasification [106]. In most cases, a gas turbine can be used to convert landfill gas into electricity. Based on their findings, the authors of [106] agree that landfill gas is rich in methane (40–60%) and thus has great potential for power generation (58%) and should be treated as a valuable resource. In terms of feedstock or waste types, incineration stands out for its ability to process a wide range of waste types. Gasification and pyrolysis plants also hold promise for treating diverse waste types with fewer environmental impacts and lower costs than incineration, but they are less advanced. On the contrary, landfill gas and anaerobic digestion are more limited, unable to handle non-biodegradable materials such as plastics [107]. Notably, while waste-to-energy (WtE) technologies boast positive impacts, they also leave some negative footprints. For instance, the process of incinerating waste releases pollutants such as dioxins, furan, ash, and heavy metals, among others, jeopardizing land, water and air quality. Landfills, linked to WtE through gas recovery, pose concerns for soil and groundwater contamination. Other WtE technologies like anaerobic digestion, which is scientifically proven to be a more environmentally benign technology, have their negative aspects, including but not limited to methane emissions and odorous releases into the atmosphere. Gasification, converting waste to synthesis gas, reduces landfill waste but raises concerns about air pollution and methane emissions, akin to incineration [101,108,109].

3.6. WtE Technology Suitability Comparison for Ghana

In order to determine whether waste-to-energy (WtE) technologies are suitable for Ghana, we perform a comparative analysis that takes technical, financial, and environmental aspects into account. Our thorough review of the relevant Ghanaian literature focuses on articles that use a multicriteria decision model to select appropriate WtE technologies. This analysis reveals the expert-derived ranking of these technologies in Ghana, which is guided by a specific set of selection criteria and sub-criteria, as illustrated below:

The authors of [57] conducted a study in which they analysed the responses of 10 experts to determine the rankings of main and sub-criteria for the selection of WtE solutions for Ghana. The experts utilised geometric means to aggregate the data. The findings of the study indicate that environmental criteria received the highest ranking, with a weight of 0.549. This was followed by technical criteria, which had a weight of 0.241, and socioeconomic criteria, which had a weight of 0.21. This is in line with the prioritisation of environmental factors in waste-to-energy selection analysis, as supported by previous studies [43,110,111]. In order to determine the most suitable waste-to-energy (WtE) technology for the city of Accra, the authors of [57] utilised the analytical hierarchy process (AHP) methodology. This approach allowed them to evaluate four distinct WtE technologies, namely landfill biogas, incineration, anaerobic digestion, and aerobic composting. According to [57], the findings of the study indicate that biochemical waste-to-energy (WtE) technologies, specifically anaerobic digestion, demonstrate greater efficacy in the conversion of organic waste. Conversely, landfill biogas and incineration methods are found to be more appropriate for the treatment of mixed waste. In a related study, the fuzzy TOPSIS theory was utilised to assess the optimal waste-to-energy (WtE) technology for potential investment in Ghana [67]. The research examined four waste-to-energy (WtE) technologies, specifically gasification, anaerobic digestion, pyrolysis, and plasma arc gasification. The least desirable options are pyrolysis, anaerobic digestion and plasma arc gasification. The results, on the other hand, demonstrate that gasification is the most technologically and economically viable WtE technology for investment in Ghana. These results are in line with those of [77,112,113].

The research employed the weight attributions of five experts for ten criteria, encompassing initial investment, energy generation per annum, cost of electricity, operations and maintenance, generation capacity, levelized cost of electricity (LCOE), payback period, internal rate of return (IRR), net present value (NPV), and conversion efficiency. The five experts’ total weights for the criteria indicate that annual energy generation is the most important, followed by conversion efficiency, initial investment, operation and maintenance cost. The research also revealed a relatively high score on the economic parameters for initial investment, operation, and maintenance costs. Previous studies have documented comparable results across various studies conducted in diverse countries [114,115,116]. The authors of [58] identified multiple crucial determinants that influence the appropriateness of waste-to-energy (WtE) technology for the Kwanwoma township. Included in these are the required plant size, feedstock type, required input volume, and initial capital or setup expenses. The research findings suggest that a sanitary landfill with gas capture is the most suitable waste-to-energy technology for the Kwanwoma township. The aforementioned conclusion is derived from the advantageous attributes of possessing the most minimal initial expenses and the potential for expansion. In summary, the research indicates that the most suitable waste-to-energy (WtE) technology for the Kwanwoma township is a sanitary landfill equipped with gas capture. This choice is based on its cost-effectiveness and capacity for future growth, as supported by the findings of [117,118].

Overall, the review of the existing literature highlights the importance of considering several factors when choosing the most appropriate waste-to-energy (WtE) technology. These factors encompass initial capital investment, the type of feedstock, plant size, input volume, and, on a broader scale, environmental, technical, and economic criteria to secure long-term sustainability. It is clear that Ghana possesses the potential to embrace diverse waste-to-energy (WtE) technologies, including anaerobic digestion, gasification, and landfill gas.

3.7. Barriers to WtE Implementation in Developing Countries

Although waste-to-energy (WtE) technologies have been effectively adopted and implemented in certain developed nations, their utilization in developing countries is impeded by considerable challenges. The barriers encompass various dimensions, including logistical, financial, socio-environmental, technical and policy aspects [119]. In terms of logistics, inadequate waste collection infrastructure and a lack of source segregation are major logistical challenges in developing countries, including Ghana. Developing countries also have a scarcity of technical data on waste quantity and quality. Analysis of the waste composition, including physical and chemical properties, is critical for determining calorific value and moisture content, among other important properties of MSW feedstock [120]. It is important to note that waste characterization knowledge gaps can lead to mismatched equipment and WtE technology choices, wasting both resources and time [121,122,123]. Waste-to-energy projects present significant financial challenges for developing nations to overcome. Not only do such projects demand substantial upfront capital investments, but ongoing operational costs are also difficult to sustain. For example, in Malaysia, incinerator operations were halted due to high expenditures on fuel and maintenance [124]. Socio-environmental concerns also pose barriers, as public opposition stems from worries over pollution and land use [125]. On the policy front, waste-to-energy legislation in many developing countries remains inconsistent or lacking [97]. To reap the benefits of waste-to-energy, nations must address obstacles in the waste management sector. For instance, establishing strict tipping fees similar to the ones in developed nations could maximise diversion from landfills and ensure stable waste feedstock supply to WtE plants. Additionally, encouraging source-separated waste will improve calorific value while reducing the operating expenses of waste-to-energy plants. Additionally, expanding the technical analysis of existing waste streams, addressing financial and public concerns, and strengthening complementary policies aid in completing the framework for effective and sustainable deployment of waste-to-energy. Only through holistic solutions across interlinked challenges can waste-to-energy fulfil its potential to sustainably manage waste as a resource. Substantial coordination is required.

3.8. Policies on WtE in Ghana

The Ghanaian government is currently making notable progress in its shift from fossil fuels to renewable energy sources, a transition that is being facilitated by a variety of established policies and incentives. These initiatives exemplify the nation’s dedication to fostering the utilisation of renewable energy sources, such as waste-to-energy, thereby propelling the progress of sustainable development. Table 6 outlines some notable ways in which Ghana is advancing its renewable energy agenda.

Table 6.

Renewable energy policies and regulations in Ghana (author’s compilation).

Table 6 provides a concise overview of the policies, laws, ministries, and regulations that facilitate Ghana’s shift from fossil fuels to renewable energy sources. The primary objectives of the initiatives are to enhance the proportion of renewable energy sources within Ghana’s overall energy composition, facilitate the adoption of more efficient energy practices, and broaden the range of energy sources utilised in the country [126]. The Ghana National Energy Policy encompasses various chapters that address significant aspects such as the implementation of renewable energy, the management of waste-to-energy, and the promotion of energy efficiency. In a similar vein, the Renewable Energy Act encompasses provisions aimed at the advancement, administration, utilisation, and guarantee of sufficient and sustainable reservoirs of renewable energy for the purpose of electricity production and associated requirements. The Ghana Renewable Energy Policy Handbook serves as a comprehensive compendium of the primary policies that govern the renewable energy market in Ghana. The Ministry of Energy is responsible for the development and implementation of policies pertaining to the power and petroleum industries. Furthermore, the Energy Commission Act of 1997 (Act 541) and the Public Utilities Regulatory Commission Act of 1997 (Act 538) serve as regulatory frameworks that govern and oversee the utilisation of energy resources in Ghana while also facilitating the coordination of associated policies. The Renewable Energy Master Plan plays a pivotal role in delineating Ghana’s renewable energy objectives and strategic initiatives. The primary objective of the Energy Sector Strategy and Development Plan is to enhance the advancement of renewable energy sources and promote energy efficiency. Efforts such as the Sustainable Energy for All initiative and the Ghana Energy Development and Access Project aim to enhance access to sustainable energy sources and foster improved energy efficiency within the context of Ghana. Overall, while the existing policies and regulations on renewable energy (as shown in the table above) help enable renewable development, management, and use, there is no explicit guidance on policies or strategies for adopting and implementing waste-to-energy in Ghana. Notwithstanding this gap, the favourable policies for renewable energy overall provide an environment conducive to the growth of waste-to-energy alongside other renewables.

3.9. Incentives for Waste-to-Energy in Ghana

The Ghanaian government has set a target to attain a total of 1.4 gigawatts of installed capacity for renewable and clean energy by the year 2030 [126]. To support this ambitious target, a variety of incentives have been established to attract investors to the sector [32]. Renewable energy projects benefit from significant corporate tax reductions on profits, making these ventures more financially appealing. Generous feed-in tariffs that range from GHS 56 to 63 per kilowatt hour are also offered, with the feed-in tariff duration now extended from 10 to 20 years to provide greater security [127,128]. Import duties are waived on machinery and components imported for renewable and clean energy production [129]. Ghana’s investment laws further protect investors by guaranteeing the unfettered transfer of 100% of profits and dividends abroad [130]. While the current incentive landscape primarily focuses on attracting private investment into Ghana’s renewable energy sector, there are also various challenges, particularly in the realm of waste-to-energy (WtE). For instance, Ghana currently offers a 5% tax rate for renewable energy companies during their first five years of operation [131]. This incentive applies to WtE facilities, but its effectiveness is limited by the specific definition of “renewable energy.” Expanding the definition to explicitly include WtE under specific technological categories (e.g., advanced WtE with high energy recovery) could significantly boost its appeal [131]. Relatedly, high import duties on WtE equipment significantly increase project costs and hinder adoption. Implementing exemptions or reductions for WtE-specific equipment, similar to those existing for solar and wind technologies, could ease the financial burden and incentivize WtE investments [132]. In addition, value-added tax (VAT) exemptions on WtE electricity generation or energy could make it more competitive with traditional energy sources and encourage its utilization locally. Similarly, considering reduced VAT rates on WtE-derived products like recycled materials could incentivize resource recovery and circular economy practices [132]. Still on the topic of recommendations for optimizing WtE to encourage development, instead of a blanket 10-year exemption, the Ghanaian government could offer tax breaks tailored to different project stages, for example, exempt feasibility studies and pre-investment costs from corporate income tax to incentivize early-stage project development [133]. It could also introduce guaranteed feed-in tariffs for electricity generated from WtE plants, similar to those successfully implemented in countries like India and China [134].

Additionally, offering tax credits for WtE projects achieving specific environmental targets, like reducing greenhouse gas emissions or exceeding waste diversion quotas, would incentivize WtE investment in Ghana [129]. The enhancement of capital allowance mechanisms, thus modifying capital allowance schedules for WtE projects by allowing for accelerated depreciation of WtE equipment or upfront deductions of a larger portion of the capital expenditure to reduce the initial financial burden, would go a long way to attract investors [135]. Sections 8 to 24 of the Renewable Energy Act outline the steps for obtaining a license in the renewable energy (RE) industry. However, these procedures seem complex and bureaucratic [129]. For instance, after submitting a license application, the Energy Commission requires five working days to acknowledge receipt and sixty days to communicate their decision [129]. While theoretically justifiable, this lengthy and demanding process may discourage potential renewable energy investors due to substantial documentation and time constraints. Moreover, the regulatory frameworks and policies included in the Renewable Energy Act, such as the Renewable Energy Fund, net metering, Renewable Energy Purchase Obligation (REPO), and Renewable Energy Authority, are crucial for renewable energy development in Ghana, of which waste-to-energy is a part. However, their implementation and enforcement have been poorly executed, posing a severe challenge to the renewable energy subsector. Some, like the Renewable Energy Fund and Renewable Energy Authority, are yet to be implemented [136,137,138].

Additionally, the power distribution market in Ghana is dominated by state-owned institutions like the Volta River Authority (VRA), Electricity Company of Ghana (ECG), and Ghana Grid Company (GRIDCo). This dominance may lead them to initiate new renewable projects themselves or through their subsidiaries, rather than allowing new entrants like renewable energy independent power producers (RE IPPs) [137,139]. Furthermore, the renewable energy purchase obligation (REPO) mandates bulk customers to buy a portion of their electricity from renewable energy sources (RES) or pay a determined premium to the energy commission (Renewable Energy Act, 2011, sec.26(4) (a and b)). The Energy Commission and Public Utility and Regulatory Commission (PURC) are tasked with setting this percentage, but it remains undetermined. This raises questions about regulatory oversight or a preference for premium payments over purchase obligations, potentially hindering renewable electricity standard market growth and impacting renewable energy penetration in the electricity generation mix. As a recommendation, crucial policy reforms within the energy sector are necessary to eliminate monopolies, streamline duplicated roles, shorten waiting times for applicants, and enhance the enforcement of the provisions outlined in the Renewable Energy Act of 2011. These reforms would significantly contribute to the broader deployment and expansion of renewable energy initiatives such as waste-to-energy in Ghana.

4. A Business Case for WtE in Ghana

This section explores the potential cost savings associated with WtE in Ghana, specifically focusing on the comparison between WtE-generated biogas and traditional fossil fuel use for electricity generation.

Cost Analysis Assumptions:

- Daily Biogas Production: We assume a daily biogas production rate of 1,226,805 cubic meters (m3) based on [93].

- Natural Gas Cost: We consider the cost of biogas to be equivalent to natural gas, currently priced at USD 2.90 per 1000 cubic feet (ft3) (28.3 m3) as of 2022 [140].

Cost Comparison:

The current cost of generating electricity in Ghana using light crude oil (LCO) is estimated at USD 15 million monthly for a capacity of 200 MW, as reported by [141].

In contrast, utilizing biogas from WtE for the same power generation (200 MW) would incur a significantly lower cost. The following is a breakdown of the cost:

- Biogas Cost per Unit Volume: USD 2.90 per 1000 ft3 translates to USD 0.103 per cubic meter (m3) (considering conversion from ft³ to m3).

- Daily Biogas Cost: Daily biogas production (1,226,805 m³) multiplied by the cost per cubic meter (USD 0.103) results in USD 126,659.36.

- Monthly Biogas Cost for 79.5 MW: Assuming biogas can generate 79.5 MW, the monthly cost is USD 126,659.36 × 30 days = USD 3,799,780.80.

- Biogas Cost for 200 MW: Since 200 MW is 2.51 times greater than 79.5 MW, the cost for 200 MW is USD 3,799,780.80 × 2.51 = USD 9,539,461.98.

Potential Cost Savings:

The comparison reveals a significant cost advantage for WtE using biogas. Generating 200 MW with LCO costs USD 15,000,000, whereas biogas achieves the same output for USD 9,539,461.98. This translates to potential monthly savings of USD 5,460,538.20 for Ghana.

5. Conclusions

This study examined the topic of municipal waste management and investigated the potential for waste-to-energy (WtE) in Ghana. Over the course of time, there has been a consistent upward trajectory in the overall volume of waste produced, a pattern that is projected to endure due to the ongoing economic and demographic expansion of the country. The primary waste management strategy in Ghana is centred around the principles of waste reduction, reuse, and recycling. Non-reusable and non-recyclable waste is predominantly disposed of in open dumps and unengineered landfills. In order to tackle this challenge, the present study examines alternative technologies aimed at achieving more sustainable waste treatment practices, with a specific emphasis on waste-to-energy (WtE) solutions. The utilisation of waste-to-energy alternatives presents a compelling opportunity due to their capacity to yield environmental advantages and potentially mitigate the nation’s dependence on fossil fuels. The literature reviewed in this study highlights the significant energy potential within Ghana’s waste, which accounted for approximately 3.5% of the nation’s total electricity demand in 2016 and 1.9% of its overall electricity installed capacity. The article discusses and compares four key technologies: incineration, anaerobic digestion, gasification, and landfill gas, with a comprehensive examination encompassing environmental, economic, and technical aspects.

The findings confirm our initial hypothesis that anaerobic digestion is the most promising WtE option due to its ability to generate renewable energy, create valuable bio-products, and minimize greenhouse gas emissions compared to other WtE methods in Ghana. Our analysis also supports the hypothesis that utilizing biogas from WtE can be more cost-effective than relying on light crude oil for electricity generation.

The study also found that various geographic locations present distinct energy potential due to variations in municipal solid waste composition. Consequently, evaluating the calorific value of MSW in a specific metropolis is a crucial step in establishing a waste-to-energy (WtE) plant. Additionally, the findings indicate that Ghana is well-positioned to embrace and expand various waste-to-energy (WtE) technologies, including anaerobic digestion, gasification, and landfill gas. Regarding policy, although explicit information on regulations and incentives governing waste-to-energy implementation in Ghana is limited, the existing policies and laws related to renewable energy create an encouraging environment for the development, management, and utilisation of renewable energy sources, including waste-to-energy technologies. Nevertheless, further research is essential to understand why Ghana’s renewable energy agenda has remained primarily on the policy agenda with minimal practical implementation.

Author Contributions

Conceptualisation, A.-W.T. and W.A.; methodology, S.J.C., W.A. and A.-W.T.; validation, A.-W.T., S.J.C., W.A. and S.U.T.; writing—original draft preparation, S.U.T., A.-W.T. and W.A.; writing—review and editing, A.-W.T. and W.A.; visualisation, A.-W.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank everyone who has contributed to improving the quality of this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Cerqueti, R.; Cinelli, M.; Minervini, L.F. Municipal waste management: A complex network approach with an application to Italy. Waste Manag. 2021, 126, 597–607. [Google Scholar] [CrossRef] [PubMed]

- Iyamu, H.O.; Anda, M.; Ho, G. A review of municipal solid waste management in the BRIC and high-income countries: A thematic framework for low-income countries. Habitat Int. 2020, 95, 102097. [Google Scholar] [CrossRef]

- Wan, C.; Shen, G.Q.; Choi, S. Waste management strategies for sustainable development. In Encyclopedia of Sustainability in Higher Education; Springer International Publishing: Cham, Switzerland, 2019; pp. 2020–2028. [Google Scholar]

- Woon, K.S.; Phuang, Z.X.; Lin, Z.; Lee, C.T. A novel food waste management framework combining optical sorting system and anaerobic digestion: A case study in Malaysia. Energy 2021, 232, 121094. [Google Scholar] [CrossRef]

- Obaideen, K.; Abdelkareem, M.A.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Maghrabie, H.M.; Olabi, A.G. Biogas role in achievement of the sustainable development goals: Evaluation, Challenges, and Guidelines. J. Taiwan Inst. Chem. Eng. 2022, 131, 104207. [Google Scholar] [CrossRef]

- Ikhlayel, M. An integrated approach to establish e-waste management systems for developing countries. J. Clean. Prod. 2018, 170, 119–130. [Google Scholar] [CrossRef]

- Tahirua, A.W.; Cobbina, S.J.; Asare, W. Unlocking the Renewable Energy Potential in Developing Countries: The Case of Ghana. In Proceedings of the Africa International Conference on Clean Energy and Energy Storage, online, 23–24 November 2023. [Google Scholar]

- Ardra, S.; Barua, M.K. Halving food waste generation by 2030: The challenges and strategies of monitoring UN sustainable development goal target 12.3. J. Clean. Prod. 2022, 380, 135042. [Google Scholar] [CrossRef]

- He, J.; Yang, Y.; Liao, Z.; Xu, A.; Fang, K. Linking SDG 7 to assess the renewable energy footprint of nations by 2030. Appl. Energy 2022, 317, 119167. [Google Scholar] [CrossRef]

- Beyene, H.D.; Werkneh, A.A.; Ambaye, T.G. Current updates on waste to energy (WtE) technologies: A review. Renew. Energy Focus 2018, 24, 1–11. [Google Scholar] [CrossRef]

- Boakes, E.; Voogd, J.; Wauters, G.; Caneghem, J. The influence of energy output and substitution on the environmental impact of waste-to-energy operation: Quantification by means of a case study. Clean Technol. Environ. Policy 2021, 25, 253–267. [Google Scholar] [CrossRef]

- Ali, J.; Rasheed, T.; Afreen, M.; Anwar, M.T.; Nawaz, Z.; Anwar, H.; Rizwan, K. Modalities for conversion of waste to energy—Challenges and perspectives. Sci. Total Environ. 2020, 727, 138610. [Google Scholar] [CrossRef]

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H. Perspective review on Municipal Solid Waste-to-energy route: Characteristics, management strategy, and role in circular economy. J. Clean. Prod. 2022, 359, 131897. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Liang, X.; O’Callaghan, E.; Goh, H.; Othman, M.H.D.; Avtar, R.; Kusworo, T.D. Transformation of solid waste management in China: Moving towards sustainability through digitalization-based circular economy. Sustainability 2022, 14, 2374. [Google Scholar] [CrossRef]

- Gómez-Sanabria, A.; Kiesewetter, G.; Klimont, Z.; Schoepp, W.; Haberl, H. Potential for future reductions of global GHG and air pollutants from circular waste management systems. Nat. Commun. 2022, 13, 106. [Google Scholar] [CrossRef]

- Lima, M.A.; Mendes, L.F.R.; Mothé, G.A.; Linhares, F.G.; de Castro, M.P.P.; Da Silva, M.G.; Sthel, M.S. Renewable energy in reducing greenhouse gas emissions: Reaching the goals of the Paris agreement in Brazil. Environ. Dev. 2020, 33, 100504. [Google Scholar] [CrossRef]

- Abbasi, S.A.; Harijan, K.; Khan, M.W.A.; Mengal, A.; Shaikh, F.; Memon, Z.A.; Mirjat, N.H.; Kumar, L. Long-term optimal power generation pathways for Pakistan. Energy Sci. Eng. 2021, 9, 2252–2267. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Wu, F. Research on carbon emission reduction benefit of wind power project based on life cycle assessment theory. Renew. Energy 2020, 155, 456–468. [Google Scholar] [CrossRef]

- Tahiru, A.W.; Takal, S.U.; Sunkari, E.D.; Ampofo, S. A Review on Renewable Energy Scenario in Ethiopia. Iran. (Iran.) J. Energy Environ. 2023, 14, 372–384. [Google Scholar] [CrossRef]