Wettability’s Challenge to High-Voltage Insulators: Polyurethane as Preventive Coating

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Material

2.1.1. Polyurethane

2.1.2. Application Process

2.2. Finite Element Method (FEM)

2.3. Flashover Testing

3. Results and Discussion

3.1. Simulations for Electric Field Distribution

3.1.1. Dry Condition

3.1.2. Wet Condition

- (I)

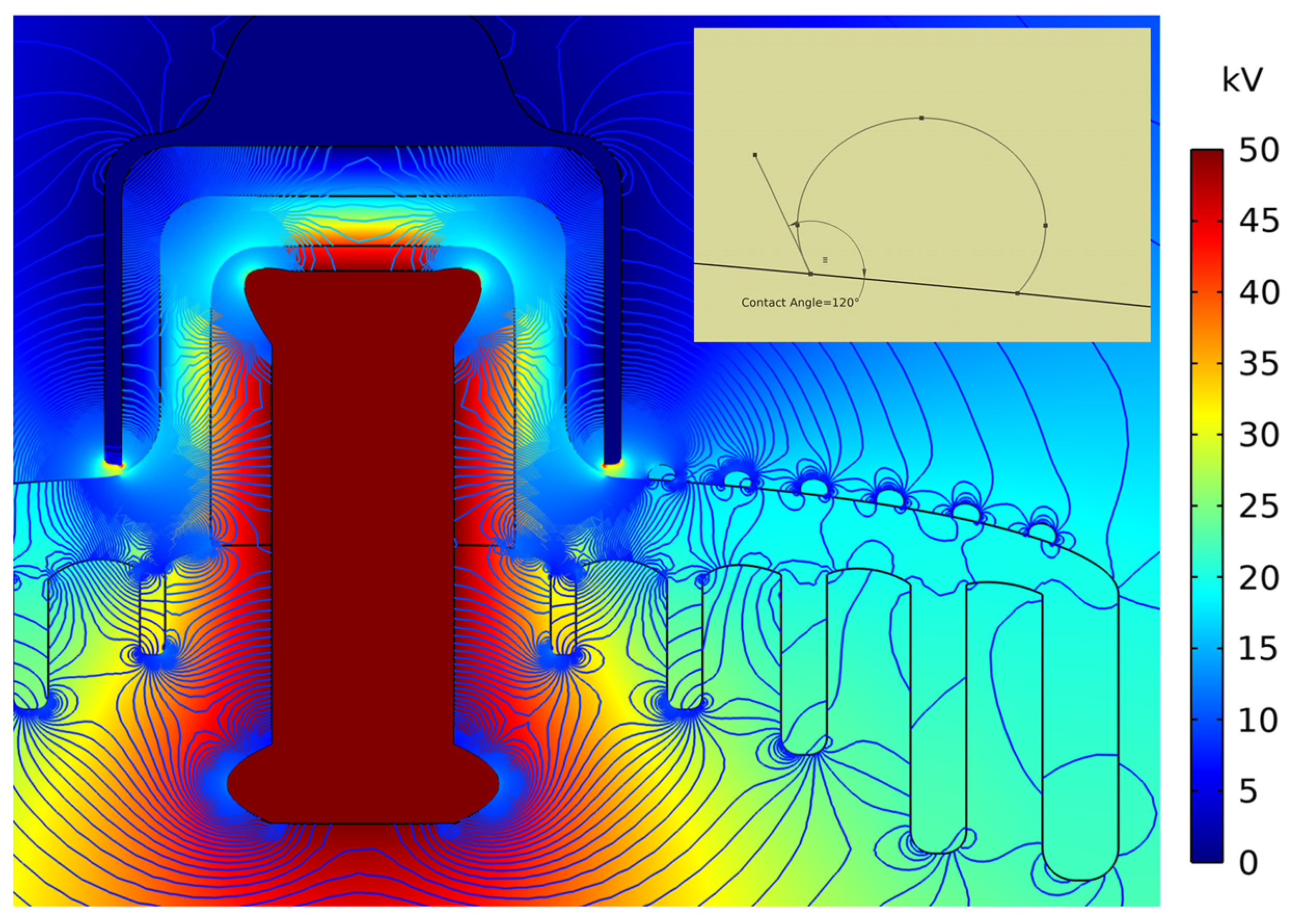

- Hydrophobic case: The contact angle of the water droplets has now been changed to , resembling a hydrophobic case, as shown in Figure 12, where voltage distribution is indicated through varying colors and electric field patterns are indicated through lines. As discussed in Section 1, referring to Figure 1b, the water droplet splits over the surface with a low contact angle, and it tends to be spherical when the contact angle is high (approaching to ); however, its volume remains the same. In 2D geometry, volume cannot be modeled; thus, the area of the shape has been kept the same.The shape of the water droplets changes, as does the electric field around them. Electric field distribution has been plotted along the outer surface, as shown in Figure 13, where it can be seen that the curve is still distorted; however, the peaks have been narrowed down. The magnified first peak is shown at the top right corner, where the reduction in width is evident, i.e., 0.835 cm. Though the amplitude of the first peak is bit higher, the overall stress (average) is reduced to 2.425 kV/cm, compared with 2.588 kV/cm for the hydrophilic surface (Table 3). The maximum value of the curve (at the start of the curve) also has a declining pattern, as can be seen in Table 3. Average values have been measured using a measuring probe in the software, which traverses the predefined path and integrates the data then dividesby the path length; thus, the unit remains same i.e: kV/cm. The maximum values presented in Table 3 refer to the highest point on entire curve that appearsat the beginning of the curve the region closer to center, in the vicinity of first droplet It was noted that the values decreased with the increase in contact angle.

- (II)

- Strongly hydrophobic case: The water droplets tend to be more sphere-shaped with a higher contact angle of the hydrophobic surface and have a tendency to roll off from the surface, making it dry before too long [10,11,74]. It has been noted elsewhere that a contact angle of polyurethane up to 140 is achievable [30]. Here, an example of strongly hydrophobicity, with a contact angle of , where the voltage distribution is shown through colors and the lines represent electric field patterns, has been simulated for the worst-case scenario with the droplets still present on the surface, as illustrated in Figure 14.Referring to Figure 15, the electric field plot for the strongly hydrophobic case still shows distortion; however, peaks have been further narrowed down. The magnified first peak (the top right corner of Figure 15) shows a width reduction to 0.719 cm, and overall stress is noted to be 2.412 kV/cm (Table 3), making this case better than that of the and cases.Maximum values are indeed observed to decline with higher contact angles, showing less accumulation of field lines in the vicinity of the water droplet for the higher contact angle. This is mainly due to the fact that water droplets spread more on hydrophilic surfaces, while in case of hydrophobic surfaces, water droplets tend to be spherical in shape, resulting in a smaller contact area.

3.2. Simulations for Current Density

3.3. Polyurethane as a Remedial Coating

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lan, L.; Zhang, G.; Wang, Y.; Wen, X.; Wang, W.; Pei, H. The Influence of Natural Contamination on Pollution Flashover Voltage Waveform of Porcelain Insulators in Heavily Polluted Area. IEEE Access 2019, 7, 121395–121406. [Google Scholar] [CrossRef]

- Salem, A.A.; Lau, K.Y.; Rahiman, W.; Abdul-Malek, Z.; Al-Gailani, S.A.; Mohammed, N.; Rahman, R.A.; Al-Ameri, S.M. Pollution Flashover Voltage of Transmission Line Insulators: Systematic Review of Experimental Works. IEEE Access 2022, 10, 10416–10444. [Google Scholar] [CrossRef]

- Topalis, F.V.; Gonos, I.F.; Stathopulos, I.A. Dielectric Behavior of Polluted Porcelain Insulators. IEE Proc. Gener. Transm. Distrib. 2001, 148, 269. [Google Scholar] [CrossRef]

- Jiang, X.; Yuan, J.; Zhang, Z.; Hu, J.; Sun, C. Study on AC Artificial-Contaminated Flashover Performance of Various Types of Insulators. IEEE Trans. Power Deliv. 2007, 22, 2567–2574. [Google Scholar] [CrossRef]

- Yang, Z.; Jiang, X.; Han, X.; Zhang, Z.; Hu, J. Influence of Pollution Chemical Components on AC Flashover Performance of Various Types of Insulators. High Voltage 2019, 4, 105–112. [Google Scholar] [CrossRef]

- Khatoon, S.; Khan, A.A.; Sharma, A. Study the effect of contaminants on flashover performance of porcelain disc insulator by artificial pollution testing. In Proceedings of the 2016 International Conference on Recent Advances and Innovations in Engineering (ICRAIE), Jaipur, India, 23–25 December 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Gencoglu, M.T.; Cebeci, M. The Pollution Flashover on High Voltage Insulators. Electr. Power Syst. Res. 2020, 181, 106180. [Google Scholar]

- Salem, A.A.; Rahman, R.A.; Al-Ameri, S. Pollution Flashover Characteristics of High-Voltage Outdoor Insulators: Analytical Study. Arabian J. Sci. Eng. 2021, 47, 2711–2729. [Google Scholar] [CrossRef]

- Cui, L.; Ramesh, M. Prediction of flashover voltage using electric field measurement on clean and polluted insulators. Int. J. Electr. Power Energy Syst. 2020, 116, 105574. [Google Scholar] [CrossRef]

- Shirtcliffe, N.J.; McHale, G.; Atherton, S.; Newton, M.I. An introduction to superhydrophobicity. Adv. Colloid Interface Sci. 2010, 161, 124–138. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C. Wetting, adhesion and friction of superhydrophobic and hydrophilic leaves and fabricated micro/nanopatterned surfaces. J. Phys. Condens. Matter 2008, 20, 225010. [Google Scholar] [CrossRef]

- Koch, K.; Bhushan, B.; Barthlott, W. Diversity of Structure, Morphology and Wetting of Plant Surfaces. Soft Matter 2008, 4, 1943–1963. [Google Scholar] [CrossRef]

- Drelich, J.; Marmur, A. Physics and Applications of Superhydrophobic and Superhydrophilic Surfaces and Coatings. Surf. Innov. 2014, 2, 211–227. [Google Scholar] [CrossRef]

- Farzane, M.; Chisholm, W.A. Protective Coatings for Overhead Lines in Winter Conditions. In Techniques for Protecting Overhead Lines in Winter Conditions; Springer: Berlin/Heidelberg, Germany, 2022; pp. 195–309. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Nguyen, T.A.; Nguyen, T.H. The Synergistic Effects of SiO2 Nanoparticles and Organic Photostabilizers for Enhanced Weathering Resistance of Acrylic Polyurethane Coating. J. Compos. Sci. 2020, 4, 23. [Google Scholar] [CrossRef]

- Aman, A.; Abdullah, A.R.; Yaacob, M.M. Dielectric Property of Waste Tire Dust Polypropylene (WTD-PP) Composite for High Voltage Outdoor Insulation Application. In Proceedings of the IEEE International Power Engineering and Optimization Conference (PEOCO 2012), Melaka, Malaysia, 6–7 June 2012. [Google Scholar]

- Sawane, Y.B.; Ogale, S.B.; Banpurkar, A.G. Low Voltage Electrowetting on Ferroelectric PVDF-HFP Insulator with Highly Tunable Contact Angle Range. ACS Appl. Mater. Interfaces 2016, 8, 24049–24056. [Google Scholar] [CrossRef]

- Xia, Y.; Chen, J.; Zhu, Z.; Zhang, Q.; Yang, H.; Wang, Q. Significantly Enhanced Dielectric and Hydrophobic Properties of SiO2@MgO/PMMA Composite Films. RSC Adv. 2018, 8, 4032. [Google Scholar] [CrossRef]

- Ahmadi-Joneidi, I.; Majzoobi, A.; Shayegani-akmal, A.A.; Mohseni, H.; Jadidian, J. Aging Evaluation of Silicone Rubber Insulators Using Leakage Current and Flashover Voltage Analysis. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 212–220. [Google Scholar] [CrossRef]

- Cardoso, R.; Balestro, A.C.; Dellallibera, A.; Costa, E.C.M.; Angelini, J.M.G.; Mei, L.H.I. Silicone Insulators of Power Transmission Lines with a Variable Inorganic Load Concentration: Electrical and Physiochemical Analyses. Measurement 2014, 50, 63–73. [Google Scholar] [CrossRef]

- Othman, N.A.; Piah, M.A.M.; Adzis, Z. Contamination Effects on Charge Distribution Measurement of High Voltage Glass Insulator String. Measurement 2017, 105, 34–40. [Google Scholar] [CrossRef]

- Verma, A.R.; Subba Reddy, B. Interpretation of Surface Degradation on Polymeric Insulators. Eng. Failure Anal. 2019, 95, 214–225. [Google Scholar] [CrossRef]

- Mahmoodi, J.; Mirzaie, M.; Shayegani-Akmal, A.A. Surface Charge Distribution Analysis of Polymeric Insulator Under AC and DC Voltage Based on Numerical and Experimental Tests. Int. J. Electr. Power Energy Syst. 2019, 105, 283–296. [Google Scholar] [CrossRef]

- Al-Karawi, S.; Al-Taie, A. Insulators Used in Outdoor Power Applications: Materials and Coatings. In Proceedings of the 2023 6th International Conference on Engineering Technology and its Applications (IICETA), Al-Najaf, Iraq, 15–16 July 2023; IEEE: Piscataway, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Küchler, A. High Voltage Engineering: Fundamentals—Technology—Applications; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Zhang, Z.; Du, J.; Li, J.; Huang, X.; Kang, T.; Zhang, C.; Wang, S.; Ajao, O.O.; Wang, W.-J.; Liu, P. Polymer Nanocomposites with Aligned Two-Dimensional Materials. Prog. Polym. Sci. 2021, 114, 101360. [Google Scholar] [CrossRef]

- Lan, L.; Gorur, R. Computation of AC Wet Flashover Voltage of Ceramic and Composite Insulators. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1346–1352. [Google Scholar] [CrossRef]

- Bala, P.; Bose, R.; Chatterjee, S. Electric Stress Analysis of a 11kV RTV Silicone Rubber Coated Porcelain Insulator. In Proceedings of the 2016 Biennial International Conference on Power and Energy Systems: Towards Sustainable Energy (PESTSE), Bangalore, India, 21–23 January 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Allahdini, A.; Momen, G.; Munger, F.; Brettschneider, S.; Fofana, I.; Jafari, R. Performance of a Nanotextured Superhydrophobic Coating Developed for High-Voltage Outdoor Porcelain Insulators. Colloids Surf. A Physicochem. Eng. Asp. 2022, 649, 129461. [Google Scholar] [CrossRef]

- Gu, X.; Gao, T.; Meng, X.; Zhu, Y.; Wang, G. Enhanced Hydrophobicity of Polyurethane with the Self-Assembly of Perfluoropolyether-Based Triblock Copolymers. Prog. Org. Coat. 2022, 163, 106561. [Google Scholar] [CrossRef]

- De Souza, F.M.; Kahol, P.K.; Gupta, R.K. Introduction to Polyurethane Chemistry. In Polyurethane Chemistry: Renewable Polyols and Isocyanates; American Chemical Society: Washington, DC, USA, 2021; pp. 1–24. [Google Scholar]

- Kausar, A. Polyurethane Nanocomposite Coatings: State of the Art and Perspectives. Polym. Int. 2018, 67, 1470–1477. [Google Scholar] [CrossRef]

- John, K.; Naidu, S.V. Sisal Fiber/Glass Fiber Hybrid Composites: The Impact and Compressive Properties. J. Reinf. Plast. Compos. 2004, 23, 1253–1258. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Q.; Fu, L.; Shen, G.; Zhang, W.; Yang, R.; Sun, K.; Lv, F.; Fan, S. Superhydrophobic Meta-Aramid Papers Prepared by the Surface-Embedded Spray Coating Strategy. Appl. Surf. Sci. 2023, 648, 159044. [Google Scholar] [CrossRef]

- Liu, B.; Lv, F.; Fan, X.; Li, Y.; Jiang, B. Molecular Dynamics Study of the Influence of Nano SiO2 on the Thermodynamic Properties of PMIA Composites. Polymers 2022, 14, 3134. [Google Scholar] [CrossRef]

- Liu, B.; Lv, F.; Fan, X.; Xiao, H.; Bi, H. Insulation Performance and Simulation Analysis of SiO2-Aramid Paper under High-Voltage Bushing. Nanomaterials 2022, 12, 748. [Google Scholar] [CrossRef]

- Biesuz, M.; Tomasi, M.; Santhosh, B.; Sglavo, V.M.; Sorarù, G.D. Polymer-Derived Si3N4 Nanofelts as a Novel Oil Spills Clean-Up Architecture. J. Environ. Chem. Eng. 2020, 8, 104134. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, P.; Tanaka, T. A Review of Dielectric Polymer Composites with High Thermal Conductivity. IEEE Electr. Insul. Mag. 2011, 27, 8–16. [Google Scholar] [CrossRef]

- Matsunaga, C.; Zhou, Y.; Kusano, D.; Hyuga, H.; Hirao, K. Dielectric Breakdown of Silicon Nitride Substrates with Various Thicknesses. J. Ceram. Soc. Jpn. 2018, 126, 693–698. [Google Scholar] [CrossRef]

- Feoktistov, D.V.; Kuznetsov, G.V.; Sivkov, A.A.; Ivashutenko, A.S.; Nikitin, D.S.; Shanenkov, I.I.; Abdelmagid, A.M.; Orlova, E.G. Expanding the Scope of SiC Ceramics through Its Surface Modification by Different Methods. Surf. Coat. Technol. 2022, 435, 128263. [Google Scholar] [CrossRef]

- Han, Y.; Wang, Z.; Sun, J.; Li, Z. Enhanced Switching Electric Field and Breakdown Strength of Epoxy Composites with Core-Shell Silicon Carbide Nanoparticles. High Voltage 2023, 8, 583–589. [Google Scholar] [CrossRef]

- Jayasinghe, S.N.; Edirisinghe, M.J. Effect of Viscosity on the Size of Relics Produced by Electrostatic Atomization. J. Aerosol Sci. 2002, 33, 1379–1388. [Google Scholar] [CrossRef]

- Qasim, S.A.; Gupta, N. Comparison of the Dielectric Properties of Functionally Graded Material Dielectrics and Layered Dielectrics Used for Electric Stress Control. IET Sci. Meas. Technol. 2020, 14, 471–477. [Google Scholar] [CrossRef]

- Rachmawati, N.; Kojima, H.; Hayakawa, N.; Kato, K.; Zebouchi, N. Electric Field Simulation of Permittivity and Conductivity Graded Materials (ε/σ-FGM) for HVDC GIS Spacers. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 736–744. [Google Scholar] [CrossRef]

- Zaputra, S.; Fabio, M.R.; Hidayat, S. Application of Non-Linear Discrete Spatial Permittivity Distributions in Reducing Electric Field Concentration in GIS Spacer. In Proceedings of the 2023 4th International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Denpasar Bali, Indonesia, 6–10 August 2023; pp. 717–721. [Google Scholar] [CrossRef]

- Peng, S.; Iroh, J.O. Dependence of the Dynamic Mechanical Properties and Structure of Polyurethane-Clay Nanocomposites on the Weight Fraction of Clay. J. Compos. Sci. 2022, 6, 173. [Google Scholar] [CrossRef]

- Zafar, F.; Sharmin, E. Polyurethane/Monograph; Intech: Rijeka, Croatia, 2012. [Google Scholar]

- Moody, V.; Needles, H.L. Polyurethane Coating. In Tufted Carpet; Elsevier: Amsterdam, The Netherlands, 2004; pp. 105–108. [Google Scholar] [CrossRef]

- Sonnenschein, M.F. Introduction to Polyurethane Chemistry. In Polyurethanes; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 105–126. [Google Scholar] [CrossRef]

- Barksby, N.; Dormish, J.F.; Haider, K.W. Polyurethane Synthesis. In Encyclopedia of Polymeric Nanomaterials; Kobayashi, S., Müllen, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Dong, B.; Jiang, X.; Hu, J.; Shu, L.; Sun, C. Effects of Artificial Polluting Methods on AC Flashover Voltage of Composite Insulators. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 714–722. [Google Scholar] [CrossRef]

- Balakrishnan, A.; Saha, M.C. Influence of Air-Draft on Fabrication of Polyurethane Thin Films via Ultrasonic Atomization. At. Sprays 2012, 22, 23–35. [Google Scholar] [CrossRef]

- High Voltage Insulator Coatings: State of the Art & Future Development. INMR. Available online: https://www.inmr.com/high-voltage-insulator-coatings-state-of-the-art-future-development/ (accessed on 13 January 2025).

- Courant, R. Variational Methods for the Solution of Problems of Equilibrium and Vibrations. Bull. Am. Math. Soc. 1943, 49, 1–24. [Google Scholar] [CrossRef]

- Silvester, P. Finite Element Solution of Homogeneous Waveguide Problems. Alta Freq. 1969, 38, 313–317. [Google Scholar]

- Inoue, K.; Hayata, K.; Koshiba, M. Finite-Element Solution of Three-Dimensional Periodic Waveguide Problems. Electron. Commun. Jpn. Part II Electron. 1989, 72, 68–77. [Google Scholar] [CrossRef]

- Axelsson, O.; Barker, V.A. The Finite Element Method. In Finite Element Solution of Boundary Value Problems; SIAM: Philadelphia, PA, USA, 2001; pp. 163–267. [Google Scholar] [CrossRef]

- Gokhale, N.S. Practical Finite Element Analysis; Finite To Infinite: Maharashtra, India, 2020. [Google Scholar]

- Jin, J.-M. Finite Element Method in Electromagnetics; Wiley Sons, Inc., John: Hoboken, NJ, USA, 2014. [Google Scholar]

- Sastry, S.S. Introductory Methods of Numerical Analysis; Prentice Hall India Pvt., Ltd.: New Delhi, India, 2012. [Google Scholar]

- Rao, S.S. Finite Element Method in Engineering; Elsevier Science and Technology Books: Cambridge, MA, USA, 2017. [Google Scholar]

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method: Its Basis and Fundamentals, 7th ed.; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Arora, R.; Mosch, W. High Voltage and Electrical Insulation Engineering, 2nd ed.; IEEE Press: Piscataway, NJ, USA; Wiley: Hoboken, NJ, USA, 2022. [Google Scholar]

- Polycarpou, A.C. Introduction to the Finite Element Method in Electromagnetics; Springer Nature: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- IEC 60060-1:2025; High-Voltage Test Techniques—Part 1: General Terminology and Test Requirements, 4th ed. International Electrotechnical Commission: Geneva, Switzerland, 2025.

- Pei, S.; Liu, Y.; Ji, X.; Geng, J.; Zhou, G.; Wang, S. UV-Flashover Evaluation of Porcelain Insulators Based on Deep Learning. IET Sci. Meas. Technol. 2018, 12, 770–776. [Google Scholar] [CrossRef]

- Klüss, J.; Bichik, A.; Arshad, A.; Strandberg, J.; Kazmi, S.; Laiho, M.; Stark, T.; Panchal, J.; Ahmad, B.; Väkeväinen, K. Simulation Precision and the Human Factor. In Proceedings of the 24th Nordic Insulation Symposium on Materials, Components and Diagnostics, Copenhagen, Denmark, 15–17 June 2015. [Google Scholar] [CrossRef][Green Version]

- Meyer, K.; Erdogmus, E.; Morcous, G.; Naughtin, M. Use of Ground Penetrating Radar for Accurate Concrete Thickness Measurements. In Proceedings of the AEI 2008 Conference—AEI 2008: Building Integration Solutions, Denver, CO, USA, 24–27 September 2008; Volume 328, pp. 1–10. [Google Scholar] [CrossRef]

- Archer, G.G.; Wang, P. The Dielectric Constant of Water and Debye-Hückel Limiting Law Slopes. J. Phys. Chem. Ref. Data 1990, 19, 371–411. [Google Scholar] [CrossRef]

- Ellison, W.J. Permittivity of Pure Water, at Standard Atmospheric Pressure, over the Frequency Range 0–25THz and the Temperature Range 0–100 °C. J. Phys. Chem. Ref. Data 2007, 36, 1–18. [Google Scholar] [CrossRef]

- Jones, R.G. Measurements of the Electrical Conductivity of Water. IEE Proc. Sci. Meas. Technol. 2002, 149, 320–322. [Google Scholar] [CrossRef]

- Lekouch, I.; Mileta, M.; Muselli, M.; Milimouk-Melnytchouk, I.; Šojat, V.; Kabbachi, B.; Beysens, D. Comparative Chemical Analysis of Dew and Rain Water. Atmos. Res. 2010, 95, 224–234. [Google Scholar] [CrossRef]

- Huhtamäki, T.; Tian, X.; Korhonen, J.; Ras, R.H.A. Surface-Wetting Characterization Using Contact-Angle Measurements. Nat. Protoc. 2018, 13, 1521–1538. [Google Scholar] [CrossRef]

- Danish, M. Contact Angle Studies of Hydrophobic and Hydrophilic Surfaces. In Handbook of Magnetic Hybrid Nanoalloys and their Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2022; pp. 761–782. [Google Scholar] [CrossRef]

- Chaudhuri, S.P.; Sarkar, P.; Chakraborty, A.K. Electrical Resistivity of Porcelain in Relation to Constitution. Ceram. Int. 1999, 25, 91–99. [Google Scholar] [CrossRef]

- Kamsali, N.; Prasad, B.S.N.; Datta, J.; Nejadkoorki, F. The Electrical Conductivity as an Index of Air Pollution in the Atmosphere. In Advanced Air Pollution; Springer: Berlin/Heidelberg, Germany, 2011; pp. 365–390. [Google Scholar]

- Su, J.; Yang, C.; Wu, W.; Huang, R. Effect of Moisture Content on Concrete Resistivity Measurement. J. Chin. Inst. Eng. 2002, 25, 117–122. [Google Scholar] [CrossRef]

- National Nondestructive Testing Education Center. Copper Properties. In NDT Techniques: Eddy Current. Available online: https://www.nde-ed.org/NDETechniques/EddyCurrent/ET_Tables/ET_matlprop_Copper.xhtml (accessed on 13 January 2025).

| Sr. | Material | Hydrophobicity | Thermal Conductivity (Wm−1K−1) | Relative Permittivity | Density (g/cm3) | Breakdown Strength (kV/mm) |

|---|---|---|---|---|---|---|

| 1 | Polyurethane | [30] | 0.16–0.2 [31] | 5–6.5 [32] | 1.125 [32] | 15.75–19.7 [33] |

| 2 | PMIA Paper (with Nano-SiO2) | [34] | 0.396 [35] | 2.9–4.4 [36] | 0.6 [35] | 35 [34] |

| 3 | Silicon Nitride (Si3N4) | [37] | 86–120 [38] | 7.5–8.3 [18] | 3.17 [38] | 18 [39] |

| 4 | Silicon Carbide (SiC) | [40] | ~85 [38] | ~6.5 [38] | 3.21 [38] | 8–14 [41] |

| Sr.# | Properties | Values |

|---|---|---|

| 1 | Specific gravity | 1.1–1.46 |

| 2 | Tensile strength | 18 MPa |

| 3 | Tensile modulus | 0.8–1.1 GPa |

| 4 | Compressive strength | 90–250 MPa |

| 5 | Dielectric strength | 400–500 volt/mil (15.75–19.7) kV/mm |

| Sr. | Case | Wettability | Electric Field | |

|---|---|---|---|---|

| Maximum (kV/cm) | Average (kV/cm) | |||

| 1 | Hydrophilic | Contact Angle: | 53.301 | 2.588 |

| 2 | Hydrophobic | Contact Angle: | 52.708 | 2.425 |

| 3 | Strongly Hydrophobic | Contact Angle: | 51.527 | 2.412 |

| Sr. | Case | Wettability | Current Density | |

|---|---|---|---|---|

| Average (nA/cm2) | Maximum (nA/cm2) | |||

| 1 | Hydrophilic | Contact Angle: | 0.004248 | 0.18743 |

| 2 | Hydrophobic | Contact Angle: | 0.003481 | 0.07807 |

| 3 | Strongly Hydrophobic | Contact Angle: | 0.003174 | 0.06768 |

| Insulator | AC Flashover Voltage Dry (kV) | AC Flashover Voltage Wet (kV) | ||

|---|---|---|---|---|

| Uncoated | 79.14 kV | 1.2 | 48.4 kV | 1.4 |

| Coated | 82.04 kV | 1.3 | 53.8 kV | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raza, T.A.; Kamran, M.; Shah, S.A.M.; Bashir, M.M. Wettability’s Challenge to High-Voltage Insulators: Polyurethane as Preventive Coating. Surfaces 2025, 8, 40. https://doi.org/10.3390/surfaces8020040

Raza TA, Kamran M, Shah SAM, Bashir MM. Wettability’s Challenge to High-Voltage Insulators: Polyurethane as Preventive Coating. Surfaces. 2025; 8(2):40. https://doi.org/10.3390/surfaces8020040

Chicago/Turabian StyleRaza, Touqeer Ahmad, Muhammad Kamran, Syed Ahtisham Mehmood Shah, and Muhammad Mehran Bashir. 2025. "Wettability’s Challenge to High-Voltage Insulators: Polyurethane as Preventive Coating" Surfaces 8, no. 2: 40. https://doi.org/10.3390/surfaces8020040

APA StyleRaza, T. A., Kamran, M., Shah, S. A. M., & Bashir, M. M. (2025). Wettability’s Challenge to High-Voltage Insulators: Polyurethane as Preventive Coating. Surfaces, 8(2), 40. https://doi.org/10.3390/surfaces8020040