Abstract

This study reports the discovery, contextualization, and archaeometric analysis of a unique metal pilgrim flask recovered from the sacred well of Santa Cristina (Paulilatino, Sardinia, Italy), a major sanctuary complex of the Nuragic period. Misidentified for several decades following its 20th-century excavation, the object has now been reinterpreted as a nearly intact, full-scale pilgrim flask manufactured from pewter—a material previously unrecorded in Sardinian protohistoric contexts. Typological comparison with related artefacts from the Levant, Cyprus, and Etruria reveals close formal and morphological affinities with Sardinian ceramic flasks and, in particular, with miniature bronze flasks documented in Nuragic and Villanovan assemblages. The morphological congruence suggests that the Santa Cristina vessel may have functioned as a prototype or symbolic referent for these miniature exemplars. The associated presence of eastern Mediterranean-style figurines and other imported materials further underscores the sanctuary’s involvement in elite ritual practices and participation in long-distance exchange networks. From a technological perspective, selected areas of the vessel were investigated using non-destructive Energy-Dispersive X-Ray Fluorescence (EDXRF) analysis, supported by Monte Carlo simulation of the in situ measurements, and External Reflectance Fourier-Transform Infrared (ER-FTIR) spectroscopy. The combined results indicate a pewter alloy characterized by elevated tin and lead contents, confirming the object’s exceptional technological status within the Sardinian protohistoric metallurgical repertoire.

1. Introduction

In 2003, the archaeological collections from the excavations of the sacred well of Santa Cristina at Paulilatino (Oristano, Sardinia) were returned to local custody. These materials, removed in the late 1960s, had been stored in approximately thirty crates and derive from the excavation campaigns directed by Enrico Atzeni between 1967 and 1983. The assemblage is dominated by ceramic materials but also includes numerous fragments of metal artefacts. Several complete objects—such as bronze statuettes, fibulae, and ornaments—had previously been transferred to the Superintendence of Cagliari for conservation.

Among the materials re-examined during the 2003 reassessment was a metal vessel that had long been overlooked. At the time of its discovery, the artifact attracted little attention, likely because it was hastily identified as a modern military canteen. However, a detailed analysis of its morphology, manufacturing technique, and the associated materials recovered from the same ritual context has led to a new interpretation and chronological reassessment, as proposed in this study.

The vessel’s shape closely resembles that of a remarkably well-preserved pilgrim flask, a type well documented in protohistoric contexts, including in Sardinia. Its manufacture by means of the lost-wax casting technique aligns with the well-established Sardinian metallurgical tradition of employing this method to produce vessels and other objects of notable technical sophistication. Nevertheless, the use of a lead–tin alloy is highly unusual, as this composition is not otherwise attested among protohistoric Sardinian metal artifacts.

The purpose of this study is to provide a revised contextualization of the object and to characterize the material from which it was produced.

1.1. The Sacred Well of Santa Cristina

Situated adjacent to the church of Santa Cristina, the sacred well has attracted scholarly attention since the 19th century (see Figure 1). Early interpretations alternated between viewing the monument as a utilitarian or medieval structure and recognizing it as a Nuragic cult installation. Its definitive attribution to the Nuragic culture was established in the early 20th century, following the survey undertaken by the British School at Rome in 1909.

Figure 1.

Aerial view of the exterior of the well (photo courtesy of the Municipality of Paulilatino).

Excavations initiated by Atzeni in 1967 exposed the full layout of the sanctuary: a subterranean tholos chamber accessed by a stairway of approximately twenty-six steps, an elliptical temenos measuring about 20 × 26 m, and a vestibule bounded by both rectilinear and curvilinear walls. Restoration became necessary after portions of the structure collapsed; the stairway was subsequently dismantled and partially rebuilt.

The underground chamber measures 2.54 m in diameter and nearly 7 m in height. At its base lies a circular basin carved into basalt bedrock, designed to collect spring water. Archaeological evidence indicates that the site was in use from the Final Bronze Age through the Early Iron Age, with episodes of reuse during the Punic, Roman, and medieval periods [1,2].

1.2. Archaeological Context of the Flask

Documentation of the 1967–1970 campaigns remains mostly unpublished; existing studies focus primarily on the architecture or selected artefacts. Stratigraphic information is incomplete, partly due to the restoration activities and the long delay before the assemblage was reorganized in 2003. The flask was recovered from the muddy deposits at the bottom of the water basin, together with bronze figurines and fibulae.

The artefactual assemblage indicates intense ritual activity during the Early Iron Age (9th–8th centuries BCE), although residual material suggests the presence of earlier Bronze Age phases. The bronze figurines, which display strong Near Eastern stylistic influence, exemplify hybrid production processes likely involving itinerant eastern craftsmen or locally adapted workshops. The fibulae provide a consistent chronological framework, placing the principal phase of use in the early stages of the Iron Age. Later intrusions—comprising Punic thymiateria, Roman artefacts, and medieval Tuscan maiolica—attest to successive episodes of reuse and reoccupation of the sanctuary.

1.3. Description of the Flask

The flask, exceptionally well preserved, has a flat, discoidal body with a short cylindrical neck, and ring handles located at approximately 10 and 2 o’clock (see Figure 2).

Figure 2.

Four views of the flask: (a) front face; (b) rear face; (c,d) lateral views.

Two small feet were originally affixed at the 5 and 7 o’clock positions, although one is now missing. The vessel’s body exhibits carefully finished surfaces, decorated with concentric frames and shallow incised grooves. At the junction of the neck and body, a slight internal casting burr is visible, indicating minimal post-casting refinement. Two fixed lugs support movable suspension rings, likely intended for carrying or hanging the vessel. The preserved foot terminates in a pronged element, possibly designed to secure a suspension strap. The flask measures approximately 19 cm in height, with a maximum diameter of 14.5 cm, and weighs 1.2 kg. The absence of visible joining seams suggests manufacture by the lost-wax casting process, although certain elements—such as the feet—may have been added by casting-on. The heavily oxidized condition of one foot further suggests an ancient repair, possibly undertaken to reinforce a fragmentary attachment.

2. Materials and Methods

The analyses of the flask were performed using portable Energy Dispersive X-Ray Fluorescence (EDXRF) and portable External Reflection (ER FT-IR) spectroscopy, which will be described in detail in the following subsections. The use of portable instruments was necessary because the sample could not be removed from the deposit. In Figure 3 some details of the surface of the flask are reported together with a map indicating some of the measurement’s points.

Figure 3.

Corrosion patterns on the surface of the flask, with a map indicating some of the measurement points (in red color).

2.1. EDXRF

Energy-Dispersive X-Ray Fluorescence (EDXRF) is a well-established non-destructive analytical technique widely applied across various fields of research. It is based on the interaction between an X-Ray beam and the sample, resulting in the generation of an X-Ray spectrum typically characterized by a continuous background with a series of superimposed peaks. The background mainly originates from radiation scattering, whereas the peaks correspond to characteristic X-Ray fluorescence emissions. These fluorescence peaks are crucial for sample characterization, as their energies are element-specific and their intensities are approximately proportional to the elemental concentrations.

The standard and most commonly employed procedure for quantifying elemental composition involves two main steps: (1) background subtraction and (2) application of the Fundamental Parameter Method (FPM) to the net peak areas [3,4,5,6]. This approach performs well for smooth surfaces and when background removal is efficient—conditions that are often not satisfied in the study of ancient metallic artifacts, especially when dealing with rough or corroded surfaces and weakly defined peaks.

To overcome these limitations, an alternative methodology based on Monte Carlo (MC) simulation of the XRF experiment has been proposed [7,8,9,10]. In this approach, background subtraction is inherently included in the simulation process. The specific simulation protocol used here follows that described in detail by [11].

In the case of corroded metals, such as those examined in this study, the sample can be modeled as a multilayered structure, typically comprising at least one corrosion layer covering the metallic core. Occasionally, a protective coating (e.g., Paraloid) may be applied, but this was not present in the current sample. It is worth recalling that EDXRF is essentially a surface-sensitive technique, providing compositional information from a depth of up to approximately 100 μm, depending on the sample composition. Thus, it is essential that the primary radiation penetrating beneath the corrosion layer can still generate detectable fluorescence signals.

Several MC codes are available for EDXRF simulation [12,13,14,15,16,17,18,19,20,21]. In this study, we employed the XRMC code [19,20], a fast and efficient software capable of producing simulated spectra with statistical quality comparable to measured data within seconds. This computational efficiency is achieved through the implementation of variance-reduction techniques and the omission of electron transport simulations. The latter simplification does not introduce significant errors for XRF simulations below 100 keV, as in this work. However, it cannot be applied to X-Ray tube emission modeling, where accurate electron transport representation is required. In such cases, a more comprehensive MC code, such as PENELOPE [21], is necessary.

Measurements were carried out in situ at the museum using a custom-built portable EDXRF system. The setup includes an Ag-anode X-Ray tube (operating at 40 keV and 5–20 mA) and a 1–2–3 SDD detector, both manufactured by Amptek (Bedford, MA, USA). The geometry of the system is adjustable to accommodate irregular sample shapes. Typically, both the X-Ray tube and detector were positioned 2–3 cm from the sample surface. The X-Ray beam, collimated to a 1 mm spot, was directed at a 30° angle relative to the sample’s normal surface, while the detector was placed vertically above the surface without collimation. This configuration minimizes the effects of surface roughness and corrosion [22].

Several multilayer models were tested, with the two-layer configuration providing the best fit in most cases. For a few measurement points, a three-layer model yielded a better agreement with the experimental data.

2.2. ER FT-IR

ER FT-IR spectra were collected using a portable Alpha spectrometer (Bruker Optics, Ettlingen, Germany) equipped with an external reflection module, operating over the 7500–375 cm−1 range. Spectra were acquired on areas corresponding to the probe head diameters of 3 or 5 mm, using 64 scans at a spectral resolution of 4 cm−1.

The Kramers–Kronig transformation (KKT) was applied in the 4000–375 cm−1 region to correct derivative-like band distortions. A full correction of the spectra was avoided due to the variability in the optical and morphological properties of the surface [23,24,25].

3. Results

The sample was analyzed at several locations, including the ring and the neck of the flask (see Figure 3). The results reported here refer to the main structural components of the artifact: the neck, the rings, the fractured stand, and a relatively clean area of the surface. In addition, two further zones exhibiting distinct corrosion products, a dark green patina and a white patina, were also examined.

3.1. EDXRF

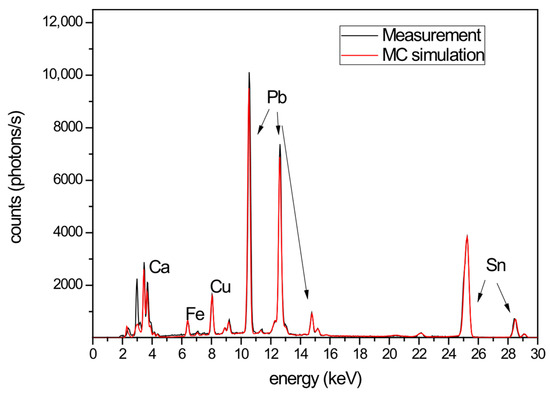

In Figure 4 the measured and simulated spectra are shown for the fractured stand. In this case, a three-layer model provided the best fit. The structure consists of two corrosion layers:

Figure 4.

Measured and simulated spectra acquired at the fractured stand location. The unfitted peak on the left corresponds to the X-Ray tube emission. The same chemical elements were detected in all analyzed spots and are therefore not repeated in the following graphs.

- The external layer (5 µm thick) is enriched with tin (39.5%).

- The inner layer (300 µm thick) contains mainly tin (5%) and lead (4.0%), with small amounts of iron and copper.

- The bulk layer is composed of tin (84.1%), lead (12.9%), iron (1.5%), and copper (1.5%).

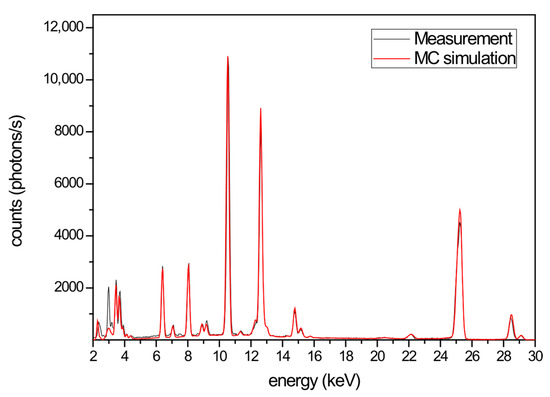

For the flask neck, the best fit was obtained with a two-layer structure (Figure 5):

Figure 5.

Neck: measured and simulated spectrum.

- The 200 µm thick corrosion layer contains iron (0.6%), copper (0.6%) and sulfur (2%).

- The bulk consists of tin (76.5%), lead (19.6%), iron (2.3%), and copper (1.5%).

In Figure 6, the simulated and measured spectra of an apparently cleaner spot are shown. The best fit supports this hypothesis. The structure consists of two layers:

Figure 6.

Almost cleaned spot: simulated and measured spectra.

- The corrosion layer (100 µm thick) has a composition similar to the bulk, with tin (62%), lead (20%), iron (1%), copper (2.5%) and sulfur (2%).

- The bulk is composed of tin (70.2%), lead (24.0%), iron (3.0%), and copper (2.0%).

This area may have been accidentally cleaned.

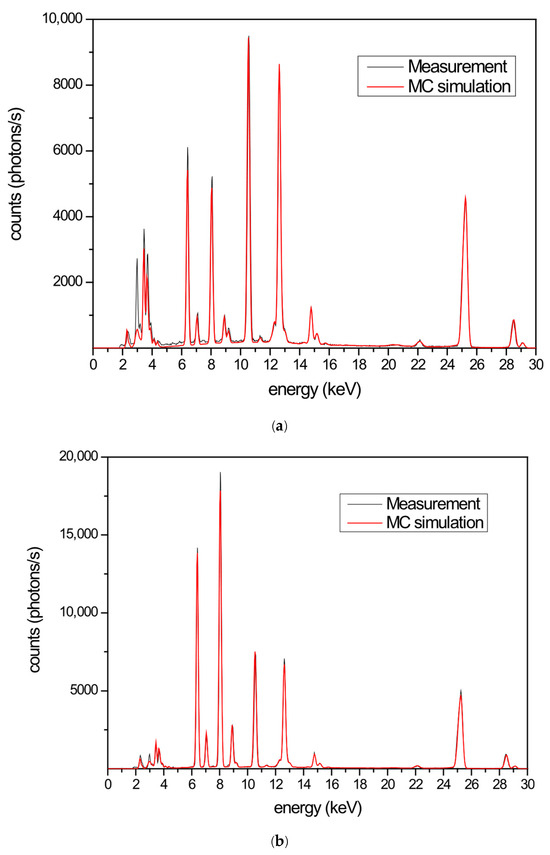

The analysis of the rings revealed interesting results (see also the ER FTIR section). The structure can be represented as two layers:

- The patina layer (150 µm thick) contains tin (6%), lead (5%), iron (1%), and copper (1%).

- The bulk has a higher lead content (32%) and lower tin (62%), along with elevated iron (4.3%) and copper (3.5%) levels compared to other parts.

The eyelet into which the ring is inserted was also modeled as a three-layer structure:

- Outer layer (270 μm thick): Iron (3.0%), copper (3.0%). Tin (10.6%), lead (2.0%) and sulfur (1.5%)

- Middle layer (30 mm thick): Iron (2.4%), copper (1.6%). Tin (12.5.0%), lead (4.0%).

- Bulk: Fe (2.3%), Cu (2.0%), Sn (73%) and Pb (22%).

Finally, the white, dark green and black spots were analyzed. In both cases, a three-layer structure provided the best fit.

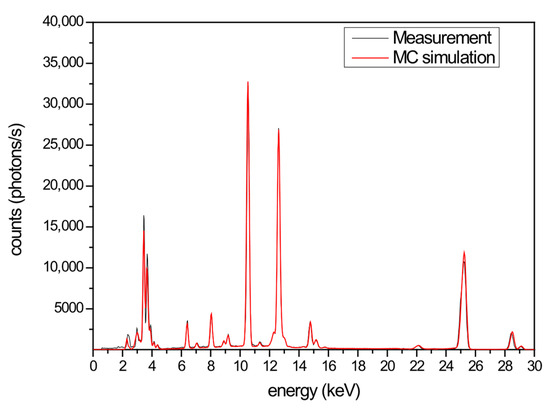

White spot (Figure 7a):

Figure 7.

White spot: measured and simulated spectra (a); dark green spot: measured and simulated spectra (b).

- Outer layer (260 µm thick): Primarily tin (10%), with minor amounts of lead (1.0%), iron (1.5%), copper (1%), and sulfur (1.5%).

- Middle layer (30 µm thick): Tin (16%), lead (3.0%), iron (1.7%), and copper (1%).

- Bulk: Tin (70%), lead (25%), iron (2.6%), and copper (1.5%).

Dark green spot (Figure 7b):

- Outer layer (100 µm thick): Iron (6%), copper (7.5%), tin (7.0%), lead (2.0%), and sulfur (2.0%). The high iron and copper contents likely give this area its color.

- Middle layer (10 µm thick): Less oxidized, containing iron (6.0%), copper (7.5%), tin (51%), and lead (8.5%).

- Bulk: Iron (1.3%), copper (1.5%), tin (79%), and lead (17.0%).

Black spot:

- Outer layer (260 μm thick): Iron (8.0%), copper (8.6%). Tin (5.0%), lead (1.0%) and (sulfur (1.5%)

- Middle layer (30 mm thick): Iron (5.4%), copper (8.1%). Tin (7.0%), lead (4.0%).

- Bulk: Fe (2.3%), Cu (2.0%), Sn (73%) and Pb (22%).

The higher concentrations of copper and iron detected in the corrosion layer may be attributed to accidental contact with bronze objects during burial or to environmental contamination. It is worth noting that the sample was recovered from a muddy deposit containing numerous other artifacts. The humid burial environment could also account for the flask’s coloration.

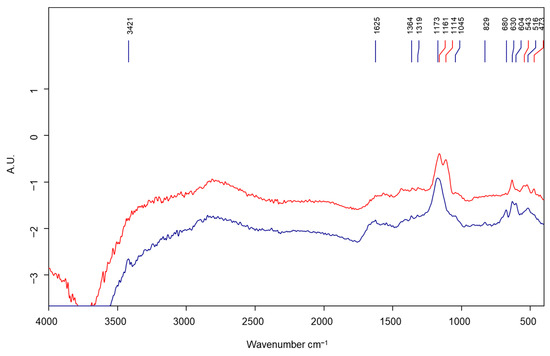

3.2. ER FT-IR

The flask was analyzed using Fourier-transform infrared spectroscopy (FT-IR) in external reflection (ER) mode to identify surface materials and alteration products without sampling.

The spectra indicate the presence of alteration compounds, with particular emphasis on sulphates, oxalates, and silicates. Oxalates and silicates can be attributed to burial conditions, whereas sulphates, carbonates, and oxides are directly associated with superficial alloy alteration. The sulphates identified in the spectra correspond to elements readily detected within the alteration patina, such as lead [26].

Spectra collected from the white surface residues suggest the presence of oxalates, hydrated tin oxide (indicated by hydroxyl group bands) [27,28,29], lead sulphate (band at 1173 cm−1) [30], silicates, and minor amounts of anhydrite and carbo nates, likely lead carbonate. A second analyzed area displays additional functional groups with bands at 1161 and 1114 cm−1, likely representing a mixture of two types of sulphate compounds that could not be fully identified (Figure 8).

Figure 8.

KKT spectra of two white areas with the indication of characteristic bands.

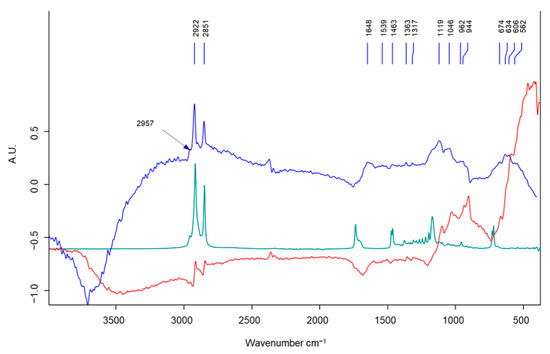

The spectrum of the eyelet ring exhibits several bands attributable to organic material, most likely a waxy substance, characterized by the presence of methylene and methyl group absorptions. In addition to these organic features, bands corresponding to silicates, oxalates, and carboxylates are also observed, suggesting the presence of lead alteration compounds associated with the organic material [31] (Figure 9).

Figure 9.

Area corresponding to the eyelet ring with the ER FT-IR spectrum in red, KKT in blue and spectrum reference of the beeswax in green.

The organic component cannot be definitively identified as beeswax, since not all characteristic bands are clearly visible and overlapping signals from surrounding compounds may cause slight wavenumber shifts or obscure key absorptions. Nevertheless, the material can be confidently described as waxy in nature.

3.3. ED-XRF and ER FT IR

Most of the analyzed ER FT-IR spectra exhibit a noisy pattern caused by the non-uniform surface, which hampers the clear identification of specific compounds. Nevertheless, where conditions permitted, an interpretation was attempted, and the results are summarized in Table 1, together with the corresponding XRF data. A notable consistency was observed between the results obtained from the EDXRF–MC analysis and those from the ER FT-IR measurements.

Table 1.

Description of the ER FT-IR analysis points (see Figure 3), with their corresponding observations, tentative material identifications, and the associated EDXRF results.

Overall, there is good agreement among the patina color, the analytical measurements, and the descriptions reported in the literature [32]. In cases where the ER FT-IR spectra were of sufficient quality, the results matched the multilayer composition derived from the MC simulations and EDXRF measurements, as shown in Table 1. These findings once again demonstrate the effectiveness of combining EDXRF with Monte Carlo simulation for the characterization of complex, corroded metallic artifacts.

4. Discussion and Conclusions

The pilgrim flask from the sacred well of Santa Cristina is a unique full-scale metal artifact, providing critical comparative insight into the typological evolution of bronze miniature flasks documented across Sardinia and the Italian peninsula [33]. Its form and size, with a cylindrical neck, asymmetrical body, shoulder grips, and distinct feet—mirror miniature votive versions, suggesting that full-scale metal prototypes existed alongside the more familiar miniature forms. Produced through lost-wax casting, the vessel demonstrates advanced technical skill, particularly in its seamless body and suspension devices.

While its shape recalls Near Eastern prototypes [34], the Santa Cristina flask represents a fully localized reinterpretation in both material and ritual function. Chronologically, it aligns with Early Iron Age phases, consistent with associated fibulae and ceramics, and parallels both Sardinian and peninsular miniature flasks. Although some Sardinian examples were previously attributed to the Late Bronze Age, recent reassessments indicate a shared chronology across island and mainland contexts in the 9th–8th centuries BCE.

The rediscovery of the Santa Cristina flask expands the known repertoire of Nuragic metalwork. Its morphology, distinctive alloy composition, manufacturing technology, and likely role as a ritual container or votive offering provide new insights into metallurgical practices, cult behavior, and cultural interaction in the western Mediterranean during the transition from the Late Bronze Age to the Early Iron Age. Its alloy, unusually rich in tin and low in lead, resembles pewter and diverges from standard Sardinian practices. While the form may have been inspired by organic containers such as gourds, the flask embodies a distinct typology with symbolic and aesthetic value. Parallels with bronze pendants and ceramic flasks suggest a tradition of replicating prestigious objects across media, where concentric decorative motifs conveyed meaning beyond utility.

The flask likely functioned to store or transport valuable liquids, especially wine, in a ritual context. Found within a sanctuary associated with elite offerings and metallurgical activity, it reflects strategies of social prestige, cult practice, and intercultural connections. Moreover, its curatorial history highlights challenges inherent in archaeological research, particularly the fragmentation of assemblages and the dispersal of artifacts among multiple institutions, which often impede coherent reconstruction of ritual contexts within Nuragic sanctuary sites.

Author Contributions

Conceptualization, A.D.; methodology, A.D. and A.B.; software, A.B.; validation, A.B. and R.I.; formal analysis, A.B. and R.I.; investigation, A.D., R.I. and A.B.; resources, A.D. and A.B.; data curation, A.D., R.I. and A.B.; writing—original draft preparation, A.D., R.I. and A.B.; writing—review and editing, A.D., R.I. and A.B.; visualization, A.D.; supervision, A.D. and A.B.; project administration, A.D. and A.B.; funding acquisition, A.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to thank the CIRTEBEC center of University of Sassari for having made some of the measuring instruments available.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Moravetti, A. The Nuragic Sanctuary of Santa Cristina. In Guide Books and Itineraries 32; Carlo Delfino: Sassari, Italy, 2003. [Google Scholar]

- Hermon, S.; Depalmas, A.; Vico Lopez, M.D.; Atzeni, I. A 3D approach to the archaeological study of the built remains at the Santa Cristina well sanctuary, Sardinia, Italy. Digit. Appl. Archaeol. Cult. Herit. 2017, 6, 4–9. [Google Scholar] [CrossRef]

- Sherman, J. The theoretical derivation of fluorescent X-ray intensities from mixtures. Spectrochim. Acta Part A 1955, 7, 283–306. [Google Scholar] [CrossRef]

- Shiraiwa, T.; Fujino, N. Theoretical calculation of fluorescent X-ray intensities in fluorescent X-ray spectrochemical analysis. Jpn. J. Appl. Phys. 1966, 5, 886. [Google Scholar] [CrossRef]

- Mantler, M. X-ray fluorescence analysis of multiple-layer films. Anal. Chim. Acta 1986, 188, 25–35. [Google Scholar] [CrossRef]

- De Boer, D.K.G. Calculation of X-ray fluorescence intensities from bulk and multilayer samples. X-Ray Spectrom. 1990, 19, 145–154. [Google Scholar] [CrossRef]

- Brunetti, A.; Porcaro, M.; Bustamante, A.; Stegel, G.; Cesareo, R. Combining X-ray Fluorescence and Monte Carlo Simulation Methods to Differentiate between Tumbaga and Gold-Alloy or Gildings. Material 2022, 15, 4452. [Google Scholar] [CrossRef] [PubMed]

- Porcaro, M.; Depalmas, A.; Lins, S.; Bulla, C.; Pischedda, M.; Brunetti, A. Nuragic Working Tools Characterization with Corrosion Layer Determinations. Materials 2022, 15, 3879. [Google Scholar] [CrossRef]

- Manso, M.; Schiavon, N.; Queralt, I.; Arruda, A.M.; Sampaio, J.M.; Brunetti, A. Alloy characterization of a 7th Century BC archeological bronze vase—Overcoming patina constraints using Monte Carlo simulations. Spectrochim. Acta Part B At. Spectrosc. 2015, 107, 93–96. [Google Scholar] [CrossRef]

- Pessanha, S.; Manso, M.; Antunes, V.; Carvalho, M.L.; Sampaio, J.M. Monte Carlo simulation of portable XRF setup: Non-invasive determination of gold leaf thickness in indo-Portuguese panel paintings. Spectrochim. Acta Part B At. Spectrosc. 2019, 156, 1–6. [Google Scholar] [CrossRef]

- Brunetti, A.; Golosio, B.; Schoonjans, T.; Oliva, P. Use of Monte Carlo simulations for Cultural Heritage X-ray fluorescence analysis. Spectrochim. Acta Part B At. Spectrosc. 2015, 108, 15–20. [Google Scholar] [CrossRef]

- He, T.; Gardner, R.P.; Verghese, K. An improved Si(Li) detector response function. Nucl. Instrum. Methods Phys. Res. Sect. A 1990, 299, 354–366. [Google Scholar] [CrossRef]

- Gardner, R.P.; Doster, J.M. Reduction of matrix effects in x-ray fluorescence analysis by the Monte Carlo, fundamental parameters method. Adv. X-Ray Anal. 1979, 22, 343–356. [Google Scholar]

- Gardner, R.P.; Doster, J.M. The complete spectral response for EDXRF Systems—Calculation by Monte Carlo and Analysis applications. 1—Homogeneous samples. X-Ray Spectrom. 1982, 11, 173–180. [Google Scholar] [CrossRef]

- Gardner, R.P.; Doster, J.M. The complete spectral response for EDXRF Systems—Calculation by Monte Carlo and Analysis applications. 2—Heterogeneous samples. X-Ray Spectrom. 1982, 11, 181–186. [Google Scholar] [CrossRef]

- Fernandez, J.E. Monte Carlo computer simulation of the XRF intensity dependence on the propagation plane inclination. Comput. Phys. Commun. 1989, 54, 211–220. [Google Scholar] [CrossRef]

- Schoonjans, T.; Vincze, L.; Solé, V.A.; Sanchez del Rio, M.; Brondeel, P.; Silversmit, G.; Appel, K.; Ferrero, C. A general Monte Carlo simulation of energy-dispersive X-ray fluorescence spectrometers—Part 5. Polarized radiation, stratified samples, cascade effects, M-lines. Spectrochim. Acta Part B 2012, 70, 10–23. [Google Scholar] [CrossRef]

- Vincze, L.; Janssens, K.; Adams, F. A general Monte Carlo simulation of energy-dispersive X-ray fluorescence spectrometers-I. Unpolarized radiation, homogeneous samples. Spectrochim. Acta Part B 1993, 48, 553–573. [Google Scholar] [CrossRef]

- Golosio, B.; Schoonjans, T.; Brunetti, A.; Oliva, P.; Masala, G.L. Monte Carlo simulation of X-ray imaging and spectroscopy experiments using quadric geometry and variance reduction techniques. Comput. Phys. Commun. 2014, 185, 1044–1052. [Google Scholar] [CrossRef]

- Brunetti, A.; Golosio, B. A new Monte Carlo code for simulation of the effect of irregular surfaces on X-ray spectra. Spectrochim. Acta Part B 2014, 94, 58–62. [Google Scholar] [CrossRef]

- Salvat, F.; Fernández-Varea, J.M.; Sempau, J. PENELOPE-2006: A Code System for Monte Carlo Simulation of Electron and Photon Transport; Nuclear Energy Agency, Organization for Economic Co-Operation and Development: Issy-les-Moulineaux, France, 2006. [Google Scholar]

- Robbiola, L.; Blengino, J.M.; Fiaud, C. Morphology and mechanisms of formation of natural patinas on archaeological Cu-Sn alloys. Corros. Sci. 1998, 40, 2083–2111. [Google Scholar] [CrossRef]

- Derrik, M.R.; Stulik, D.; Landy, J.M. Infrared Spectroscopy in Conservation Science; The Getty Conservation Institute: Los Angeles, CA, USA, 1983. [Google Scholar]

- Meilunas, R.J.; Bentsen, J.G.; Steinberg, A. Analysis of aged paint binders by FTIR spectroscopy. Stud. Conserv. 1990, 35, 33–51. [Google Scholar] [CrossRef]

- Rosi, F.; Cartechini, L.; Monico, L.; Gabrieli, F.; Vagnini, M.; Buti, D.; Doherty, B.; Anselmi, C.; Brunetti, B.G.; Miliani, C. Tracking Metal Oxalates and Carboxylates on Painting Surfaces by Non-Invasive Reflection Mid-FTIR Spectroscopy. In Metal Soaps in Art: Conservation and Research; Casadio, F., Keune, K., Noble, P., Van Loon, A., Hendriks, E., Centeno, S.A., Osmond, G., Eds.; Cultural Heritage Science; Springer: Cham, Switzerland, 2019; pp. 173–193. [Google Scholar] [CrossRef]

- Robbiola, L.; Portier, R. A global approach to the authentication of ancient bronzes based on the characterization of the alloy–patina–environment system. J. Cult. Herit. 2006, 7, 1–12. [Google Scholar] [CrossRef]

- Albini, M.; Ridolfi, S.; Giuliani, C.; Pascucci, M.; Staccioli, M.P.; Riccucci, C. Multi-Spectroscopic Approach for the Non-invasive Characterization of Paintings on Metal Surfaces. Front. Chem. 2020, 8, 289. [Google Scholar] [CrossRef] [PubMed]

- Rémazeilles, C.; Conforto, E. A Buried Roman Bronze Inkwell: Chemical Interactions with Agricultural Fertilizers. Stud. Conserv. 2008, 53, 110–117. [Google Scholar] [CrossRef]

- Janardhan, E.; Reddy, M.; Reddy, P.; Reddy, M. Synthesis of SnO Nanopatricles—A Hydrothermal Approach. World J. Nano Sci. Eng. 2018, 8, 33–37. [Google Scholar] [CrossRef]

- Trettenhahn, G.L.J.; Nauer, G.E.; Neckel, A. In situ Fourier-transform infrared investigations of lead electrodes in sulfuric acid: Formation of lead sulfate on lead and lead alloys. J. Power Sources 1993, 42, 137–144. [Google Scholar] [CrossRef]

- Poli, T.; Piccirillo, A.; Nervo, M.; Chiantore, O. Aging of Natural Resins in Presence of Pigments: Metal Soap and Oxalate Formation. In Metal Soaps in Art: Conservation and Research; Casadio, F., Keune, K., Noble, P., Van Loon, A., Hendriks, E., Centeno, S.A., Osmond, G., Eds.; Cultural Heritage Science; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Selwyn, L. Metal and Corrosion: A Handbook for the Conservation Professional; Canadian Conservation Institute: Ottawa, ON, Canada, 2004. [Google Scholar]

- Acquaro, E. (Ed.) Alle Soglie della Classicità. Il Mediterraneo tra Tradizione e Innovazione, Studi in Onore di Sabatino Moscati; Istituti Editoriali e Poligrafici Internazionali: Pisa/Rome, Italy, 1996; pp. 844–848. [Google Scholar]

- Marzoli, D. Bronzefeldflaschen in Italien; Prähistorische Bronzefunde, Abteilung II, Band 4; C.H. Beck: Munich, Germany, 1989. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).