Abstract

Bismuth layer-structured ferroelectrics (BLSFs) are core candidates for high-temperature piezoelectric applications owing to their excellent thermal stability and fatigue resistance, yet traditional Bi4Ti3O12 (BiT)-based ceramics suffer from limited piezoelectric performance. To address this, MBi4Ti4O15-Bi4Ti3O12 (M=Ba, Sr, Ca) symbiotic structure bismuth-layered piezoelectric ceramics were fabricated via the conventional solid-state reaction method. Their crystal structure, microstructure, and electrical properties were systematically characterized using a X-ray diffractometer, scanning electron microscope, high-temperature dielectric spectrometer, and quasi-static d33 meter to explore the effects of different A-site divalent elements. Results show that all samples form a pure-phase symbiotic structure with the P21am space group, without secondary phases. The lattice constant decreases with increasing A-site ionic radius, while symbiosis-induced lattice mismatch and long-range disorder refine grains, reduce aspect ratio, lower conductivity, enhance spontaneous polarization, and improve piezoelectric properties. The ceramics exhibit d33 of 10 to 15 pC/N and TC of 502 to 685 °C, with SrBi4Ti4O15-Bi4Ti3O12 showing optimal comprehensive performance (d33 ≈ 15 pC/N, TC = 593 °C, tanδ = 0.6% at 1 kHz/475–575 °C, and a low AC conductivity of 5.3 × 10−5~4.8 × 10−4 S/m). This study improves bismuth-layered ceramics’ performance via A-site regulation and symbiotic structure design, offering theoretical and technical support for high-performance lead-free high-temperature piezoelectric ceramics.

1. Introduction

As a class of functional materials with spontaneous polarization whose polarization direction can be reversed by an external electric field, ferroelectric materials occupy an indispensable position in the fields of sensors, transducers, memories, etc [1]. Among them, bismuth layer-structured ferroelectrics (BLSFs) have emerged as one of the core candidate materials for high-temperature piezoelectric applications, thanks to their excellent performance endowed by the unique crystal structure [2]. These materials generally exhibit prominent characteristics such as high-temperature stability, excellent fatigue resistance, high Curie temperature, low dielectric loss and low aging rate, enabling stable operation in high-tech fields, including extreme environment monitoring in aerospace, high-temperature pressure sensing in oil drilling, and measurement and control of energy and metallurgical equipment. They effectively meet the stringent service requirements that are difficult to be satisfied by traditional materials [3].

A representative material among bismuth layer-structured ferroelectrics is Bi4Ti3O12-based piezoelectric ceramics, which possess strong ferroelectricity, excellent fatigue resistance, good thermal stability and a high Curie temperature of 675 °C [4], thus holding promising application prospects for high-temperature sensors, high-temperature actuators and piezoelectric films [3]. However, the relatively high coercive field and low crystal structure symmetry result in the poor piezoelectric performance of BiT-based piezoelectric ceramics, with the maximum d33 value only reaching 8 pC/N [4]. CaBi4Ti4O15 (CBT) piezoelectric ceramics exhibit the highest Curie temperature and the lowest piezoelectric constant among the four-layer perovskite-like bismuth layer-structured ferroelectrics, with a Curie temperature of up to 720 °C but a piezoelectric constant of merely 5.5 pC/N [5]. To address the issue of the poor piezoelectric performance of the aforementioned bismuth layer-structured ferroelectrics, researchers have carried out extensive modification studies. Among these approaches, the construction of symbiotic structures has been proven to be an effective strategy for enhancing the remanent polarization and piezoelectric activity of bismuth layer-structured ceramics [6]. Previous studies have shown that compared with single-layer bismuth layer-structured ceramics, symbiotic structure samples not only display higher polarization intensity but can also effectively integrate the electrical performance advantages of each constituent unit, making them a category of lead-free piezoelectric ceramics with great application potential. It has been demonstrated that symbiotic-structured bismuth-layered high-temperature piezoelectric ceramics generally refer to materials composed of bismuth-layered structured ferroelectrics (BLSFs) with perovskite-like layer counts differing by one, which are alternately arranged along the c-axis [7]. Their general formula can be expressed as (Bi2O2)2+(Am−1BmO3m+1)2−-(Bi2O2)2+(An−1BnO3n+1)2− (where m and n differ by 1) [8]. Owing to the lattice mismatch between the perovskite-like layers (with differing layer counts) linked by the bismuth–oxygen layers in the symbiotic structure, significant lattice distortion is induced, which in turn enhances the remanent polarization of the piezoelectric ceramics. Taking BaBi4Ti4O15-Bi4Ti3O12 piezoelectric ceramics as an example, their remanent polarization intensity can reach 15 μC/cm2, which is significantly higher than that of single-phase SrBi4Ti4O15 (SBT) or Bi4Ti3O12 (BiT) ceramics; meanwhile, their Curie temperature is approximately 480 °C, far exceeding that of pure BaBi4Ti4O15 (BBT) ceramics [9], fully demonstrating the superiority of symbiotic structure design.

The introduction of A-site elements to construct a symbiotic structure can effectively enhance the piezoelectric properties of BiT-based ceramics. However, due to their inherent characteristics, the introduction of A-site elements also induces lattice distortion to varying degrees, thereby affecting the structure and properties of the material. Based on this, this paper will fabricate MBi4Ti4O15 (M=Ba, Sr, Ca)-based symbiotic structure bismuth layer-structured piezoelectric ceramics, comparatively analyze the effects of three different A-site elements on the microstructure and properties of the constructed symbiotic structure bismuth layer-structured piezoelectric ceramics, and aim to achieve bismuth layer-structured ferroelectrics with excellent piezoelectric properties and high Curie temperature.

2. Experimental Setup

Ceramic samples of MBi4Ti4O15-Bi4Ti3O12 (M=Ba, Sr, Ca) were fabricated via the conventional solid-state reaction method, and the names of these samples are hereinafter abbreviated as BBT-BiT, SBT-BiT and CBT-BiT correspondingly. The raw materials used were BaCO3 (99%, Sinopharm, Shanghai, China), SrCO3 (99%, Sinopharm, Shanghai, China), CaCO3 (99%, Sinopharm, Shanghai, China), Bi2O3 (99.99%, Aladdin Biochemical, Shanghai, China), and TiO2 (99.9%, Shanghai Aladdin Biochemical Technology Co., Ltd.). All materials were weighed according to their stoichiometric ratios and ground into a mixed powder in ethanol using a planetary ball mill for 16 h. The milled powder was calcined at 820 °C for 4 h in a resistance box furnace. After full regrinding, the calcined powder was mixed with 6 wt% polyvinyl alcohol (PVA) as a binder. The sieved powder was axially pressed into disks with a diameter of 12 mm and a thickness of approximately 1 mm using an automatic bench-top press ((YST-16, Jiuyajiu, Changzhou, China, the pressure is 30 MPa). All samples were subjected to stepwise heating at 500 °C for 15 h to burnout the PVA, followed by sintering at 1050 °C for 2 h in a sealed crucible to minimize the loss of volatile bismuth. Finally, silver electrodes were deposited on the surfaces of the ceramic samples, which were then annealed at 800 °C for 30 min. The samples were polarized in silicone oil at 90 °C under an electric field of 7 to 8 kV/mm for 0.5 h and left to stand at room temperature for 24 h before electrical property measurements.

The phase structure of the ceramics was characterized using an X-ray diffractometer (XRD, Rigaku, Tokyo, Japan). The surface morphology was observed via a field-emission scanning electron microscope (SEM, Zeiss, Oberkochen, Germany). The dielectric temperature spectra and impedance spectra were measured using a high-temperature dielectric spectrometer (WK 6500B, WayneKerr, West Sussex, UK, the measurement accuracy is ±0.05%). The piezoelectric properties of the polarized ceramic wafers were determined using a quasi-static d33 meter (ZJ-3A, Jingkezhichuang, Beijing, China). The piezoelectric constant and dielectric loss were measured at room temperature.

3. Results and Discussion

3.1. Microscopic Characterizations of Samples

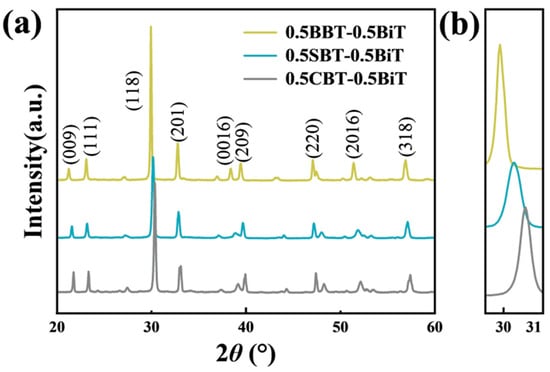

In this study, MBi4Ti4O15-Bi4Ti3O12 (M=Ba, Sr, Ca) ceramic samples with different A-site ions were subjected to X-ray diffraction (XRD) analysis to investigate their crystal structure characteristics under the sintering condition of 1050 °C. As shown in Figure 1a, XRD pattern analysis reveals that all diffraction peaks are highly consistent with the characteristic diffraction peaks of the symbiotic structure phase corresponding to the P21am space group, and no obvious impurity peaks are observed in the patterns, indicating that no other secondary phases are formed during the sintering process [10]. Furthermore, Figure 1b presents the locally magnified view of the strongest XRD peak (118) of the MBi8Ti7O27 ceramic samples. This strongest peak corresponds to the crystal plane at the characteristic plane index (112m + 1) in bismuth-layered structure ferroelectrics (PDF#:31-1342). For the (118) diffraction peak, with the increase in the ionic radius of A-site ions, the diffraction peak of MBi8Ti7O27 ceramics shows a tendency to shift gradually toward higher angles. According to Bragg’s diffraction law, the lattice constant of MBi8Ti7O27 ceramics decreases gradually.

Figure 1.

(a) Room-temperature XRD patterns showing the peak intensities for all ceramics in the 2θ range of 20–60° and (b) variations in the (112m + 1) XRD peaks.

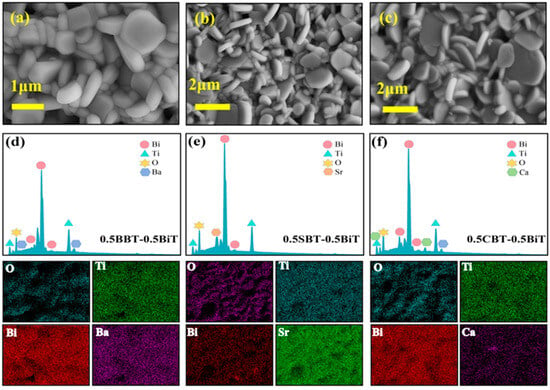

Figure 2 shows the surface scanning electron microscopy (SEM) images of all MBi8Ti7O27 ceramic samples. Since the growth rate of grains in the direction perpendicular to the c-axis is significantly higher than that in other directions during the grain growth of bismuth-layered structure ferroelectrics, all ceramic samples exhibit a typical plate-like grain structure with random orientations [6]. Furthermore, the lamellar grains of symbiotic structure ferroelectrics have a lower aspect ratio (diameter/thickness) compared to piezoelectric ceramics with a single structure. This lower aspect ratio is mainly associated with lattice distortion caused by the combination of perovskite-like layers with different numbers of layers [11]. When perovskite-like layers with different numbers of layers are combined, lattice mismatch occurs due to the inconsistency of the lattice parameters. Meanwhile, the new long-range disordered symbiotic structure also exerts a significant inhibitory effect on grain growth. The synergistic effect of this lattice mismatch and the symbiotic structure can effectively restrict grain growth, thereby reducing the aspect ratio of grains. Finally, a certain degree of pores exists in the microstructure of all samples. These pores are likely caused by the binder burnout. From the elemental distribution maps of the ceramic samples shown in Figure 2d–f, it can be seen that the ceramic samples are free from contamination, and their elemental distribution is relatively uniform, with no significant agglomeration or segregation phenomena observed.

Figure 2.

SEM images of piezoelectric ceramics: (a) microscopic morphology of BaBi8Ti7O27, (b) SrBi8Ti7O27, (c) CaBi8Ti7O27, and EDS result of piezoelectric ceramics: (d) microscopic morphology of BaBi8Ti7O27, (e) SrBi8Ti7O27, (f) CaBi8Ti7O27.

3.2. Electrical Properties of Samples

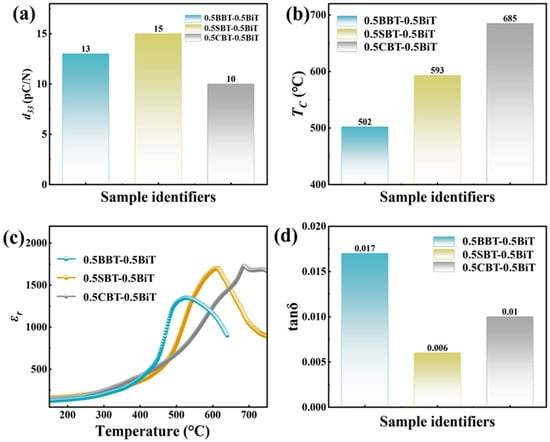

In Figure 3, the electrical properties of MBi8Ti7O27 (where M represents Ba, Sr, Ca) ceramic samples, including piezoelectric constant, Curie temperature, dielectric temperature spectrum, and dielectric loss are presented in detail. As can be clearly observed from Figure 3a, after the construction of the symbiotic structure, the piezoelectric properties of these ceramic samples have been significantly improved compared to traditional single-structure bismuth-layered ferroelectrics. Among them, the SrBi8Ti7O27 ceramic sample exhibits the most outstanding performance, with a piezoelectric constant reaching 15 pC/N, the highest among all samples. However, the poor piezoelectric performance of the BaBi8Ti7O27 ceramic sample may be attributed to its excessively small grain size, which limits the switching of ferroelectric domains to a certain extent, thereby leading to inferior piezoelectric properties. Figure 3b shows the Curie temperatures of different ceramic samples. The Curie temperatures of BaBi8Ti7O27, SrBi8Ti7O27, and CaBi8Ti7O27 ceramic samples are 502 °C, 593 °C, and 685 °C, respectively. These Curie temperatures all fall within the Curie temperature range of the corresponding single-structure piezoelectric ceramics and BiT piezoelectric ceramics. This variation trend of Curie temperature is closely related to the crystal structure characteristics of the material. Furthermore, calculated from the tolerance factor formula, the tolerance factor of MBi8Ti7O27 piezoelectric ceramic samples decreases in sequence, and the lattice distortion increases accordingly, resulting in an increase in their Curie temperatures. In addition, for the CBT-BiT piezoelectric ceramics (CaBi8Ti7O27-Bi4Ti3O12), the dielectric constant continues to increase even after the Curie temperature. This phenomenon is mainly due to the influence of the behavior of space charges at high temperatures. At high temperature, thermal activation enhances the mobility of oxygen vacancies and other charge carriers. These carriers break free from traps, migrate over longer distances under the applied electric field, accumulate at interfaces or grain boundaries, and greatly strengthen space charge polarization [12]. Figure 3d presents the dielectric loss of all ceramic samples. It can be found from the figure that the SrBi8Ti7O27 and CaBi8Ti7O27 ceramic samples exhibit excellent dielectric loss performance, both at a low level of 1% or below. Meanwhile, the dielectric loss of the BaBi8Ti7O27 ceramic sample is also relatively low, only 1.7%. In summary, the piezoelectric property of this SrBi8Ti7O27 sample is much higher than that of single-structure bismuth-layered piezoelectric ceramics and consistent with those of the BBT samples [4,5,6,9]. However, the Curie temperature of this SrBi8Ti7O27 sample is significantly higher than that of BBT ceramics [9].

Figure 3.

Electrical properties of ceramic samples: (a) piezoelectric constant (d33), (b) Curie temperature (TC), (c) temperature dependence of dielectric constant at 10 kHz, and (d) dielectric loss (tanδ).

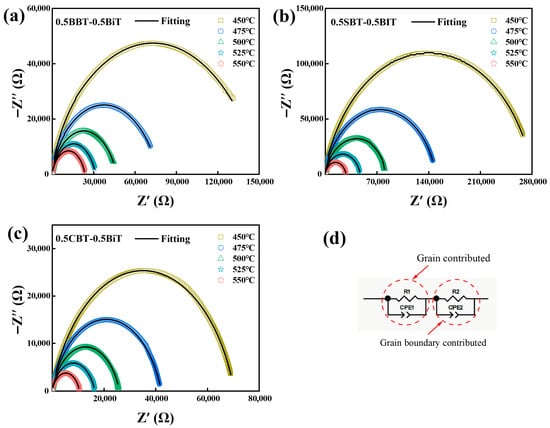

Figure 4 presents the complex impedance spectra (Z′-Z″) measured at different temperatures over a wide frequency range of 100 Hz to 10 MHz. These complex impedance spectra were fitted and analyzed using Z-View software (Version 4.1b), and Figure 4d shows the equivalent circuit model employed for the fitting analysis. Analysis of the complex impedance spectra enables us to distinguish between electrode effects, the electrical behavior within grains, and the influence of grain boundaries. As observed from the figures, the complex impedance spectra of all samples exhibit only a single semicircular arc, indicating that grain impedance makes a dominant contribution to the total impedance, while the grain boundary effect is not distinctly reflected in the spectra. Furthermore, the centers of the semicircular arcs for all samples are significantly located below the real axis at different temperatures, a phenomenon that demonstrates that the material exhibits non-Debye relaxation behavior. With the increase in temperature, the impedance values in the complex impedance spectra show a gradual decreasing trend. This phenomenon reveals that the ceramic samples possess a negative temperature coefficient (NTC) characteristic. Among all the samples studied, the SrBi4Ti4O15-Bi4Ti3O12 piezoelectric ceramics exhibit the highest impedance value. This characteristic is extremely beneficial for reducing leakage current during the polarization process, as a higher impedance can effectively suppress the generation of leakage current, thereby facilitating more sufficient polarization and ultimately enhancing the piezoelectric properties of the ceramics. To further investigate the conductive behavior of these ceramic samples, alternating current (AC) conductivity analysis and calculation of oxygen vacancy activation energy were performed.

Figure 4.

Nyquist plots of (a) BaBi8Ti7O27, (b) SrBi8Ti7O27, and (c) CaBi8Ti7O27 ceramics at different temperatures and (d) the corresponding analog circuit model.

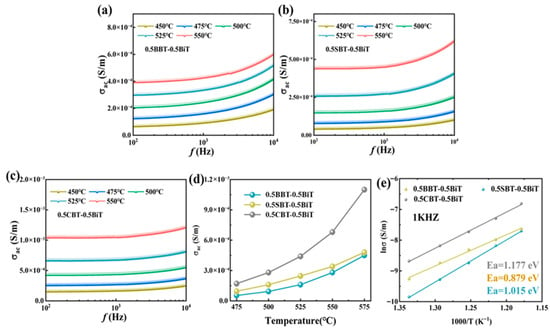

To analyze the electrical conductivity of MBi8Ti7O27 (where M denotes Ba, Sr, or Ca) piezoelectric ceramics, the AC conductivity (σac) of the ceramics was calculated using the following Equation (1).

where d and A represent the thickness and area of the samples, respectively. The frequency dependence of AC conductivity for all ceramic samples at different temperatures is shown in Figure 5. It can be observed that the AC conductivity increases with increasing temperature, which is mainly attributed to the thermal activation of charge carriers (primarily oxygen vacancies). In the high-frequency range, the conductivity increases significantly with temperature due to the effect of space charge hopping. Additionally, at low frequencies, the conductivity of the ceramics is nearly a straight line, indicating that the charge carriers undergo long-range migration; at this point, the AC conductivity is approximately a constant, which is generally referred to as the DC conductivity. As shown in the figure, SrBi4Ti4O15-Bi4Ti3O12 exhibits lower conductivity compared to the other two samples, primarily originating from the suppression of oxygen vacancy concentration by the symbiotic structure [13]. Lower conductivity is favorable for polarization, which explains why SrBi4Ti4O15-Bi4Ti3O12 ceramics possess the highest piezoelectric performance. Literature reports indicate that the AC conductivity activation energy can be calculated using the following Equation (2).

where σ0 is the pre-exponential factor.

Figure 5.

(a–d) Frequency dependence of AC conductivity of piezoelectric ceramics at different temperatures, (d) relationship between AC conductivity and temperature of piezoelectric ceramics at a frequency of 1 kHz, (e) Arrhenius plots of DC conductivity of ceramic samples at different temperatures.

Figure 5e presents the Arrhenius plots of DC conductivity for MBi8Ti7O27 (M=Ba, Sr, Ca) piezoelectric ceramics at a frequency of 1 kHz. The activation energy was calculated from the linear fitting data of the Lnσ-1000/T curves and summarized in the figure. The activation energies of all ceramics range from 0.879 to 1.117 eV, which are close to the activation energy of doubly ionized oxygen vacancies (1.0 eV). This indicates that the dominant conductive mechanism at 1 kHz is the migration of doubly ionized oxygen vacancies.

4. Conclusions

In this paper, ceramic samples of MBi4Ti4O15-Bi4Ti3O12 (M=Ba, Sr, Ca) with a symbiotic bismuth-layered structure were prepared via the traditional solid-state sintering method. Through systematic analysis of these samples, the following conclusions are drawn:

- (1)

- The crystal structure of MBi4Ti4O15-Bi4Ti3O12 (M=Ba, Sr, Ca) ceramic samples was confirmed by XRD analysis. The results show that the diffraction peaks of these ceramic samples are fully consistent with the orthorhombic P21am structure, and no secondary phases or obvious impurity peaks were detected.

- (2)

- Compared with traditional single-structure bismuth-layered piezoelectric ceramics, the long-range disordered array symbiotic structure introduced in MBi8Ti7O27 ceramics significantly modifies the microstructure and macro-performance of the material. Specifically, due to the lattice mismatch between the two perovskite-like layers connected above and below the bismuth–oxygen layer (Bi2O2)2+, the grain size of the ceramics is refined, and the aspect ratio of the grains is reduced simultaneously. This microstructural change effectively decreases the electrical conductivity of the ceramics, thereby enhancing the spontaneous polarization intensity and significantly improving the piezoelectric properties, while also altering the Curie temperature.

- (3)

- The MBi4Ti4O15-Bi4Ti3O12 (M=Ba, Sr, Ca) ceramic samples exhibit excellent piezoelectric properties and high Curie temperatures. Specifically, the piezoelectric constants (d33) of these samples range from 10 to 15 pC/N, and the Curie temperatures (TC) are in the range of 502~685 °C. Among them, the SrBi4Ti4O15-Bi4Ti3O12 ceramic sample performs particularly outstandingly, achieving the optimal comprehensive performance: the piezoelectric constant d33 is approximately 15 pC/N, and the Curie temperature TC is 593 °C. In addition, the alternating current (AC) conductivity (σac) of this sample is 5.3 × 10−5~4.8 × 10−4 S/m, and the dielectric loss (tanδ) is only 0.6% under the conditions of a temperature range of 475~575 °C and a frequency of 1 kHz. Owing to the excellent piezoelectric properties of this sample, it can offer potential application prospects in the fields of high-temperature sensors and actuators, while providing feasible reference ideas for the formulation optimization and performance regulation of related BiT-based high-temperature piezoelectric materials.

Author Contributions

Conceptualization, D.Z.; Investigation, J.F.; Resources, D.Z.; Data curation, X.Z.; Writing—original draft, J.F. and X.Z.; Writing—review & editing, J.F. and D.Z.; Funding acquisition, D.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This project is supported by the Guizhou Provincial Science and Technology Department [grant number QKHZC (2022) YB 080], the Guizhou Provincial Science and Technology Department [grant number QKHJC-ZK (2021) ZD 049].

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jin, H.N.; Gao, X.Y.; Ren, K.L. Review on Piezoelectric Actuators Based on High-Performance Piezoelectric Materials. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 3057–3069. [Google Scholar] [CrossRef] [PubMed]

- Moure, A. Review and Perspectives of Aurivillius Structures as a Lead-Free Piezoelectric System. Appl. Sci. 2018, 8, 62. [Google Scholar] [CrossRef]

- Jiang, D.W.; Zhou, Z.Y.; Liang, R.H.; Dong, X.L. Highly orientated Bi4Ti3O12 piezoceramics prepared by pressureless sintering. J. Eur. Ceram. Soc. 2021, 41, 1244–1250. [Google Scholar] [CrossRef]

- Li, X.D.; Chen, Z.N.; Sheng, L.S.; Li, L.L.; Bai, W.F.; Wen, F.; Zheng, P.; Wu, W.; Zheng, L.; Zhang, Y. Remarkable piezoelectric activity and high electrical resistivity in Cu/Nb co-doped Bi4Ti3O12 high temperature piezoelectric ceramics. J. Eur. Ceram. Soc. 2019, 39, 2050–2057. [Google Scholar] [CrossRef]

- Hu, Z.; Koval, V.; Zhang, H.; Chen, K.; Yue, Y.; Zhang, D.; Yan, H. Enhanced piezoelectricity in Na and Ce co-doped CaBi4Ti4O15 ceramics for high-temperature applications. J. Adv. Ceram. 2023, 12, 1331–1344. [Google Scholar] [CrossRef]

- Wang, Y.Y. Modification of BiT-Based High-Temperature Piezoelectric Ceramics via Point Defect and Symbiotic Structure Design. Ph.D. Thesis, Guizhou University, Guiyang, China, 2024. [Google Scholar]

- Carrillo-Aravena, E.; Consiglio, A.; Heßdörfer, J.; Friedrich, R.; Di Sante, D.; Ruck, M. Symmetry, Structural and Electronic Correlations in a Family of Bismuth-based Layered Materials. Acta Crystallogr. Sect. A Found. Adv. 2022, 78, E440–E441. [Google Scholar] [CrossRef]

- Qiu, R.H.; Li, Y.X.; Zhang, W.Q. Phase Competition in Bismuth Layered Structure Based on First Principles Thermodynamics. J. Inorg. Mater. 2014, 29, 1156–1160. [Google Scholar] [CrossRef]

- Kobayashi, T.; Noguchi, Y.; Miyayama, M. Enhanced spontaneous polarization in superlattice-structured Bi4Ti3O12–BaBi4Ti4O15 single crystals. Appl. Phys. Lett. 2005, 86, 012907. [Google Scholar] [CrossRef]

- Hou, R.Z.; Chen, X.M. Dielectric properties of La3+ substituted BaBi8Ti7O27 ceramics. Mater. Res. Bull. 2003, 38, 63–68. [Google Scholar] [CrossRef]

- Park, Y.; Cho, K.; Kim, H.G. Effect of Internal Stress on Physical Temperature Characteristics of Ceium-Doped and Gadolinium-Doped Barium Titanate Ceramics. J. Am. Ceram. Soc. 2010, 81, 1893–1899. [Google Scholar] [CrossRef]

- Zeng, F.F.; Liu, Q.B.; Cai, E.P.; Wang, Y.Y. Relaxor phenomenon of (1-x)(Ba0.85Ca0.15)(Zr0.09Ti0.91)O3-xTa+0.6wt%Li2CO3 ceramics with high piezoelectric constant and Curie temperature. Ceram. Int. 2018, 44, 10677–10684. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Zheng, D.Y.; Mao, R.Y.; Wang, X. Influences of intergrowth structure construction on the structural and electrical properties of the BBT-BiT ceramics. Front. Chem. 2022, 10, 1089739. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.