Surface Modification of Wood Fibers with Citric Acid as a Sustainable Approach to Developing Novel Polycaprolactone-Based Composites for Packaging Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Experimental Techniques

2.3.1. Characterization of Wood Fibers

2.3.2. Characterization of the Composites

3. Results and Discussion

3.1. Characterization of Wood Fibers

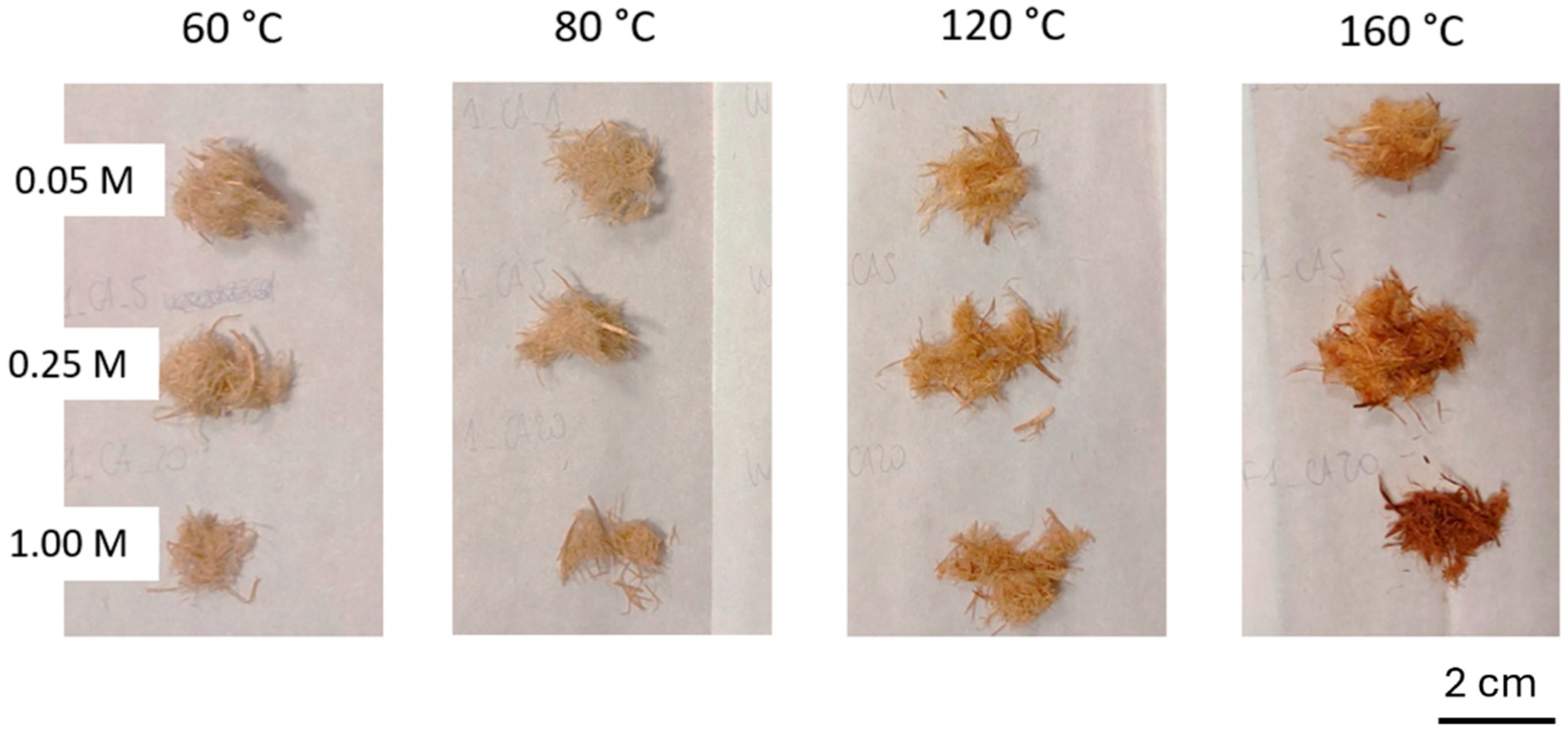

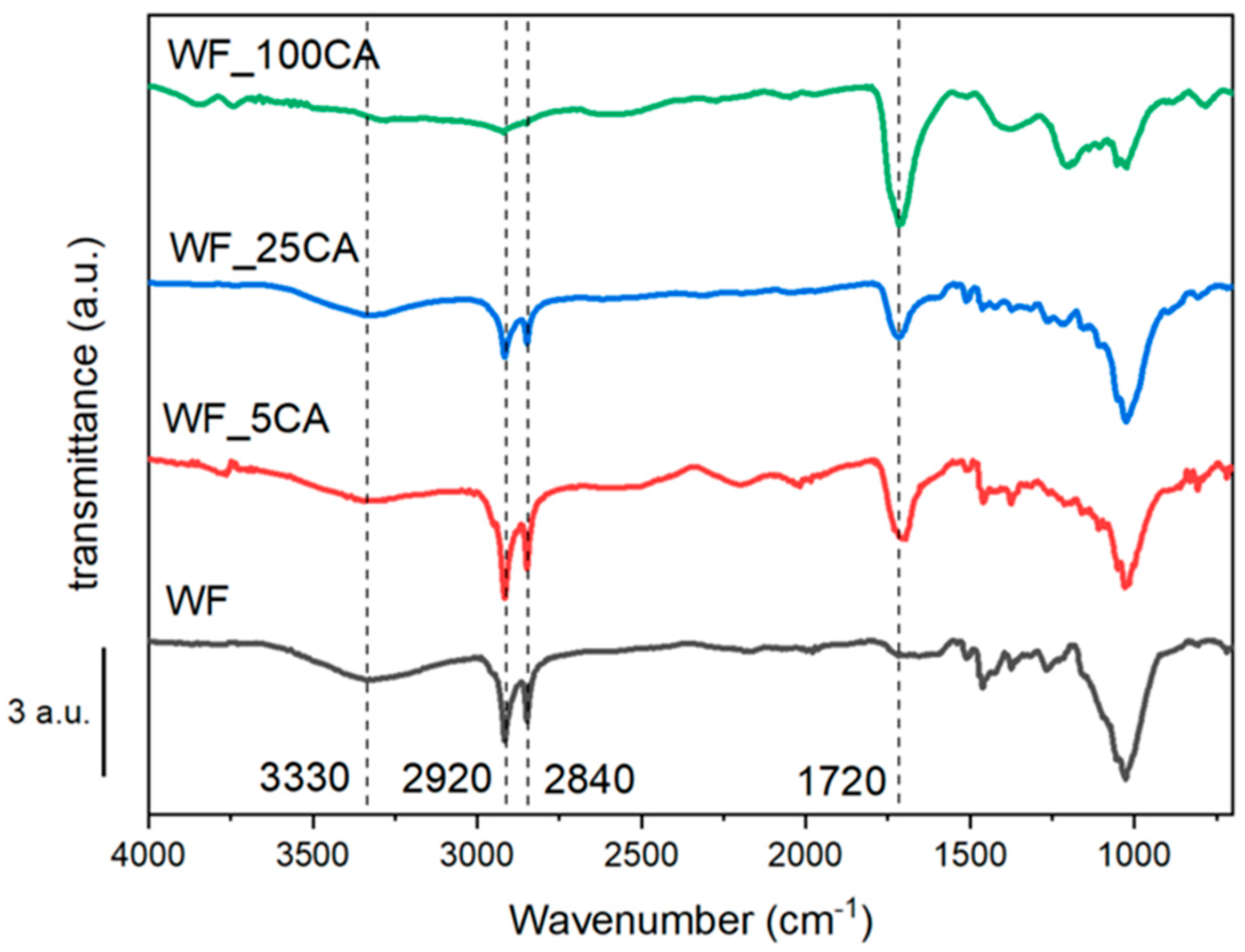

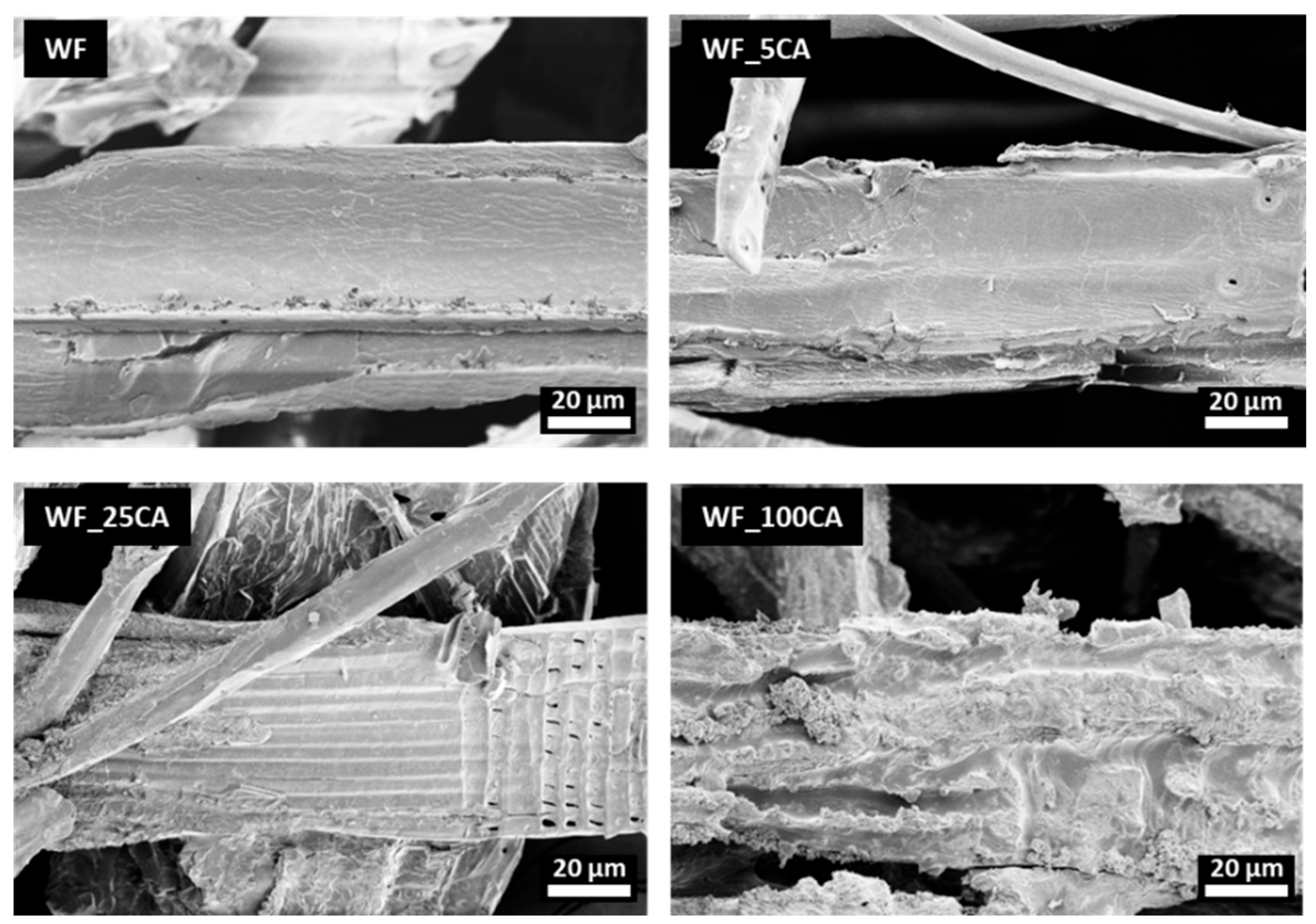

3.1.1. Chemical and Microstructural Characterization of Wood Fibers

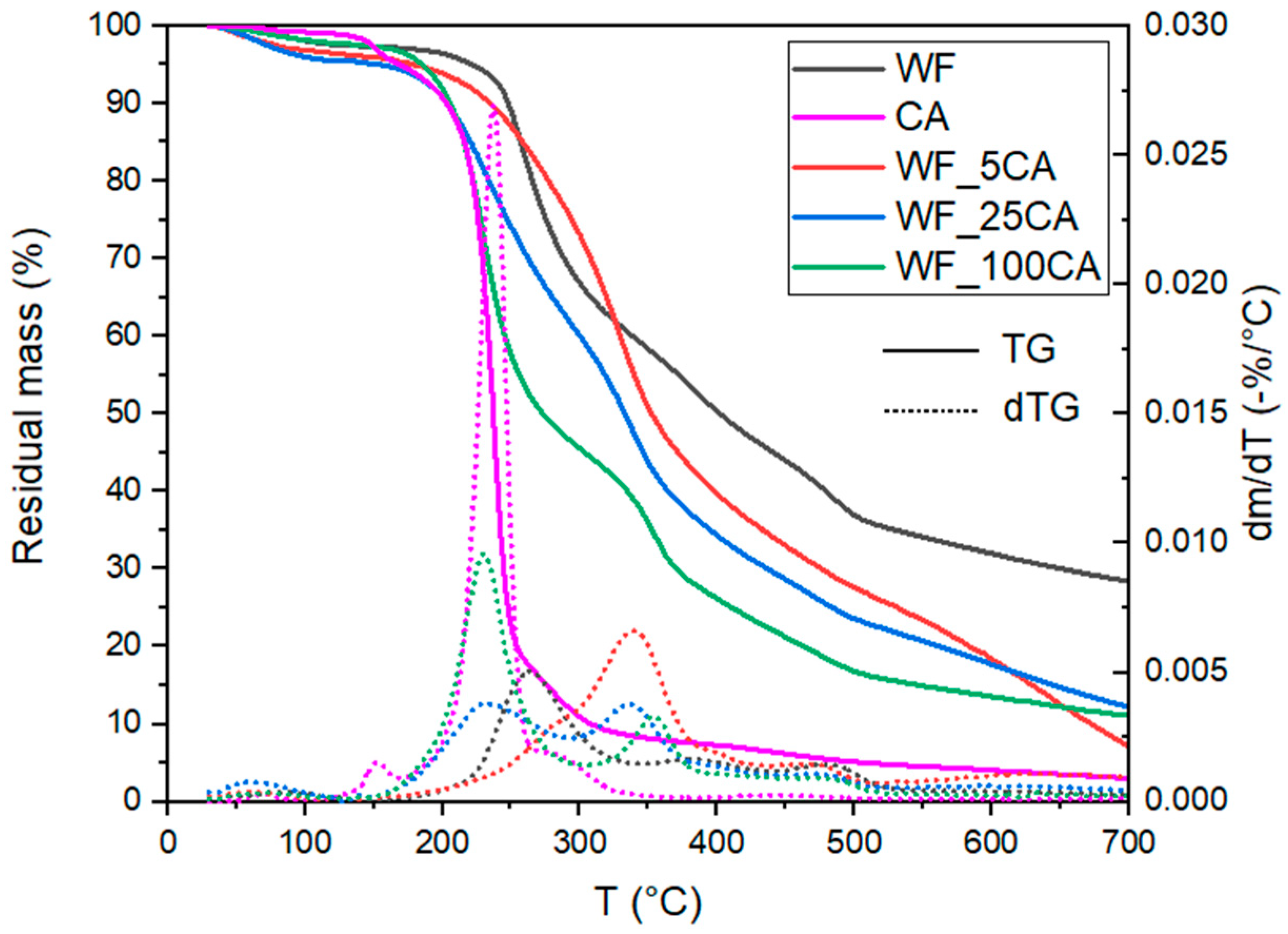

3.1.2. Thermal Characterization of Wood Fibers

3.2. Characterizaion of the Composites

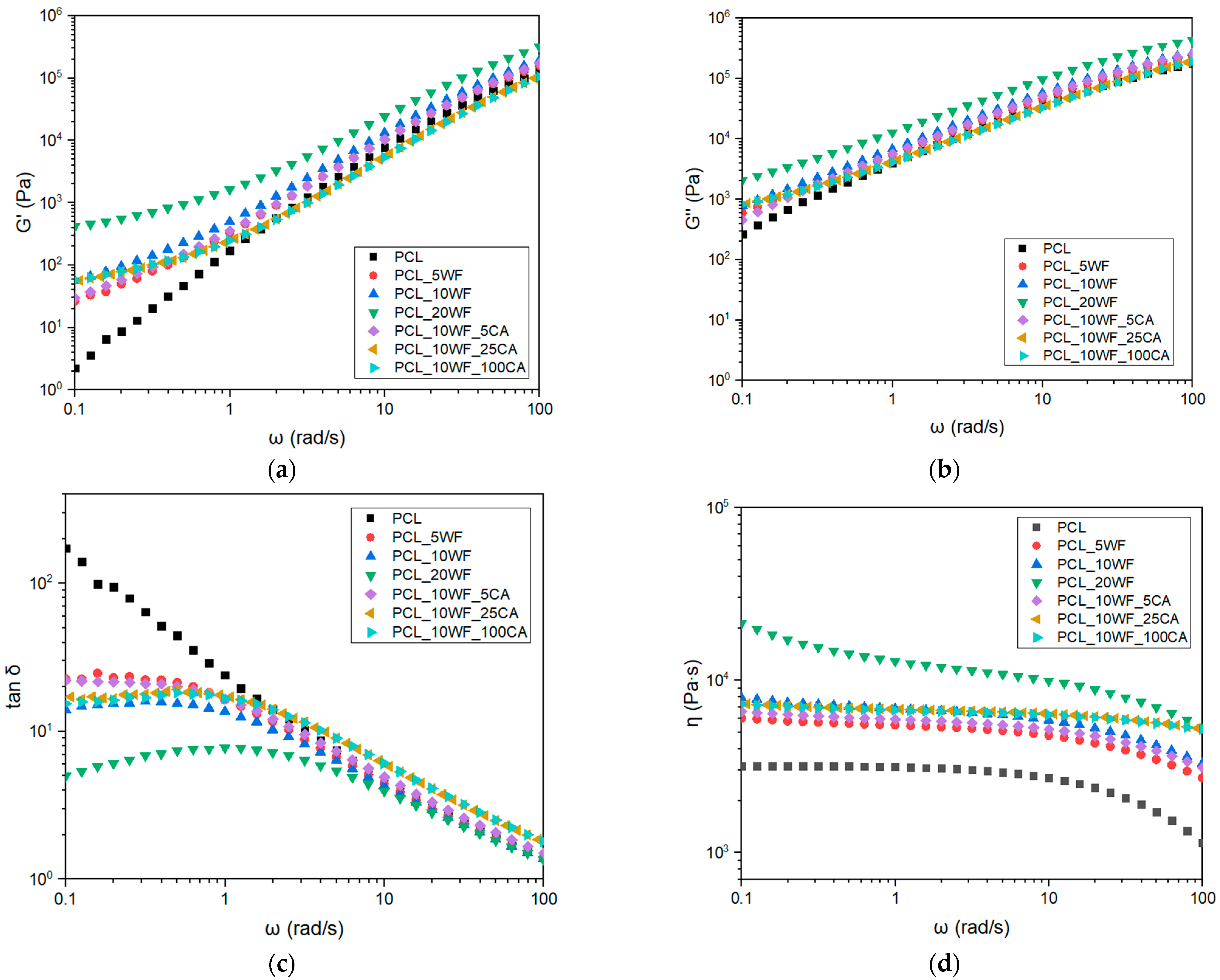

3.2.1. Rheological Characterization of the Composites

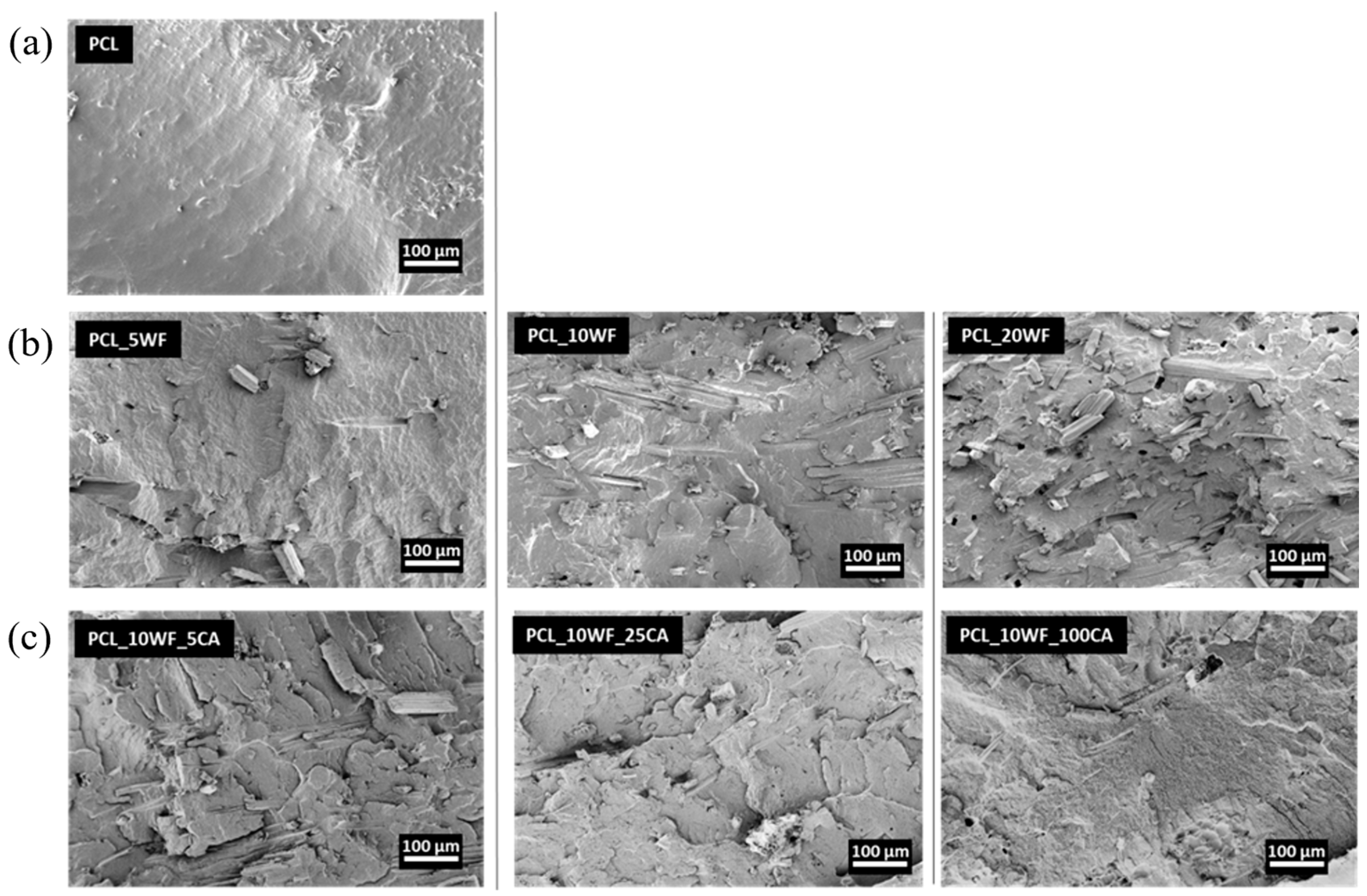

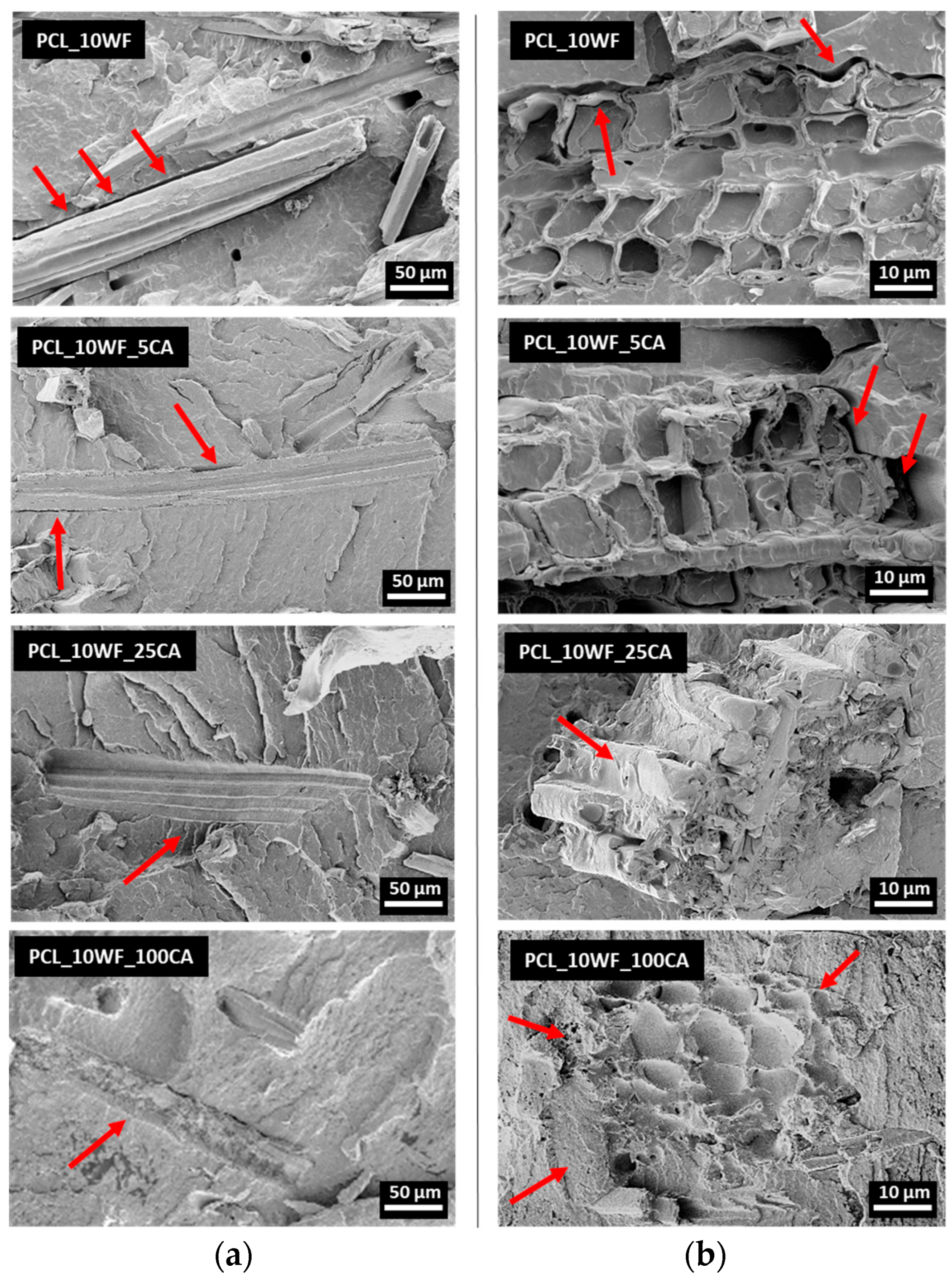

3.2.2. Morphological Characterization of Composites

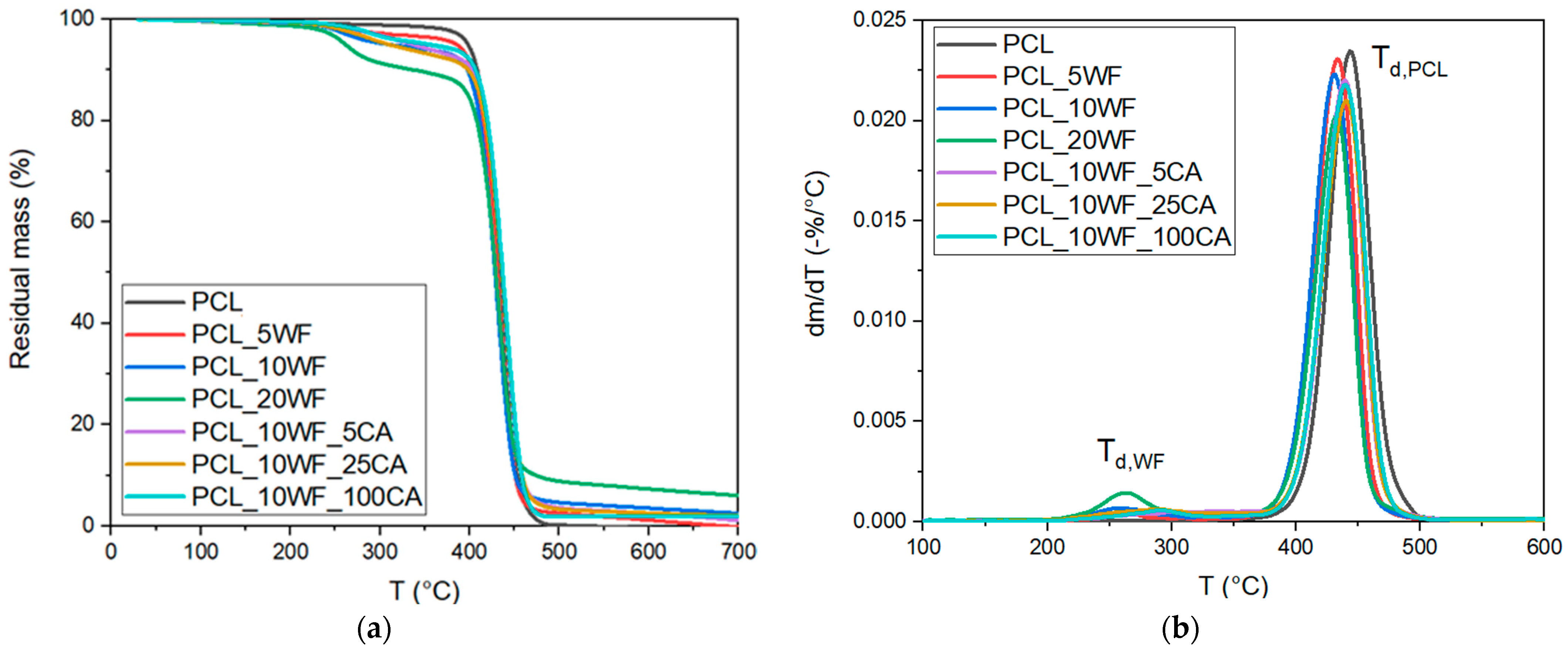

3.2.3. Thermal Characterization of the Composites

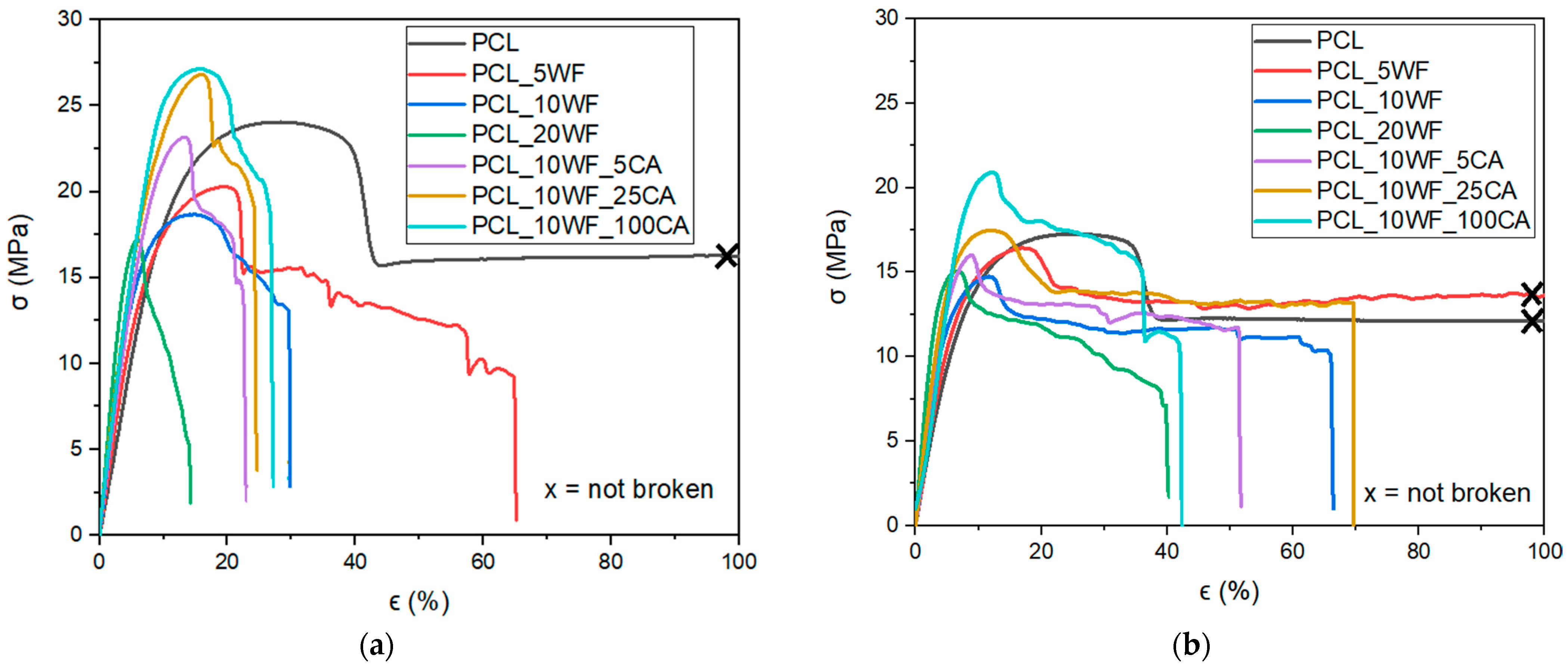

3.2.4. Mechanical Characterization of the Composites

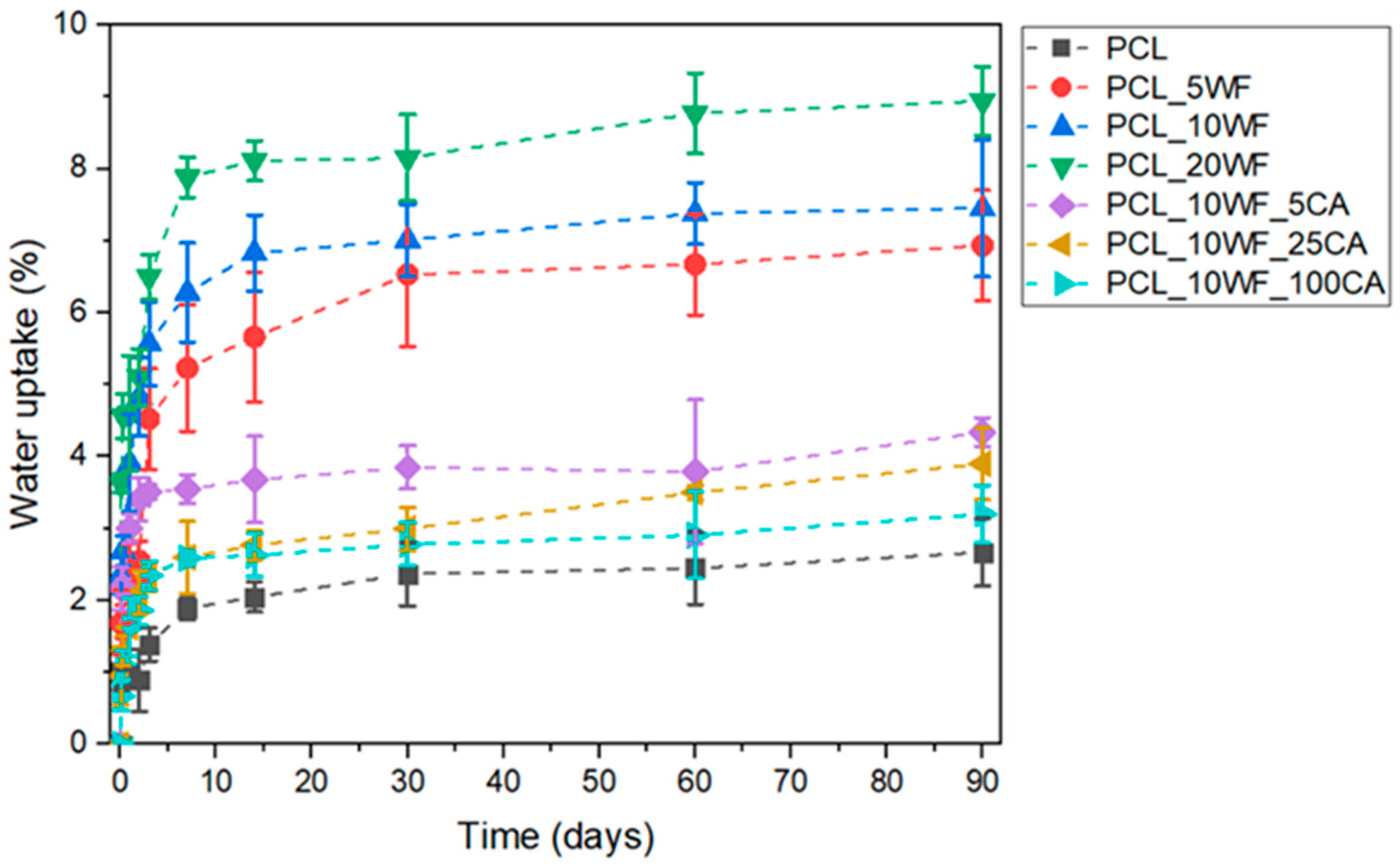

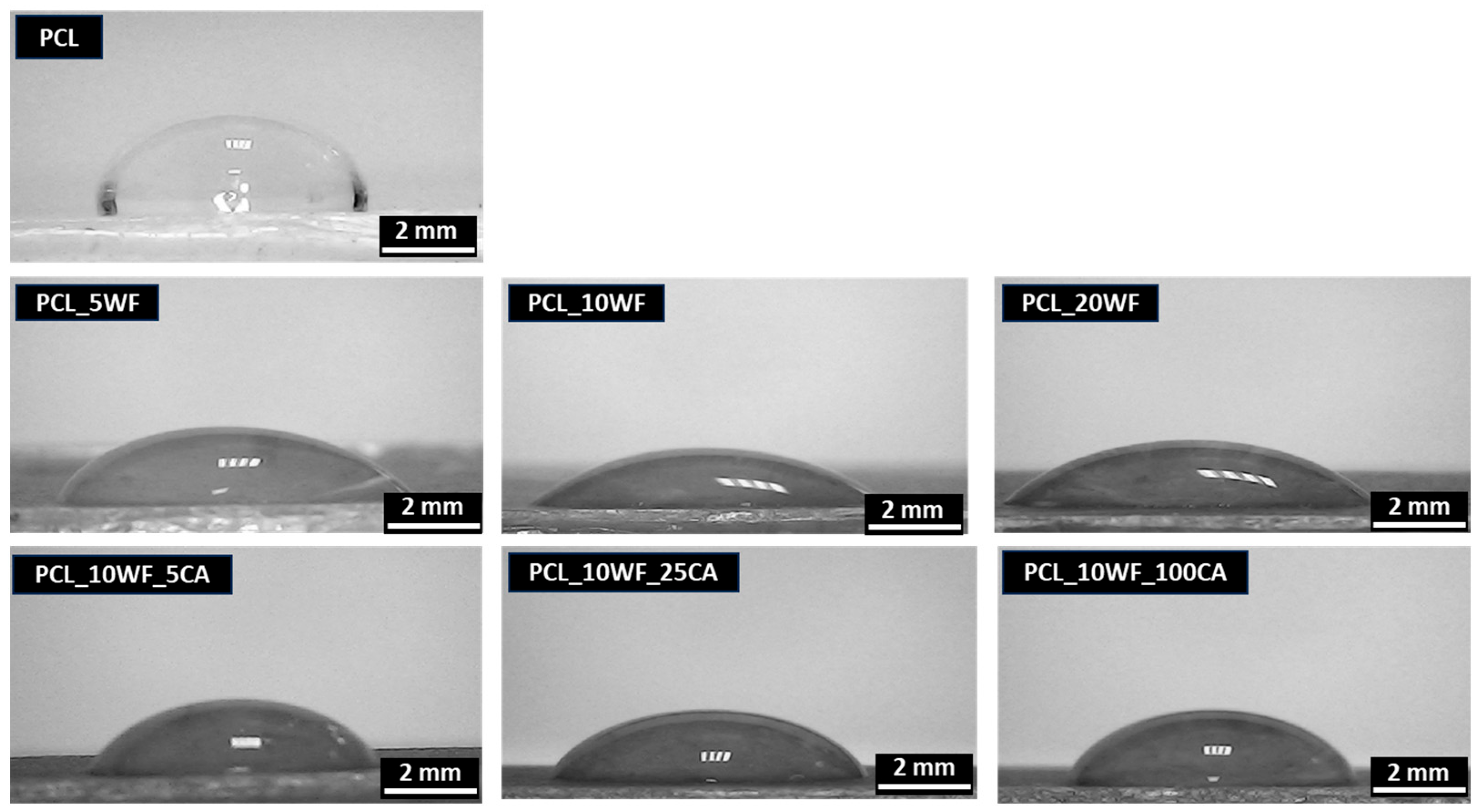

3.2.5. Water Uptake and Contact Angle Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ncube, L.; Ude, A.; Ogunmuyiwa, E.; Zulkifli, R.; Beas, I. An overview of plastic waste generation and management in food packaging industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Muhib, M.; Uddin, M.; Rahman, M.; Malafaia, G. Occurrence of microplastics in tap and bottled water, and food packaging: A narrative review on current knowledge. Sci. Total Environ. 2023, 865, 161274–161285. [Google Scholar] [CrossRef] [PubMed]

- Tas, C.; Unal, H. Thermally buffering polyethylene/halloysite/phase change material nanocomposite packaging films for cold storage of foods. J. Food Eng. 2021, 292, 110351–110359. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Simonini, L.; Sorze, A.; Maddalena, L.; Carosio, F.; Dorigato, A. Mechanical reprocessing of polyurethane and phenolic foams to increase the sustainability of thermal insulation materials. Polym. Test. 2024, 8, 108539. [Google Scholar] [CrossRef]

- Souza, V.; Pires, J.; Rodrigues, C.; Coelhoso, I.; Fernando, A. Chitosan composites in packaging industry—Current trends and future challenges. Polymers 2020, 11, 417. [Google Scholar] [CrossRef]

- Amara, C.; El Mahdi, A.; Medimagh, R.; Khwaldia, K. Nanocellulose-based composites for packaging applications. Curr. Opin. Green Sustain. Chem. 2021, 31, 100512–100527. [Google Scholar] [CrossRef]

- Deng, J.; Zhu, E.; Xu, G.; Naik, N.; Murugadoss, V.; Ma, M.; Guo, Z.; Shi, Z. Overview of renewable polysaccharide-based composites for biodegradable food packaging applications. Green Chem. 2022, 24, 480–492. [Google Scholar] [CrossRef]

- Stark, N.; Matuana, L. Trends in sustainable biobased packaging materials: A mini review. Mater. Today Sustain. 2021, 15, 100084–100093. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M. Bacterial cellulose as a biodegradable food packaging material: A review. Food Hydrocoll. 2021, 113, 106530–106539. [Google Scholar] [CrossRef]

- Thakur, M.; Majid, I.; Hussain, S.; Nanda, V. Poly (ε-caprolactone): A potential polymer for biodegradable food packaging applications. Packag. Technol. Sci. 2021, 34, 449–461. [Google Scholar] [CrossRef]

- Diken, M.; Kocer Kizilduman, B.; Doğan, S.; Doğan, M. Antibacterial and antioxidant phenolic compounds loaded PCL biocomposites for active food packaging application. J. Appl. Polym. Sci. 2022, 139, 52423–52438. [Google Scholar] [CrossRef]

- Amini, E.; Valls, C.; Roncero, M. Promising nanocomposites for food packaging based on cellulose–PCL films reinforced by using ZnO nanoparticles in an ionic liquid. Ind. Crops Prod. 2023, 193, 116246–116257. [Google Scholar] [CrossRef]

- Gutiérrez, T.; Mendieta, J.; Ortega-Toro, R. In-depth study from gluten/PCL-based food packaging films obtained under reactive extrusion conditions using chrome octanoate as a potential food grade catalyst. Food Hydrocoll. 2021, 111, 106255–106270. [Google Scholar] [CrossRef]

- Gürler, N.; Pekdemir, M.; Torğut, G.; Kök, M. Binary PCL–waste photopolymer blends for biodegradable food packaging applications. J. Mol. Struct. 2023, 1279, 134990–134997. [Google Scholar] [CrossRef]

- Khan, S.; Dhakal, H.; Saifullah, A.; Zhang, Z. Improved Mechanical and Thermal Properties of Date Palm Microfiber-Reinforced PCL Biocomposites for Rigid Packaging. Molecules 2025, 30, 857. [Google Scholar] [CrossRef] [PubMed]

- Simonini, L.; Canale, R.; Mahmood, H.; Dorigato, A.; Pegoretti, A. Multifunctional epoxy/carbon composites with a fully reparable interface. Polym. Compos. 2024, 45, 2558–2568. [Google Scholar] [CrossRef]

- Simonini, L.; Kakkonen, M.; Dsouza, R.; Kanerva, M.; Mahmood, H.; Dorigato, A.; Pegoretti, A. Tailoring the interfacial properties of glass fiber-epoxy microcomposites through the development of a self-healing poly (ϵ-caprolactone) coating. Compos. Sci. Technol. 2024, 261, 110991–111007. [Google Scholar] [CrossRef]

- Simonini, L.; Mahmood, H.; Dorigato, A.; Pegoretti, A. Evaluation of self-healing capability of a polycaprolactone interphase in epoxy/glass composites. Compos. Part A Appl. Sci. Manuf. 2023, 169, 107539–107548. [Google Scholar] [CrossRef]

- Dorigato, A.; Rigotti, D.; Pegoretti, A. Novel poly(caprolactone)/epoxy blends by additive manufacturing. Materials 2020, 13, 819. [Google Scholar] [CrossRef]

- Cescato, R.; Rigotti, D.; Mahmood, H.; Dorigato, A.; Pegoretti, A. Thermal mending of electroactive carbon/epoxy laminates using a porous poly(ε-caprolactone) electrospun mesh. Polymers 2021, 13, 2723. [Google Scholar] [CrossRef]

- Simonini, L.; Rigotti, D.; Pidapa, J.; Pegoretti, A. Poly (butylene adipate-co-terephthalate) as a new healing agent for epoxy/basalt composites. Compos. Part A Appl. Sci. Manuf. 2025, 6, 109010–109019. [Google Scholar] [CrossRef]

- Archer, E.; Torretti, M.; Madbouly, S. Biodegradable polycaprolactone (PCL) based polymer and composites. Phys. Sci. Rev. 2023, 8, 4391–4414. [Google Scholar] [CrossRef]

- Luna, C.; Siqueira, D.; Ferreira, E.; Araujo, E.; Wellen, R. Effect of injection parameters on the thermal, mechanical and thermomechanical properties of polycaprolactone (PCL). J. Elastomers Plast. 2021, 53, 1045–1062. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395–101435. [Google Scholar] [CrossRef]

- Dybka-Stępień, K.; Antolak, H.; Kmiotek, M.; Piechota, D.; Koziróg, A. Disposable food packaging and serving materials—Trends and biodegradability. Polymers 2021, 19, 3606. [Google Scholar] [CrossRef]

- Bezerra, E.; França, D.; Morais, D.; Rosa, M.; Morais, J.; Araújo, E.; Wellen, R. Processing and properties of PCL/cotton linter compounds. Mater. Res. 2017, 20, 317–325. [Google Scholar] [CrossRef]

- Rytlewski, P.; Stepczyńska, M.; Moraczewski, K.; Malinowski, R.; Jagodziński, B.; Żenkiewicz, M. Mechanical properties and biodegradability of flax fiber-reinforced composite of polylactide and polycaprolactone. Polimery 2018, 63, 603–610. [Google Scholar] [CrossRef]

- Dhakal, H.; Ismail, S.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.; Beaugrand, J. Development of sustainable biodegradable lignocellulosic hemp fiber/polycaprolactone biocomposites for light weight applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef]

- Ilyas, R.; Zuhri, M.; Norrrahim, M.; Misenan, M.; Jenol, M.; Samsudin, S.; Nurazzi, N.; Asyraf, M.; Supian, A.; Bangar, S.; et al. Natural fiber-reinforced polycaprolactone green and hybrid biocomposites for various advanced applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef]

- Jian, B.; Mohrmann, S.; Li, H.; Li, Y.; Ashraf, M.; Zhou, J.; Zheng, X. A review on flexural properties of wood-plastic composites. Polymers 2022, 14, 3942. [Google Scholar] [CrossRef] [PubMed]

- Cintra, S.; Braga, N.; Morgado, G.; Montanheiro, T.; Marini, J.; Passador, F.; Montagna, L. Development of new biodegradable composites materials from polycaprolactone and wood flour. Wood Mater. Sci. Eng. 2022, 17, 586–597. [Google Scholar] [CrossRef]

- Herrera, N.; Olsen, P.; Berglund, L. Strongly improved mechanical properties of thermoplastic biocomposites by PCL grafting inside holocellulose wood fibers. ACS Sustain. Chem. Eng. 2020, 20, 11977–11985. [Google Scholar] [CrossRef]

- Lo Re, G.; Spinella, S.; Boujemaoui, A.; Vilaseca, F.; Larsson, P.; Adås, F.; Berglund, L. Poly (ε-caprolactone) biocomposites based on acetylated cellulose fibers and wet compounding for improved mechanical performance. ACS Sustain. Chem. Eng. 2018, 6, 6753–6760. [Google Scholar] [CrossRef]

- Mohammed, M.; Rahman, R.; Mohammed, A.; Adam, T.; Betar, B.; Osman, A.; Dahham, O. Surface treatment to improve water repellence and compatibility of natural fiber with polymer matrix: Recent advancement. Polym. Test. 2022, 115, 107707–107732. [Google Scholar] [CrossRef]

- Mahmood, H.; Simonini, L.; Dorigato, A.; Pegoretti, A. Graphene deposition on glass fibers by triboelectrification. Appl. Sci. 2021, 11, 3123. [Google Scholar] [CrossRef]

- Pozueco, S.; Simonini, L.; Mahmood, H.; Rigotti, D.; Kakkonen, M.; Riveiro, A.; Comesaña, R.; Pou, J.; Tanhuanpää, O.; Kanerva, O.; et al. Influence of CO2 laser surface treatment of basalt fibres on the mechanical properties of epoxy/basalt composites. Polym. Compos. 2024, 45, 10965–10975. [Google Scholar] [CrossRef]

- Simonini, L.; Mahmood, H.; Dorigato, A.; Pegoretti, A. Tailoring the physical properties of poly (lactic acid) through the addition of thermoplastic polyurethane and functionalized short carbon fibers. Polym. Compos. 2023, 44, 4719–4733. [Google Scholar] [CrossRef]

- Show, P.; Oladele, K.; Siew, Q.; Aziz Zakry, F.; Lan, J.; Ling, T. Overview of citric acid production from Aspergillus niger. Front. Life Sci. 2015, 8, 271–283. [Google Scholar] [CrossRef]

- Sorze, A.; Valentini, F.; Mucignat, M.; Pegoretti, A.; Dorigato, A. Multifunctional xanthan gum/wood fibers based hydrogels as novel topsoil covers for forestry and agricultural applications. Carbohydr. Polym. Technol. Appl. 2024, 7, 100520–100530. [Google Scholar] [CrossRef]

- Behera, B.; Mishra, R.; Mohapatra, S. Microbial citric acid: Production, properties, application, and future perspectives. Food Front. 2021, 2, 62–76. [Google Scholar] [CrossRef]

- Huang, F.; Tian, Z.; Wang, Y.; Ji, X.; Wang, D.; Fatehi, P. ellulose fiber drainage improvement via citric acid crosslinking. Int. J. Biol. Macromol. 2024, 281, 136338–136347. [Google Scholar] [CrossRef]

- Cui, X.; Ozaki, A.; Asoh, T.; Uyama, H. Cellulose modified by citric acid reinforced Poly (lactic acid) resin as fillers. Polym. Degrad. Stab. 2020, 175, 109118–109125. [Google Scholar] [CrossRef]

- ISO 527; Plastic—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2021.

- ASTM D1525; Standard Test Method for Vicat Softening Temeperature of Plastic. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D570; Standard Test Method for Water Absorption of Plastic. ASTM: West Conshohocken, PA, USA, 2022.

- Sorze, A.; Valentini, F.; Smolar, J.; Logar, J.; Pegoretti, A.; Dorigato, A. Effect of different cellulose fillers on the properties of xanthan-based composites for soil conditioning applications. Materials 2023, 16, 7285. [Google Scholar] [CrossRef]

- Wu, Q.; Jiang, K.; Wang, Y.; Chen, Y.; Fan, D. Cross-linked peach gum polysaccharide adhesive by citric acid to produce a fully bio-based wood fiber composite with high strength. Int. J. Biol. Macromol. 2023, 253, 127514–127523. [Google Scholar] [CrossRef] [PubMed]

- Gebke, S.; Thümmler, K.; Sonnier, R.; Tech, S.; Wagenführ, A.; Fischer, S. Flame retardancy of wood fiber materials using phosphorus-modified wheat starch. Molecules 2020, 25, 335. [Google Scholar] [CrossRef]

- Zakaria, R.; Bawon, P.; Lee, S.; Salim, S.; Lum, W.; Al-Edrus, S.; Ibrahim, Z. Properties of particleboard from oil palm biomasses bonded with citric acid and tapioca starch. Polymers 2021, 13, 3494. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Dun, M.; Chen, B.; Zhou, Z.; Wang, H.; Wang, W.; Xie, Y.; Wang, Q. Compression rheological behavior of ultrahighly filled wood flour-polyethylene composites. Compos. Part B Eng. 2021, 215, 108766–108781. [Google Scholar] [CrossRef]

- Olonisakin, K.; Lin, H.; Haojin, P.; Aishi, W.; Wang, H.; Li, R.; Xin-Xiang, Z.; Yang, W. Fiber treatment impact on toughness and interfacial bonding in epoxidized soya bean oil compatibilized PLA/PBAT bamboo fiber composites. Mater. Today Commun. 2024, 38, 107790–107803. [Google Scholar] [CrossRef]

- Arman, N.; Chen, R.; Ahmad, S. Review of state-of-the-art studies on the water absorption capacity of agricultural fiber-reinforced polymer composites for sustainable construction. Constr. Build. Mater. 2021, 302, 124174–124188. [Google Scholar] [CrossRef]

- Sekar, S.; Suresh Kumar, S.; Vigneshwaran, S.; Velmurugan, G. Evaluation of mechanical and water absorption behavior of natural fiber-reinforced hybrid biocomposites. J. Nat. Fibers 2022, 19, 1772–1782. [Google Scholar] [CrossRef]

- Arul, S.; Adhikary, P.; SiP, J.; Haiter Lenin, A. Moisture diffusion analysis and their effects on the mechanical properties of organic particle filled natural fiber reinforced hybrid polymer composites. Int. J. Polym. Anal. Charact. 2024, 29, 42–55. [Google Scholar] [CrossRef]

- Khorramnezhad, M.; Akbari, B.; Akbari, M.; Kharaziha, M. Effect of surface modification on physical and cellular properties of PCL thin film. Colloids Surf. B Biointerfaces 2021, 200, 111582–111589. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, M.; Martin, J.; Celada, L.; Olsén, P.; Wågberg, L. Strategic functionalization of wood fibers for the circular design of fiber-reinforced hydrogel composites. Cell Rep. Phys. Sci. 2025, 1, 102455. [Google Scholar]

| Sample | PCL Content (%wt) | WF Content (%wt) | CA Solution (M) |

|---|---|---|---|

| PCL | 100 | 0 | - |

| PCL_5WF | 95 | 5 | - |

| PCL_10WF | 90 | 10 | - |

| PCL_20WF | 80 | 20 | - |

| PCL_10WF_5CA | 90 | 10 | 0.05 |

| PCL_10WF_25CA | 90 | 10 | 0.25 |

| PCL_10WF_100CA | 90 | 10 | 1.00 |

| Samples | T5% (°C) | Td,CA (°C) | Td,WF_1 (°C) | Td,WF_2 (°C) | Td,WF_3 (°C) | m700 (%) |

|---|---|---|---|---|---|---|

| WF | 227.3 | - | 264.6 | 391.3 | 482.8 | 27.8 |

| WF_5CA | 190.4 | - | 256.3 | 338.3 | 479.3 | 7.5 |

| WF_25CA | 175.2 | 235.7 | - | 336.8 | 476.8 | 12.4 |

| WF_100CA | 182.3 | 225.5 | - | 355.5 | 477.2 | 11.2 |

| CA | 170.2 | 235.3 | - | - | - | 0.0 |

| Samples | T5% (°C) | Td,WF (°C) | Td,PCL (°C) | m700 (%) |

|---|---|---|---|---|

| PCL | 398.2 | - | 433.5 | 0.0 |

| PCL_5WF | 386.5 | 259.0 | 433.3 | 0.0 |

| PCL_10WF | 321.2 | 258.0 | 432.3 | 2.5 |

| PCL_20WF | 259.2 | 260.5 | 431.2 | 6.0 |

| PCL_10WF_5CA | 334.3 | 284.7 | 438.5 | 1.1 |

| PCL_10WF_25CA | 314.1 | 296.2 | 437.5 | 1.9 |

| PCL_10WF_100CA | 321.2 | 298.7 | 437.7 | 2.0 |

| Sample | 0 °C | 25 °C | |||||

|---|---|---|---|---|---|---|---|

| E (MPa) | σy (MPa) | ϵb (%) | E (MPa) | σy (MPa) | ϵb (%) | VST (°C) | |

| PCL | 228 ± 14 | 23 ± 1 | 358 ± 83 | 202 ± 5 | 17 ± 1 | 1301 ± 4 | 52.7 ± 0.6 |

| PCL_5WF | 259 ± 16 | 19 ± 1 | 46 ± 19 | 271 ± 15 | 14 ± 3 | 1016 ± 50 | 54.2 ± 0.5 |

| PCL_10WF | 327 ± 14 | 19 ± 1 | 27 ± 10 | 333 ± 3 | 15 ± 1 | 61 ± 21 | 56.1 ± 0.5 |

| PCL_20WF | 458 ± 15 | 17 ± 1 | 14 ± 1 | 467 ± 69 | 14 ± 1 | 36 ± 11 | 58.8 ± 0.7 |

| PCL_10WF_5CA | 337 ± 30 | 23 ± 1 | 23 ± 2 | 337 ± 37 | 14 ± 2 | 49 ± 10 | 56.5 ± 0.3 |

| PCL_10WF_25CA | 354 ± 27 | 27 ± 2 | 33 ± 7 | 348 ± 31 | 15 ± 2 | 54 ± 19 | 57.7 ± 0.5 |

| PCL_10WF_100CA | 354 ± 31 | 26 ± 3 | 27 ± 2 | 348 ± 21 | 19 ± 3 | 53 ± 22 | 58.8 ± 0.5 |

| Samples | D (10−13 × m2/s) | WU90 (%) |

|---|---|---|

| PCL | 1.06 ± 0.36 | 2.67 ± 0.47 |

| PCL_5WF | 1.31 ± 0.46 | 6.93 ± 0.77 |

| PCL_10WF | 1.27 ± 0.52 | 7.44 ± 0.95 |

| PCL_20WF | 1.27 ± 0.64 | 8.94 ± 0.48 |

| PCL_10WF_5CA | 1.22 ± 0.43 | 4.34 ± 0.20 |

| PCL_10WF_25CA | 1.18 ± 0.36 | 3.90 ± 0.51 |

| PCL_10WF_100CA | 1.19 ± 0.62 | 3.22 ± 0.42 |

| Samples | θc (°) |

|---|---|

| PCL | 84.2 ± 3.1 |

| PCL_5WF | 47.8 ± 2.9 |

| PCL_10WF | 51.2 ± 2.4 |

| PCL_20WF | 45.4 ± 4.5 |

| PCL_10WF_5CA | 55.2 ± 3.4 |

| PCL_10WF_25CA | 56.5 ± 1.3 |

| PCL_10WF_100CA | 61.2 ± 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simonini, L.; Dorigato, A. Surface Modification of Wood Fibers with Citric Acid as a Sustainable Approach to Developing Novel Polycaprolactone-Based Composites for Packaging Applications. J. Compos. Sci. 2025, 9, 274. https://doi.org/10.3390/jcs9060274

Simonini L, Dorigato A. Surface Modification of Wood Fibers with Citric Acid as a Sustainable Approach to Developing Novel Polycaprolactone-Based Composites for Packaging Applications. Journal of Composites Science. 2025; 9(6):274. https://doi.org/10.3390/jcs9060274

Chicago/Turabian StyleSimonini, Laura, and Andrea Dorigato. 2025. "Surface Modification of Wood Fibers with Citric Acid as a Sustainable Approach to Developing Novel Polycaprolactone-Based Composites for Packaging Applications" Journal of Composites Science 9, no. 6: 274. https://doi.org/10.3390/jcs9060274

APA StyleSimonini, L., & Dorigato, A. (2025). Surface Modification of Wood Fibers with Citric Acid as a Sustainable Approach to Developing Novel Polycaprolactone-Based Composites for Packaging Applications. Journal of Composites Science, 9(6), 274. https://doi.org/10.3390/jcs9060274