1. Introduction

Polymer concrete (PC) is a lightweight, wear-resistant, skid-resistant and waterproof material, which makes it a viable selection for infrastructure maintenance, rehabilitation and preservations [

1,

2]. PC has characteristics that make it highly suitable for accelerated construction. Generally, PC is applied at a thickness of ½ to ¾ inches; also, it cures rapidly [

3,

4,

5]. A polymer concrete overlay on concrete substrates can minimize traffic disruption. Sometimes, workers can apply the overlay at night and then allow traffic on the following day. Typically, polymer concrete comprises fine and coarse aggregates, a catalyst, and a binder. The choice of binder for bridge deck overlays is an important factor in achieving several characteristics. The suggested ratio of binder to aggregate (filler and coarse) for the design of the PC mix is usually 1:3.7 [

6]. Studies have shown that maintaining a 7:3 weight ratio between filler and coarse aggregate can enhance the performance of PC. On the other hand, PC has great crack resistance and durability. Also, in order to decrease galvanic corrosion, it acts as a barrier between different substances [

7,

8]. A solid adhesion to the concrete substrate is necessary when considering bridge deck overlays. The ability of the bonded joint to withstand all anticipated in-service loads and climatic conditions—which can differ greatly—is crucial [

9]. In this regard, enhancing the bond strength of PC with the concrete substrate is of great importance and needs to be explored. Previous studies have added carbon fibers and synthetic chopped glass to PC in weight-based amounts ranging from 0.3% to 7.5%, but the mechanical characteristics of PC were only slightly improved [

10,

11,

12]. Nevertheless, fiber addition limits the use of PC and decreases its workability [

13]. This problem stems from the fact that using chopped fibers makes it harder to achieve an ideal finish, in addition to the lower flowability. Although ductility can be improved by raising the ratio of resin to filler, the compressive strength can be reduced by up to 26% and flexural strength by up to 70% [

14]. So, there is a need for new approaches to improve the bond strength of PC overlay material with a concrete substrate without sacrificing its applications.

Within the last decade, research studies have evaluated the potential of using nanomaterials to change the performance of materials. The much greater surface area of nanomaterials, relative to microfibers and other additives, enables interactions at multiple levels and therefore promotes an impact on the mesoscale [

15]. The role of a PC binder’s chemical composition is critical for the efficiency of nanomaterials [

16]. Nanomaterials are more efficient in performance when they are in close contact with the host matrix and a chemical binder because they enhance chemical interactions throughout the polymerization process [

17,

18]. One of the nanomaterials that has been widely utilized is carbon nanotubes (CNTs). CNTs feature a high aspect ratio, with diameters on the nanometer scale and lengths on the micrometer scale, coupled with low densities [

19]. These exceptional characteristics make CNTs a highly regarded potential filler material for polymeric nanocomposites. Since carbon nanotubes (CNTs) were first discovered [

20], their unique structural, chemical, and physical characteristics have drawn considerable interest. Researchers have aimed to harness these remarkable traits for various types of applications, such as field emission displays, electronic devices, hydrogen storage, and polymer composites [

21]. CNTs are divided into multi-walled carbon nano tubes (MWCNTs) and single-walled carbon nanotubes (SWCNTs). SWCNTs are more flexible and have fewer defects compared to MWCNTs. By rolling concentric graphene sheets, MWCNTs can be made from SWCNTs. This means that the choice of using either MWCNTs or SWCNTs should be made based on the area of application [

22]. Regarding mechanical properties, a single-walled carbon nanotube (SWCNT) is significantly stiffer than steel [

23]. For multi-walled nanotubes (MWCNTs), the modulus can range from 200 to 4000 GPa. MWCNTs offer outstanding mechanical characteristics and have been linked to enhancements in durability, fatigue resistance, glass transition temperature strength, fracture toughness, and the controlled viscoelastic properties of polymers [

24,

25]. The effectiveness of dispersion of carbon nanotubes (CNTs) differs based on the amount and type of nanomaterials used. The most widely used methods include stirring, shear mixing, ball milling, ultrasonication, chemical functionalization, and extrusion [

26]. Nanomaterials which have higher aspect ratios, such as MWCNTs, are difficult to disperse relative to other nanomaterials, due to the high friction and energy granted to them by strong van der Waals forces [

26].

In addition to bonding with regular concrete, the bonds that PC develops with concrete exposed to extreme harsh climatic conditions need to be strong. Such conditions cause degradation and negatively impact the performance of concrete infrastructure [

24,

27]. The two main negative influences on concrete performance, particularly in unfavorable climatic environments, are sulfate and corrosion [

28,

29,

30]. Chloride poses a threat to steel reinforcement and impacts the durability of concrete [

31]. Meanwhile, sulfate reacts with the products of cement hydration, resulting in the formation of gypsum, ettringite, and other compounds [

32]. The formation of these compounds causes cracking and expansion, which creates additional pathways for other deleterious ions to enter and accelerates the deterioration of concrete materials [

33,

34]. The sources of sulfate attack can be categorized as external and internal. The internal source originates from sulfate being made available within the concrete elements themselves. The external source is composed of the surrounding environment, including soil, groundwater, contaminated fluids or soils, transported from coastal areas, seawater, river water, acid rain, and fluids; this also contributes to sulfate exposure [

35,

36,

37]. Concrete exposed to these conditions may experience sulfate attacks, which typically results in the deterioration of their bearing capacity [

29]. Han et al. [

38] discovered that multiwalled carbon nanotubes (MWCNTs) can reduce the gas permeability of cement-based materials, water permeability, and the absorption coefficient. Li et al. [

39] found that adding carbon nanotubes to cement can refine pores larger than 200 nm to 50–100 nm, and improve pore disconnection. Camacho et al. [

40] observed an increase in porosity when CNTs were added to cement-based materials. Their results also indicated that the inclusion of CNTs accelerated concrete deterioration under carbonation and facilitated the ingress of chloride ions. Bheel et al. [

41] found that incorporating 0.05% CNTs in cementitious composites caused a 23% improvement in compressive strength. Additionally, the presence of CNTs in the cementitious matrix reduced expansion due to sulfate resistance and minimized length changes caused by acid attack. Furthermore, increasing the percentage of CNTs in the composites led to reduced pH values and weight loss due to acid attack, as well as lower chloride permeability rates. While previous studies highlighted the durability benefits of CNTs against chemical attacks, the specific impact of sulfate-induced deterioration on the bond strength of polymer concrete overlays remains largely underexplored. Gaining insight into this interaction is essential for developing materials capable of withstanding harsh environmental conditions.

The primary objective of this research is to investigate the effect of carbon nanotube incorporation on the pull-off strength of polymer concrete bonded to both healthy and deteriorated concrete substrates. To achieve this goal, a comprehensive experimental program was conducted, including the preparation and characterization of PC mixtures with varying concentrations of multi-walled carbon nanotubes, as well as mechanical testing such as modulus of rupture and compressive strength evaluations. Concrete specimens were exposed to sulfate environments to simulate deterioration, and both unmodified and nanomodified PC overlays were applied to these substrates. Bond strength was assessed using ASTM C1583, which involves drilling cores through the PC overlay into the concrete substrate. Microscopic analysis was performed to examine the dispersion of MWCNTs within the PC matrix and to evaluate the failure surfaces after pull-off testing. This study, therefore, bridges a critical knowledge gap by providing a direct comparative analysis of pristine versus functionalized MWCNTs on the overlay bond strength to concrete substrates explicitly damaged by sulfate attack, directly informing more resilient repair strategies. The findings provide valuable insight into the influence of nanomaterials on the bond behavior of PC overlays, supporting the development of more durable and effective rehabilitation strategies for degraded bridge decks.

2. Materials and Methods

Portland cementitious concrete (PCC) mix was used in this study to fabricate the concrete substrate to perform pull-off test methods. The PCC in this study contains superplasticizer, fine aggregate, water, and type I/II Portland cement.

Table 1 presents its properties. In this investigation, 738 cc of MasterGlenium 7920 superplasticizer per 100 kg was utilized, which is in the range of the recommended dosage of 130 cc to 780 cc per 100 kg for cementitious materials. The fine aggregate used in this mix has a nominal maximum size of 2.36 mm. T-17 Polymer Concrete Powder Component and T-17 Polymer Concrete Liquid Component were the two main PC components that were utilized as the overlay material for the concrete substrate (Transpo Industries, New Rochelle, NY, USA). In this study, the selection of the binder material and the design of the polymer concrete mix was governed by not only the mechanical properties but, importantly, the effectiveness of dispersion of nanomaterials in the resin for a homogeneous product.

2.1. Mix Design Properties

Cylinders and beams were fabricated and tested according to ASTM C39, ASTM C579, ASTM C78 and ASTM C580 using this mix design for establishing the baseline properties of the two concrete materials. Twelve cylinders in total—six PCC and six PC—were tested to ascertain the two distinct varieties of compressive strengths of concrete in accordance with ASTM C579 and ASTM C39, respectively. A four-point bending test was used to test three beams per type in order to estimate the modulus of rupture. Forney machines were employed in the two assessments. A Forney machine was used for both the tests.

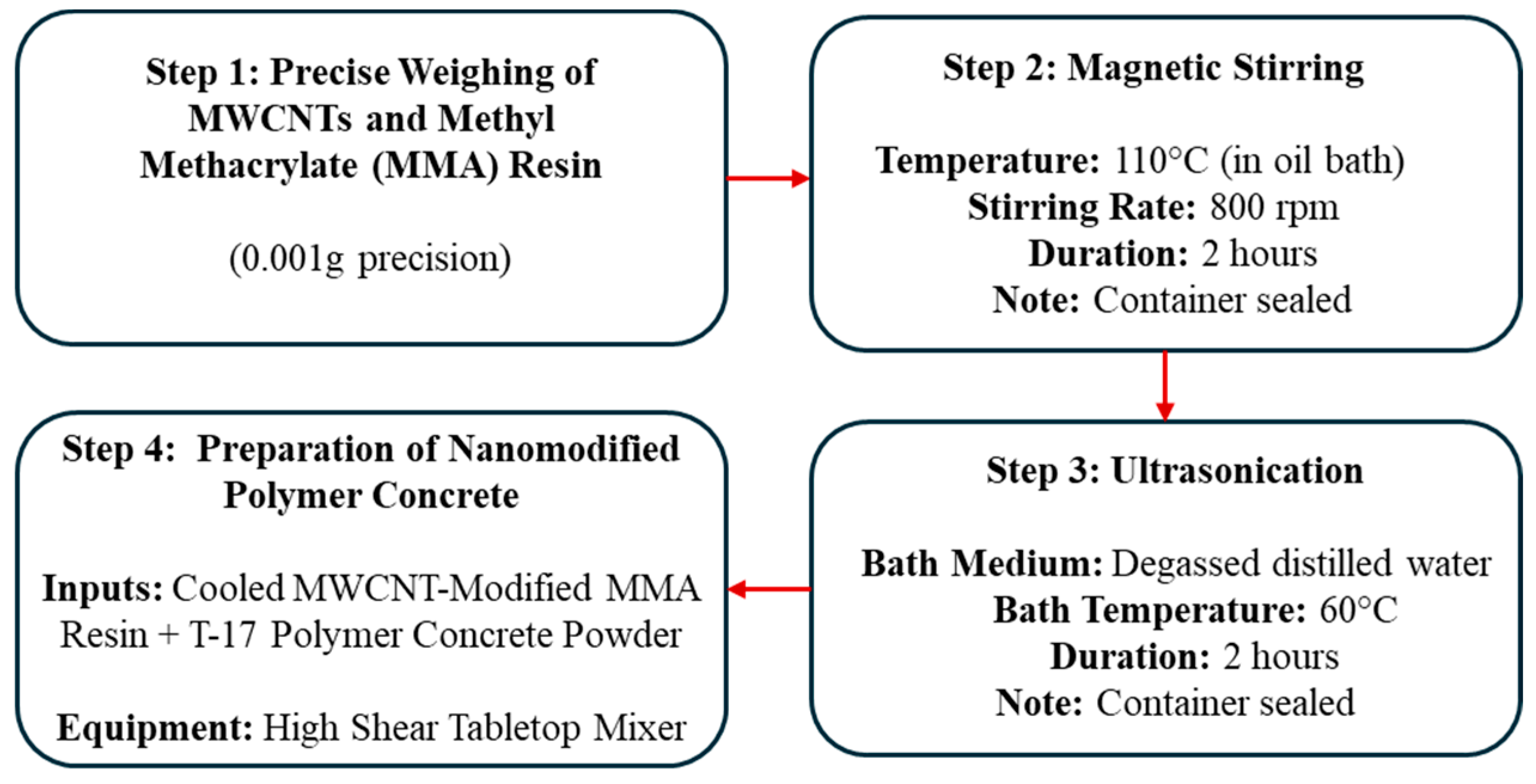

2.2. Preparation of Nanomodified Polymer Concrete

Pristine MWCNTs and the two most suitable functionalization of carboxyl group (COOH) and ammonia group (NH

3) MWCNTs with respect to binder weight, using weight contents of 0.25 wt.% and 0.5 wt.%, were chosen to be added to polymer concrete and compared with neat (0 wt.%) polymer concrete. The chosen MWCNT concentrations of 0.25% and 0.5% align with findings from previous studies [

17,

42,

43] where optimal mechanical improvements were observed within this range for nanomodified composites. Pristine MWCNTs are unmodified carbon nanotubes with their original surface chemistry. On the other hand, functionalized types of CNTs, such as COOH-functionalized MWCNTs, have carboxyl groups (-COOH) attached to their surface. This functionalization enhances their dispersibility in the polymer matrix and can improve interfacial bonding between the MWCNTs and the polymer. The COOH functionalization can lead to better load transfer and potentially improved mechanical properties compared to pristine MWCNTs [

44]. This is especially true during the elastic and plastic stress transfer stage, from the concrete to the MWCNT, and during the fracture stage, as the MWCNTs attempt to bridge cracks in the concrete, according to the principles of stress transfer and fracture mechanics in discontinuous fiber systems [

45]. A content of 0 wt.% MWCNTs indicated no incorporation of MWCNTs to establish a baseline database. MWCNTs were acquired from Cheap Tubes, Inc., Grafton, VT, USA. Two phases were used to disperse the carbon nanotubes into the resin: magnetic stirring and ultrasonication. The strong van der Waals forces among MWCNTs pose dispersion challenges, leading to agglomeration. As shown by [

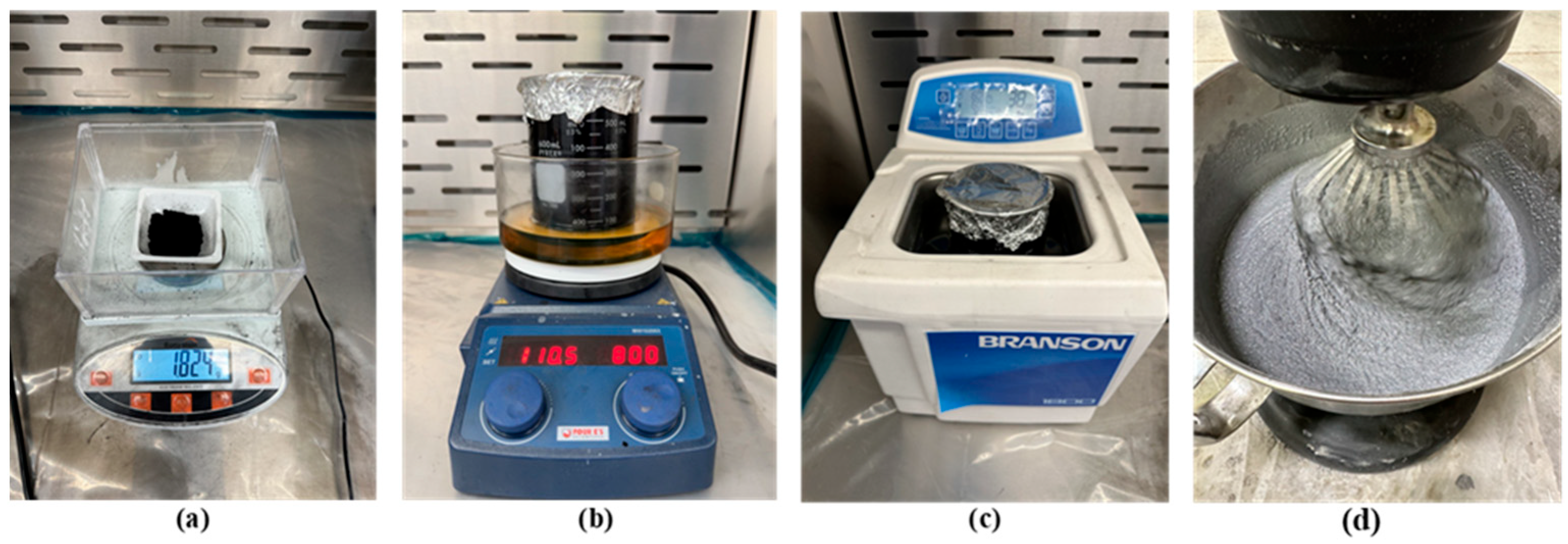

26], employing a combination of ultrasonication and magnetic stirring minimizes agglomerates, thereby ensuring uniform distribution and improved mechanical performance. So, before adding the nanomaterials to the methyl methacrylate (MMA) resin, the precise amount of each material was weighed with a precision of 0.01 g. After that, the resin containing MWCNTs was heated to 110 °C in an oil bath while being stirred magnetically at 800 rpm. To trap heat and keep the resin sealed at a fast stirring rate, the resin container was sealed with aluminum foil. The resin nanocomposite was placed in an ultrasonication bath after two hours of magnetic stirring. Degassed distilled water heated to 60 °C was present in the bath. After that, ultrasonic waves were used for two more hours. Before being used, the resin nanocomposite was removed from the bath and left to cool to room temperature for almost two hours. The chosen temperatures, stirring rate and time, and ultrasonication time were intended to minimize the viscosity of the resins during dispersion without causing any molecular polymer damage. The use of ultrasonication enhances dispersion by creating microscopic bubbles inside the resin that release energy and prevent particle agglomeration, resulting in a more even distribution of the particles. The resin container was kept at a constant temperature by the usage of the oil and water baths. The purpose of using distilled water is to limit the quantity of particles such as minerals and salts that would otherwise reduce the effectiveness of the ultrasonication bath. Degassing removes extra air bubbles from the distilled water solution to guarantee that ultrasonic waves are used to their full potential [

46]. This prepared mixture with each MWCNT concentration was added to the T17 powder component and mixed using a high-shear tabletop mixer. The T-17 Polymer Concrete was selected for its excellent inherent workability (e.g., low resin viscosity: 10–12 cPs; good mortar pot life: 8–15 min), which readily accommodated the low concentrations of MWCNTs (0.25–0.5 wt.%) used without unmanageably altering the observed workability or finishability. Also, the PCC substrate was designed for suitable casting consistency.

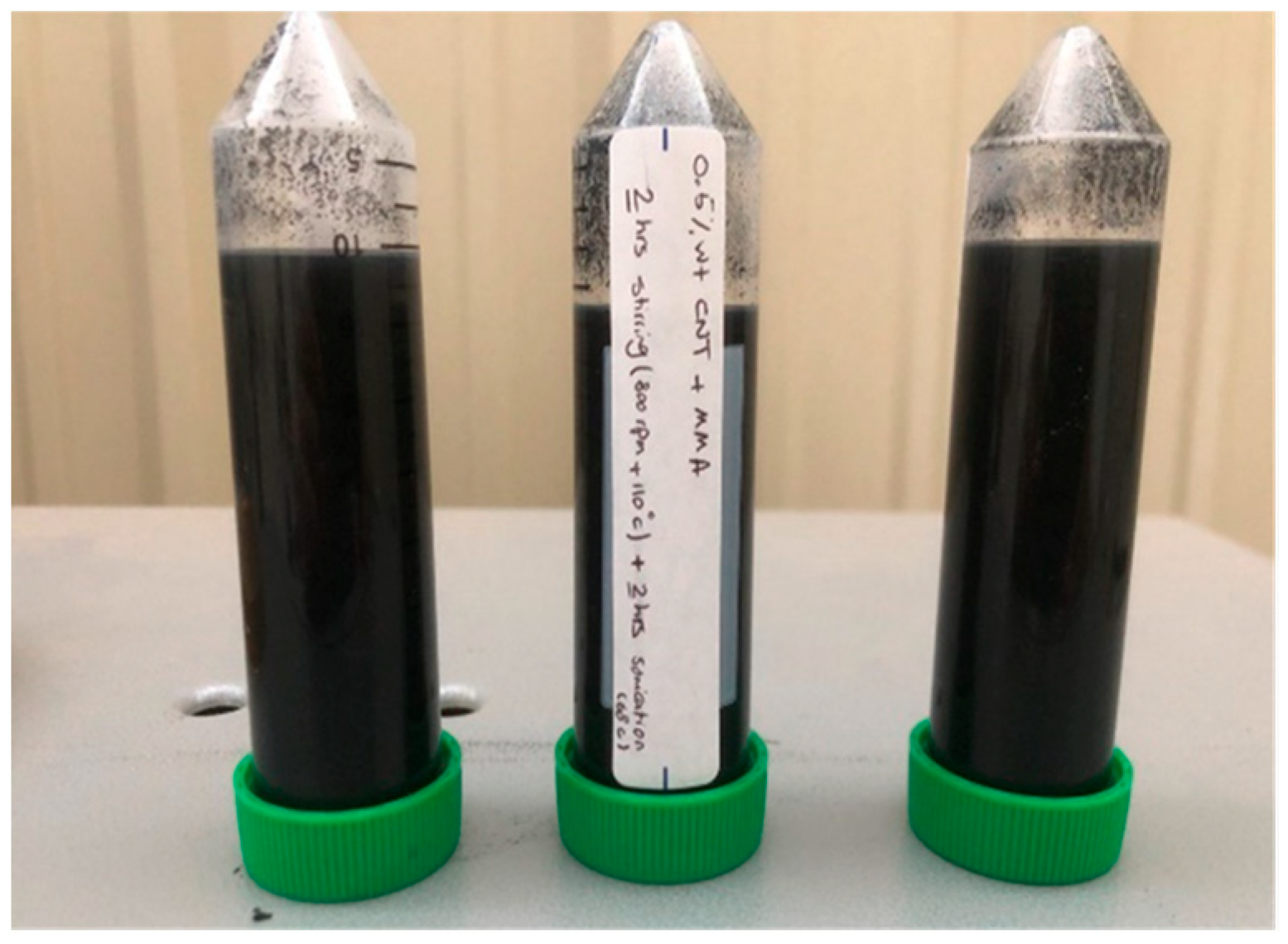

Figure 1 and

Figure 2 represent the stages of MWCNT dispersion in the MMA and the preparation of the mixture.

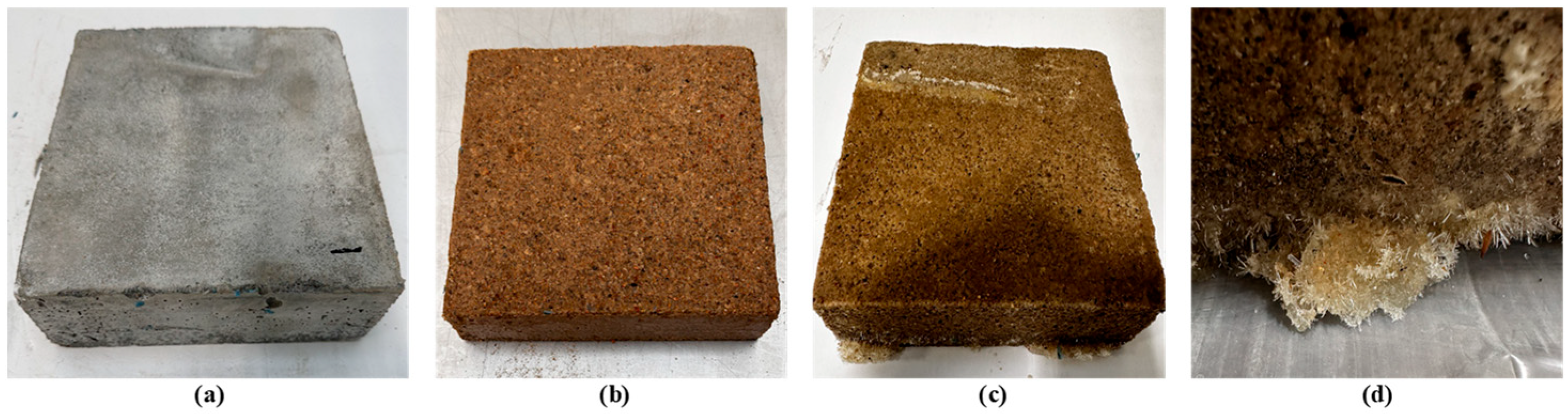

2.3. Preparation of Sulfate Exposure Environment

To understand the effect of sulfate attack on the bond strength between the nanomodified PC and concrete substrate, a sulfate solution container was prepared. An artificial sulfate solution was prepared using Na

2SO

4 (Na

+ cation). The sodium sulfate solution’s mass fraction was 6%. Because acid attacks are more destructive at lower pH values, sulfuric acid was used to maintain the pH of the fluid in the container at 3. The specimens were cured in the sulfate container for 210 days. Sulfate exposure was performed for 210 days upon stage-wise observation for deterioration before PC overlays were applied. Visual observations were conducted regularly for signs of deterioration. Visible and extreme signs were observed after 7 months of exposure and the specimens were removed.

Figure 3 depicts the progress of sulfate attack on the specimens.

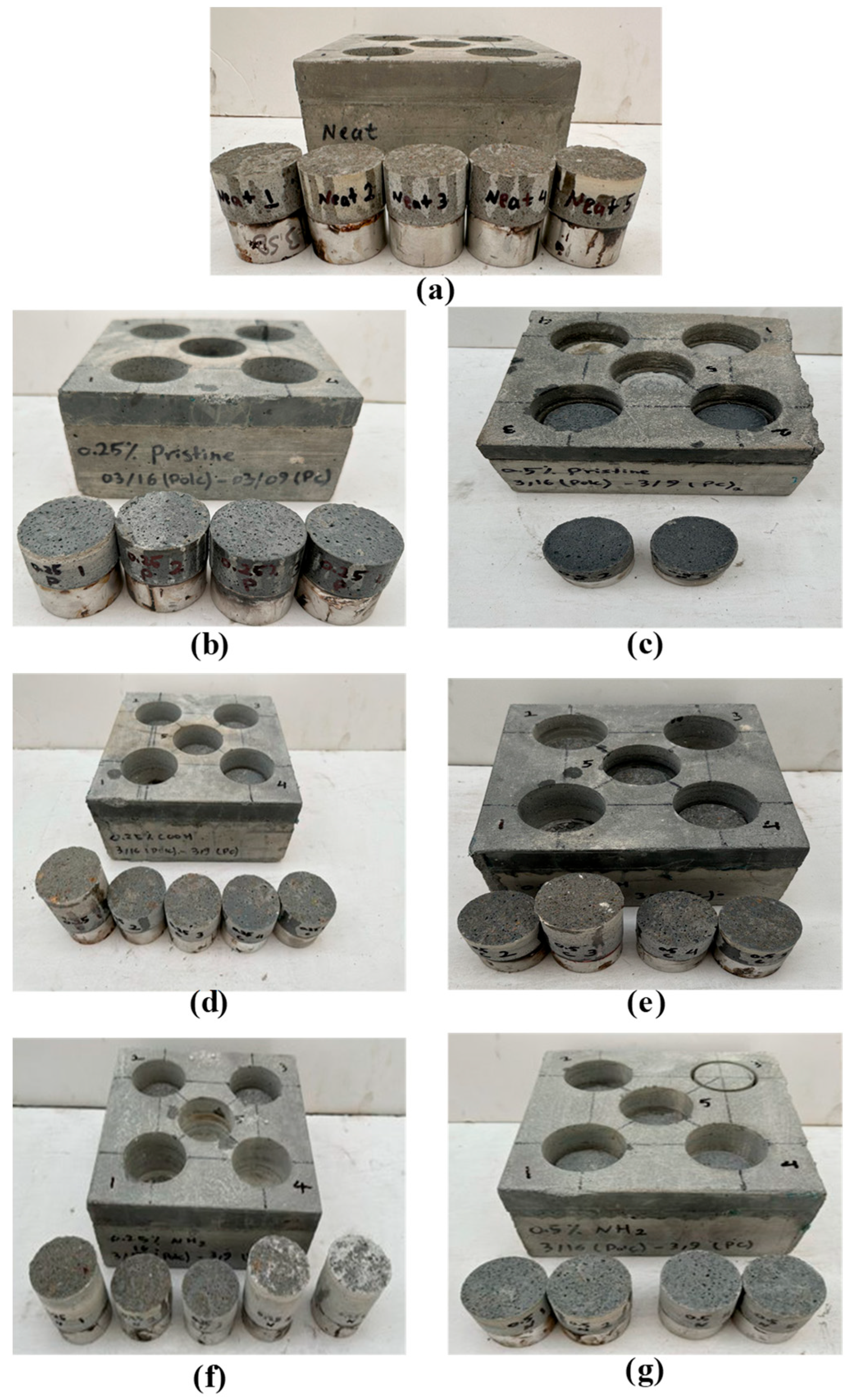

2.4. Preparation of Specimens for ASTM C1583 Test

To evaluate the bond strength between the PC overlays and the PCC substrates, the test specimens were meticulously prepared in accordance with ASTM C1583. The preparation involved several distinct stages, from substrate preparation through to the final pull-off test configuration.

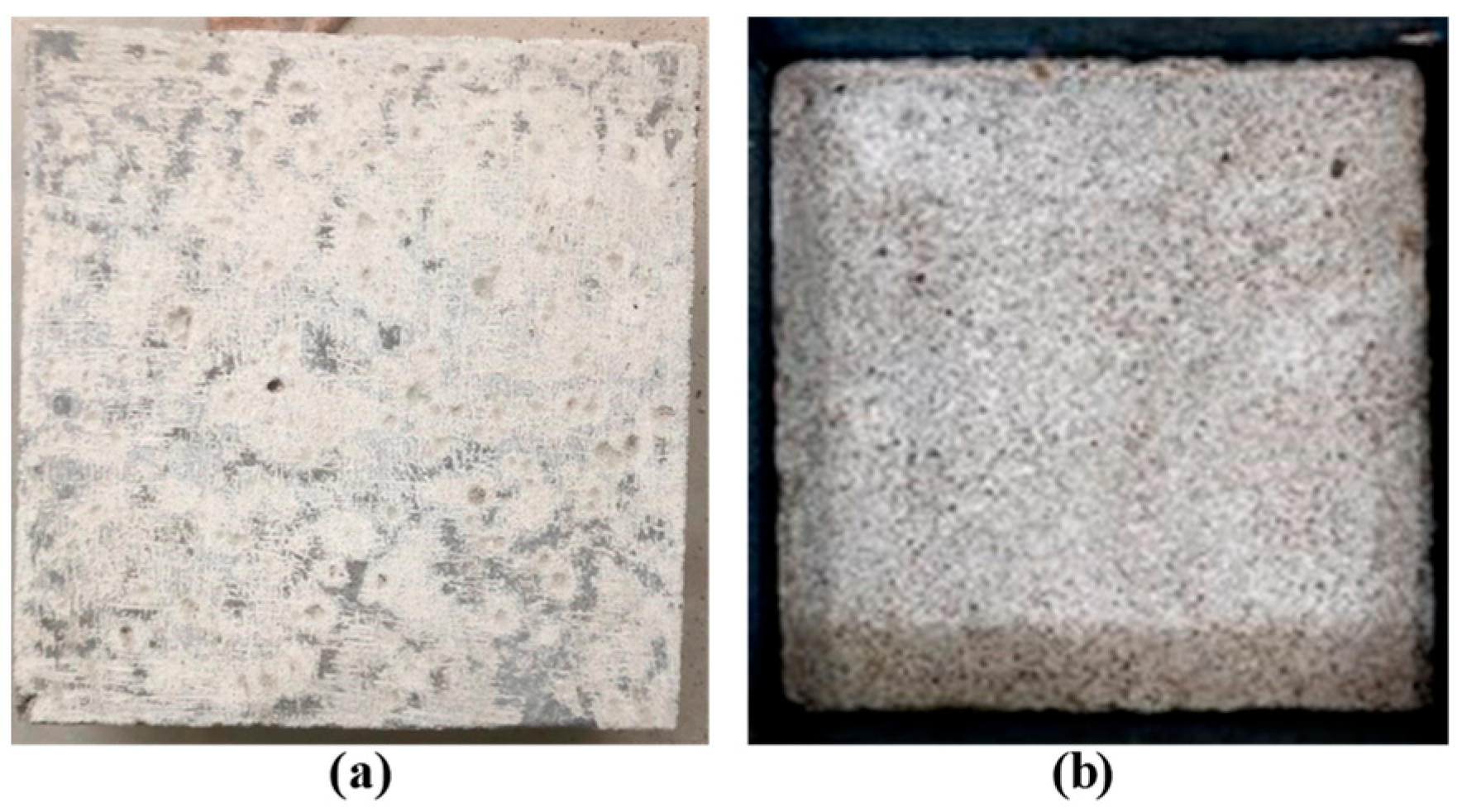

Initially, Portland cement concrete (PCC) substrate blocks were cast in molds with internal dimensions of 20 cm × 20 cm × 8.89 cm. In the first casting step, the molds were filled to a depth of 6.35 cm with PCC, thus creating a substrate layer with dimensions of 20 cm × 20 cm × 6.35 cm. These substrates were cured for 28 days under 100% relative humidity. Following this initial curing period, the PCC specimens were divided into two groups for different environmental conditioning:

For both groups, the surface of the PCC substrates designated for overlay was prepared according to the International Concrete Repair Institute (ICRI) guidelines for polymer concrete overlays.

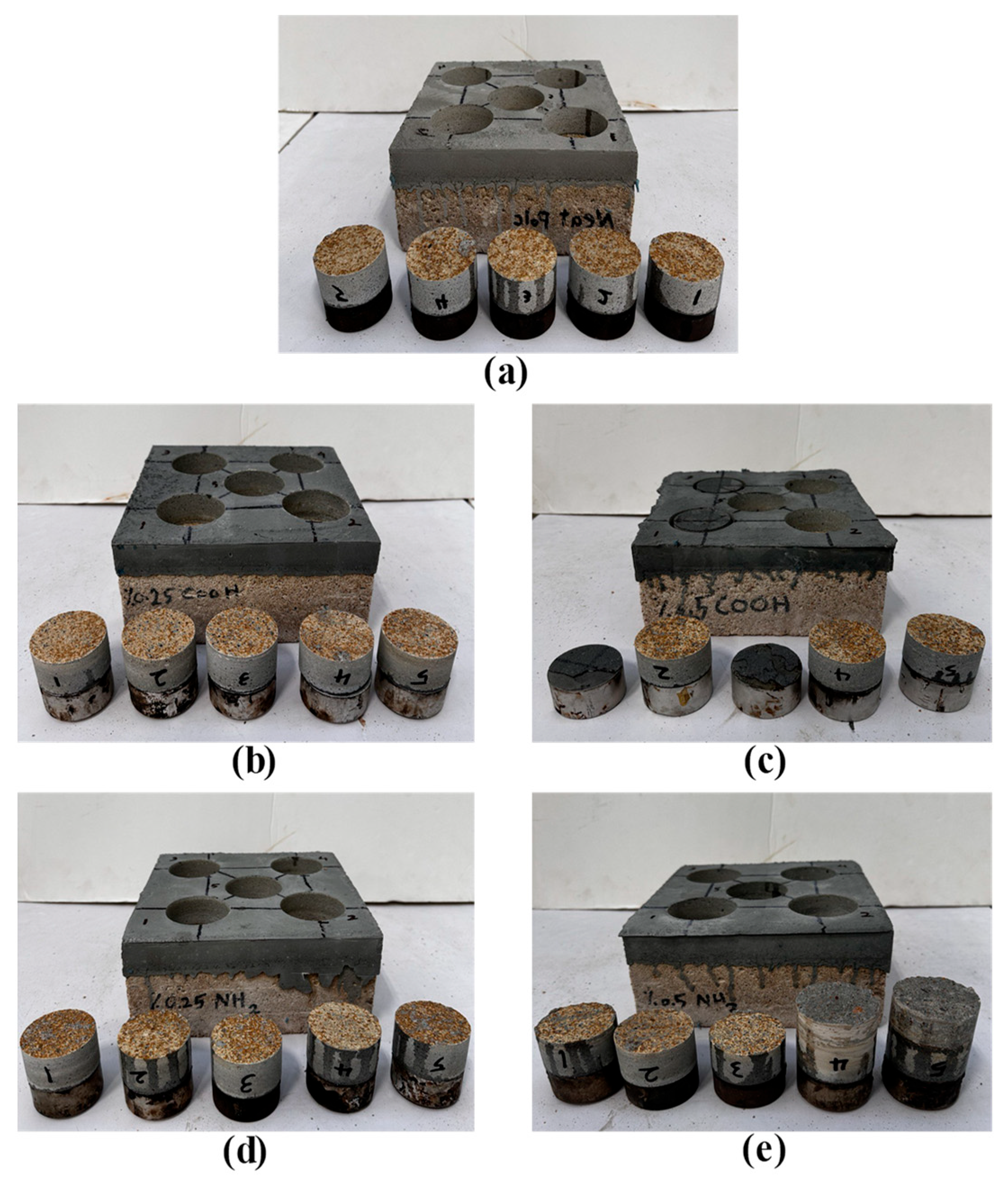

Figure 4 shows representative PCC specimens from both conditioning groups after the completion of the surface preparation.

After surface preparation, the PCC blocks were placed back into the original 20 cm × 20 cm × 8.89 cm molds. The prepared polymer concrete (PC) overlay material, formulated as described in

Section 2.2, was then cast on top of the prepared PCC substrate, filling the remaining depth of the molds. This resulted in a PC overlay thickness of approximately 2.54 cm. These composite specimens were then allowed to cure for 7 days under ambient laboratory conditions (approximately 23 ± 2 °C and 50 ± 5% RH), forming monolithic test units composed of the PCC substrate and the integrally bonded PC overlay.

These monolithic units were then prepared for the direct tensile pull-off test. Using a universal coring machine equipped with a diamond-bit core drill, 5 cm diameter cores were drilled to a depth of 5.08 cm. This depth ensured that each core passed completely through the PC overlay and extended slightly into the PCC substrate. Steel tensile loading dollies, also 5 cm in diameter, were then bonded to the top surface of the PC cores using a high-strength, two-part epoxy adhesive. The epoxy was allowed to cure fully according to the manufacturer’s specifications, ensuring a strong bond between the dolly and the PC overlay.

Figure 5 and

Figure 6 illustrate the core drilling process, the attachment of the tensile loading dollies, and the Hydrajaws 2000 pull-off test apparatus employed for applying the tensile load.

The pull-off tests were conducted using the Hydrajaws 2000 portable adhesion tester (Hydrajaws Limited, Birmingham, UK), which applied a continually increasing uniaxial tensile load perpendicular to the plane of the overlay until failure occurred. The maximum tensile load at failure (

P, in Newtons) was recorded. The bond strength, or the tensile strength of the material at the point of failure, was then calculated using Equation (1):

where

A is the cross-sectional area of the cored test specimen (mm

2).

According to ASTM C1583/C1583M-20, several failure modes are possible: (i) cohesive failure within the substrate (PCC), indicating the tensile strength in PCC and overlay are stronger than the substrate; (ii) cohesive failure within the overlay material (PC), indicating the tensile strength in PC and substrate are stronger than the overlay; (iii) adhesive failure at the bond interface between the overlay and the substrate, representing the true bond strength as this is the weakest plane; or (iv) failure at the interface between the loading dolly and the overlay. For this study, adhesive failure at the PC/PCC interface (iii) was considered valid for assessing bond performance between the PCC and PC. Results from tests where failure occurred primarily at the dolly/overlay interface (iv) were disregarded as per the ASTM guidelines, as these do not reflect the properties of the overlay system itself. The location of failure for each test was carefully recorded.

2.5. Microscopic Analysis

Advanced light microscopy was performed using a Keyence VHX-7000 ultramicroscope at the University of Oklahoma’s Samuel Roberts Noble Microscopy Lab (SRMNL) to obtain an understanding of failure surfaces. Information on the homogeneity and distribution of nanomaterials was obtained from microscopic images. The microscope is fully automated and has the ability to capture images at a high magnification of up to 6500X.

3. Results

Twelve cylinders in total—six PCC and six PC—were tested to ascertain the two distinct varieties of concrete’s compressive strengths in accordance with ASTM C579 and ASTM C39, respectively. The results obtained are shown in

Table 2. With a two percent coefficient of variation, the average compressive strengths of PC and PCC were 59.9 and 67.4 MPa, respectively. This shows how consistently the results were obtained for both PCC and PC. A prior investigation examined the compressive strengths of five cylinders measuring 50.8 mm by 101.6 mm for PC and PCC, concluding that the respective mean compressive strengths were 68.9 ± 5.1 MPa and 53.9 ± 5.8 MPa [

47]. As a result, the compressive strength found during the initial PC compressive strength testing is within the range of values reported in the literature. For PC and PCC, the average modulus of rupture was 23.7 MPa and 7.8 MPa, respectively. The consistency of the tests was shown by the coefficient of variance, which was 3% for PC and 1% for PCC. Two concrete mixes with comparable compressive strengths were produced, based on the findings of the modulus of rupture and compressive strength tests. According to the literature, the tensile strength of PC, as determined by the modulus of rupture, is approximately three times higher than that of PCC, indicating a suitable mix design.

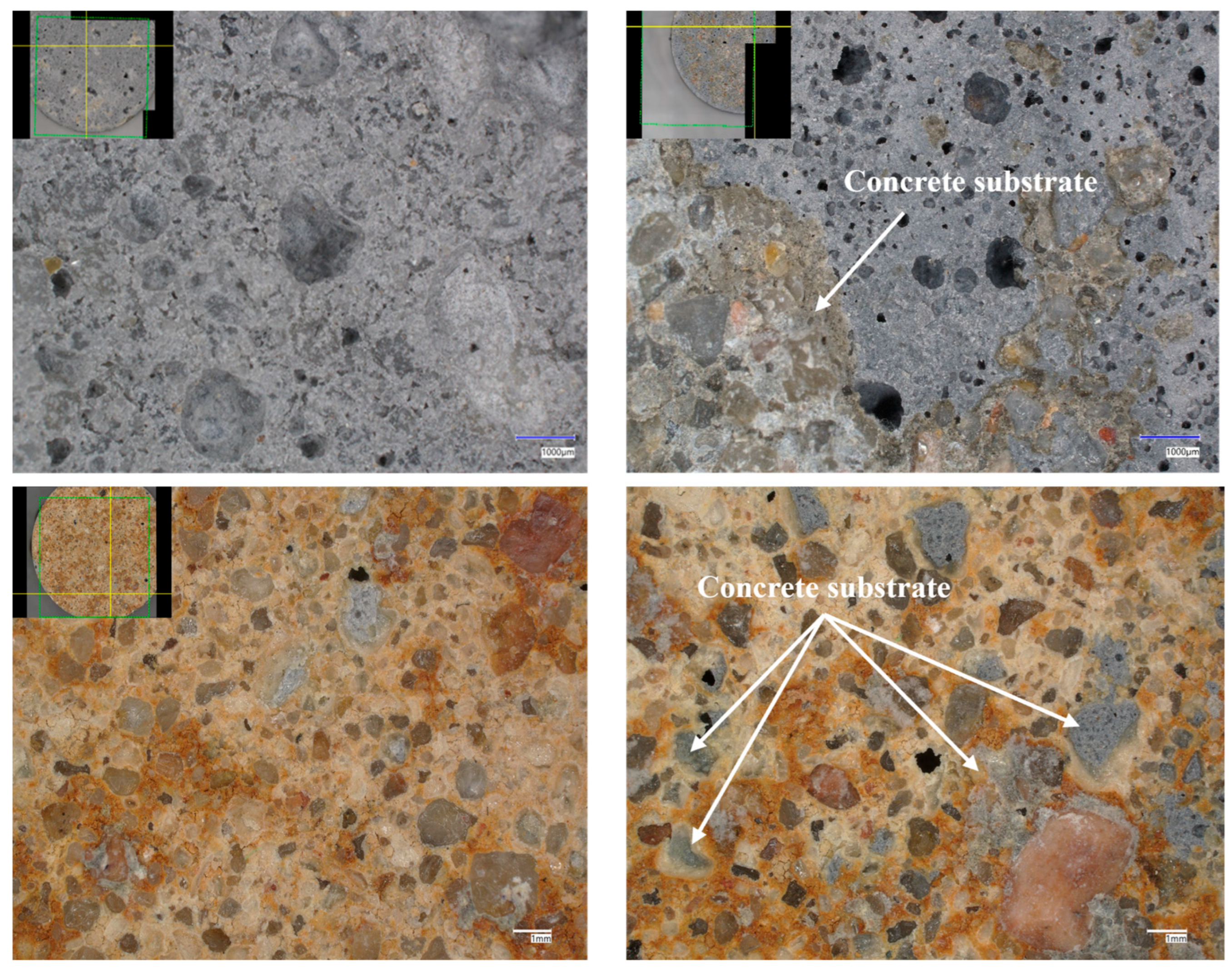

Following the 48 h dispersion process, visual observation of the polymer liquid component, as depicted in

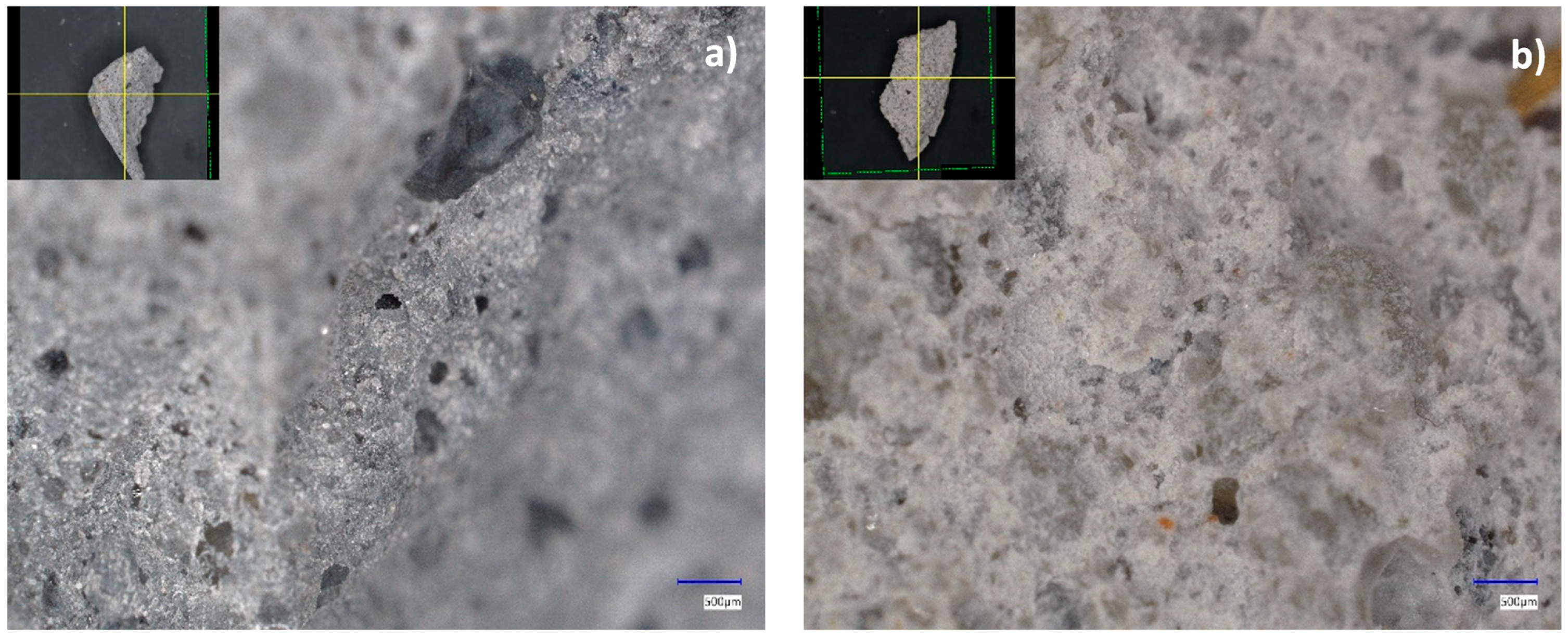

Figure 7, demonstrated the stabilization of MWCNTs in the resin, indicating efficient dispersion. Subsequent microscopic observations of the cured PC specimens (

Figure 8) revealed the presence of small, dark particles, inferred to be MWCNTs or small agglomerates, distributed homogeneously within the nanomodified polymer concrete (e.g., PC-FC50,

Figure 8a). These were absent in the non-modified polymer concrete (PC-Neat,

Figure 8b). This homogeneous distribution may also be attributed to the surface coating of aggregate particles by the carbon nanotubes due to cohesive forces.

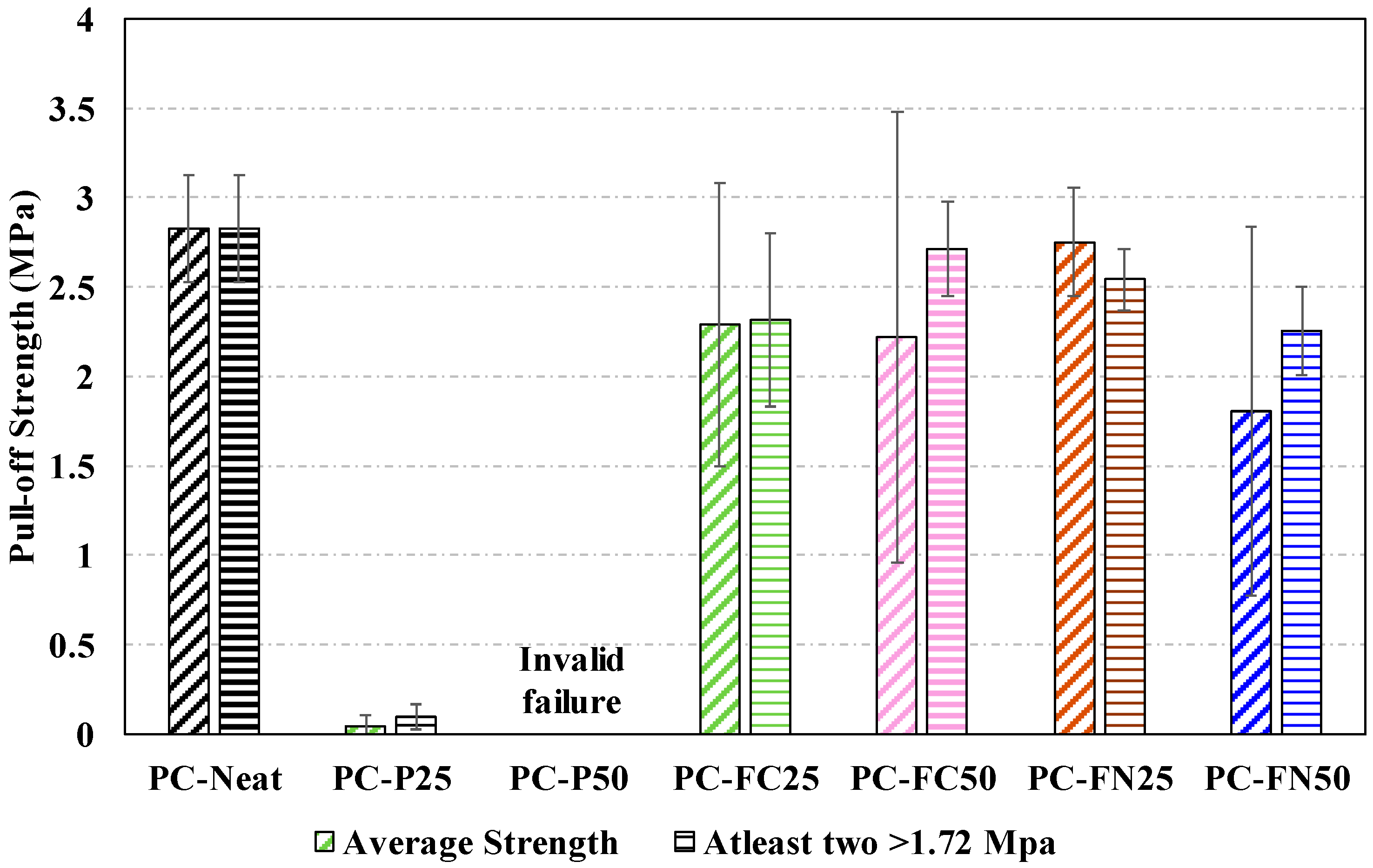

The pull-off strength of various polymer concrete (PC) compositions with PCC substrates was evaluated according to ASTM 1583 standards [

48].

Figure 9 presents the obtained results. The analysis and conclusions were based on two key assumptions: first, only interface failures were considered, as specified by ASTM 1583, and second, results were considered valid if at least two pull-off strengths exceeded 1.72 MPa (250 psi), following Transpo Inc. guidelines.

The neat polymer concrete (PC-Neat) exhibited a high and consistent average pull-off strength of 2.82 MPa with a standard deviation of 0.30 MPa. In contrast, the polymer concrete with 0.25% pristine MWCNTs (PC-P25) showed a significantly lower average pull-off strength of 0.039 MPa. It can be concluded that at 0.25%, the concentration of MWCNT inside the resin was not enough to make changes in better bonding between the resin and aggregates. Despite considering only specimens with at least two pull-off strengths over 1.72 MPa, the average considered strength increased to 0.099 MPa, but the overall performance remained poor. The polymer concrete with 0.5% pristine MWCNTs (PC-P50) demonstrated no measurable pull-off strength, as all tested samples failed to meet the minimum criteria. The 0.25% COOH-functionalized MWCNTs (PC-FC25) mix showed an average pull-off strength of 2.29 MPa and a standard deviation of 0.79 MPa, indicating reliable performance with a considered strength of 2.32 MPa. Similarly, the 0.5% COOH-functionalized MWCNTs (PC-FC50) composition had an average pull-off strength of 2.22 MPa and a standard deviation of 1.26 MPa, with a considered strength of 2.71 MPa, demonstrating consistent bond strength. The polymer concrete with 0.25% NH2-functionalized MWCNTs (PC-FN25) had an average pull-off strength of 2.75 MPa and a standard deviation of 0.31 MPa, showing reliable performance with a considered strength of 2.54 MPa. However, the 0.5% NH2-functionalized MWCNTs (PC-FN50) mix exhibited an average pull-off strength of 1.81 MPa, with higher variability indicated by a standard deviation of 1.03 MPa and a considered strength of 2.26 MPa. It can be concluded that the reduction in pull-off strength of the nanomodified specimens happened because the dispersion of CNTs inside the resin did not cause an improvement in bonding between the MMA resin and aggregates.

Overall, the results indicate that incorporating functionalized MWCNTs into polymer concrete can induce a similar pull-off strength compared to neat polymer concrete while giving rise to a wide range of other chemical improvements, such as improvements in ductility and fracture toughness. Notably, the polymer concrete with 0.25% and 0.5% COOH-functionalized MWCNTs (PC-FC25) demonstrated the highest and most consistent average pull-off strengths of the PCC containing carbon nanotubes. In contrast, the polymer concrete with 0.25% pristine MWCNTs (PC-P25) showed minimal pull-off strength, highlighting the importance of the type and functionalization of MWCNTs in achieving the desired bond strength. These findings suggest that functionalized MWCNTs, particularly COOH-functionalized ones, are more effective in improving the bond strength of PCC than PC.

Figure 10 illustrates the specimens after failure.

3.1. Sulfate Conditions

In normal conditions, functionalized MWCNTs, particularly COOH-functionalized ones, showed better results in terms of the adhesion and durability of the polymer concrete overlays. However, pristine MWCNTs did not provide any significant results. Under sulfate conditions, the performance generally declined, but the 0.5% COOH-functionalized MWCNTs (PC-FC50) still provided a measurable improvement. This improvement highlights their potential in environments subjected to aggressive chemical attacks, such as coastal regions and industrial zones [

40]. Furthermore, this highlights the importance of selecting appropriate functionalized MWCNTs for maintaining the performance of polymer concrete overlays in harsh environments, which is crucial for developing robust and long-lasting solutions for bridge deck maintenance and repair. The specimens after failure are depicted in

Figure 11.

Figure 12 compares the pull-off strength of PC-Neat and PC-FC50 in normal and sulfate environments. As one can see, in normal conditions, the bond strength between the neat polymer concrete and healthy substrate was higher than the polymer concrete containing 0.5% COOH. However, it should be mentioned that in deteriorated conditions, when the substrate had experienced damage due to sulfate attack, the bond strength of the polymer concrete containing 0.5% COOH was 15% higher than the neat polymer concrete.

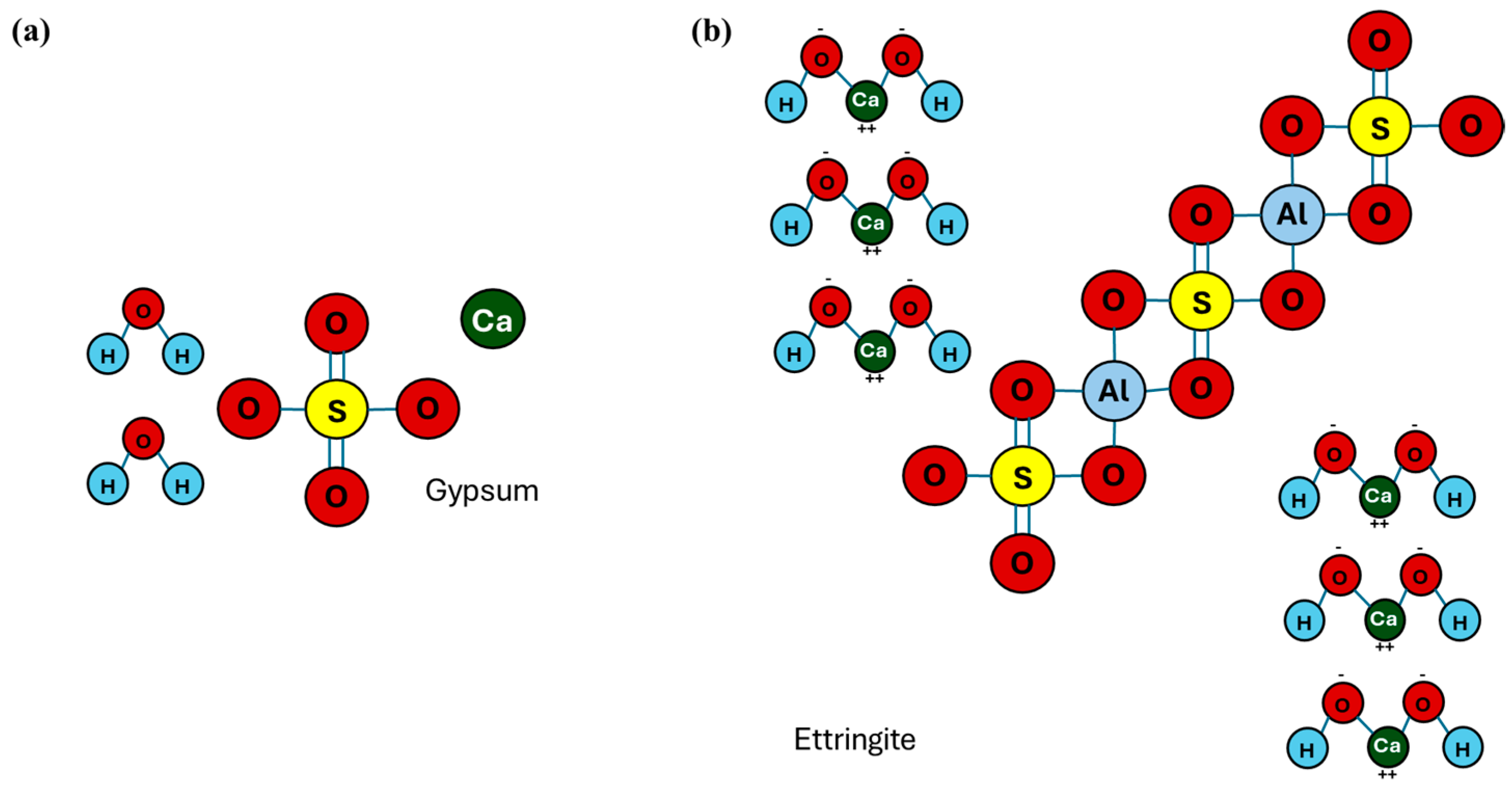

Sulfate attack typically leads to the formation of ettringite (Ca

6Al

2(SO

4)

3(OH)

12·26H

2O) and gypsum (CaSO

4·2H

2O) in a concrete substrate. The chemical structures of these produced materials are presented in

Figure 13. These secondary products weaken the microstructure of the concrete, creating a more reactive surface with higher surface energy [

32]. The chemical reactions are represented in Equations (1) and (2):

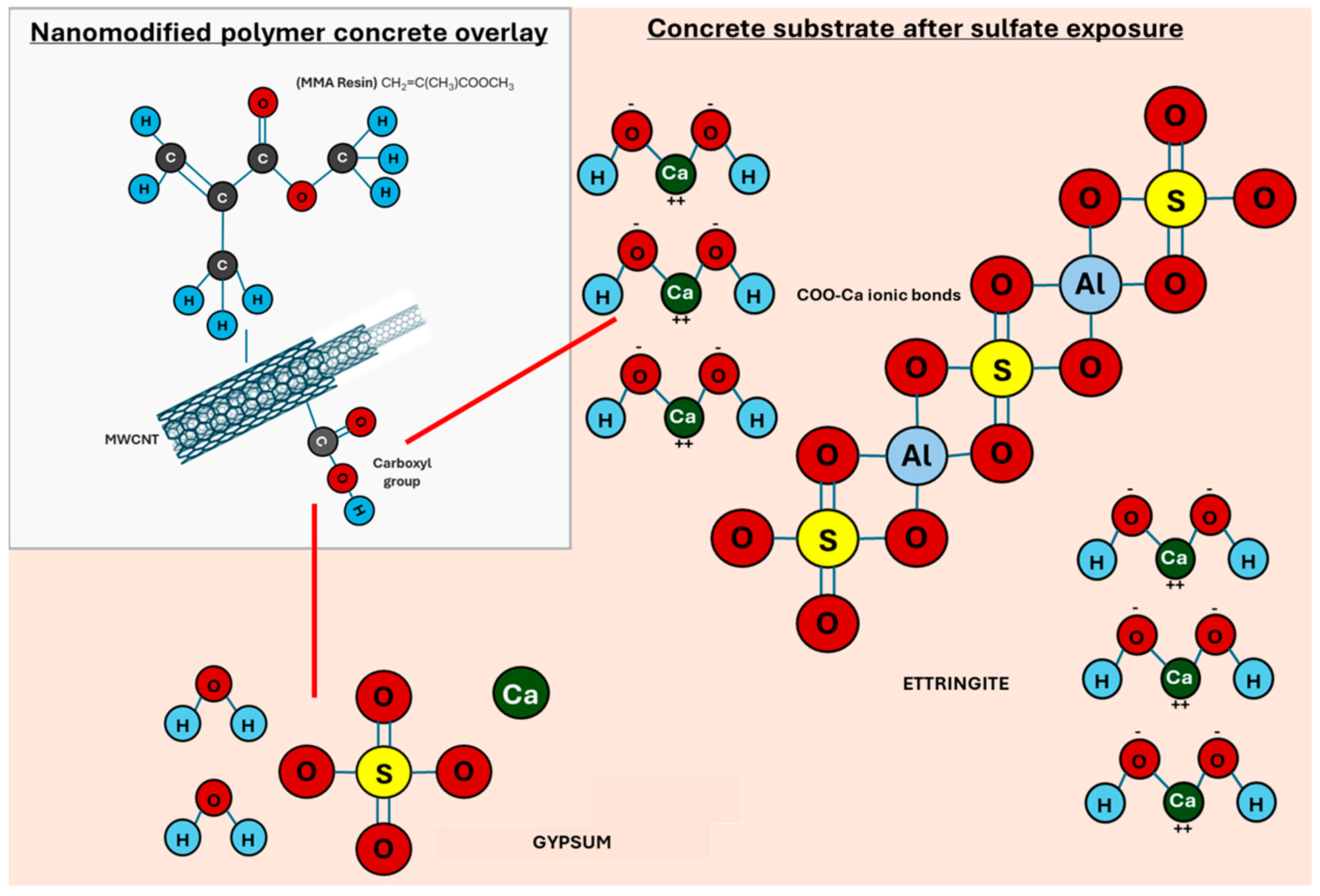

The COOH functionalization facilitates stronger interfacial bonding in harsh environments by introducing polar groups that interact with the polymer matrix and substrate, as observed in [

16]. This interaction leads to improved load transfer and mechanical properties. This is key to ensuring that the shear lag mechanism can take place during elastic stress transfer, via the strong bonds between the MWCNTs and polymer concrete [

45]. Moreover, functionalized MWCNTs, such as COOH-MWCNTs, promote better chemical bonding with the sulfate-attacked substrate. The polar groups in functionalized MWCNTs can interact with these secondary products, forming stronger interfacial bonds [

40]. Hydrogen bonding and ionic interactions occur between the -COOH groups of the MWCNTs and the calcium ions or sulfate ions in gypsum and ettringite. In sulfate conditions, the microcracks and weakened substrate create a more reactive surface. The chemical reactions are presented below. Also, a schematic of the chemical reactions is presented in

Figure 14.

On the other hand, MWCNTs serve as a physical reinforcement, bridging microcracks and providing mechanical interlocking that is less significant in normal conditions [

49]. Therefore, this dual mechanism—chemical bonding and mechanical bridging—leads to improved load transfer and bond strength. Chemical bonding is key to ensuring that the shear lag mechanism can take place during elastic stress transfer, via the strong bonds between the MWCNTs and polymer concrete; mechanical bridging is key to ensuring that the MWCNTs have the capacity to bridge cracks, after which the shear-sliding mechanism occurs and chemical bonds are disrupted, and then frictional loading takes over [

45]. In normal conditions, however, the substrate is less reactive, and the functionalized MWCNTs do not have the same opportunity to enhance chemical or mechanical interlocking. Consequently, neat polymer concrete, with its intrinsically high bond strength, performs better in non-degraded substrates compared to MWCNT-modified polymer concrete. This leads us to the conclusion that in deteriorated conditions, incorporating functionalized COOH can improve the bond strength between a polymer concrete overlay and concrete substrate.

3.2. Microscopic Analysis

Various evaluations were performed to evaluate the MWCNTs’ dispersion in the resin and PC. A visual inspection was performed to evaluate the dispersion stabilization of the MWCNTs in the resin.

Figure 7 depicts the resins incorporating MWCNTs after 48 h. When the dispersion in the resin was satisfactory, the process was continued via addition of the mix to the PC in order to produce nanomodified PC. The macrodispersion states of carbon fillers in the unmodified and nanomodified polymer concrete specimens were evaluated using optical microscopy (OM). A KEYENCE VHX-7000 microscope was utilized to study the macrodispersion of the carbon nanotubes. The images clearly show shared morphological characteristics as well as notable variances in the materials under investigation. The MWCNT agglomerates had a characteristic spherical shape with diameters up to 600 μm. Also, it is acceptable to see CNT agglomerates in a matrix if there are few and they are not large [

50].

Figure 8 illustrates the microscopic images of PC-Neat and PC-FC50. The microscopic images reveal a homogeneous distribution of MWCNTs in PC-FC50, corresponding to its superior bond strength. Similar observations were reported in [

50], where smaller agglomerates improved interfacial adhesion. As one can see in

Figure 15, there are more PC particles attached to the PCC after failure in sulfate conditions, which shows that the tensile strength of the PC decreased after 210 days of exposure to the sulfate environment.

4. Discussion

The findings of this study indicate that MWCNTs interact more effectively with concrete substrates exposed to sulfate environments. As previously noted, polymer concrete modified with MWCNTs exhibited a 15% increase in pull-off strength compared to unmodified (neat) polymer concrete when bonded to sulfate-exposed substrates. However, in normal curing conditions, neat polymer concrete showed the highest pull-off strength compared to all MWCNT-modified mixes. These observations suggest that while MWCNTs may reduce bond strength under standard conditions, their benefits become more pronounced in chemically aggressive environments. Similar improvements in the performance of cementitious materials exposed to sulfate ions through the use of CNTs have been reported in previous studies [

39,

40,

41].

Comparing the different MWCNT types, it was evident that functionalization played a crucial role. Pristine MWCNTs (PC-P25 and PC-P50) generally resulted in a significant degradation of bond strength compared to neat PC under normal conditions, likely due to agglomeration and poor interfacial bonding. In contrast, both COOH-functionalized (PC-FC25, PC-FC50) and NH2-functionalized (PC-FN25, PC-FN50) MWCNTs demonstrated performance closer to, albeit generally not exceeding, that of neat PC in normal conditions. However, the key benefit of functionalized MWCNTs, particularly PC-FC50, emerged under sulfate exposure, where they helped retain or even enhance bond strength relative to neat PC under the same deteriorated conditions.

Also, statistical comparisons of mean pull-off strengths (N = 5 per group for the analyzed raw data) were made using independent two-sample t-tests (Welch’s). Under healthy conditions, PC-Neat (2.82 MPa) was compared to modified groups: PC-FC25 (2.29 MPa), PC-FC50 (2.22 MPa), PC-FN25 (2.75 MPa), and PC-FN50 (1.81 MPa). For these specific raw datasets, none of the observed differences reached statistical significance (all p > 0.05). Under sulfate-exposed conditions, PC-Neat (1.30 MPa) exhibited statistically significantly higher strength than PC-FC25 (0.00 MPa, p = 0.0073, as all samples showed no bond). The mean strength of PC-FC50 (1.65 MPa) was numerically higher than PC-Neat, though this difference was not statistically significant (p = 0.4036) with the current sample size. Pull-off strengths for PC-FN25 (1.23 MPa) and PC-P50 (0.74 MPa) under sulfate exposure also did not differ significantly from PC-Neat (p > 0.05). While these tests provide a rigorous assessment of statistical significance (using α = 0.05), it should be acknowledged that with a sample size of N = 5 per group, the statistical power to detect more subtle, yet potentially real, differences is limited.