Abstract

Sensors and transducers are essential components of measurement systems. The achievement of a sustainable economy requires environmentally friendly solutions and processes in order to develop sensors and transducers that are capable of being recycled, disposed, and, degraded without releasing pollutants into the environment. In this context, we propose a comparative analysis of deformation sensors based on bacterial cellulose impregnated with choline malonate and EMIM-BF4 ionic liquids (ILs). Their features and performance will be compared while also considering the green aspect of the proposed sensors.

1. Introduction

Environmental pollution can harm human, animal, and plant lives. To mitigate the negative effect of environmental degradation, tech conglomerates and educational and research institutions have made relevant efforts to create biodegradable and eco-friendly electronic devices. In recent years, bioderived polymers have gained popularity, and the development of greener devices has been prioritized. Various solutions have been addressed in the literature, including the use of bio-derived and natural materials such as bacterial cellulose (BC) [1]. BC has been considered as an environmentally friendly substitute to plant-derived cellulose. The authors of [2] have previously proposed using BC impregnated with ILs and covered by poly (3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) as conducting polymer-based electrodes to generate deformation transducers. Here, we propose a comparative analysis of a BC-based device impregnated with choline malonate and EMIM-BF4 as ILs.

2. Devices and Results

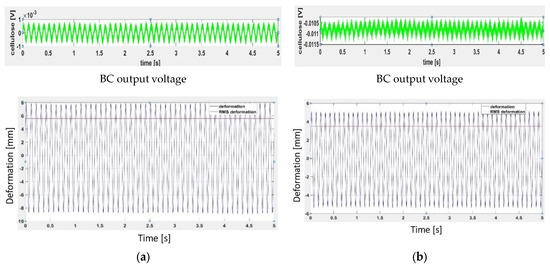

The BC-based sensors were ~5 cm in length, ~1 cm in width, and ~500 µm in thickness. Each device was impregnated with a family of ILs and, in particular, 1-Ethyl-3-methylimidazolium tetrafluoroborate (EMIM-BF4) and greener ILs, represented by choline malonate (CH MAL). A cantilever configuration was considered to investigate the generating properties of the two devices. The following setup was used to characterize the sensing elements as deformation sensors: A function generator was used to drive an electromechanical shaker via an amplifier. The shaker’s base plate caused vibrations, which generated an output voltage across the two terminals of the BC. Two laser sensors were used to measure the anchor and tip displacements of the BC, and the difference was assumed as the composites’ deformation. The two laser sensor output voltages, the signals produced by the BC-based sensors, and the output from the reference accelerometer were recorded on an oscilloscope. The data were stored in a data storage device for post-processing in MATLAB® R2021. The output voltages in the time domain for both green and non-green BC-based composites are shown in Figure 1. The experimental analyses were carried out at a resonant frequency of 10 Hz.

Figure 1.

The time domain graphs of the deformation and the output voltages for the BC-based composites when the shaker is driven at 400 mV and 10 Hz. (a) EMIM-BF4; (b) CH MAL.

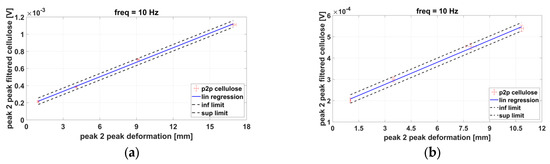

Figure 2 shows two calibration diagrams at 10 Hz. The deformation values were obtained by varying the input amplitude, and the results show the relationship between the peak-to-peak BC output voltage and RMS deformation.

Figure 2.

Characterization of RMS deformation for BC-based composites: (a) EMIM-BF4 and (b) CH MAL.

From the graphs shown above, it is possible to conclude that CH MAL’s RMS deformation is lower than that of EMIM-BF4, and this is the cost of performance for the greener device. The results evince that CH MAL has a lower sensitivity with respect to EMIM-BF4. Compared to CH MAL, EMIM-BF4’s output voltage exhibits a higher resolution. Nevertheless, the authors’ focus is on developing greener sensors so that these features are counterbalanced by a greener aspect for CH MAL ILs. Their work is in progress, and they are conducting an exhaustive analysis on the materials’ biodegradability.

Author Contributions

Conceptualization, C.T. and S.G.; methodology, C.T., S.G., G.D.P., A.P., K.P.-E. and A.A.; validation, S.K., S.C., C.T., S.G., G.D.P. and A.P.; formal analysis, S.K. and S.C.; investigation, C.T., S.G., G.D.P., A.P., K.P.-E. and A.A.; data curation, C.T., S.G., G.D.P. and A.P.; writing—original draft preparation, S.K., C.T. and S.G. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful to BioFaber for furnishing the BC used as the base material for the transducer fabrication. The research activity was partially funded by the 4FRAILTY project, PNR 2015–2020-Area di specializzazione tecnologie per gli ambienti di vita.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available if required.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Di Pasquale, G.; Graziani, S.; Pollicino, A.; Trigona, C. Performance characterization of a biodegradable deformation sensor based on bacterial cellulose. IEEE Trans. Instrum. Meas. 2019, 69, 2561–2569. [Google Scholar] [CrossRef]

- Di Pasquale, G.; Graziani, S.; Pollicino, A.; Trigona, C. “Paper” Based Sensor for Deformation Measurements. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; pp. 1–5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).