Abstract

In order to analyse the exposure-response relationship between hand–arm-vibration exposure and the risk of musculoskeletal disorders (MSDs) of upper extremities in an epidemiological case-control study, a database was established to provide technical characteristics such as vibration exposure data and its frequency component measured at workplaces. This hand-arm vibration database consists of over 730 technical tools and devices, whereas 422 devices were used for exposure assessment in the epidemiological case-control study. The devices used were divided into a total of 13 device groups: hammers, grinding machines, compactors, screwdrivers and saws were the most frequently used devices.

1. Introduction

According to expert estimates, there are currently around 1.5 to 2 million employees in Germany who are exposed to hand-arm vibration [1]. In Germany, there are two different diseases caused by hand-arm vibration exposure. The most extensively studied forms of hand-arm vibration syndrome are vascular and neurological disorders [2]. Recent studies and reviews also indicate an elevated risk of musculoskeletal symptoms and osteoarthritis among vibration-exposed workers [2,3,4,5]. However, so far, an exposure-response relationship between hand-arm vibration exposure and MSDs of upper extremities has been poorly established.

In order to evaluate the exposure–response relationship between hand–arm vibration exposure and the risk of MSDs, an epidemiological case-control study was carried out among workers in the construction, mining, metal and wood working industries in Germany. Within this project, a database was to establish providing physical characteristics of the investigated tools. The database was designed to provide information about the vibration exposure but also working conditions and workpieces, which can be used for retrospective analysis.

2. Material and Methods

To quantify individual vibration exposures, a database of industrial hygiene measurements of over 700 power tools at workplaces was established. This database allows for detailed quantification of vibration exposures over time.

According to international standard ISO 5349-1:2001 [6], vibration generated by the technical power tools was measured in three orthogonal directions (x, y, and z). Vibration values are expressed as accelerations ahwx, ahwy, and ahwz in the three measuring directions. The vibration total value (ahv) was determined as the root-sum-of-squares of the three component values (ahwx, ahwy and ahwz):

In addition to the vibration total value (ahv), acceleration (ahw) in the direction along the forearm (direction z) was also considered in the exposure–response analyses of this study.

Based on the guideline VDI 2057, part 2 [7], the frequency components of the vibration exposure for the forearm direction have been detected for the following frequency ranges: 4 to 20 Hz, 4 to 31.5 Hz, 4 to 50 Hz, 4 to 80 Hz, and 4 to 100 Hz. These frequency components could be a distinguishing feature for determining the low- and high-frequency devices.

3. Results and Conclusions

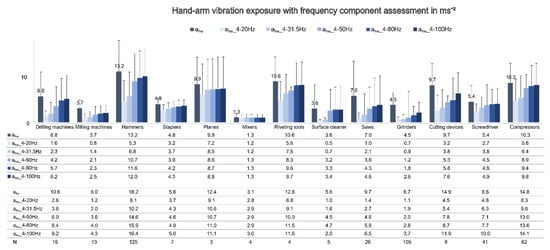

The hand-arm vibration exposure for the forearm direction and the vibration total value with their frequency components of 422 devices are given in Figure 1.

Figure 1.

Hand-arm vibration exposure assessment for the forearm direction, vibration total value and their frequency components.

Hammers followed by riveting tools, compressors, planes and cutting devices are the most vibration generating devices (13.2 ms−2, 10.6 ms−2, 10.3 ms−2, 9.9 ms−2 and 9.7 ms−2 respectively for forearm direction). The lowest vibration exposure in this project was assessed for the mixers with 1.3 ms−2 in the forearm direction.

Regarding the frequency components, staples, planes and mixers did not show any notable differences between the frequency ranges. On the contrary, hammers, surface cleaner, saws, cutting devices and compressors showed big differences within the frequency ranges, especially regarding the range between 4 and 50 Hz.

Author Contributions

Conceptualization, methodology: C.F., Y.S., F.B., W.E., B.E., U.K., U.N., C.S., C.v.d.B. and N.R. Software, validation, formal analysis, investigation, resources, data curation, writing—original draft preparation, writing—review and editing, visualization, supervision, project administration: N.R., U.K. and C.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Social Accident Insurance, grant number FP-297.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, [N.R.], upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mohr, D. Eine Einfache Methode zur Beurteilung Stoßhaltiger Ganzkörper-Schwingungen; VDI Tagung Humanschwingungen; VDI Verlag: Duesseldorf, Germany, 2004. [Google Scholar]

- House, R.; Wills, M.; Liss, G.; Switzer-McIntyre, S.; Manno, M.; Lander, L. Upper extremity disability in workers with hand-arm vibration syndrome. Occup. Med. 2009, 59, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Hagberg, M. Clinical assessment of musculoskeletal disorders in workers exposed to hand-arm vibration. Int. Arch. Occup. Environ. Health 2002, 75, 97–105. [Google Scholar] [CrossRef] [PubMed]

- Bovenzi, M. Health risks from occupational exposures to mechanical vibration. Med. Lav. 2006, 97, 535–541. [Google Scholar] [PubMed]

- Charles, L.E.; Ma, C.C.; Burchfiel, C.M.; Dong, R.G. Vibration and Ergonomic Exposures Associated With Musculoskeletal Disorders of the Shoulder and Neck. Saf. Health Work 2018, 9, 125–132. [Google Scholar] [CrossRef] [PubMed]

- ISO 5349-1:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2001.

- VDI 2057 BLATT 2; Human Exposure to Mechanical Vibration—Hand-Arm Vibration. VDI Verlag: Duesseldorf, Germany, 2016.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).