Harvesting is an important part of the downstream processing of the microalgae culture and one of the most price-demanding [1] and represents more than 30% of the overall production costs. One of the alternatives to high-yield but expensive harvesting methods, such as centrifugation, is electrocoagulation/flocculation, in which an electric current is passed through a sacrificial electrode that releases metal ions which help flocculate the microalgae cells [2].

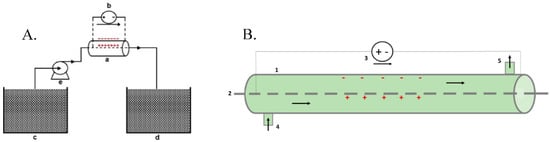

The innovative system (Figure 1) for continuous microalgae harvesting by electrocoagulation/flocculation and sedimentation proposes the harvesting of microalgae biomass by the use of prototype equipment for a continuous electrocoagulation/flocculation system with a total volume of 6.2 L that can process large volumes of microalgae suspension. The microalgae suspension is pumped through a reactor made of plastic, between the electrodes present inside: four aluminum bars placed inside the plastic cylindrical wall of the reactor and one sacrificial anode comprised of an aluminum bar passed through the middle of the reactor. The electrodes are connected to an adjustable electrical current source that goes up to 24 V/10 A. The aluminum sacrificial anode releases Al3+ ions that attract microalgae cells that are negatively charged and coagulate, finally forming flocks that facilitate separation. The recovery efficiency is about 90%.

Figure 1.

(A) Installation for microalgae suspension electroflocculation: (a) electrocoagulation reactor, (b) electric current source, (c) microalgae suspension vessel, (d) coagulated microalgae suspension vessel and (e) pump for suspension circulation through the reactor; (B) electrocoagulation reactor—simplified view: (1) tubular reactor—plastic cylinder with 4 aluminum bars (catode), bar aluminum electrode (sacrificial anode), (3) electrical current source, (4) suspension inlet and (5) suspension outlet.

Using this system, a concentrated microalgae suspension is obtained (15% v/v), at the bottom of the separation vessel, which contains about 20 g/L microalgae biomass. The top liquid fraction still contains small amounts of microalgae biomass.

Acknowledgments

This work was supported by PN III Program, PN-III-P1-1.2-PCCDI-2017; Program 1—Development of national CD system; Subprogram 1.2—Institutional performance, complex projects developed in CDI consortia, Contract 32PCCDI/2018 and PN 19.23.01.02.

References

- González-Fernández, C.; Ballesteros, M. Microalgae autoflocculation: An alternative to high-energy consuming harvesting methods. J. Appl. Phycol. 2013, 25, 991–999. [Google Scholar] [CrossRef]

- Amaro, H.M.; Guedes, A.C.; Malcata, F.X. Advances and perspectives in using microalgae to produce biodiesel. Appl. Energy 2011, 88, 3402–3410. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).