Abstract

Pillar-shaped Gallium arsenide (GaAs) micromechanical resonators are fabricated, and the feasibility to measure the inside of the pillars in the axial direction with laser-induced GHz ultrasound based on picosecond ultrasonics is tested. Measurements on the pillars with head sizes in the µm range show excellent agreement with theoretical predictions.

Mechanical micro- and nano-resonators show intriguing size-dependent properties regarding their elastic behavior. The elastic moduli derived for wire- and pillar-resonators from dynamic flexural mode measurements often deviate significantly from their bulk counterpart, thus making them interesting for a wide range of applications. This behavior has been mainly ascribed to the increasing influence of surface stresses on the resonance frequency when resonators become smaller. However, despite also showing considerable different elastic moduli, some experiments on pillar resonators do not show a distinct size dependence. In order to test different models and the actual origin of the observed deviations, we started to combine nanomechanical flexural mode measurements with picosecond ultrasonics to not only obtain information about the effective elastic modulus but to spatially resolve the local elastic properties inside pillar resonators.

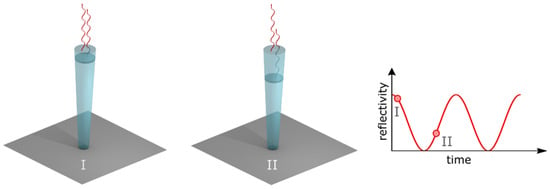

Gallium arsenide (GaAs) pillars were fabricated [1] by a top-down approach using e-beam lithography and subsequent etching. The first experiments were conducted on tapered pillars with head sizes of about 2 µm in radius and lengths around 5–6 µm. These are usually used, e.g., for sensing applications using their flexural modes. Picosecond ultrasonics was then used to look inside the pillars. This requires an additional fabrication step where a thin absorbing metal layer is evaporated on top of the pillars as optoacoustic transducer. The technique utilizes ps- and fs-resolved pump–probe spectroscopy to excite and detect elastic waves or pulses in the GHz-to-THz frequency range. We used a special scheme to realize the pump–probe measurement based on asynchronous optical sampling [2] (ASOPS) where the repetition rate of two locked and stabilized 800 MHz lasers has a slight offset and thus allows an automatic sweep of the time delay between optical pulses. Since the GaAs pillars are semi-transparent at the used wavelengths, time-resolved Brillouin scattering can be applied. The principle is depicted in Figure 1. Here, an acoustic pulse was launched by the pump laser inside the material, and the respective position was monitored by the change in reflectivity. Due to interference between the light reflected off the static surface and the propagating acoustic pulse, minima and maxima in the reflected light intensity were detected. The speed with which the acoustic propagates through the corresponding positions inside the pillar thus determines the detected frequency of the reflectivity oscillation and can be calculated for normal light incidence by

where n denotes the index of refraction of the material, v the longitudinal sound velocity and λ the wavelength of the probe laser.

f = 2n v/λ,

Figure 1.

Schematic of time-domain Brillouin scattering inside the tapered GaAs pillar resonators. The positions of the acoustic pulses and the respective interference of the probe pulse are depicted, as well as the corresponding reflectivity at each position.

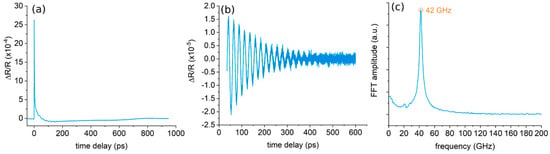

A measurement from a pillar is shown in Figure 2a. The strong initial rise reflects the response of the electron system on the pump pulse. Subsequent decay via electron–electron and electron–phonon scattering follows. Oscillations that are caused by the time-domain Brillouin scattering inside the pillar are superimposed. These are extracted and shown in Figure 2b, with the corresponding fast Fourier transform in Figure 2c. We obtained a mode frequency of 42 GHz, which is in excellent agreement with the expected frequency calculated by Equation (1).

Figure 2.

(a) Time-domain signal; (b) extracted oscillatory component; (c) corresponding fast Fourier transform of the signal in (b).

With knowledge of the index of refraction, this allows the calculation of the longitudinal sound velocity and deduction of the elastic properties along the axial direction of the pillar. Currently, we are only probing roughly 3 µm of the pillars. This is a point we are improving on. Additionally, changes in elastic behavior have only been reported for pillars and wires below a 1 µm diameter. Therefore, we aim to push the methodology to resonators with smaller head sizes.

Funding

This research was funded by the SFB 767 of the DFG, grant number 32152442 and received further support by the strategic economic- and research program “Innovative Upper Austria 2020” of the province of Upper Austria.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Doster, J.; Hoenl, S.; Lorenz, H.; Paulitschke, P.; Weig, E.M. Collective dynamics of strain-coupled nanomechanical pillar resonators. Nat. Commun. 2019, 10, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Bartels, A.; Cerna, R.; Kistner, C.; Thoma, A.; Hudert, F.; Janke, C.; Dekorsy, T. Ultrafast time-domain spectroscopy based on high-speed asynchronous optical sampling. Rev. Sci. Instrum. 2007, 78, 035107. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).