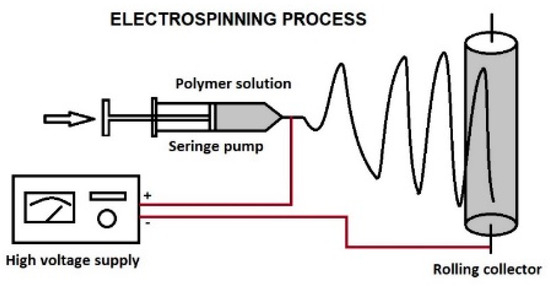

Graphene and its derivatives have attracted considerable attention in recent years as potential materials for various applications because of their unique physical-chemical properties [1]. The study aimed to obtain by electrospinning nanofibers using styrene-butadiene block-copolymers (SBS) and styrene-isoprene block-copolymers (SIS), as well as their composites with graphene, and to investigate their structural, thermal and mechanical properties. In the first step, styrene-butadiene block-copolymers (SBS) and styrene-isoprene block-copolymers (SIS) were obtained by anionic sequential polymerization. The reactions were carried out in cyclohexane solution through a three-stage process and were initiated with n-butyl lithium. In the second step, polymer composites were obtained, using the synthesized thermoplastic elastomers and graphene in tetrahydrofuran solution. The polymeric composites obtained from thermoplastic elastomers and graphene were used for the manufacture of nanofibers by electrospinning (Figure 1).

Figure 1.

Electrospinning process scheme.

The polymer nanofibers obtained by electrospinning were characterized by ATR-FTIR analysis, Differential Scanning Calorimetry (DSC), and Thermo-gravimetric Analysis (TGA). The results indicated an improvement of thermal and chemical properties of nanofibers composites with graphene, compared to basic thermoplastic elastomers.

Acknowledgments

This paper was supported by a Nucleu Program conducted with MCI support, project no. PN.19.23.03.01.04, contract no. 23N/2019.

Reference

- Jing, X.; Mi, H.-Y.; Salick, M.R.; Cordie, T.M.; Peng, X.-F.; Turng, L.-S. Electrospinning thermoplastic polyurethane/graphene oxide scaffolds for small diameter vascular graft applications. Mater. Sci. Eng. C 2015, 49, 40–50. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).