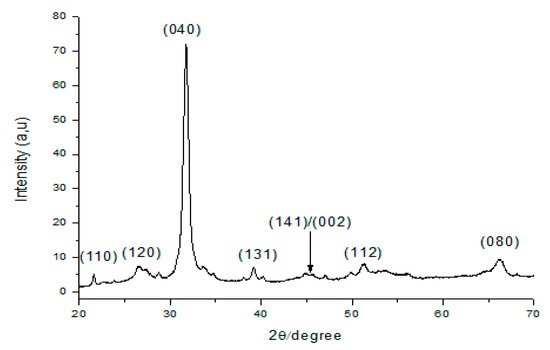

The tin sulfide (SnS) has p-type conductivity, high absorption coefficient (≥104 cm−1), bad gap energy in the range of 1.1–1.7 eV and crystalized on the cubic and orthorhombic phase [1]. The semiconductor SnS thin film is used for gas sensor and photovoltaic applications [2,3]. SnS-based layers are promising candidates for gas sensor applications compared to other layered materials such as graphene and phosphorene. For example, SnS thin film performance in chemical sensors for the detection of acetone and ethanol shows: a response of (~190%) with a fast response time of (2 s) and a recovery time of (9 s) for acetone, and a response (~130%), with a fast response time (2 s) and a recovery time (9 seconds) for ethanol, the concentration used is 10 ppm respectively [2]. The present work describes the preparation and characterization of thin films of tin (II) sulfide (SnS) by the chemical spray pyrolysis method for gas sensors applications. The layers obtained were characterized by X-ray photoelectron spectra (XPS), XPS analysis shows the existence of the constituent elements of SnS. And X-ray diffraction (XRD) that revealed the appearance of the orthorhombic phase of tin sulfide Figure 1, this phase was confirmed by vibratory modes measured by Raman spectroscopy. The optical properties such as optical conductivity, refractive-reflectivity index, extinction coefficient, and band gap energy were determined using the absorbance and transmittance data, determined by the UV-visible spectrophotometer.

Figure 1.

X-Ray diffraction patterns of SnS thin films deposited at various substrate temperatures.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nair, P.K.; Garcia-Angelmo, A.R.; Nair, M.T.S. Cubic and orthorhombic SnS thin-film absorbers for tin sulfide solar cells. Phys. Status Solidi 2016, 213, 170–177. [Google Scholar] [CrossRef]

- Afsar, M.F.; Rafiq, M.A.; Tok, A.I.Y. Two-dimensional SnS nanoflakes: synthesis and application to acetone and alcohol sensors. RSC Adv. 2017, 7, 21556–21566. [Google Scholar] [CrossRef]

- Di Mare, S.; Menossi, D.; Salavei, A.; Artegiani, E.; Piccinelli, F.; Kumar, A.; Mariotto, G.; Romeo, A. SnS Thin Film Solar Cells: Perspectives and Limitations. Coatings 2017, 7, 34. [Google Scholar] [CrossRef]

- Hu, F.; Tan, C.; Ye, H.; Chen, X.; Zhang, G. SnS monolayer as gas sensors: Insights from a first-principles investigation. In Proceedings of the 2017 18th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Dresden, Germany, 3–5 April 2017. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).