Introduction

The work is aimed at creating ZnO/SiC composites for resistive type gas sensors towards main components of exhaust gases CO and NH3 in temperature range 400–550 °C. The highly dispersed silicon carbide SiC was used to enhance the stability of nanostructured ZnO at high temperature. In this work we prepared the ZnO/SiC nanocomposite materials by mixing and heat treatment of electrospun ZnO nanofibers and nanocrystalline silicon carbide of 3C-SiC polytype.

Materials Synthesis

Nanocrystalline SiC and ZnO were prepared separately by electrospinning of polymer solutions followed by heat treatment to polymer removing and materials crystallization. For SiC fabrication the solution of polycarbosilane (PCS) and polyvinylpyrrolidone (PVP, M = 1 300 000) in chloroform was used as a precursor. The electrospinning was carried out at the conditions of 3 mL/h solution feed rate, with 150 mm distance and 6 kV voltage between the needle and metal collector. The 3C- SiC nanofibers of a cubic structure were obtained from amorphous SiC using the spark plasma sintering method (SPS) on a Spark Plasma Sintering System LABOX-625 at a temperature of 1600°°C for 1 h under vacuum. For ZnO fabrication the zinc acetate (Zn(CH3COO)2 2H2O) was used as a precursor. The electrospinning of polymer solution was carried out at the conditions of 1 mL/h solution feed rate, with 125 mm distance and 12 kV voltage between the needle and metal collector. The fibrous material was heated at 550 °С (5 h) in air.

Material Characterizations

The effect of silicon carbide on the structure and electrical properties of composite materials was studied using different techniques: SEM-EDX, XRD, XPS, FTIR. The FTIR absorption spectra of ZnO/SiC nanocomposites contain intense peaks with absorption maxima at 900 cm−1 and 1067 cm−1, corresponding to the stretching vibrations of the Si–C and Si–O bonds. This indicates the formation of amorphous SiO2 shell on the surface of SiC nanoparticles, which does not appear on the diffraction patterns. XPS spectra reveal interactions between SiC and ZnO nanoparticles. The formation of silicon oxide was observed in the photoelectron spectrum in the O1s region, containing two components at 532.9 (O1) and 536 (O2) eV and Si2p region contains three components at 100.6 (Si1), 103.0 (Si2), 106.3 (Si3) eV. The formation of nanocomposites is accompanied by a significant increase in the electrical resistance of the material in comparison with ZnO nanofibres.

Sensor Measurements

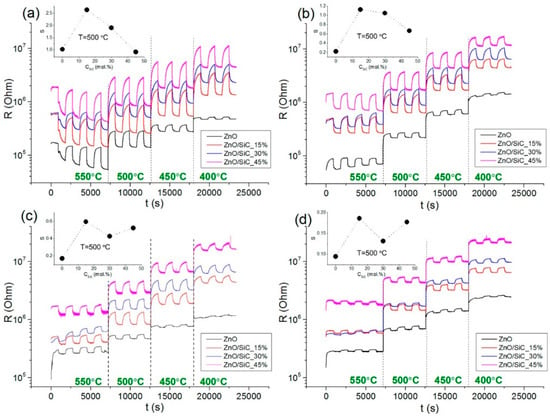

The ZnO/SiC nanocomposites containing 0, 15, 30, 45 and 100 mol% SiC were prepared by mixing components in a single homogeneous paste with using a solution of α-terpineol in ethanol as a binder. The sensors were fabricated by thick films technology via drop-deposition of the paste onto alumina microhotplates provided with vapor-deposited Pt contacts (0.3 × 0.2 mm) separated by 0.2 mm gap and with embedded Pt-meanders. The paste was dried at room temperature in ambient air and then calcined at 250 °C in purified air for 20 h to remove the binder. Sensor properties (Figure 1) were investigated as resistance response towards 20 ppm NH3 (a, b) and 20 ppm CO (c,d) in dry air (a,c) and at relative humidity RH25 = 30% (b,d). In both cases, the formation of ZnO/SiC nanocomposites leads to an increase in the sensor response compared to the bare ZnO nanofibres. Nanocomposites containing 15 and 30 mol% SiC demonstrate the highest values of the sensor response. A further increase in the SiC content leads to an increase in resistance and a decrease in the sensor response of the nanocomposites.

Figure 1.

Change in the resistance of ZnO/SiC nanocomposites to 20 ppm NH3 (a,b) and 20 ppm CO (c,d) in dry air (a,c) and at relative humidity RH25 = 30% (b,d).

Conclusions

ZnO/SiC nanocomposites based on ZnO nanofibers (wurtzite) and nanocrystalline SiC (3C polytype), obtained by the electrospining method, were investigated as sensitive materials for high- temperature gas sensors of the resistive type. The introduction of SiC results in the magnification in the sensitivity of zinc oxide nanofibers towards reducing gases CO and NH3 in the temperature range of 400–550 °C. This effect is accompanied by the increase in the activation energy of conductivity in this temperature range. The results obtained are interpreted in the context of the assumption of the formation of an n–n heterojunction at the ZnO/SiC interface, resulting in the electrons transfer from SiC to ZnO. Growth in the concentration of electrons in the near-surface layer of ZnO leads to an increase in the concentration of chemisorbed oxygen on its surface, which is confirmed by XPS. In turn, this determines an increase in the activation energy of conductivity and causes a magnification in the sensor response of ZnO/SiC nanocomposites compared with ZnO nanofibres.

Funding

The work was financially supported by RFBR grant No. 18-03-00091 and in part by a grant from the St. Petersburg State University–Event 3-2018 (id: 26520408).

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).