Abstract

Semiconductor functional materials play an increasingly important role in science and technology because of their unique optical, electrical, magnetic, catalytic and chemical properties. They are widely used in fields such as solar cell, photo-catalysts, optical coating, capacitors for large scale integrated devices, electrochromic systems and gas sensors. One important application for semiconductor gas sensors is the detection of pollutant gases for the control of the combustion process.

Published: 19 June 2019

Nanostructured titanium dioxide (TiO2) is a cheap, non-toxic and biodegradable materials that is widely used in industry. For gas sensing application, it can be used as sensing elements for chemoresistive gas sensors. The physical properties of such materials and their electrical performance largely depend on their methods of production. Nowadays, considerable efforts were dedicated to enhance the TiO2 sensing performance, e.g., by adding dopants or metal/metal-oxide decorations in the sensing layer.

In this work, we used sol-gel method associated to spin and dip coating techniques to produce titanium dioxide mixed with tin dioxide (TiO2/SnO2) and pure TiO2 thin films, the concentrations of SnO2 used are 3 and 7%. The samples were mainly characterized by means of X-ray Diffraction (XRD) and Scanning Electron Microscopy (SEM).

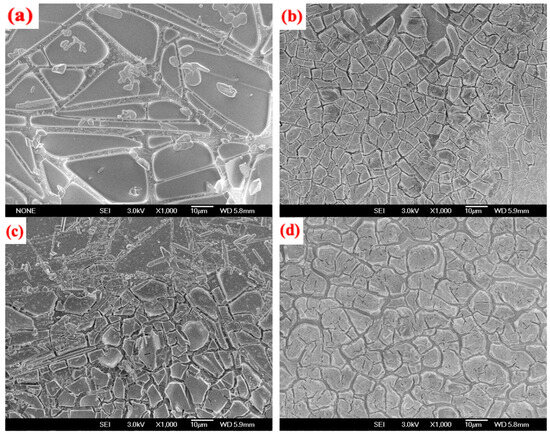

The SEM characterization highlighted a nanostructured morphology of the films prepared and homogeneous layers of TiO2 and TiO2/SnO2 deposited onto alumina substrates (Figure 1).

Figure 1.

SEM images of synthesized samples ((a) Undoped TiO2 using dip coating (b) SnO2 doped TiO2 using spin coating, (c) Undoped TiO2 using spin coating and (d) SnO2 doped TiO2 using dip coating).

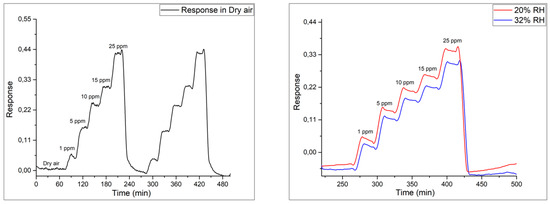

The electrical characterization of the sensors produced was performed for two different gases (Ethanol and Ethylene), both in dry air and in presence of different percentages of relative humidity.

Only TiO2/SnO2 (7%) deposited using spin coating technique gave a good response in both dry and wet air, to different concentrations of ethanol (Figure 2). It can be seen from Figure 2 that the sensor gave relatively low gas sensing response to this gas target, but the sensor resulted to be not affected by the presence of the humidity, highlighting about the same response values both in dry and wet air.

Figure 2.

Response of TiO2/SnO2 to Ethanol in both dry air and in the presence of relative humidity with .

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).