1. Introduction

As global populations expand and the demand for infrastructure and services grows, the availability of suitable land for construction has become increasingly limited. However, in many regions, soft soil presents significant challenges, as it lacks the strength required for conventional shallow foundations. To cost-effectively address these limitations, stone columns and geosynthetic reinforcement have emerged as highly adaptable techniques for enhancing soil stability on-site. These methods are particularly valued for their affordability, straightforward application, climate forcing and construction efficiency. The use of reinforced sand layers and stone columns has been shown to substantially improve foundation performance in soft clay soils [

1].

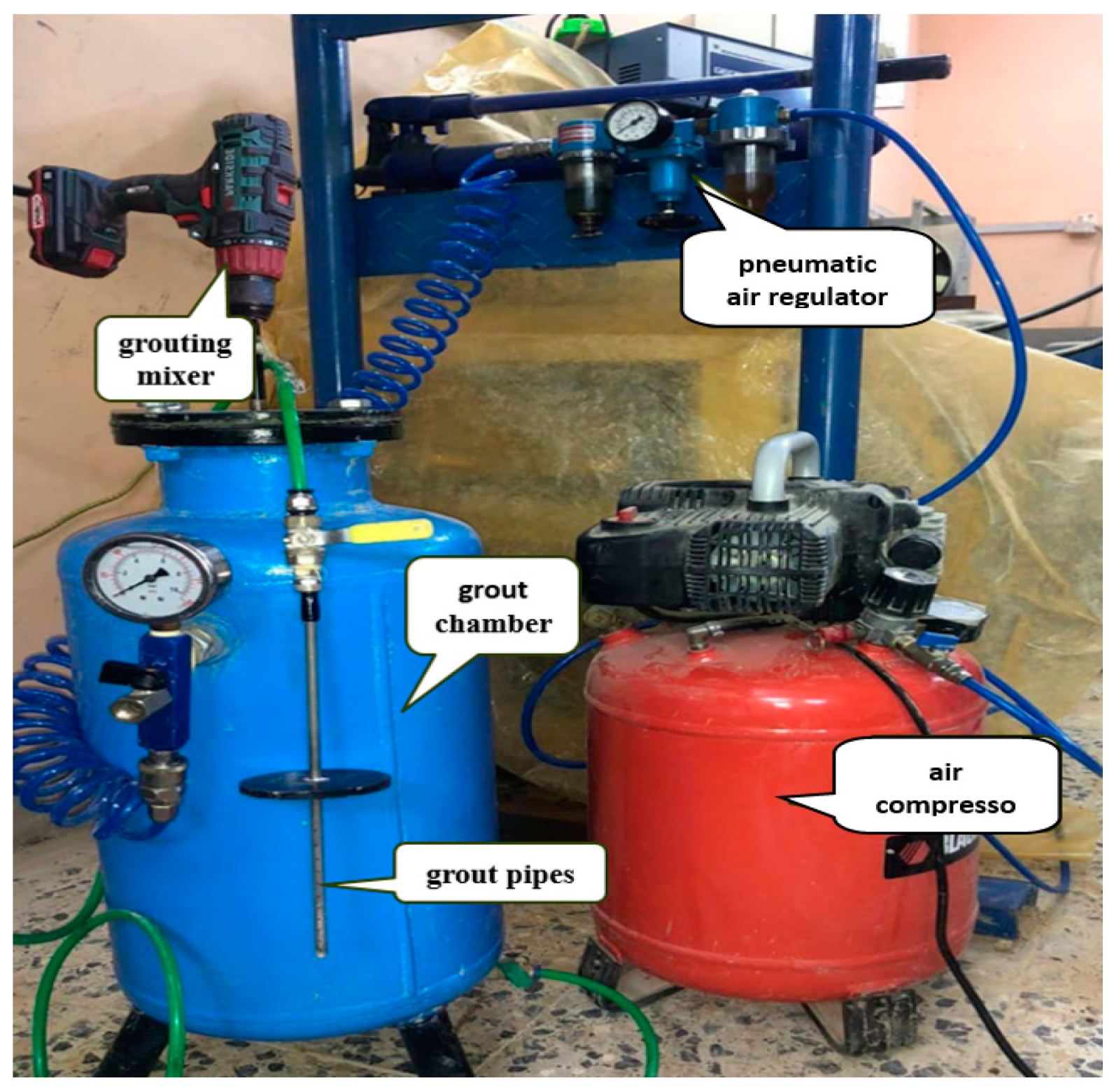

When grouting technology is integrated with stone columns, it significantly enhances soil stability and addresses some limitations associated with stone columns alone. While the individual applications of stone columns, geosynthetic reinforcement, and soil grouting have been well documented, the combined use of all three techniques remains largely unexplored.

Ambily and Gandhi [

2] described experimental and finite-element analyses conducted to investigate the behavior of stone columns with the soil’s shear strength, the angle of internal friction of the stones, and the distance between the stones.

Numerous attempts have been made to improve the behavior of conventional stone columns. Structural elements such as sleeves, discs, and others have been introduced to interact with backfill material [

3]. Furthermore, it has been shown that using additives such as cement, lime, and asphalt can effectively enhance the performance of stone columns [

4].

Fattah et al. [

5] and Ali et al. [

6] examined the failure stress resulting from various types of reinforcement on long floating and end-bearing single and group columns with and without reinforcement.

In geotechnical engineering, grouting is a technique used to improve the properties of soil, especially unstable soils. This method entails injecting materials like cement, chemical resins, or a combination of chemicals into the soil via pipes to reduce permeability, improve its strength, and increase stability [

7]. The types of grouting differ based on the material used and the properties of the targeted soil [

8,

9].

A prevalent application of grouting is strengthening foundations and large structures, including dams and bridges. Grouting enhances the soil’s capacity to support substantial loads and diminishes the probability of differential settlements [

10]. Additionally, grouting is employed in subterranean construction endeavors, such as tunnels, to regulate groundwater infiltration and avert soil collapse during excavation [

8]. The procedure is based on several methods, such as high-pressure grouting, employed when considerable structural alterations in the soil are necessary, and permeation grouting, which attempts to fill big gaps [

7]. In many different engineering contexts, grouting is a versatile and successful way to improve weak soils.

The research gap lies in the limited studies addressing the interaction between grouted sand columns and geogrids for improving bearing capacity and reducing settlement in soft clay soils in order to get resilient buildings. While most studies have focused on the use of each technique separately, this study is unique in its approach of combining both techniques.

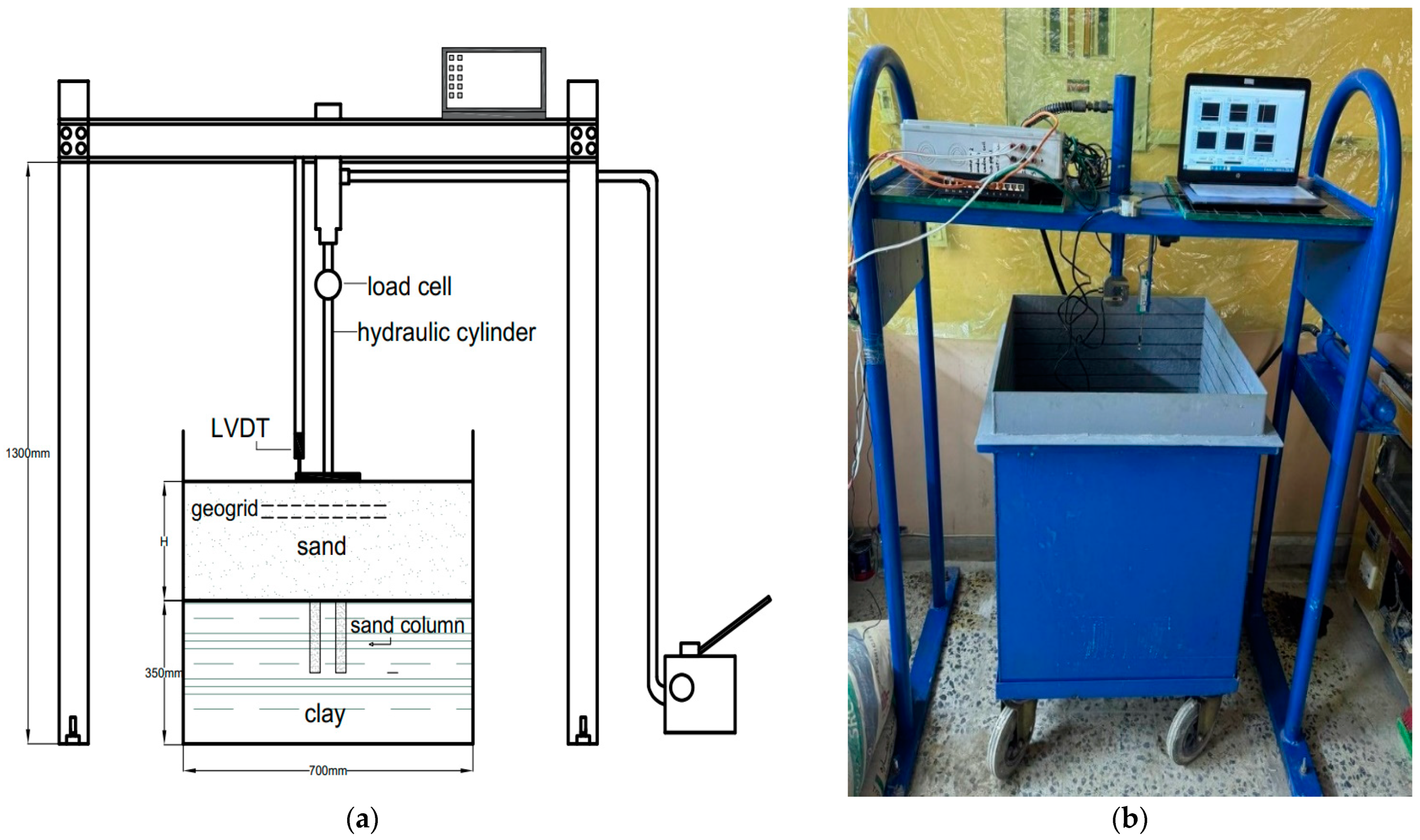

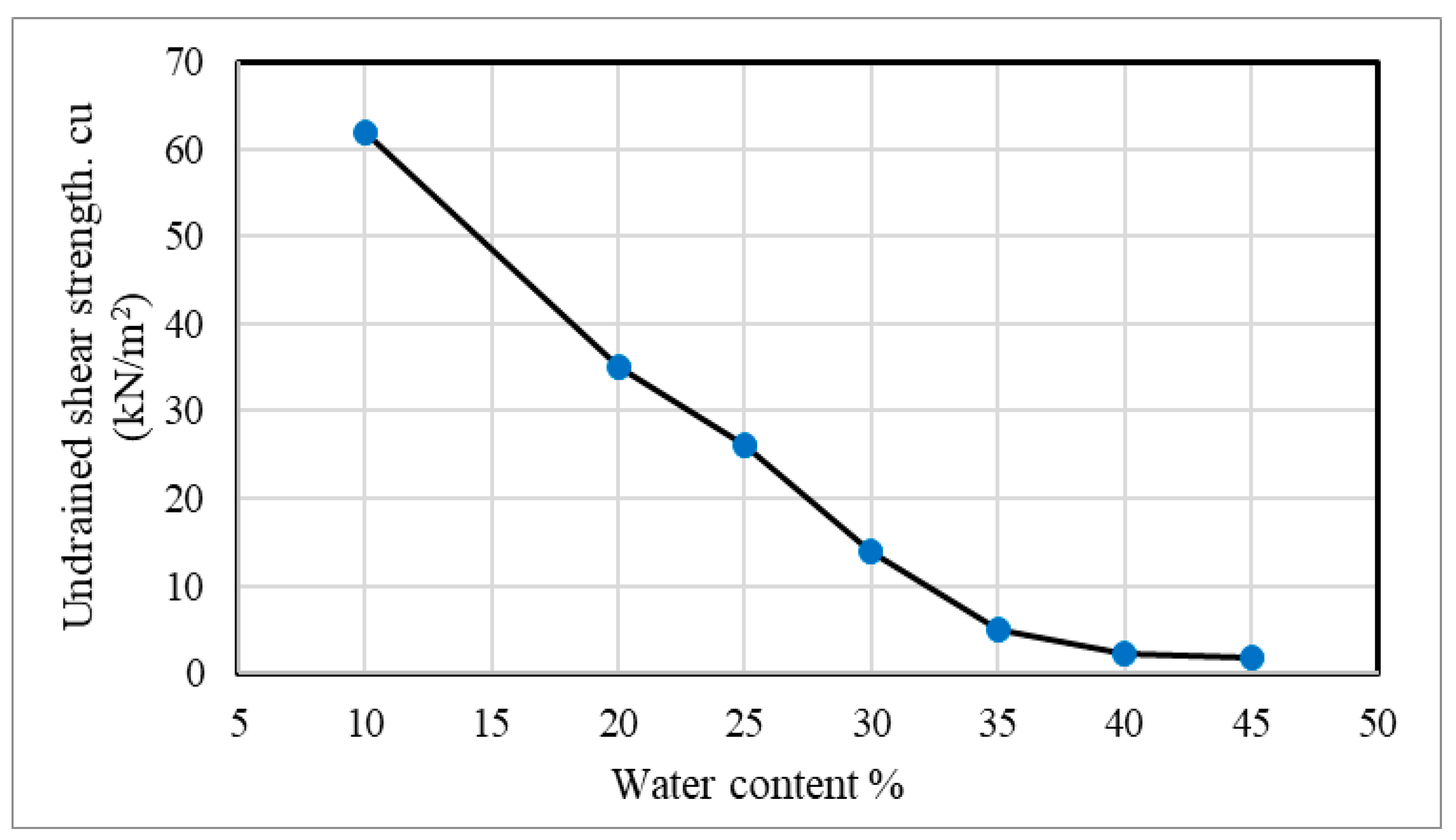

Based on the existing literature, the objective of the current study is to compare various soil improvement methods, including ordinary sand columns, grouted sand columns, and sand layers reinforced with geogrids. An experimental investigation was carried out on a soft clay bed with an undrained shear strength of 14 kPa to gain a deeper understanding of the load behavior.

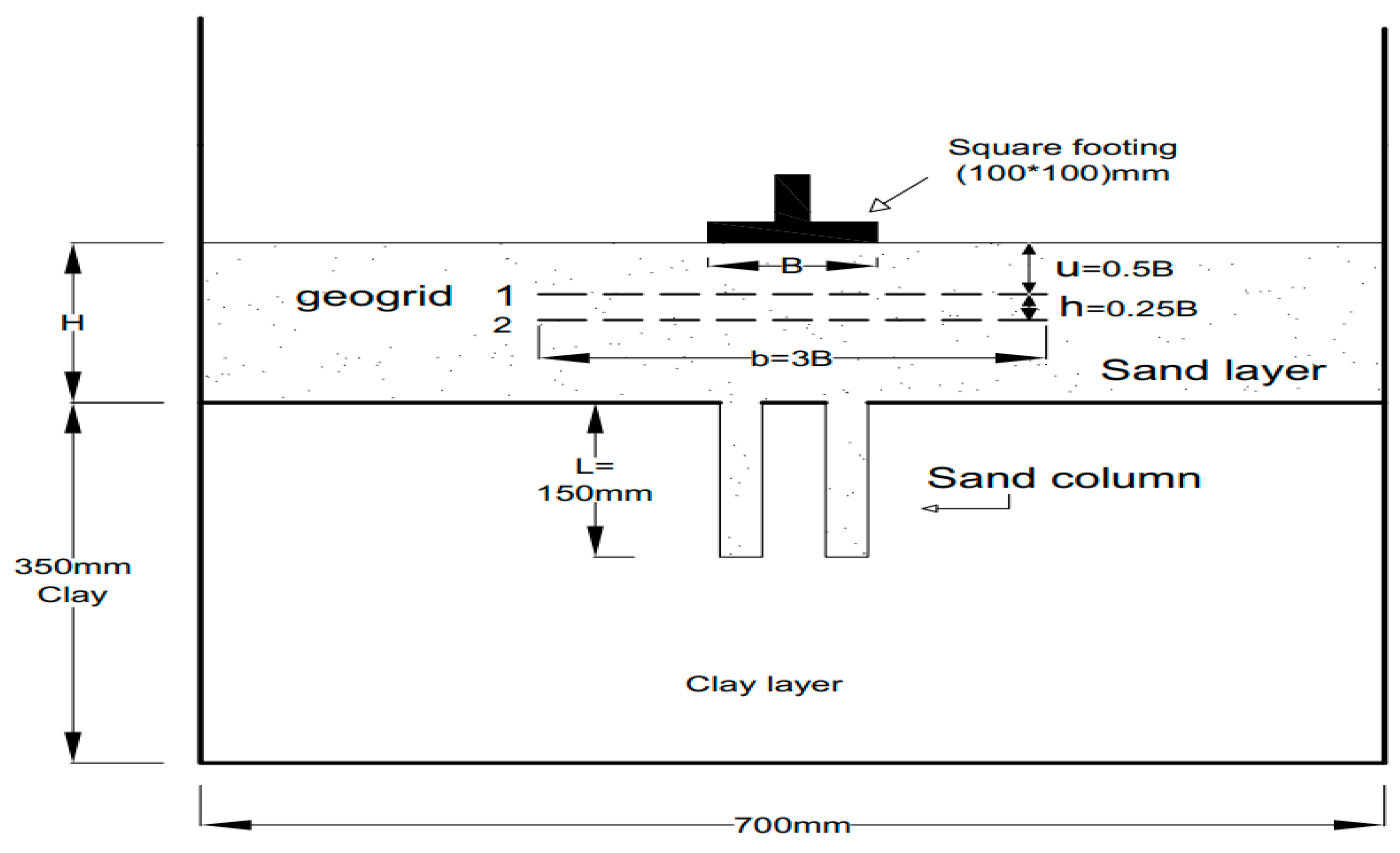

3. Results and Discussion

The primary aim of this laboratory study was to compare the effects of various key elements on bearing capacity enhancement, including reinforcing layers, sand beds, and grouted sand columns. In all model tests, failure was defined, following Terzaghi (1947) as cited by [

29], as the stress needed to produce a settlement equal to 10% of the model footing width.

The bearing capacity ratios (BCRs) for various values of H/B ratios across all model tests under different reinforcement conditions are summarized in

Table 6. It is calculated as the ratio of the bearing capacity (q) of reinforced soil (q

reinforced) to that of unreinforced soil (q

unreinforced) at specific s/B ratios, where s/B represents the footing settlement to footing width ratio and the BCR represents the percentage improvement ratio, providing a clear indication of the efficiency of the reinforcement technique used, which can be represented by the equation below:

Additionally, the settlement reduction ratio (St/Sunt)—the ratio of settlement in treated soil to that in untreated soil under the same applied pressure—is used to demonstrate the reduction in settlement achieved by the model tests.

3.1. Effect of a Group of Four Floating Sand Columns (4SC), Grouted and Non-Grouted, Without a Sand Blanket

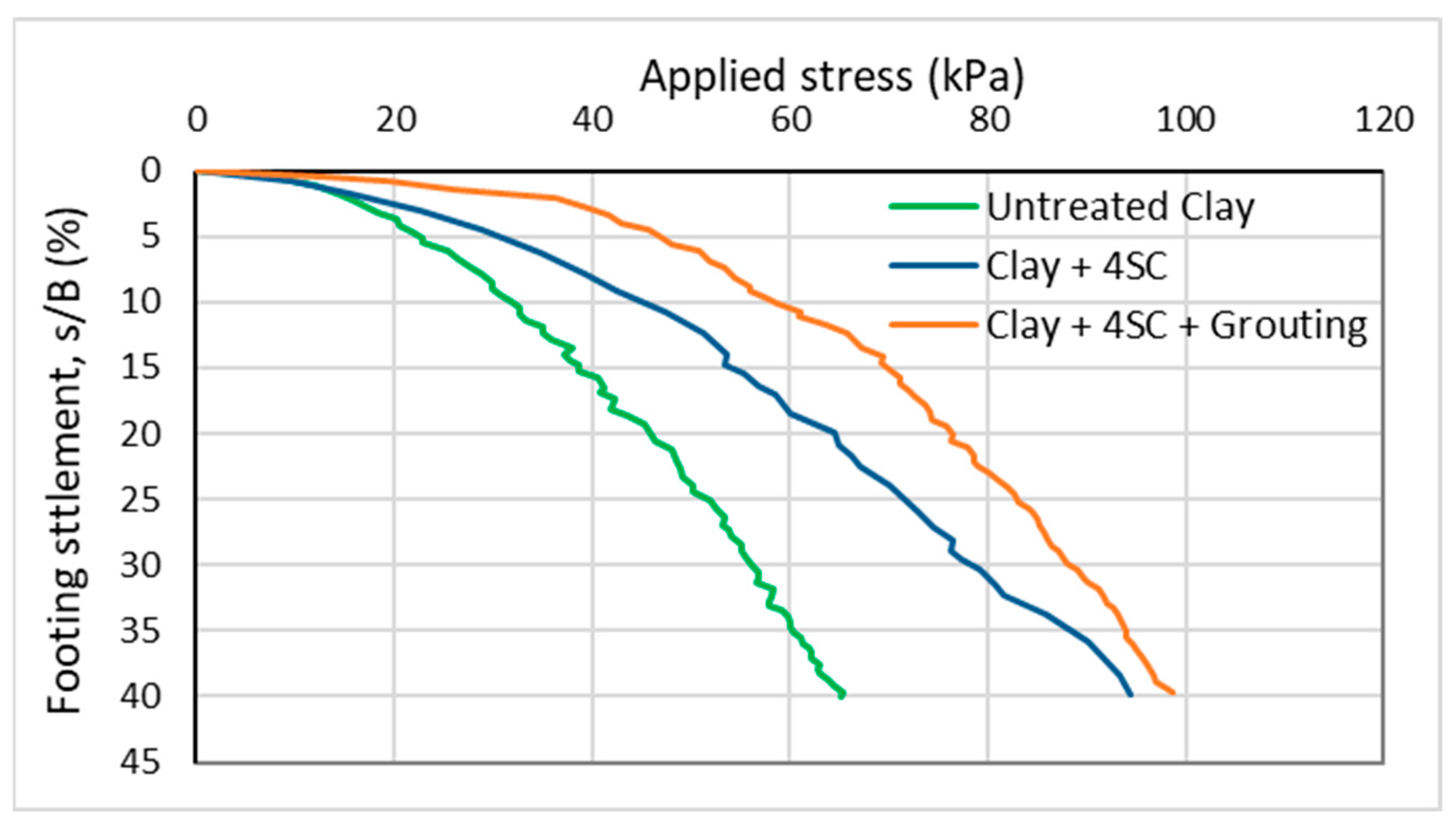

Figure 8 shows the relationship between the applied surface pressure (q) and footing settlement (s/B) (%) for model tests on untreated clay, sand columns, and grouted sand columns.

For the untreated clay bed, the pressure–settlement response shows a steady increase in slope without a clear peak, with a bearing pressure at failure of 31 kPa, equivalent to a 10% settlement ratio (s/B).

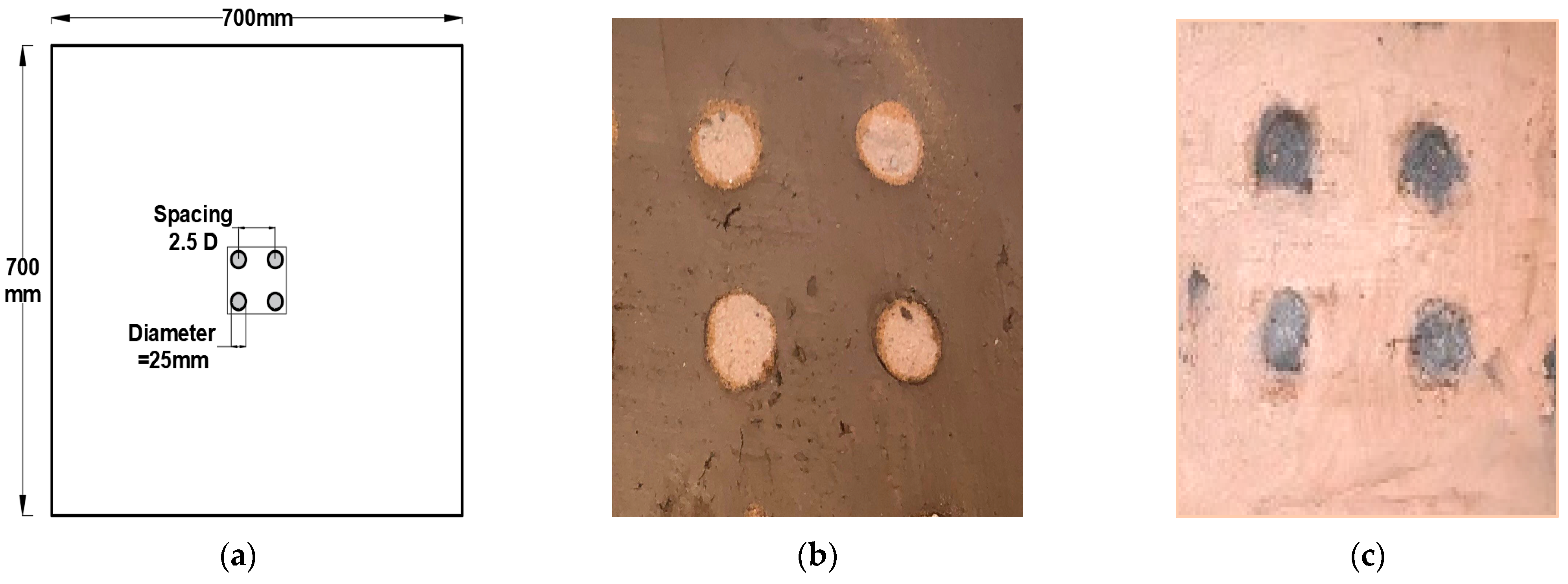

In the next model, four floating-type sand columns were constructed on a saturated soil bed with a spacing ratio of S/D = 2.5, positioned directly beneath a footing (100 mm × 100 mm) and tested under compressive loading. The bearing capacity at failure reached 47 kPa, compared to 31 kPa for untreated clay, indicating a 50% improvement in bearing capacity, as illustrated in

Figure 9. This improvement can be attributed to the sand columns’ ability to distribute loads over a broader area, reducing direct pressure on the clay soil, enhancing compression resistance, and decreasing settlement. The columns act as “control elements” in deformation, transferring portions of the load to greater depths within the clay, thereby relieving pressure on the softer layers.

In this experiment, no sand blanket was placed between the foundation and the sand columns, so the columns relied solely on their inherent properties to distribute pressure and minimize settlement. Although the absence of a blanket might impact the uniformity of load distribution, the results indicated that the columns still provided substantial improvement in the soil’s bearing properties.

A third test was conducted using four floating sand columns grouted with cement. These columns were also positioned beneath a footing (100 mm × 100 mm) and tested under compressive loading. The bearing capacity at failure for soil treated with grouted columns reached 59 kPa, achieving a BCR of 90%, as shown in

Figure 9. This improvement was achieved solely by the grouted sand columns positioned directly beneath the footing, without the addition of a sand blanket layer, demonstrating further enhancement in soil improvement.

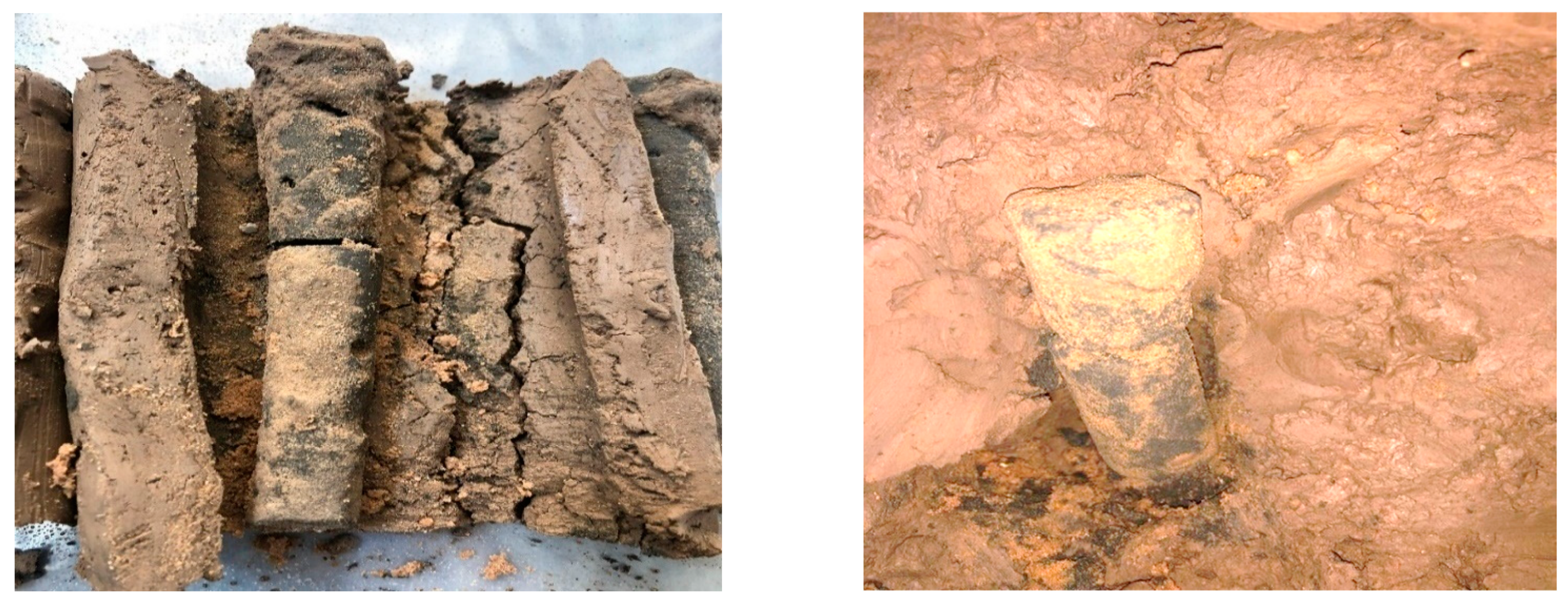

Figure 10 shows the configuration of the cement-grouted sand columns.

The interlocking effect, when using a geogrid, plays a significant role in providing remarkable resistance. The soil particles lock the apertures of the geogrid sheet and prevent its lateral movement, providing additional shearing resistance [

30].

Fattah et al. [

31] concluded that during grouting, contact between particles is prevented, which causes a reduction in friction. It was observed that there was a reduction in the soaking cohesion component in comparison with the unsoaked case, while a small reduction in the friction component was observed. This reduction may be attributed to the destruction of the interparticle cemented bonds (due to the presence of grouting liquid and gypsum) in the particle system. These results from the specimens indicated that the void ratio was changed after grouting.

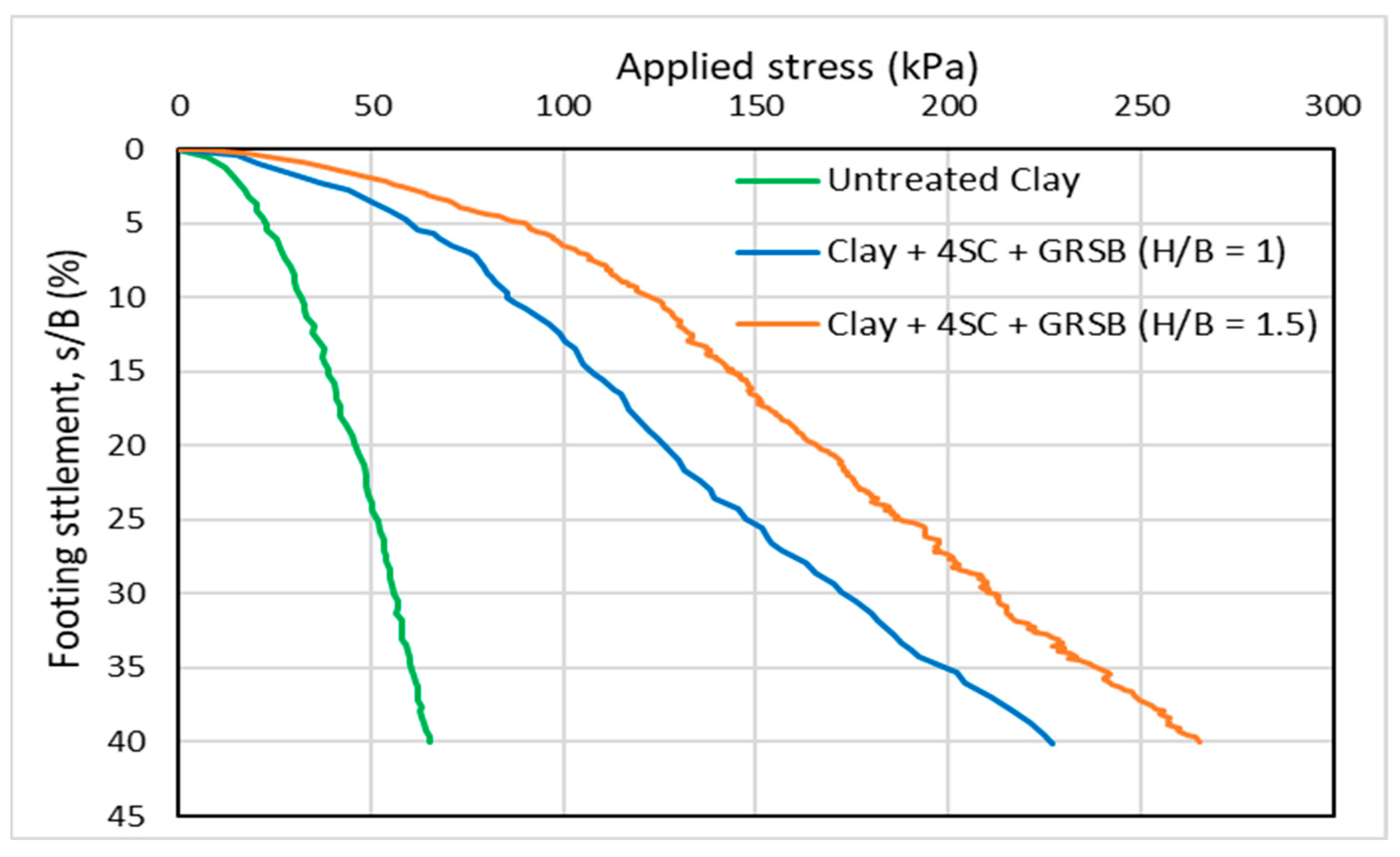

3.2. Model Tests on Soil Treated with Floating Sand Columns and a Geogrid-Reinforced Sand Bed (GRSB)

Figure 11 illustrates the response of bearing pressure to footing settlement for a geogrid-reinforced sand cushion placed over a clay base supported by sand columns. The results indicate that introducing a sand cushion with a thickness of H/B = 1 reinforced with a geogrid achieves a bearing pressure of 86 kPa. When the thickness of the sand cushion was increased to H/B = 1.5, the bearing pressure reached up to 123 kPa.

Additionally, the lower slope observed in the pressure–settlement response suggests a marked increase in the stiffness of the foundation bed. This improvement is attributed to the enhanced resistance to deformation provided by the sand columns, resulting from the mobilization of stiffness and friction within the sand, which collectively support the sand columns and the geogrid-reinforced layer. The combined application of sand columns and sand cushions proves more effective than using either method independently; reinforcing the sand cushion with geogrid significantly enhances the load-bearing efficiency of both the sand columns and the cushion. Furthermore, the interlocking effect and high tensile strength of the transverse ribs of the geogrid contribute to the load-carrying capacity of the soil.

In very soft soils, unreinforced stone columns may not support significant loads due to low lateral confinement. In such situations, additional confinement can be provided by encasing the stone columns with geosynthetics. The encasement increases the bearing capacity, increases stiffness, and reduces lateral bulging of stone columns even in very soft soil.

These findings align with the results of a three-dimensional numerical analysis conducted by [

32] who examined sand reinforced both with and without the addition of a geogrid. The study focused on encased and conventional columns positioned beneath a sand cushion and demonstrated that a sand cushion supported by traditional stone columns and encased geogrid columns resulted in significant improvements. Specifically, incorporating a geogrid layer within the sand cushion and installing geogrid-encased sand columns yielded an improvement of up to 148% in comparison to untreated cohesive soil.

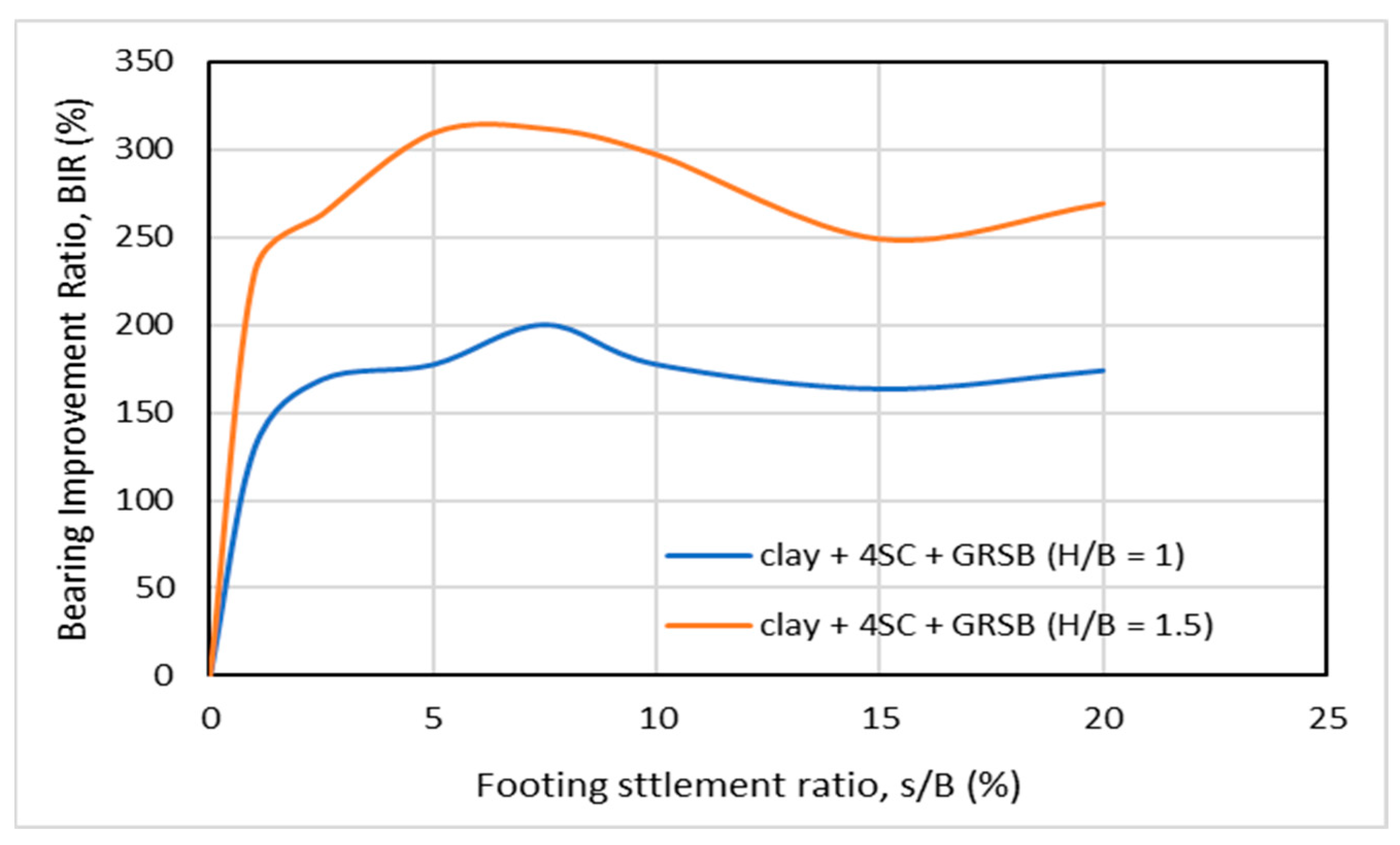

Figure 12 presents the relationship between the bearing capacity ratio (BCR) and settlement ratio (s/B) for treated soil incorporating floating sand columns and a geogrid-reinforced sand bed (GRSB) at varying heights. The peak of the BCR appears between a settlement (s/B) of 200 and 320%, after which the values gradually decrease or stabilize as settlement ratios increase. This behavior can be attributed to the stiffness contrast between the sand columns and the surrounding soil. As the model is subjected to loading, the load is transmitted from the foundation, through the sand layer, and subsequently, to the clay layer containing the sand columns. Consequently, the load concentration initially engages the reinforced columns, yielding peak BCR values, before gradually redistributing to the surrounding soil, which is reflected in the subsequent decline in the improvement ratio.

At failure, the bearing capacity ratios are recorded as 180% for H/B = 1 and 300% for H/B = 1.5. The results indicate that utilizing sand columns alongside geogrid reinforcement not only provides independent improvements but also creates an integrated system that enhances bearing capacity and overall stability. This finding aligns with the conclusions of [

33], who identified the combination of these methods as an innovative approach that yields superior performance compared to the use of each technique in isolation.

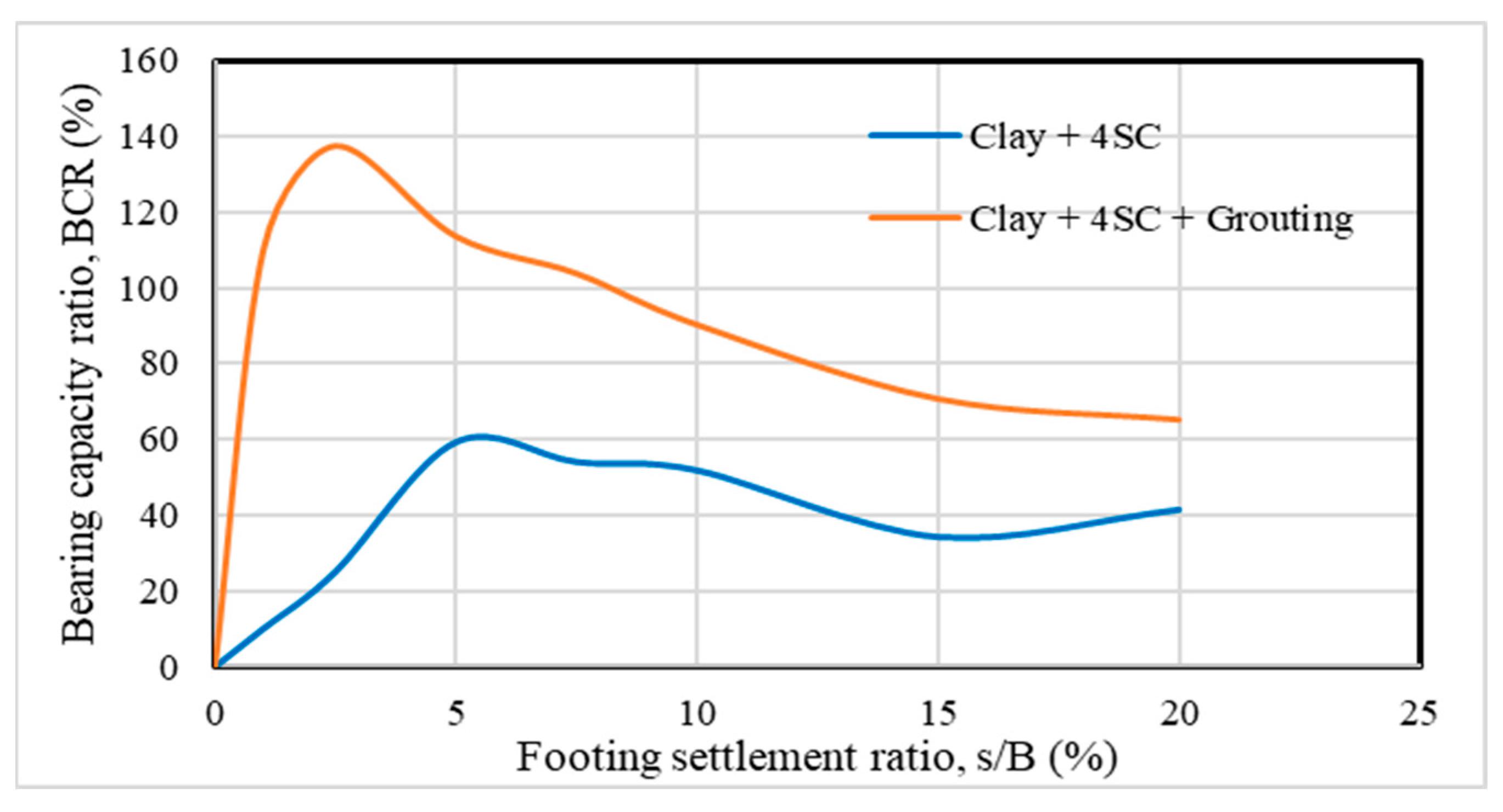

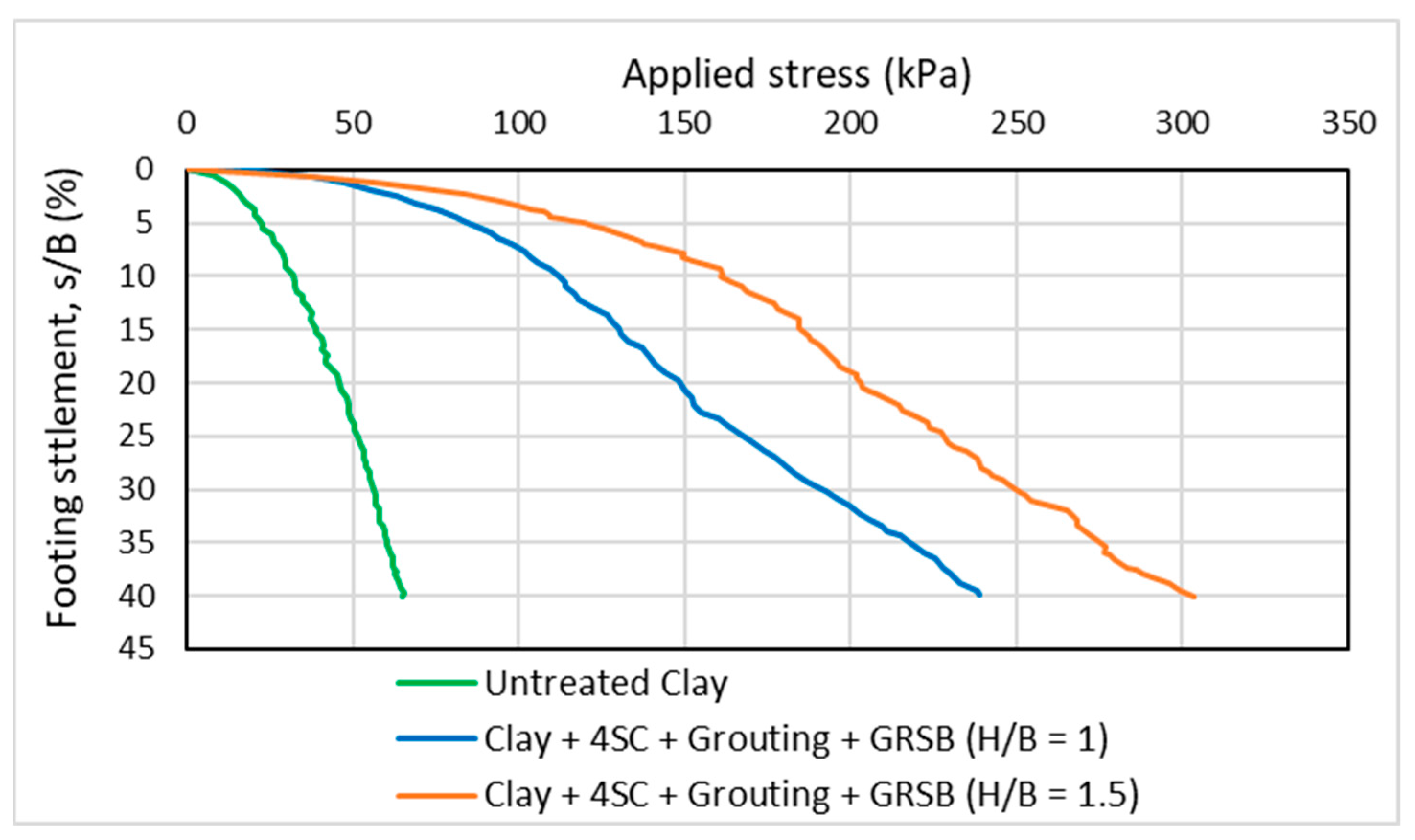

3.3. Model Tests on Soil Treated with Grouted Sand Columns and a Geogrid-Reinforced Sand Bed (GRSB)

The results presented in

Figure 13 demonstrate that the cement grouting of sand columns significantly improves bearing capacity and reduces settlement. This enhancement is due to the grouting process, which reinforces the sand columns, making them both sturdy and resistant to bulging. Furthermore, the pressure applied during grouting compresses the surrounding clay, increasing its density and boosting frictional resistance between the columns and the soft clay.

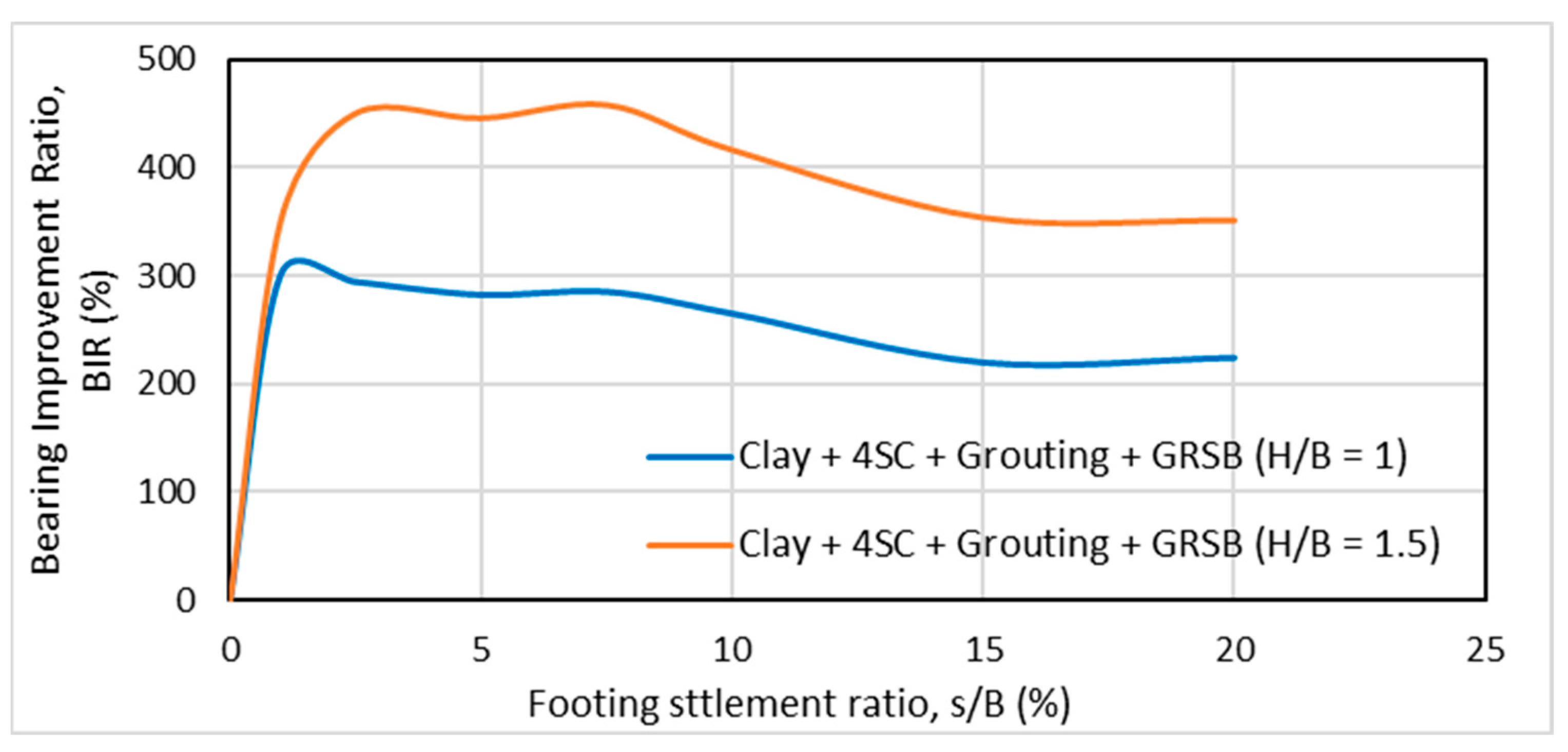

Figure 14 shows the bearing capacity ratio (BCR) in relation to normalized settlement (s/B) for treated soil with a group of four grouted sand columns, combined with a sand layer (H/B = 1 and 1.5) reinforced by two layers of geogrid. A substantial increase in the BCR is observed when these columns are grouted compared to untreated sand columns. This increase can be attributed to the solidification of the grouted sand columns, which become stiffer than the surrounding clay, as well as the additional lateral pressure exerted by the grout, which enhances the soil’s stability.

Additionally, cement grouting of the sand columns helps seal voids and pores within the clay soil, closing any existing cavities and further strengthening the overall structure.

Table 6,

Table 7,

Table 8 and

Table 9 summarize the results of the bearing pressure, BCR, settlement, and settlement reduction ratio for all the tests.