The Influence of Synthetic Reinforcing Fibers on Selected Properties of Asphalt Mixtures for Surface and Binder Layers

Abstract

1. Introduction

2. Materials and Methods

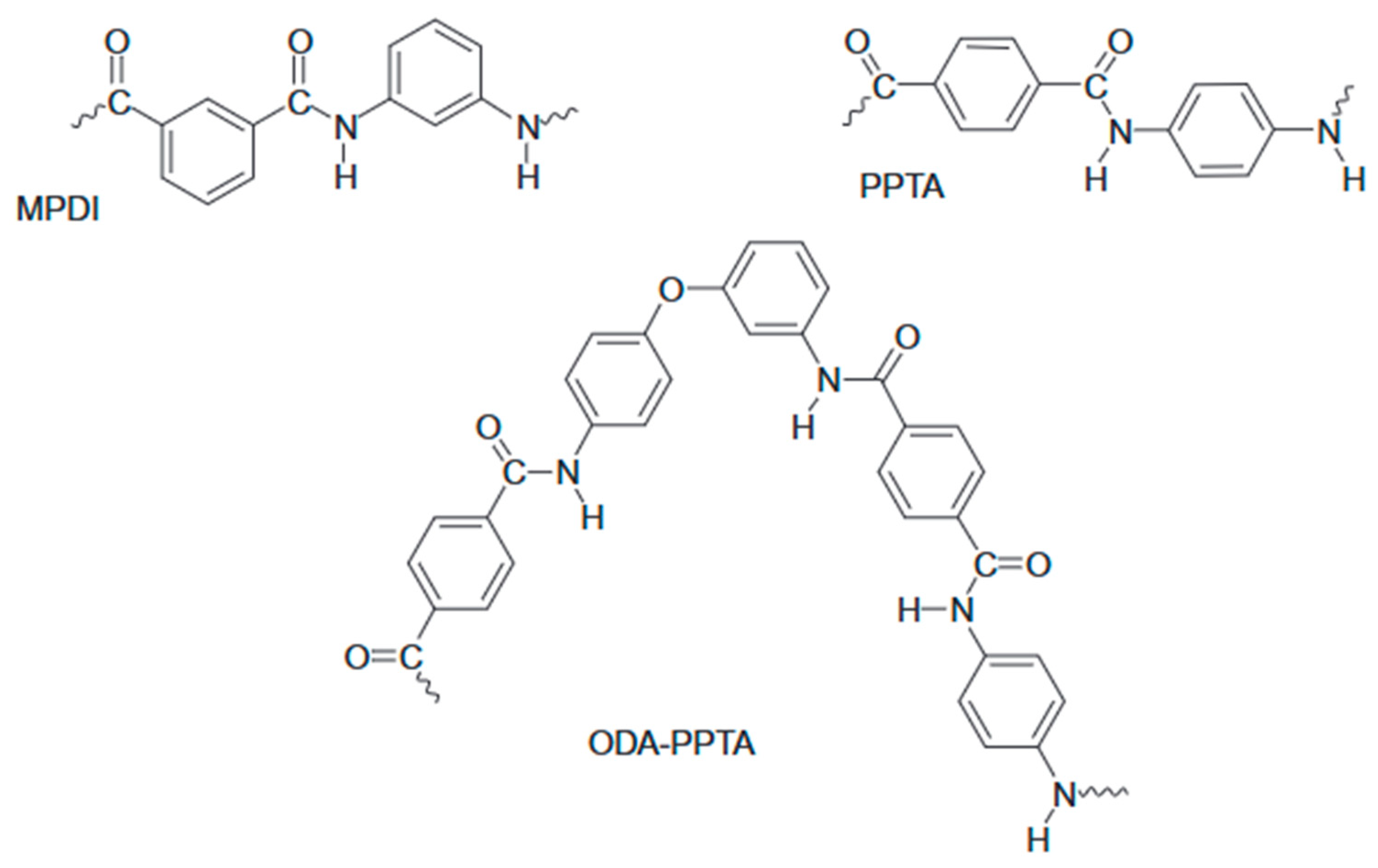

2.1. Fibres

- High tensile strength;

- High modulus of elasticity;

- Surface properties conducive to efficient stress transfer at the matrix–fibre interface.

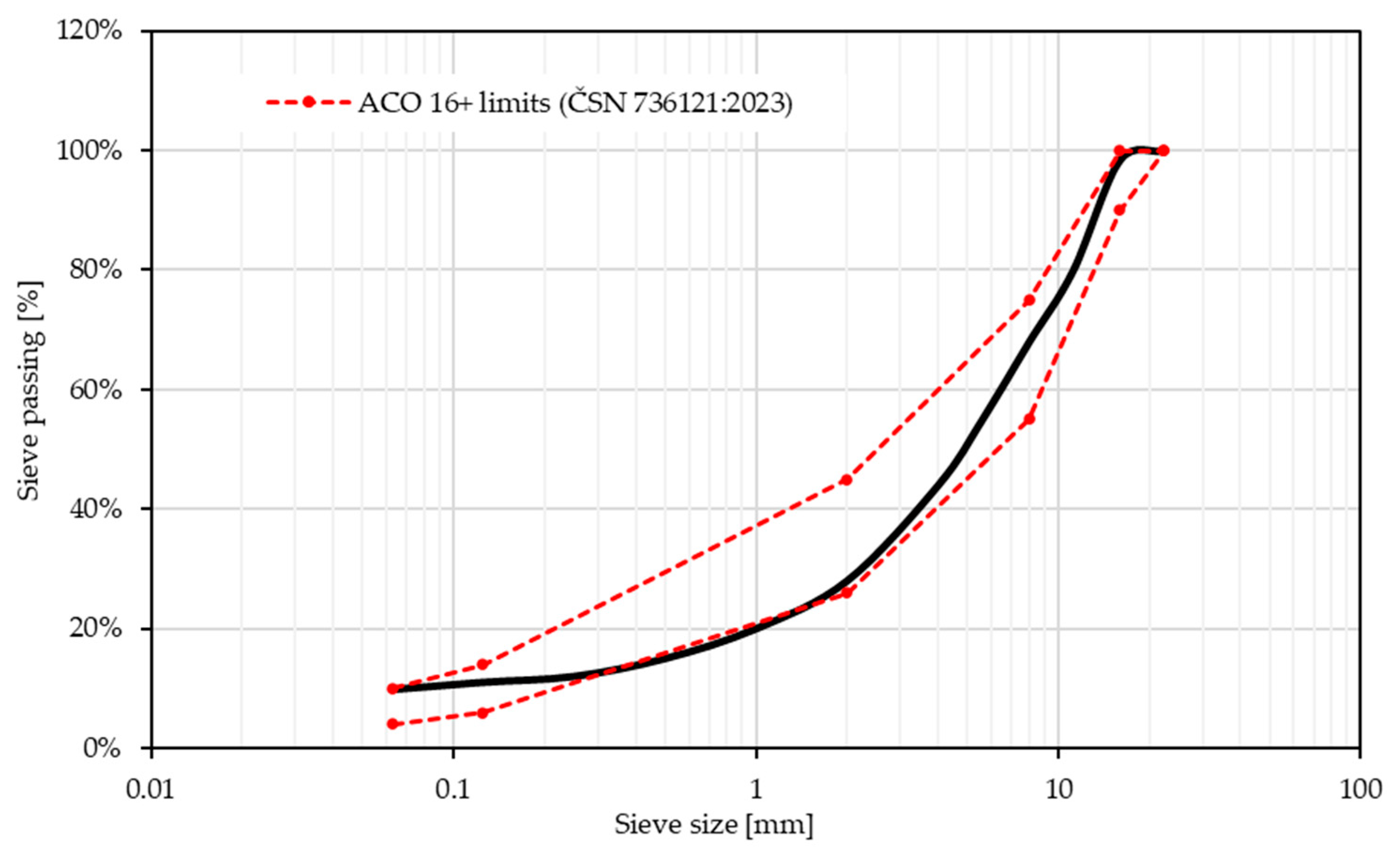

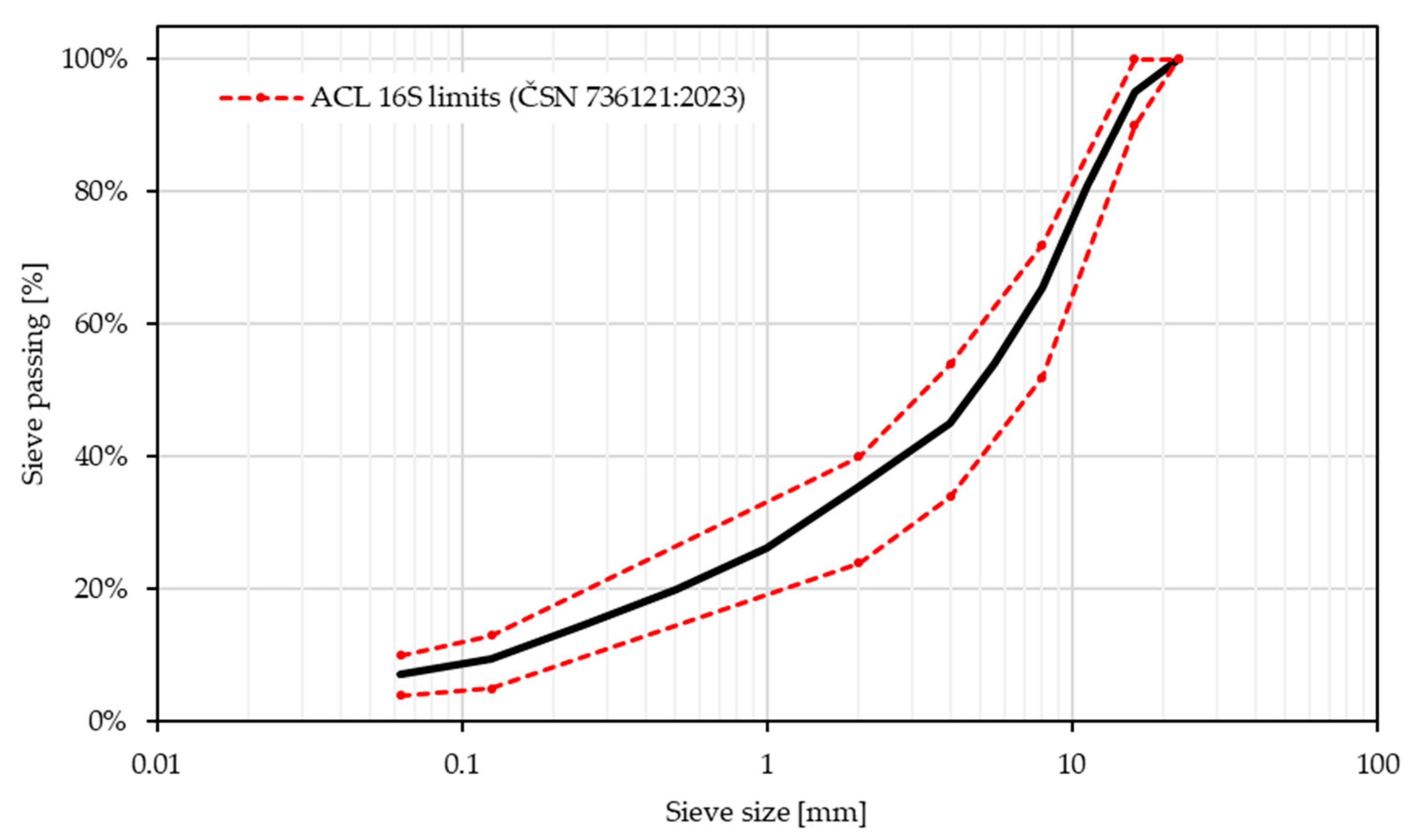

2.2. Bitumen Mixtures

- AC 16 surf (ACO 16+): 2 × 50 blows at 150 °C for used paving grade bitumen and 160 °C for used PMB;

- AC 16 bin (ACL 16S): 2 × 75 blows at 160 °C, only PMB was used.

| Mix ID | Mixture Type | Binder | Additive |

|---|---|---|---|

| Mix 1 | AC 16 surf/ACO 16+ | PMB 45/80-75 | – |

| Mix 2 | 0.02% FlexForce (FF) | ||

| Mix 3 | 50/70 | 0.04% FlexForce (FF) | |

| Mix 4 | AC 16 bin/ACL 16S | PMB 25/55-60 | – |

| Mix 5 | 0.02% FlexForce (FF) | ||

| Mix 6 | 0.04% FlexForce (FF) |

2.3. Testing Methodology

2.3.1. Air Void and Compactability

2.3.2. Indirect Tensile Strength (ITS) and Moisture Susceptibility (ITSR)

2.3.3. Stiffness (IT-CY)

2.3.4. Crack Propagation Resistance (SCB Test)

2.3.5. Resistance to Permanent Deformation (Wheel Tracking Test)

2.3.6. Dynamic Modulus (4-Point Bending Test)

3. Results

3.1. Air Void and Compactability

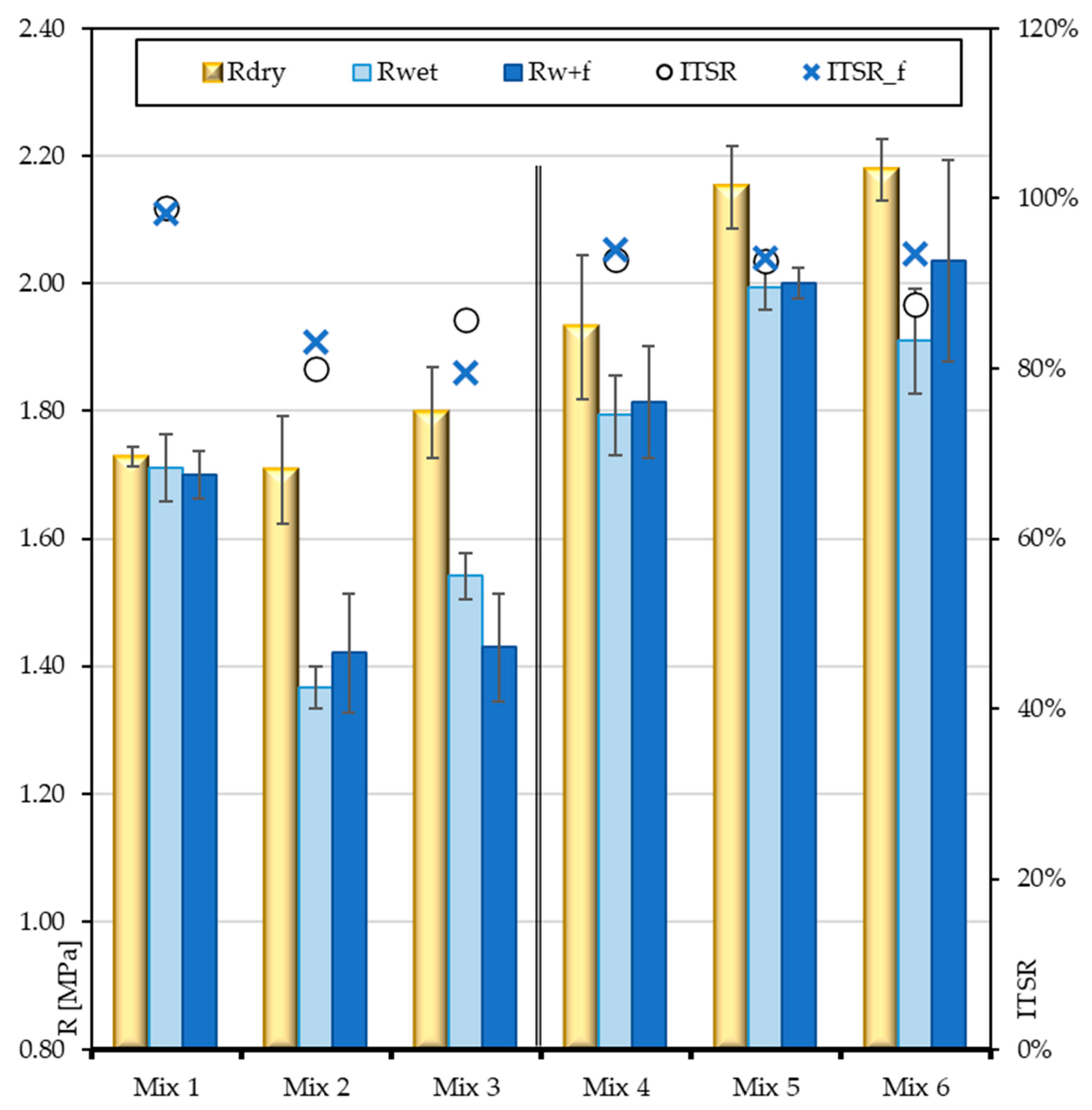

3.2. Indirect Tensile Strength (ITS) and Moisture Susceptibility (ITSR)

3.3. Stiffness (IT-CY)

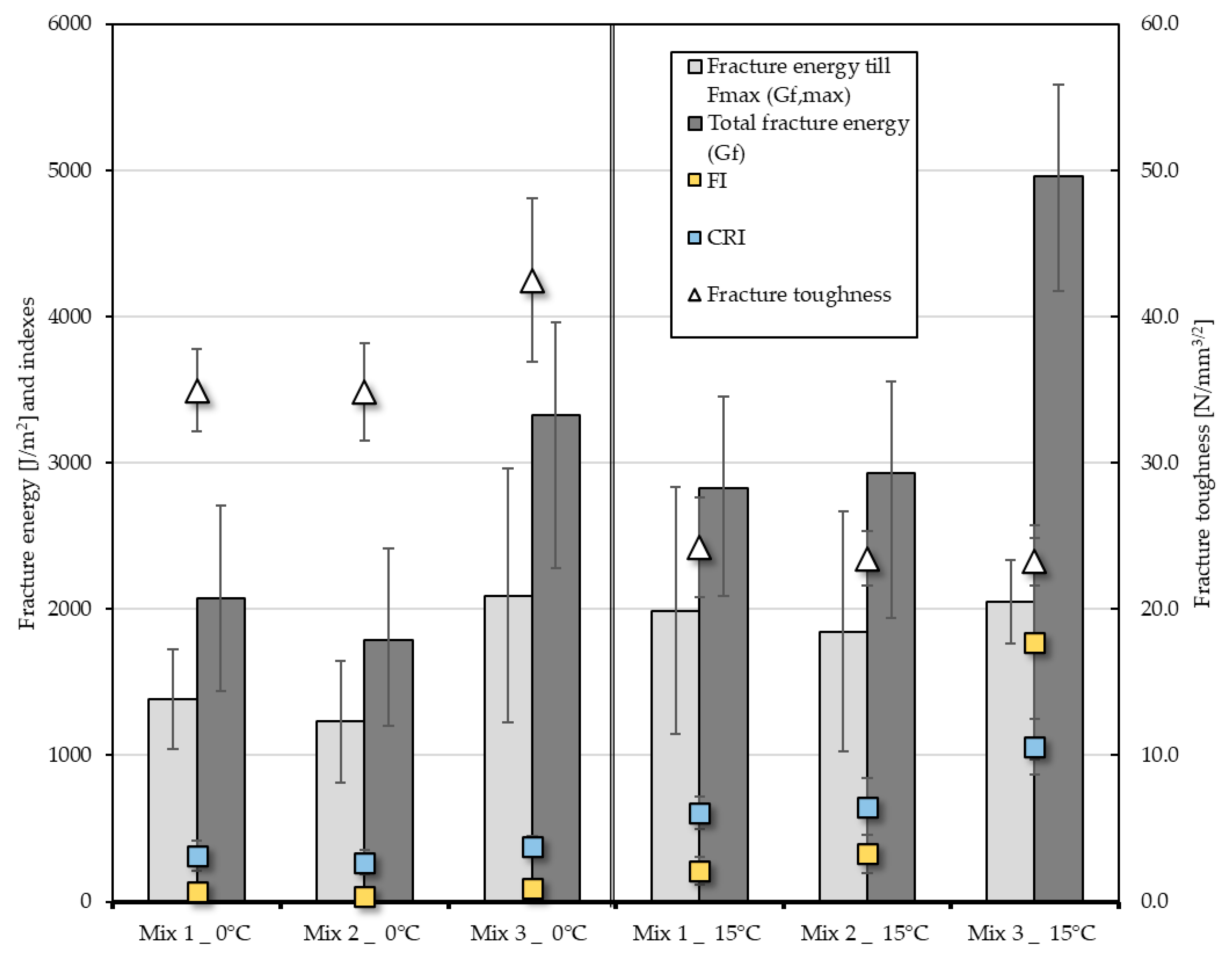

3.4. Crack Propagation Resistance (SCB Test)

3.5. Resistance to Permanent Deformation (Wheel Tracking Test)

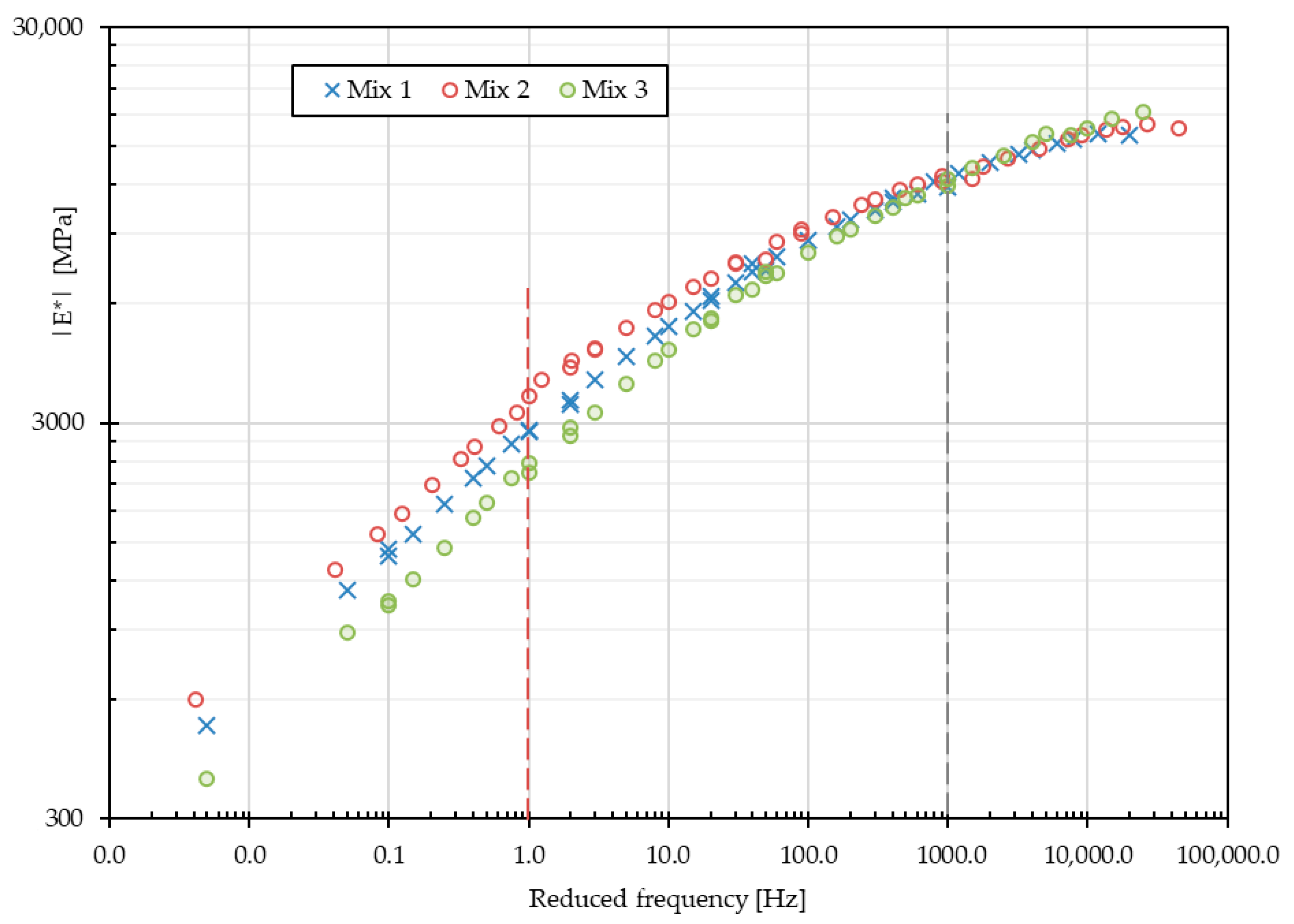

3.6. Dynamic Modulus (4-Point Bending Test)

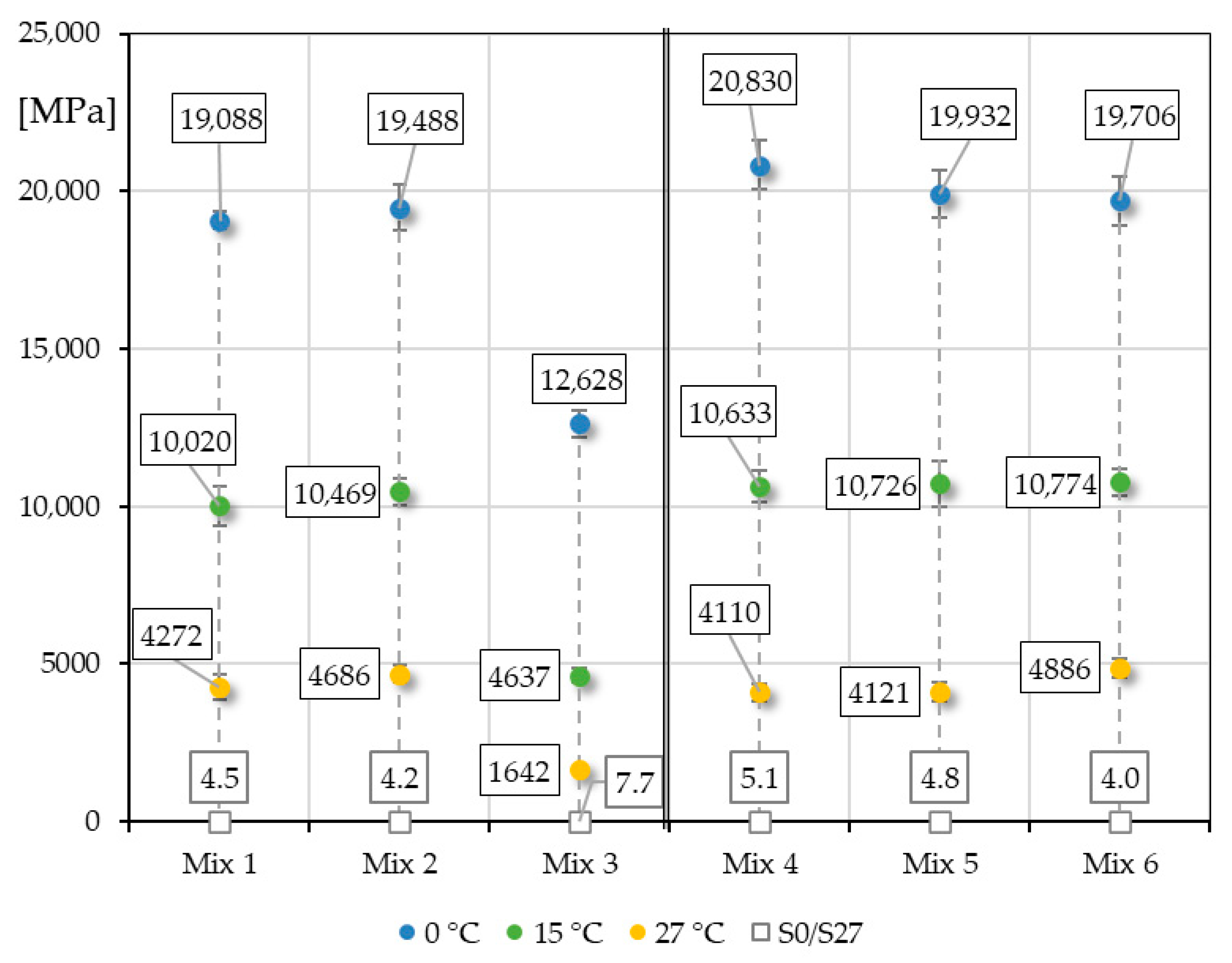

4. Conclusions

- Compactability and Air-Void Content: The addition of FF fibres had no consistent influence on compactability. In surface-course mixtures, one fibre-reinforced variant showed slightly higher air-void content, whereas binder course mixtures exhibited comparable values across all variants. Overall, the fibres did not impair workability or mixture density.

- Moisture Susceptibility: A slight increase in dry ITS was observed in most fibre-reinforced mixtures, confirming a moderate reinforcing effect under dry conditions. Conversely, all fibre-modified mixtures showed lower ITSR values, suggesting that limited bonding at the fibre–binder interface reduces moisture resistance.

- Stiffness and Thermal Sensitivity: Fibre incorporation generally resulted in similar or marginally higher stiffness (IT-CY) compared with the reference mixtures, particularly at elevated temperatures (27 °C). This demonstrates that fibre reinforcement enhances stiffness without increasing thermal susceptibility, especially when combined with polymer-modified binders.

- Crack Propagation Resistance: Fracture behaviour exhibited temperature-dependent trends. At 0 °C, fibres did not improve fracture resistance and occasionally induced brittleness, whereas at 15 °C, a partial improvement in fracture energy and flexibility indices was achieved. This confirms that the beneficial fibre effect becomes most pronounced at intermediate temperatures, where the binder–fibre system maintains sufficient ductility.

- Resistance to Permanent Deformation: For AC 16 surf mixtures, adding 0.02% FF fibres (Mix 2) improved rutting resistance, while higher fibre dosage or the use of unmodified binder (Mix 3) reduced this benefit. In contrast, AC 16 bin mixtures with 0.04% fibres (Mix 6) showed greater deformation despite similar air voids, likely due to increased mastic viscosity and weak fibre–binder adhesion caused by the smooth, inert fibre surface. This limited bonding reduced stress transfer and energy dissipation under repeated loading. Nevertheless, the fibres helped to stabilise the aggregate skeleton, indicating potential for improved performance through enhanced surface treatment or polymer coupling.

- Dynamic Modulus and Viscoelastic Behaviour: Dynamic modulus testing confirmed that FF fibres can improve stiffness and viscoelastic balance. For both mixture types, fibre addition resulted in smoother master curves and reduced temperature susceptibility, indicating enhanced temperature stability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kowalski, K.J.; Król, J.; Radziszewski, P.; Casado, R.; Casado, R.; Pérez, D.; Viñas, V.M.; Brijsse, Y.; Frosch, M.; Le, D.M.; et al. Eco-friendly Materials for a New Concept of Asphalt Pavement. Transp. Res. Procedia 2016, 14, 3582–3591. [Google Scholar] [CrossRef]

- Gogoi, R.; Biligiri, K.P.; Das, N.C. Performance prediction analyses of styrene-butadiene rubber and crumb rubber materials in asphalt road applications. Mater. Struct. 2016, 49, 3479–3493. [Google Scholar] [CrossRef]

- Wiśniewski, D.; Słowik, M.; Kempa, J.; Lewandowska, A.; Malinowska, J. Assessment of Impact of Aramid Fibre Addition on the Mechanical Properties of Selected Asphalt Mixtures. Materials 2020, 13, 3302. [Google Scholar] [CrossRef]

- Marienfeld, M.L.; Guram, S.K. Overview of field installation procedures for paving fabrics in North America. Geotext. Geomembr. 1999, 17, 105–120. [Google Scholar] [CrossRef]

- Castro, M.; Sánchez, J.A. Estimation of asphalt concrete fatigue curves—A damage theory approach. Constr. Build. Mater. 2008, 22, 1232–1238. [Google Scholar] [CrossRef]

- Gorkem, C.; Sengoz, B. Predicting stripping and moisture induced damage of asphalt concrete prepared with polymer modified bitumen and hydrated lime. Constr. Build. Mater. 2009, 23, 2227–2236. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C.; Zoorob, S.E.; Elliott, R.C. The influence of aggregate, filler and bitumen on asphalt mixture moisture damage. Constr. Build. Mater. 2008, 22, 2015–2024. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Eskandarsefat, S.; Dondi, G.; Sangiorgi, C. Recycled and rubberized SMA modified mixtures: A comparison between polymer modified bitumen and modified fibres. Constr. Build. Mater. 2019, 202, 681–691. [Google Scholar] [CrossRef]

- Tayfur, S.; Ozen, H.; Aksoy, A. Investigation of rutting performance of asphalt mixtures containing polymer modifiers. Constr. Build. Mater. 2007, 21, 328–337. [Google Scholar] [CrossRef]

- Zahran, S.Z.; Fatani, M. Glass Fiber Reinforced Asphalt Paving Mixture: Feasibility Assessment. J. King Abdulaziz Univ. Eng. Sci. 1999, 11, 85–98. [Google Scholar] [CrossRef]

- Tataranni, P.; Sangiorgi, C. A Preliminary Laboratory Evaluation on the Use of Shredded Cigarette Filters as Stabilizing Fibers for Stone Mastic Asphalts. Appl. Sci. 2021, 11, 5674. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Zou, F.; Yu, H. Effects of rubber absorption on the aging resistance of hot and warm asphalt rubber binders prepared with waste tire rubber. J. Clean. Prod. 2021, 303, 127082. [Google Scholar] [CrossRef]

- Tarsi, G.; Caputo, P.; Porto, M.; Sangiorgi, C. A Study of Rubber-REOB Extender to Produce Sustainable Modified Bitumens. Appl. Sci. 2020, 10, 1204. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Fang, C.; Ruien, Y.; Liu, S.; Li, Y. Nanomaterials Applied in Asphalt Modification: A Review. J. Mater. Sci. Technol. 2013, 29, 589–594. [Google Scholar] [CrossRef]

- Nazirizad, M.; Kavussi, A.; Abdi, A. Evaluation of the effects of anti-stripping agents on the performance of asphalt mixtures. Constr. Build. Mater. 2015, 84, 348–353. [Google Scholar] [CrossRef]

- Yu, J.; Guo, Y.; Peng, L.; Guo, F.; Yu, H. Rejuvenating effect of soft bitumen, liquid surfactant, and bio-rejuvenator on artificial aged asphalt. Constr. Build. Mater. 2020, 254, 119336. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; Loise, V.; Ashimova, S.; Teltayev, B.; Sangiorgi, C. A New Green Rejuvenator: Evaluation of Structural Changes of Aged and Recycled Bitumens by Means of Rheology and NMR. In RILEM 252-CMB Chemo-Mechanical Characterization of Bituminous Materials; Springer: Cham, Switzerland, 2019; pp. 177–182. [Google Scholar]

- Słowik, M. Thermorheological Properties of Styrene-Butadiene-Styrene (SBS) Copolymer Modified Road Bitumen. Procedia Eng. 2017, 208, 145–150. [Google Scholar] [CrossRef]

- Ahmedzade, P. The investigation and comparison effects of SBS and SBS with new reactive terpolymer on the rheological properties of bitumen. Constr. Build. Mater. 2013, 38, 285–291. [Google Scholar] [CrossRef]

- Airey, G.D. Styrene butadiene styrene polymer modification of road bitumens. J. Mater. Sci. 2004, 39, 951–959. [Google Scholar] [CrossRef]

- Mielczarek, M.; Słowik, M.; Andrzejczak, K. The assessment of influence of styrene-butadiene-styrene elastomer’s content on the functional properties of asphalt binders. Eksploat. I Niezawodn. —Maint. Reliab. 2020, 22, 148–153. [Google Scholar] [CrossRef]

- Yilmaz, M.; Çeloğlu, M.E. Effects of SBS and different natural asphalts on the properties of bituminous binders and mixtures. Constr. Build. Mater. 2013, 44, 533–540. [Google Scholar] [CrossRef]

- Bilski, M.; Słowik, M. Natural asphalt modified binders used for high stiffness modulus asphalt concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 356, 012007. [Google Scholar] [CrossRef]

- Slowik, M.; Bilski, M. An Experimental Study of the Impact of Aging on Gilsonite and Trinidad Epuré Modified Asphalt Binders Properties. Balt. J. Road Bridge Eng. 2017, 12, 71–81. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

- Ma, X.; Li, Q.; Cui, Y.-C.; Ni, A.-Q. Performance of porous asphalt mixture with various additives. Int. J. Pavement Eng. 2018, 19, 355–361. [Google Scholar] [CrossRef]

- Gupta, A.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Incorporation of Additives and Fibers in Porous Asphalt Mixtures: A Review. Materials 2019, 12, 3156. [Google Scholar] [CrossRef] [PubMed]

- Hassan, H.F.; Al-Jabri, K.S. Effect of organic fibers on open-graded friction course mixture properties. Int. J. Pavement Eng. 2005, 6, 67–75. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, T.; Wang, L. Influences of Interface Properties on the Performance of Fiber-Reinforced Asphalt Binder. Polymers 2019, 11, 542. [Google Scholar] [CrossRef]

- Calister, W.D., Jr.; Retwcich, D.G. Fundamentals of Materials Science and Engineering: An Integrated Approach, 3rd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete—A review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- Abiola, O.S.; Kupolati, W.K.; Sadiku, E.R.; Ndambuki, J.M. Utilisation of natural fibre as modifier in bituminous mixes: A review. Constr. Build. Mater. 2014, 54, 305–312. [Google Scholar] [CrossRef]

- Mitchell, M.; Link, R.; Kaloush, K.; Biligiri, K.P.; Zeiada, W.; Rodezno, M.; Reed, J. Evaluation of Fiber-Reinforced Asphalt Mixtures Using Advanced Material Characterization Tests. J. Test. Eval. 2010, 38, 400–411. [Google Scholar] [CrossRef]

- Guo, F.; Li, R.; Lu, S.; Bi, Y.; He, H. Evaluation of the Effect of Fiber Type, Length, and Content on Asphalt Properties and Asphalt Mixture Performance. Materials 2020, 13, 1556. [Google Scholar] [CrossRef]

- Qin, X.; Shen, A.; Guo, Y.; Li, Z.; Lv, Z. Characterization of asphalt mastics reinforced with basalt fibers. Constr. Build. Mater. 2018, 159, 508–516. [Google Scholar] [CrossRef]

- Saliani, S.S.; Tavassoti, P.; Baaj, H.; Carter, A. Characterization of asphalt mixtures produced with short Pulp Aramid fiber (PAF). Constr. Build. Mater. 2021, 280, 122554. [Google Scholar] [CrossRef]

- Fejdyś, M.; Łandwijt, M. Technical fibers reinforcing composite materials. Tech. Wyr. Włókiennicze 2010, 18, 12–22. [Google Scholar]

- Ertekin, M. 7—Aramid fibers. In Fiber Technology for Fiber-Reinforced Composites; Seydibeyoğlu, M.Ö., Mohanty, A.K., Misra, M., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 153–167. [Google Scholar]

- McDaniel, R.S. Fiber Additives in Asphalt Mixtures; Transportation Research Board of the National Academies Press: Washington, DC, USA, 2015; p. 50. [Google Scholar]

- Abtahi, S.M.; Esfandiarpour, S.; Kunt, M.; Hejazi, S.M.; Ebrahimi, M.G. Hybrid Reinforcement of Asphalt-Concrete Mixtures Using Glass and Polypropylene Fibers. J. Eng. Fibers Fabr. 2013, 8, 25. [Google Scholar] [CrossRef]

- Alnadish, A.; Aman, Y. Evaluation of Aramid Fibre-Reinforced Asphalt Mixtures; Springer: Singapore, 2019; pp. 1377–1388. [Google Scholar]

- Jaskuła, P.; Stienss, M.; Szydłowski, C. Effect of Polymer Fibres Reinforcement on Selected Properties of Asphalt Mixtures. Procedia Eng. 2017, 172, 441–448. [Google Scholar] [CrossRef]

- Mateos, A.; Harvey, J. Laboratory Evaluation of the Mechanical Properties of Asphalt Concrete Reinforced with Aramid Synthetic Fibers; UCPRC-RR-2019-01; University of California, Pavement Research Center: Davis, CA, USA; Berkeley, CA, USA, 2019. [Google Scholar]

- Klinsky, L.M.G.; Kaloush, K.E.; Faria, V.C.; Bardini, V.S.S. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef]

- Badeli, S.; Carter, A.; Doré, G.; Saliani, S. Evaluation of the durability and the performance of an asphalt mix involving Aramid Pulp Fiber (APF): Complex modulus before and after freeze-thaw cycles, fatigue, and TSRST tests. Constr. Build. Mater. 2018, 174, 60–71. [Google Scholar] [CrossRef]

- Saliani, S.; Carter, A.; Baaj, H.; Badeli, S. Investigation on Tensile Strength of the Hot Mix Asphalt with Inclusion of Pulp Aramid Fiber (PAF). In Proceedings of the Sixth-Second Annual Conference of the Canadian Technical Asphalt Association (CTAA), Halifax, NS, Canada, 12–15 November 2017. [Google Scholar]

- Ziari, H.; Saghafi, Y.; Moniri, A.; Bahri, P. The effect of polyolefin-aramid fibers on performance of hot mix asphalt. Pet. Sci. Technol. 2020, 38, 170–176. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Castro-Fresno, D.; Bueno, M. An experimental laboratory study of fiber-reinforced asphalt mortars with polyolefin-aramid and polyacrylonitrile fibers. Constr. Build. Mater. 2020, 248, 118622. [Google Scholar] [CrossRef]

- Guo, Y.; Tataranni, P.; Sangiorgi, C. The use of fibres in asphalt mixtures: A state of the art review. Constr. Build. Mater. 2023, 390, 131754. [Google Scholar] [CrossRef]

- Blankenship, P. Evaluation of the Environmental Impacts of Aramid Fiber in Asphalt Mixtures: A Cradle-to-Grave Life Cycle Assessment. In Proceedings of the Road Forward International Summit, Chicago, IL, USA, 29 September–1 October 2025; Available online: https://surface-tech.ai/storage/577/napa-decarbonization-conference-lca-with-aramid-fiber-5-2025.pdf (accessed on 22 July 2025).

- ČSN 736101; Design of Highways and Motorways. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2023.

- ČSN EN 14023; Bitumen and Bituminous Binders—Specification Framework for Polymer Modified Bitumens. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2010.

- ČSN EN 12697-30; Bituminous Mixtures—Test Methods for Hot Mix Asphalt— Part 30: Specimen Preparation by Impact Compactor. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2020.

- ČSN 73 6120; Road Building—Other Asphalt Pavement Courses—Construction and Conformity Assessment. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2022.

- EN 13108-1; Bituminous Mixtures—Material Specifications—Part 1: Asphalt Concrete. European Committee for Standardization: Brussels, Belgium, 2016.

- ČSN EN 12697-8; Bituminous Mixtures—Test Methods—Part 8: Determination of Void Characteristics of Bituminous Specimens. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2020.

- ČSN EN 12697-6; Bituminous Mixtures—Test Methods—Part 6: Determination of Bulk Density of Bituminous Specimens. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2021.

- ČSN EN 12697-23; Bituminous Mixtures—Test Methods—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2019.

- ČSN EN 12697-12; Bituminous Mixtures—Test Methods—Part 12: Determination of the Water Sensitivity of Bituminous Specimens. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2020.

- ČSN EN 12697-26; Bituminous Mixtures—Test Methods—Part 26: Stiffness. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2019.

- ČSN EN 12697-44; Bituminous Mixtures—Test Methods—Part 44: Crack Propagation by Semi-Circular Bending Test. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2020.

- Vackova, P.; Valentin, J. Comparison of fracture parameters obtained from modified semi-circular bending (SCB) test. Roads Bridges Drog. Mosty 2021, 20, 173–187. [Google Scholar] [CrossRef]

- AASHTO Designation: TP 105-20; Determining the Fracture Energy of Asphalt Mixtures Using the Semicircular Bend Geometry (SCB). AASHTO: Washington, DC, USA, 2020.

- Al-Qadi, I.L.; Ozer, H.; Zhu, Z.; Singhvi, P.; Ali, U.M.; Sawalha, M.; Luque, A.F.E.; Mainieri, J.J.G.; Zehr, T.G. Development of Long-Term Aging Protocol for Implementation of the Illinois Flexibility Index Test (I-FIT); FHWA-ICT-19-009; Illinois Center for Transportation, Department of Civil and Environmental Engineering, University of Illinois at Urbana-Champaign: Urbana, IL, USA, 2019. [Google Scholar]

- Kaseer, F.; Yin, F.; Arámbula-Mercado, E.; Martin, A.E.; Daniel, J.S.; Salari, S. Development of an index to evaluate the cracking potential of asphalt mixtures using the semi-circular bending test. Constr. Build. Mater. 2018, 167, 286–298. [Google Scholar] [CrossRef]

- ČSN EN 12697-22+A1; Bituminous Mixtures—Test Methods—Part 22: Wheel Tracking. Česká Agentura pro Standardizaci: Prague, Czech Republic, 2024.

- Zhao, M.; Liu, X.; Yuan, H.; Wu, K.; Xu, X. Enhancing Aramid Fibre Modified Asphalt Mixture Through a Two Step Surface Treatment. Road Mater. Pavement Des. 2025, 1–24. [Google Scholar] [CrossRef]

- Phan, T.M.; Nguyen, S.N.; Seo, C.-B.; Park, D.-W. Effect of Treated Fibers on Performance of Asphalt Mixture. Constr. Build. Mater. 2021, 274, 122051. [Google Scholar] [CrossRef]

- Khan, A.R.; Ali, A.; Mehta, Y.; Lein, W. Laboratory performance characterization of polyolefin/ Aramid Fibers and Synthetic Aramid Fibers Reinforced Asphalt Mixes. Constr. Build. Mater. 2024, 419, 135576. [Google Scholar] [CrossRef]

| Trade Name | Polymer | Fibre Type | Density (g/cm3) | Tensile Strength (GPa) | Elongation at Break (%) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|---|

| Kevlar [40] | PPTA | K-29 | 1.44 | 2.90 | 3.60 | 71.00 |

| Twaron [40] | PPTA | K-49 | 1.44 | 3.00 | 2.40 | 112.00 |

| Technora [40] | ODA/PPTA | Standard | 1.44 | 2.90 | 3.60 | 70.00 |

| Nomex [40] | MPDI | Standard | 1.39 | 3.40 | 4.60 | 72.00 |

| FlexForce (aramid) | PPTA | Standard | 1.44 | 3.15 | 3.65 | 86.00 |

| FlexForce (polypropylene) | PP | Standard | 0.91 | 0.2–0.5 | - | - |

| Mixture | Thickness | Bulk Density | Compaction Degree | Rut Depth After 10,000 Cycles | WTSAIR | PRDAIR |

|---|---|---|---|---|---|---|

| (mm) | (g.cm−3) | (%) | (mm) | [mm/103 Cycles] | [%] | |

| Mix 1 | 60.33 | 2416 | 100.8% | 1.58 | 0.021 | 2.4 |

| Mix 2 | 61.26 | 2371 | 99.9% | 0.91 | 0.014 | 1.4 |

| Mix 3 | 60.68 | 2444 | 100.4% | 2.23 | 0.034 | 3.4 |

| Mix 4 | 62.18 | 2431 | 99.2% | 0.95 | 0.015 | 1.4 |

| Mix 5 | 60.71 | 2439 | 99.2% | 1.56 | 0.022 | 2.4 |

| Mix 6 | 61.1 | 2437 | 100.0% | 2.26 | 0.032 | 3.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallo, P.; Ben Ameur, A.; Valentin, J. The Influence of Synthetic Reinforcing Fibers on Selected Properties of Asphalt Mixtures for Surface and Binder Layers. Infrastructures 2025, 10, 303. https://doi.org/10.3390/infrastructures10110303

Gallo P, Ben Ameur A, Valentin J. The Influence of Synthetic Reinforcing Fibers on Selected Properties of Asphalt Mixtures for Surface and Binder Layers. Infrastructures. 2025; 10(11):303. https://doi.org/10.3390/infrastructures10110303

Chicago/Turabian StyleGallo, Peter, Amira Ben Ameur, and Jan Valentin. 2025. "The Influence of Synthetic Reinforcing Fibers on Selected Properties of Asphalt Mixtures for Surface and Binder Layers" Infrastructures 10, no. 11: 303. https://doi.org/10.3390/infrastructures10110303

APA StyleGallo, P., Ben Ameur, A., & Valentin, J. (2025). The Influence of Synthetic Reinforcing Fibers on Selected Properties of Asphalt Mixtures for Surface and Binder Layers. Infrastructures, 10(11), 303. https://doi.org/10.3390/infrastructures10110303