Performance Assessment of Asphalt Binder Modified with Batu Pahat Soft Clay as an Eco-Friendly Additive

Abstract

1. Introduction

2. Materials and Testing Procedures

2.1. Materials

2.2. BPSC Particles Mixing Process

2.3. Viscosity Test

2.4. Storage Stability Test

2.5. Temperature Susceptibility

- L: Softening point penetration of asphalt binder. The consistency of the binder is essential for comprehending its performance at elevated temperatures.

- X: Penetration at 25 degrees Celsius. This serves as a standard for evaluating binder performance across various thermal conditions.

- M: The penetration of asphalt binder at elevated temperatures, typically at the upper limit of its practical temperature range. This value quantifies the sensitivity of binder temperature.

2.6. DSR Test Procedure

2.7. FTIR Test Procedure

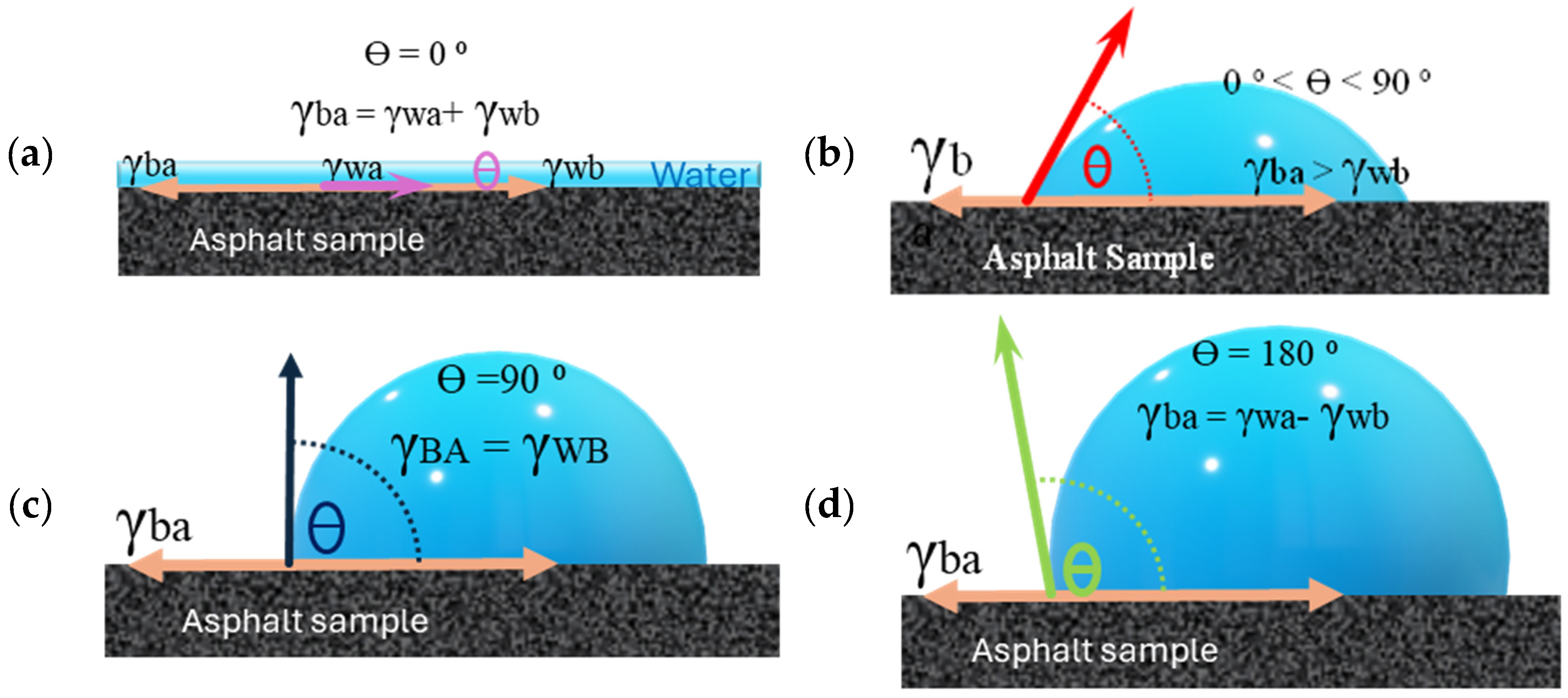

2.8. Surface Energy Test Procedure

2.9. SEM Test and Analysis of Procedure

3. Results

3.1. Homogenization Evaluation

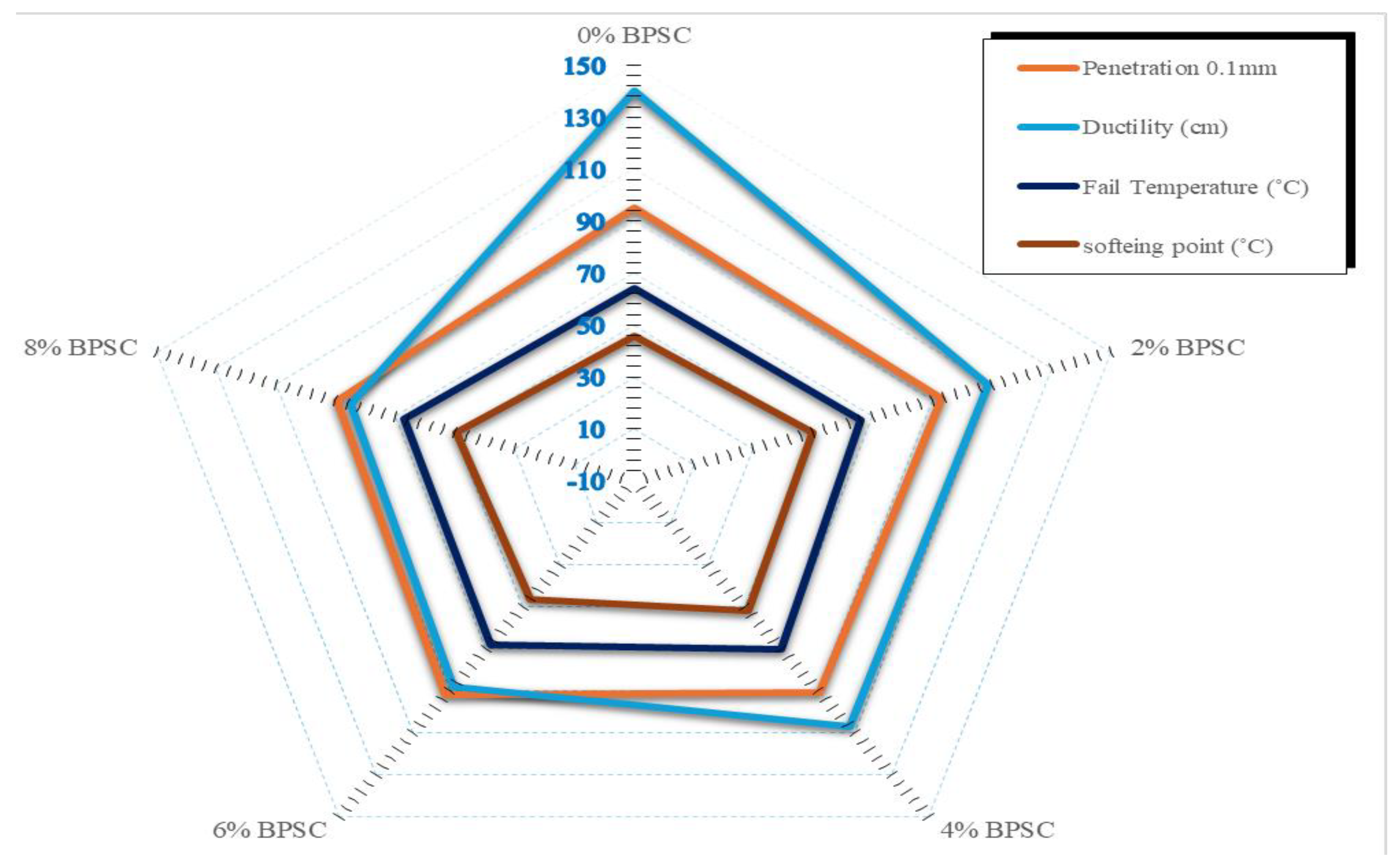

3.2. Effects of BPSC on the Consistency Test

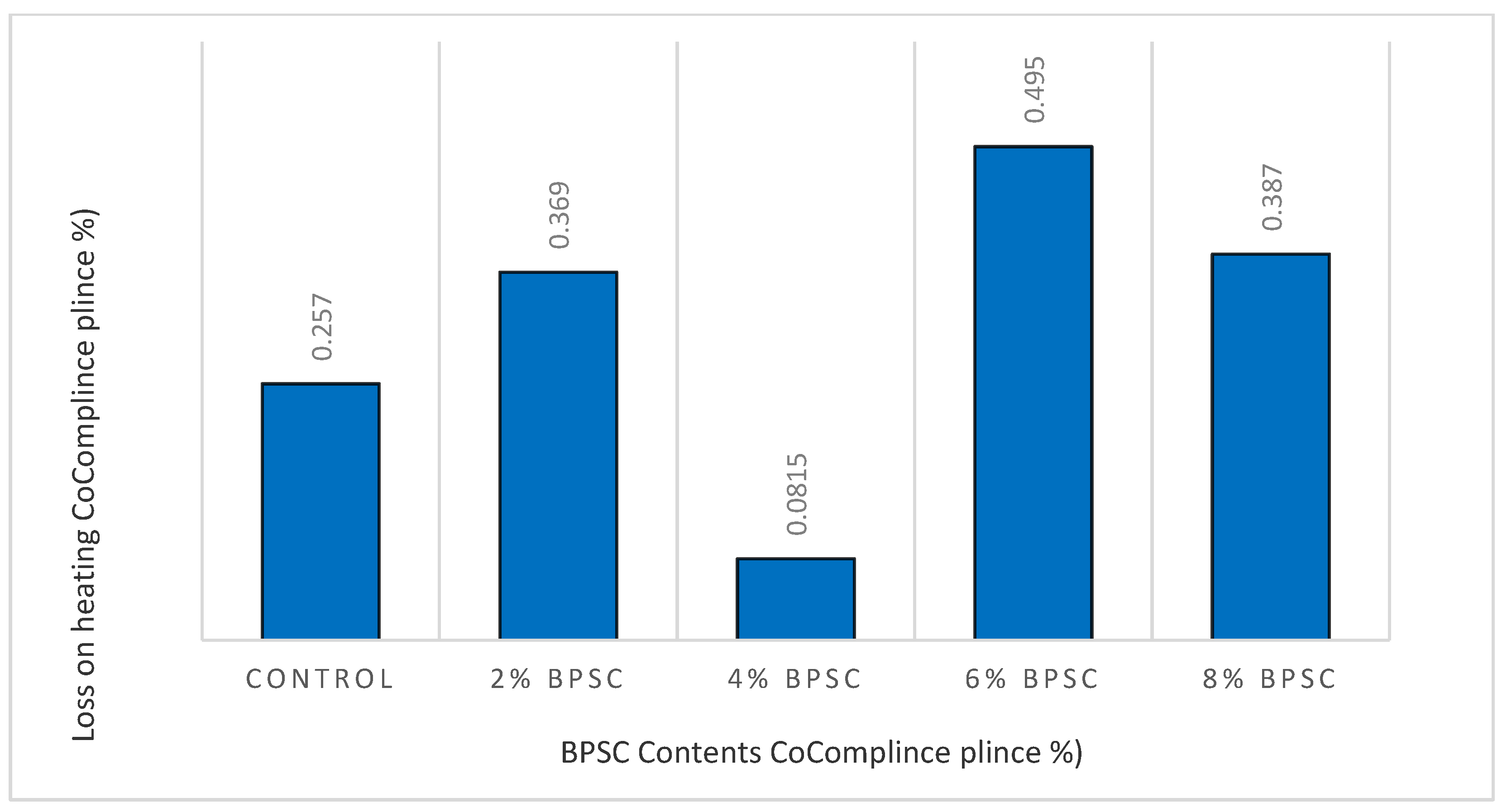

3.3. Effects of BPSC on Mass Loss

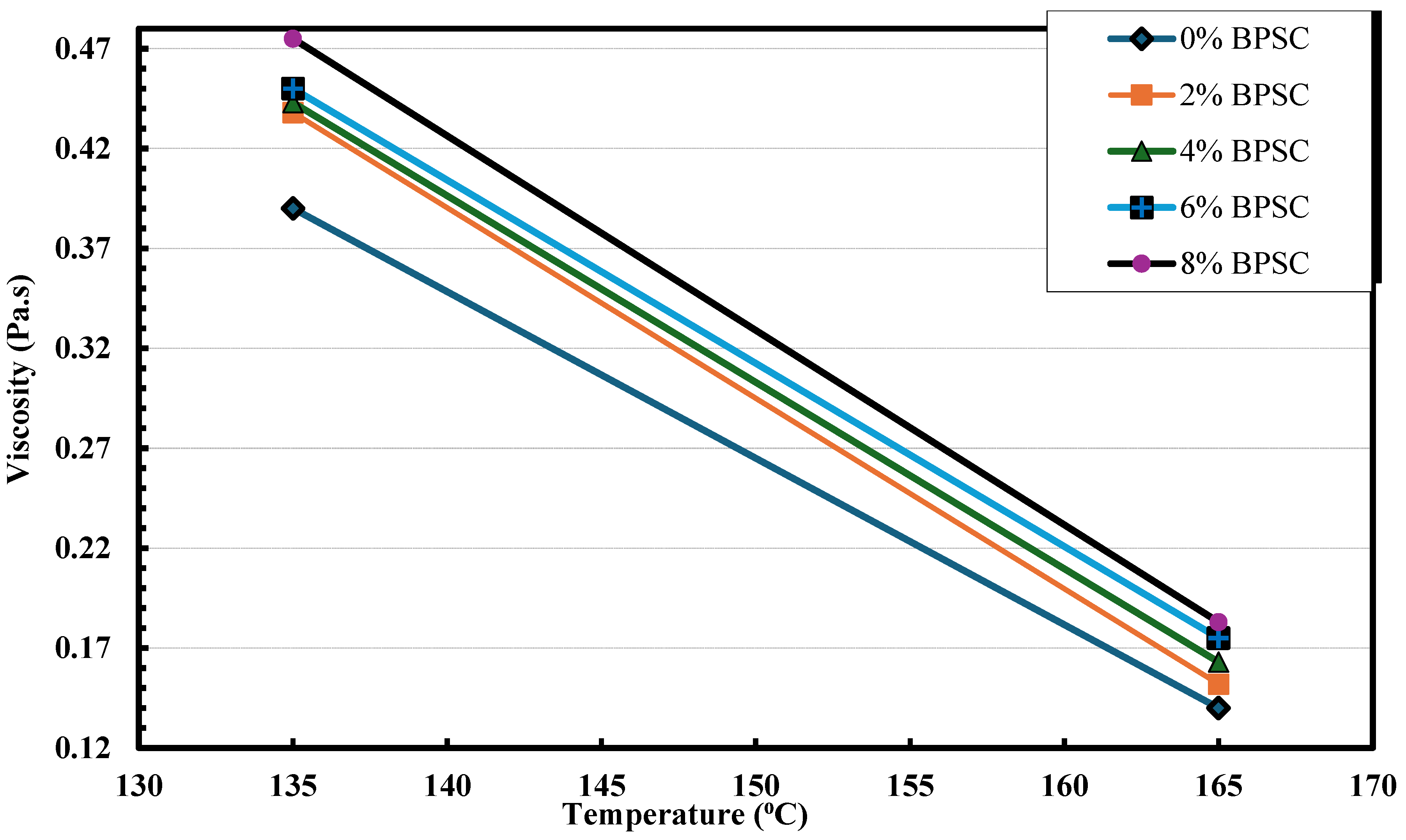

3.4. Effects of BPSC on Viscosity

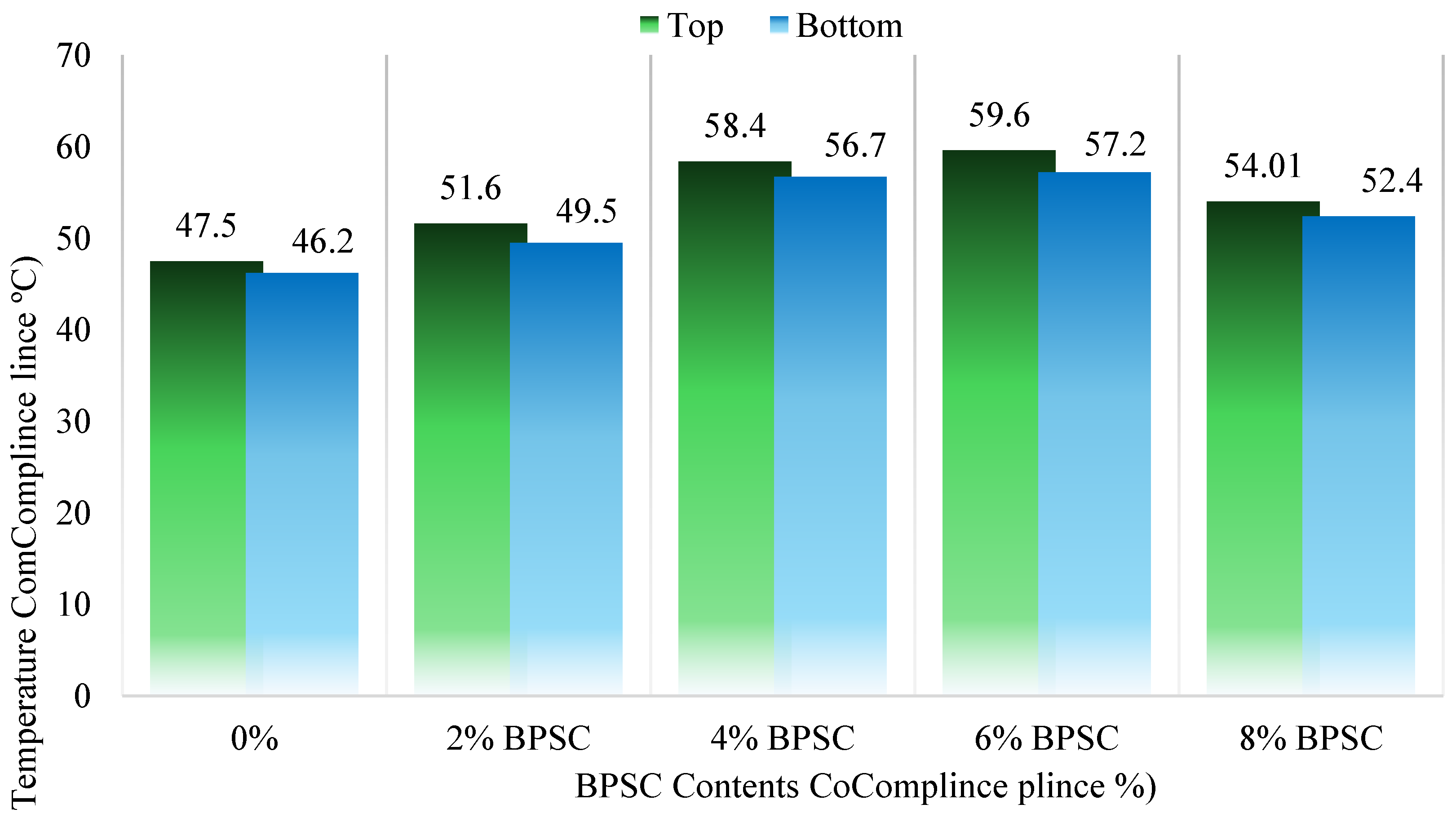

3.5. Effects of BPSC on Storage Stability

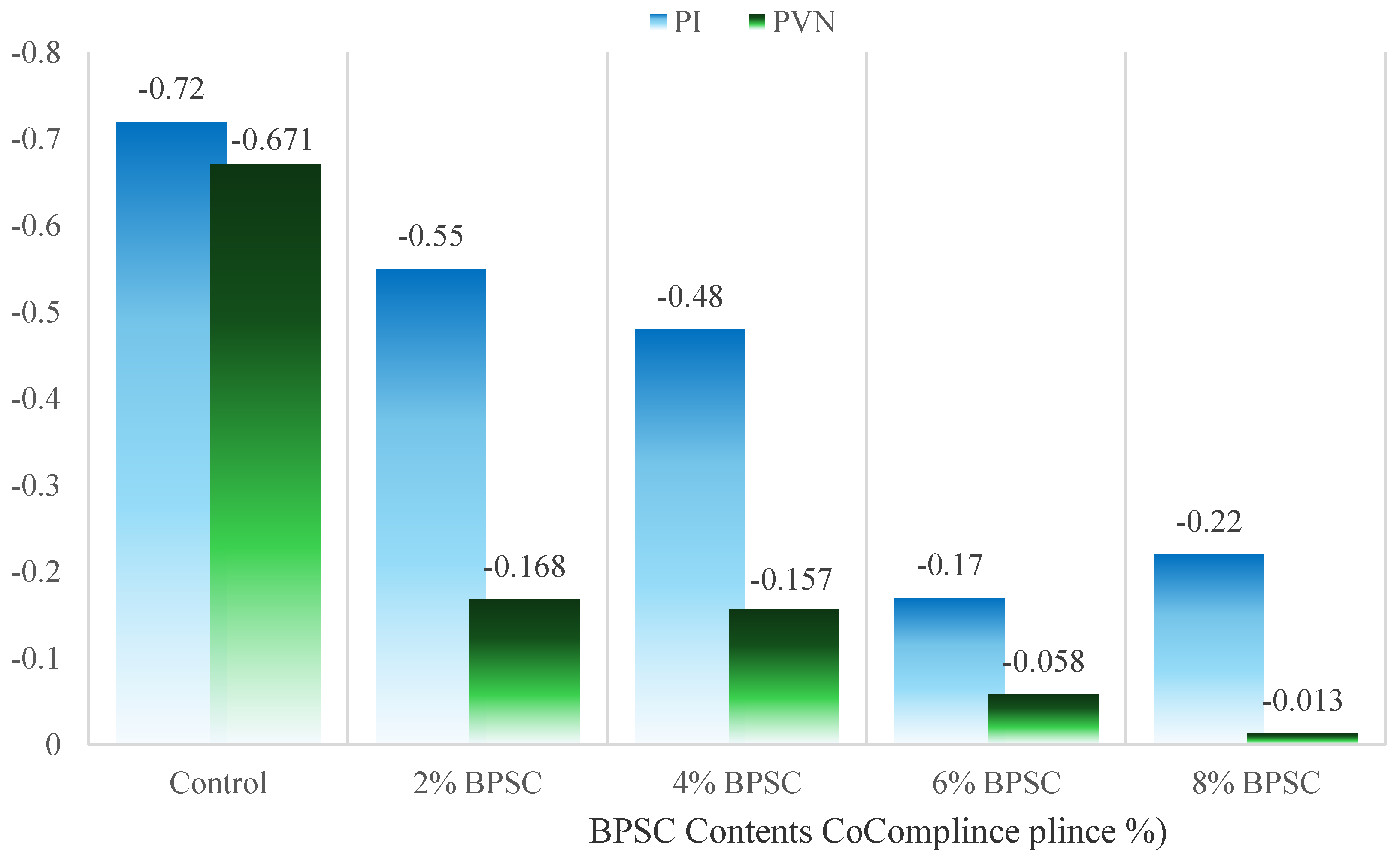

3.6. Effects of BPSC on Temperature Susceptibility

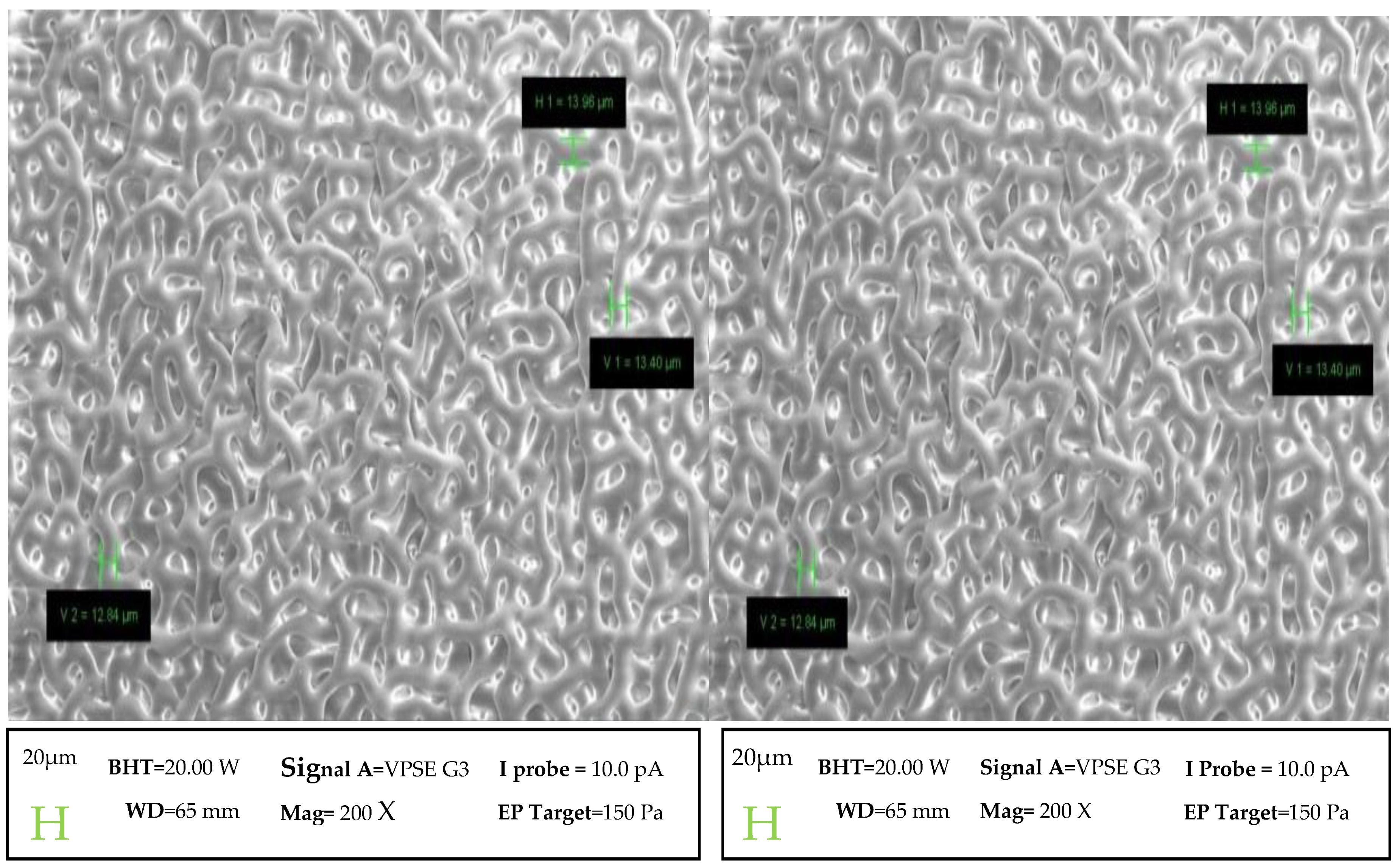

3.7. SEM

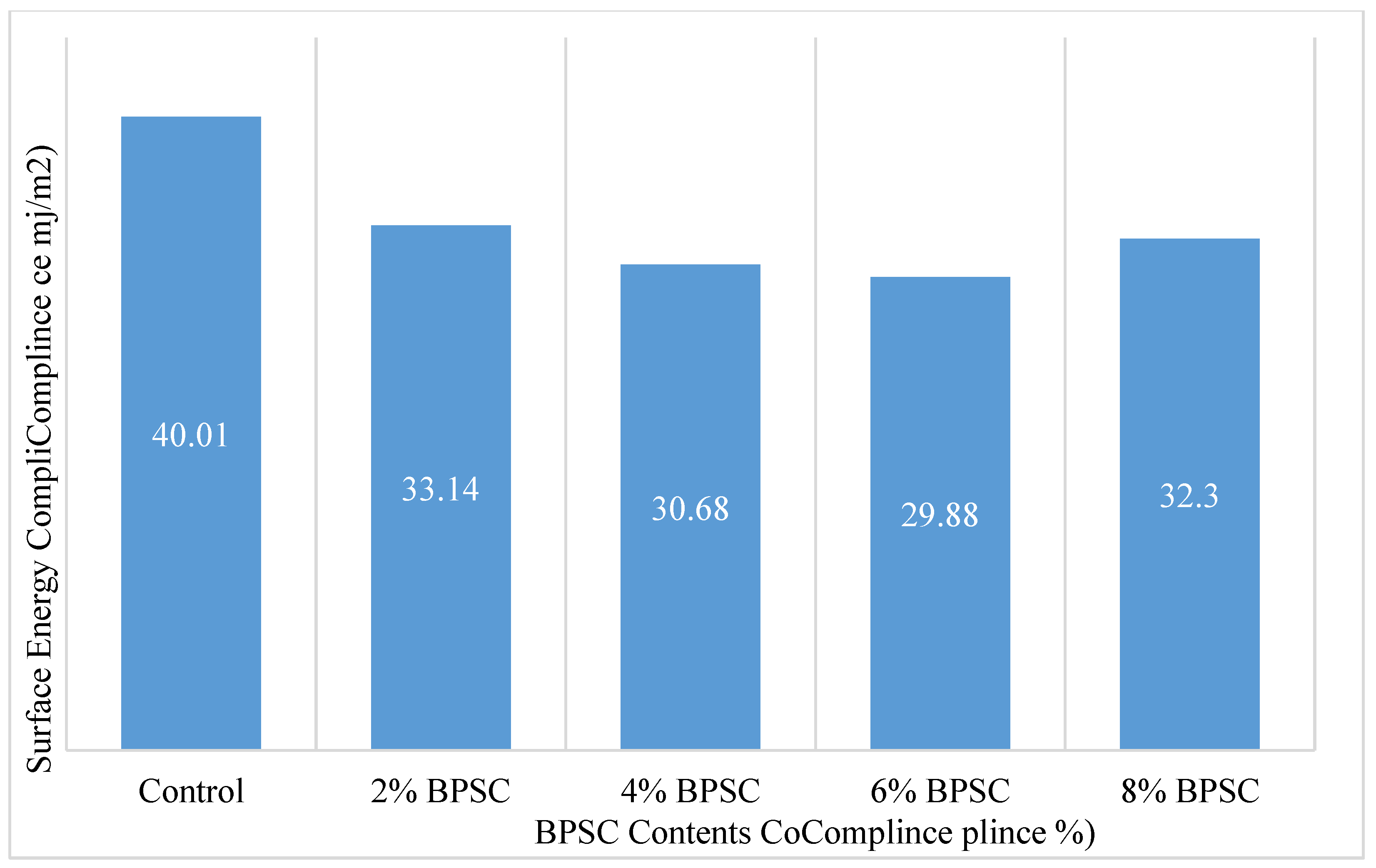

3.8. Surface Energy of Asphalt Binder

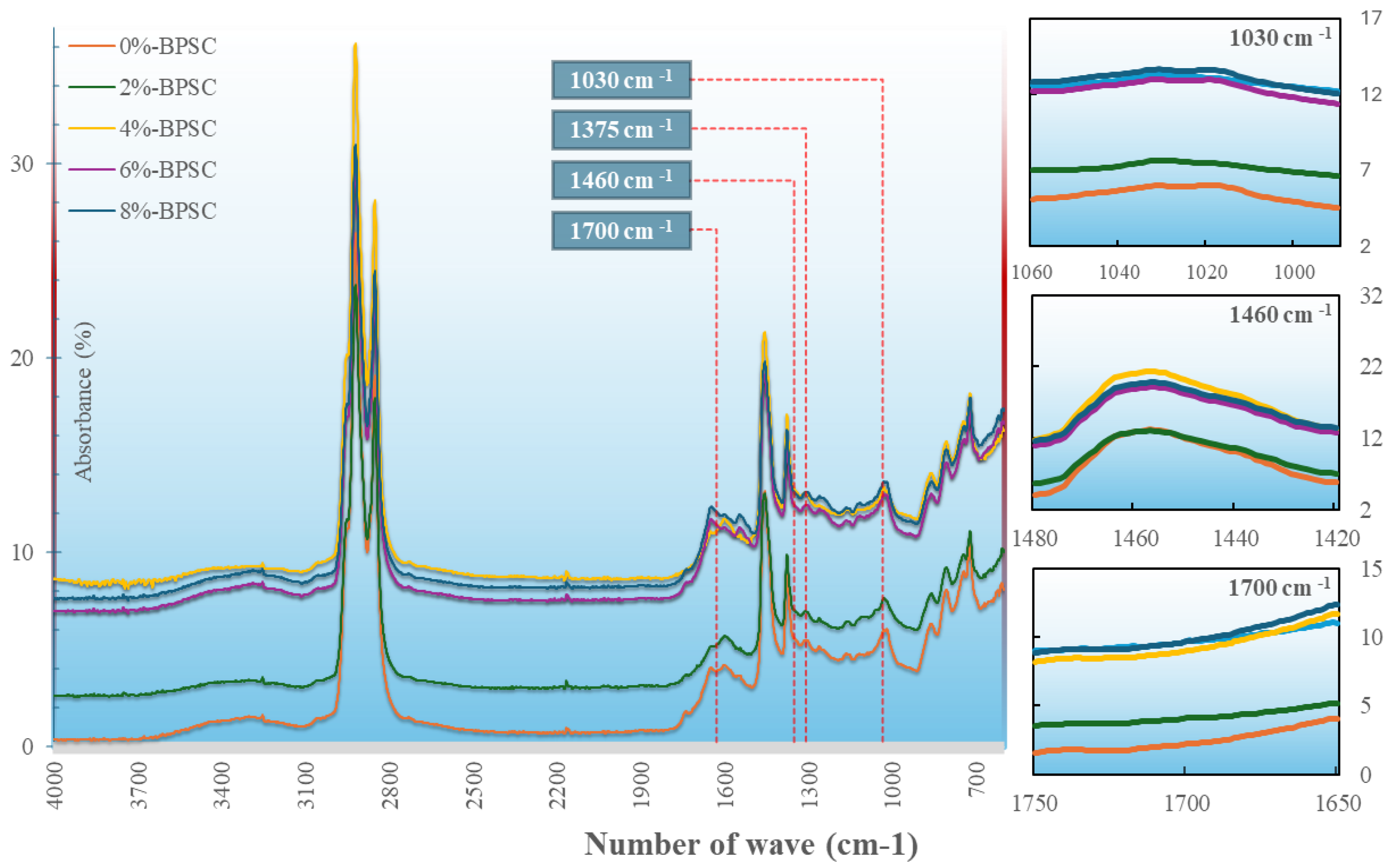

3.9. Fourier Transform Infrared Spectroscopy

3.10. Effects of BPSC on the Rheological Properties of Asphalt

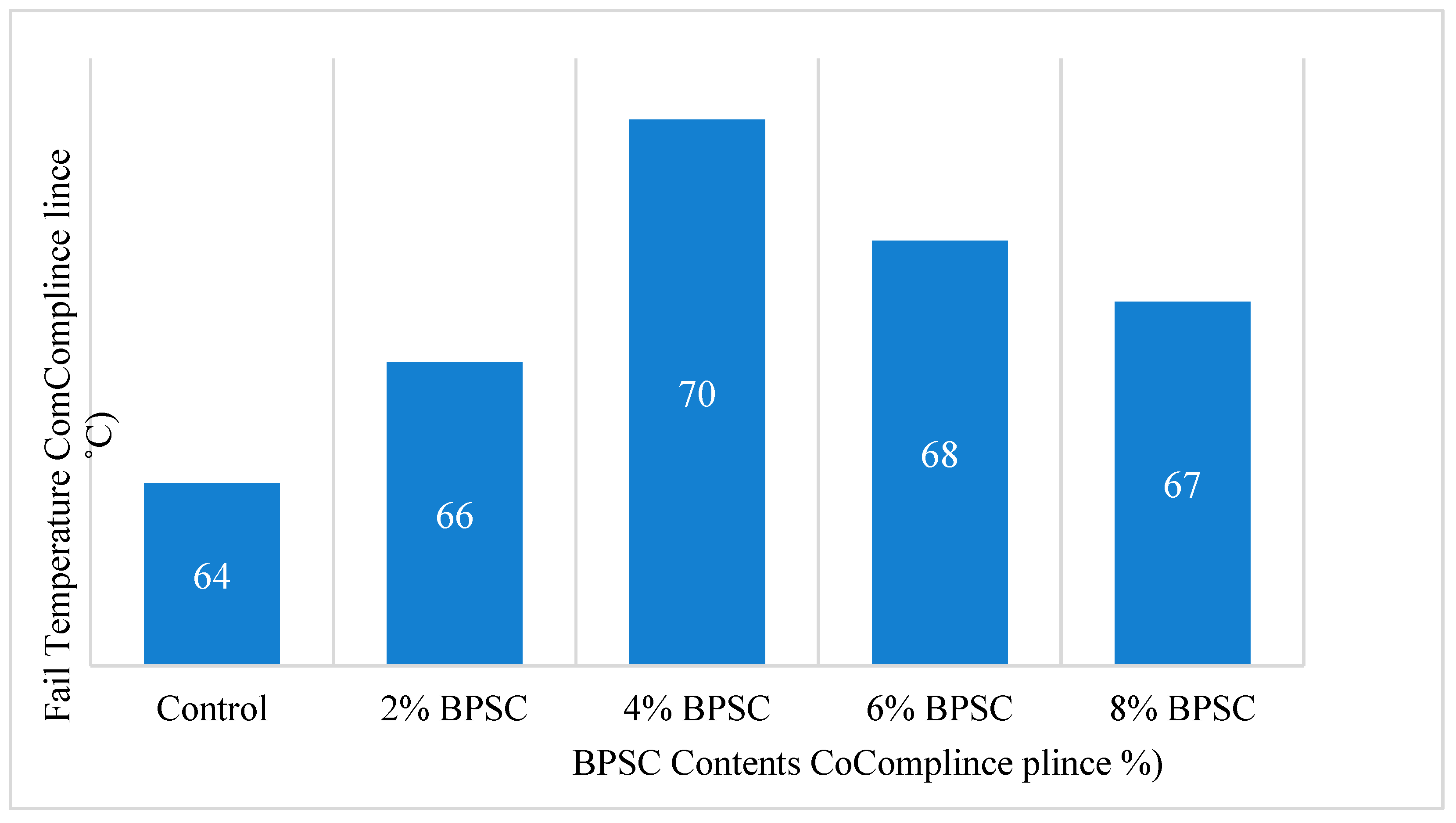

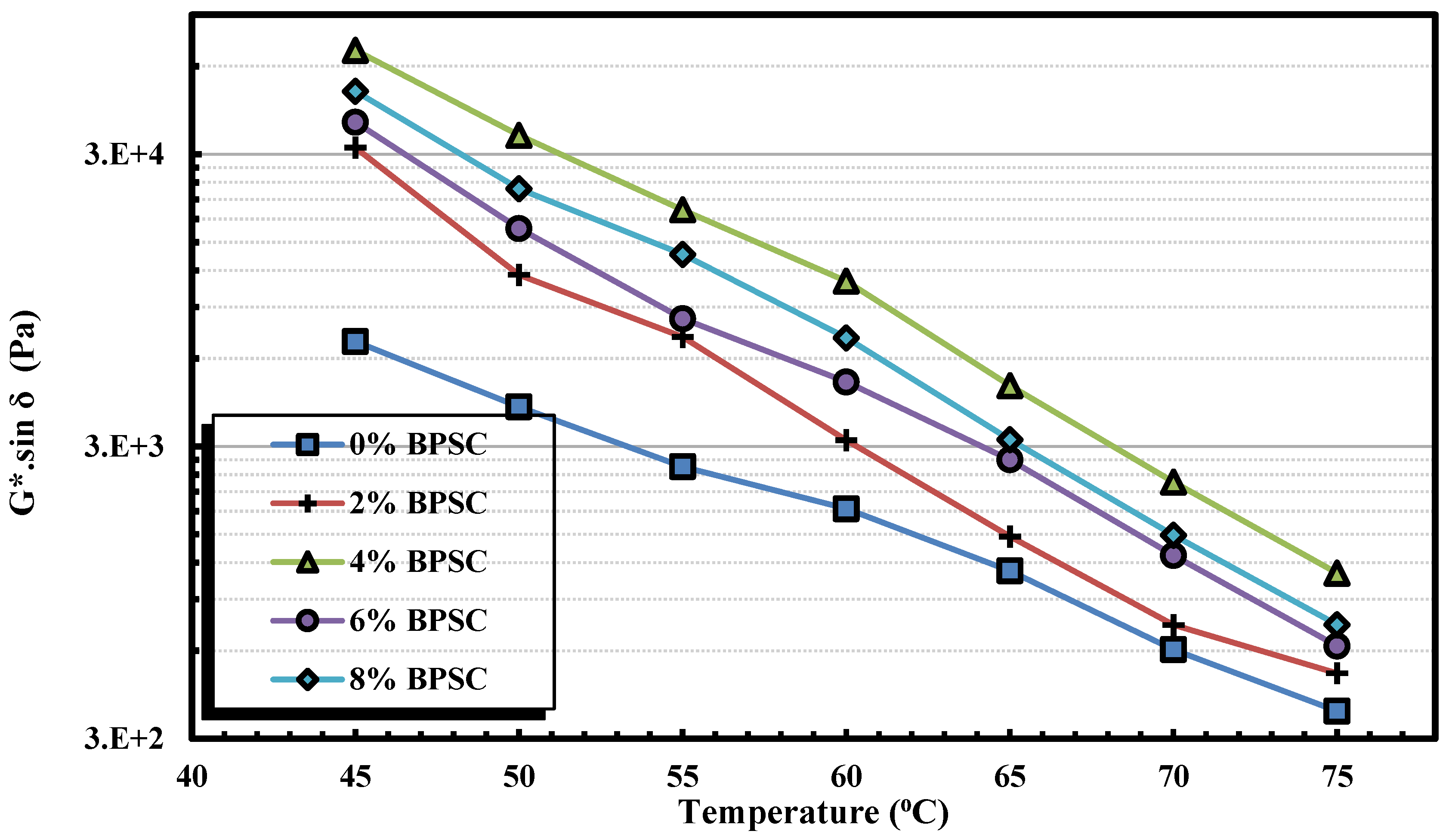

3.10.1. Failure Temperatures

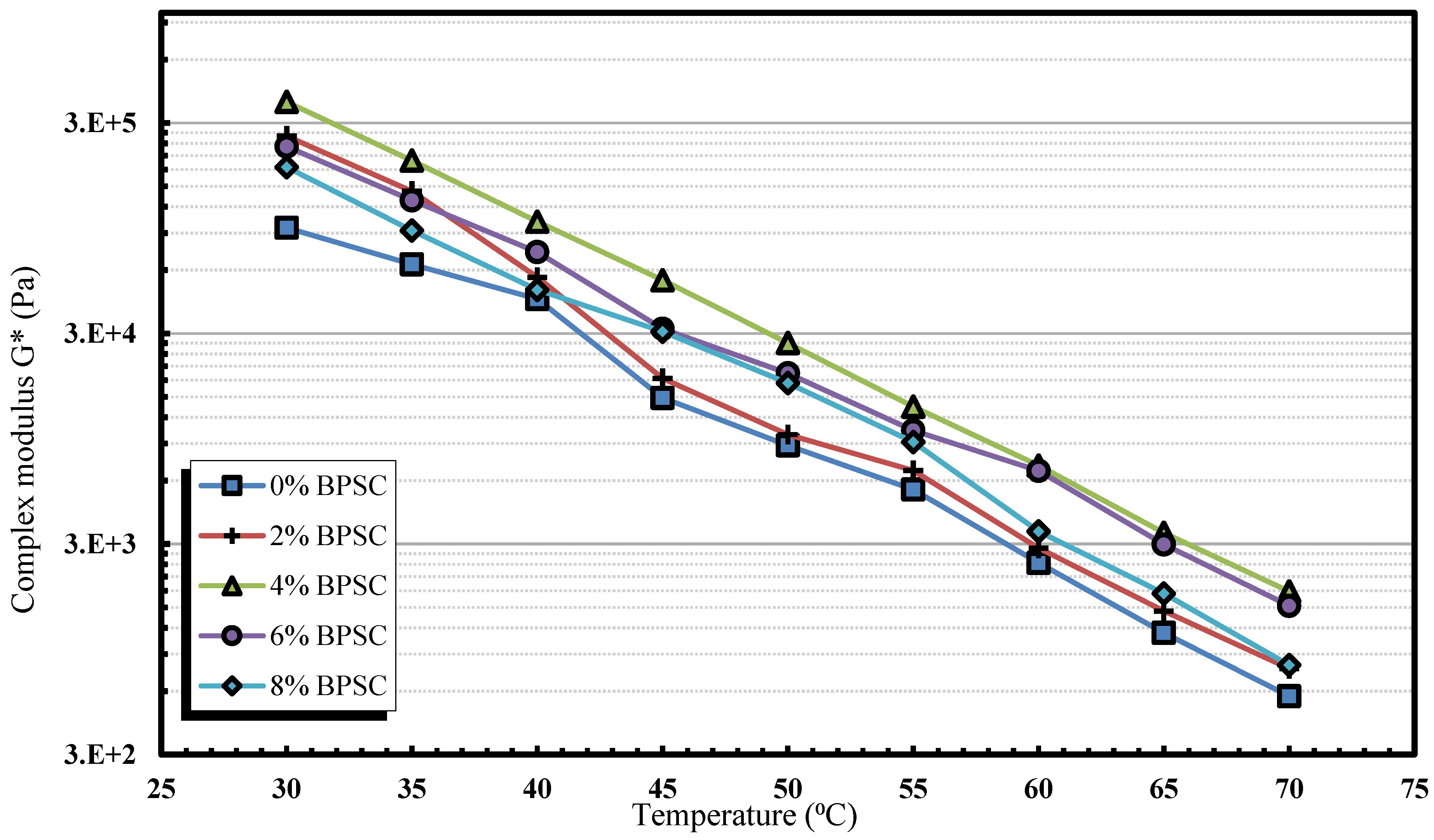

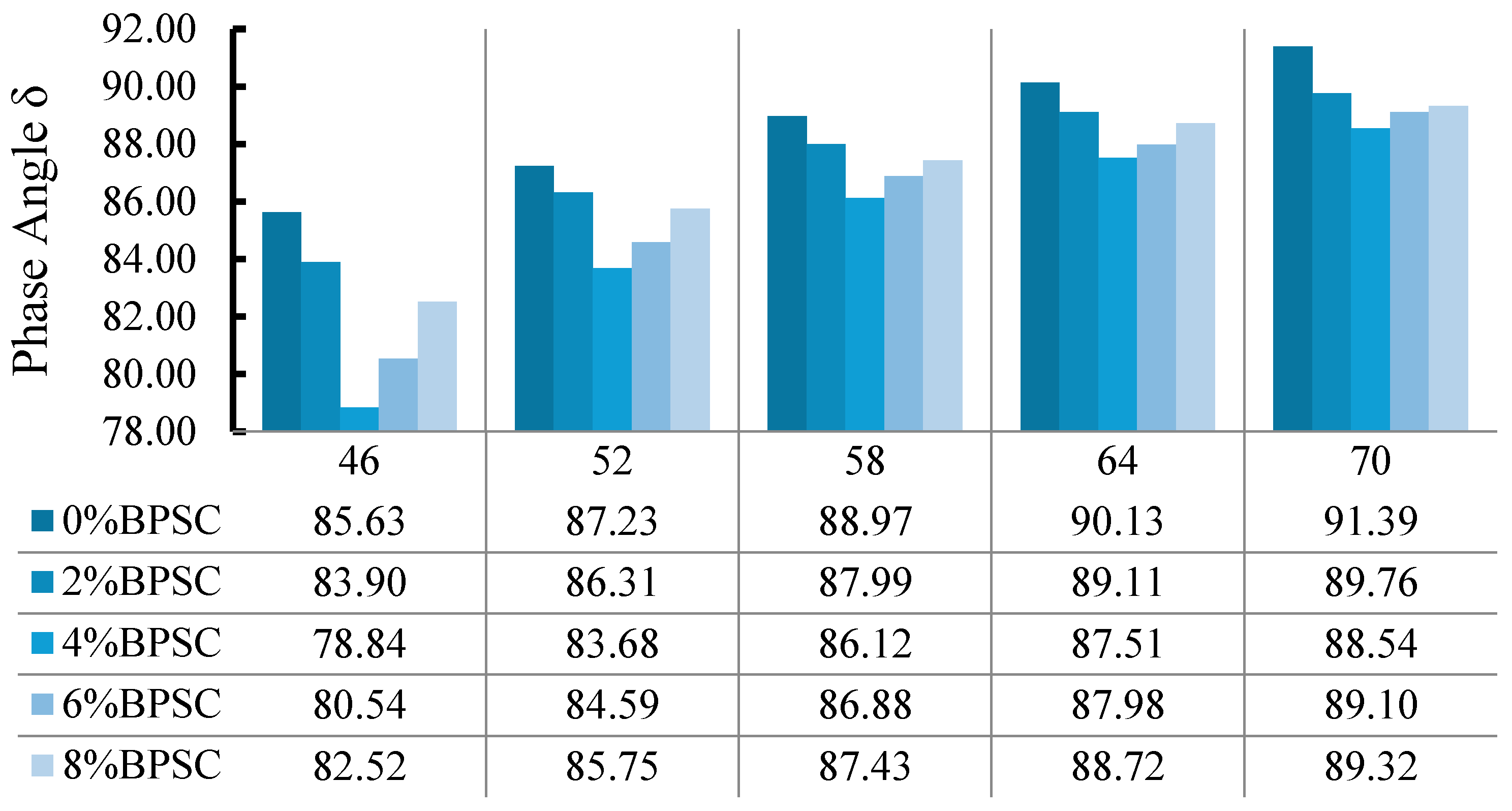

3.10.2. Isochronal Plots

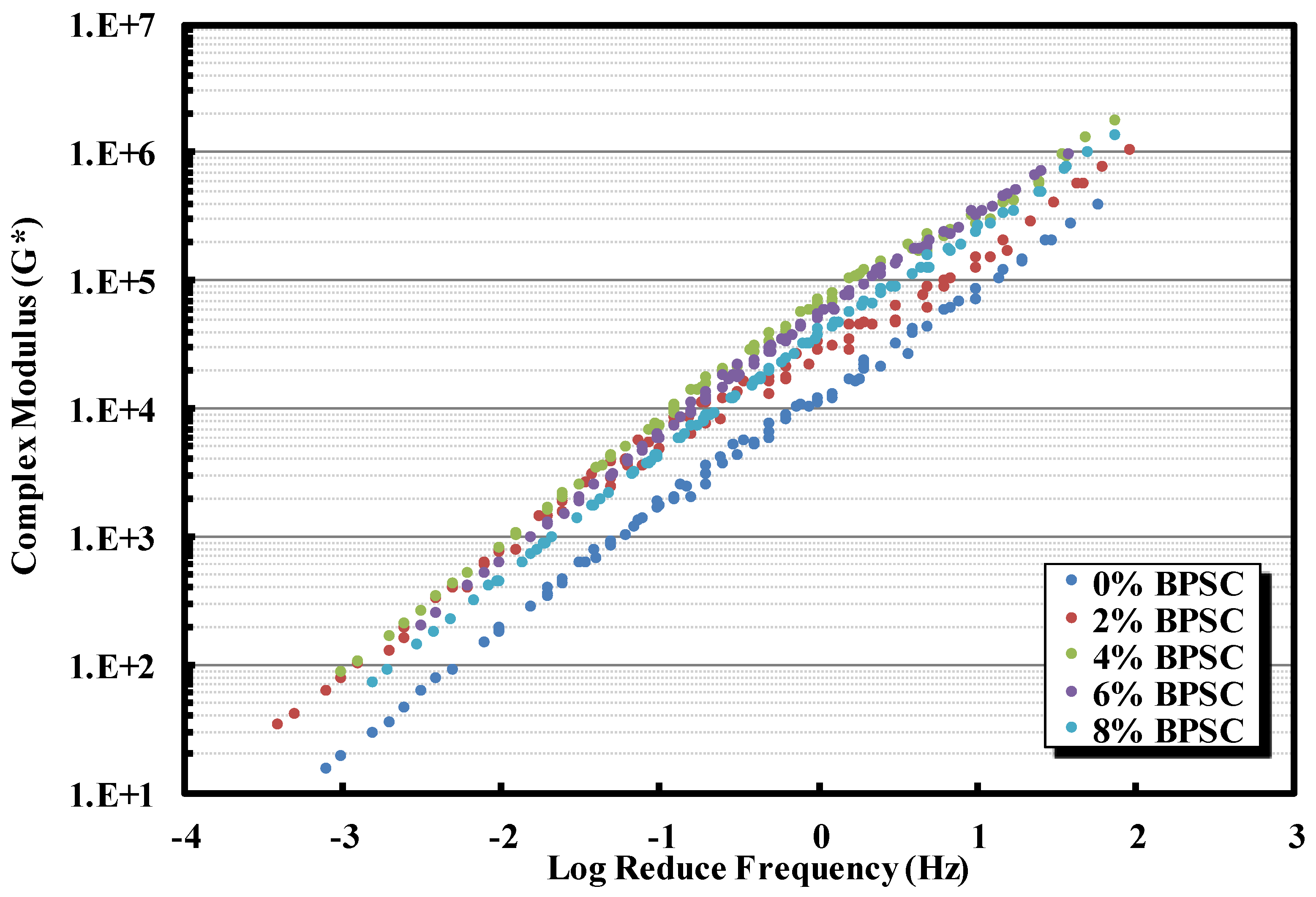

3.10.3. Master Curve

3.10.4. Rutting Parameter Performance

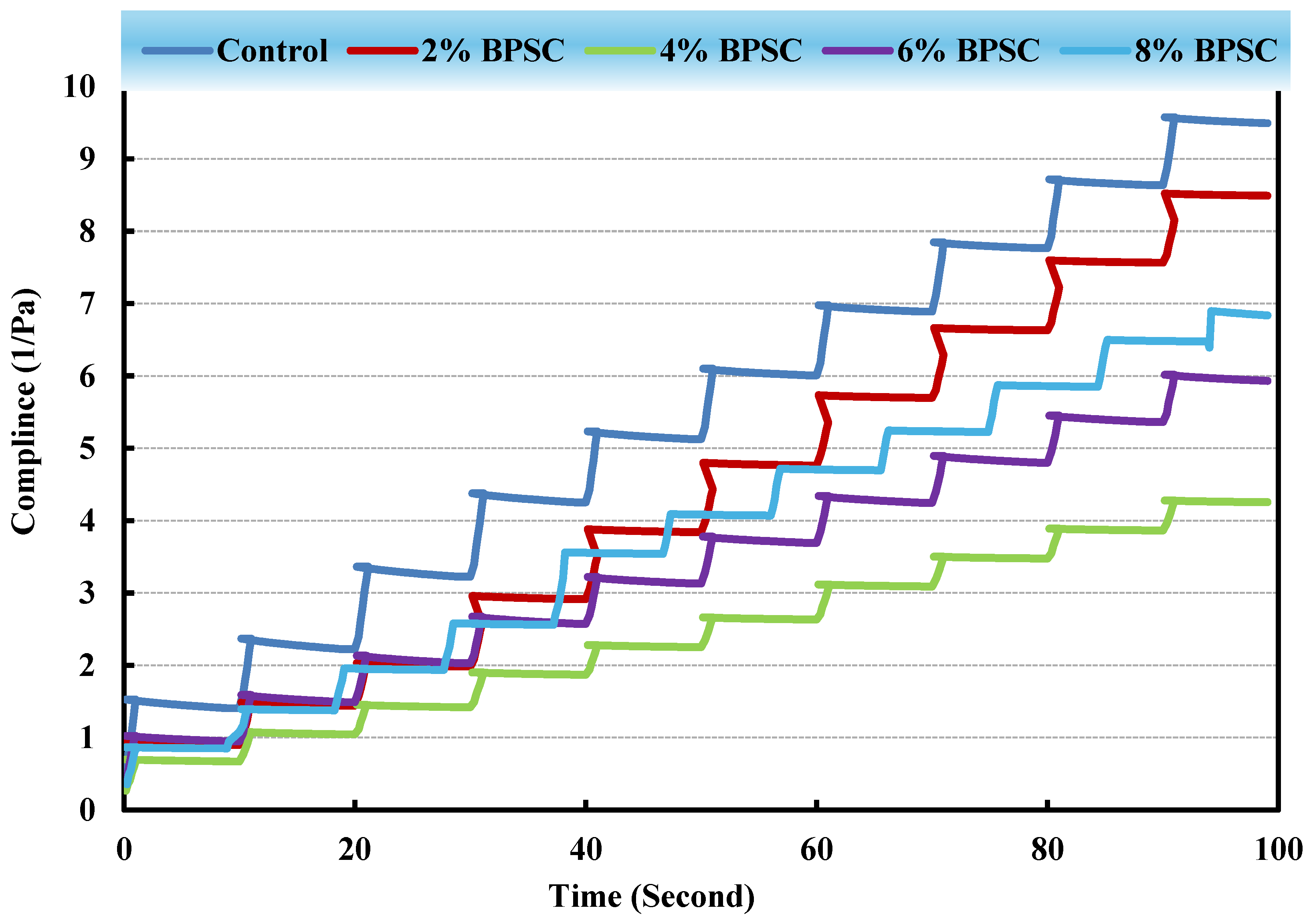

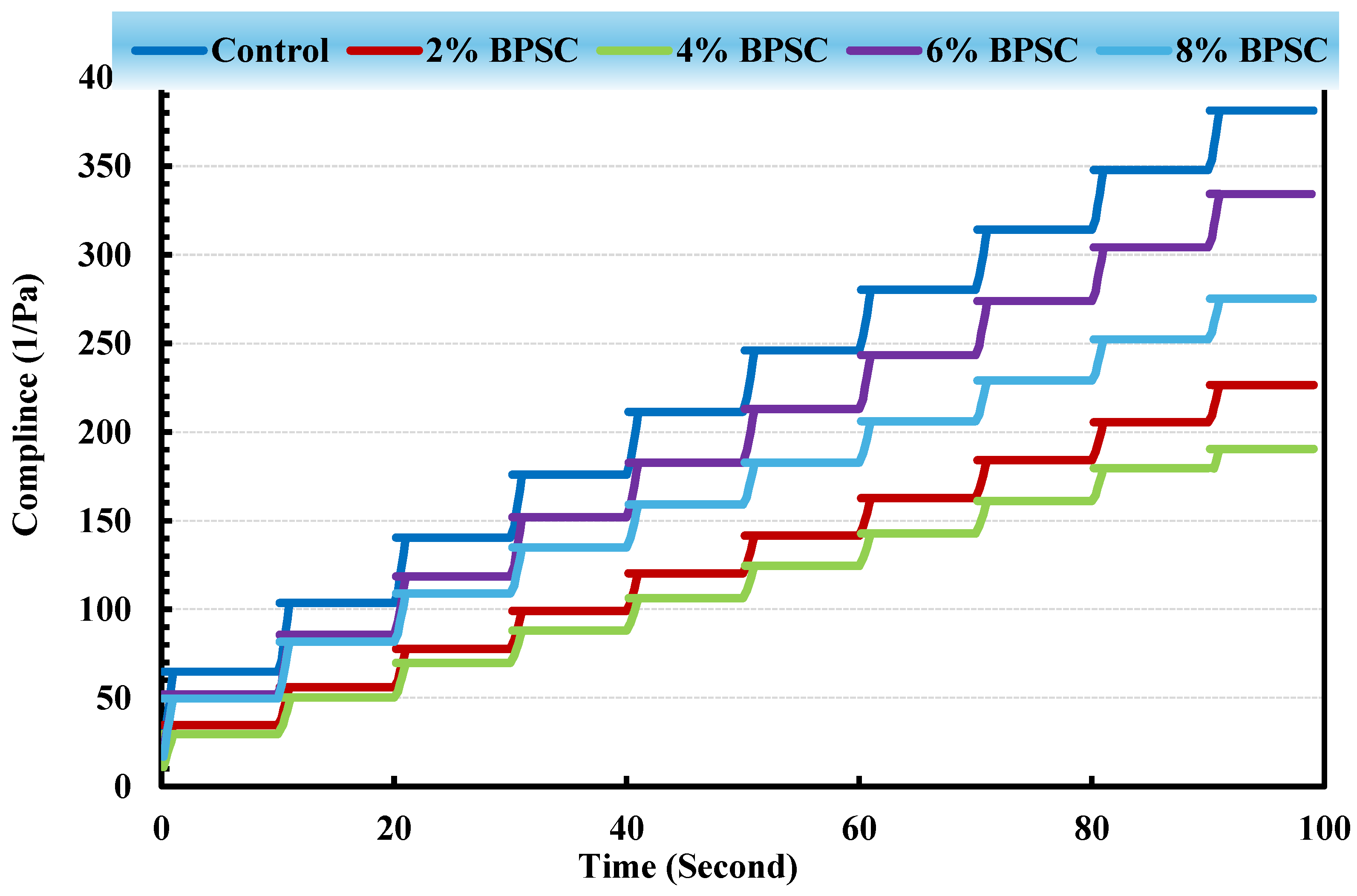

3.10.5. Creep and Recovery

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BPSC | Batu Pahat Soft Clay |

| FTIR | Fourier Transform Infrared Spectroscopy |

| DSR | Dynamic Shear Rheometer |

| SEM | Scanning Electron Microscopy |

| G* | Complex Shear Modulus |

| δ | Phase Angle |

| SBS | Styrene–Butadiene–Styrene |

| SBR | Styrene–Butadiene–Rubber |

| °C | Celsius |

| PE | Polyethylene |

| PVC | Polyvinyl Chloride |

| PI | Penetration Index |

| PVN | Penetration Viscosity Number |

| MSCR | Multiple Creep Stress and Recovery |

| EDS | Energy Dispersive Spectroscopy |

| TTSP | Time–Temperature Superposition Principle |

References

- Cao, P.C.; Guo, Z.Y.; Yang, Y.S.; Xue, Z.C. Analysis of Effects of High Temperature and Loading Frequency on Asphalt Binder. Appl. Mech. Mater. 2013, 372, 314–317. [Google Scholar] [CrossRef]

- Kuchiishi, A.K.; Carvalho, J.P.B.; Bessa, I.S.; Vasconcelos, K.L.; Bernucci, L.L. Effect of temperature on the fatigue behavior of asphalt binder. Appl. Rheol. 2019, 29, 30–40. [Google Scholar] [CrossRef]

- Emmaima, A.M.; Ali, S.I.A.; Gallouz, K.S. Experimental investigation of polymer and nanomaterial modified asphalt binder. Eng. Technol. Appl. Sci. Res. 2024, 14, 12869–12874. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Y.; Wu, X.; Zhang, J.; Huang, X. Nanomaterials for modified asphalt and their effects on viscosity characteristics: A comprehensive review. Nanomaterials 2024, 14, 1503. [Google Scholar] [CrossRef]

- Sackey, S.; Lee, D.-E.; Kim, B.-S. Duration estimate at completion: Improving earned value management forecasting accuracy. KSCE J. Civ. Eng. 2020, 24, 693–702. [Google Scholar] [CrossRef]

- Ali, S.I.A.; Gallouz, K.S.; Uwanuakwa, I.D.; Alas, M.; Mohd Hasan, M.R. Evaluations on the Properties of Polymer and Nanomaterials Modified Bitumen Under Different Aging Conditions. Nanomaterials 2025, 15, 1071. [Google Scholar] [CrossRef]

- Kazim, H.; Naser, A.; Jawad, Z. A review study on the improving the hot mixture asphalt properties by using different types of polymers as additive for asphalt material. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2023; p. 012022. [Google Scholar]

- Hemmati, N.; Vigneswaran, S.; Kim, H.H.; Lee, M.-S.; Lee, S.-J. Laboratory evaluation of asphalt binders containing styrene-butadiene-styrene (SBS) and processed oil. Materials 2023, 16, 1235. [Google Scholar] [CrossRef] [PubMed]

- Ameri, M.; Mohammadi, R.; Mousavinezhad, M.; Ameri, A.; Shaker, H.; Fasihpour, A. Evaluating properties of asphalt mixtures containing polymers of styrene butadiene rubber (SBR) and recycled polyethylene terephthalate (rPET) against failures caused by rutting, moisture and fatigue. Fract. Struct. Integr. 2020, 14, 177–186. [Google Scholar] [CrossRef]

- Masri, T.D.K.A.; Ferdaus, R.; Ramadhansyah, P. Sustainable use of polymer in asphalt mixture: A review. Construction 2022, 2, 12–21. [Google Scholar] [CrossRef]

- Yousif, M.A.; Zghair, H.H.; Alsaeedi, F. Optimal design of mechanical performances of asphalt mixtures comprising nano-clay additives. Open Eng. 2024, 14, 20220586. [Google Scholar] [CrossRef]

- Zghair, H.H.; Jony, H.; Hassan, M. Rheological characteristics of nano silica modified asphalt binder material. In Proceedings of the 2019 International engineering conference (IEC), Erbil, Iraq, 23–25 June 2019; pp. 79–84. [Google Scholar]

- Abdel-Wahed, T.; Abdel-Raheem, A.; Moussa, G. Performance Evaluation of Asphalt Mixtures Modified with Nanomaterials. MEJ-Mansoura Eng. J. 2022, 47, 1–15. [Google Scholar] [CrossRef]

- Eisa, M.S.; Mohamady, A.; Basiouny, M.E.; Abdulhamid, A.; Kim, J.R. Mechanical properties of asphalt concrete modified with carbon nanotubes (CNTs). Case Stud. Constr. Mater. 2022, 16, e00930. [Google Scholar] [CrossRef]

- Faramarzi, M.; Arabani, M.; Haghi, A.; Motaghitalab, V. Effects of using carbon Nano-tubes on thermal and ductility properties of bitumen. arXiv 2019, arXiv:1907.05819. [Google Scholar] [CrossRef]

- Saedi, S.; ORUÇ, Ş. The effects of nano bentonite and fatty arbocel on improving the behavior of warm mixture asphalt against moisture damage and rutting. Civ. Eng. J.-Tehran 2020, 6, 877–888. [Google Scholar] [CrossRef]

- Jaya, R.P.; Yaacob, H.; Hassan, N.A.; Al-Saffar, Z.H. Effectiveness and efficiency of nano kaolin clay as bitumen modifier: Part A. In Risk, Reliability and Sustainable Remediation in the Field of Civil and Environmental Engineering; Elsevier: Amsterdam, The Netherlands, 2022; pp. 449–460. [Google Scholar]

- Mohamed Jaafar, Z.; Ramadhansyah, P.; Masri, K.; Mashros, N.; Mohd Warid, M.; Norhidayah, A.; Yaacob, H. The effects of nano kaolin clay modified bitumen on the softening point and storage stability. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012062. [Google Scholar]

- Jaya, R.P.; Masri, K.A.; Mudjanarko, S.W.; Setiawan, M.I. Nano kaolin clay as bitumen modifier for sustainable development: Part B. In Risk, Reliability and Sustainable Remediation in the Field of Civil and Environmental Engineering; Elsevier: Amsterdam, The Netherlands, 2022; pp. 461–475. [Google Scholar]

- Warid, M.M.; Al-Saffar, Z.; Ramadhansyah, P.; Masri, K.; Muzamir, H.; Mudjanarko, S. Performance of nano kaolin clay modified bitumen under aging through the viscosity. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012064. [Google Scholar]

- Zhambolova, A.; Ongarbayev, Y.; Kenzhegaliyeva, A.; Abdikhan, D. Mechanochemically Activated Shungite as an Additive to Improve Bitumen Characteristics. J. Ecol. Eng. 2023, 24, 218–226. [Google Scholar] [CrossRef]

- Al-Mansob, R.A.; Ismail, A.; Yusoff, N.I.M.; Albrka, S.I.; Azhari, C.H.; Karim, M.R. Rheological characteristics of unaged and aged epoxidised natural rubber modified asphalt. Constr. Build. Mater. 2016, 102, 190–199. [Google Scholar] [CrossRef]

- Navarro, F.; Partal, P.; Martınez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- McLeod, N. Asphalt cements: Pen-vis number and its application to moduli of stiffness. J. Test. Eval. 1976, 4, 275–282. [Google Scholar] [CrossRef]

- AASHTO T 315-04; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2004.

- Xiaohu, L.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2002, 16, 15–22. [Google Scholar] [CrossRef]

- Wei, J.; Li, Y.; Dong, F.; Feng, H.; Zhang, Y. Study on the amorphous poly alpha olefin (APAO) modified asphalt binders. Constr. Build. Mater. 2014, 66, 105–112. [Google Scholar] [CrossRef]

- Tan, Y.; Guo, M. Using surface free energy method to study the cohesion and adhesion of asphalt mastic. Constr. Build. Mater. 2013, 47, 254–260. [Google Scholar] [CrossRef]

- AASHTO T. 240-09; Standard Method to Test for the Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film oven Test). In Standard Specifications for Transportation Materials and Methods of Sampling and Testing; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009.

- Djurekovic, A.; Mladenovic, G. The performance of bitumen mastics with the addition of fly ash. In Bituminous Mixtures and Pavements VI; CRC Press: Boca Raton, FL, USA, 2015; p. 115. [Google Scholar]

- Al-Qadi, I.L.; Abauwad, I.M.; Dhasmana, H.; Coenen, A.R. Effects of Various Asphalt Binder Additives/Modifiers on Moisture-Susceptible Asphaltic Mixtures; 0197-9191; Illinois Center for Transportation: Rantoul, IL, USA, 2014. [Google Scholar]

- Golalipour, A. Modification of Multiple Stress Creep and Recovery Test Procedure and Usage in Specification. Ph.D. Thesis, University of Wisconsin–Madison, Madison, WI, USA, 2011. [Google Scholar]

- Kim, H.; Lee, S.-J.; Amirkhanian, S.N. Rheology of warm mix asphalt binders with aged binders. Constr. Build. Mater. 2011, 25, 183–189. [Google Scholar] [CrossRef]

- Nuñez, J.Y.M.; Domingos, M.D.I.; Faxina, A.L. Susceptibility of low-density polyethylene and polyphosphoric acid-modified asphalt binders to rutting and fatigue cracking. Constr. Build. Mater. 2014, 73, 509–514. [Google Scholar] [CrossRef]

| Characteristics | Test Method | Requirement |

|---|---|---|

| Penetration at 25 °C | ASTM-D5 | 80–100 |

| Softening Point °C | ASTM-D36 | 45–52 |

| Ductility at 25 °C | ASTM-D113 | Min. 100 |

| Retained penetration after thin-film oven test, % | ASTM-D5 | Min. 47.0 |

| Loss on heating, % wt | AASHTO-T240 | Max. 1.00 |

| Original G*/sin δ at 64 °C @ 10 rad, kPa | AASHTO-TP5 | Min. 1.00 |

| RTFO G*/sin δ at 64 °C @ 10 rad, kPa | AASHTO-TP5 | Min. 2.20 |

| Specific Gravity at 25 °C | AST-D70 | 1.01–1.05 |

| Parameters | Results |

|---|---|

| Bulk Density (Mg/m3) | 1.36 |

| Specific Gravity | 2.66 |

| Plastic-Limit (PL)% | 29.70 |

| Liquid-Limit (LL) (%) | 37.55 |

| Plasticity-Index (PI) (%) | 7.85 |

| Moisture Content (%) | 29.35 |

| Asphalt Weight (kg) | BPSC Percentages (%) | Total Weight (g) | Blending Speed (rpm) | Blending Temperature (C°) | Blending Time (min) |

|---|---|---|---|---|---|

| 0.4 | 2 | 8.2 | 3000 | 155 | 60 |

| 0.4 | 4 | 16.7 | |||

| 0.4 | 6 | 25.5 | |||

| 0.4 | 8 | 34.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.I.A.; Al Allam, A.M.; Ali, A.S.B.; Alhamali, D.I.; Ali, A.A.; Emmaima, A.M.; Ismail, A. Performance Assessment of Asphalt Binder Modified with Batu Pahat Soft Clay as an Eco-Friendly Additive. Infrastructures 2025, 10, 302. https://doi.org/10.3390/infrastructures10110302

Ali SIA, Al Allam AM, Ali ASB, Alhamali DI, Ali AA, Emmaima AM, Ismail A. Performance Assessment of Asphalt Binder Modified with Batu Pahat Soft Clay as an Eco-Friendly Additive. Infrastructures. 2025; 10(11):302. https://doi.org/10.3390/infrastructures10110302

Chicago/Turabian StyleAli, Shaban Ismael Albrka, Allam Musbah Al Allam, Ahmed Suliman B. Ali, Dhawo Ibrahim Alhamali, Abdualmtalab Abdualaziz Ali, Ali Mohamed Emmaima, and Amiruddin Ismail. 2025. "Performance Assessment of Asphalt Binder Modified with Batu Pahat Soft Clay as an Eco-Friendly Additive" Infrastructures 10, no. 11: 302. https://doi.org/10.3390/infrastructures10110302

APA StyleAli, S. I. A., Al Allam, A. M., Ali, A. S. B., Alhamali, D. I., Ali, A. A., Emmaima, A. M., & Ismail, A. (2025). Performance Assessment of Asphalt Binder Modified with Batu Pahat Soft Clay as an Eco-Friendly Additive. Infrastructures, 10(11), 302. https://doi.org/10.3390/infrastructures10110302