Effects of the Aggregate Shape and Petrography on the Durability of Stone Mastic Asphalt

Abstract

1. Introduction

1.1. Research Motivation

1.2. Literature Review and Novelty

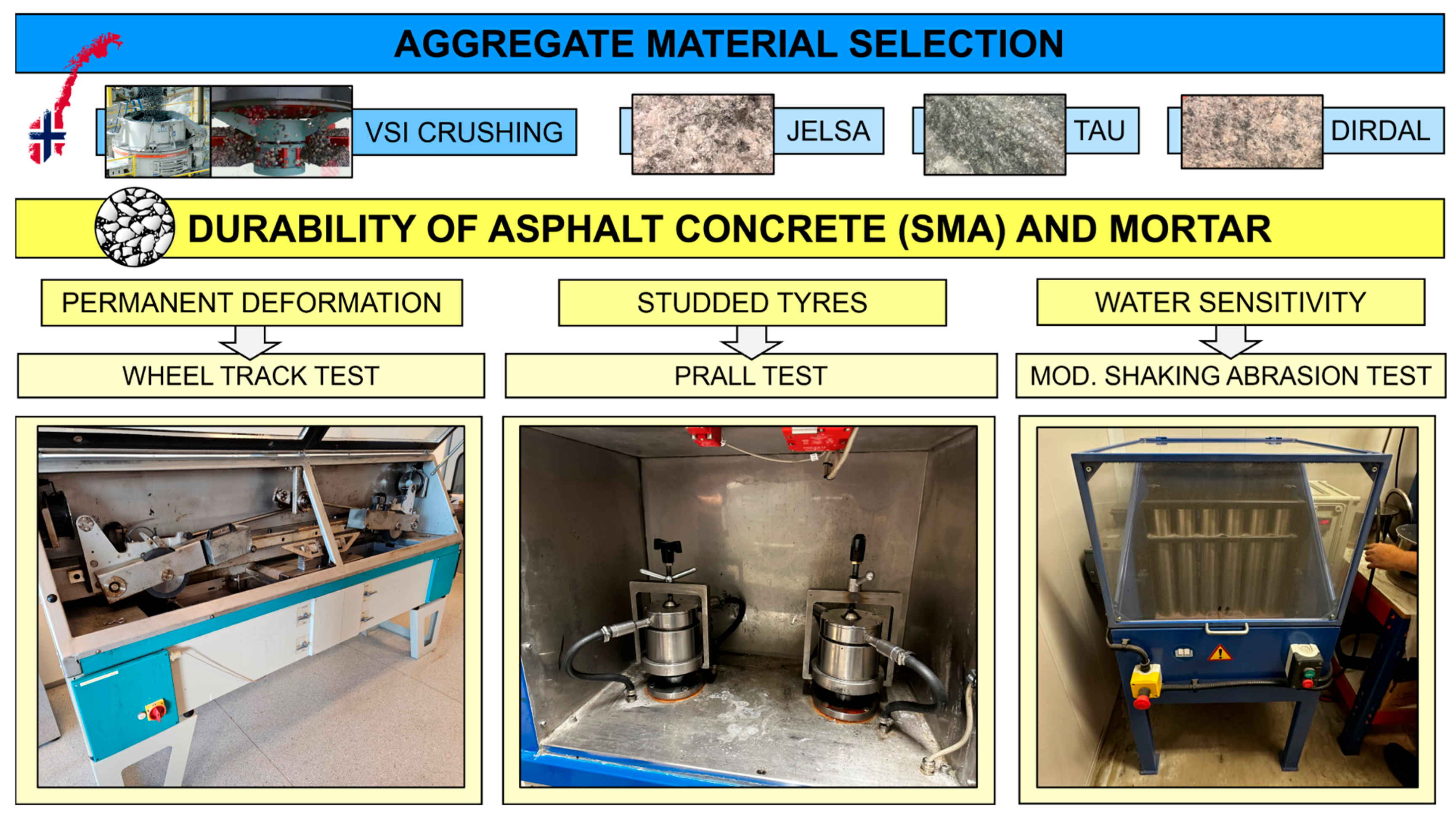

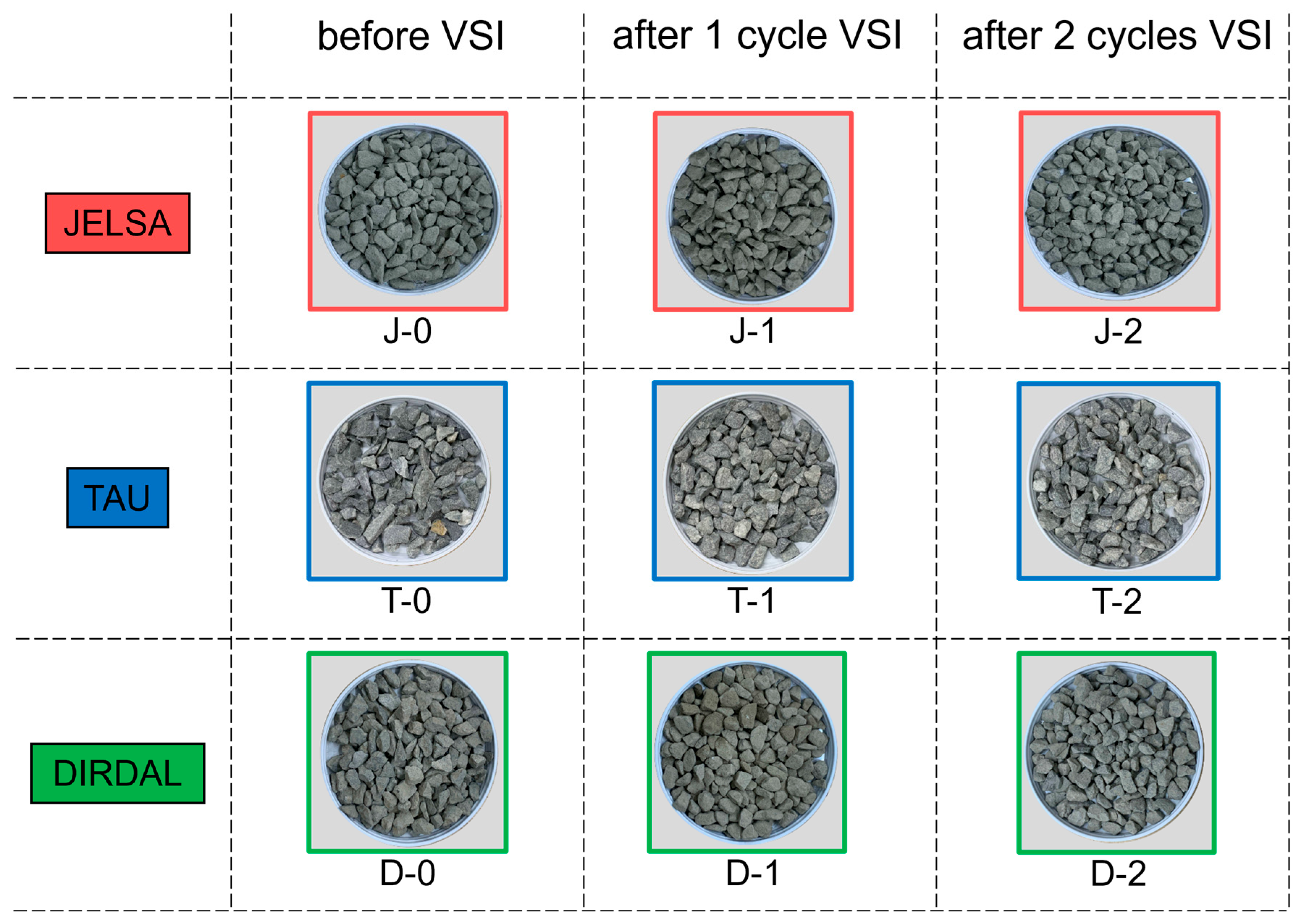

2. Materials

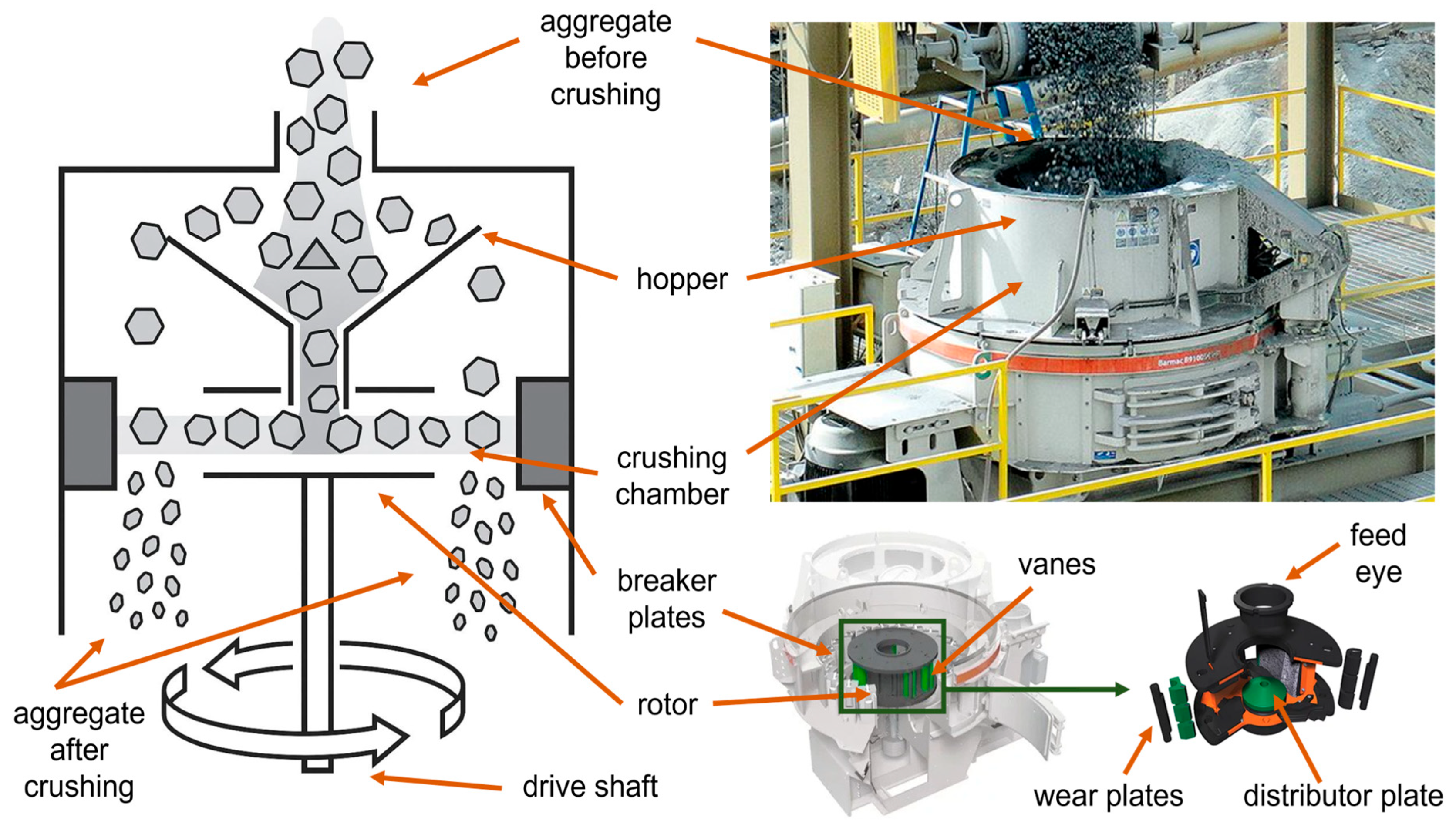

2.1. Rock Aggregate

2.2. Bitumen and Fibre

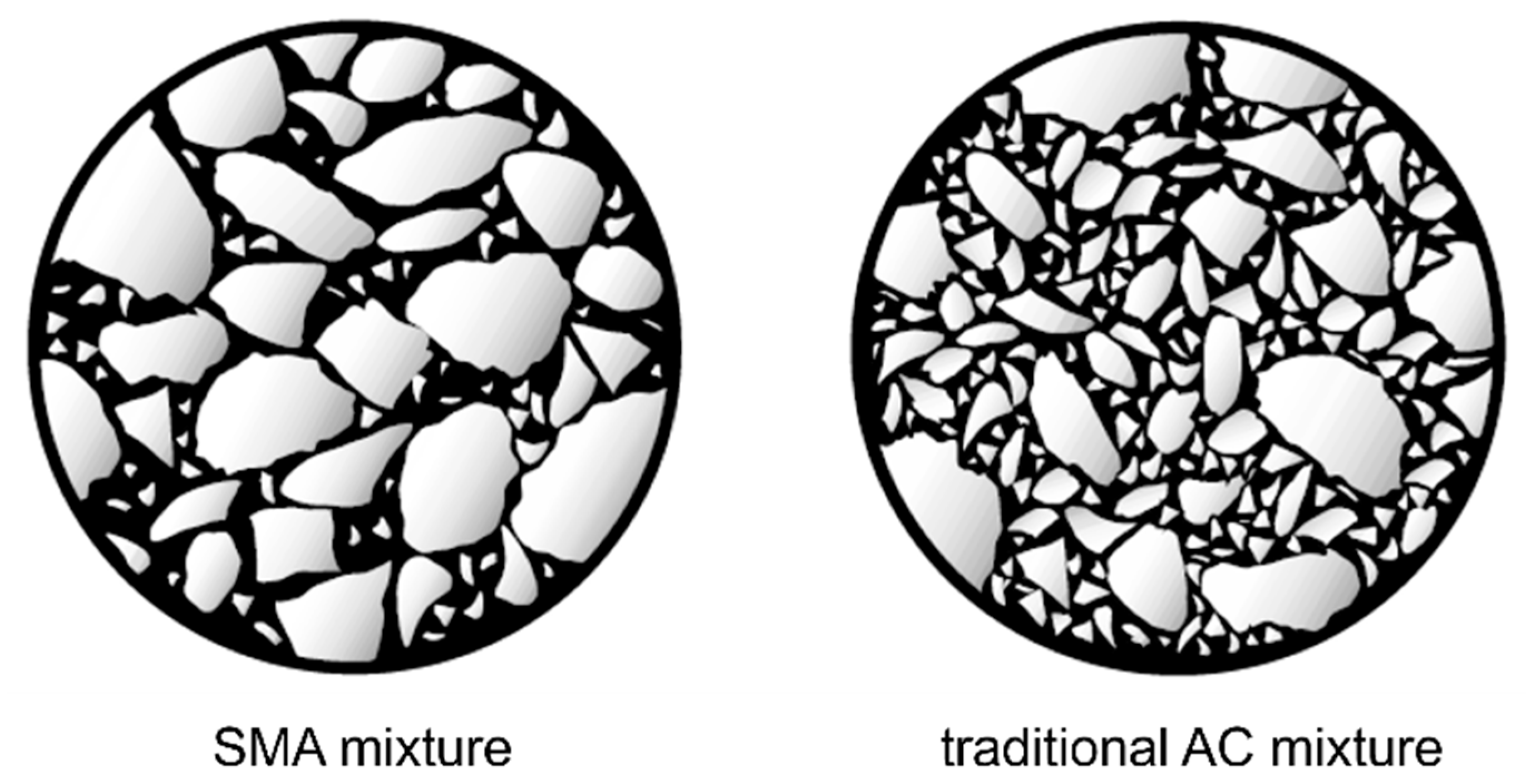

2.3. Asphalt Concrete and Asphalt Mortar

2.4. Sample Preparation

3. Experimental Methodology

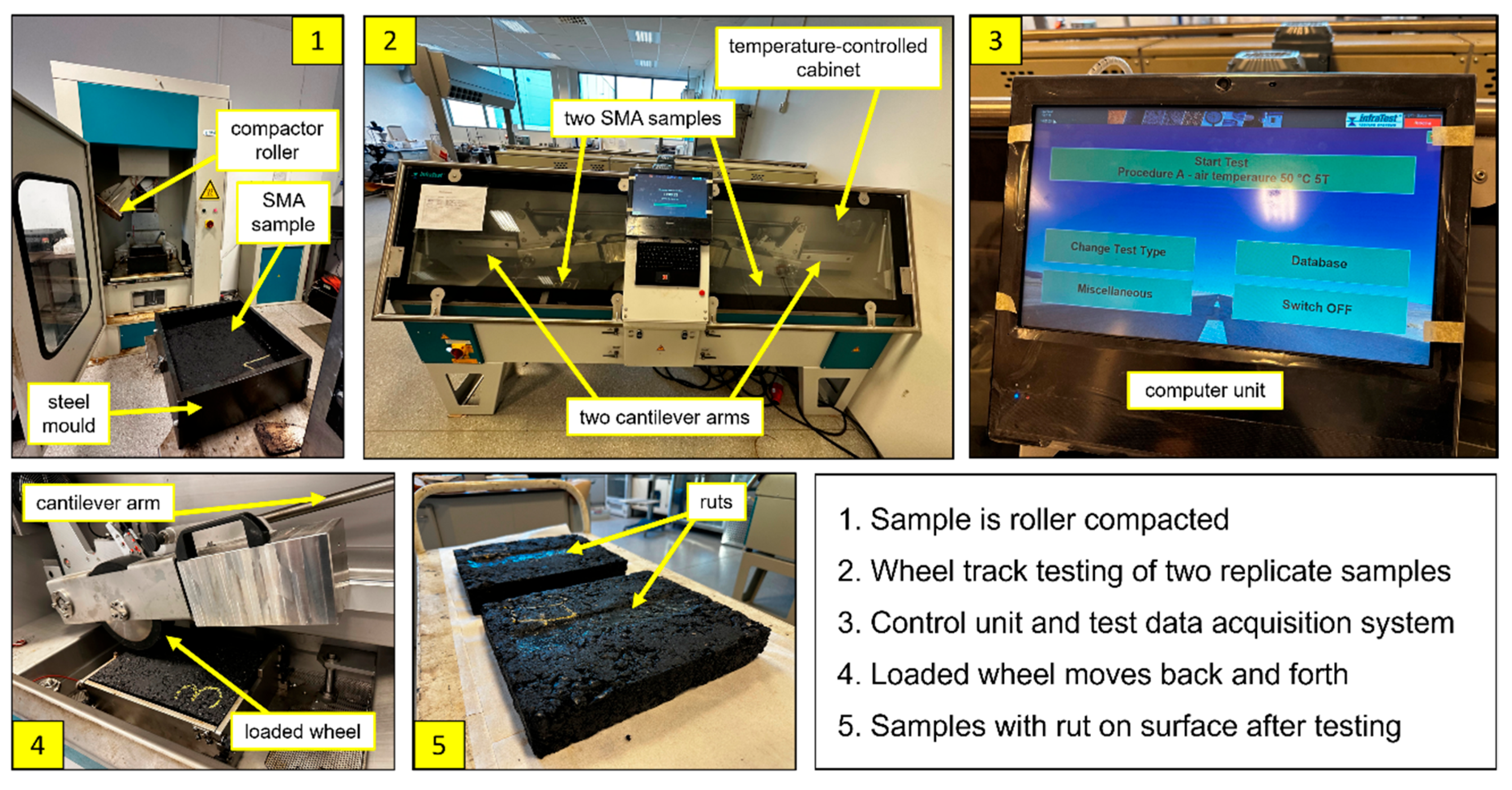

3.1. Permanent Deformation

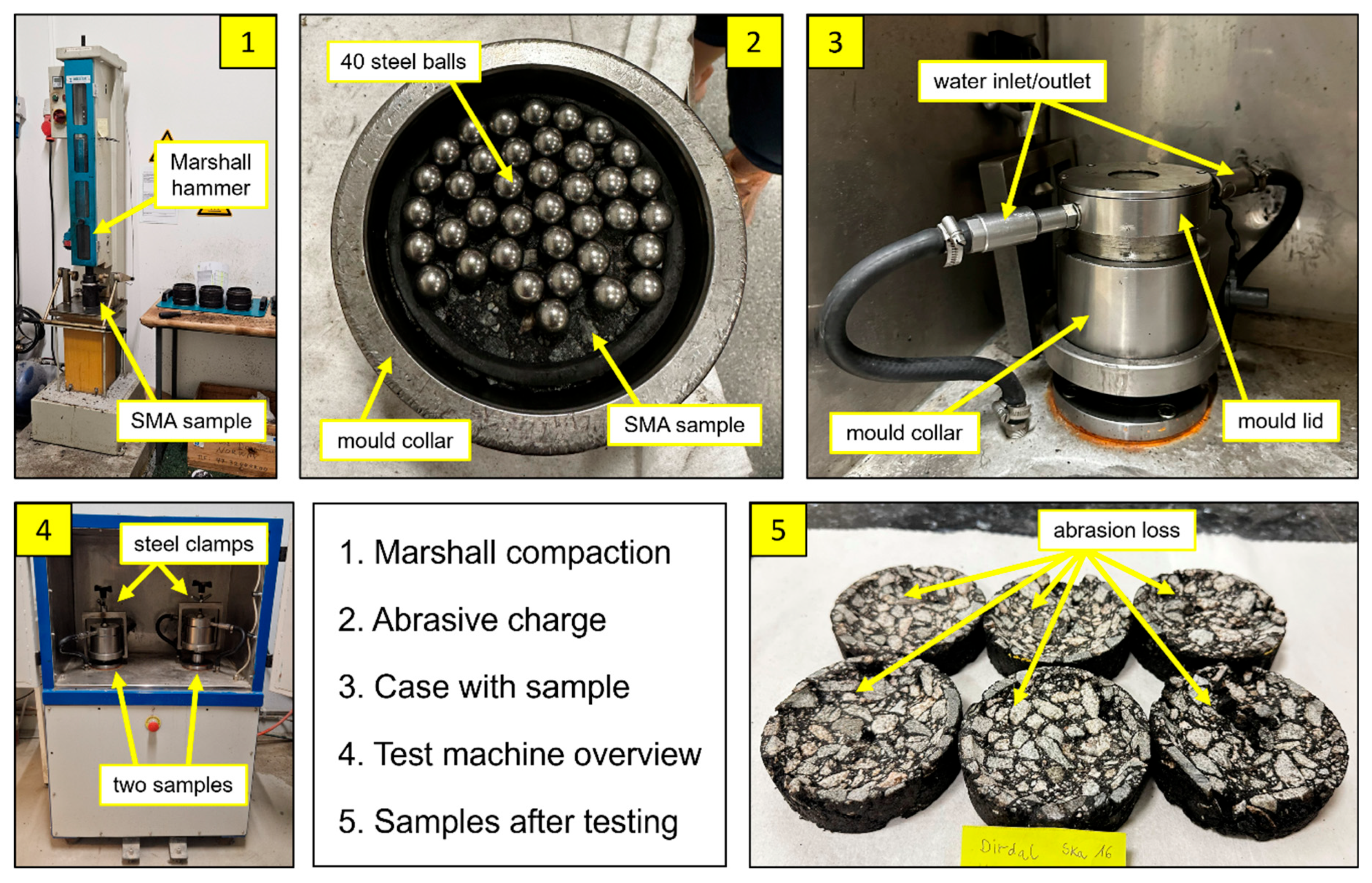

3.2. Abrasion by Studded Tyres

3.3. Water Sensitivity of Asphalt Mortar

4. Results and Discussion

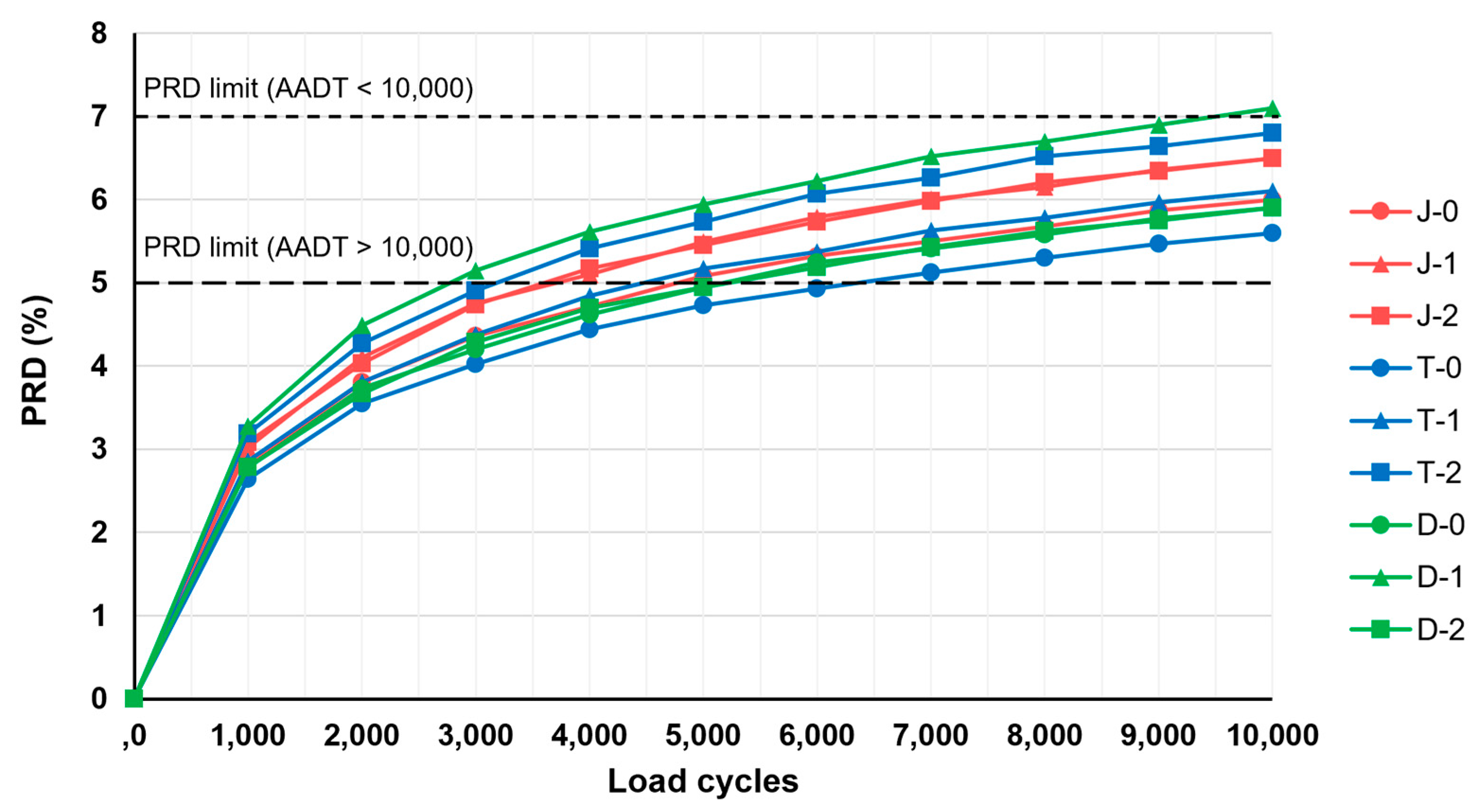

4.1. Wheel Track Test

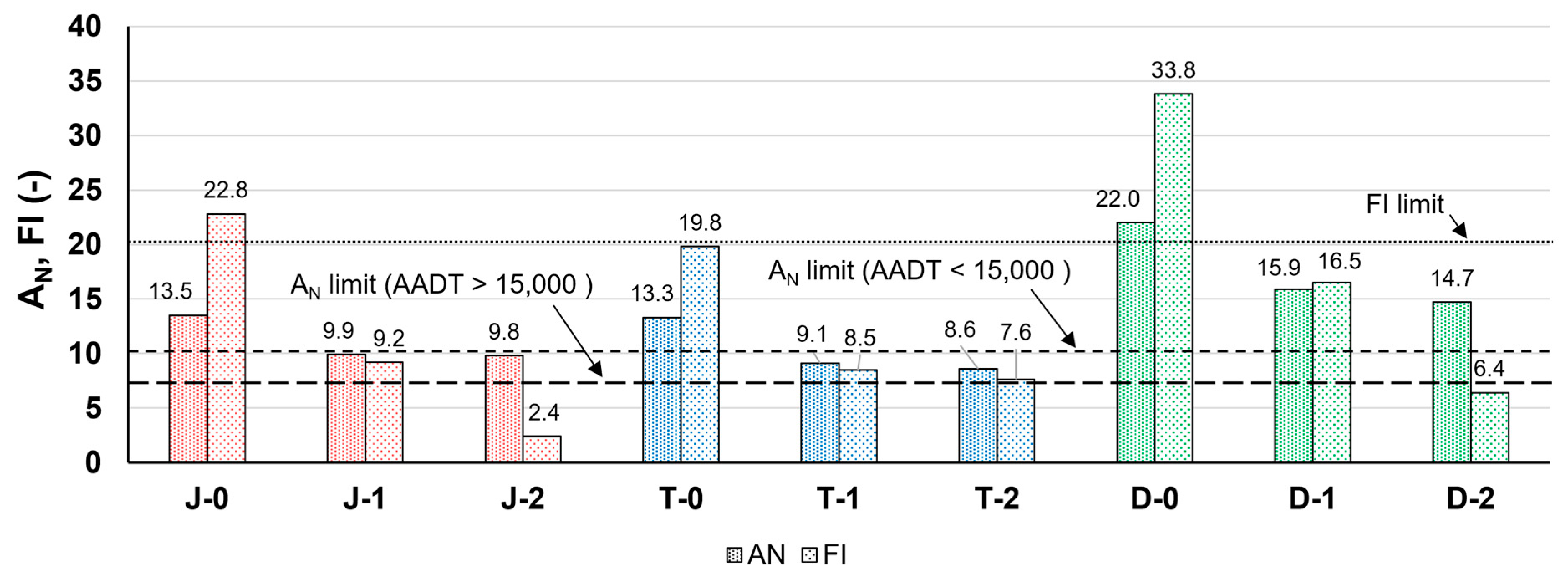

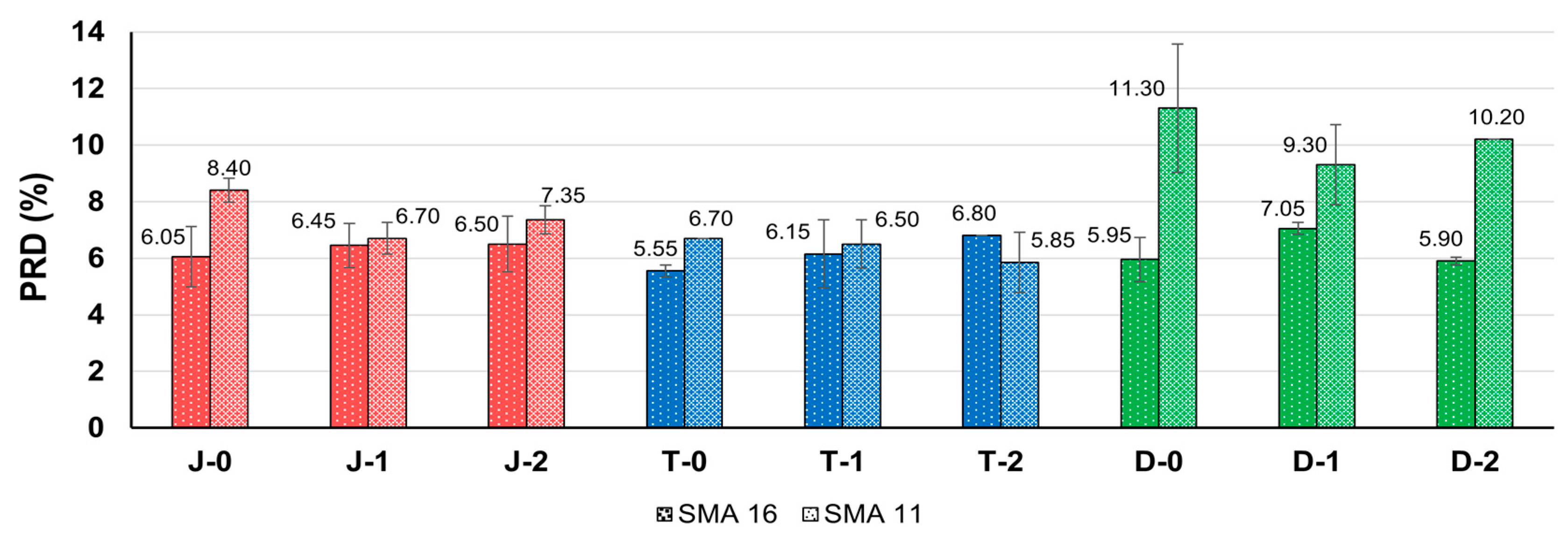

4.2. Prall Test

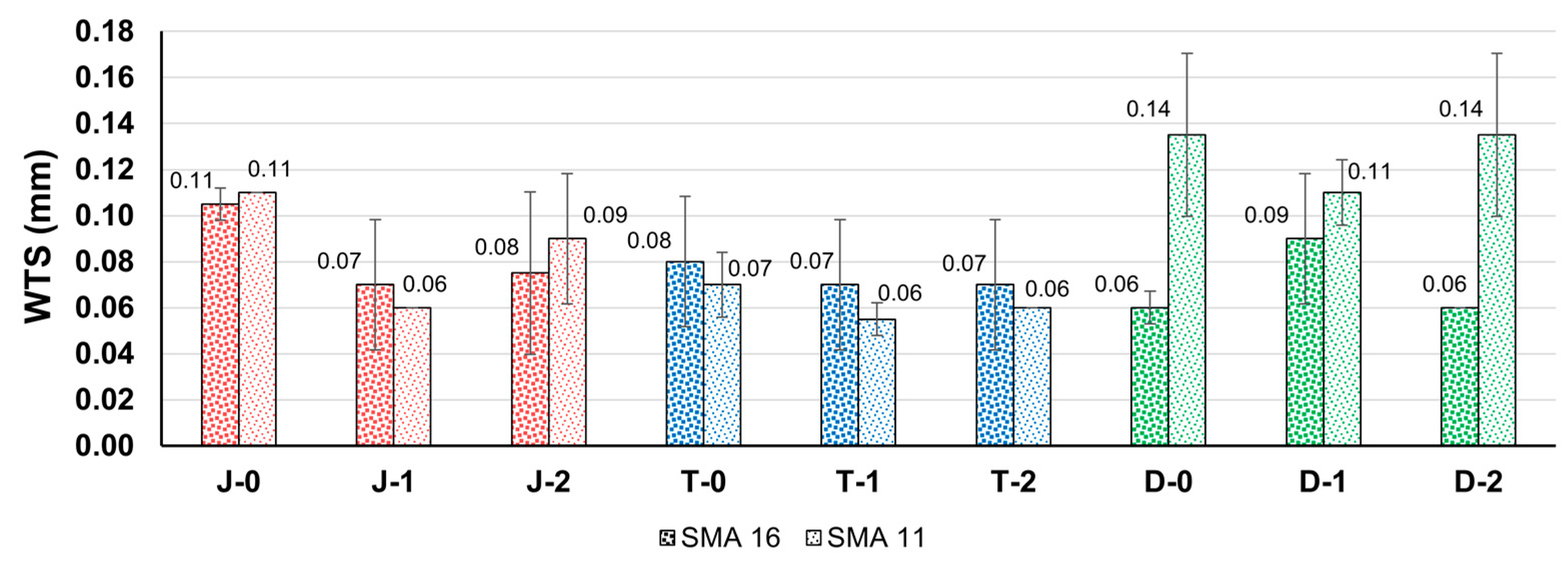

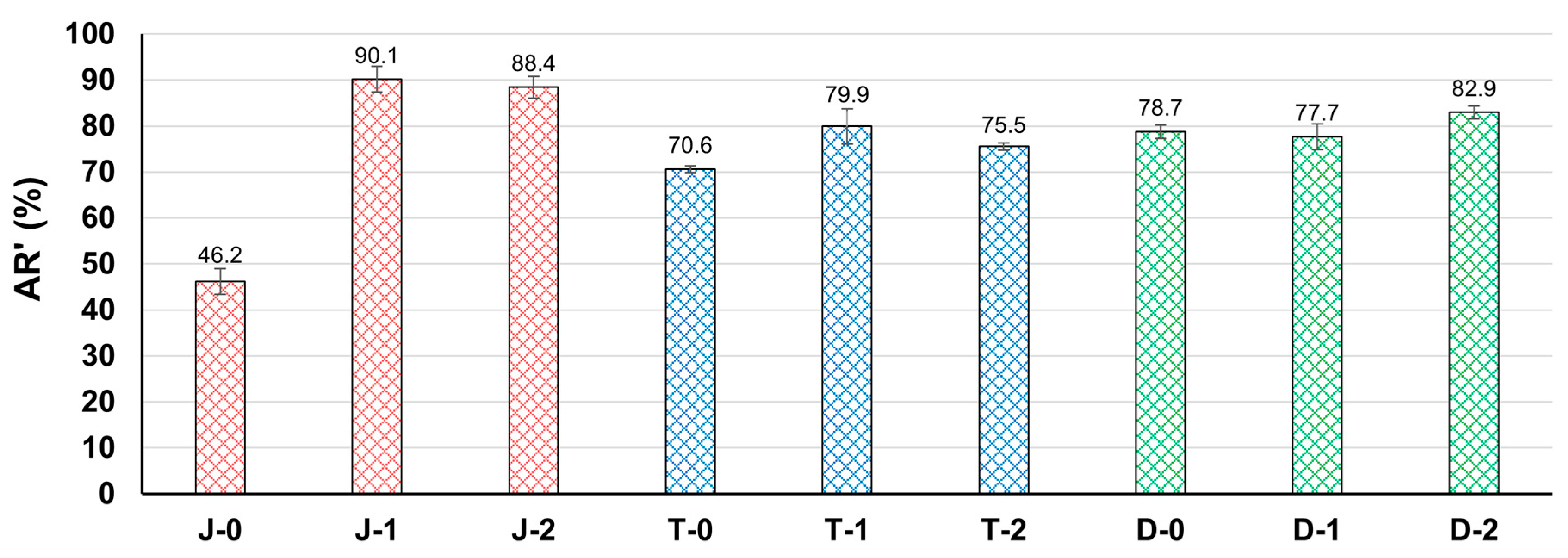

4.3. Modified Shaking Abrasion Test

5. Conclusions

- (1)

- The outcomes pertaining to the aggregates deriving from Jelsa (granodiorite) and Tau (quartz diorite) show better performance than the ones sourced from Dirdal (granite). This discrepancy can be attributed to the fact that the rock material quarried in Dirdal, which shows a degree of chemical alteration, displays a high degree of variability between large and small mineral grains compared to the homogenous fine grains for Jelsa and Tau. In this regard, fine-grained aggregates are proved to be more resistant and sounder.

- (2)

- When it comes to the results deriving from the WT test, the VSI comminution process led to an improved rutting performance for SMA 11. On the other hand, the permanent deformation of the treated aggregates (i.e., one or two VSI cycles) was worse than the untreated ones (i.e., before VSI crusher) for SMA 16. Such a discrepancy in the outcomes related to SMA 16 and SMA 11 suggests that more research is needed to identify the effect of VSI crushing. Further, the wheel tracking slope (WTS) results indicate that the values after one or two VSI cycles are similar.

- (3)

- The Prall test highlighted a slight beneficial effect apported by the impact crushing when it comes to the SMA containing aggregates sourced from Jelsa and Dirdal, but the test results did not indicate a clear trend for Tau. Further, the statistical method, ANOVA, highlighted that the aggregate petrography seems to play a much more important role than the aggregate shape for the Prall test results.

- (4)

- The outcomes derived from the modified shaking abrasion test show that the VSI process seems to worsen the durability of all investigated materials. However, the generalized massive degradation of all samples suggests that future research should use alternative methods to appreciate the mechanical response in the presence of moisture.

- (1)

- The geological origin of the aggregates exerted a major impact on the durability performance of SMA. The fine-grained aggregates sourced from Jelsa and Tau provided a better mechanical response than the rock material quarried in Dirdal, which displays a high degree of variability between large and small mineral grains.

- (2)

- The different aggregate shapes obtained without or with VSI crushing played a secondary role, except for the rutting resistance of SMA 11 and for the abrasion by studded tyres of SMA containing aggregates quarried in Jelsa and Dirdal.

- (3)

- This research did not unequivocally identify a possible general improvement related to the comminution process. Therefore, material selection based on the petrography should be prioritized in asphalt mixture design, with VSI refinement serving as an effective but secondary tool for improving aggregate morphology.

- (1)

- This research focused on aggregates sourced from southwest Norway. The investigation can be expanded by comprising other rock mineralogy that is widespread in the country. Further, future studies can also ascertain the influence exerted by other factors (e.g., different types and amount of bitumen, fibre and grading curves).

- (2)

- In addition to the thin-section microscopy described in this work, more advanced investigations (e.g., X-ray diffraction, X-ray fluorescence, computed tomography scanning, electron microscopy, pull-off test) can be conducted to assess the mineral composition, the aggregate surface texture and the mechanism affecting the aggregate–bitumen interface.

- (3)

- Based on the asphalt mixtures that display the most promising laboratory results, future research can perform full-scale testing to investigate the main mechanical properties such as rutting and stiffness. Furthermore, lifecycle assessments and lifecycle cost assessments for different asphalt mixtures can also be developed.

- (4)

- The creation of a wide experimental database would enable the opportunity to perform thorough statistical analyses. For instance, performing the f-test on larger datasets is necessary to identify whether asphalt mixtures exhibiting different characteristics (e.g., mineral composition, particle shape) are statistically different.

- (5)

- As many stakeholders involved across public institutes and private industries can benefit from the research results, a central goal could be the creation of guidelines indicating how to choose and prioritize the petrography and shape refinement of the rock aggregates used in the asphalt mixtures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haas, R.; Hudson, W.R. Pavement Asset Management, 1st ed.; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Lay, M.; Metcalf, J.; Sharp, K. Paving Our Ways: A History of the World’s Roads and Pavements, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Thom, N. Principles of Pavement Engineering, 2nd ed.; ICE: London, UK, 2014. [Google Scholar]

- Mallick, R.B.; El-Korchi, T. Pavement Engineering: Principles and Practice, 4th ed.; Taylor & Francis: Boca Raton, FL, USA, 2023. [Google Scholar]

- Thives, L.P.; Ghisi, E. Asphalt mixtures emission and energy consumption: A review. Renew. Sustain. Energy Rev. 2017, 72, 473–484. [Google Scholar] [CrossRef]

- Praticò, F.G. Metrics for management of asphalt plant sustainability. J. Constr. Eng. Manag. 2017, 143, 04016116. [Google Scholar] [CrossRef]

- Khair, M.; Strzalkowski, P.; Faizi, A.Q.; Barkal, M.G.; Fawakherji, I.; Lima, M.; Adeysey, M.; Barbieri, D.M.; Lou, B. Materials carbon budget in road projects: A case study from the Greater Oslo Region. Infrastructures 2024, 9, 132. [Google Scholar] [CrossRef]

- Sha, A.; Jiang, W.; Wang, W.; Lou, B.; Cao, Y.; Jia, M. Design and prospect of new pavement materials for smart road. Chinese Sci. Bull. 2020, 65, 3259–3269. [Google Scholar] [CrossRef]

- Wiedenhofer, D.; Baumgart, A.; Matej, S.; Virág, D.; Kalt, G.; Lanau, M.; Tingley, D.D.; Liu, Z.; Guo, J.; Tanikawa, H.; et al. Mapping and modelling global mobility infrastructure stocks, material flows and their embodied greenhouse gas emissions. J. Clean. Prod. 2024, 434, 139742. [Google Scholar] [CrossRef]

- Barbieri, D.M.; Lou, B.; Passavanti, M.; Hui, C.; Lessa, D.A.; Maharaj, B.; Banerjee, A.; Wang, F.; Chang, K.; Naik, B.; et al. Survey data regarding perceived air quality in Australia, Brazil, China, Ghana, India, Iran, Italy, Norway, South Africa, United States before and during COVID-19 restrictions. Data Br. 2020, 32, 106169. [Google Scholar] [CrossRef]

- Solomon, S.; Plattner, G.K.; Knutti, R.; Friedlingstein, P. Irreversible climate change due to carbon dioxide emissions. Proc. Natl. Acad. Sci. USA 2009, 106, 1704–1709. [Google Scholar] [CrossRef]

- Samferdselsdepartement. Nasjonal Transportplan 2025–2036; Samferdselsdepartement: Oslo, Norway, 2024. [Google Scholar]

- NPRA. Håndbok N200 Vegbygging; NPRA: Oslo, Norway, 2024.

- SINTEF. Asfaltdekkers Levetid. 2024. Available online: https://www.sintef.no/prosjekter/2024/asfaltdekkers-levetid/ (accessed on 26 May 2025).

- CEN EN 13108-5; Bituminous Mixtures-Material Specifications-Part 5: Stone Mastic Asphalt. European Committee For Standardization: Brussels, Belgium, 2016.

- Chen, H.; Garba, R.; Liu, G.; Barbieri, D.M.; Zhang, X.; Hoff, I. Influence of material factors on the determination of dynamic moduli and associated prediction models for different types of asphalt mixtures. Constr. Build. Mater. 2023, 365, 130134. [Google Scholar] [CrossRef]

- Brown, E.R.; Colley, L.A. NCHRP Report 425: Designing Stone Matrix Asphalt Mixtures for Rut-Resistant Pavements; NCHRP: Auburn, AL, USA, 1999. [Google Scholar]

- National Asphalt Pavement Association. Designing and Constructing SMA Mixtures–State-of-the-Practice; NAPA: Lanham, MD, USA, 2002. [Google Scholar]

- Ling, S.; Yu, F.; Sun, D.; Sun, G.; Xu, L. A comprehensive review of tire-pavement noise: Generation mechanism, measurement methods, and quiet asphalt pavement. J. Clean. Prod. 2021, 287, 125056. [Google Scholar] [CrossRef]

- Zakerzadeh, M.; Shahbodagh, B.; Ng, J.; Khalili, N. The use of waste tyre rubber in Stone Mastic Asphalt mixtures: A critical review. Constr. Build. Mater. 2024, 418, 135420. [Google Scholar] [CrossRef]

- Mattinzioli, T.; Sol-Sanchez, M.; Moreno-Navarro, F.; Rubio-Gamez, M.C.; Martinez, G. Benchmarking the embodied environmental impacts of the design parameters for asphalt mixtures. Sustain. Mater. Technol. 2022, 32, e00395. [Google Scholar] [CrossRef]

- Leng, Z.; Al-Qadi, I.L.; Cao, R. Life-cycle economic and environmental assessment of warm stone mastic asphalt. Transp. A Transp. Sci. 2018, 14, 562–575. [Google Scholar] [CrossRef]

- Arasan, S.; Yenera, E.; Hattatoglu, F.; Hinislioglua, S.; Akbuluta, S. Correlation between shape of aggregate and mechanical properties of asphalt concrete: Digital image processing approach. Road Mater. Pavement Des. 2011, 12, 239–262. [Google Scholar] [CrossRef]

- Bessa, I.S.; Branco, V.T.F.C.; Soares, J.B.; Neto, J.A.N. Aggregate shape properties and their influence on the behavior of hot-mix asphalt. J. Mater. Civ. Eng. 2015, 27, 04014212. [Google Scholar] [CrossRef]

- Aragão, F.T.S.; Pazos, A.R.G.; da Motta, L.M.G.; Kim, Y.R.; do Nascimento, L.A.H. Effects of morphological characteristics of aggregate particles on the mechanical behavior of bituminous paving mixtures. Constr. Build. Mater. 2016, 123, 444–453. [Google Scholar] [CrossRef]

- Anastasio, S.; Perez Fortes, A.P.; Hoff, I. Effect of aggregate petrology on the durability of asphalt pavements. Constr. Build. Mater. 2017, 146, 652–657. [Google Scholar] [CrossRef]

- Anastasio, S.; Fortes, A.P.P.; Kuznetsova, E.; Danielsen, S.W. Relevant petrological properties and their repercussions on the final use of aggregates. Energy Procedia 2016, 97, 546–553. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Y.; Sun, W.; Nair, H.; Lane, D.S.; Wang, L. Effect of coarse aggregate morphology on the mechanical properties of stone matrix asphalt. Constr. Build. Mater. 2017, 152, 48–56. [Google Scholar] [CrossRef]

- Cui, P.; Xiao, Y.; Yan, B.; Li, M.; Wu, S. Morphological characteristics of aggregates and their influence on the performance of asphalt mixture. Constr. Build. Mater. 2018, 186, 303–312. [Google Scholar] [CrossRef]

- Aboutalebi Esfahani, M.; Kalani, M. Petrographic analysis method for evaluation and achieving durable hot mix asphalt. Constr. Build. Mater. 2020, 234, 117408. [Google Scholar] [CrossRef]

- Hassan, H.M.Z.; Wu, K.; Huang, W.; Chen, S.; Zhang, Q.; Xie, J.; Cai, X. Study on the influence of aggregate strength and shape on the performance of asphalt mixture. Constr. Build. Mater. 2021, 294, 123599. [Google Scholar] [CrossRef]

- Mibau Stema Group. Våre Steinbrudd. 2025. Available online: https://www.mibau-stema.no/vaare-steinbrudd/norske-steinbrudd (accessed on 26 May 2025).

- Bratthammer, A.L. Knuseprosessens Påvirkning på Asfalttilslag og Sammenhengen Mellom Kornform, Mekaniske Egenskaper og Petrografi. Master’s Thesis, Norwegian University of Life Sciences, Ås, Norway, 2024. [Google Scholar]

- Rothery, K.; Mellor, S. Crushing and Screening, 3rd ed.; Institute of Quarrying: Nottingham, UK, 2007. [Google Scholar]

- Wang, C.; Wang, H.; Oeser, M.; Mohd Hasan, M.R. Investigation on the morphological and mineralogical properties of coarse aggregates under VSI crushing operation. Int. J. Pavement Eng. 2021, 22, 1611–1624. [Google Scholar] [CrossRef]

- Bengtsson, M.; Evertsson, C.M. Measuring characteristics of aggregate material from vertical shaft impact crushers. Miner. Eng. 2006, 19, 1479–1486. [Google Scholar] [CrossRef]

- Metso. Barmac B Series. 2025. Available online: https://www.metso.com/portfolio/barmac-b-series/ (accessed on 26 May 2025).

- Metso. Crushing and Screening Handbook, 7th ed.; Metso: Helsinki, Finland, 2023. [Google Scholar]

- CEN EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates: Determination of Particle Density and Water Absorption. SIST: Brussels, Belgium, 2022.

- CEN EN 932-3; Tests for General Properties of Aggregates: Procedure and Terminology for Simplified Petrographic Description. SIST: Brussels, Belgium, 2022.

- Barbieri, D.M.; Hoff, I.; Mork, H. Laboratory investigation on unbound materials used in a highway with premature damage. In Proceedings of the 10th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Athens, Greece, 28–30 June; Loizos, A., Al-Qadi, I.L., Scarpas, A.T., Eds.; Taylor & Francis: Abingdon, UK, 2017; pp. 101–108. [Google Scholar]

- Barbieri, D.M.; Hoff, I.; Mørk, M.B.E. Mechanical assessment of crushed rocks rerived from tunnelling operations. In Proceedings of the Sustainable Civil Infrastructures, Hangzhou, China, 23–25 July 2018; Cheng, W.-C., Yang, J., Wang, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 225–241. [Google Scholar]

- CEN EN 1097-9; Tests for Mechanical and Physical Properties of Aggregates: Determination of the Resistance to Wear by Abrasion from Studded Tyres–Nordic Test. SIST: Brussels, Belgium, 2014.

- CEN EN 933-3; Tests for Geometrical Properties of Aggregates: Determination of Particle Shape–Flakiness Index. SIST: Brussels, Belgium, 2012.

- CEN EN 933-1; Tests for Geometrical Properties of Aggregates: Determination of Particle Size Distribution–Sieving Method. SIST: Brussels, Belgium, 2012.

- CEN EN 1426; Bitumen and Bituminous Binders: Determination of Needle Penetration. SIST: Brussels, Belgium, 2024.

- CEN EN 1427; Bitumen and Bituminous Binders: Determination of the Softening Point–Ring and Ball Method. SIST: Brussels, Belgium, 2015.

- CEN EN 12591; Bitumen and Bituminous Binders: Specifications for Paving Grade Bitumens. SIST: Brussels, Belgium, 2009.

- Qiu, Y.F.; Lum, K.M. Design and performance of stone mastic asphalt. J. Transp. Eng. 2006, 132, 956–963. [Google Scholar] [CrossRef]

- NCC Industry. Asfaltlaboratorium. 2025. Available online: https://www.ncc.no/vare-tjenester/infrastruktur/veier/asfaltlaboratorium/ (accessed on 26 May 2025).

- CEN EN 12697-38; Bituminous Mixtures–Test Methods: Common Equipment and Calibration. SIST: Brussels, Belgium, 2004.

- CEN EN 12697-30; Bituminous Mixtures–Test Methods: Specimen Preparation by Impact Compactor. SIST: Brussels, Belgium, 2018.

- CEN EN 12697-34; Bituminous Mixtures–Test Methods: Marshall Test. SIST: Brussels, Belgium, 2020.

- CEN EN 12697-8; Bituminous Mixtures–Test Methods: Determination of Void Characteristics of Bituminous Specimens. SIST: Brussels, Belgium, 2018.

- CEN EN 12697-6; Bituminous Mixtures–Test Methods for Hot Mix Asphalt: Determination of Bulk Density of Bituminous Specimens. SIST: Brussels, Belgium, 2020.

- CEN EN 12697-5; Bituminous Mixtures–Test Methods for Hot Mix Asphalt: Determination of the Maximum Density. SIST: Brussels, Belgium, 2018.

- NCC Industry. Determination of Water Sensitivity on Fines (Mastix); NCC Industry: Lier, Norway, 2002. [Google Scholar]

- CEN EN 12274-7; Slurry Surfacing–Test Methods: Shaking Abrasion Tes. SIST: Brussels, Belgium, 2005.

- CEN EN 12697-35; Bituminous Mixtures–Test Methods: Laboratory Mixing. SIST: Brussels, Belgium, 2025.

- CEN EN 12697-33; Bituminous Mixtures–Test Methods for Hot Mix Asphalt: Specimen Prepared by Roller Compactor. SIST: Brussels, Belgium, 2019.

- CEN EN 12697-22; Bituminous Mixtures–Test Methods: Wheel Tracking. SIST: Brussels, Belgium, 2020.

- CEN EN 12697-16; Bituminous Mixtures–Test Methods: Abrasion by Studded Tyres. SIST: Brussels, Belgium, 2024.

- Elvik, R. The effects on accidents of studded tires and laws banning their use: A meta-analysis of evaluation studies. Accid. Anal. Prev. 1999, 31, 125–134. [Google Scholar] [CrossRef]

- Elvik, R.; Fridstrøm, L.; Kaminska, J.; Meyer, S.F. Effects on accidents of changes in the use of studded tyres in major cities in Norway: A long-term investigation. Accid. Anal. Prev. 2013, 54, 15–25. [Google Scholar] [CrossRef]

- Jørgensen, T.; Fiske, T.H.; Telle, R. High content of Reclaimed Asphalt Pavement (RAP) in asphalt mixtures–Optimal use of rejuvenators. In Proceedings of the 11th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 27–30 June 2022; Hoff, I., Mork, H., Saba, R., Eds.; Taylor & Francis: Abingdon, UK, 2022; Volume 3, pp. 407–417. [Google Scholar]

- Rogg, D. Modification of the performance properties of asphalt by using fine aggregates with different water sensitivities. In Bituminous Mixtures and Pavements VIII; Nikolaides, A.F., Manthos, E., Eds.; CRC Press: London, UK, 2024. [Google Scholar]

- Ulmgren, N. The influence of the mastic on the durability of asphalt pavements as studied by the shaking abrasion test. In Proceedings of the 3rd Eurasphalt & Eurobitume Congress, Vienna, Austria, 12–14 May 2004; pp. 1464–1475. [Google Scholar]

- Devulapalli, L.; Sarang, G.; Kothandaraman, S. Characteristics of aggregate gradation, drain down and stabilizing agents in stone matrix asphalt mixtures: A state of art review. J. Traffic Transp. Eng. 2022, 9, 167–179. [Google Scholar] [CrossRef]

- Kazi, A.; Al-Mansour, Z.R. Influence of geological factors on abrasion and soundness characteristics of aggregates. Eng. Geol. 1980, 15, 195–203. [Google Scholar] [CrossRef]

- Sun, W.; Wang, L.; Wang, Y. Mechanical properties of rock materials with related to mineralogical characteristics and grain size through experimental investigation: A comprehensive review. Front. Struct. Civ. Eng. 2017, 11, 322–328. [Google Scholar] [CrossRef]

- Miskovsky, K.; Taborda Duarte, M.; Kou, S.Q.; Lindqvist, P.A. Influence of the mineralogical composition and textural properties on the quality of coarse aggregates. J. Mater. Eng. Perform. 2004, 13, 144–150. [Google Scholar] [CrossRef]

- Ferreira, J.L.S.; Babadopulos, L.F.A.L.; Bastos, J.B.S.; Soares, J.B. A tool to design rutting resistant asphalt mixes through aggregate gradation selection. Constr. Build. Mater. 2020, 236, 117531. [Google Scholar] [CrossRef]

- Topal, A.; Sengoz, B. Determination of fine aggregate angularity in relation with the resistance to rutting of hot-mix asphalt. Constr. Build. Mater. 2005, 19, 155–163. [Google Scholar] [CrossRef]

- Rajan, B.; Singh, D. Effects of coarse aggregate shape parameters on workability, design, and performance characteristics of stone matrix asphalt mixes. Transp. Res. Rec. 2023, 2677, 1496–1511. [Google Scholar] [CrossRef]

- Adomako, S.; Engelsen, C.J.; Thorstensen, R.T.; Barbieri, D.M. Review of the relationship between aggregates geology and Los Angeles and micro-Deval tests. Bull. Eng. Geol. Environ. 2021, 80, 1963–1980. [Google Scholar] [CrossRef]

- Barbieri, D.M.; Hoff, I.; Mørk, M.B.E. Organosilane and lignosulfonate as innovative stabilization techniques for crushed rocks used in road unbound layers. Transp. Geotech. 2020, 22, 100308. [Google Scholar] [CrossRef]

- Loaiza-Monsalve, D.; Bilodeau, J.P.; Fournier, B.; Doucet, F.; Chabchoub, S. Quantification of influence factors in the studded tire wear using the prall device. In Proceedings of the Cold Regions Engineering 2024: Sustainable and Resilient Engineering Solutions for Changing Cold Regions, Anchorage, AK, USA, 13–16 May 2024; Zufelt, J., Yang, Z., Eds.; ASCE: Reston, VA, USA, 2024; pp. 505–517. [Google Scholar]

- Baimukhametov, G.; Gayfutdinov, R.; Khafizov, E. Calculation of the influence of various compaction on the wear resistance of asphalt concrete using material loss calculation approach. Mag. Civ. Eng. 2024, 17, 122. [Google Scholar] [CrossRef]

- Cala, A.; Caro, S.; Lleras, M.; Rojas-Agramonte, Y. Impact of the chemical composition of aggregates on the adhesion quality and durability of asphalt-aggregate systems. Constr. Build. Mater. 2019, 216, 661–672. [Google Scholar] [CrossRef]

- Feng, P.; Wang, H.; Ding, H.; Xiao, J.; Hassan, M. Effects of surface texture and its mineral composition on interfacial behavior between asphalt binder and coarse aggregate. Constr. Build. Mater. 2020, 262, 120869. [Google Scholar] [CrossRef]

- Zou, G.; Xu, J.; Wu, C. Evaluation of factors that affect rutting resistance of asphalt mixes by orthogonal experiment design. Int. J. Pavement Res. Technol. 2017, 10, 282–288. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, L.; Li, J.; Liu, L. Effect of key design parameters on high temperature performance of asphalt mixtures. Constr. Build. Mater. 2022, 348, 128651. [Google Scholar] [CrossRef]

- Jørgensen, T.; Teigen, M.; Torgersen, K. Water susceptibility of asphalt mixtures: Testing the effect of adhesion agents on different binder/aggregate mixtures. In Proceedings of the 7th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 25–27 June 2005; Horvli, I., Ed.; NTNU: Trondheim, Norway, 2005. [Google Scholar]

- CEN EN 12697-23; Bituminous Mixtures–Test Methods: Determination of the Indirect Tensile Strength of Bituminous Specimens. SIST: Brussels, Belgium, 2017.

- CEN EN 12697-12; Bituminous Mixtures–Test Methods: Determination of the Water Sensitivity of Bituminous Specimens. SIST: Brussels, Belgium, 2018.

- CEN EN 12697-17; Bituminous Mixtures–Test Methods: Particle Loss of Porous Asphalt Specimens. SIST: Brussels, Belgium, 2017.

| Quarry | Geology | Density (Mg/m3) | Code Abbreviation | ||

|---|---|---|---|---|---|

| Before VSI | After 1 Cycle VSI | After 2 Cycles VSI | |||

| Jelsa | granodiorite | 2.766 | J-0 | J-1 | J-2 |

| Tau | quartz diorite | 2.759 | T-0 | T-1 | T-2 |

| Dirdal | granite | 2.773 | D-0 | D-1 | D-2 |

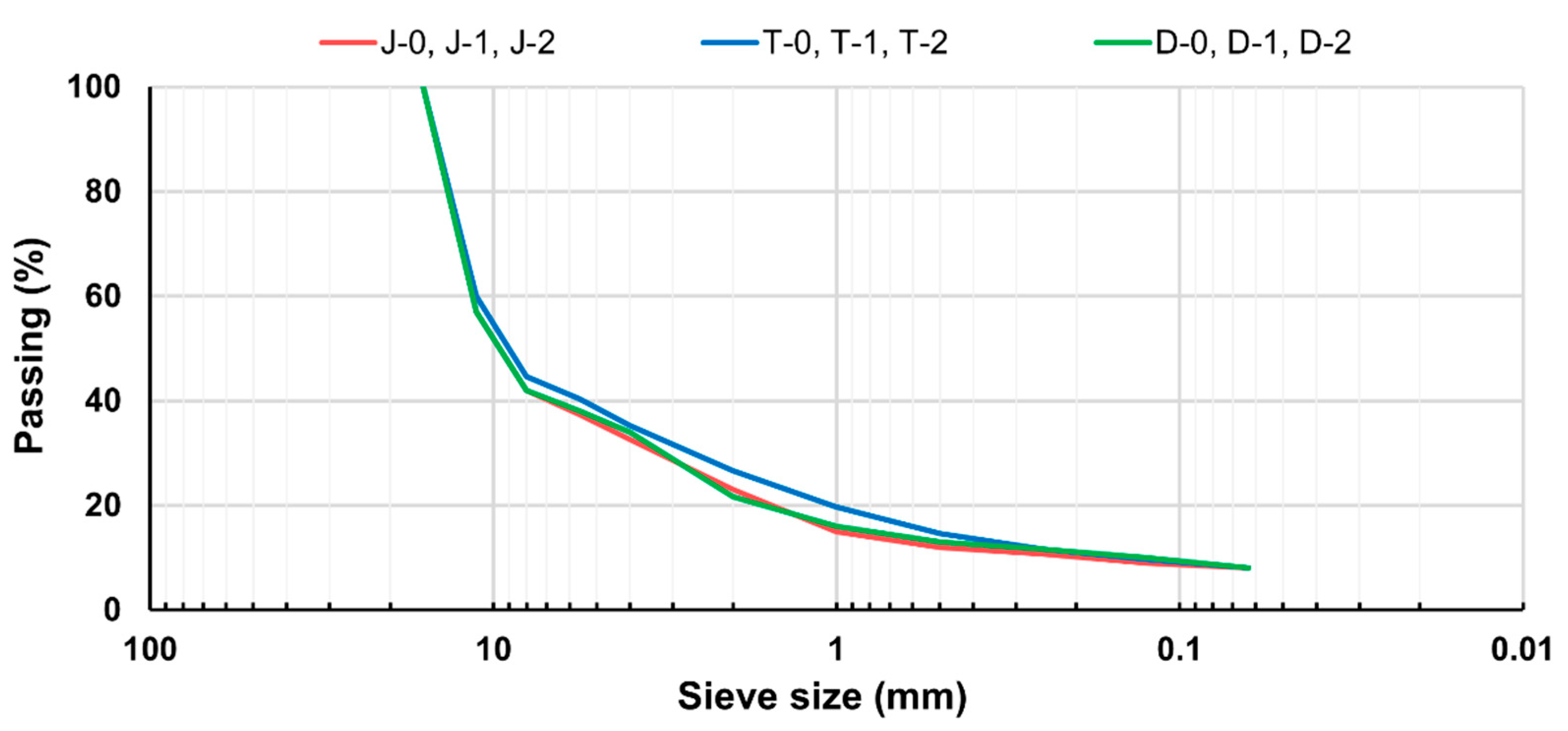

| Sieve Size (mm) | BC (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 11.2 | 8 | 5.6 | 4 | 2 | 1 | 0.5 | 0.25 | 0.125 | 0.063 | ||

| Passing (%) | ||||||||||||

| Jelsa | 100.0 | 57.0 | 42.0 | 37.3 | 32.7 | 23.0 | 15.0 | 12.0 | 10.7 | 9.0 | 8.0 | 5.75 |

| Tau | 100.0 | 60.0 | 44.7 | 40.3 | 35.3 | 26.7 | 19.7 | 14.7 | 11.7 | 9.7 | 8.0 | 5.76 |

| Dirdal | 100.0 | 57.0 | 42.0 | 38.0 | 34.0 | 21.7 | 16.0 | 13.0 | 11.7 | 10.0 | 8.0 | 5.73 |

| Sieve Size (mm) | BC (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 11.2 | 8 | 5.6 | 4 | 2 | 1 | 0.5 | 0.25 | 0.125 | 0.063 | ||

| Passing (%) | ||||||||||||

| Jelsa | 100.0 | 100.0 | 56.0 | 49.7 | 43.0 | 30.0 | 19.0 | 14.3 | 12.0 | 10.7 | 9.0 | 5.94 |

| Tau | 100.0 | 100.0 | 58.0 | 52.0 | 45.0 | 33.3 | 23.7 | 17.7 | 13.3 | 10.7 | 8.7 | 5.96 |

| Dirdal | 100.0 | 100.0 | 56.0 | 51.0 | 45.0 | 27.7 | 19.0 | 15.7 | 13.3 | 11.3 | 9.3 | 5.93 |

| SMA 16 | SMA 11 | |||||

|---|---|---|---|---|---|---|

| Density (Mg/m3) | Va (%) | VFB (%) | Density (Mg/m3) | Va (%) | VFB (%) | |

| Jelsa | 2.422 | 3.37 | 79.53 | 2.449 | 2.63 | 84.03 |

| Tau | 2.413 | 3.42 | 79.30 | 2.409 | 3.17 | 81.70 |

| Dirdal | 2.427 | 3.70 | 77.80 | 2.429 | 2.55 | 84.90 |

| Sieve Size (mm) | 2 | 1 | 0.5 | 0.25 | 0.125 | 0.063 |

| Passing (%) | 17 | 16 | 22 | 18 | 13 | 14 |

| VSI 0 | VSI 1 | VSI 2 | ||||

|---|---|---|---|---|---|---|

| SMA 16 | SMA 11 | SMA 16 | SMA 11 | SMA 16 | SMA 11 | |

| Jelsa|Tau | 0.033 * | 0.615 ns | 0.010 * | 0.420 ns | 0.029 * | 0.403 ns |

| Jelsa|Dirdal | <0.001 *** | 0.011 * | 0.007 ** | <0.001 *** | <0.001 *** | 0.006 ** |

| Tau|Dirdal | <0.001 *** | 0.011 * | <0.001 *** | <0.001 *** | <0.001 *** | 0.002 ** |

| Jelsa | Tau | Dirdal | ||||

|---|---|---|---|---|---|---|

| SMA 16 | SMA 11 | SMA 16 | SMA 11 | SMA 16 | SMA 11 | |

| VSI 0|VSI 1 | 0.998 ns | 0.268 ns | 0.891 ns | 0.920 ns | 0.016 * | 0.172 ns |

| VSI 0|VSI 2 | 0.010 * | 0.014 * | 0.894 ns | 0.996 ns | <0.001 *** | 0.054 ns |

| VSI 1|VSI 2 | 0.010 * | 0.089 ns | 0.276 ns | 0.012 * | 0.140 ns | 0.385 ns |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sondey, A.S.B.; Maleriado, V.A.; Fridgeirsdottir, H.R.; Serwin, D.; Thodesen, C.C.; Barbieri, D.M. Effects of the Aggregate Shape and Petrography on the Durability of Stone Mastic Asphalt. Infrastructures 2025, 10, 198. https://doi.org/10.3390/infrastructures10080198

Sondey ASB, Maleriado VA, Fridgeirsdottir HR, Serwin D, Thodesen CC, Barbieri DM. Effects of the Aggregate Shape and Petrography on the Durability of Stone Mastic Asphalt. Infrastructures. 2025; 10(8):198. https://doi.org/10.3390/infrastructures10080198

Chicago/Turabian StyleSondey, Alain Stony Bile, Vincent Aaron Maleriado, Helga Ros Fridgeirsdottir, Damian Serwin, Carl Christian Thodesen, and Diego Maria Barbieri. 2025. "Effects of the Aggregate Shape and Petrography on the Durability of Stone Mastic Asphalt" Infrastructures 10, no. 8: 198. https://doi.org/10.3390/infrastructures10080198

APA StyleSondey, A. S. B., Maleriado, V. A., Fridgeirsdottir, H. R., Serwin, D., Thodesen, C. C., & Barbieri, D. M. (2025). Effects of the Aggregate Shape and Petrography on the Durability of Stone Mastic Asphalt. Infrastructures, 10(8), 198. https://doi.org/10.3390/infrastructures10080198